A Method for Calculating Soil Deformation Induced by Shielded Tunneling in Ground Stratum with Cavities

Abstract

1. Introduction

2. Insufficiency of Existing Research and Description of Improvement

2.1. Shortcomings and Difficulties of Existing Research

- First, the mechanism of cavity deformation is complex and influenced by many factors, making it difficult to accurately predict it.

- Second, the shape of cavities differs in actual projects, and it is necessary to establish a suitable and reasonable theoretical calculation model.

- Third, because cavities are located below the surface, the convergence of the cavities is difficult to measure, and there is a lack of relevant empirical values.

- Fourth, there are few theoretical solutions to the ground settlement and the soil displacement caused by tunnel excavation in the ground strata containing cavities. Among them, Yang et al. [10] studied the theoretical solution through the Schwarz alternating method and the elastic solution for the complex variable function. However, they could not examine the distribution law of the surface settlement along the direction of the shielded tunneling and did not derive the calculation formula for the deformation of the soil layer at different depths. In addition, complexity and cumbersome calculations are not conducive to popularization and application.

2.2. Instructions for Remedying Shortcomings

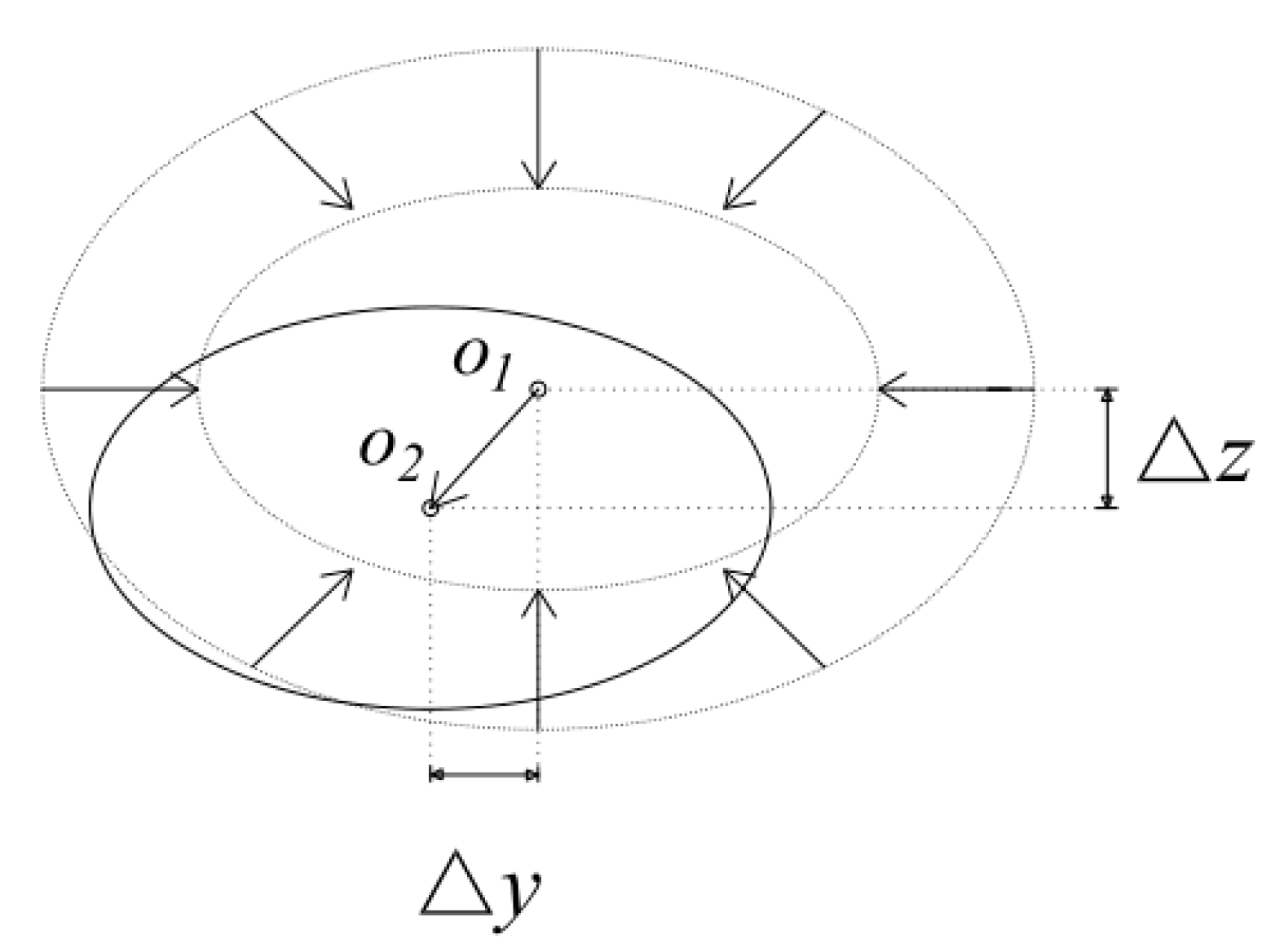

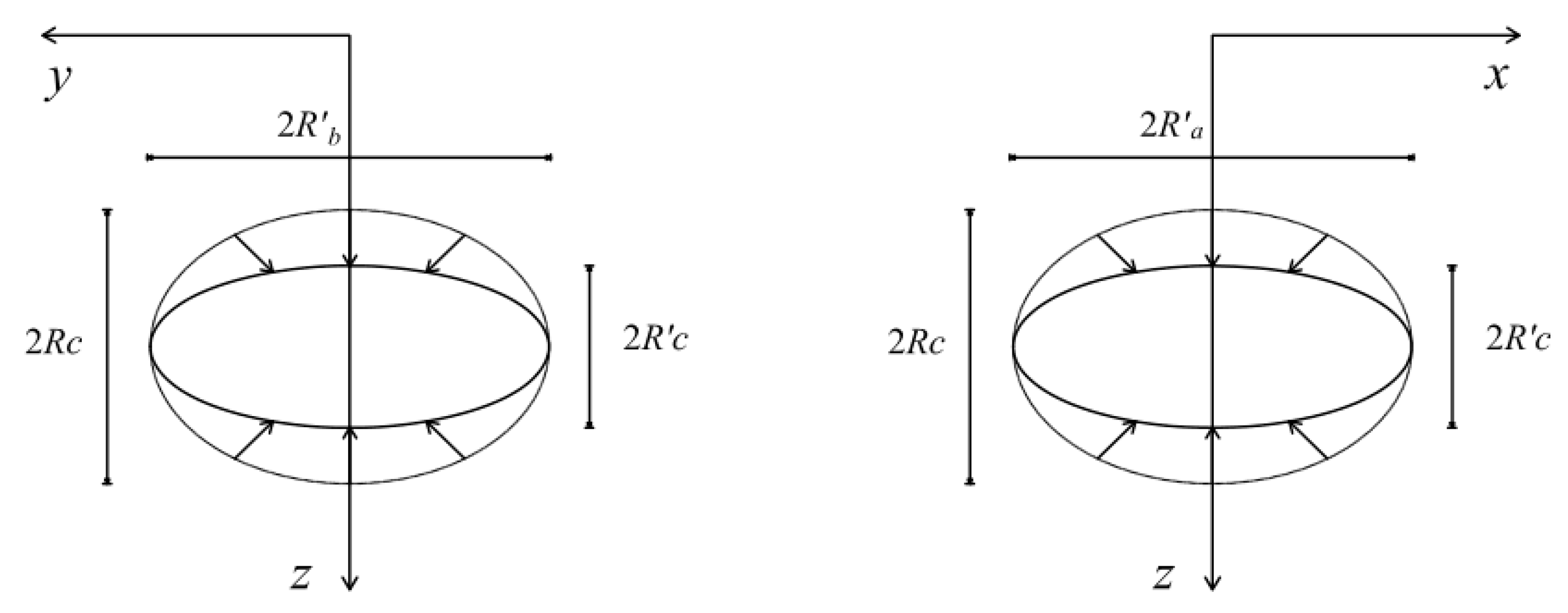

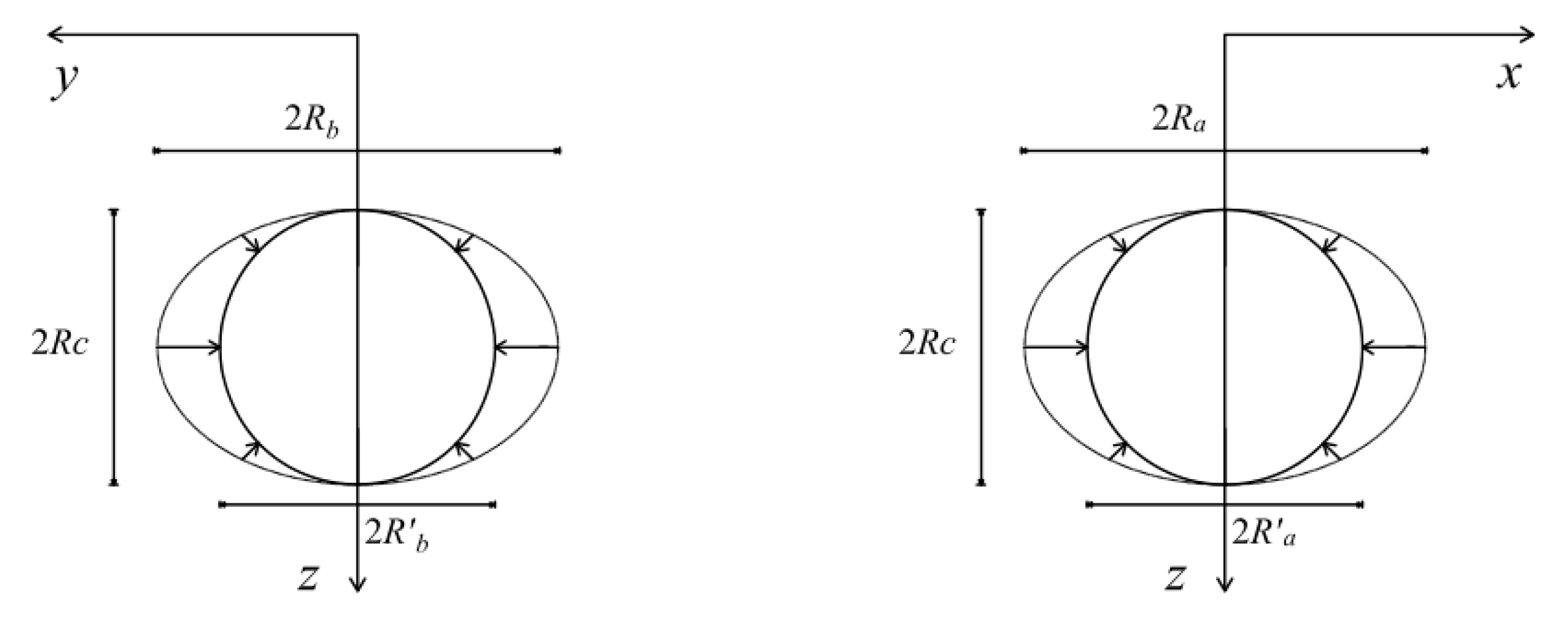

- First, this work believes that the impact of tunnel excavation on the cavity chiefly includes the overall movement and the convergence of the boundary. In order to effectively estimate the surface settlement and the displacement of the upper soil caused by the cavity, three symmetrical modes of shape convergence are proposed: the uniform convergence, the horizontal elliptical convergence, and the vertical elliptical convergence.

