Research on Segmented Primary Consequent-Pole Permanent Magnet Linear Synchronous Motor with Symmetric and Periodic End Force

Abstract

:1. Introduction

2. End Force Model of CP-PMLSM

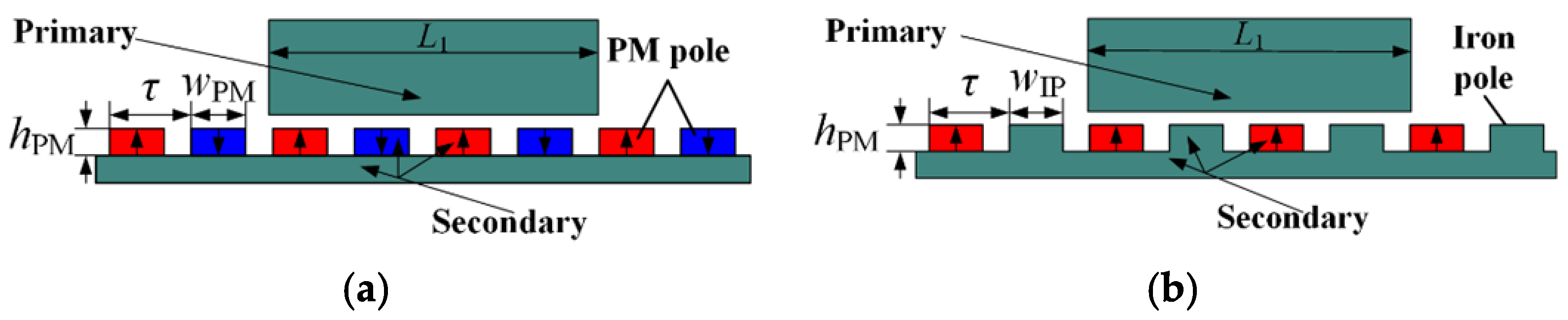

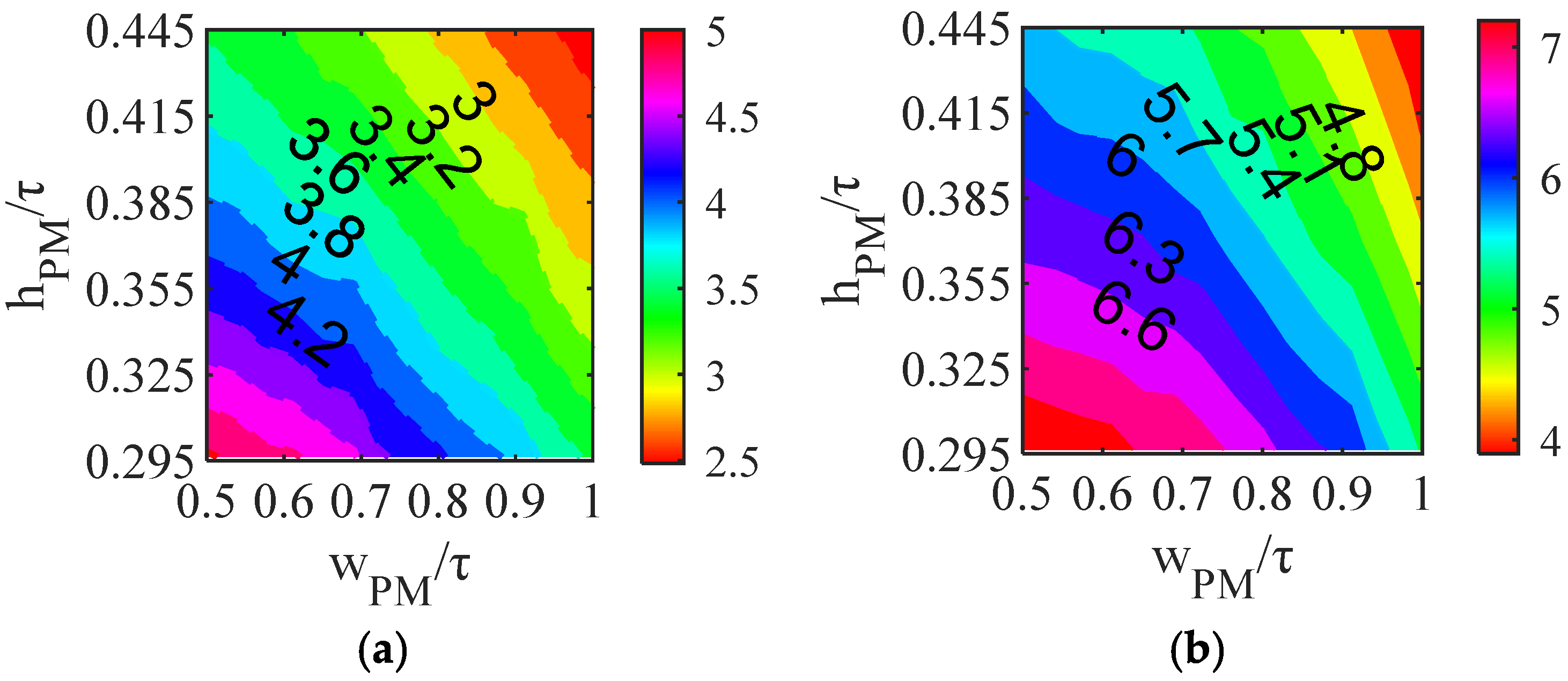

