Control of Robot Arm Motion Using Trapezoid Fuzzy Two-Degree-of-Freedom PID Algorithm

Abstract

1. Introduction

2. Literature Review

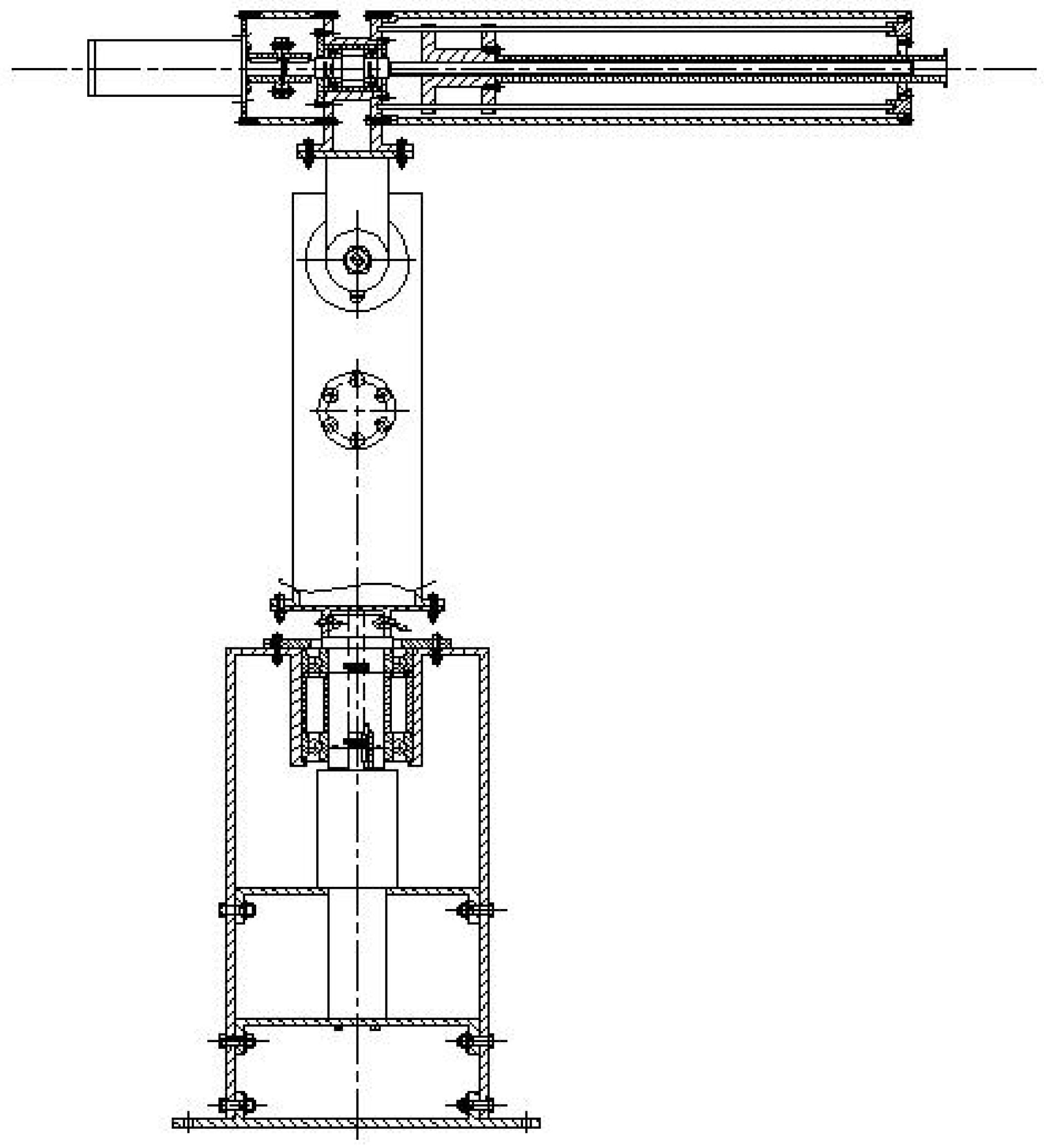

3. Transmission Model of the Industrial Robot

3.1. Transmission Structure

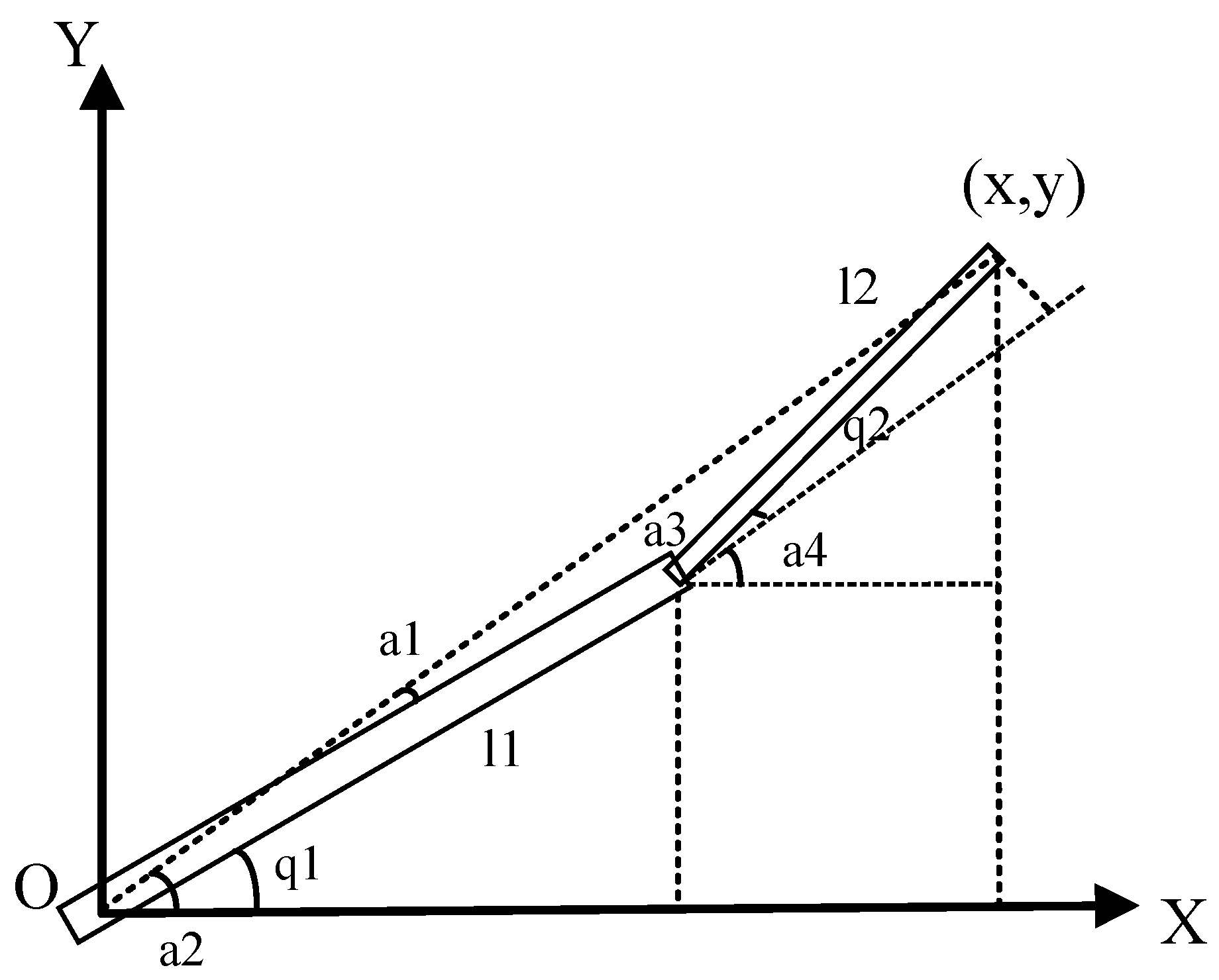

3.2. The Inverse Solution in Kinematics of the 2-DOF Robot Arm

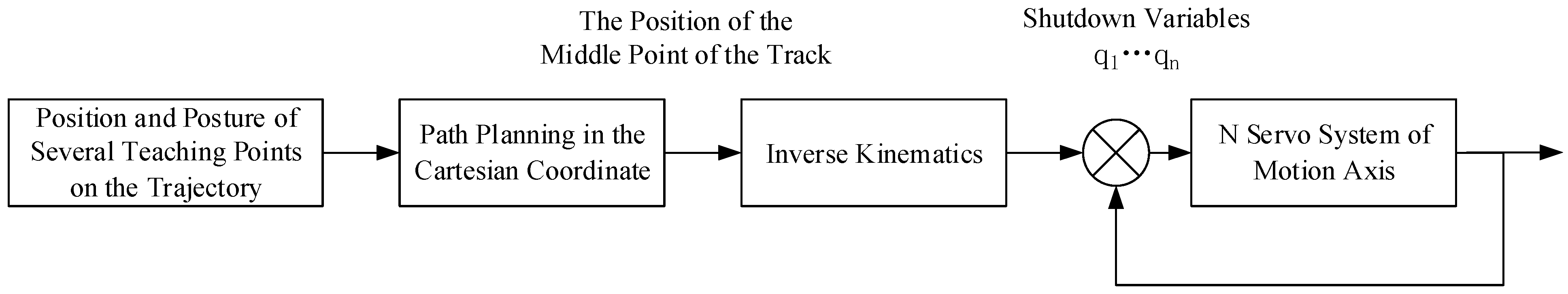

