Application of Acoustic Agglomeration Technology to Improve the Removal of Submicron Particles from Vehicle Exhaust

Abstract

:1. Introduction

2. Materials and Methods

3. Results

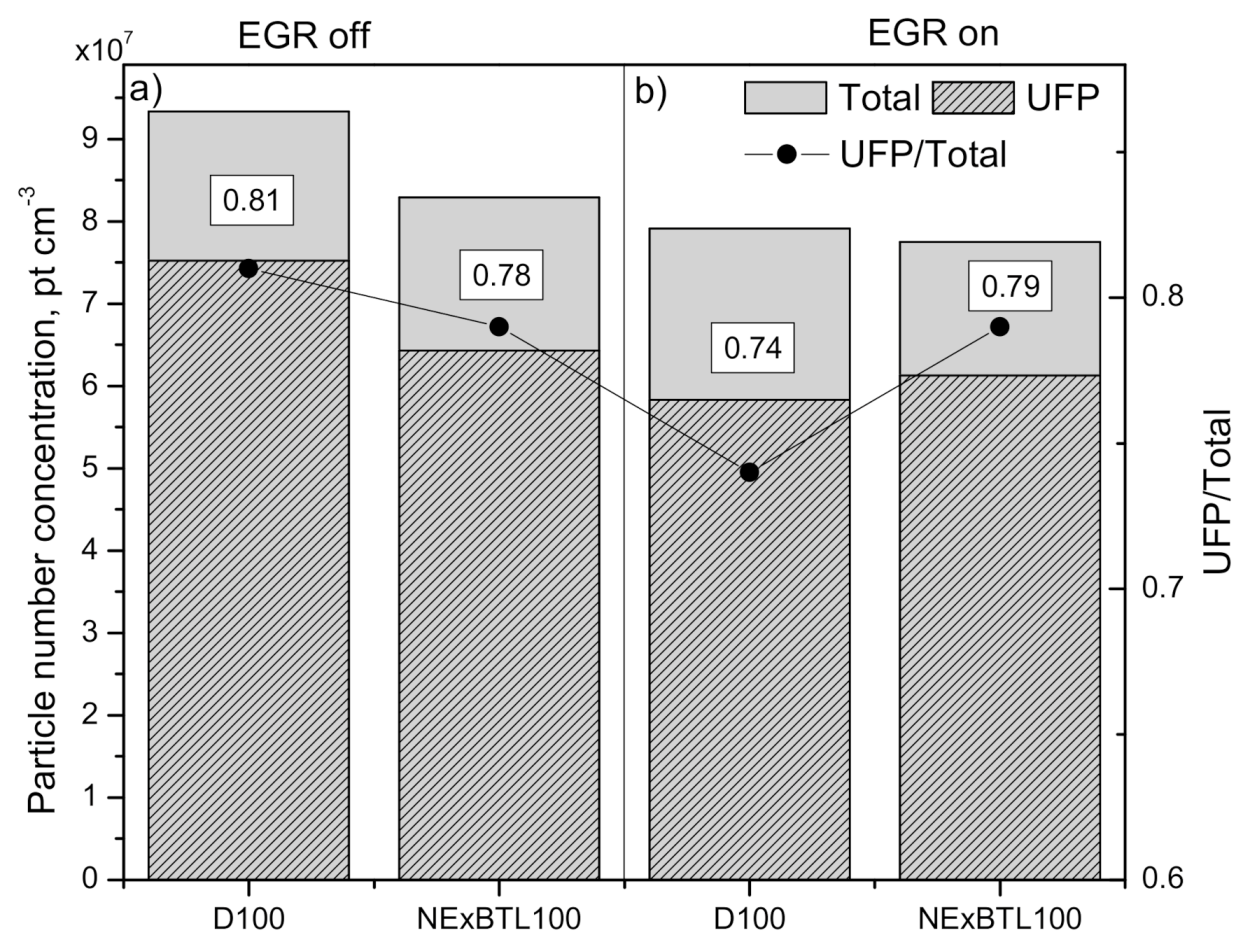

3.1. Exhaust Gas Recirculation (EGR) Effect on Particle Number Concentration and Size Distribution of the Tested Fuels

3.2. Acoustic Effect

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rajé, F.; Tight, M.; Pope, F.D. Traffic Pollution: A Search for Solutions for a City like Nairobi. Cities 2018, 82, 100–107. [Google Scholar] [CrossRef]