2.1. Structure of CP-PMLSM

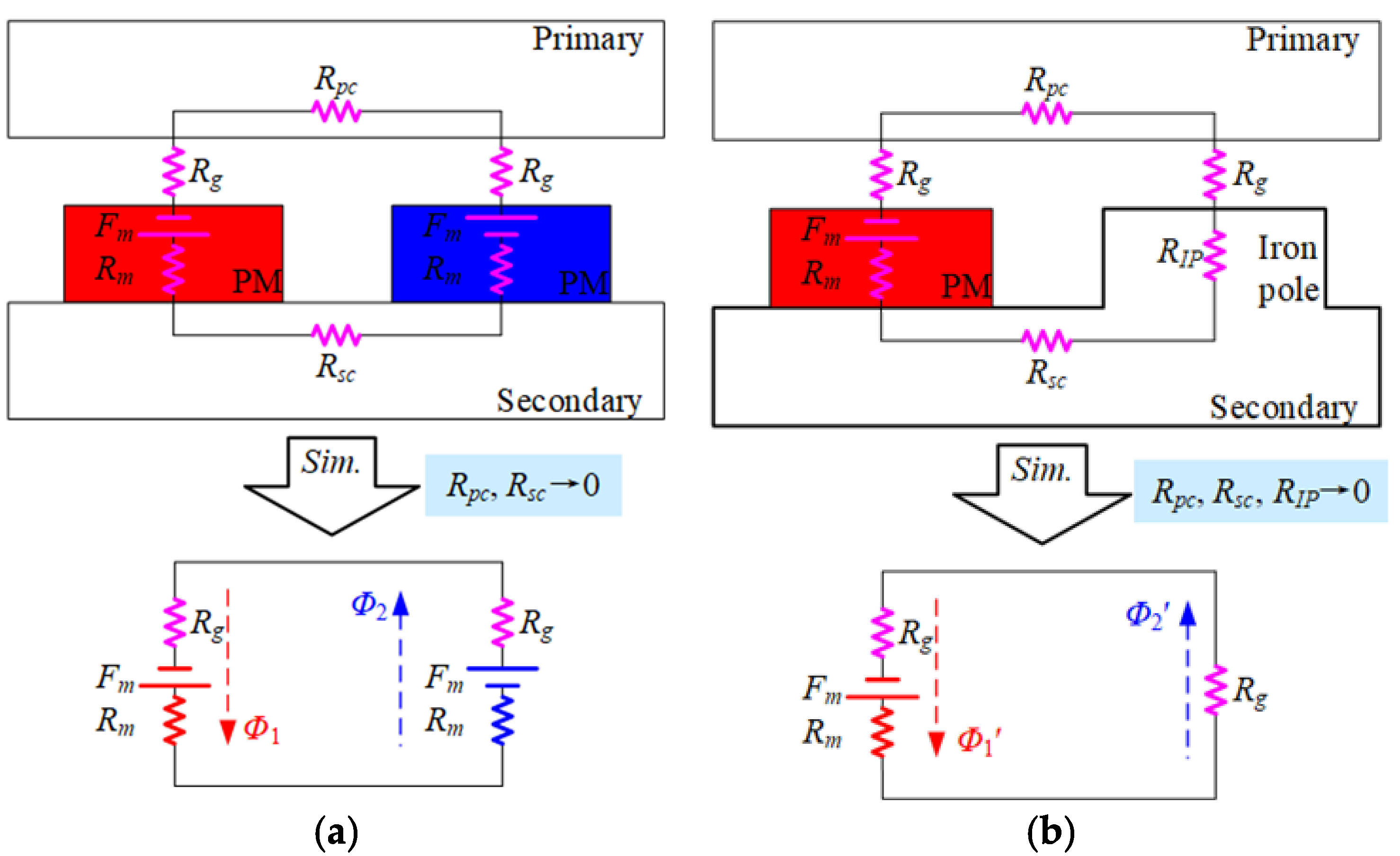

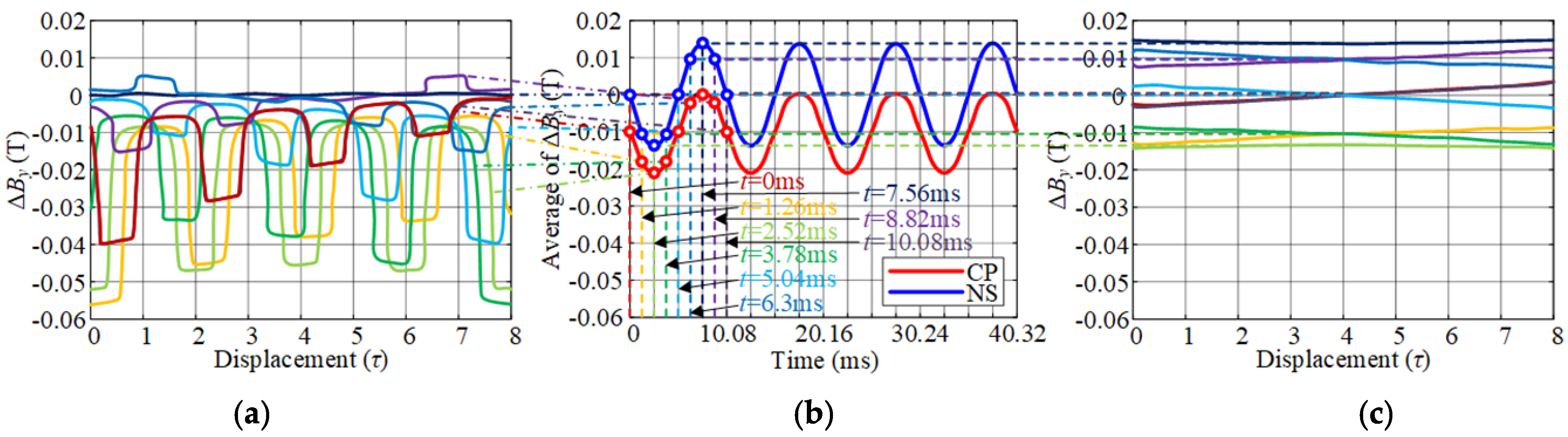

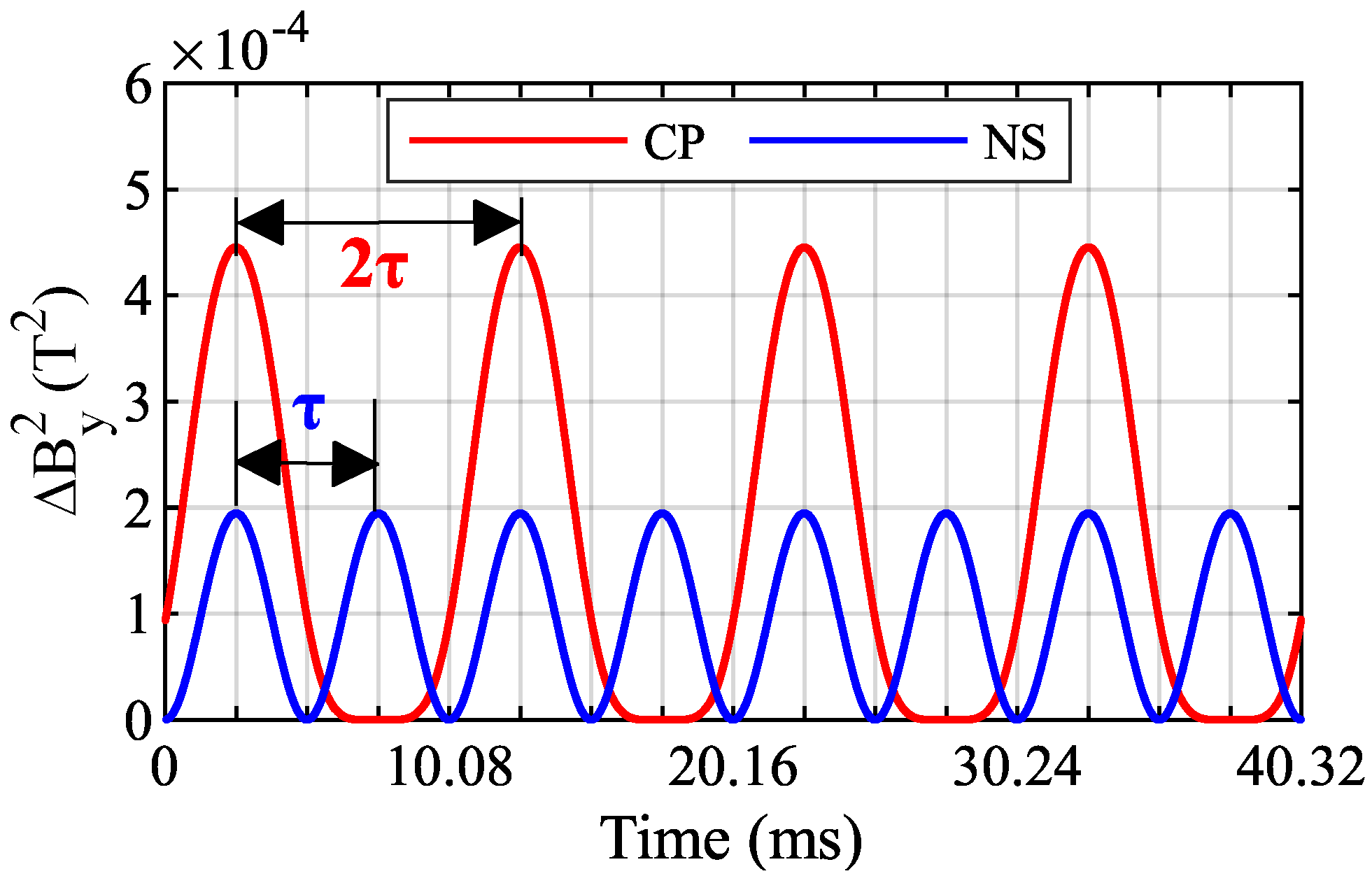

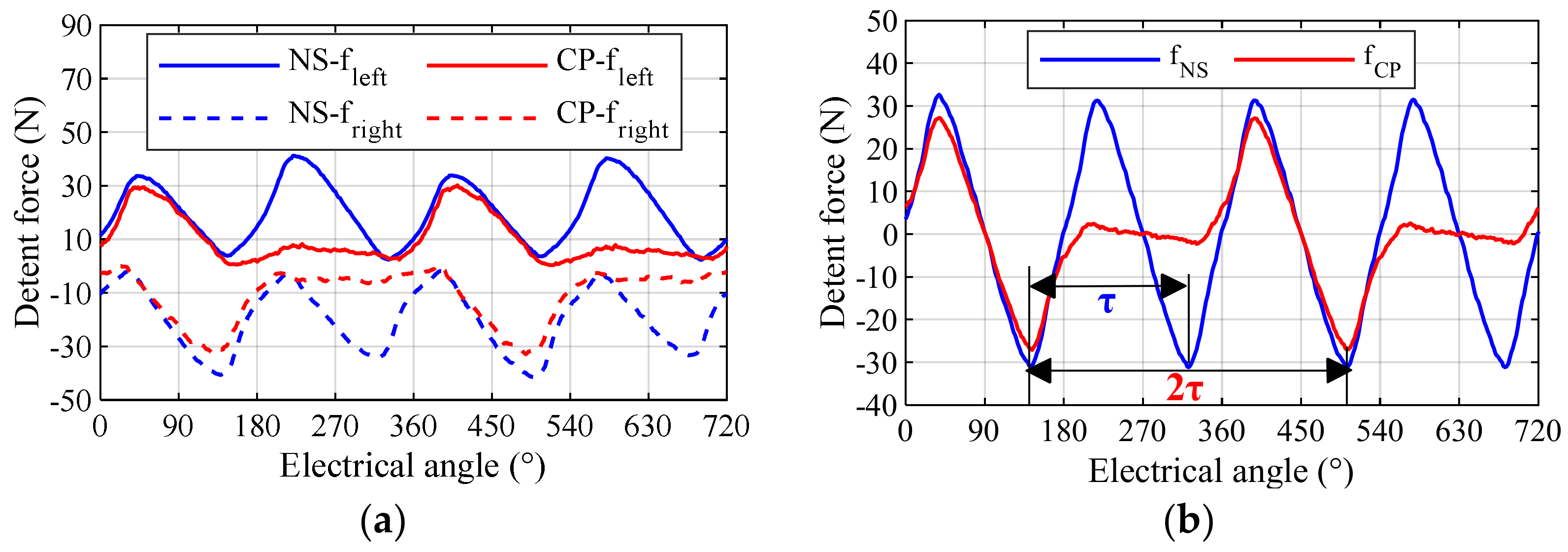

2.2. Characteristics of Pulsating Magnetic Fields

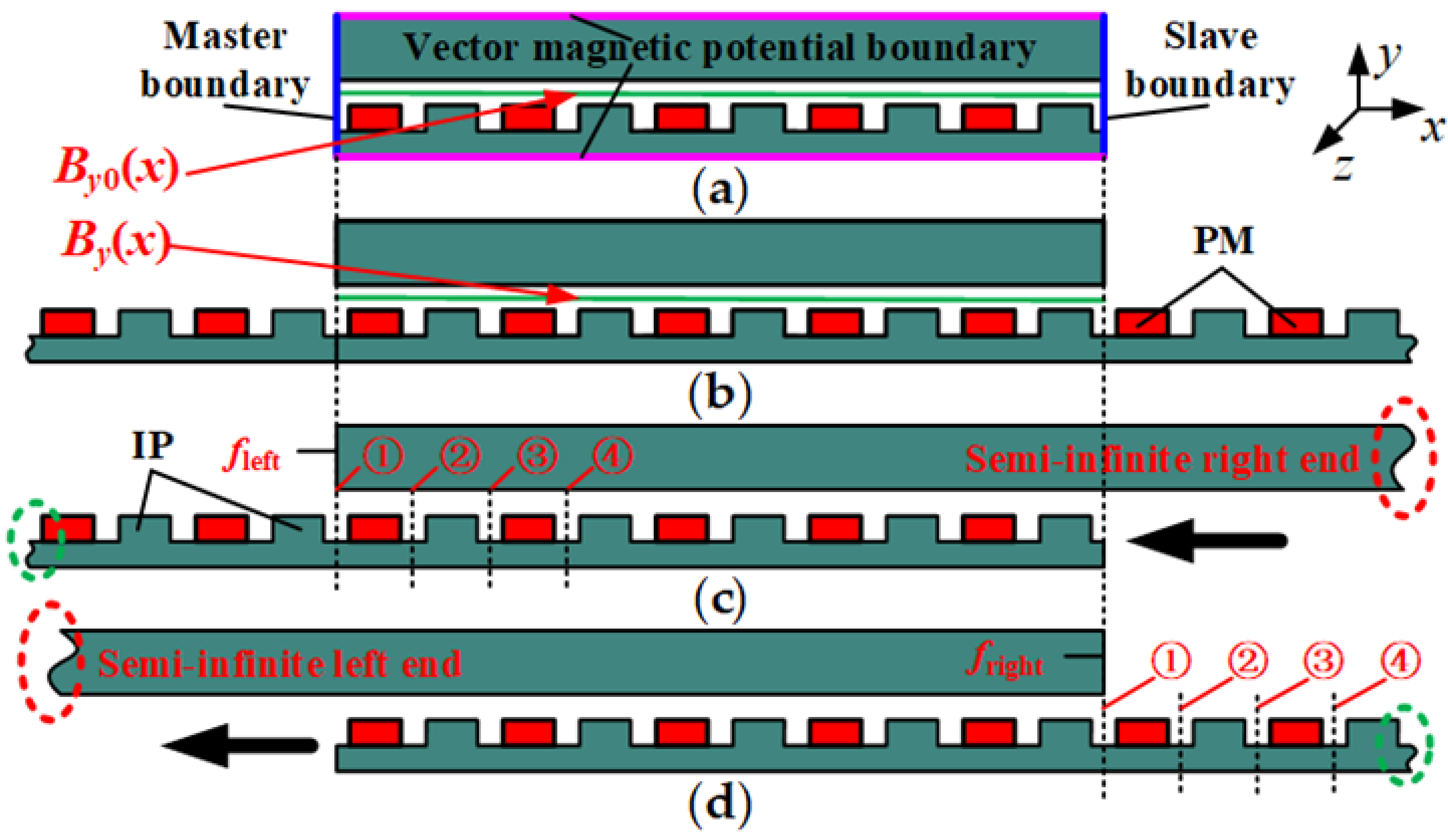

