Optical Inspection Systems for Axisymmetric Parts with Spatial 2D Resolution

Abstract

:1. Introduction

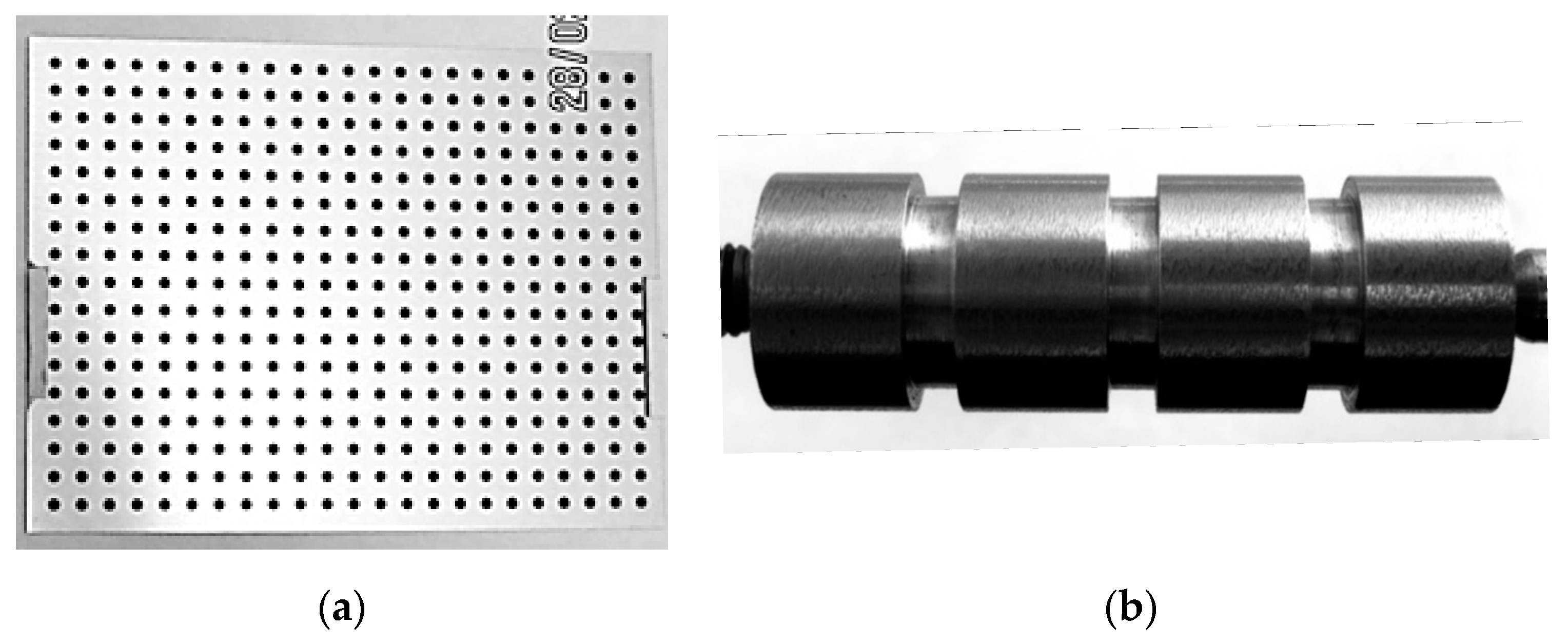

2. Statement of Research Objectives

3. Materials and Methods

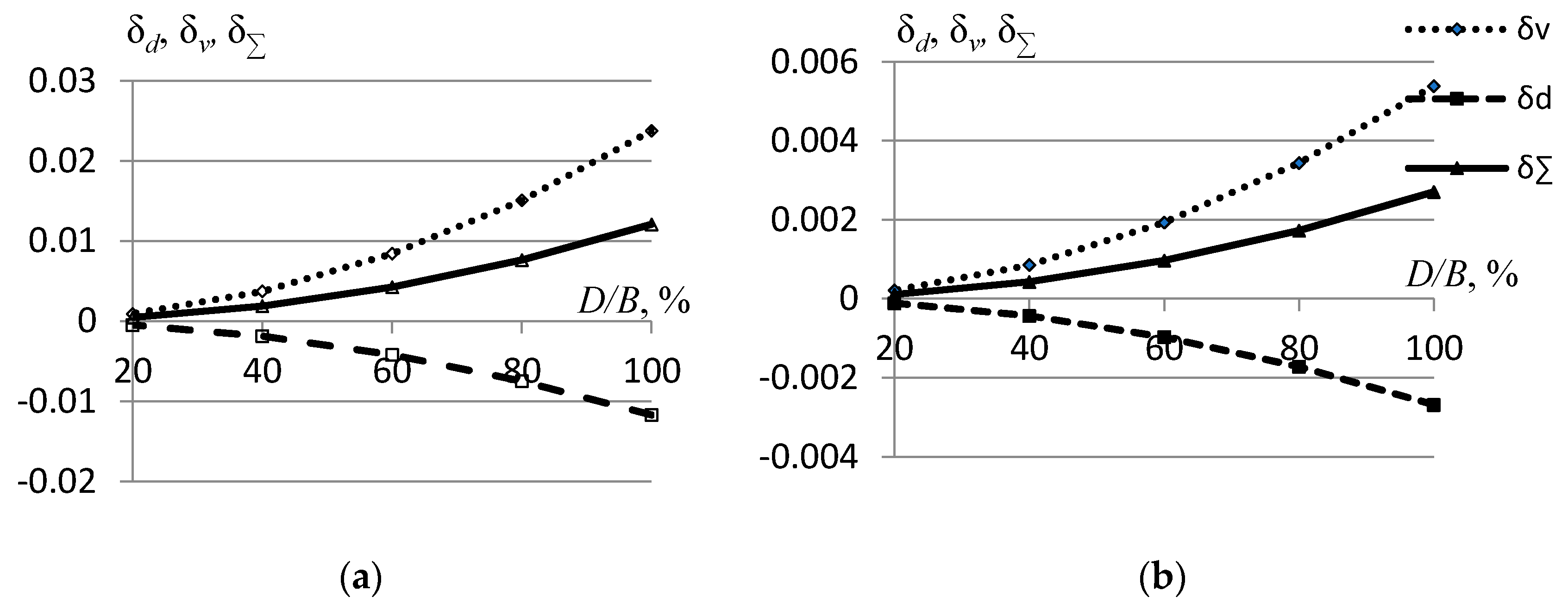

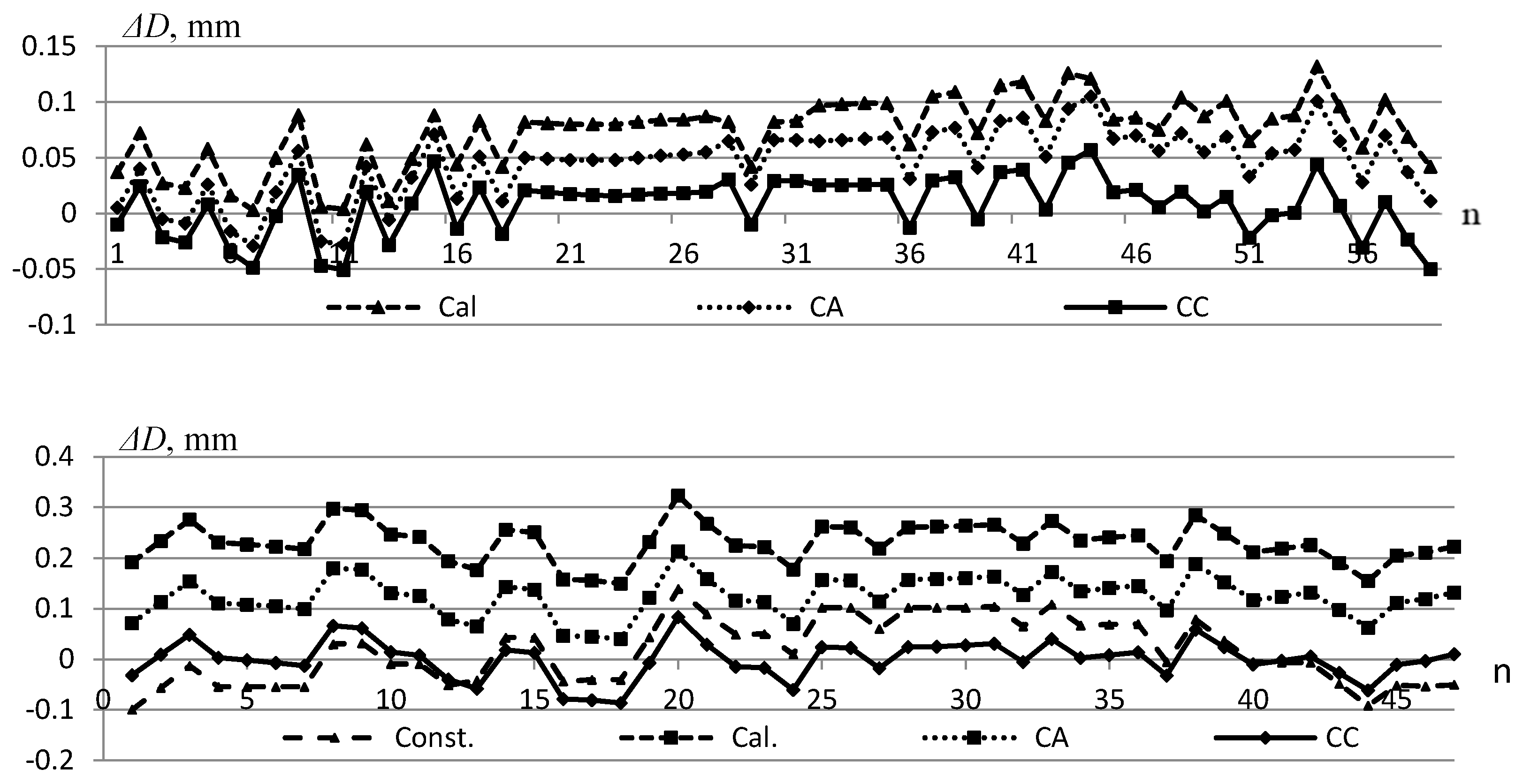

4. Results

5. Discussion

6. Conclusions

Funding

Conflicts of Interest

References

- Computer Vision: Technologies, Market Prospects. Available online: https://www.tadviser.ru/index.php/Article:_Computer_vision_:_technologies_,_market_,_prospects/ (accessed on 14 March 2021).