- Second, in actual engineering, cavities have their own stability due to their long-term existence and deformation development. Tian [21] proposed the concept of “cavity shell” and believed that cavities can maintain their stability under normal conditions but lose their stability and deform when they are disturbed by the outside world. Although the reason for the formation of cavities is complex, and their shape is irregular, for a cavity with stable surrounding rock, its shape should satisfy the reasonable distribution of the surrounding rock force. Moreover, because the surrounding stress is slightly concentrated, the stability of the circular hole-shaped cavities is higher than that of other linear cavities with angles. Therefore, in the related literature, cavities have mostly been simplified into spherical or ellipsoidal ones. Thus, this paper chiefly discusses the deformation mode of an ellipsoidal cavity and the soil settlement caused by it.

- Third, this work introduces the concept of the convergence rate of the cavity (εs) to express the size of the convergence of a cavity. On the basis of the research results of Loganathan [22], it is proposed that the convergence rate of the cavity can be estimated according to the relative position of the tunnel and the loss rate of the soil (ηs) caused by the tunnel excavation.

- Fourth, this paper studies the variation in the soil settlement value with the direction of the tunnel excavation and the depth of burial of the cavity.

3. Methodology

3.1. Introduction of Our Research Ideas and Calculation Models

3.1.1. Research Ideas

- A theoretical calculation model is established.

- The soil displacement value caused by the excavation of the shielded tunnel is calculated.

