Finite Element Study on the Wear Performance of Movable Jaw Plates of Jaw Crushers after a Symmetrical Laser Cladding Path

Abstract

1. Introduction

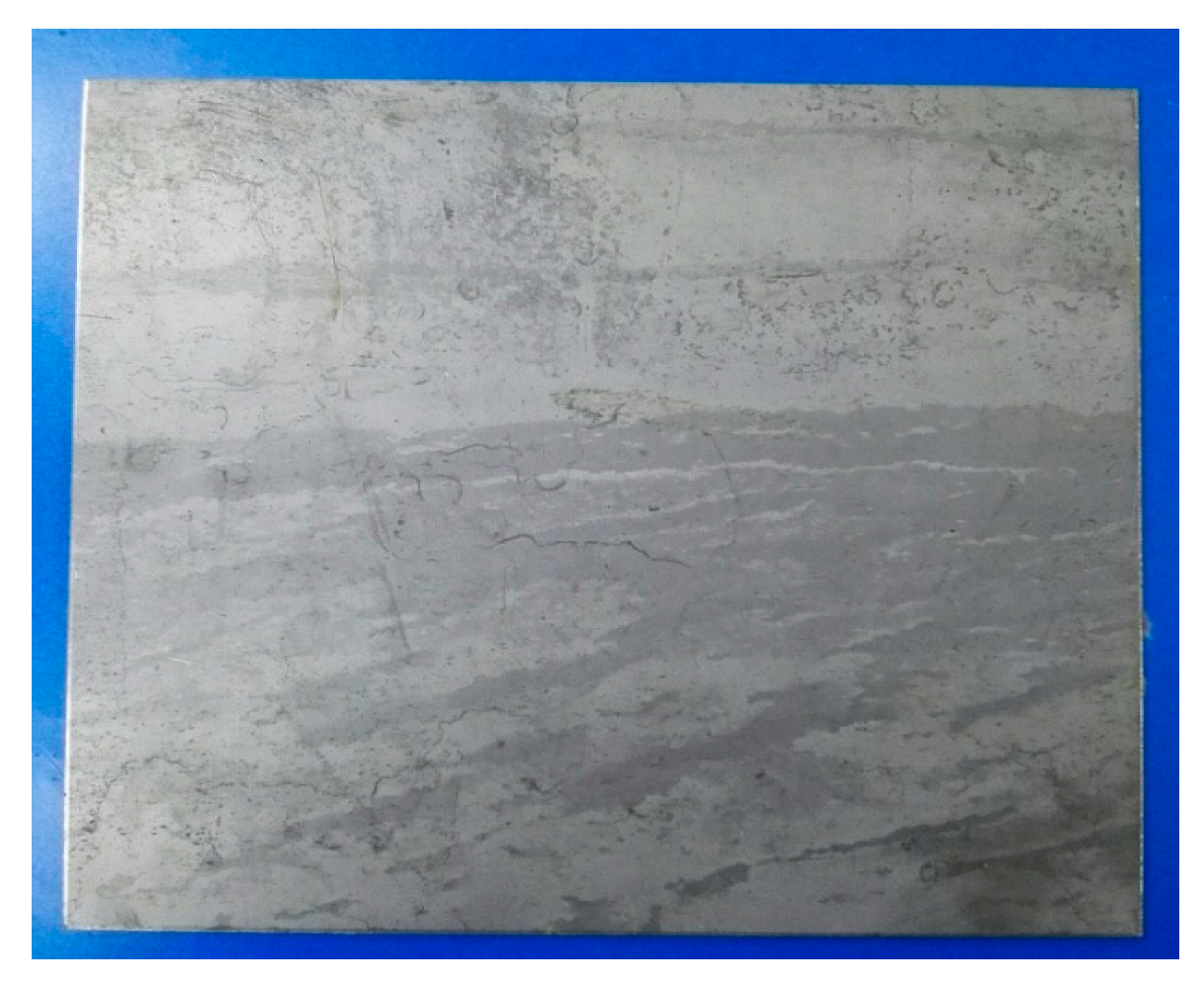

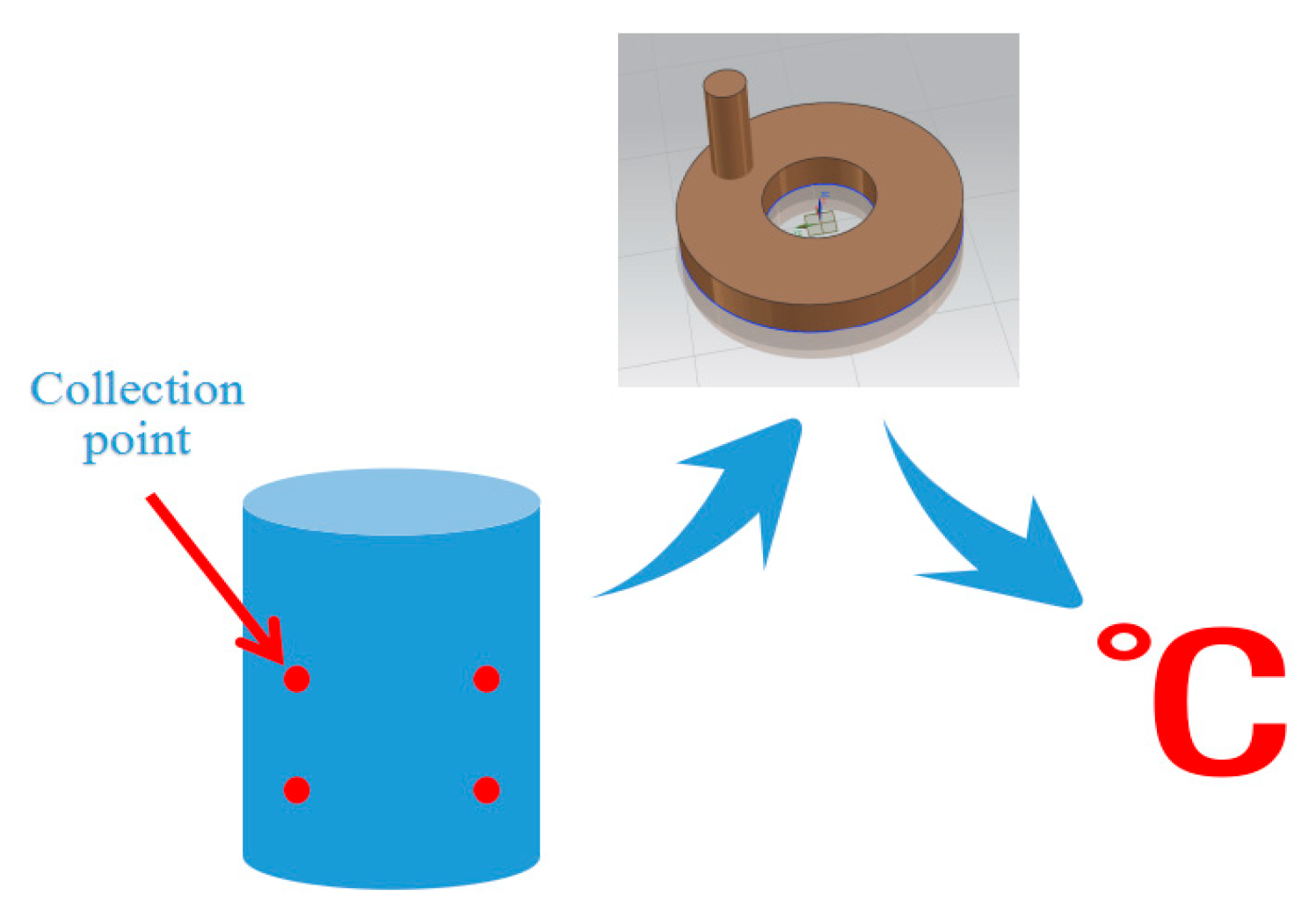

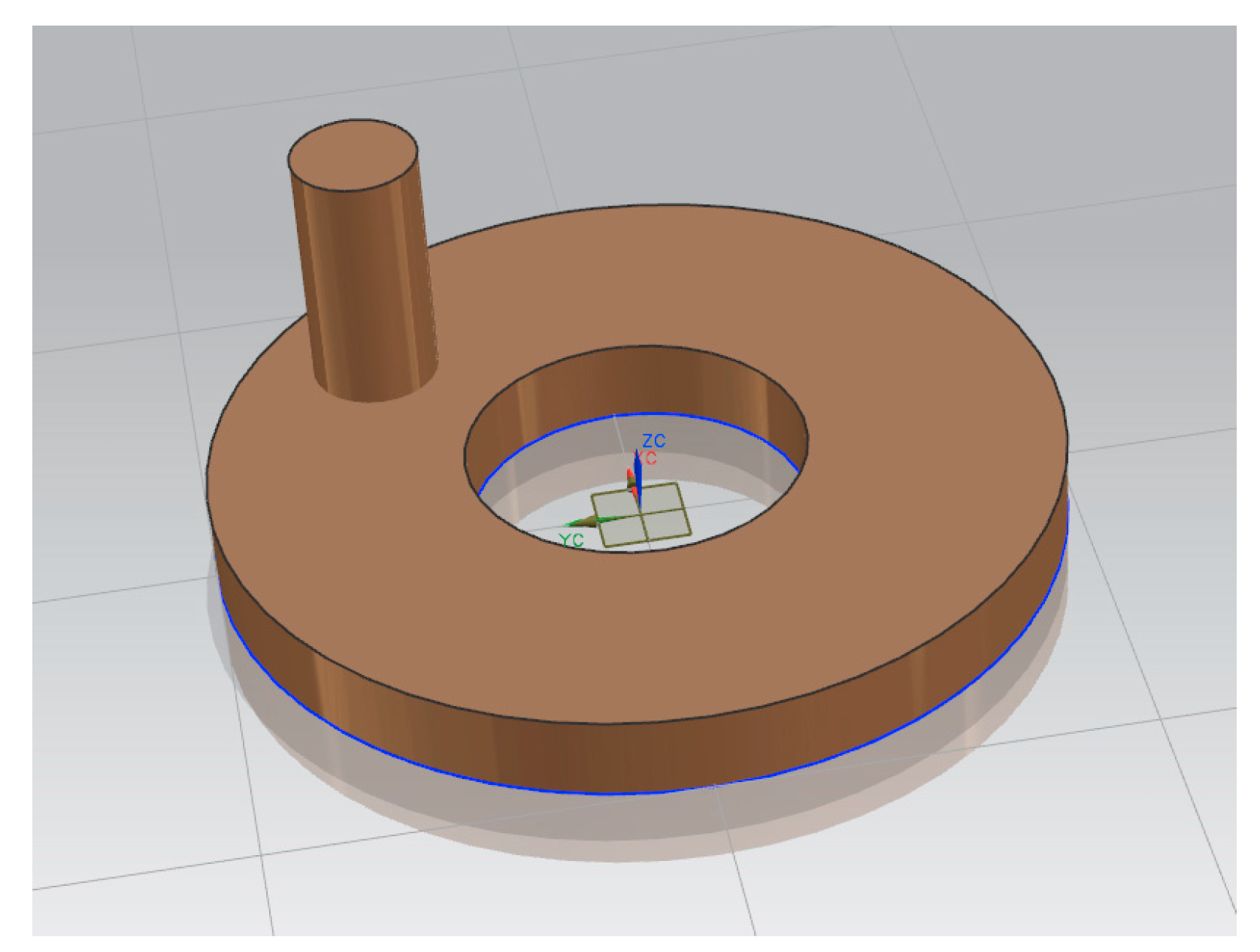

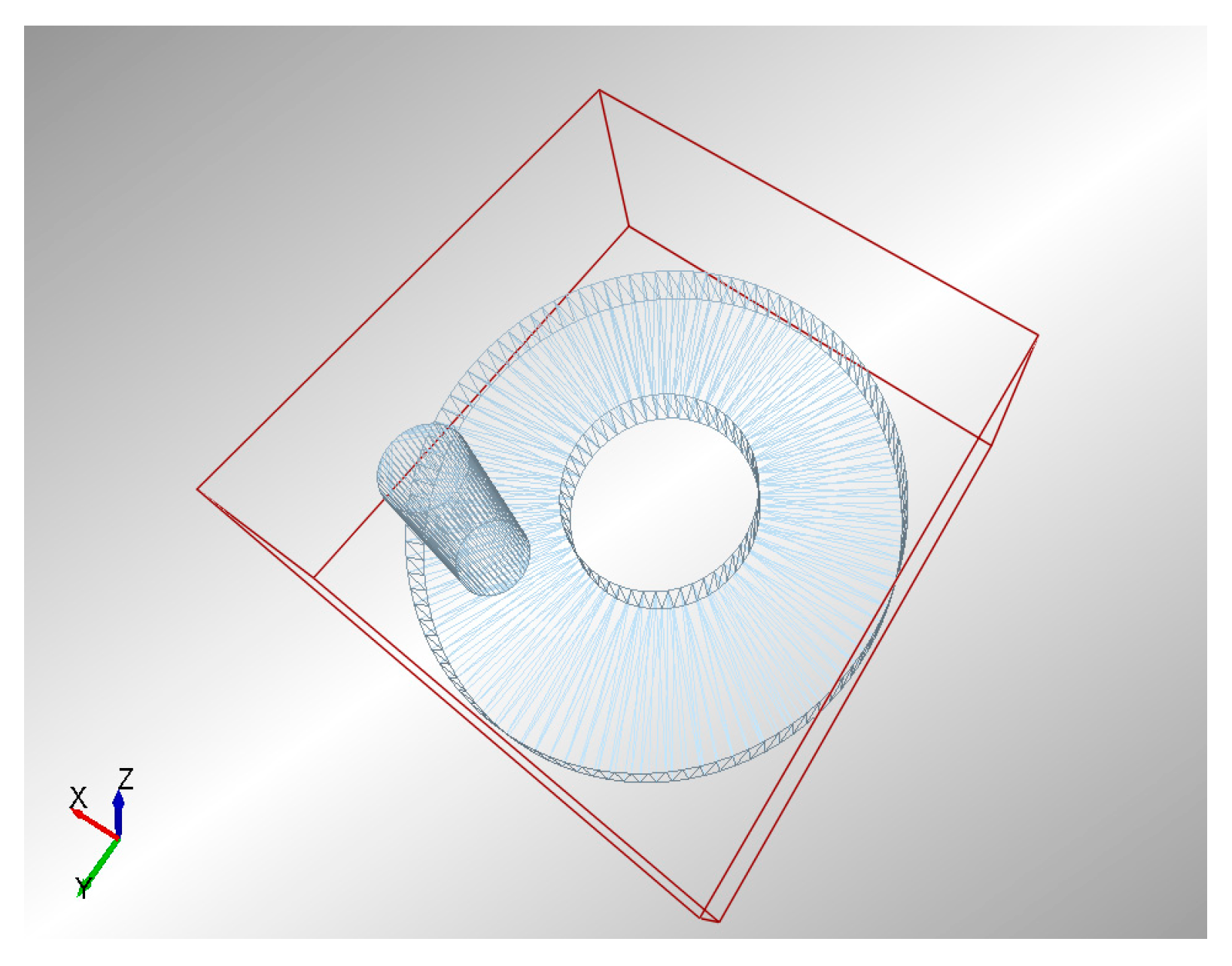

2. Materials and Methods

3. Results and Discussion

