The Recent Progress in Modification of Polymeric Membranes Using Organic Macromolecules for Water Treatment

Abstract

1. Introduction

2. Membrane and Membrane Processes

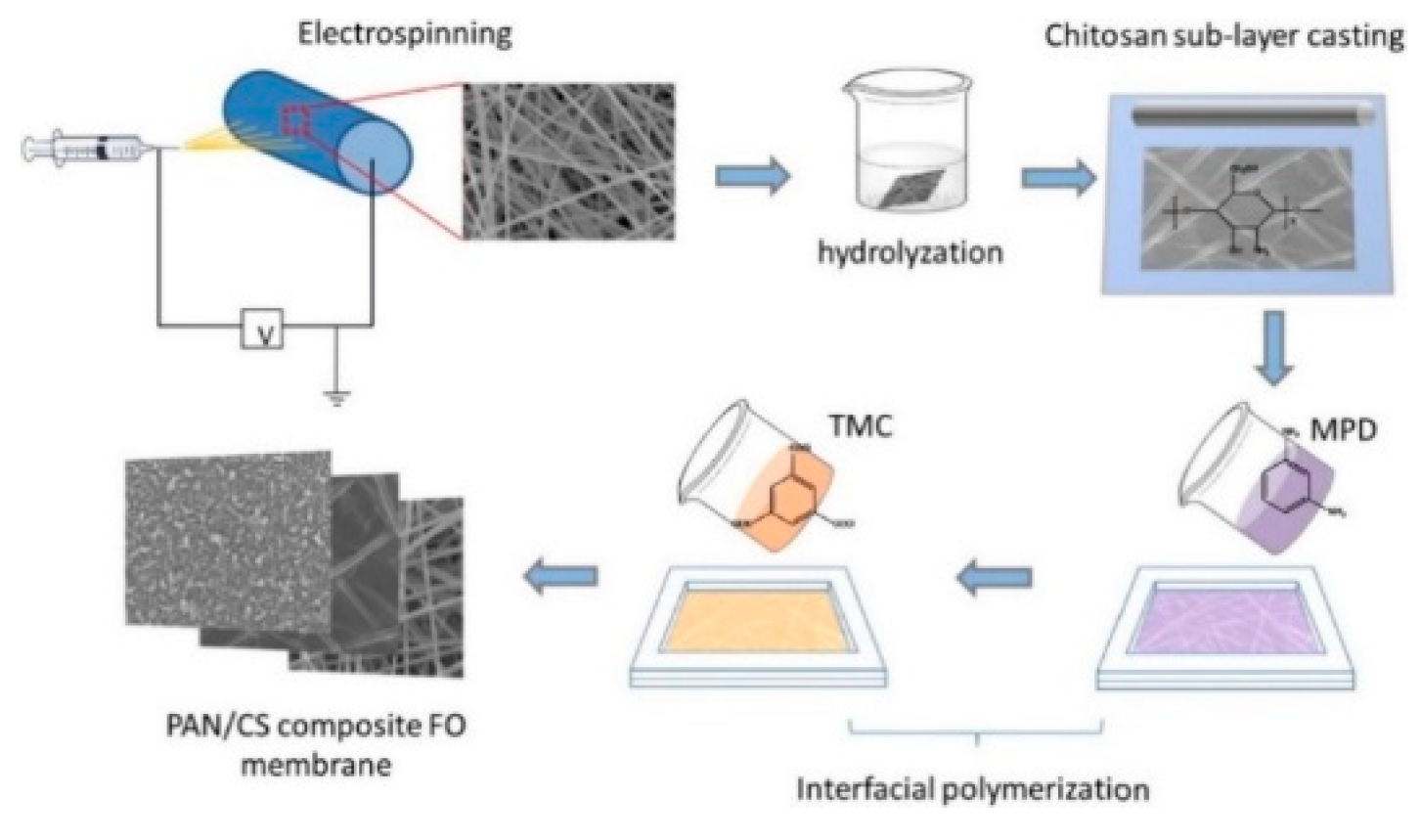

3. The Role of Macromolecules in Polymeric Membrane

4. Modifications of Membrane Using Macromolecules