- The overall displacement and convergence of the cavity are considered, and the soil displacement value caused by the cavity deformation is calculated.

- The soil displacement values of steps 2 and 3 are superimposed to determine the total displacement value of the soil layer.

- The test data are combined for reliability verification.

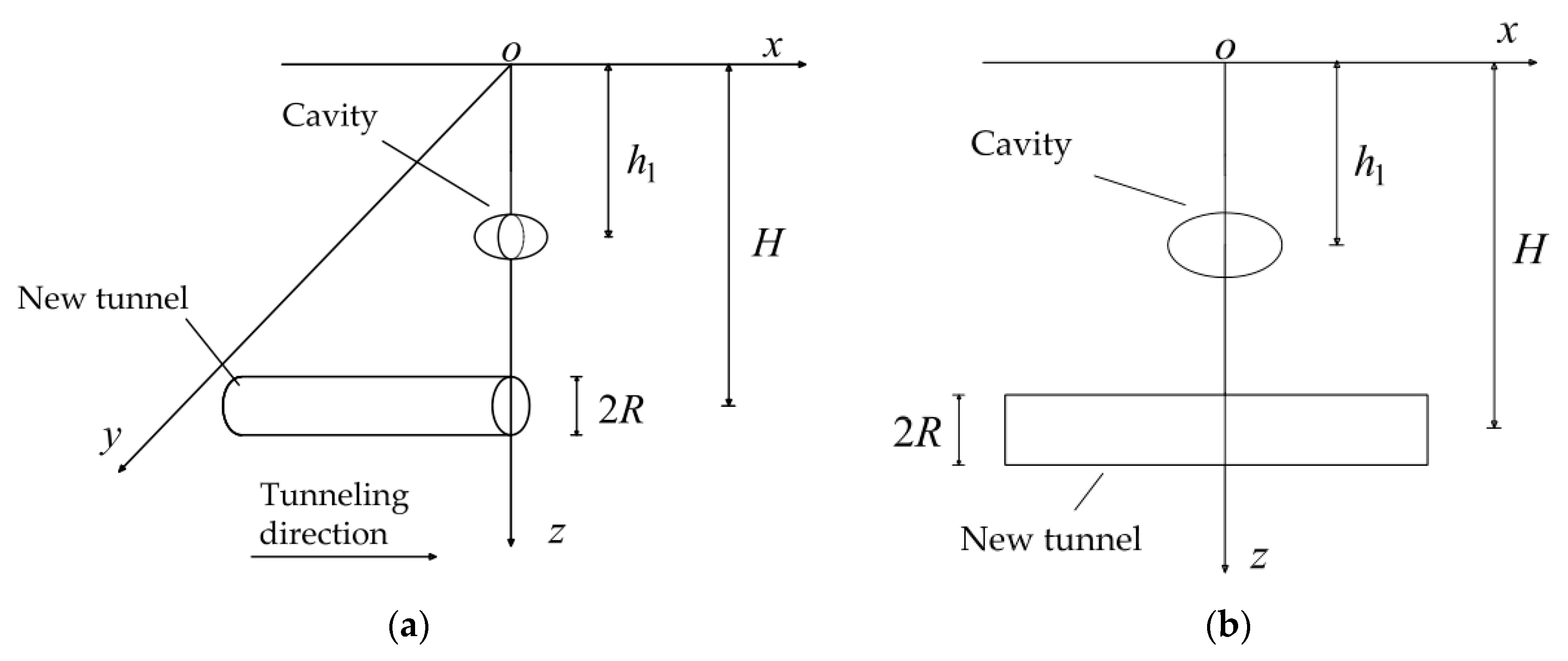

3.1.2. Building Calculation Model

3.2. Calculation of Soil Deformation Caused by Tunnel Excavation