- Karagulian, F.; Belis, C.A.; Dora, C.F.C.; Prüss-Ustün, A.M.; Bonjour, S.; Adair-Rohani, H.; Amann, M. Contributions to Cities’ Ambient Particulate Matter (PM): A Systematic Review of Local Source Contributions at Global Level. Atmos. Environ. 2015, 120, 475–483. [Google Scholar] [CrossRef]

- Rönkkö, T.; Timonen, H. Overview of Sources and Characteristics of Nanoparticles in Urban Traffic-Influenced Areas. J. Alzheimers Dis. 2019, 72, 15–28. [Google Scholar] [CrossRef] [Green Version]

- Riera-Franco de Sarabia, E.; Gallego-Juárez, J.A.; Rodríguez-Corral, G.; Elvira-Segura, L.; González-Gómez, I. Application of High-Power Ultrasound to Enhance Fluid/Solid Particle Separation Processes. Ultrasonics 2000, 38, 642–646. [Google Scholar] [CrossRef]

- González, I.; Hoffmann, T.L.; Gallego, J.A. Precise measurements of particle entrainment in a standing-wave acoustic field between 20 and 3500 Hz. J. Aerosol Sci. 2000, 31, 1461–1468. [Google Scholar] [CrossRef]

- Dong, S.; Lipkens, B.; Cameron, T.M. The Effects of Orthokinetic Collision, Acoustic Wake, and Gravity on Acoustic Agglomeration of Polydisperse Aerosols. J. Aerosol Sci. 2006, 37, 540–553. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, G.; Zhou, J.; Wang, J.; Zhao, W.; Cen, K. Experimental Study of Acoustic Agglomeration of Coal-Fired Fly Ash Particles at Low Frequencies. Powder Technol. 2009, 193, 20–25. [Google Scholar] [CrossRef]

- Wang, J.; Liu, J.; Zhang, G.; Zhou, J.; Cen, K. Orthogonal Design Process Optimization and Single Factor Analysis for Bimodal Acoustic Agglomeration. Powder Technol. 2011, 210, 315–322. [Google Scholar] [CrossRef]

- Hoffmann, T.L. Environmental Implications of Acoustic Aerosol Agglomeration. Ultrasonics 2000, 38, 353–357. [Google Scholar] [CrossRef]

- Riera-Franco de Sarabia, E.; Elvira-Segura, L.; González-Gómez, I.; Rodríguez-Maroto, J.J.; Muñoz-Bueno, R.; Dorronsoro-Areal, J.L. Investigation of the Influence of Humidity on the Ultrasonic Agglomeration of Submicron Particles in Diesel Exhausts. Ultrasonics 2003, 41, 277–281. [Google Scholar] [CrossRef]

- Yan, J.; Chen, L.; Li, Z. Removal of Fine Particles from Coal Combustion in the Combined Effect of Acoustic Agglomeration and Seed Droplets with Wetting Agent. Fuel 2016, 165, 316–323. [Google Scholar] [CrossRef]

- Zhang, G.; Zhou, T.; Zhang, L.; Wang, J.; Chi, Z.; Hu, E. Improving Acoustic Agglomeration Efficiency of Coal-Fired Fly-Ash Particles by Addition of Liquid Binders. Chem. Eng. J. 2018, 334, 891–899. [Google Scholar] [CrossRef]

- Liu, H.; Li, Z.; Tan, H.; Yang, F.; Feng, P.; Du, Y.; Ren, M.; Dong, M. Experimental Investigation on a Novel Agglomeration Device Based on Charged Ultrasonic Spray and Vortex Generators for Improving the Removal of Fine Particles. Fuel 2021, 287, 119549. [Google Scholar] [CrossRef]