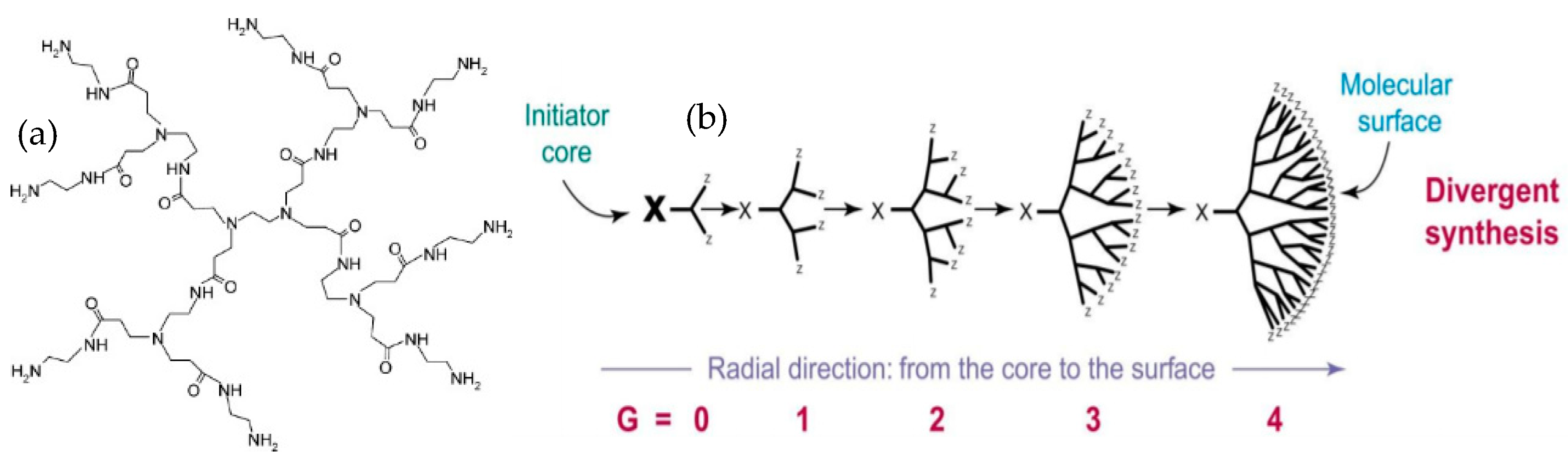

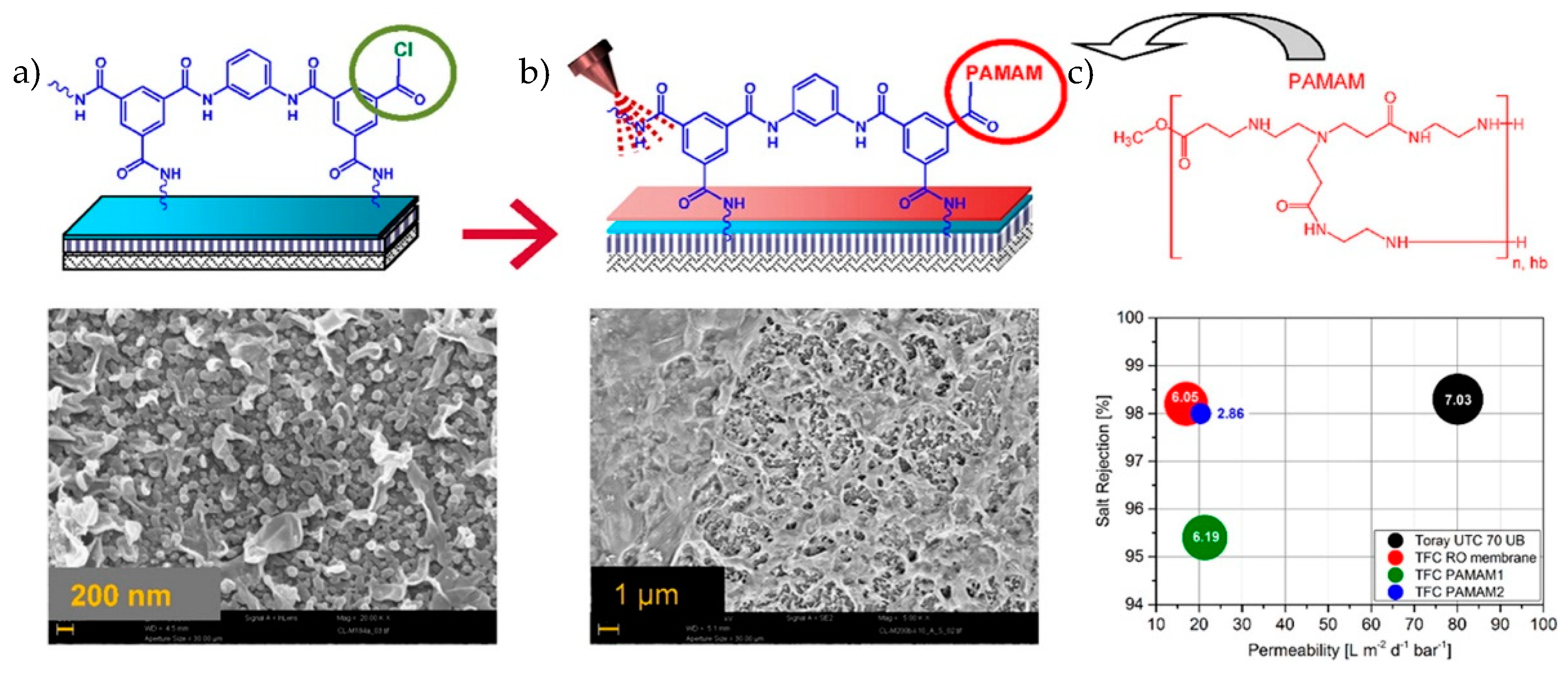

4.1. Dendrimers

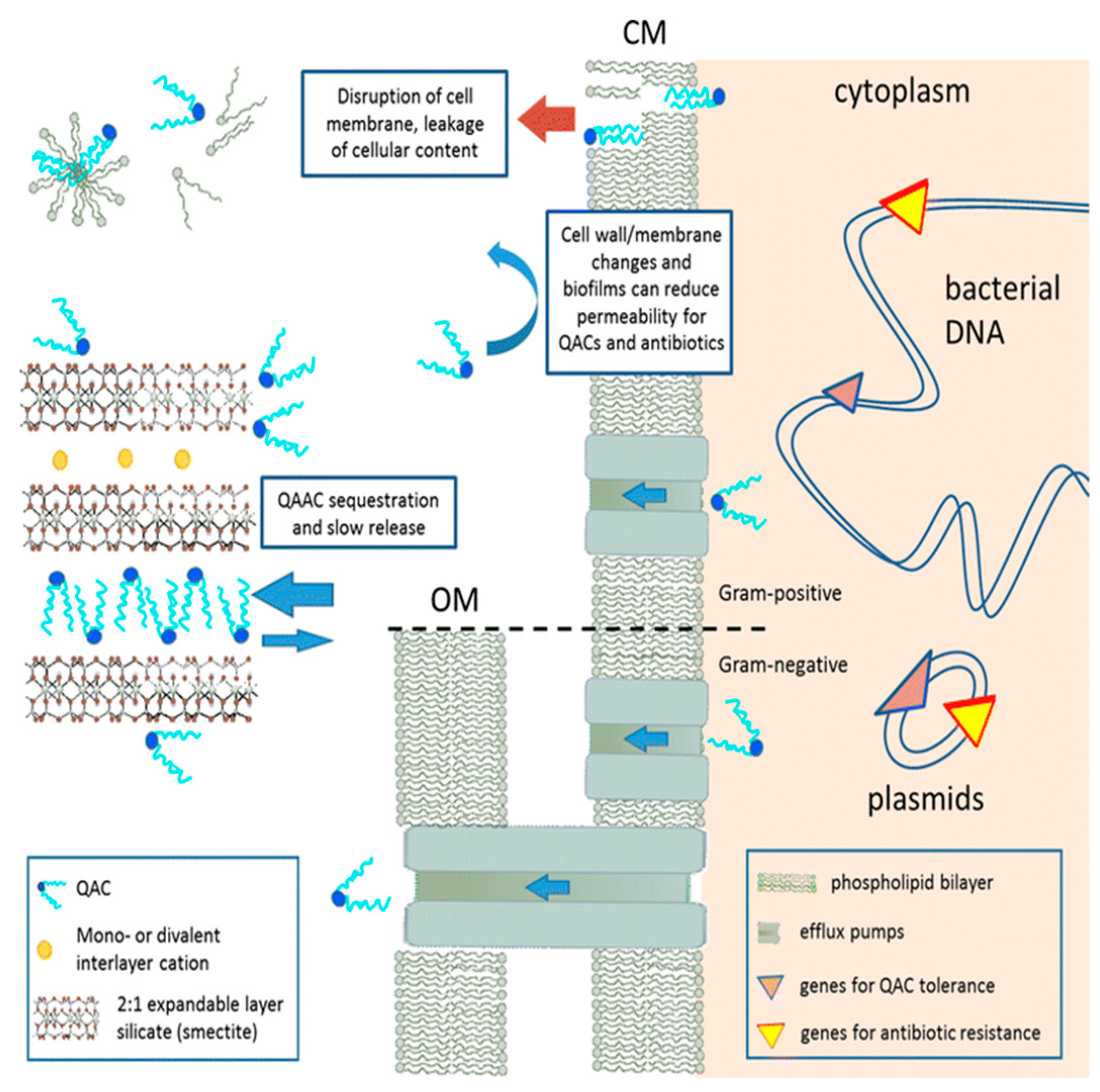

4.2. Quaternary Ammonium Compounds (QAC)

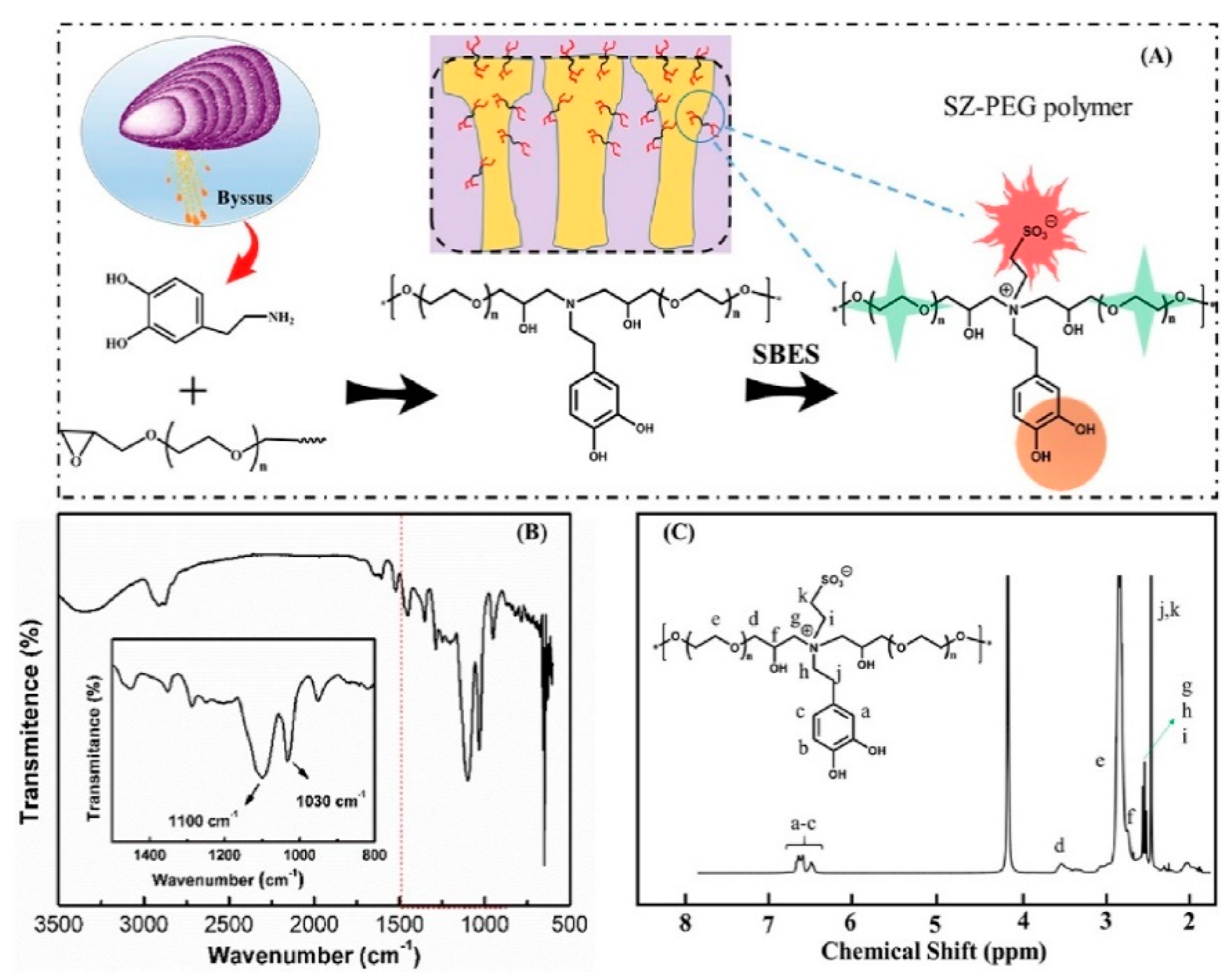

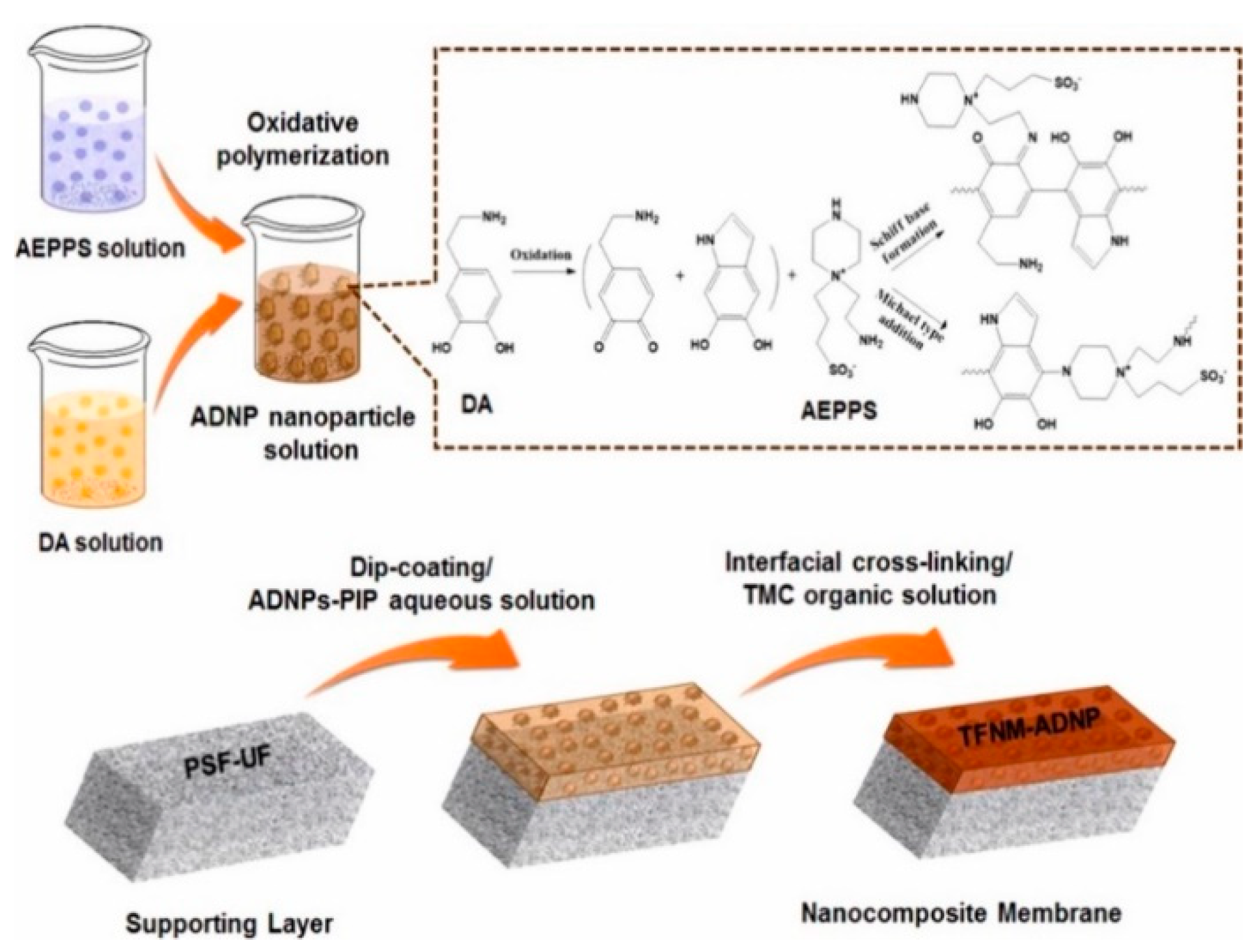