3.3. Calculation of Soil Deformation Caused by Cavity Deformation

3.3.1. Introduction to Basic Theory

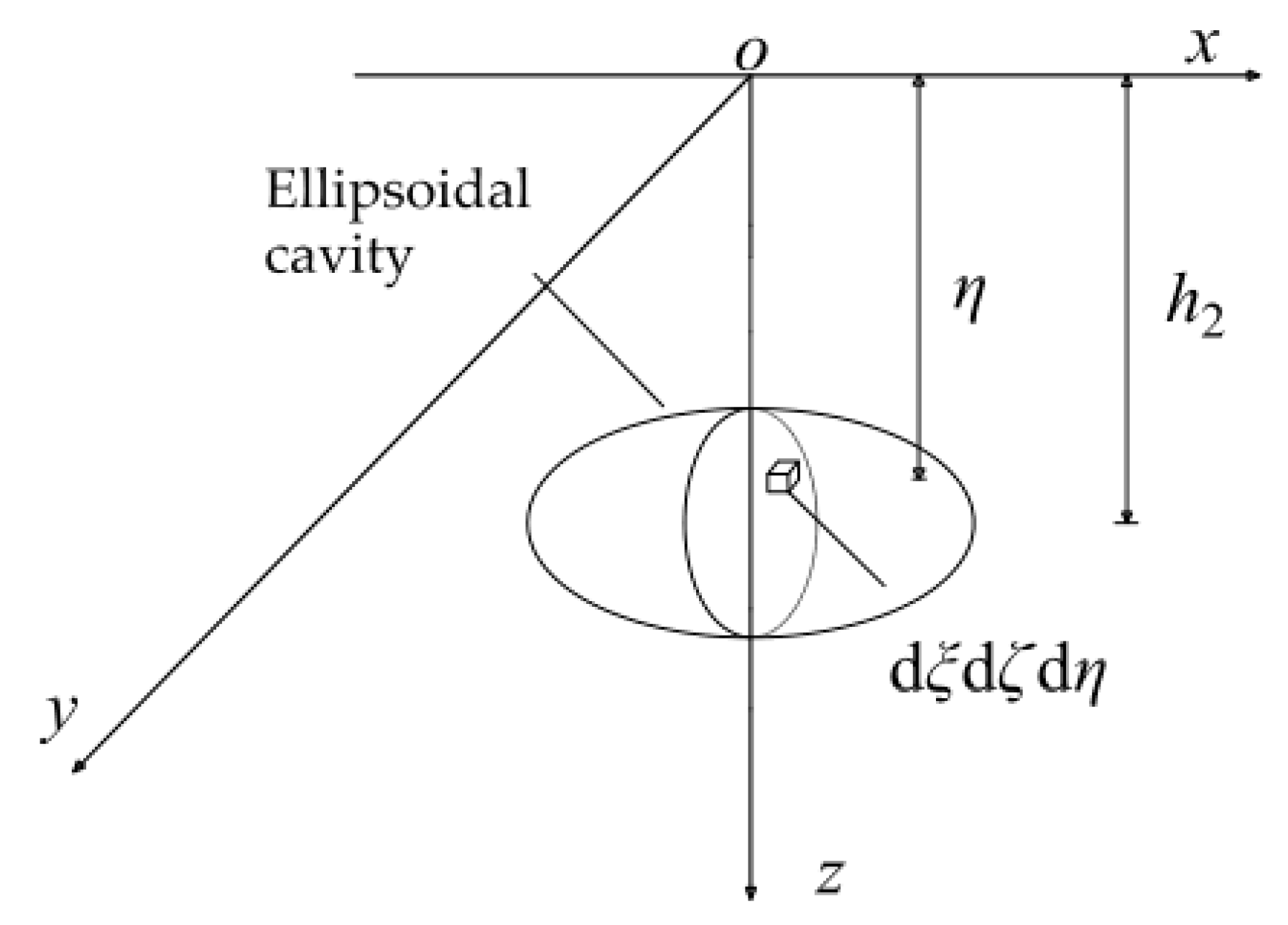

3.3.2. Derivation of Calculation Formula

3.3.3. Calculation of Convergence Rate of Cavity and Discussion of Convergence Modes

3.4. Calculation of Total Displacement of Ground with Cavity under Influence of Shielded Tunneling

4. Instance Verification

4.1. Case Introduction

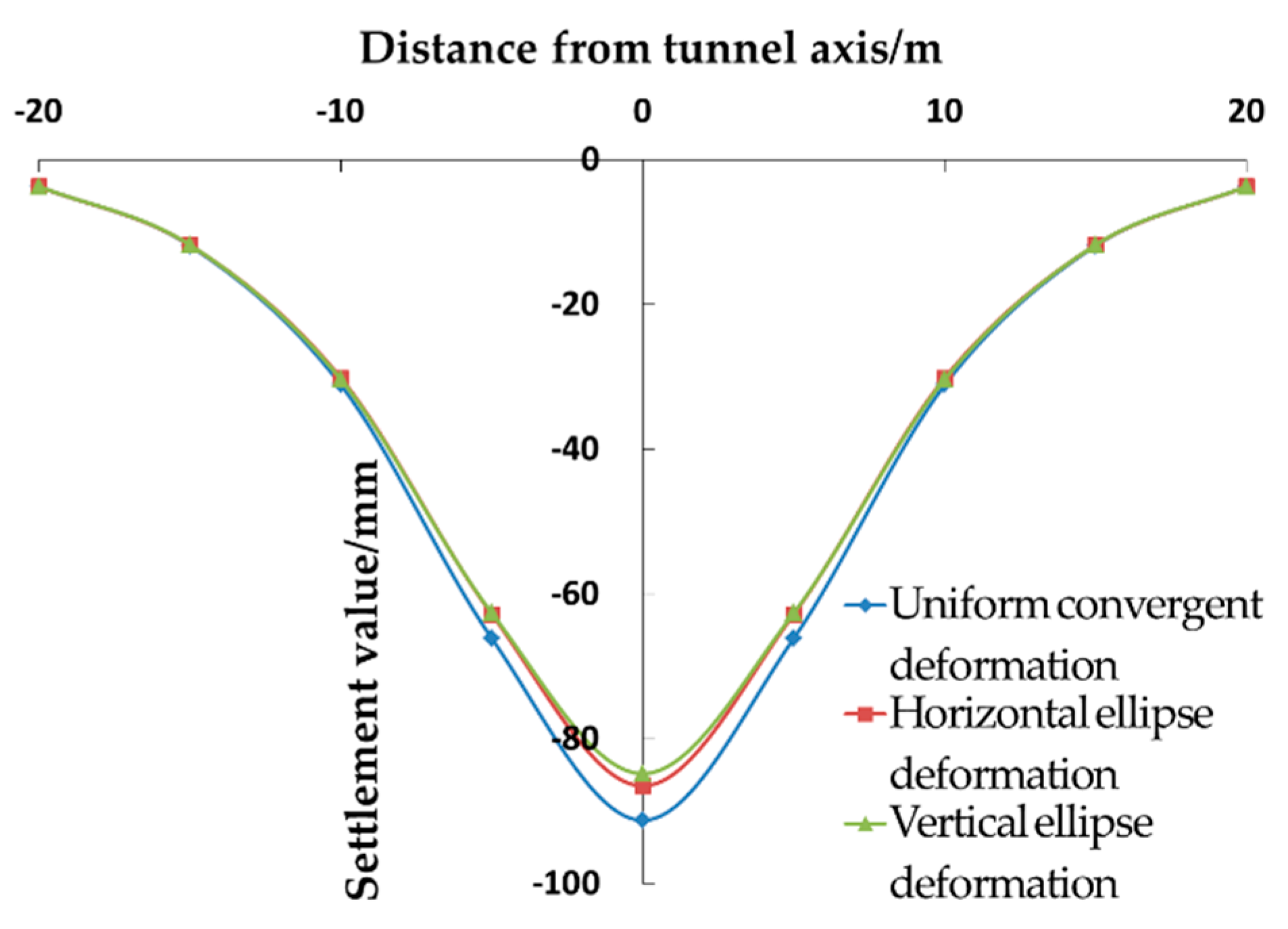