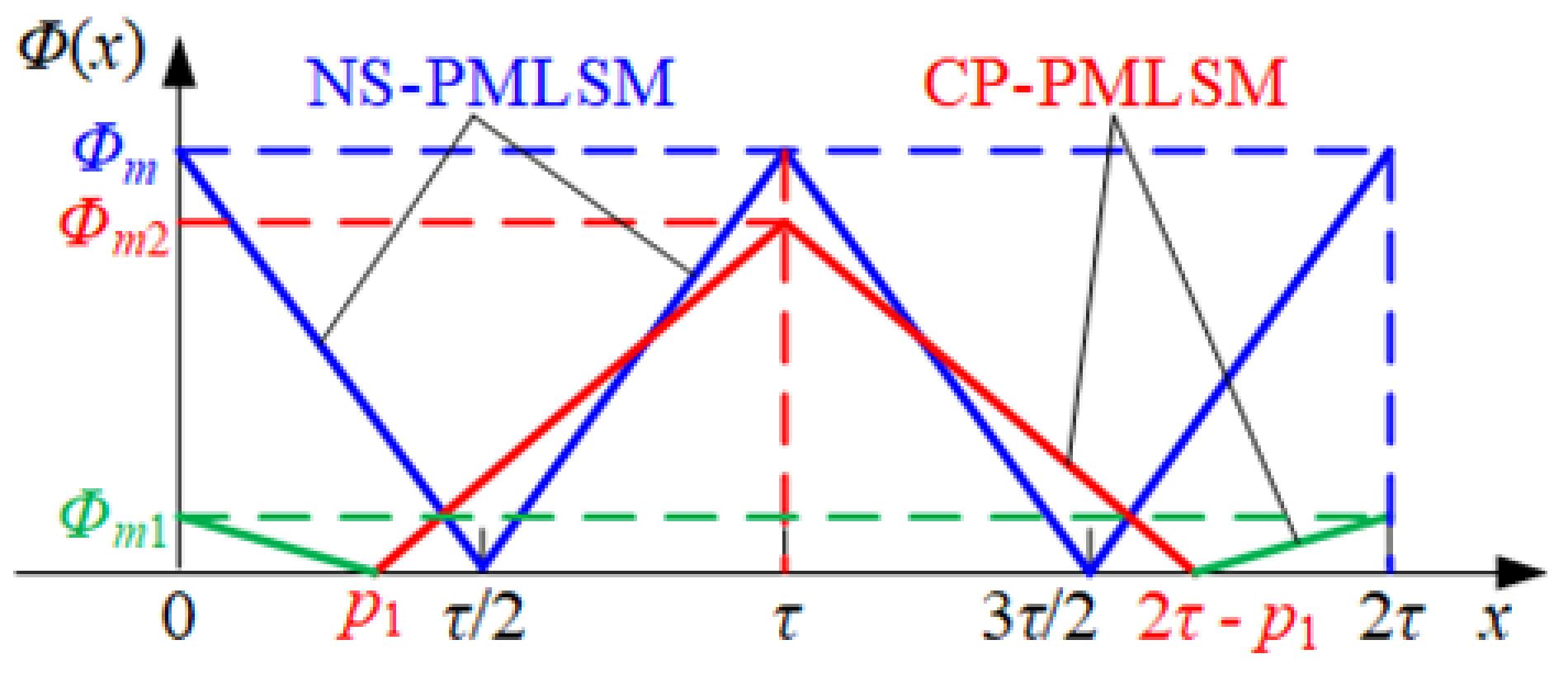

2.3. Modeling of CP-PMLSM’s Magnetic Flux Function through the Primary End

2.4. Modeling of CP-PMLSM’s End Force

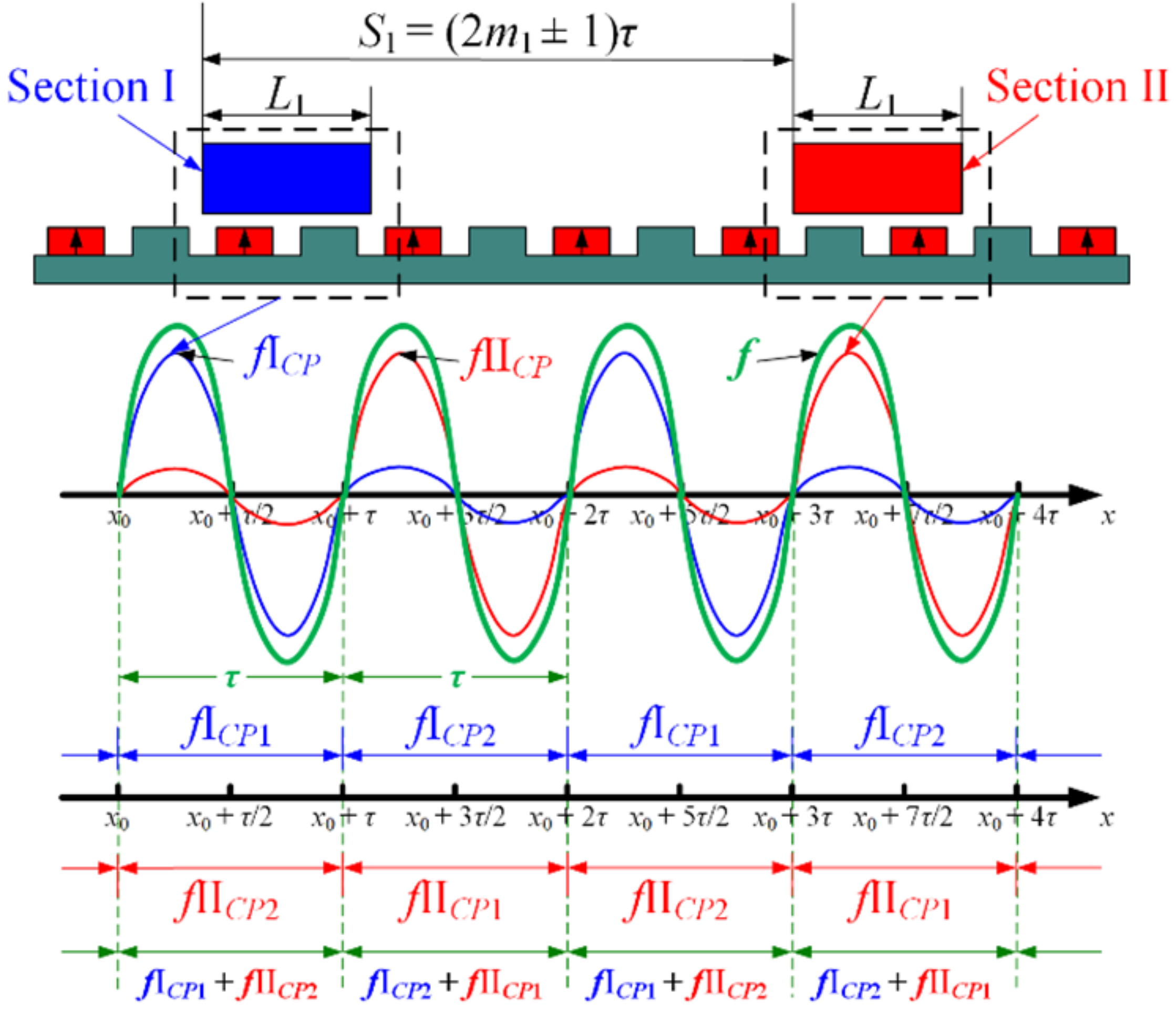

3. Two-Segment Design to Adjust the Period and Symmetry of the CP-PMLSM’s End Force