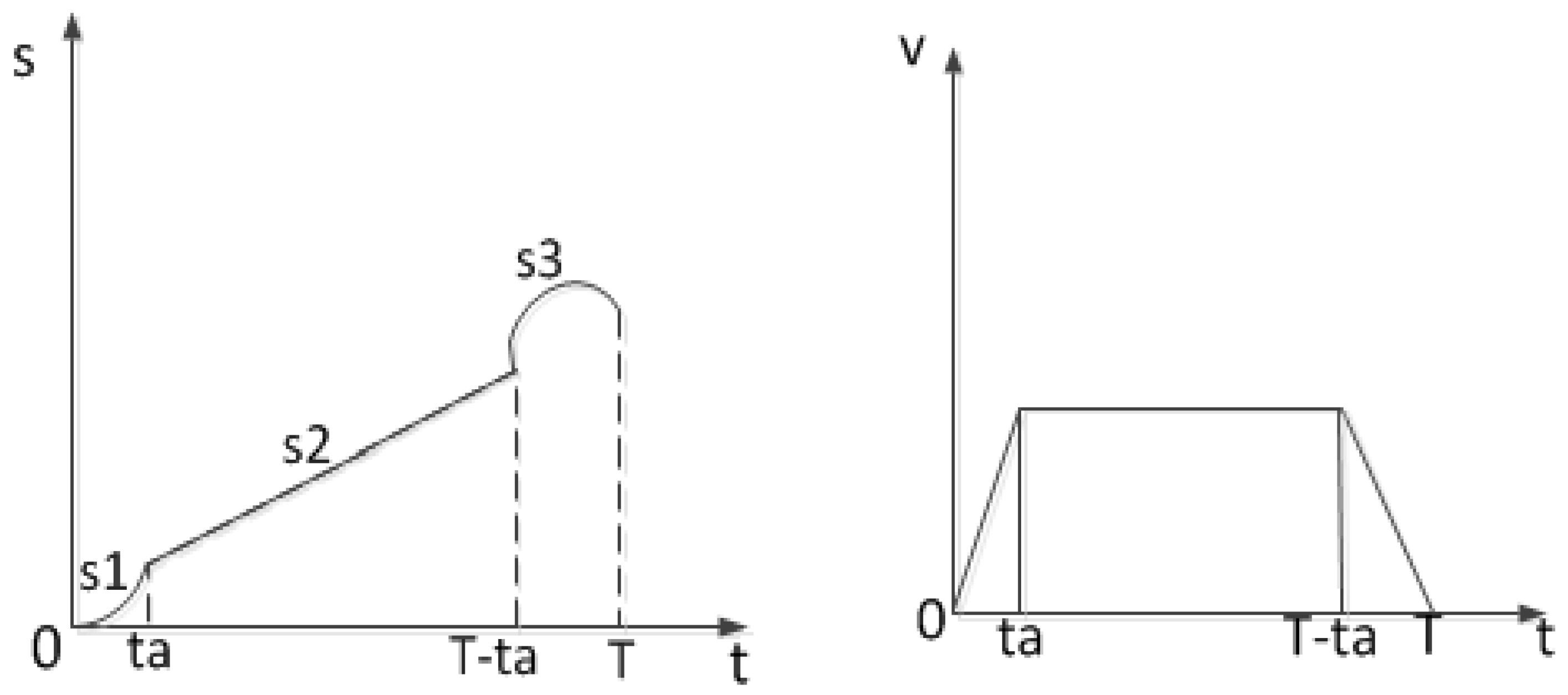

4. 2-DOF Motion Path Planning

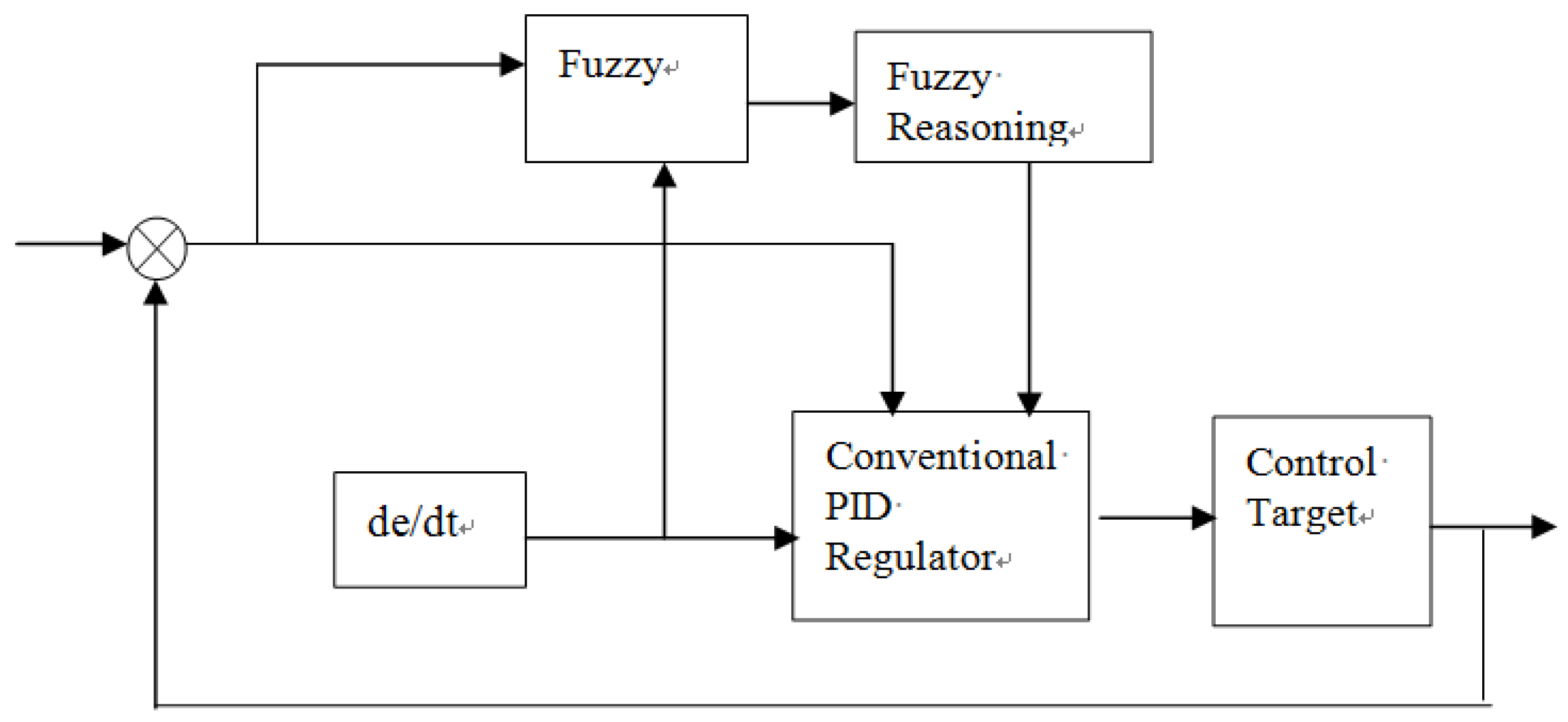

4.1. Algorithm Structure

4.2. Fuzzy PID Control

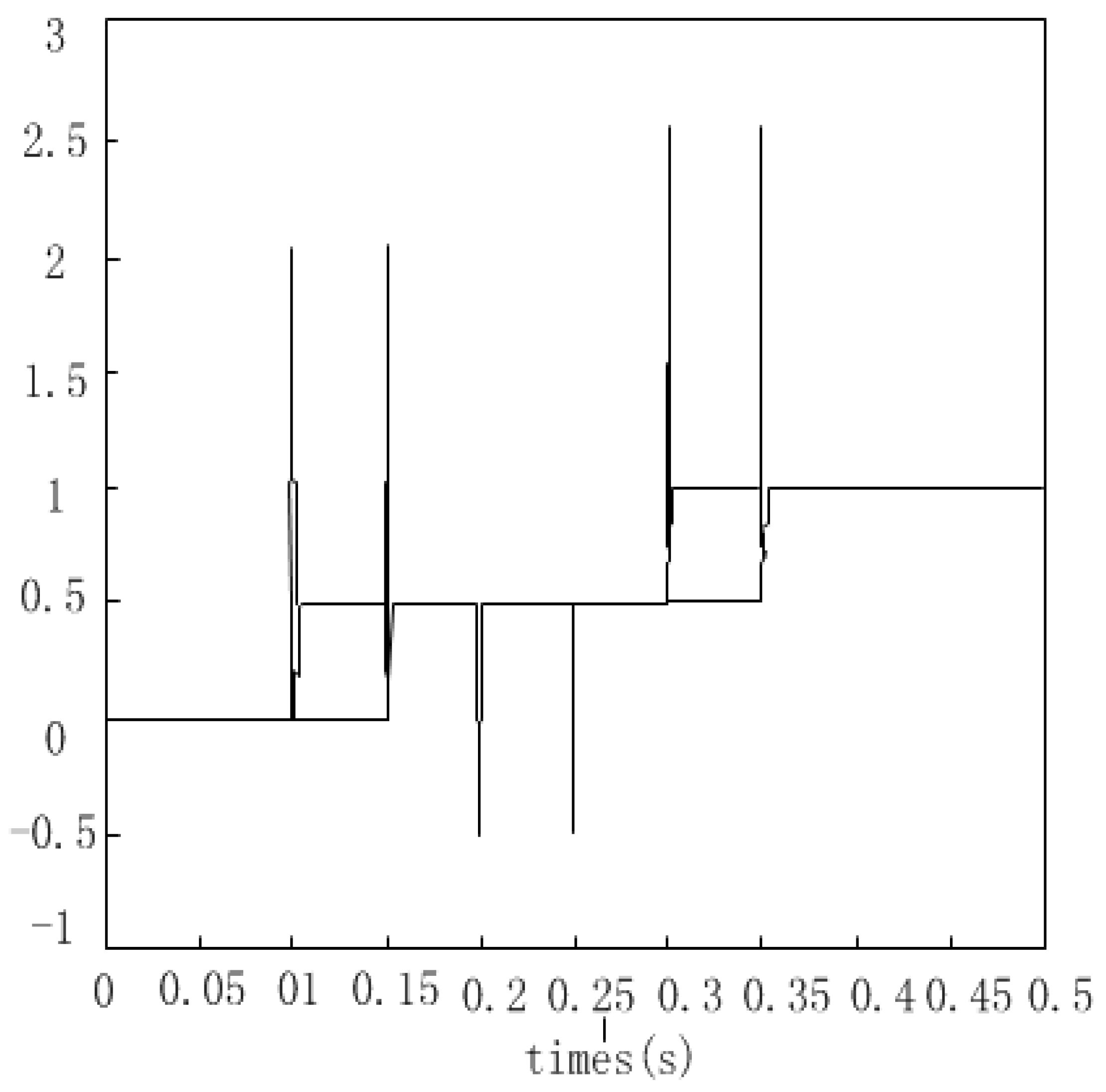

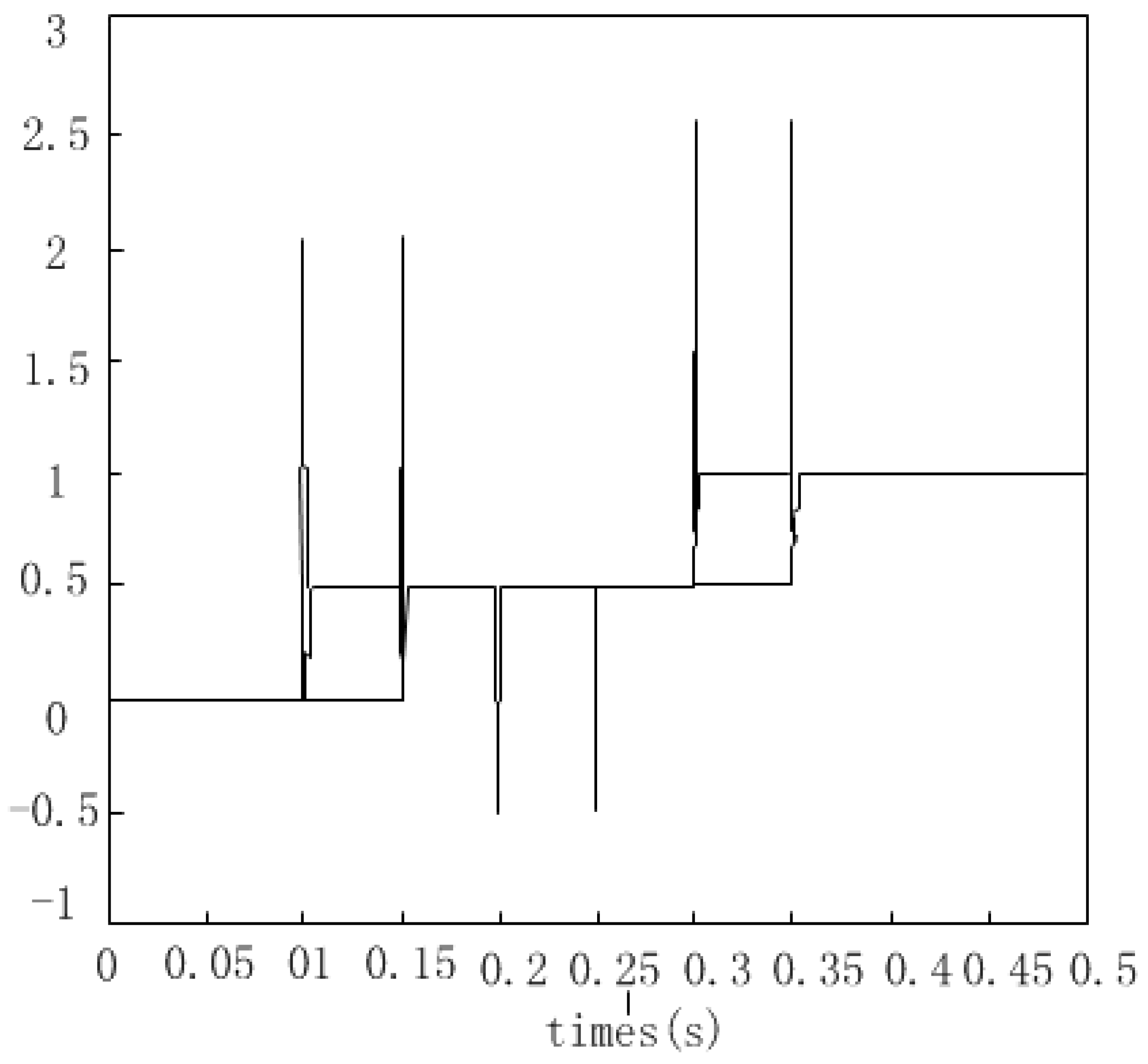

5. Experimental Analysis

6. Conclusions

Funding

Conflicts of Interest

References