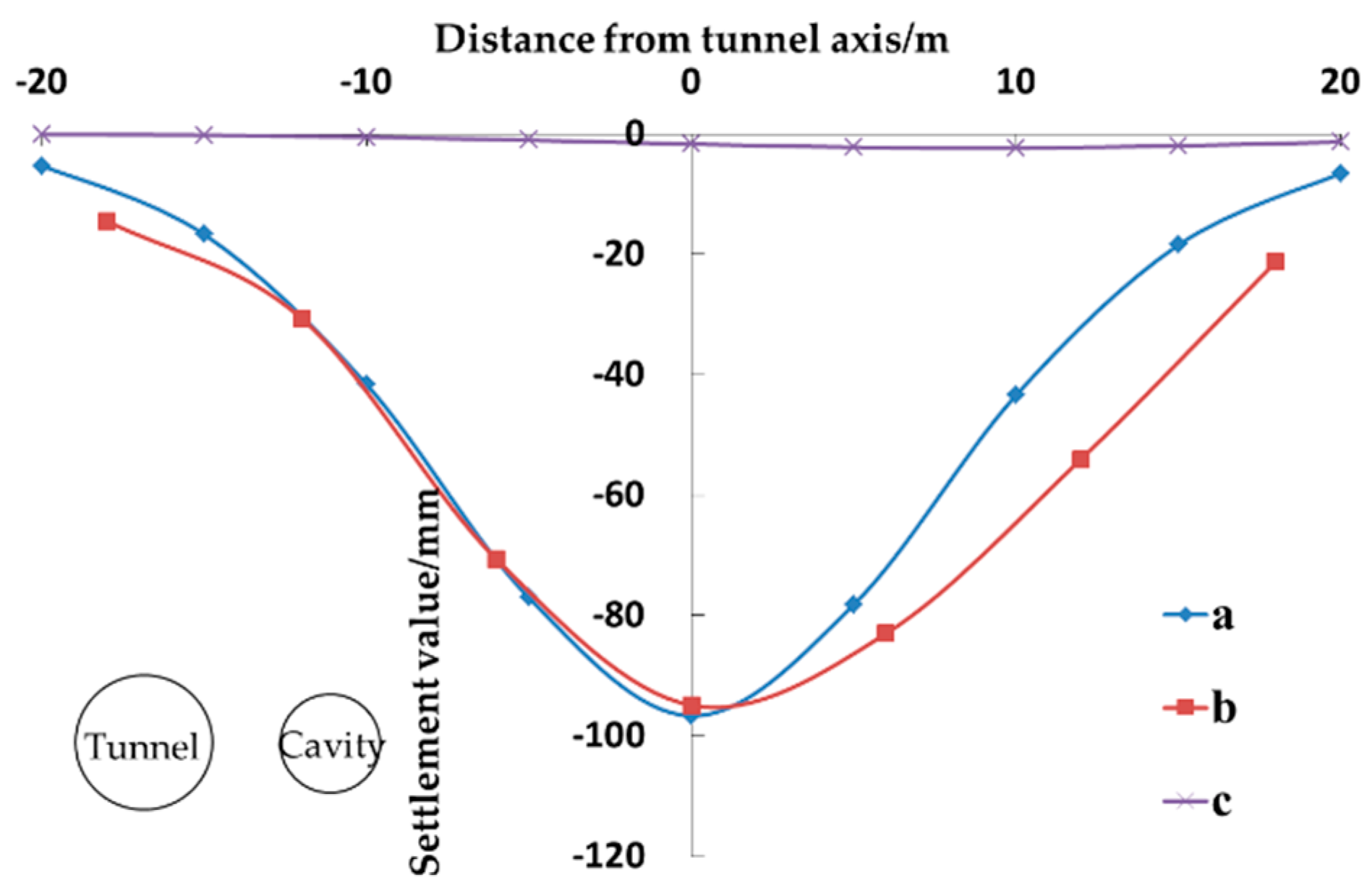

4.2. Comparison of Results in Different Convergence Deformation Modes

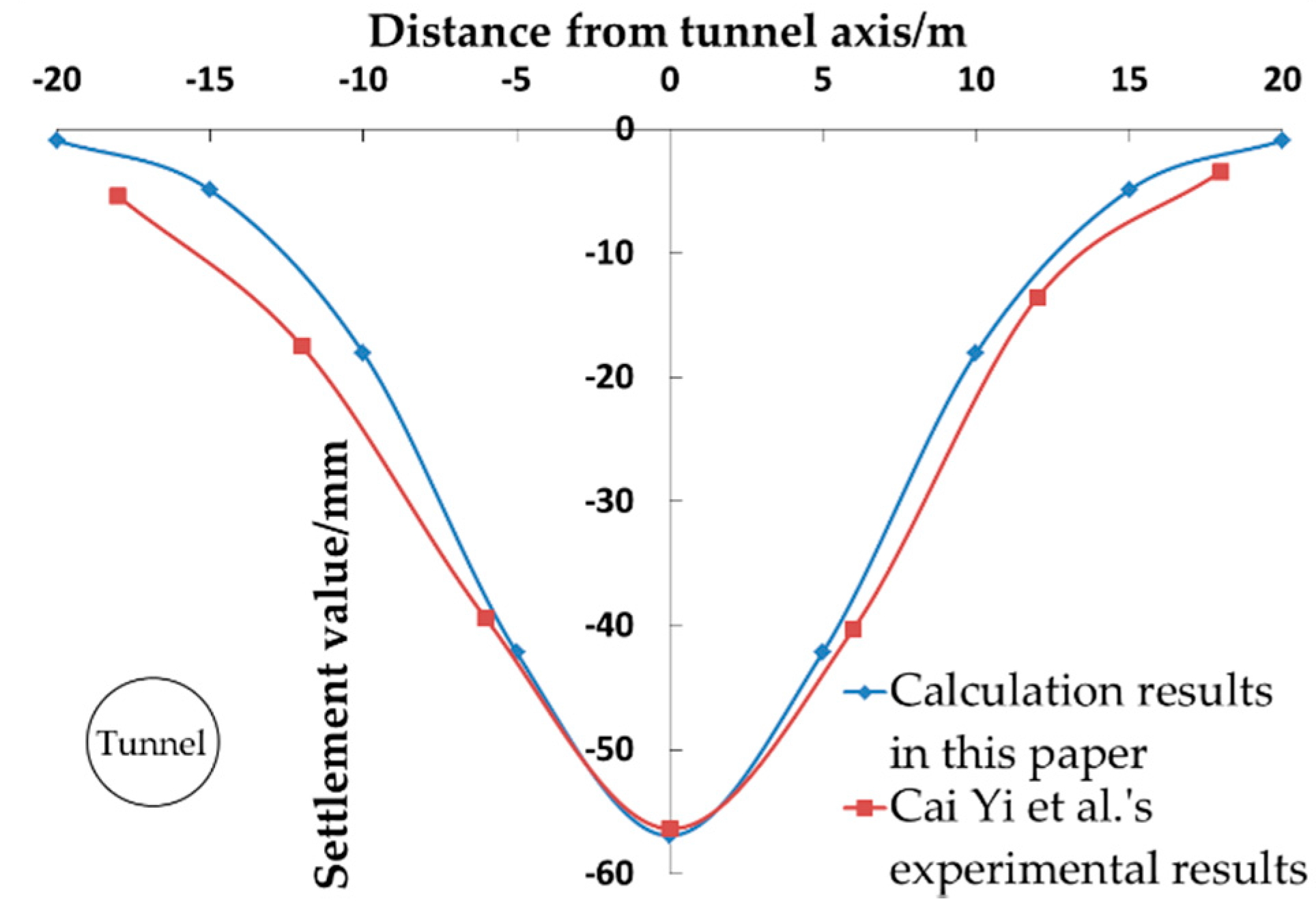

4.3. Calculation Results and Reliability Verification of Devised Method

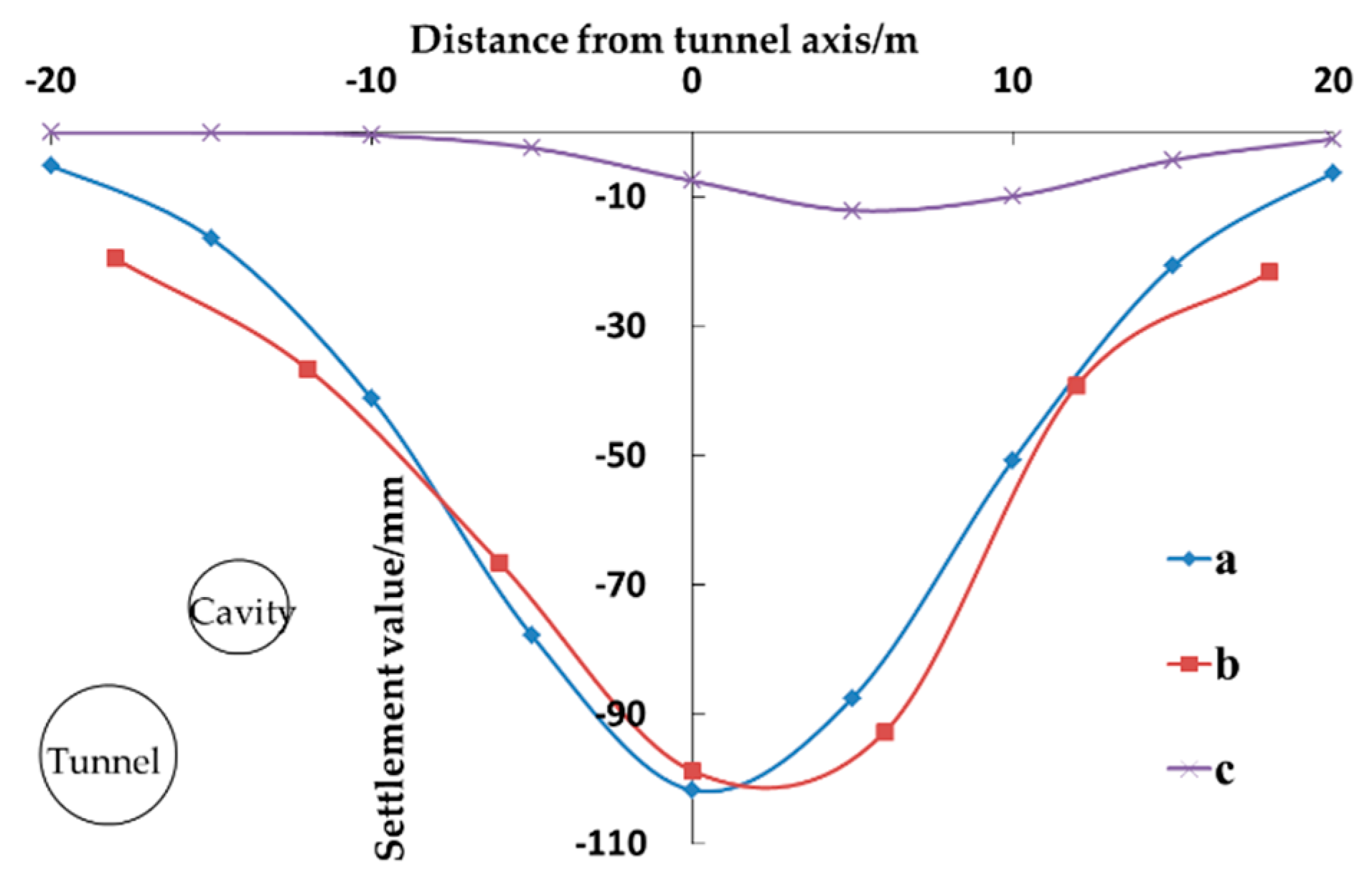

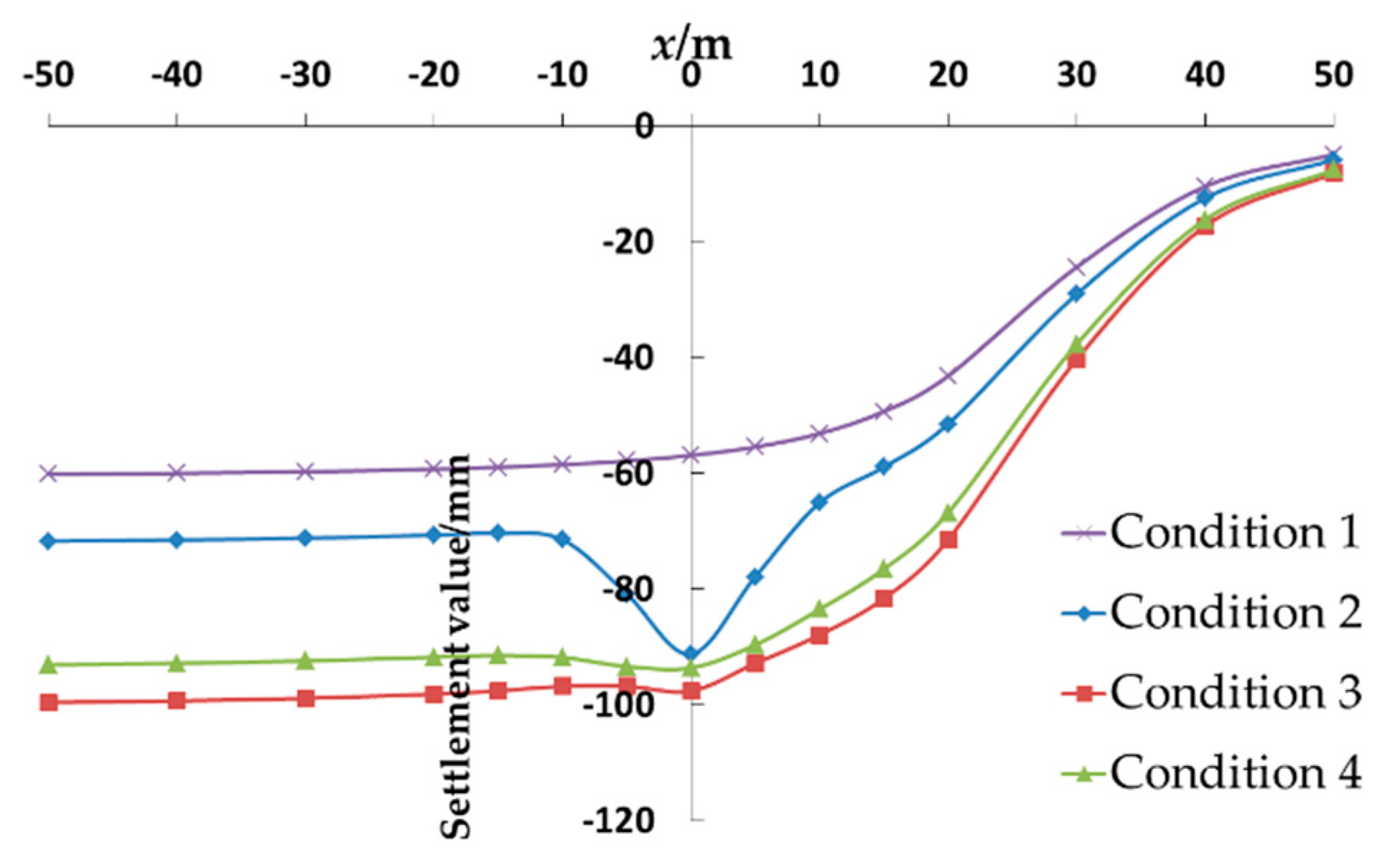

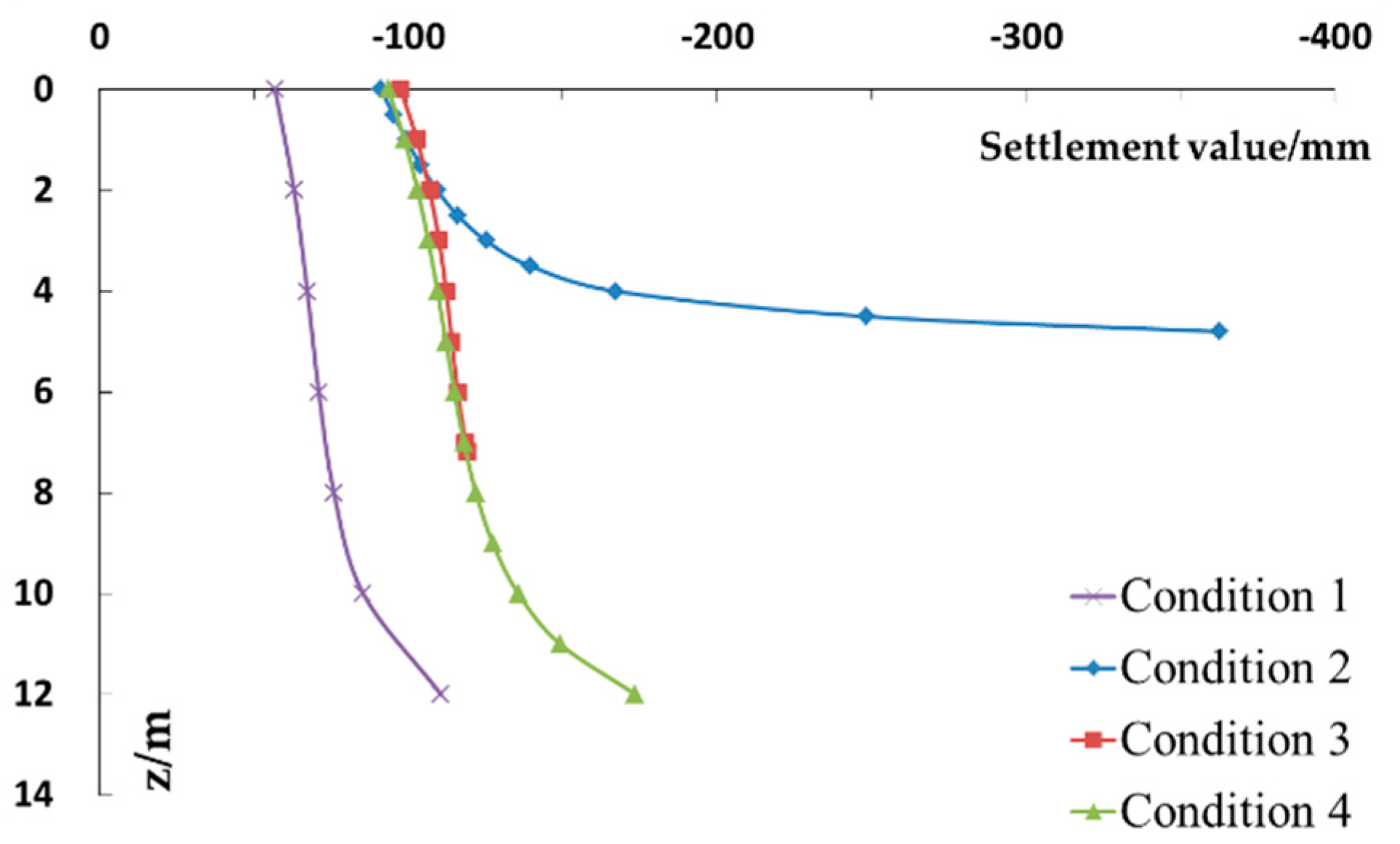

4.4. Distribution Law of Vertical Displacement of Soil along x-Axis and z-Axis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fang, Q.; Zhang, D.; Wang, L. Environmental risk management for a cross interchange subway station construction in China. Tunn. Undergr. Space Technol. 2011, 26, 750–763. [Google Scholar] [CrossRef]

- Meguid, M.A.; Dang, H.K. The effect of erosion voids on existing tunnel linings. Tunn. Undergr. Space Technol. 2009, 24, 278–286. [Google Scholar] [CrossRef]

- Leung, C.; Meguid, M.A. An experimental study of the effect of local contact loss on the earth pressure distribution on existing tunnel linings. Tunn. Undergr. Space Technol. 2011, 26, 139–145. [Google Scholar] [CrossRef]

- Cai, Y.; Zhang, C.P.; Min, B. Deformation characteristics of ground with voids induced by shallow metro tunneling. Chin. J. Geotech. Eng. 2019, 41, 534–543. [Google Scholar]

- Islam, R.; Jalali, J.S.; Vaziri, H.H. An analytical model for stability analysis of rock layers over a circular opening. Int. J. Solids Struct. 2001, 38, 3735–3757. [Google Scholar]