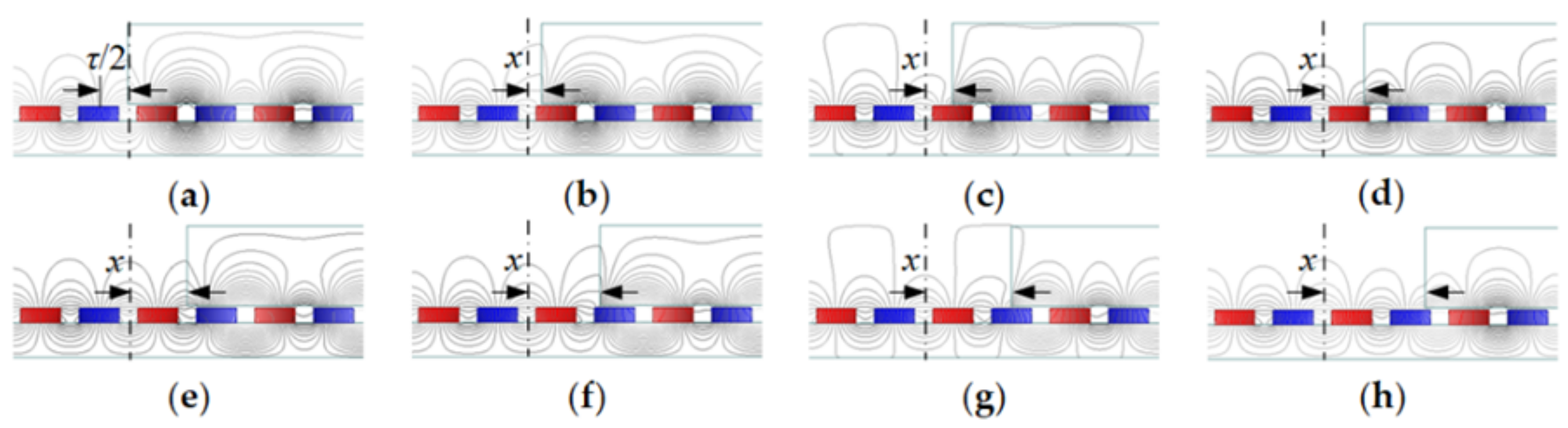

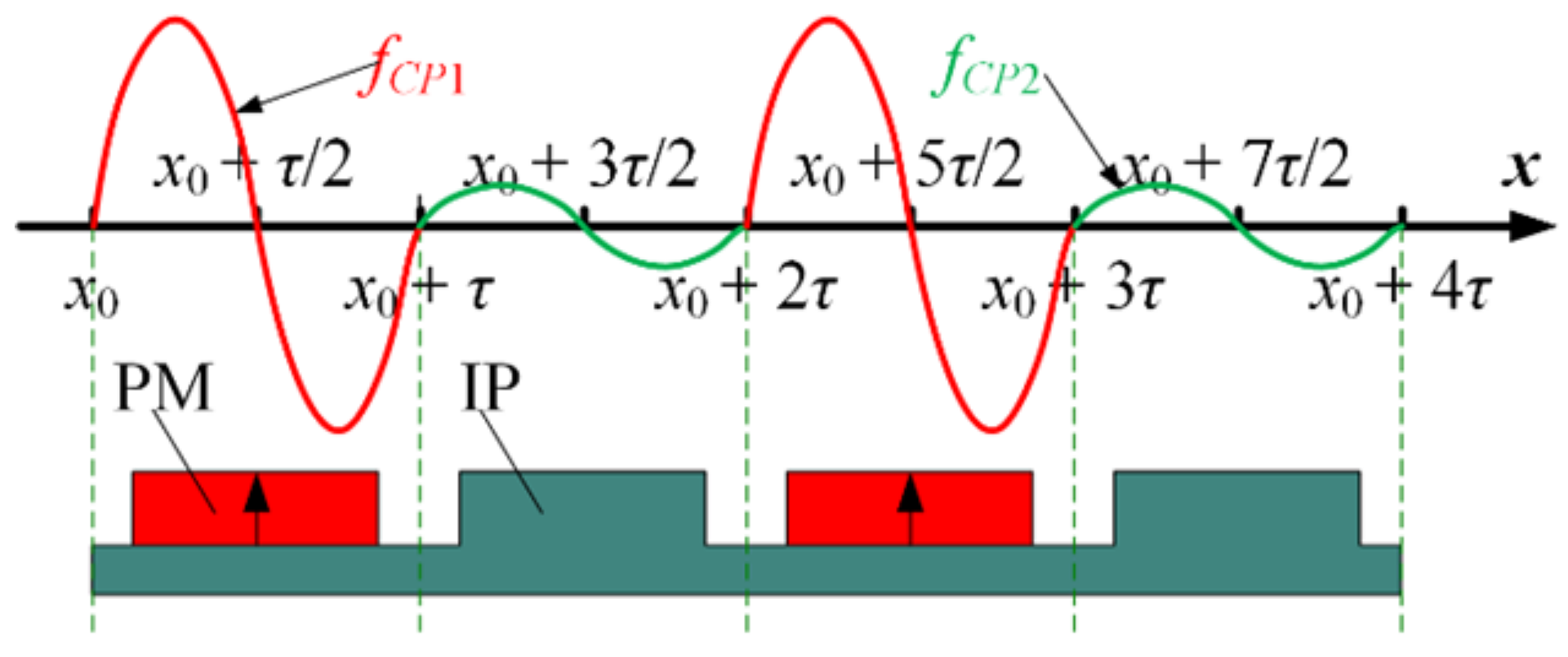

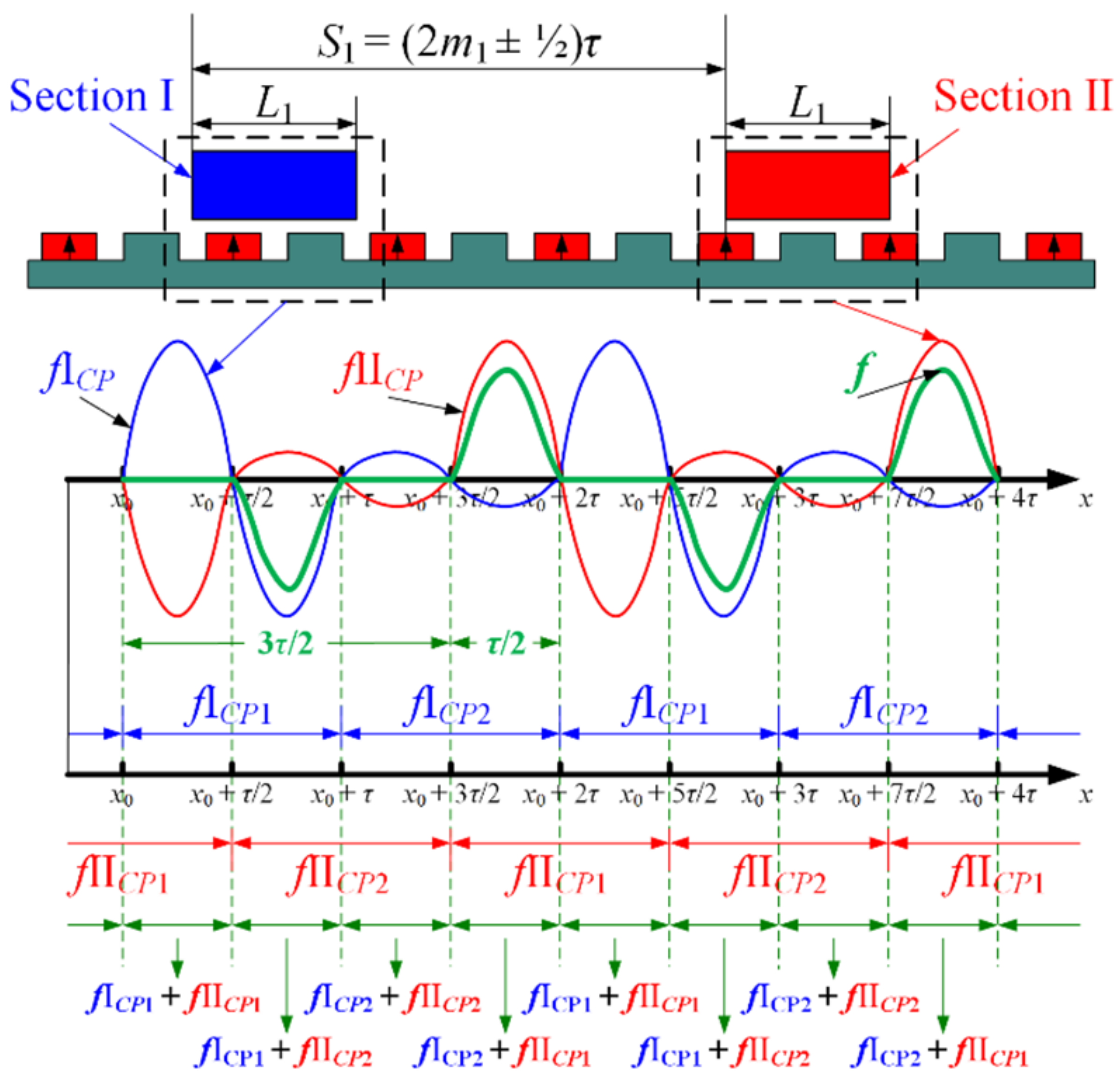

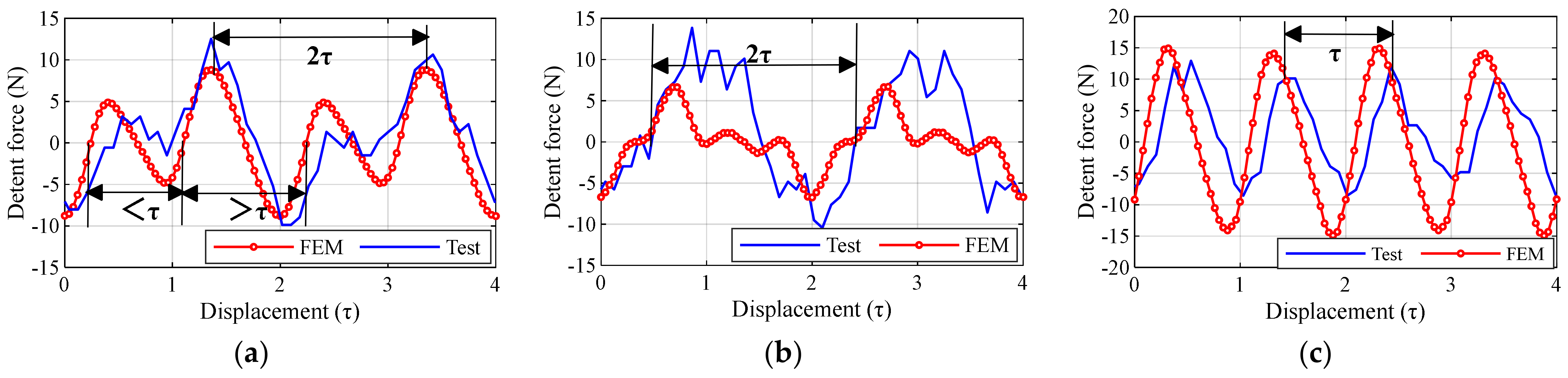

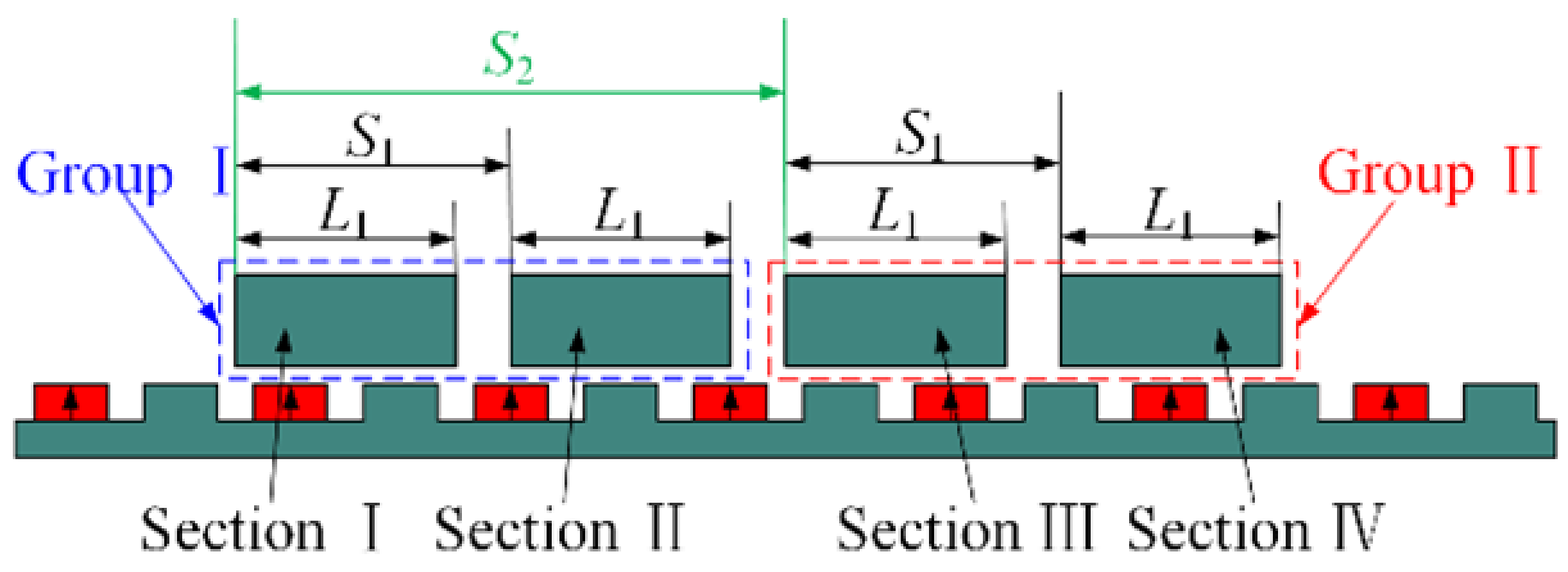

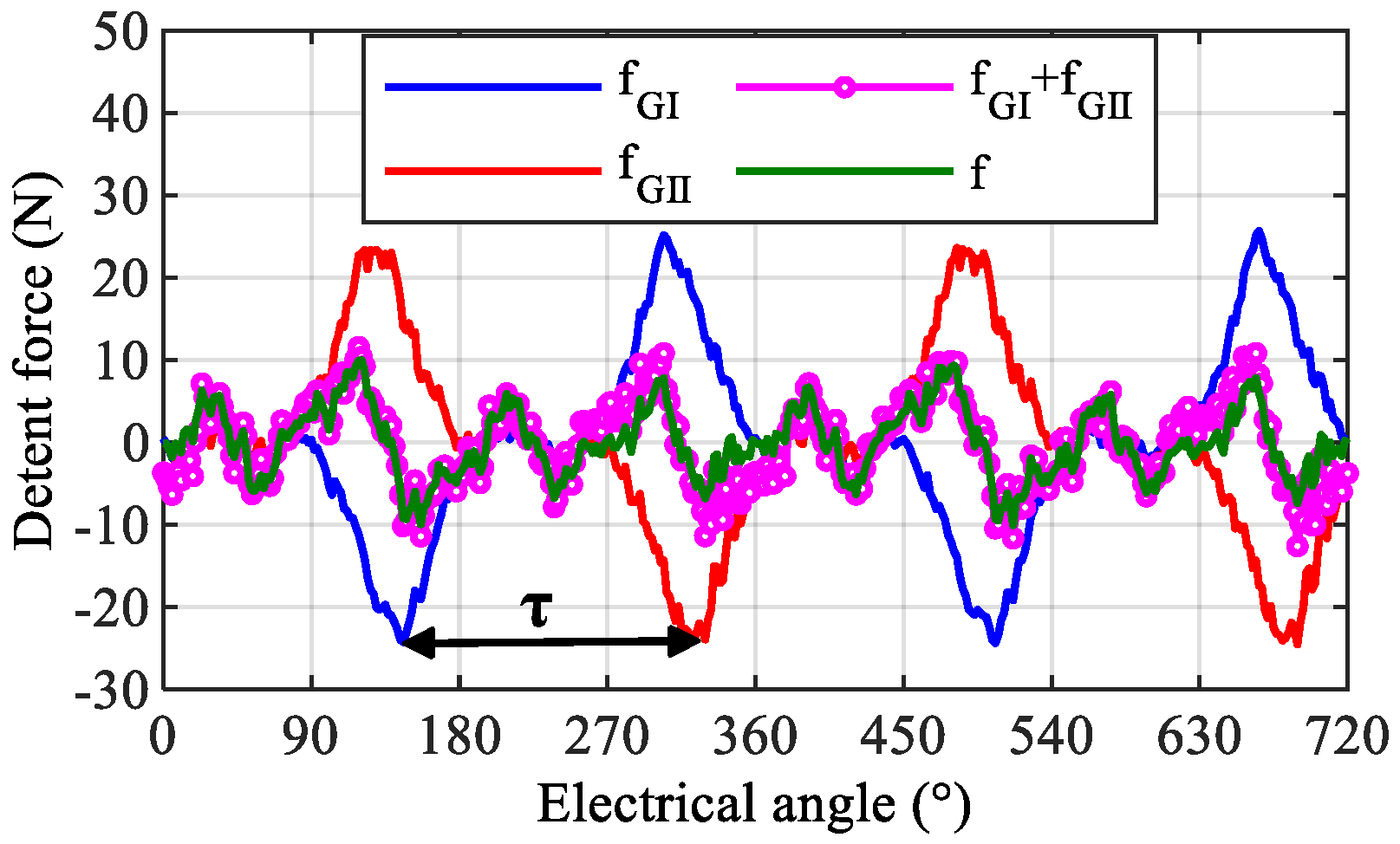