- Yan, F.; Song, J.; Zhuang, Y.; Qiu, L.; Li, Z.; Meng, Z. Three-Dimension Soft X-Ray Tomographic Reconstruction of Particulates Emitted from a Diesel Engine. J. Aerosol Sci. 2021, 156, 105784. [Google Scholar] [CrossRef]

- Bin, H.; Yang, Y.; Cai, L.; Zhulin, Y.; Roszak, S.; Linjun, Y. Experimental Study on Particles Agglomeration by Chemical and Turbulent Agglomeration before Electrostatic Precipitators. Powder Technol. 2018, 335, 186–194. [Google Scholar] [CrossRef]

- Lin, W.-Y.; Hsiao, T.-C.; Hong, B.-L. Improving the Removal Efficiency of Fine Particulate Matters in Air Pollution Control Devices: Design and Performance of an Electrostatic Aerosol Particle Agglomerator. J. Taiwan Inst. Chem. Eng. 2020, 107, 110–118. [Google Scholar] [CrossRef]

- Kilikevičienė, K.; Kačianauskas, R.; Kilikevičius, A.; Maknickas, A.; Matijošius, J.; Rimkus, A.; Vainorius, D. Experimental Investigation of Acoustic Agglomeration of Diesel Engine Exhaust Particles Using New Created Acoustic Chamber. Powder Technol. 2020, 360, 421–429. [Google Scholar] [CrossRef]

- Jedliński, Ł.; Caban, J.; Krzywonos, L.; Wierzbicki, S.; Brumerčík, F. Application of Vibration Signal in the Diagnosis of IC Engine Valve Clearance. J. Vibroengineering 2015, 17, 175–187. [Google Scholar]

- Nasrabadi, A.M.; Todea, A.M.; Wolf, C.; Demirel, T.; Habryka, D.; Asbach, C. Investigation of the Effect of Aerosolized TiO2 Nanoparticles on the NO2 Concentrations under UVA Exposure. Aerosol Air Qual. Res. 2021, 21, 200612. [Google Scholar] [CrossRef]

- Dudoitis, V.; Mordas, G.; Byčenkienė, S.; Plauškaitė, K.; Pauraitė, J.; Jasinevičienė, D.; Marozas, V.; Pivoras, G.; Mozgeris, G.; Augustaitis, A.; et al. Aerosol Particle Formation in the Lithuanian Hemi-Boreal Forest. Lith. J. Phys. 2018, 58. [Google Scholar] [CrossRef]

- Wiedensohler, A.; Birmili, W.; Nowak, A.; Sonntag, A.; Weinhold, K.; Merkel, M.; Wehner, B.; Tuch, T.; Pfeifer, S.; Fiebig, M.; et al. Mobility Particle Size Spectrometers: Harmonization of Technical Standards and Data Structure to Facilitate High Quality Long-Term Observations of Atmospheric Particle Number Size Distributions. Atmos. Meas. Tech. 2012, 5, 657–685. [Google Scholar] [CrossRef] [Green Version]

- Gormley, P.G.; Kennedy, M. Diffusion from a Stream Flowing through a Cylindrical Tube. Proc. R. Ir. Acad. Sect. Math. Phys. Sci. 1948, 52, 163–169. [Google Scholar]

- Nikezic, D.; Haque, A.K.M.M.; Yu, K.N. Effects of Different Deposition Models on the Calculated Dose Conversion Factors from 222Rn Progeny. J. Environ. Radioact. 2002, 61, 305–318. [Google Scholar] [CrossRef]

- Šakalys, J.; Kvietkus, K.; Sucharová, J.; Suchara, I.; Valiulis, D. Changes in Total Concentrations and Assessed Background Concentrations of Heavy Metals in Moss in Lithuania and the Czech Republic between 1995 and 2005. Chemosphere 2009, 76, 91–97. [Google Scholar] [CrossRef]