- Bazhin, V.Y.; Boikov, A.V.; Ivanov, P.V. Optoelectronic method for monitoring the state of the cryolite melt in aluminum electrolyzers. Russ. J. Non-Ferr. Met. 2015, 56, 6–9. [Google Scholar] [CrossRef] [Green Version]

- Martynov, S.A.; Bazhin, V.Y. Improving the control efficiency of metallurgical silicon production technology. J. Phys. Conf. Ser. 2019, 1399. [Google Scholar] [CrossRef] [Green Version]

- Romachev, A.; Kuznetsov, V.; Ivanov, E.; Jörg, B. Flotation froth feature analysis using computer vision technology. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2020; p. 192. [Google Scholar] [CrossRef]

- Maksarov, V.V.; Makhov, V.E. Reduction of defects in the process of formation of preci-sion surfaces of titanium alloy products. J. Phys. Conf. Ser. 2020, 1661. [Google Scholar] [CrossRef]

- Zmarzły, P. Influence of bearing raceway surface topography on the level of generated vibration as an example of operational heredity. Indian J. Eng. Mater. Sci. 2020, 27, 356–364. [Google Scholar]

- Fuqin, D.; Liu, C.; Sze, W.; Deng, J.; Fung, K.; Leung, W.; Lam, E. An illumination-invariant phase-shifting algorithm for three-dimensional profilometry. In Image Processing: Machine Vision Applications V; International Society for Optics and Photonics: Bellingham, DC, USA, 2021; Volume 8300. [Google Scholar] [CrossRef] [Green Version]

- Boikov, A.V.; Payor, V.A.; Savelev, R.V. Technicalvisionsystem for analysing the mechan-ical characteristics of bulk materials. J. Phys. Conf. Ser. 2018, 944. [Google Scholar] [CrossRef]

- Beloglazov, I.I.; Boikov, A.V.; Petrov, P.A. Discrete element simulation of powder sintering for spherical particles. Key Eng. Mater. 2020, 854, 164–171. [Google Scholar] [CrossRef]

- Maksarov, V.V.; Olt, J. Dynamic stabilization of machining process based on local metastability in controlled robotic systems of CNC machines. Zap. Gorn. Inst. 2017, 226, 446–451. [Google Scholar] [CrossRef]

- The Opticline CS Measurement Systems [Electronic Resource]. Available online: https://www.jenoptik.com/products/metrology/opticline-optical-shaft-metrology/opticline%20cs-serie (accessed on 28 March 2020).

- Makhov, V.E. Control of linear dimensions of products based on technologies from “National Instruments”. Izvestiya vysshikh uchebnykh zavedeniy. Priborostroenie 2010, 7, 54–60. [Google Scholar]

- Bazhin, V.Y.; Kulchitskiy, A.A.; Kadrov, D.N. Complex control of the state of steel pins in soderberg electrolytic cells by using computer vision systems. Tsvetnye Met. 2018, 27–32. [Google Scholar] [CrossRef]

- Maksarov, V.V.; Makhov, V.E. Intelligent systems for monitoring and controlling chip for-mation when cutting difficult-to-machine materials. IOP Conf. Ser. Mater. Sci. Eng. 2019, 560. [Google Scholar] [CrossRef]

- Tan, Q.; Kou, Y.; Miao, J.; Liu, S.; Chai, B.A. Model of diameter measurement based on the machine vision. Symmetry 2021, 13, 187. [Google Scholar] [CrossRef]

- Certificate of Type Approval of Measuring Instruments DE.C.27.004.A No. 52362, Optical Coordinate-Measuring Topometric Systems ATOS, Manufacturer GOMmbH, Germany Registration No. 54916-13, Type of Measuring Instruments Approved by Order of the Federal Agency for Technical Regulation and Metrology from September 23, 2013, No. 1110. Available online: https://www.ktopoverit.ru/prof/opisanie/54916-13.pdf (accessed on 14 March 2021).

- Certificate of Approval of Measuring Instruments OS.C.27.004.A No. 75179 Optical Three-Dimensional Scanners RangeVisionPRO, Manufacturer RangeVision Limited Liability Company (Range Vision LLC). Moscow Region, Krasnogorsk, Registration No. 76251-19, the Type of Measuring Instruments Approved by Order of the Federal Agency for Technical Regulation and Metrology Dated September 27, 2019, No. 2316. Available online: https://rangevision.com/company/news/rangevision-pro-ofitsialno-zanesen-v-gosudarstvennyy-reestr-sredstv-izmereniy/ (accessed on 6 June 2021).

- Eldib, I.S.A. Development of a Methodology for Improving the Technological Process of Cold Stamping of Products Based on Optical 3d-Scanning and Numerical Modeling, Dissertation for the Degree of Candidate of Technical Sciences-Specialty 05.16.05 Processing of Metals by Pressure, Moscow, Moscow Polytechnic University, 2020. Available online: https://viewer.rusneb.ru/ru/rsl01010248295?page=1&rotate=0&theme=white (accessed on 6 June 2021).

