1. Introduction

The tunnel boring machine is a game-changer in mechanized tunneling technology. It is used for boring tunnels for various purposes such as irrigation, metro, subway, hydel, canals, and sewage [

1]. The cutter head is located in front of the TBM structure and it rotates at a very slow rpm (2 to 8 rpm). It cuts the rocks by chipping and causes advancement of the tunnel face. Disc cutters are positioned on the cutter head and these disc cutters are a combination of various parts such as cutter ring, bearing, seal, cage, etc. Cutter rings are generally made of H13 tool steel and they directly interact with the rocks during the cutting process. Friction and abrasion occur between the cutter rings and the rocks resulting in wearing-out of the cutter ring [

2]. Initially, the hardness of new cutter rings was observed to be in the range of 540 to 560 HV0.2. After running against rock their hardness decreases (413 to 460 HV0.2) due to wear-out of the hard face as well as an increase in ring width, chipping, abrasion, and spalling and pitting occurs. Typically, a TBM cutter head consists of 50–60 disc cutters as per the nature of rock to be tunneled through. The cost of each disc cutter ranges from 2500–

$2800. New and worn out cutter rings are shown in

Figure 1.

Cutter rings are costly and their replacement is quite time-consuming. Refurbishment happens to be a much acceptable option for ease of operation. Different types of rapid prototyping (RP) technologies are used for the refurbishment of material such as stereolithography (SLA), fused deposition modeling (FDM) and laminated object manufacturing (LOM) [

3]. In SLA, parts are contrived by a fluid photosensitive resin within sight of laser radiation. The FDM method is used for fabricating layered surfaces. In this method, a thermoplastic filament is used in a supply head, and then this fused material is extruded from the head for making layers. In LOM, layers are formed with the help of paper, plastics, and metals with glued together. These layers are cut by a laser cutter. However, RP technologies are used for developing the functional parts directly from the metals without the aid of binders or other activities. Laser surface cladding (LSC) meets this challenging requirement. It is widely utilized for producing metal parts by metal powders with higher productivity. In this strategy, the materials are bolstered on the substrate under the laser beam by various means such as powder paste, powder blowing and wire feed [

4]. In a comparatively short time, a laser beam interacts with them and thus, chemical and microstructural changes are observed [

5]. The laser power, scanning speed, and beam diameter are the deciding factors for the thickness of the coating [

6]. Different types of surface treatment and the composite coating is done using LSC. It is widely used for non-porous and crack-free surface treatment.

In mining and heavy engineering, failure due to the wear of cutting tools is a frequent phenomenon [

7]. It affects the production, operation and economic strategies of the company [

8]. Enhancement of the wear resistance of the machine cutting tools can be obtained by hard facing or coating of abrasion-resistant material [

9]. A common method for the production of this hard facing is by using metal matrix composites (MMC). It is a mixture of hard ceramic phase and a ductile metal matrix. Ni- and Co-based compounds are frequently used with tungsten carbide (WC) for the hard facing of material [

10]. WCs are usually supplied in the form of alloy powder, in which binding-agglomerates of WC particles are included and its hardness is in the range of 1500–2000 HV. Cermets of WC-Co are also used as abrasion-resistant materials in the industries. Using a CO

2 laser, the coating of 83% WC on the surface of AISI 1043 presents less porosity, a high coating hardness and a very good adhesive layer substrate [

11,

12]. The other benefits of the coatings are erosion resistance, corrosion and oxidation barrier, reclamation of worn-out parts, enhanced electrical and thermal property [

13,

14].