- Kvietkus, K.; Šakalys, J.; Didžbalis, J.; Garbarienė, I.; Špirkauskaitė, N.; Remeikis, V. Atmospheric Aerosol Episodes over Lithuania after the May 2011 Volcano Eruption at Grimsvötn, Iceland. Atmos. Res. 2013, 122, 93–101. [Google Scholar] [CrossRef]

- Miller, S.J. Chapter 24. The Method of Least Squares. In The Probability Lifesaver; Princeton University Press: Princeton, NJ, USA, 2017; pp. 625–635. ISBN 978-1-4008-8538-1. [Google Scholar]

- Wu, Z.; Hu, M.; Lin, P.; Liu, S.; Wehner, B.; Wiedensohler, A. Particle Number Size Distribution in the Urban Atmosphere of Beijing, China. Atmos. Environ. 2008, 42, 7967–7980. [Google Scholar] [CrossRef]

- Walsh, M.P. PM2.5: Global Progress in Controlling the Motor Vehicle Contribution. Front. Environ. Sci. Eng. 2014, 8, 1–17. [Google Scholar] [CrossRef]

- Hunicz, J.; Matijošius, J.; Rimkus, A.; Kilikevičius, A.; Kordos, P.; Mikulski, M. Efficient Hydrotreated Vegetable Oil Combustion under Partially Premixed Conditions with Heavy Exhaust Gas Recirculation. Fuel 2020, 268, 117350. [Google Scholar] [CrossRef]

- Rimkus, A.; Žaglinskis, J.; Stravinskas, S.; Rapalis, P.; Matijošius, J.; Bereczky, Á. Research on the Combustion, Energy and Emission Parameters of Various Concentration Blends of Hydrotreated Vegetable Oil Biofuel and Diesel Fuel in a Compression-Ignition Engine. Energies 2019, 12, 2978. [Google Scholar] [CrossRef] [Green Version]

- Bortel, I.; Vávra, J.; Takáts, M. Effect of HVO Fuel Mixtures on Emissions and Performance of a Passenger Car Size Diesel Engine. Renew. Energy 2019, 140, 680–691. [Google Scholar] [CrossRef]

- Suarez-Bertoa, R.; Kousoulidou, M.; Clairotte, M.; Giechaskiel, B.; Nuottimäki, J.; Sarjovaara, T.; Lonza, L. Impact of HVO Blends on Modern Diesel Passenger Cars Emissions during Real World Operation. Fuel 2019, 235, 1427–1435. [Google Scholar] [CrossRef]

| Properties | D100 | NExBTL100 |

|---|---|---|

| Density at 40 °C, g/mL | 0.844 | 0.778 |

| Dynamic viscosity, MPa·s | 3.271 | 2.262 |

| Kinematic viscosity, mm2/s | 3.947 | 2.959 |

| Water content acc. CF, % | 0.0033 | 0.002 |

| Amount of hydrogen, % | 14.63 | 16.75 |

| Filtration temperature, °C | −10 | −40 |

| CFPP, °C | −39 | −58 |

| Poor point, °C | −39 | −58 |

| Cetane number | 50.9 | 74.5 |

| Lower heating value, MJ/kg | 42.57 | 43.45 |

| Parameter | Value |

|---|---|

| Displacement, cm3 | 1896 |

| Number of cylinders/gas distribution | 4/OHV |

| Compression ratio | 19.5 |

| Bore, mm | 79.5 |

| Stroke, mm | 95.5 |

| Power, kW | 66 (4000 rpm) |

| Torque, Nm | 180 (2000–2500 rpm) |

| Injector opening pressure, bar | 190 |

| EGR Off | EGR On | |||

|---|---|---|---|---|

| D100 | NE × BTL100 | D100 | NE × BTL100 | |

| Aitken mode (I) median diameter (Dm), nm | 32 | 31 | 36 | 39 |

| Number concentration, pt cm−3 | 5.13 × 107 | 4.43 × 107 | 4.37 × 107 | 4.46 × 107 |

| Aitken mode (II) median diameter (Dm), nm | 57 | 64 | 71 | 64 |

| Number concentration, pt cm−3 | 2.39 × 107 | 2.00 × 107 | 1.49 × 107 | 1.67 × 107 |