3.1. First Two-Segment Design to Adjust the Period to 2τ

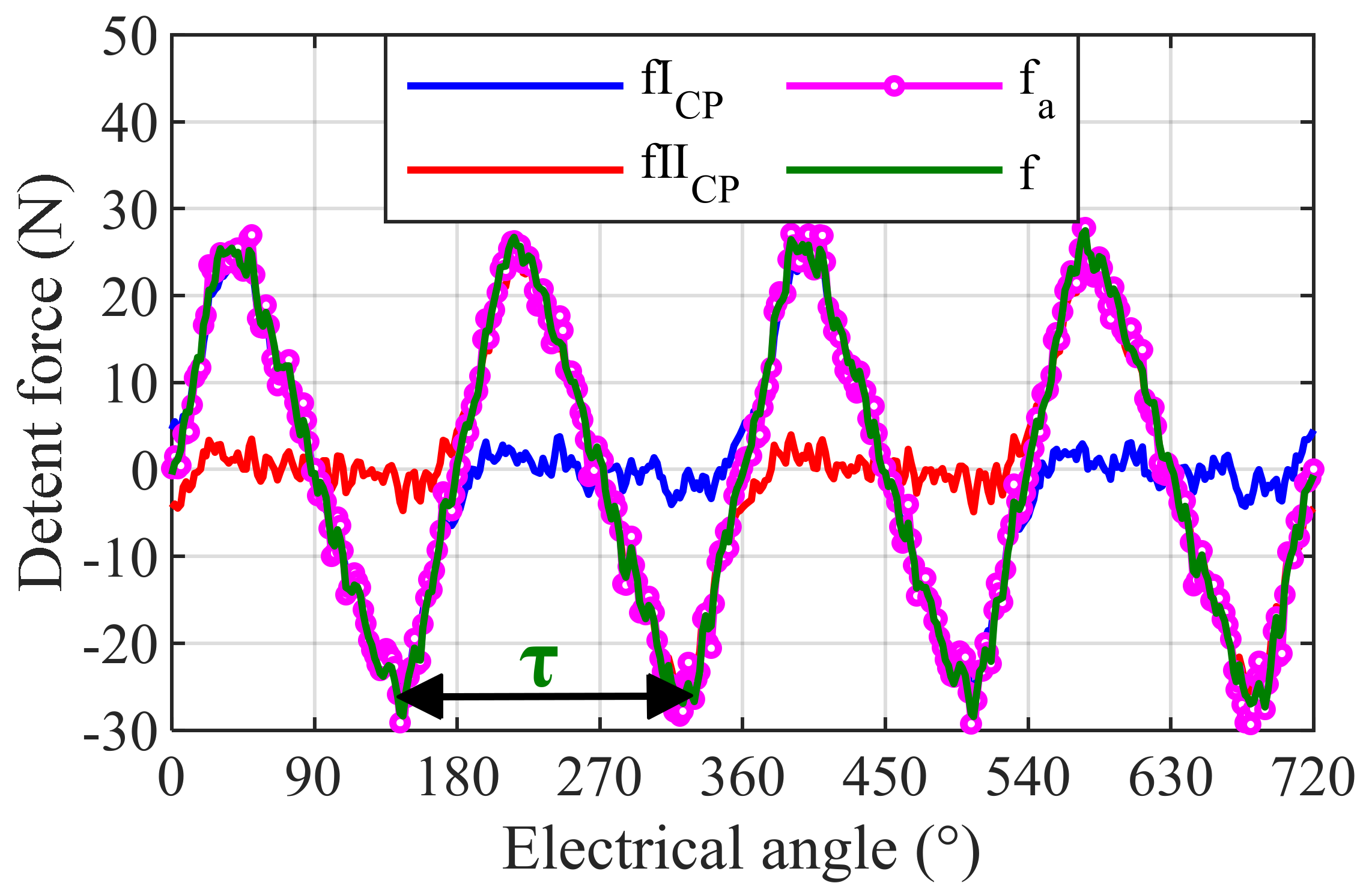

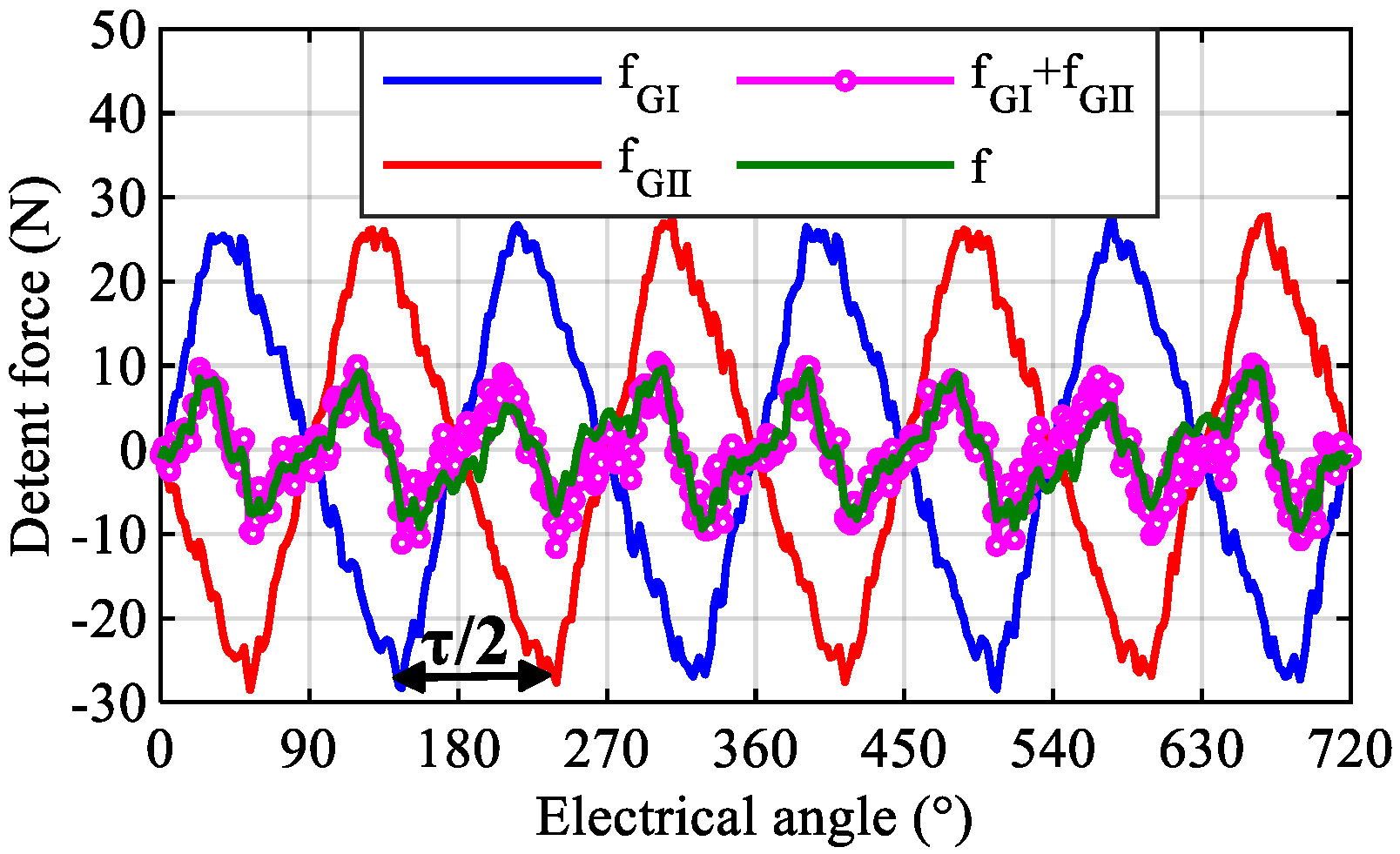

3.2. Second Two-Segment Design to Adjust the Period to τ

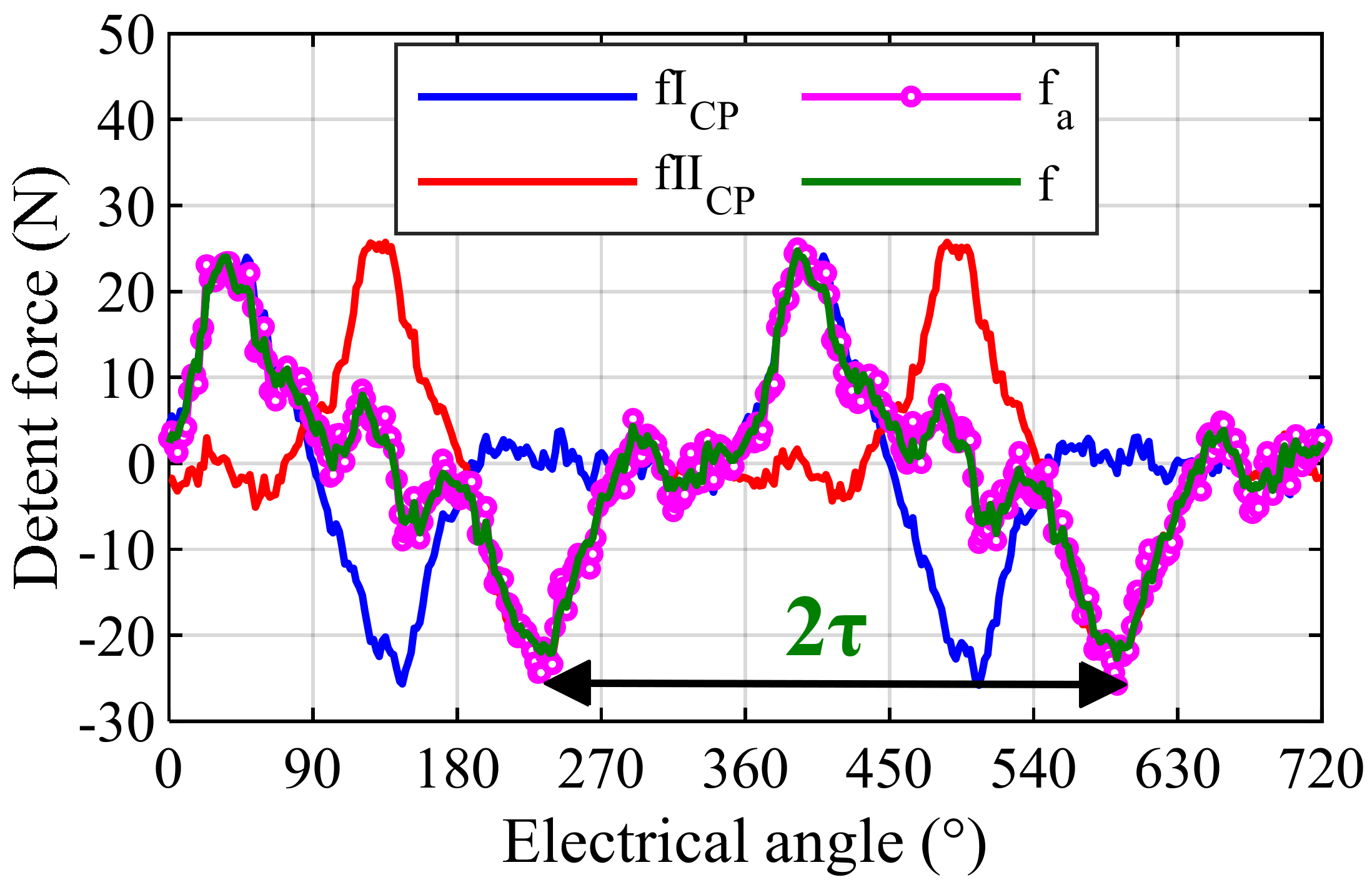