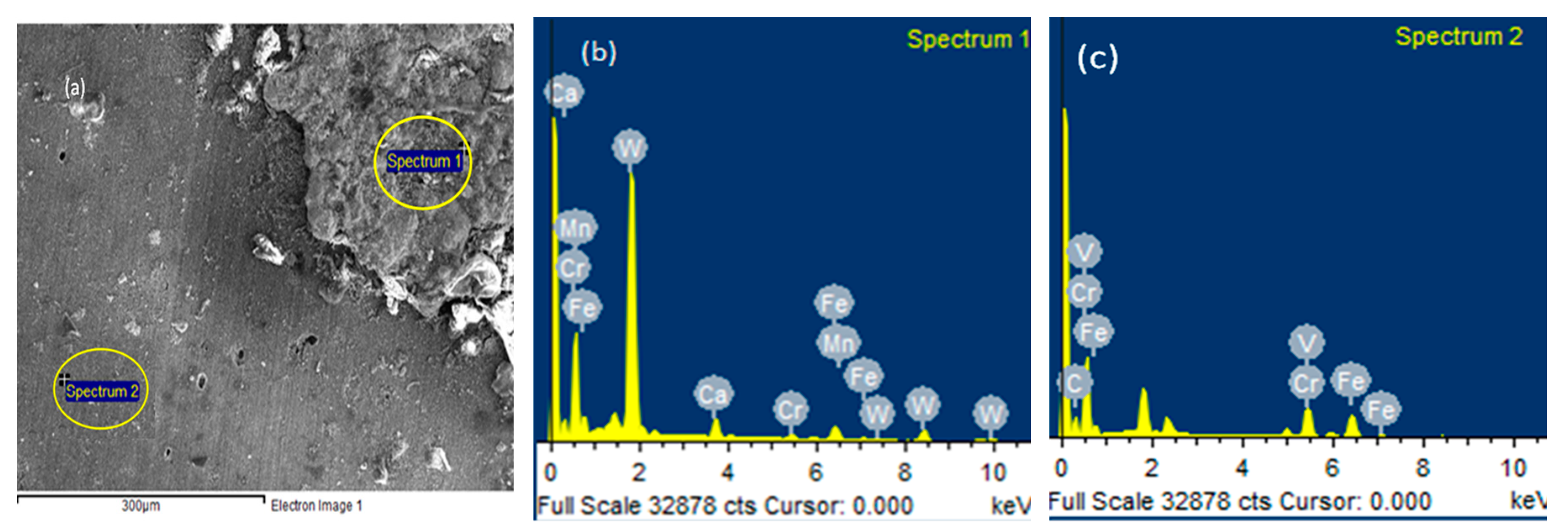

This paper reports the investigations carried out on the usage of WC coating on the worn-out cutter rings of disc cutters used in tunnel boring machine. The coating has been made with the help of a fiber laser in the presence of N2 shielding gas. WC nanopowder has been used as a coating material and H13 tool steel as a substrate. Initially, a 5 mm thick plate of H13 was made with the help of an abrasive cutter and wire electric discharge machining (WEDM). A 1 mm thick layer of WC paste has been formed with the help of polyvinyl alcohol (PVA) solution. A laser beam with different process parameters has been passed over the paste of WC. In situ formation of coating has been investigated by an optical microscope, FESEM and EDS. Hardness testing was done by the Vicker’s hardness testing machine. Wear testing has been performed on a pin on disc setup. ANOVA was employed to analyze the impact of laser processing-related parameters (laser speed, scanning speed) on the yields (hardness and wear rate) of the coating. A desirability test was performed to get the correlation of input and output parameters. A correlation test has also been carried out between the hardness and wear rate of coating, with the help of R-software.

4. Conclusions

In this paper, a nano-WC powder was coated on the worn-out cutter ring (substrate) using the LSC process. Laser power and scanning speed are two major process control parameters that are used for the coating. Thirteen samples were prepared on the basis of CCD at different input parameters.

The results of the study confirm the following observations:

The laser cladding was performed at different values of the process control parameters provided a layered and uneven coating on the substrate.

Dendritic and needle type microstructures were formed and that shows the presence of WC on the cladding. Different types of deformities are present on the coating in the form of micro-holes, cracks, globules.

The hardness of coating layers varied from 580 to 870 HV0.2, which is much higher than that of the substrate (400–460 HV0.2). The microhardness increased due to strong bonding among the elements.

Wear of the substrate is 68 × 10−5 (loss in mass) g/min whereas the wear of the coated samples lies between 4 to 41 × 10−5 (loss in mass) g/min at different levels of process control parameters.

ANOVA depicts the crucial role of the major input parameters (laser power, scanning speed) on the response variables (hardness and wear).

The desirability function provides the optimal response of input parameters on the yield parameters. It shows that maximum hardness and minimum wear rate are attained at laser power (220 W) and scanning speed (179 mm/min).

A negative correlation (Spearman rho = −0.9807163) was observed between the hardness values and the wear of the coating. This depicts that with the increase in hardness of coating wear decreases.

These results show that the coating of WC on the substrate is an effective approach for eco-friendly reuse and refurbishment of worn out cutter rings for enhanced cutter life. This has direct economic benefits in deploying TBM technologies for tunneling projects.