- Chen, C.; Luo, J. Hybrid optimal control of robot motor based on improved genetic algorithm and fuzzy logic. In Proceedings of the International Conference on Robotics & Automation Sciences, Hong Kong, China, 26–29 August 2017. [Google Scholar]

- Bhatia, V.; Kalaichelvi, V.; Karthikeyan, R. Comparison of GA tuned fuzzy logic and NARMA-L2 controllers for motion control in 5-DOF robot. Int. J. Comput. Appl. 2017, 39, 69–78. [Google Scholar] [CrossRef]

- Wen, R.; Tong, M. Mecanum wheels with Astar algorithm and fuzzy PID algorithm based on genetic algorithm. In Proceedings of the International Conference on Robotics & Automation Sciences, Hong Kong, China, 26–29 August 2017. [Google Scholar]

- Jian, G.; Jin, X.; Guo, S.; Du, W. Study on the tracking performance of the vascular interventional surgical robotic system based on the fuzzy-PID controller. In Proceedings of the IEEE International Conference on Mechatronics & Automation, Takamatsu, Japan, 6–9 August 2017. [Google Scholar]

- Ren, Q.; Bigras, P. A Highly Accurate Model-Free Motion Control System with a Mamdani Fuzzy Feedback Controller combined with a TSK Fuzzy Feed-forward Controller. J. Intell. Robot. Syst. 2017, 86, 367–379. [Google Scholar] [CrossRef]

- Liang, C.; Zhao, S.; Zhang, J. Multi-criteria group decision making method based on generalized intuitionistic trapezoidal fuzzy prioritized aggregation operators. Int. J. Mach. Learn. Cybern. 2017, 8, 597–610. [Google Scholar] [CrossRef]

- Yin, K.; Yang, B.; Li, X. Multiple Attribute Group Decision-Making Methods Based on Trapezoidal Fuzzy Two-Dimensional Linguistic Partitioned Bonferroni Mean Aggregation Operators. Int. J. Environ. Res. Public Health 2018, 15, 194. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Yao, Y.; Wang, M. The Optimizing Design of Wheeled Robot Tracking System by PID Control Algorithm Based on BP Neural Network. In Proceedings of the International Conference on Industrial Informatics-Computing Technology, Wuhan, China, 3–4 December 2017. [Google Scholar]