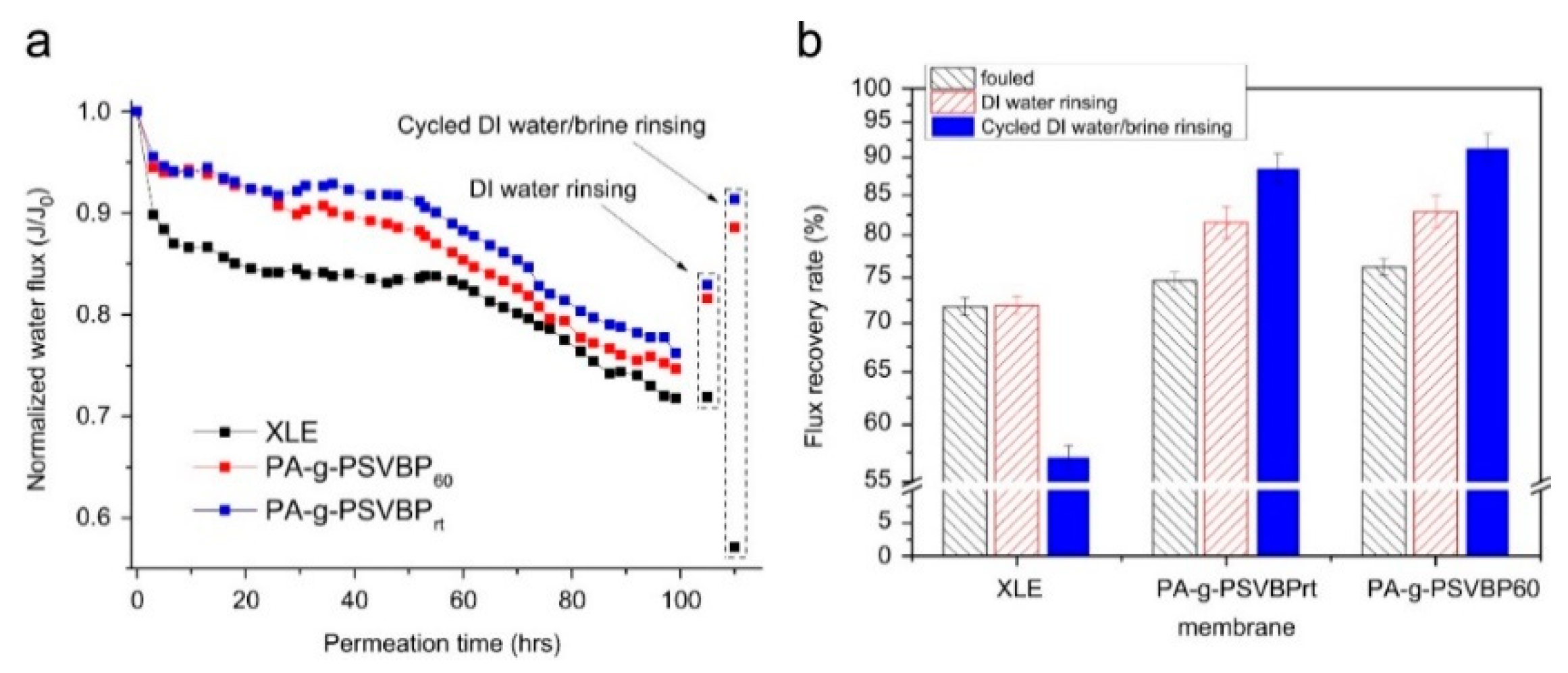

4.3. Polyzwitterions

4.4. Chitosan, CS

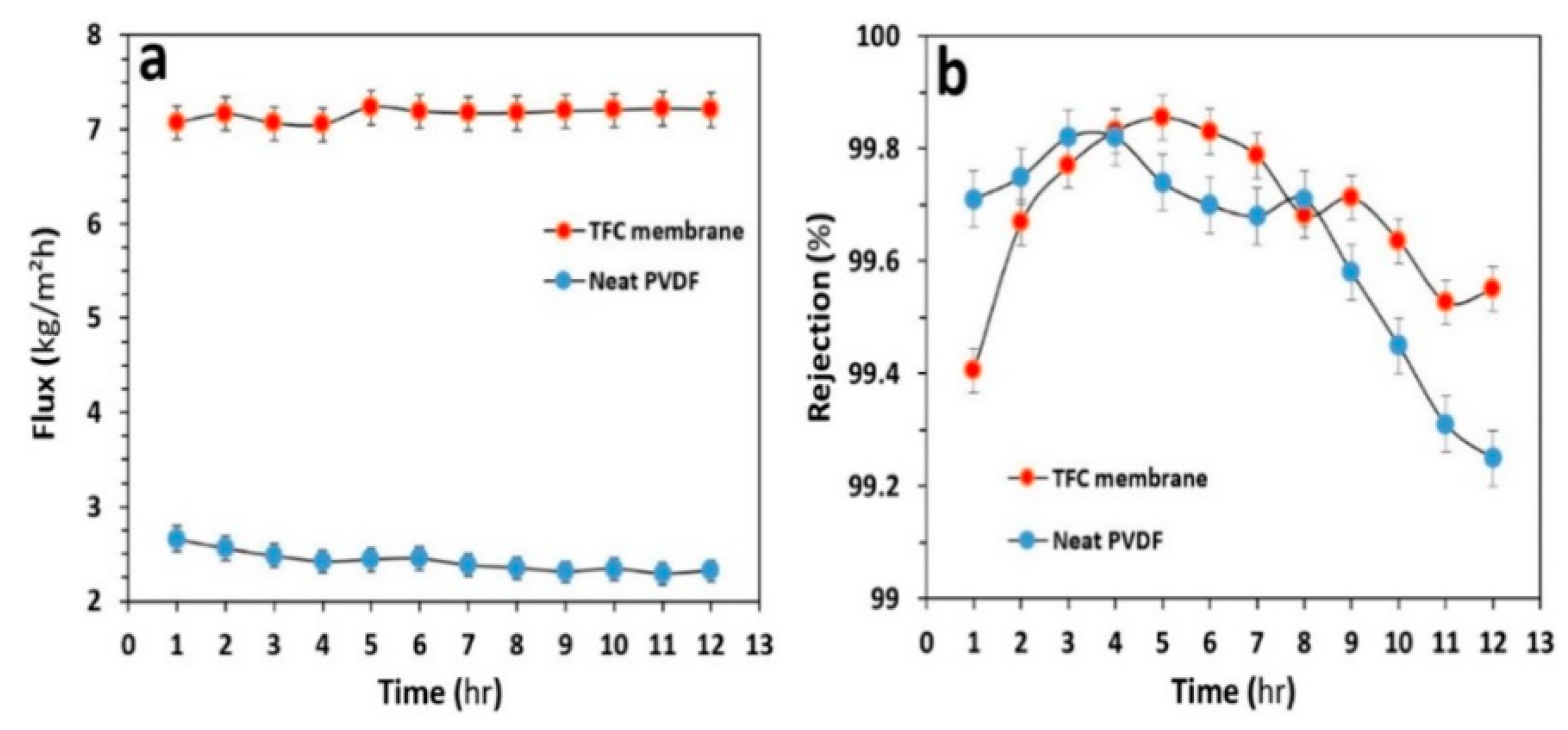

4.5. Cellulose

4.6. Polydopamine, PDA

5. Future Perspective and Concluding Remarks

Author Contributions

Funding

Conflicts of Interest

References

- Bolisetty, S.; Peydayesh, M.; Mezzenga, R. Sustainable technologies for water purification from heavy metals: Review and analysis. Chem. Soc. Rev. 2019, 48, 463–487. [Google Scholar] [CrossRef] [PubMed]

- Parlar, I.; Hacıfazlıoğlu, M.; Kabay, N.A.L.A.N.; Pek, T.Ö.; Yüksel, M. Performance comparison of reverse osmosis (RO) with integrated nanofiltration (NF) and reverse osmosis process for desalination of MBR effluent. J. Water Process Eng. 2019, 29, 100640. [Google Scholar] [CrossRef]

- Nthunya, L.N.; Gutierrez, L.; Derese, S.; Nxumalo, E.N.; Verliefde, A.R.; Mamba, B.B.; Mhlanga, S.D. A review of nanoparticle-enhanced membrane distillation membranes: Membrane synthesis and applications in water treatment. J. Chem. Technol. Biotechnol. 2019, 94, 2757–2771. [Google Scholar] [CrossRef]

- Kırtel, O.; Versluys, M.; Van den Ende, W.; Öner, E.T. Fructans of the saline world. Biotechnol. Adv. 2018, 36, 1524–1539. [Google Scholar] [CrossRef]