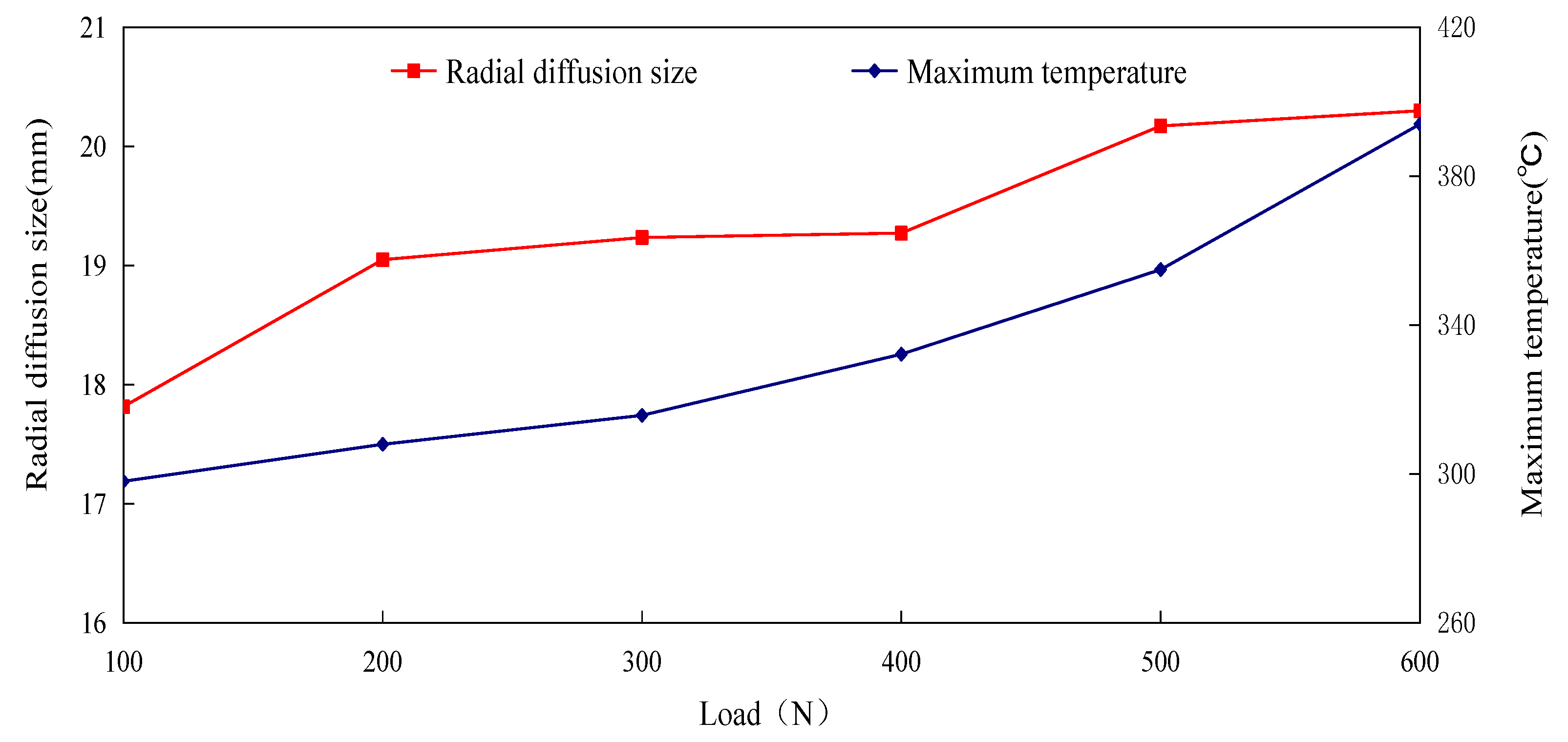

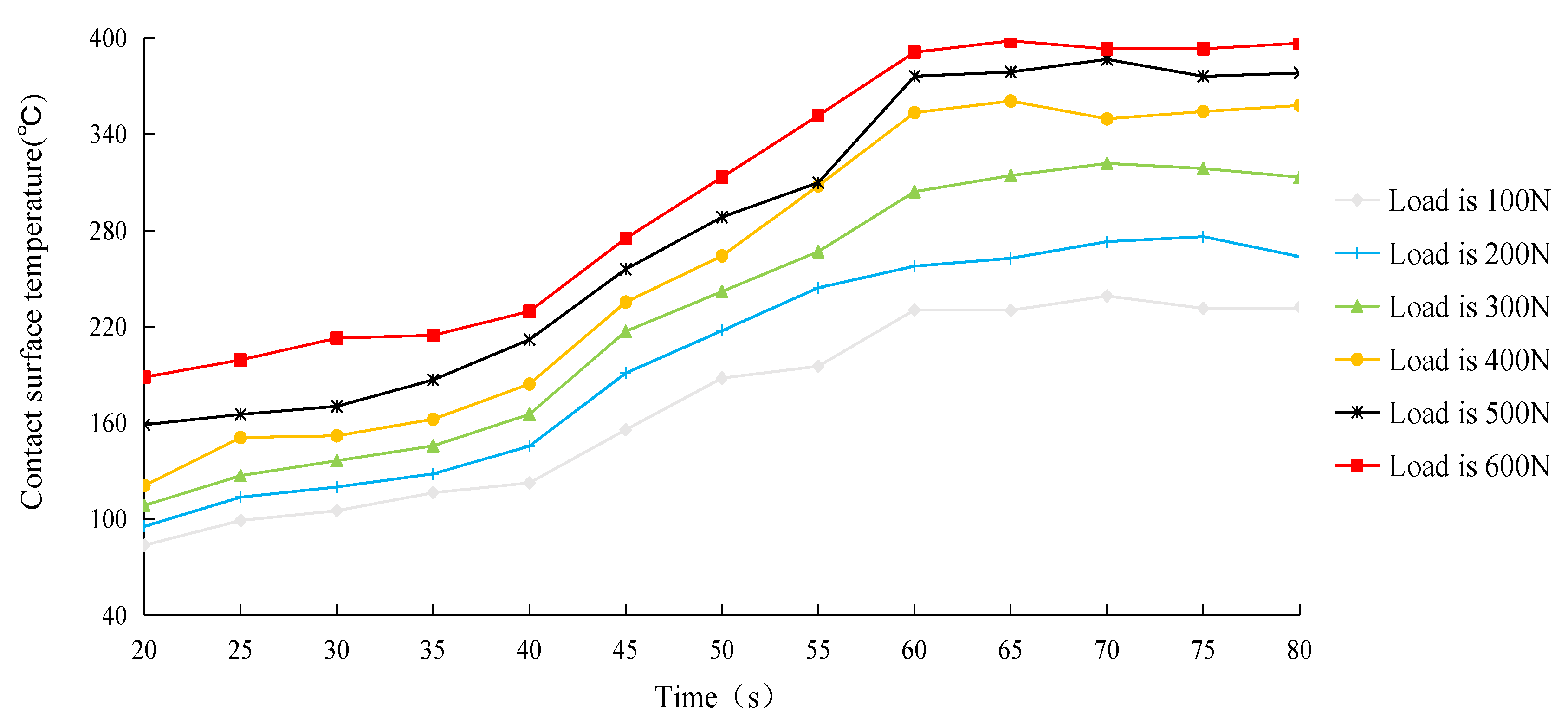

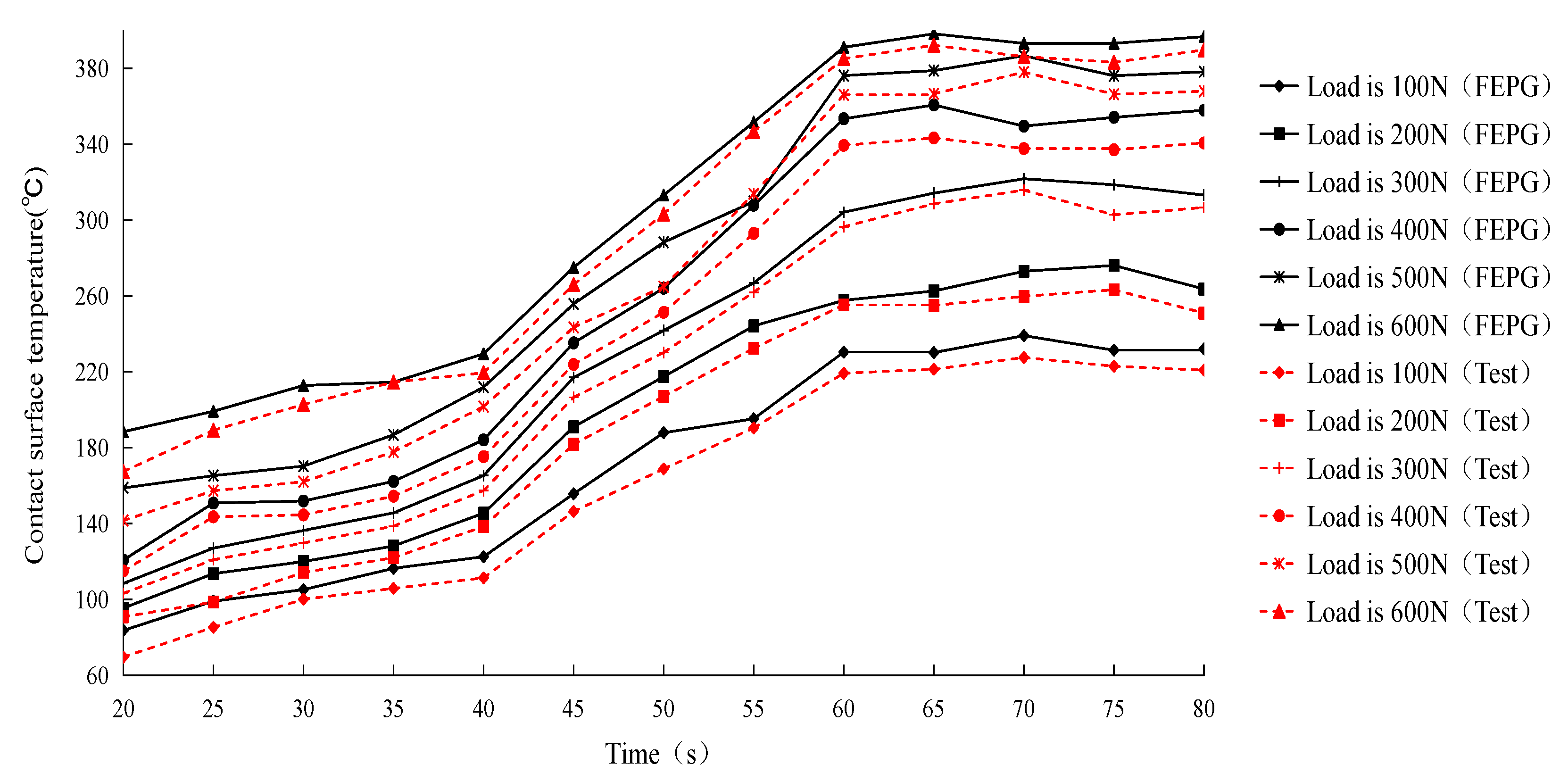

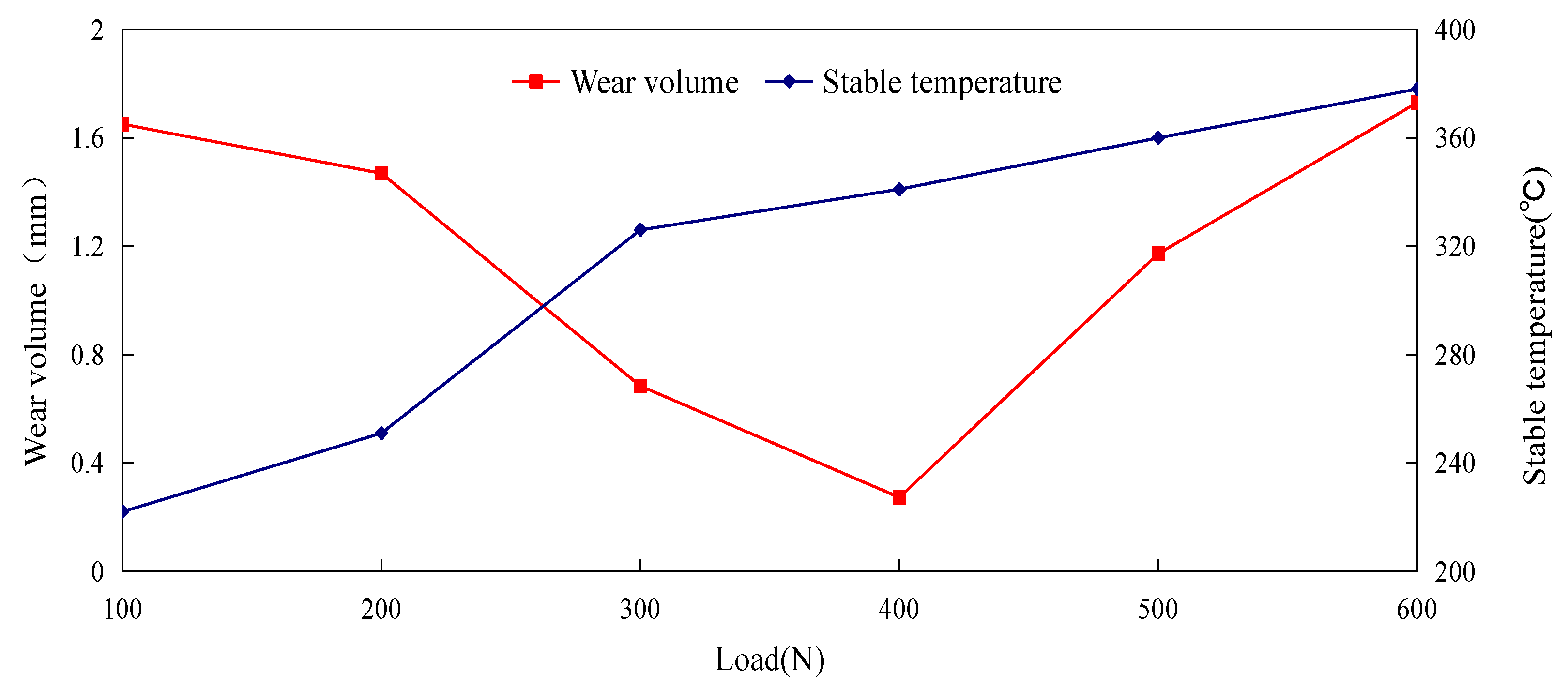

3.1. FEPG and Test Results

3.2. Effect of Temperature on the Performance of the Moving Jaw

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jiang, J.; Xie, Y.; Qian, W.; Hall, R. Important factors affecting the gouging abrasion resistance