- Kulchitsky, A.A.; Potapov, A.I.; Smirnov, A.G.; Boykov, V.I. The control system of the geometry of axisymmetric products with an angular mirror converter, Bulletin of higher educational institutions. Instrumentation 2020, 63, 720–726. [Google Scholar]

- Brown, D.C. Close-range camera calibration. Photogramm. Eng. 1971, 37, 855–866. [Google Scholar]

- Tsai, R.Y. A versatile camera calibration technique for high-accuracy 3D machine vision metrology using off-the-shelf TV cameras and lenses. IEEE Int. J. Robot. Autom. 1987, 3, 323–344. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z. A flexible new technique for camera calibration. IEEE Trans. Pattern Anal. Mach. Intell. 2000, 22, 1330–1334. [Google Scholar] [CrossRef] [Green Version]

- Fitzgibbon, A.W. Simultaneous linear estimation of multiple view geometry and lens distortion. In Proceedings of the 2001 IEEE Computer Society Conference on Computer Vision and Pattern Recognition (CVPR) 2001, Kauai, HI, USA, 8–14 December 2001. [Google Scholar] [CrossRef]

- Antipov, I.T. Mathematical Foundations of Spatial Analytical Phototriangulation; Kartgeocenter-Geodezizdat: Moscow, Russia, 2003; 296p. [Google Scholar]

- Abakumov, I.I.; Kulchitsky, A.A. Compensation of errors of passive optoelectronic monitoring system of geometry. Meas. Tech. 2016, 8, 56. [Google Scholar]

- Industrial Cameras, Technical Features, and Market [Electronic Resource]. Available online: https://industryeurope.com/industrial-cameras-technical-features-and-market/ (accessed on 14 March 2021).

- Muller, R. FRAMOS Market Survey. Available online: https://www.framos.com/en/news/framos-launches-embedded-vision-ecosystem-of-sensor-modules-and-adapters/ (accessed on 5 February 2021).

- Kulchitskiy, A.A.; Kashin, D.A.; Romanova, N.A. The Program for Determining the Position of the Test Object during the Calibration of the Optical Projection System for the Control of Axisymmetric Products. Application No. 2020664591, Date of Receipt November 20, 2020, the Date of State Registration in the Register of Computer Programs November 25. 2020 year. Available online: https://elibrary.ru/download/elibrary_44762850_17629678.PDF (accessed on 6 June 2021).

- Kulchitsky, A.A.; Kashin, D.A.; Smirnov, A.G. The Program for Control of the Dimensions of Axisymmetric Products with Compensation for the Perspective Error of a Single-Channel Optical System. Application No. 2020664591, Date of Receipt November 20, 2020, the Date of State Registration in the Register of Programs for COMPUTER 25.11. February 2020. Available online: https://elibrary.ru/download/elibrary_44443086_50035226.PDF (accessed on 6 June 2021).

- Kulchitsky, A.; Zubareva, A. Reduction of measurement error of axisymmetric parts with an optical system. XIV international Scientific Conference “INTERAGROMASH 2021”. Precis. Agric. Agric. Mach. Ind. 2021, 1, 1–11. [Google Scholar]

- Abakumov, I.I.; Kulchitskiy, A.A. Algorithmic way to compensate for the errors of an automated electronic control system for geometric parameters of objects. In Innovative Systems of Planning and Management in Transport and Mechanical Engineering: Collection of Works of the II International Scientific and Practical Conference Volume II; National Mineral Resources University Mining: St. Petersburg, Russia, 2014; pp. 104–107. [Google Scholar]

- Makhov, V.E.; Potapov, A.I.; Shaldaev, S.E. Investigation of the image boundaries by the contrast extraction method using an optoelectronic system Part 1. Scientific and methodological principles of image border control by the contrast extraction method. Control. Diagn. 2017, 10, 44–51. [Google Scholar]

- Makhov, V.E.; Potapov, A.I.; Shaldaev, S.E. Investigation of the image boundaries by contrast extraction using an opto-electronic system Part 2. Experimental model studies of image boundaries based on wavelet transforms. Kontrol. Diagn. 2017, 11, 4–11. [Google Scholar] [CrossRef]

| f, mm | D, mm | L, mm | γ, ° | V | l, mm | D, mm | d’, mm | Dk, mm | , ° | , mm |

| 6 | 49.27 | 72 | 21,916 | 0.0909 | 9.1952 | 45.709 | 4828 | 53,108 | 21,916 | 49.27 |

| 6 | 30.77 | 72 | 13,480 | 0.0909 | 3.5863 | 29.922 | 2876 | 31,642 | 13,480 | 30.77 |

| 6 | 25.38 | 72 | 11,085 | 0.0909 | 2.4399 | 24.906 | 2351 | 25,863 | 11,085 | 25.38 |

| 6 | 15.43 | 72 | 6712 | 0.0909 | 0.9018 | 15.324 | 1412 | 15.5363 | 6712 | 15.43 |

| f, mm | D, mm | L, mm | γ, ° | V | l, mm | m | d’, mm | Dk, mm | , ° | , mm |

| f | D | L | α | V | l | d | Dk | |||

| 12 | 49.27 | 153 | 10,062 | 0.0851 | 4.3041 | 48.512 | 4258 | 50,040 | 10,062 | 49.27 |

| 12 | 30.77 | 153 | 6264 | 0.0851 | 1.6787 | 30.586 | 2634 | 30,955 | 6264 | 30.77 |

| 12 | 25.38 | 153 | 5163 | 0.0851 | 1.1421 | 25.277 | 2168 | 25,483 | 5163 | 25.38 |

| 12 | 15.43 | 153 | 3136 | 0.0851 | 0.4221 | 15.406 | 1315 | 15,453 | 3136 | 15.43 |

| Parameters | Calibration (Cal.) | Compensation of Projection Error (CA) | Compensation of Projection Error + Position of Test-Object | Complex Compensation (CC) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| f, mm | 25 | 12 | 25 | 12 | 25 | 12 | 25 | 12 | |||

| m | 20 | 48 | 48 | 20 | 48 | 48 | 20 | 48 | 48 | 48 | 48 |

| , mm | 0.079 | 0.073 | 0.224 | 0.042 | 0.042 | 0.118 | 0.034 | 0.033 | 0.098 | −0.004 | 0.006 |

| , | 0.079 | 0.081 | 0.237 | 0.048 | 0.053 | 0.135 | 0.041 | 0.046 | 0.118 | 0.026 | 0.057 |

| δ *, mm | 0.174 | 0.171 | 0.489 | 0.107 | 0.112 | 0.285 | 0.090 | 0.098 | 0.242 | 0.055 | 0.11 |