- Esfahani, M.R.; Aktij, S.A.; Dabaghian, Z.; Firouzjaei, M.D.; Rahimpour, A.; Eke, J.; Escobar, I.C.; Abolhassani, M.; Greenlee, L.F.; Esfahani, A.R.; et al. Nanocomposite membranes for water separation and purification: Fabrication, modification, and applications. Sep. Purif. Technol. 2019, 213, 465–499. [Google Scholar] [CrossRef]

- Anis, S.F.; Hashaikeh, R.; Hilal, N. Reverse osmosis pretreatment technologies and future trends: A comprehensive review. Desalination 2019, 452, 159–195. [Google Scholar] [CrossRef]

- Kavitha, J.; Rajalakshmi, M.; Phani, A.R.; Padaki, M. Pretreatment processes for seawater reverse osmosis desalination systems—A review. J. Water Process Eng. 2019, 32, 100926. [Google Scholar] [CrossRef]

- Zhang, Y.; Ruan, H.; Guo, C.; Liao, J.; Shen, J.; Gao, C. Thin-film nanocomposite reverse osmosis membranes with enhanced antibacterial resistance by incorporating p-aminophenol-modified graphene oxide. Sep. Purif. Technol. 2020, 234, 116017. [Google Scholar] [CrossRef]

- Buruga, K.; Song, H.; Shang, J.; Bolan, N.; Jagannathan, T.K.; Kim, K.H. A review on functional polymer-clay based nanocomposite membranes for treatment of water. J. Hazard. Mater. 2019, 379, 120584. [Google Scholar] [CrossRef]

- Bandara, P.C.; Nadres, E.T.; Peña-Bahamonde, J.; Rodrigues, D.F. Impact of water chemistry, shelf-life, and regeneration in the removal of different chemical and biological contaminants in water by a model Polymeric Graphene Oxide Nanocomposite Membrane Coating. J. Water Process Eng. 2019, 32, 100967. [Google Scholar] [CrossRef]

- Shen, H.; Wang, S.; Xu, H.; Zhou, Y.; Gao, C. Preparation of polyamide thin film nanocomposite membranes containing silica nanoparticles via an in-situ polymerization of SiCl4 in organic solution. J. Membr. Sci. 2018, 565, 145–156. [Google Scholar] [CrossRef]

- Fu, S.; Sun, Z.; Huang, P.; Li, Y.; Hu, N. Some basic aspects of polymer nanocomposites: A critical review. Nano Mater. Sci. 2019, 1, 2–30. [Google Scholar] [CrossRef]

- Qu, X.; Alvarez, P.J.; Li, Q. Applications of nanotechnology in water and wastewater treatment. Water Res. 2013, 47, 3931–3946. [Google Scholar] [CrossRef] [PubMed]

- Crock, C.A.; Rogensues, A.R.; Shan, W.; Tarabara, V.V. Polymer nanocomposites with graphene-based hierarchical fillers as materials for multifunctional water treatment membranes. Water Res. 2013, 47, 3984–3996. [Google Scholar] [CrossRef]

- Cay-Durgun, P.; McCloskey, C.; Konecny, J.; Khosravi, A.; Lind, M.L. Evaluation of thin film nanocomposite reverse osmosis membranes for long-term brackish water desalination performance. Desalination 2017, 404, 304–312. [Google Scholar] [CrossRef]

- Baek, Y.; Kim, H.J.; Kim, S.H.; Lee, J.C.; Yoon, J. Evaluation of carbon nanotube-polyamide thin-film nanocomposite reverse osmosis membrane: Surface properties, performance characteristics and fouling behavior. J. Ind. Eng. Chem. 2017, 56, 327–334. [Google Scholar] [CrossRef]

- Aljundi, I.H. Desalination characteristics of TFN-RO membrane incorporated with ZIF-8 nanoparticles. Desalination 2017, 420, 12–20. [Google Scholar] [CrossRef]

- Farahbakhsh, J.; Delnavaz, M.; Vatanpour, V. Investigation of raw and oxidized multiwalled carbon nanotubes in fabrication of reverse osmosis polyamide membranes for improvement in desalination and antifouling properties. Desalination 2017, 410, 1–9. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, V.; Romero, R.; Sharma, K.; Singh, J. Applications of Nanoparticles in Wastewater Treatment. In Nanobiotechnology in Bioformulations; Prasad, R., Kumar, V., Kumar, M., Choudhary, D., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 395–418. [Google Scholar]

- Kausar, A. Inorganic nanomaterials in polymeric water decontamination membranes. Int. J. Plast. Technol. 2019, 23, 1–11. [Google Scholar] [CrossRef]

- Zheng, K.; Setyawati, M.I.; Leong, D.T.; Xie, J. Antimicrobial silver nanomaterials. Coord. Chem. Rev. 2018, 357, 1–17. [Google Scholar] [CrossRef]

- Mocanu, A.; Rusen, E.; Diacon, A.; Isopencu, G.; Mustățea, G.; Şomoghi, R.; Dinescu, A. Antimicrobial properties of polysulfone membranes modified with carbon nanofibers and silver nanoparticles. Mater. Chem. Phys. 2019, 223, 39–45. [Google Scholar] [CrossRef]