- Augarde, C.E.; Lyamin, A.V.; Sloan, S.W. Prediction of undrained sinkhole collapse. J. Geotech. Geoenviron. Eng. 2003, 129, 197–205. [Google Scholar] [CrossRef]

- Zhang, C.-P.; Zhang, D.L.; Wang, M.S.; Li, Q.Q.; Liu, S.C. Catastrophe mechanism and control technology of ground collapse induced by urban tunneling. Rock Soil Mech. 2010, 31, 303–309. [Google Scholar]

- Zhang, Y.; Zhang, C.P.; Li, Q.Q.; Zheng, L.; Yi, C. Influence of Cavity above Tunnel on Stratum Deformation and Failure in Urban Tunneling. Appl. Mech. Mater. 2012, 170, 1810–1815. [Google Scholar] [CrossRef]

- Li, Q.Q.; Zhang, D.L.; Fang, Q. Analytic solution to initial damage of cavern strata by complex function method. Chin. J. Geotech. Eng. 2014, 36, 2110–2117. [Google Scholar]

- Yang, G.B.; Zhang, C.P.; Min, B.; Cai, Y. Elastic solution of soil displacement induced by shallow circular tunnel with a cavern in a stratum using function of complex variable method. Rock Soil Mech. 2018, 39, 25–36. [Google Scholar]

- Yang, X.L.; Wang, J.M. Ground movement prediction for tunnels using simplified procedure. Tunn. Undergr. Space Technol. 2011, 26, 462–471. [Google Scholar] [CrossRef]

- Park, K.H. Elastic Solution for Tunneling-Induced Ground Movements in Clays. Int. J. Geomech. 2004, 4, 310–318. [Google Scholar] [CrossRef]

- Golpa, S.N.M.; Do, N.A.; Dias, D. Impact of pre-existent Qanats on ground settlements due to mechanized tunneling. Transp. Geotech. 2019, 21, 100262. [Google Scholar]

- Yao, Q.; Di, H.; Ji, C. Ground collapse caused by shield tunneling in sandy cobble stratum and its control measures. Bull. Eng. Geol. Environ. 2020, 79, 5599–5614. [Google Scholar] [CrossRef]

- Wang, Z.; Qu, T.; Li, B. Analysis of Stratigraphic Subsidence Caused by Sand Leakage in Tunnel Lining. Geotech. Geol. Eng. 2020, 39, 2029–2039. [Google Scholar] [CrossRef]

- Hu, X.; Jiang, X.; Li, K.; Cui, X. Research on Tunnel Lining Cavity Treatment Technology of a Metro Tunnel in Chongqing. In IOP Conference Series Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019. [Google Scholar]

- Fazio, N.L.; Lollino, P.; Perrotti, M.; Parise, M.; Vattano, M.; Madonia, G.; Di Maggio, C. A three-dimensional back-analysis of the collapse of an underground cavity in soft rocks. Eng. Geol. 2016, 228, 301–311. [Google Scholar] [CrossRef]

- Qi, J.J.; Xu, R.Q.; Wei, G. Research on calculation method of soil 3D displacement due to shield tunnel construction. Rock Soil Mech. 2009, 30, 2442–2446. [Google Scholar]

- Wei, G. 3-D Analytical Solution of Ground Deformation Induced by Shield Tunneling Construction. Available online: https://www.researchgate.net/publication/290288412_Prediction_of_ground_deformation_induced_by_shield_tunneling_construction (accessed on 1 March 2021).

- Sun, S.; He, P.; Wang, G.; Li, W.; Wang, H.; Chen, D.; Xu, F. Shape characterization methods of irregular cavity using Fourier analysis in tunnel. Math. Comput. Simul. 2021, 187, 191–214. [Google Scholar] [CrossRef]

- Tian, S. Deformations and Progressive Failure Laws of the Ground with Voids Influenced by Shallow Tunneling. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2016. [Google Scholar]

- Loganathan, N.; Poulos, H.G. Analytical prediction for tunneling-induced ground movement in clays. J. Geotech. Geoenviron. Eng. 1998, 124, 846–856. [Google Scholar] [CrossRef]

- Verruijt, A.; Booker, J.R. Surface settlements due to deformation of a tunnel in an elastic half plane. Geotechnique 1996, 46, 753–756. [Google Scholar] [CrossRef]

- Wei, G. Prediction of ground deformation induced by shield tunneling construction. Chin. J. Rock Mech. Eng. 2009, 28, 418–424. [Google Scholar]

- Jiang, X.L.; Zhao, Z.M.; Li, Y. Analysis and calculation of surface and subsurface settlement trough profiles due to tunneling. Rock Soil Mech. 2004, 25, 1542–1544. [Google Scholar]

- Knothe, S. Observations of surface movements under influence of mining and their theoretical interpretation. In Proceedings of the European Congress on Ground Movement, Leeds, UK, 9–12 April 1957. [Google Scholar]

- Peck, R.B. Deep excavations and tunneling in soft ground. In Proceedings of the 7th International Conference on Soil Mechanics and Foundation Engineering, Mexico City, Mexico, 1969; Sociedad Mexicana de Mecanica: Mexico City, Mexico, 1969. [Google Scholar]

- O’Reilly, M.P.; New, B.M. Settlements above tunnels in the United Kingdom their magnitude and prediction. In Proceedings of the Tunneling’ 82 Symposium, Brighton, UK, 7–11 June 1982. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Y.; Qi, Y.; Dai, Z.; Wei, G. A Method for Calculating Soil Deformation Induced by Shielded Tunneling in Ground Stratum with Cavities. Symmetry 2021, 13, 1048. https://doi.org/10.3390/sym13061048

Cui Y, Qi Y, Dai Z, Wei G. A Method for Calculating Soil Deformation Induced by Shielded Tunneling in Ground Stratum with Cavities. Symmetry. 2021; 13(6):1048. https://doi.org/10.3390/sym13061048

Chicago/Turabian StyleCui, Yunliang, Yongjie Qi, Zihan Dai, and Gang Wei. 2021. "A Method for Calculating Soil Deformation Induced by Shielded Tunneling in Ground Stratum with Cavities" Symmetry 13, no. 6: 1048. https://doi.org/10.3390/sym13061048

APA StyleCui, Y., Qi, Y., Dai, Z., & Wei, G. (2021). A Method for Calculating Soil Deformation Induced by Shielded Tunneling in Ground Stratum with Cavities. Symmetry, 13(6), 1048. https://doi.org/10.3390/sym13061048