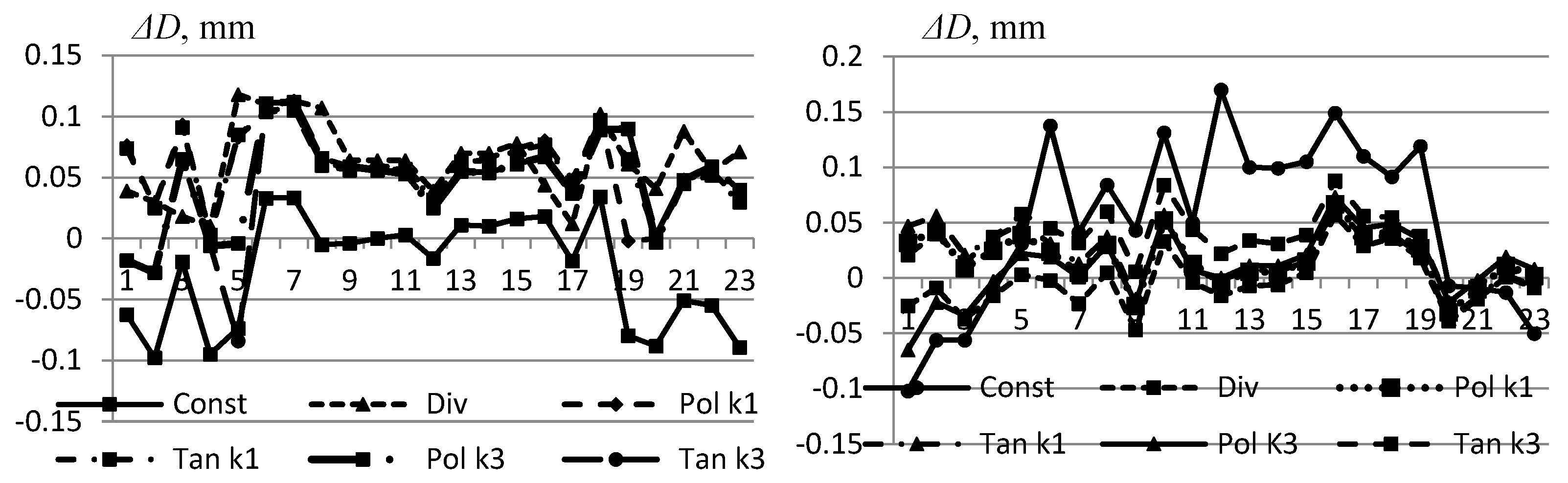

| Parameters | Sim. | Div. | Pol. k1 | Tan. k1 | Pol. k3 | Tan. K3 |

|---|---|---|---|---|---|---|

| f = 25 mm | ||||||

| , mm | −0.002 | 0.014 | 0.008 | 0.009 | −0.002 | −0.001 |

| , mm | 0.049 | 0.035 | 0.036 | 0.033 | 0.036 | 0.035 |

| δ*, mm | 0.109 | 0.078 | 0.080 | 0.072 | 0.080 | 0.078 |

| f = 12 mm | ||||||

| , mm | 0.05 | −0.003 | 0.018 | 0.020 | 0.010 | 0.034 |

| , mm | 0.092 | 0.025 | 0.030 | 0.034 | 0.033 | 0.044 |

| δ *, mm | 0.203 | 0.056 | 0.066 | 0.075 | 0.072 | 0.097 |

| Parameters | 180/255 &140/255 | 183/255 & 136/254 | ||