of materials. Miner. Eng. 2018, 128, 238–246. [Google Scholar] [CrossRef]

- Deepak, B.B.; Bahubalendruni, M.V. Numerical analysis for force distribution along the swing jaw plate of a single toggle jaw crusher. World J. Eng. 2017, 14, 255–260. [Google Scholar] [CrossRef]

- Liu, R.; Shi, B.; Li, G.; Yu, H. Influence of operating conditions and crushing chamber on energy consumption of cone crusher. Energies 2018, 11, 1102. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, P.; Bai, P.; Su, K.; Su, H. TiBCN-Ceramic-Reinforced Ti-Based Coating by Laser Cladding: Analysis of Processing Conditions and Coating Properties. Coatings 2019, 9, 407. [Google Scholar] [CrossRef]

- Gabriel, T.; Rommel, D.; Scherm, F.; Gorywoda, M.; Glatzel, U. Symmetrical laser cladding path of ultra-thin nickel-based superalloy sheets. Materials 2017, 10, 279. [Google Scholar] [CrossRef]

- Yan, X.-L.; Dong, S.-Y.; Xu, B.-S.; Cao, Y. Progress and challenges of ultrasonic testing for stress in remanufacturing symmetrical laser cladding path coating. Materials 2018, 11, 293. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, Z.; Chen, J.; Qiao, Y.; Zhang, J.; Huang, Y. Effect of rare earth oxides on microstructure and corrosion behavior of laser-cladding coating on 316l stainless steel. Coatings 2019, 9, 636. [Google Scholar] [CrossRef]

- Pang, X.; Wei, Q.; Zhou, J.; Ma, H. High-temperature tolerance in multi-scale cermet solar-selective absorbing coatings prepared by symmetrical laser cladding path. Materials 2018, 11, 1037. [Google Scholar] [CrossRef]