- Angel, L.; Viola, J. Fractional order PID for tracking control of a parallel robotic manipulator type delta. ISA Trans. 2018, 79, 172–188. [Google Scholar] [CrossRef] [PubMed]

- Pedrammehr, S.; Danaei, B.; Abdi, H.; Masouleh, M.T.; Nahavandi, S. Dynamic analysis of Hexarot: Axis-symmetric parallel manipulator. Robotica 2018, 36, 225–240. [Google Scholar] [CrossRef]

- Jinjun, D.; Yahui, G.; Ming, C.; Xianzhong, D. Symmetrical adaptive variable admittance control for position/force tracking of dual-arm cooperative manipulators with unknown trajectory deviations. Robot. Comput.-Integr. Manuf. 2019, 57, 357–369. [Google Scholar] [CrossRef]

- Kalamian, N.; Niri, M.F.; Mehrabizadeh, H. Design of a Suboptimal Controller based on Riccati Equation and State-dependent Impulsive Observer for a Robotic Manipulator. In Proceedings of the 2019 6th International Conference on Control, Instrumentation and Automation (ICCIA), Sanandaj, Iran, 30–31 October 2019; pp. 1–6. [Google Scholar]

- Peng, W.; Liu, S.; Zhou, L.; Chen, H. A fuzzy group decision making model with trapezoidal fuzzy preference relations based on compatibility measure and COWGA operator. Appl. Intell. 2018, 48, 46–67. [Google Scholar]

- Gao, X.; Wang, H.; Gan, W. Group decision model for green supplier selection based on trapezoidal fuzzy soft sets. Comput. Eng. Appl. 2017, 53, 264–270. [Google Scholar]

- Ploskas, N.; Papathanasiou, J.; Tsaples, G. Implementation of an Extended Fuzzy VIKOR Method Based on Triangular and Trapezoidal Fuzzy Linguistic Variables and Alternative Deffuzification Techniques. In Proceedings of the International Conference on Decision Support System Technology, Namur, Belgium, 31 May 2017. [Google Scholar]

- Yin, K.; Wang, P.; Li, X. The Multi-Attribute Group Decision-Making Method Based on Interval Grey Trapezoid Fuzzy Linguistic Variables. Int. J. Environ. Res. Public Health 2017, 14, 1561. [Google Scholar] [CrossRef] [PubMed]

- Simo, U.F.; Gwét, H. A New Algorithm for Ranking of Trapezoidal Fuzzy Numbers. Int. J. Fuzzy Syst. 2018, 20, 2355–2367. [Google Scholar] [CrossRef]

- Zhou, Y.; Cheng, L.; Zhou, L.; Chen, H.; Ge, J. A group decision making approach for trapezoidal fuzzy preference relations with compatibility measure. Soft Comput. 2017, 21, 2709–2721. [Google Scholar] [CrossRef]

- Liu, P.; Xi, L. The neutrosophic number generalized weighted power averaging operator and its application in multiple attribute group decision making. Int. J. Mach. Learn. Cybern. 2018, 9, 347–358. [Google Scholar] [CrossRef]

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bi, M. Control of Robot Arm Motion Using Trapezoid Fuzzy Two-Degree-of-Freedom PID Algorithm. Symmetry 2020, 12, 665. https://doi.org/10.3390/sym12040665

Bi M. Control of Robot Arm Motion Using Trapezoid Fuzzy Two-Degree-of-Freedom PID Algorithm. Symmetry. 2020; 12(4):665. https://doi.org/10.3390/sym12040665

Chicago/Turabian StyleBi, Meng. 2020. "Control of Robot Arm Motion Using Trapezoid Fuzzy Two-Degree-of-Freedom PID Algorithm" Symmetry 12, no. 4: 665. https://doi.org/10.3390/sym12040665

APA StyleBi, M. (2020). Control of Robot Arm Motion Using Trapezoid Fuzzy Two-Degree-of-Freedom PID Algorithm. Symmetry, 12(4), 665. https://doi.org/10.3390/sym12040665