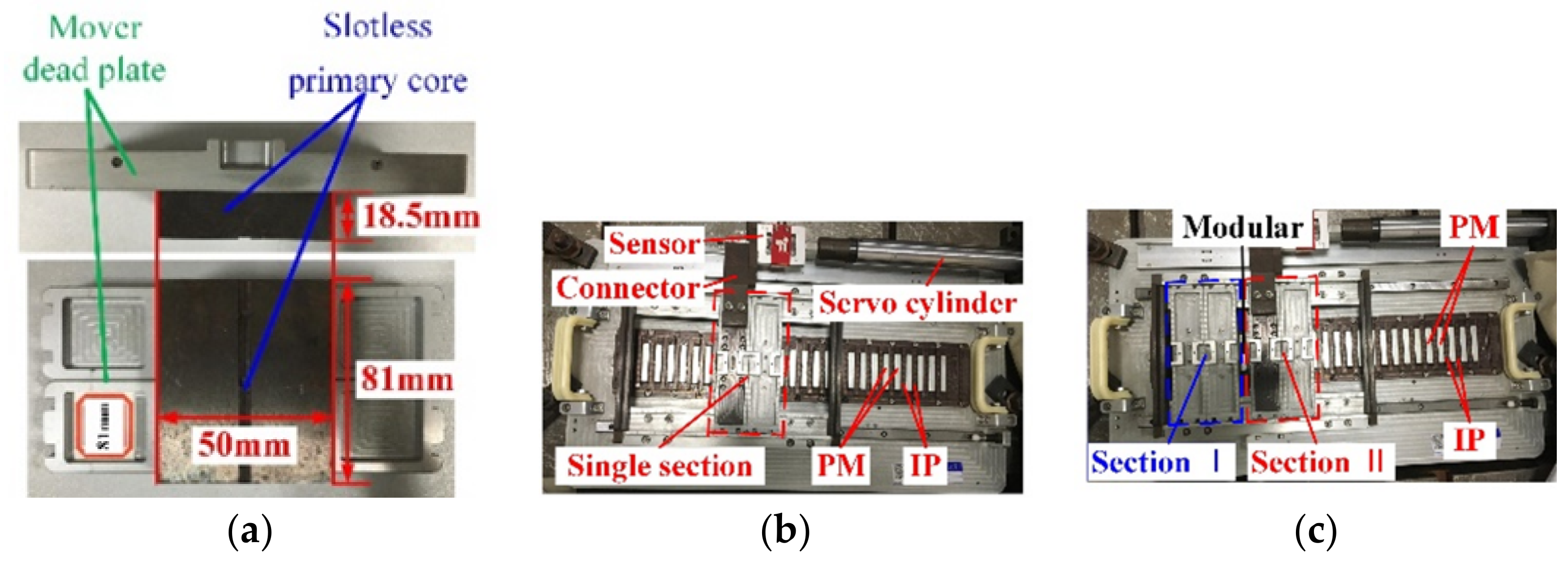

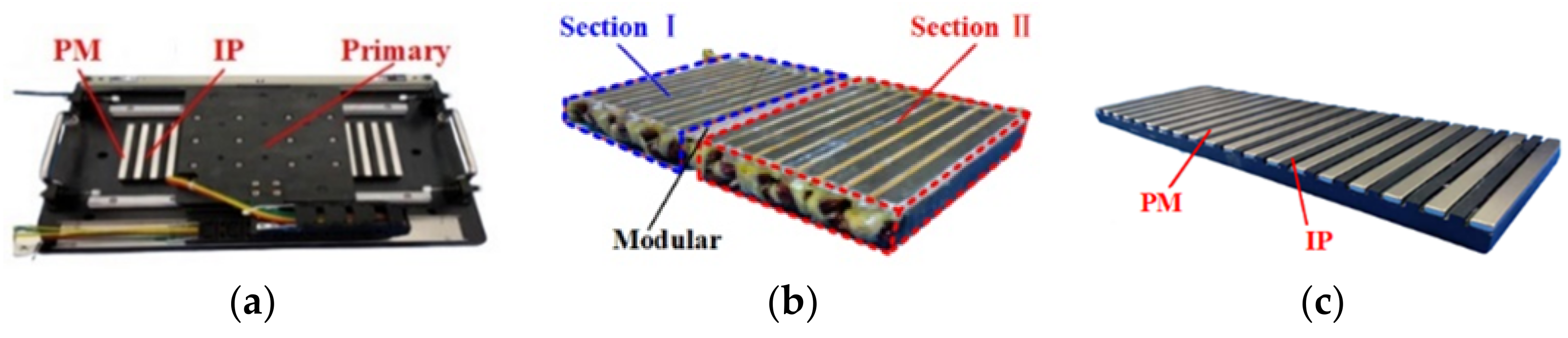

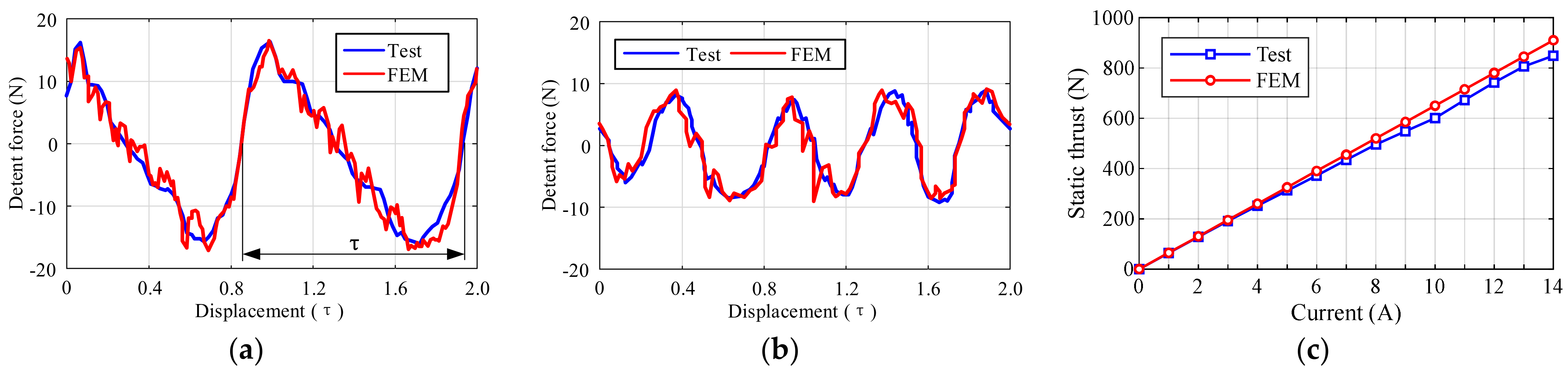

3.3. Experimental Verification

4. Four-Segment Design to Eliminate Odd Harmonics of the CP-PMLSM’s End Force

4.1. Four-Segment Structure and Spacing Matching

4.2. Experimental Verification

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Petrov, I.; Pyrhonen, J. Performance of low-cost permanent magnet material in PM synchronous machines. IEEE Trans. Ind. Electron. 2013, 60, 2131–2138. [Google Scholar] [CrossRef]