- Lian, G.; Zhang, H.; Zhang, Y.; Tanaka, M.L.; Chen, C.; Jiang, J. Optimizing processing parameters for multi-track symmetrical laser cladding path utilizing multi-response grey relational analysis. Coatings 2019, 9, 356. [Google Scholar] [CrossRef]

- Wang, S.; Liu, C. Real-time monitoring of chemical composition in nickel-based symmetrical laser cladding path layer by emission spectroscopy analysis. Materials 2019, 12, 2637. [Google Scholar] [CrossRef]

- Karan, S.K.; Samadder, S.R. Reduction of spatial distribution of risk factors for transportation of contaminants released by coal mining activities. J. Environ. Manag. 2016, 180, 280–290. [Google Scholar] [CrossRef] [PubMed]

- Drzymała, T.; Zegardło, B.; Tofilo, P. Properties of concrete containing recycled glass aggregates produced of exploded lighting materials. Materials 2020, 13, 226. [Google Scholar] [CrossRef] [PubMed]

- Limanskiy, A.V.; Vasilyeva, M.A. Using of low-grade heat mine water as a renewable source of energy in coal-mining regions. Ecol. Eng. 2016, 91, 41–43. [Google Scholar] [CrossRef]

- Amanov, A.; Ahn, B.; Lee, M.G.; Jeon, Y.; Pyun, Y. Friction and wear reduction of eccentric journal bearing made of sn-based babbitt for ore cone crusher. Materials 2016, 9, 950. [Google Scholar] [CrossRef]

- Baek, J.; Choi, Y. Deep neural network for ore production and crusher utilization prediction of truck haulage system in underground mine. Appl. Sci. 2019, 9, 4180. [Google Scholar] [CrossRef]

- Abuhasel, K.A. A comparative study of regression model and the adaptive neuro-fuzzy conjecture systems for predicting energy consumption for jaw crusher. Appl. Sci. 2019, 9, 3916. [Google Scholar] [CrossRef]

- Anticoi, H.; Guasch, E.; Ahmad Hamid, S.; Oliva, J.; Alfonso, P.; Bascompta, M.; Sanmiquel, L.; Escobet, T.; Escobet, A.; Parcerisa, D.; et al. An improved high-pressure roll crusher model for tungsten and tantalum ores. Minerals 2018, 8, 483. [Google Scholar] [CrossRef]

- Pei, Z.; Galindo-Torres, S.A.; Tang, H.; Jin, G.; Scheuermann, A.; Ling, L. An efficient discrete element lattice boltzmann model for simulation of particle-fluid, particle-particle interactions. Comput. Fluids 2017, 147, 63–71. [Google Scholar]

- Ren, X.; Liu, Z. Influence of cutting parameters on work hardening behavior of surface layer during turning superalloy Inconel 718. Int. J. Adv. Manuf. Technol. 2016, 86, 2319–2327. [Google Scholar] [CrossRef]

- Gao, P.; Wei, K.; Hanchen, Y.U.; Yang, J.; Wang, Z.; Zeng, X. Influence of layer thickness on microstructure and mechanical properties of selective laser melted Ti-5Al-2.5Sn alloy. Acta Metall. Sin. 2018, 54, 999–1009. [Google Scholar]

- Nishida, Y.; Yokoyama, S. Mechanisms of temperature dependence of threshold voltage in high-k/metal gate transistors with different TiN thicknesses. Int. J. Electron. 2016, 103, 629–647. [Google Scholar] [CrossRef]

- Cuomo, S.; Chareyre, B.; D’Arista, P.; Sala, M.D.; Cascini, L. Micromechanical modelling of rainsplash erosion in unsaturated soils by finite element method. Catena 2016, 147, 146–152. [Google Scholar] [CrossRef]

- Kroupa, M.; Vonka, M.; Soos, M.; Kosek, J. Utilizing the finite element method for the modeling of viscosity in concentrated suspensions. Langmuir 2016, 32, 8451–8460. [Google Scholar] [CrossRef] [PubMed]

- Fallahnezhad, K.; Oskouei, R.H.; Badnava, H.; Taylor, M. An adaptive finite element simulation of fretting wear damage at the head-neck taper junction of total hip replacement: The role of taper angle mismatch. J. Mech. Behav. Biomed. Mater. 2017, 75, 58–67. [Google Scholar] [CrossRef]

- Shinde, T.; Dhokey, N.B. Influence of carbide density on surface roughness and quasi-stable wear behaviour of h13 die steel. Surf. Eng. 2017, 33, 1–9. [Google Scholar] [CrossRef]

- Soltani, R.; Sohi, M.H.; Ansari, M.; Haghighi, A.; Ghasemi, H.M.; Haftlang, F. Evaluation of niobium carbide coatings produced on aisi l2 steel via thermo-reactive diffusion technique. Vacuum 2017, 146, 44–51. [Google Scholar] [CrossRef]

- Liu, G.; Sun, W.C.; Lowinger, S.M.; Zhang, Z.H.; Ming, H.; Peng, J. Coupled flow network and finite element modeling of injection-induced crack propagation and coalescence in brittle rock. Acta Geotech. 2018, 14, 1–26. [Google Scholar]

- Thomas, J.J.; Ii, J.J.V.; Craddock, P.R.; Bake, K.D.; Pomerantz, A.E. The neutron scattering length density of kerogen and coal as determined by ch 3 oh/cd 3 oh exchange. Fuel 2014, 117, 801–808. [Google Scholar] [CrossRef]