|---|---|---|---|---|

| Bias Compensation | No | Yes | No | Yes |

| , mm | 0.036 | 0.006 | 0.035 | 0.005 |

| , mm | 0.049 | 0.033 | 0.044 | 0.027 |

| δ *, mm | 0.108 | 0.073 | 0.098 | 0.059 |

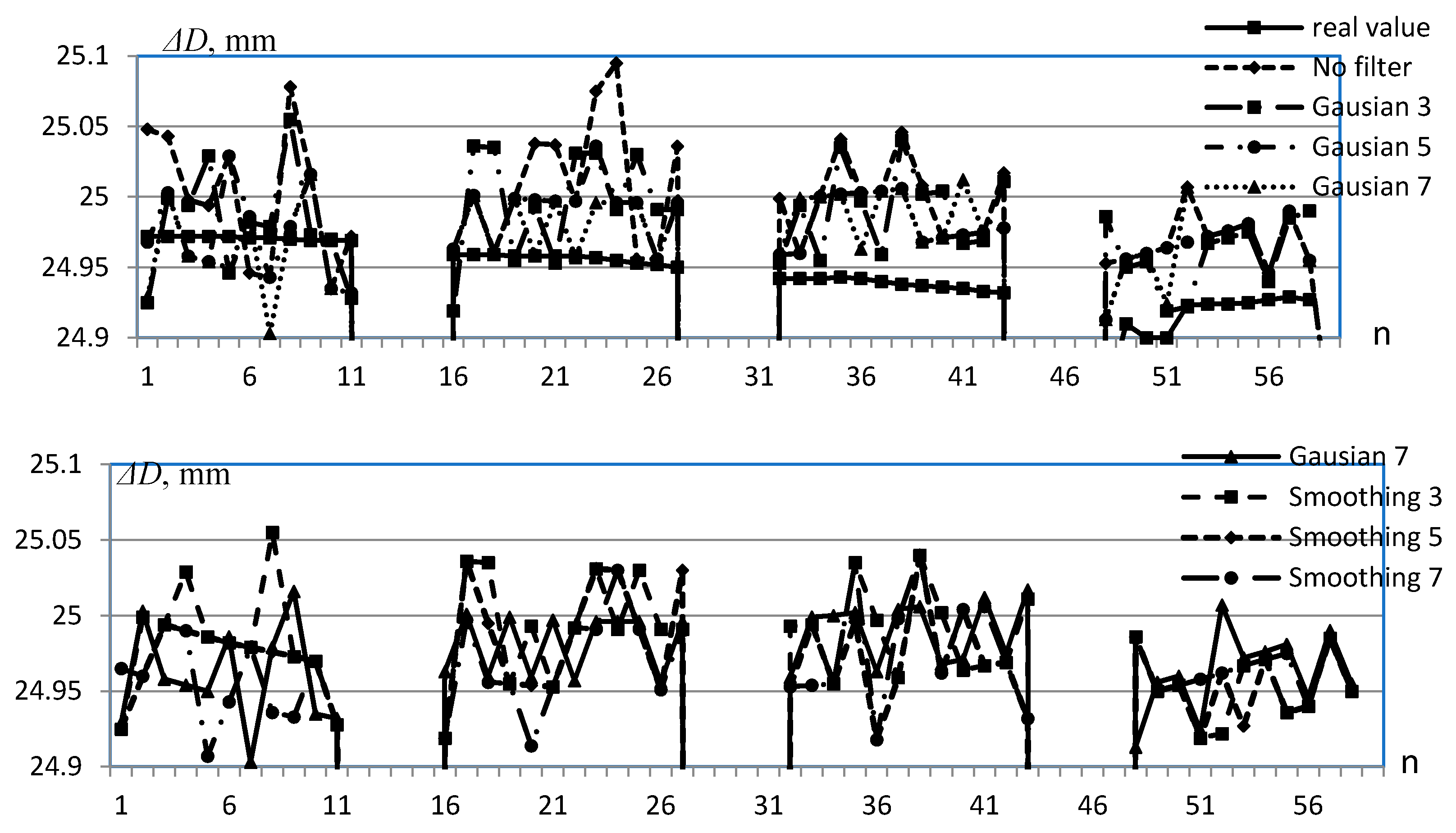

| Parameters | No Filter | Filter | |||||

|---|---|---|---|---|---|---|---|

| Gausian | Smoothing | ||||||

| Kernel | 3 | 5 | 7 | 3 | 5 | 7 | |

| , mm | 0.050 | 0.041 | 0.035 | 0.037 | 0.039 | 0.028 | 0.023 |

| , mm | 0.063 | 0.051 | 0.045 | 0.048 | 0.049 | 0.041 | 0.043 |

| δ *, mm | 0.140 | 0.114 | 0.098 | 0.107 | 0.107 | 0.089 | 0.096 |

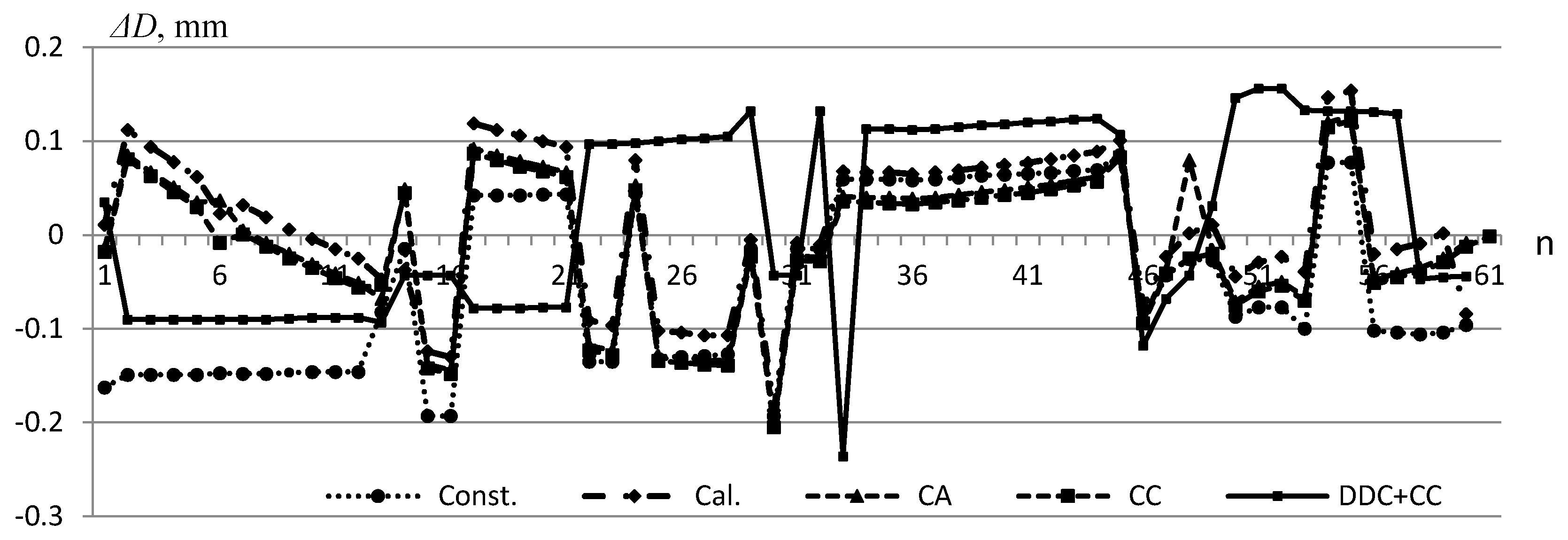