- Li, J.; Wang, K.; Liu, C. Torque improvement and cost reduction of permanent magnet machines with a dovetailed consequent-pole rotor. IEEE Trans. Energy Convers. 2018, 33, 1628–1640. [Google Scholar] [CrossRef]

- Li, J.; Wang, K.; Liu, C. Comparative study of consequent-pole and hybrid-pole permanent magnet machines. IEEE Trans. Energy Convers. 2019, 34, 701–711. [Google Scholar] [CrossRef]

- Qu, H.; Zhu, Z.Q.; Li, H.Y. Analysis of novel consequent pole flux reversal permanent magnet machines. IEEE Trans. Ind. Appl. 2021, 57, 382–396. [Google Scholar] [CrossRef]

- Yang, K.; Zhao, F.; Wang, Y.; Bao, Z.C. Consequent-pole flux reversal permanent magnet Machine with halbach array magnets in rotor slot. IEEE Trans. Magn. 2021, 57, 8100905. [Google Scholar] [CrossRef]

- Yang, X.B.; Kou, B.Q.; Luo, J.; Zhang, H. A novel dual-consequent-pole transverse flux motor and its analytical modeling. IEEE Trans. Ind. Electron. 2021, 68, 4141–4152. [Google Scholar] [CrossRef]

- Chung, S.U.; Kim, J.W.; Chun, Y.D.; Woo, B.C.; Hong, D.K. Fractional slot concentrated winding PMSM with consequent pole rotor for a low-speed direct drive: Reduction of rare earth permanent magnet. IEEE Trans. Energy Convers. 2015, 30, 103–109. [Google Scholar] [CrossRef]

- Chung, S.U.; Moon, S.H.; Kim, D.J.; Kim, J.M. Development of a 20-pole–24-slot SPMSM with consequent pole rotor for in-wheel direct drive. IEEE Trans. Ind. Electron. 2016, 63, 302–309. [Google Scholar] [CrossRef]

- Li, F.; Wang, K.; Li, J.; Zhang, H.J. Suppression of even-order harmonics and torque ripple in outer rotor consequent-pole PM machine by multilayer winding. IEEE Trans. Magn. 2018, 54, 8108605. [Google Scholar] [CrossRef]

- Li, F.; Wang, K.; Sun, H.Y.; Kong, J.W. Influence of various magnetic pole on electromagnetic performance of consequent-pole permanent magnet machine. IEEE Access 2019, 7, 121853–121862. [Google Scholar] [CrossRef]

- Li, F.; Wang, K.; Li, J.; Sun, H.Y.; Luk, P.C.K. Electromagnetic performance analysis of PMSM with eccentric consequent pole rotor. In Proceedings of the 2017 7th International Conference on Power Electronics Systems and Applications—Smart Mobility, Power Transfer & Security (PESA), Hong Kong, China, 12–14 December 2017; Institute of Electrical and Electronics Engineers: New York, NY, USA, 1963. [Google Scholar] [CrossRef]

- Li, J.; Wang, K.; Li, F.; Zhu, S.S.; Liu, C. Elimination of even-order harmonics and unipolar leakage flux in consequent-pole PM machines by employing N-S-iron–S-N-iron rotor. IEEE Trans. Ind. Electron. 2019, 66, 1736–1747. [Google Scholar] [CrossRef]

- Li, J.; Wang, K. Analytical determination of optimal PM-arc ratio of consequent-pole permanent magnet machines. IEEE/ASME Trans. Mechatron. 2018, 23, 2168–2177. [Google Scholar] [CrossRef]

- Xu, X.Z.; Sun, Z.; Du, B.Y.; Ai, L.W. Pole optimization and thrust ripple suppression of new halbach consequent-pole PMLSM for ropeless elevator propulsion. IEEE Access 2020, 8, 62042–62052. [Google Scholar] [CrossRef]

- Botha, C.D.; Kamper, M.J.; Wang, R.J.; Chama, A. Analytical modeling of surface-mounted and consequent-pole linear vernier hybrid machines. IEEE Access 2021, 9, 26251–26259. [Google Scholar] [CrossRef]

- Luo, J.; Kou, B.Q.; Yang, X.B.; Zhang, H.; Zhang, L. Development, design, and analysis of a dual-consequent-pole transverse flux linear machine for direct-drive applications. IEEE Trans. Ind. Electron. 2021, 68, 6097–6108. [Google Scholar] [CrossRef]

- Chung, S.U.; Lee, H.J.; Woo, B.C.; Kim, J.W.; Lee, J.Y.; Moon, S.R.; Hwang, S.M. A feasibility study on a new doubly salient permanent magnet linear synchronous machine. IEEE Trans. Magn. 2010, 46, 1572–1575. [Google Scholar] [CrossRef]

- Chung, S.U.; Kim, J.M.; Woo, B.C.; Hong, D.K.; Lee, J.Y. Development of doubly salient permanent magnet linear synchronous motor for general-purpose automation applications. Int. J. Precis. Eng. Manuf. 2013, 14, 2075–2080. [Google Scholar] [CrossRef]

- Chung, S.U.; Kim, J.W.; Woo, B.C.; Hong, D.K.; Lee, J.Y.; Chun, Y.D.; Koo, D.H. Design and experimental validation of doubly salient permanent magnet linear synchronous motor for precision position control. Mechatronics 2013, 23, 172–181. [Google Scholar] [CrossRef]

- Chung, S.U.; Kim, J.W.; Woo, B.C.; Hong, D.K.; Lee, J.Y.; Koo, D.H. Force ripple and magnetic unbalance reduction design for doubly salient permanent magnet linear synchronous motor. IEEE Trans. Magn. 2011, 47, 4207–4210. [Google Scholar] [CrossRef]

- Tan, Q.; Wang, M.Y.; Li, L.Y.; Li, J.C. Pulsating magnetic field of permanent magnet linear synchronous motor and its influence on detent force. IEEE Trans. Energy Convers. 2021, 36, 703–712. [Google Scholar] [CrossRef]

- Huang, X.Z.; Yu, H.C.; Zhou, B.; Li, L.Y.; Gerada, D.; Gerada, C.; Qian, Z.Y. Detent-force minimization of double-sided permanent magnet linear synchronous motor by shifting one of the primary components. IEEE Trans. Ind. Electron. 2020, 67, 180–191. [Google Scholar] [CrossRef]

- Li, J.; Huang, X.Z.; Zhou, B.; Yu, H.C.; Huang, Q. Design principle of a 16-pole 18-slot two sectional modular permanent magnet linear synchronous motor with optimisation of its end tooth. IET Electr. Power Appl. 2020, 14, 441–447. [Google Scholar] [CrossRef]

| Symbol | Quantity | NS-PMLSM I | CP-PMLSM I | CP-PMLSM II |

|---|---|---|---|---|

| wPM = wIP | wPM ≠ wIP | |||

| τ | pole pitch | 10.08 | 10.08 | 8.1 |

| wPM | PM width | 6.9 | 6.9 | 8 |

| hPM | PM height | 2.5 | 2.5 | 5 |

| wIP | IP width | / | 6.9 | 5 |

| hIP | IP height | / | 2.5 | 5 |

| L1 | primary length | 100.8 | 100.8 | 81 |

| PM% | PM dosage | 100% | 50% | 80% |

| Harmonic Order | Group I | Group II | ||

|---|---|---|---|---|

| Amplitude (N) | Phase (°) | Amplitude (N) | Phase (°) | |

| DC | 0.022 | 270.0 | 0.064 | 270.0 |

| 1 | 12.090 | 135.0 | 12.570 | −44.9 |

| 2 | 1.962 | 267.3 | 1.935 | 268.1 |

| 3 | 7.084 | 224.3 | 6.978 | 45.6 |

| 4 | 2.514 | −2.5 | 2.469 | −2.8 |

| 5 | 2.308 | −48.4 | 2.308 | 136.1 |

| Symbol | Quantity | Value | Symbol | Quantity | Value |

|---|---|---|---|---|---|

| g | air gap | 0.5 | τ | pole pitch | 8.1 |

| t1 | slot pitch | 9.0 | wPM | PM width | 8.0 |

| ws | slot width | 4.6 | hPM | PM height | 3.8 |

| wt | tooth width | 4.4 | wIP | IP width | 5.0 |

| ht | tooth height | 11.4 | hIP | IP height | 3.8 |

| he1 | primary yoke height | 3.0 | he2 | secondary yoke height | 10.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Huang, X.; Zhou, B.; Liu, Y.; Wang, Z. Research on Segmented Primary Consequent-Pole Permanent Magnet Linear Synchronous Motor with Symmetric and Periodic End Force. Symmetry 2021, 13, 2374. https://doi.org/10.3390/sym13122374

Li J, Huang X, Zhou B, Liu Y, Wang Z. Research on Segmented Primary Consequent-Pole Permanent Magnet Linear Synchronous Motor with Symmetric and Periodic End Force. Symmetry. 2021; 13(12):2374. https://doi.org/10.3390/sym13122374

Chicago/Turabian StyleLi, Jing, Xuzhen Huang, Bo Zhou, Yansong Liu, and Zheng Wang. 2021. "Research on Segmented Primary Consequent-Pole Permanent Magnet Linear Synchronous Motor with Symmetric and Periodic End Force" Symmetry 13, no. 12: 2374. https://doi.org/10.3390/sym13122374

APA StyleLi, J., Huang, X., Zhou, B., Liu, Y., & Wang, Z. (2021). Research on Segmented Primary Consequent-Pole Permanent Magnet Linear Synchronous Motor with Symmetric and Periodic End Force. Symmetry, 13(12), 2374. https://doi.org/10.3390/sym13122374