- Indimath, S.; Shunmugasundaram, R.; Balamurugan, S.; Das, B.; Singh, R.; Dutta, M. Ultrasonic technique for online measurement of bulk density of stamp charge coal cakes in coke plants. Fuel Process. Technol. 2018, 172, 155–161. [Google Scholar] [CrossRef]

- Wang, Q.; Zeng, X.; Chen, C.; Lian, G.; Huang, X. An integrated method for multi-objective optimization of multi-pass Fe50/TiC symmetrical laser cladding path on AISI 1045 steel based on grey relational analysis and principal component analysis. Coatings 2020, 10, 151. [Google Scholar] [CrossRef]

- Yu, J.; Sun, W.; Huang, H.; Wang, W.; Wang, Y.; Hu, Y. Crack sensitivity control of nickel-based laser coating based on genetic algorithm and neural network. Coatings 2019, 9, 728. [Google Scholar] [CrossRef]

- Wu, F.; Chen, T.; Wang, H.; Liu, D. Effect of Mo on microstructures and wear properties of in situ synthesized Ti(C,N)/Ni-based composite coatings by symmetrical laser cladding path. Materials 2017, 10, 1047. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Liu, C.; Li, S.; Zhang, Z.; Zeng, M.; Wang, F.; Wang, J.; Guo, Y. Numerical simulation of thermal evolution and solidification behavior of symmetrical laser cladding path AlSiTiNi composite coatings. Coatings 2019, 9, 391. [Google Scholar] [CrossRef]

- Li, Y.; Chen, T.; Liu, D. Path planning for symmetrical laser cladding path robot on artificial joint surface based on topology reconstruction. Algorithms 2020, 13, 93. [Google Scholar] [CrossRef]

- Wang, Y.; Liang, Z.; Zhang, J.; Ning, Z.; Jin, H. Microstructure and antiwear property of symmetrical laser cladding path Ni–Co duplex coating on copper. Materials 2016, 9, 634. [Google Scholar] [CrossRef]

- Yang, K.; Xie, H.; Sun, C.; Zhao, X.; Li, F. Influence of vanadium on the microstructure of IN718 alloy by symmetrical laser cladding path. Materials 2019, 12, 3839. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, Y.; Shi, C.; Mao, D. Microscopic analysis and electrochemical behavior of Fe-based coating produced by symmetrical laser cladding path. Metals 2017, 7, 435. [Google Scholar] [CrossRef]

- Lu, H.; Zhang, P.; Ren, S.; Guo, J.; Li, X.; Dong, G.I. The preparation of polytrifluorochloroethylene (PCTFE) micro-particles and application on treating bearing steel surfaces to improve the lubrication effect for copper-graphite (Cu/C). Appl. Surf. Sci. 2018, 427, 1242–1247. [Google Scholar] [CrossRef]

- Zori, M.H.; Soleimanigorgani, A. Ink-jet printing of micro-emulsion TiO2 nano-particles ink on the surface of glass. Ournal Eur. Ceram. Soc. 2012, 32, 4271–4277. [Google Scholar] [CrossRef]

- Feigenbaum, E.; Raman, R.N.; Cross, D.A.; Carr, C.W.; Matthews, M.J. Laser-induced Hertzian fractures in silica initiated by metal micro-particles on the exit surface. Opt. Express 2016, 24, 10527–10536. [Google Scholar] [CrossRef]

| Mn (%) | Rb (%) | C (%) | P (%) | V (%) | B (%) | Re (%) | Fe (%) |

|---|---|---|---|---|---|---|---|

| 2.2 | 1.3 | 22.5 | 0.3 | 1.2 | 1.7 | 3.8 | 26.4 |

| Serial Number | Load X1/N | Time X2/s | Speed X3/s |

|---|---|---|---|

| 1 | 100 | 550 | 2000 |

| 2 | 200 | 550 | 2000 |

| 3 | 300 | 550 | 2000 |

| 4 | 400 | 550 | 2000 |

| 5 | 500 | 550 | 2000 |

| 6 | 600 | 550 | 2000 |

| Material | 40Cr | WDB620 | Ceramic Powder |

|---|---|---|---|

| Shear modulus (Pa) | |||

| Heat transfer coefficient ) | 35 | 60 | 72 |

| Density ) | 7220 | 8230 | 7850 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Zhang, G.; Zhang, R.; Gupta, T.; Katayama, A. Finite Element Study on the Wear Performance of Movable Jaw Plates of Jaw Crushers after a Symmetrical Laser Cladding Path. Symmetry 2020, 12, 1126. https://doi.org/10.3390/sym12071126

Chen Y, Zhang G, Zhang R, Gupta T, Katayama A. Finite Element Study on the Wear Performance of Movable Jaw Plates of Jaw Crushers after a Symmetrical Laser Cladding Path. Symmetry. 2020; 12(7):1126. https://doi.org/10.3390/sym12071126

Chicago/Turabian StyleChen, Yuhui, Guoshuai Zhang, Ruolin Zhang, Timothy Gupta, and Ahmed Katayama. 2020. "Finite Element Study on the Wear Performance of Movable Jaw Plates of Jaw Crushers after a Symmetrical Laser Cladding Path" Symmetry 12, no. 7: 1126. https://doi.org/10.3390/sym12071126

APA StyleChen, Y., Zhang, G., Zhang, R., Gupta, T., & Katayama, A. (2020). Finite Element Study on the Wear Performance of Movable Jaw Plates of Jaw Crushers after a Symmetrical Laser Cladding Path. Symmetry, 12(7), 1126. https://doi.org/10.3390/sym12071126