| Parameters | Constant Koefficient (Const.) | No Compensation (Cal.) | Compensation of Projection Error (CA) | Complex Compensation (CC) | Complex Compensation + Developer Cal. (DDC+CC) |

|---|---|---|---|---|---|

| , MM | −0.052 | 0.026 | 0.005 | 0.004 | 0.031 |

| , MM | 0.118 | 0.080 | 0.075 | 0.075 | 0.012 |

| δ *, MM | 0.249 | 0.169 | 0.158 | 0.158 | 0.110 |

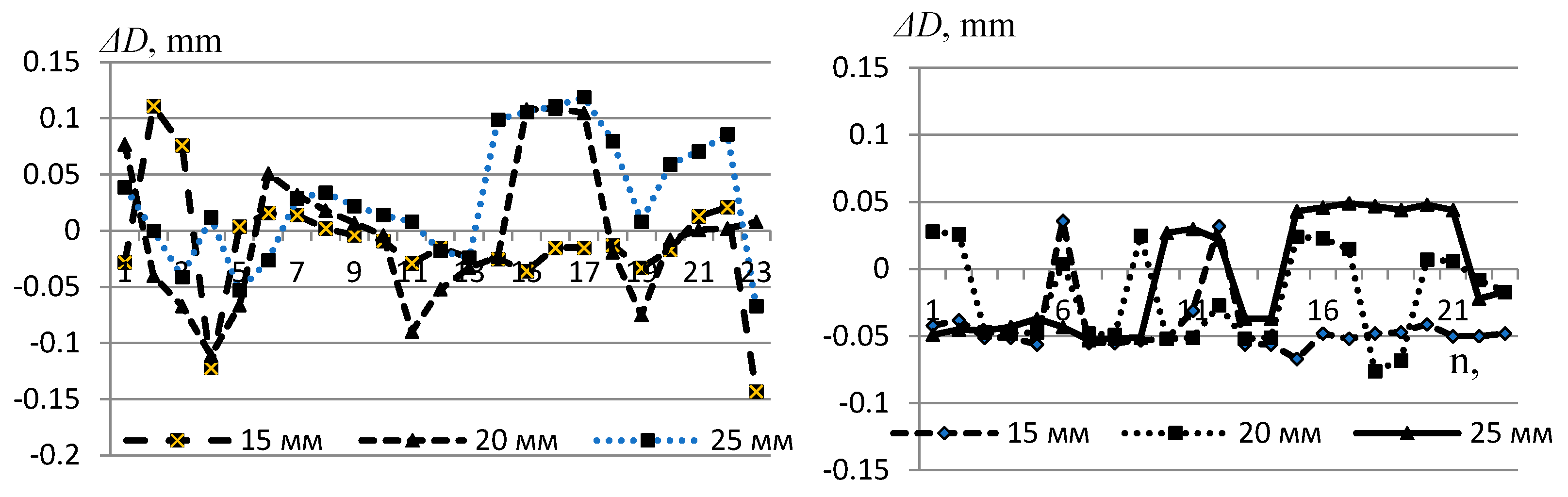

| Parameters | 15 mm | 20 mm | 25 mm | |||

|---|---|---|---|---|---|---|

| Distortion Correction Methods | Standard | Developed | Standard | Developed | Standard | Developed |