| Accumulation mode median diameter (Dm), nm | 178 | 165 | 219 | 185 |

| Number concentration, pt cm−3 | 1.81 × 107 | 1.86 × 107 | 2.05 × 107 | 1.62 × 107 |

| Total number concentration, pt cm−3 | 9.33 × 107 | 8.29 × 107 | 7.91 × 107 | 7.75 × 107 |

| EGR Off | EGR On | |

|---|---|---|

| Aitken mode (I) median diameter (Dm), nm | 40 | 62 |

| Number concentration, pt cm−3 | 4.41 × 107 | 3.11 × 107 |

| Aitken mode (II) median diameter (Dm), nm | 72 | 103 |

| Number concentration, pt cm−3 | 1.91 × 107 | 1.33 × 107 |

| Accumulation mode median diameter (Dm), nm | 170 | 174 |

| Number concentration, pt cm−3 | 2.22 × 107 | 2.02 × 107 |

| Total number concentration, pt cm−3 | 8.54 × 107 | 6.46 × 107 |

| Size Bins (nm) | Without EGR | With EGR |

|---|---|---|

| η (%) | η (%) | |

| 10–20 | 20.3 | 36.0 |

| 20–30 | 24.5 | 16.1 |

| 30–40 | 15.3 | 24.7 |

| 40–50 | 7.9 | 28.0 |

| 50–60 | 19.6 | 17.9 |

| 60–70 | 7.1 | 7.7 |

| 70–80 | 17.1 | −7.8 |

| 80–90 | 12.2 | −14.1 |

| 90–100 | −2.0 | −11.1 |

| 100–120 | −6.4 | 9.5 |

| 120–140 | 29.2 | 10.3 |

| 140–160 | 18.6 | 10.9 |

| 160–180 | 6.4 | 2.0 |

| 180–200 | −11.3 | −9.6 |

| 200–240 | −21.6 | −27.7 |

| 240–280 | −20.9 | −69.2 |

| 280–320 | 47.5 | −7.0 |

| 320–360 | −13.2 | −79.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garbarienė, I.; Dudoitis, V.; Ulevičius, V.; Plauškaitė-Šukienė, K.; Kilikevičius, A.; Matijošius, J.; Rimkus, A.; Kilikevičienė, K.; Vainorius, D.; Maknickas, A.; et al. Application of Acoustic Agglomeration Technology to Improve the Removal of Submicron Particles from Vehicle Exhaust. Symmetry 2021, 13, 1200. https://doi.org/10.3390/sym13071200

Garbarienė I, Dudoitis V, Ulevičius V, Plauškaitė-Šukienė K, Kilikevičius A, Matijošius J, Rimkus A, Kilikevičienė K, Vainorius D, Maknickas A, et al. Application of Acoustic Agglomeration Technology to Improve the Removal of Submicron Particles from Vehicle Exhaust. Symmetry. 2021; 13(7):1200. https://doi.org/10.3390/sym13071200

Chicago/Turabian StyleGarbarienė, Inga, Vadimas Dudoitis, Vidmantas Ulevičius, Kristina Plauškaitė-Šukienė, Artūras Kilikevičius, Jonas Matijošius, Alfredas Rimkus, Kristina Kilikevičienė, Darius Vainorius, Algirdas Maknickas, and et al. 2021. "Application of Acoustic Agglomeration Technology to Improve the Removal of Submicron Particles from Vehicle Exhaust" Symmetry 13, no. 7: 1200. https://doi.org/10.3390/sym13071200

APA StyleGarbarienė, I., Dudoitis, V., Ulevičius, V., Plauškaitė-Šukienė, K., Kilikevičius, A., Matijošius, J., Rimkus, A., Kilikevičienė, K., Vainorius, D., Maknickas, A., Borodinas, S., & Byčenkienė, S. (2021). Application of Acoustic Agglomeration Technology to Improve the Removal of Submicron Particles from Vehicle Exhaust. Symmetry, 13(7), 1200. https://doi.org/10.3390/sym13071200