| , mm | −0.012 | 0.042 | −0.003 | −0.021 | 0.029 | −0.005 |

| , mm | 0.052 | 0.050 | 0.062 | 0.041 | 0.062 | 0.042 |

| δ *, mm | 0.118 | 0.112 | 0.139 | 0.092 | 0.139 | 0.095 |

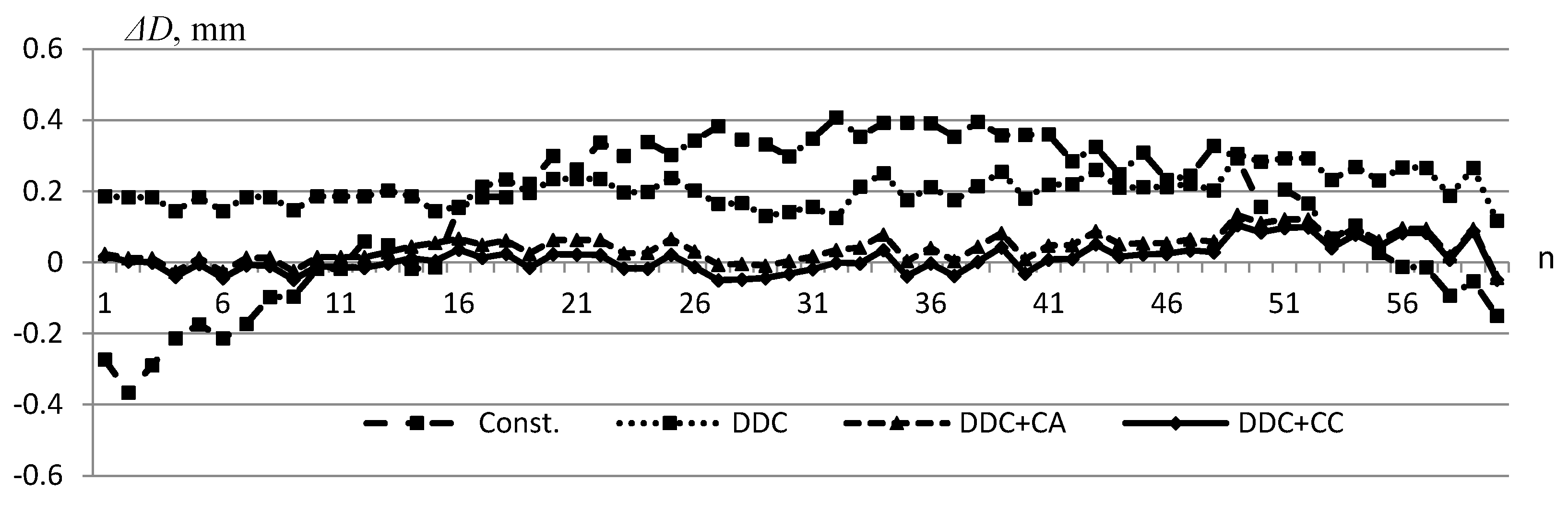

| Parameters | Constant Coefficient (Const.) | No Compensation (DDC) | Compensation of Projection Error (DDC+CA) | Complex Compensation (DDC+CC) |

|---|---|---|---|---|

| , MM | 0.154 | 0.205 | 0.042 | 0.011 |

| , | 0.264 | 0.211 | 0.057 | 0.042 |

| δ *, MM | 0.559 | 0.448 | 0.122 | 0.089 |

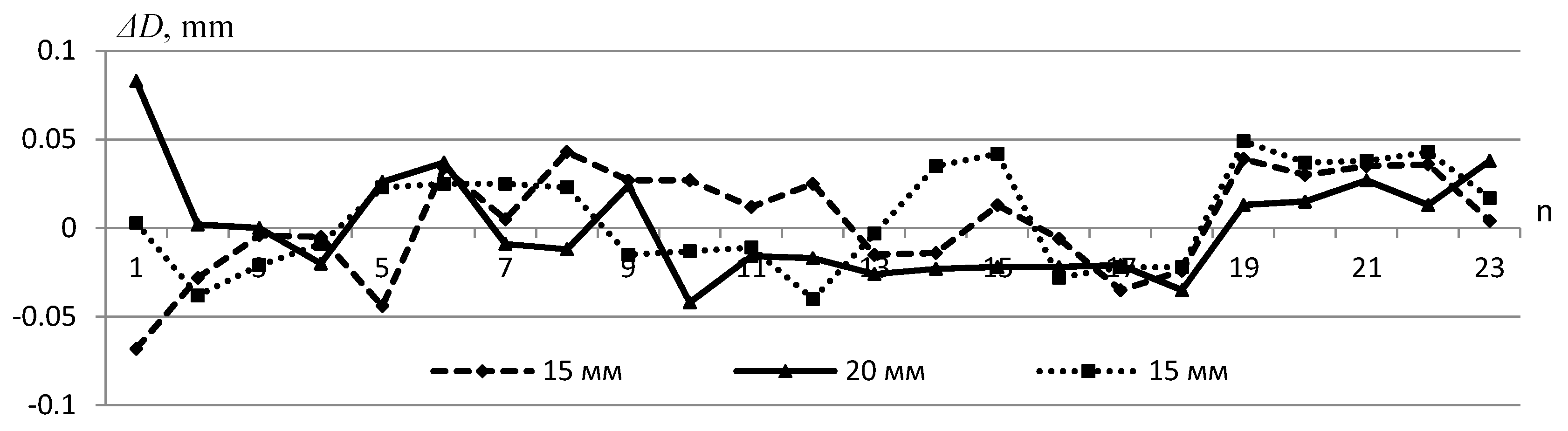

| Parameters | Dnom | ||

|---|---|---|---|

| 15 mm | 20 mm | 25 mm | |

| , mm | 0.003 | 0.001 | 0.001 |

| , | 0.033 | 0.032 | 0.035 |

| δ *, mm | 0.072 | 0.070 | 0.077 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kulchitskiy, A. Optical Inspection Systems for Axisymmetric Parts with Spatial 2D Resolution. Symmetry 2021, 13, 1218. https://doi.org/10.3390/sym13071218

Kulchitskiy A. Optical Inspection Systems for Axisymmetric Parts with Spatial 2D Resolution. Symmetry. 2021; 13(7):1218. https://doi.org/10.3390/sym13071218

Chicago/Turabian StyleKulchitskiy, Aleksandr. 2021. "Optical Inspection Systems for Axisymmetric Parts with Spatial 2D Resolution" Symmetry 13, no. 7: 1218. https://doi.org/10.3390/sym13071218

APA StyleKulchitskiy, A. (2021). Optical Inspection Systems for Axisymmetric Parts with Spatial 2D Resolution. Symmetry, 13(7), 1218. https://doi.org/10.3390/sym13071218