- Lee, E.S.; Kim, Y.O.; Ha, Y.M.; Lim, D.; Hwang, J.Y.; Kim, J.; Park, M.; Cho, J.W.; Jung, Y.C. Antimicrobial properties of lignin-decorated thin multi-walled carbon nanotubes in poly (vinyl alcohol) nanocomposites. Eur. Polym. J. 2018, 105, 79–84. [Google Scholar] [CrossRef]

- Wang, W.; Zhu, L.; Shan, B.; Xie, C.; Liu, C.; Cui, F.; Li, G. Preparation and characterization of SLS-CNT/PES ultrafiltration membrane with antifouling and antibacterial properties. J. Membr. Sci. 2018, 548, 459–469. [Google Scholar] [CrossRef]

- Ali, S.; Rehman, S.A.U.; Luan, H.Y.; Farid, M.U.; Huang, H. Challenges and opportunities in functional carbon nanotubes for membrane-based water treatment and desalination. Sci. Total Environ. 2019, 646, 1126–1139. [Google Scholar] [CrossRef]

- Henriques, P.C.; Borges, I.; Pinto, A.M.; Magalhães, F.D.; Gonçalves, I.C. Fabrication and antimicrobial performance of surfaces integrating graphene-based materials. Carbon 2018, 132, 709–732. [Google Scholar] [CrossRef]

- Han, W.; Wu, Z.; Li, Y.; Wang, Y. Graphene family nanomaterials (GFNs)—promising materials for antimicrobial coating and film: A review. Chem. Eng. J. 2019, 358, 1022–1037. [Google Scholar] [CrossRef]

- Ren, T.; Wang, Y.; Yu, Q.; Li, M. Synthesis of antimicrobial peptide-grafted graphene oxide nanosheets with high antimicrobial efficacy. Mater. Lett. 2019, 235, 42–45. [Google Scholar] [CrossRef]

- Onitsuka, S.; Hamada, T.; Okamura, H. Preparation of antimicrobial gold and silver nanoparticles from tea leaf extracts. Colloids Surf. B Biointerfaces 2019, 173, 242–248. [Google Scholar] [CrossRef]

- Cano, A.P.; Gillado, A.V.; Montecillo, A.D.; Herrera, M.U. Copper sulfate-embedded and copper oxide-embedded filter paper and their antimicrobial properties. Mater. Chem. Phys. 2018, 207, 147–153. [Google Scholar] [CrossRef]

- Pasquet, J.; Chevalier, Y.; Pelletier, J.; Couval, E.; Bouvier, D.; Bolzinger, M.A. The contribution of zinc ions to the antimicrobial activity of zinc oxide. Colloids Surfaces A Physicochem. Eng. Asp. 2014, 457, 263–274. [Google Scholar] [CrossRef]

- Zhao, Q.; Wang, M.; Yang, H.; Shi, D.; Wang, Y. Preparation, characterization and the antimicrobial properties of metal ion-doped TiO2 nano-powders. Ceram. Int. 2018, 44, 5145–5154. [Google Scholar] [CrossRef]

- Dutta, P.; Wang, B. Zeolite-supported silver as antimicrobial agents. Coord. Chem. Rev. 2019, 383, 1–29. [Google Scholar] [CrossRef]

- Ji, Y.L.; Qian, W.J.; An, Q.F.; Huang, S.H.; Lee, K.R.; Gao, C.J. Mussel-inspired zwitterionic dopamine nanoparticles as building blocks for constructing salt selective nanocomposite membranes. J. Membr. Sci. 2019, 572, 140–151. [Google Scholar] [CrossRef]

- Akther, N.; Phuntsho, S.; Chen, Y.; Ghaffour, N.; Shon, H.K. Recent advances in nanomaterial-modified polyamide thin-film composite membranes for forward osmosis processes. J. Membr. Sci. 2019, 584, 20–45. [Google Scholar] [CrossRef]

- Saleem, H.; Zaidi, S.J. Nanoparticles in reverse osmosis membranes for desalination: A state of the art review. Desalination 2020, 475, 114171. [Google Scholar] [CrossRef]

- Ahmaruzzaman, M. Nano-materials: Novel and Promising Adsorbents for Water Treatment. Asian J. Water Environ. Pollut. 2019, 16, 43–53. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E. Toxicity of graphene and graphene oxide nanowalls against bacteria. ACS Nano 2010, 4, 5731–5736. [Google Scholar] [CrossRef]

- Jia, G.; Wang, H.; Yan, L.; Wang, X.; Pei, R.; Yan, T.; Zhao, Y.; Guo, X. Cytotoxicity of carbon nanomaterials: Single-wall nanotube, multi-wall nanotube, and fullerene. Environ. Sci. Technol. 2005, 39, 1378–1383. [Google Scholar] [CrossRef]

- Ahamed, M.; AlSalhi, M.S.; Siddiqui, M.K.J. Silver nanoparticle applications and human health. Clin. Chim. Acta 2010, 411, 1841–1848. [Google Scholar] [CrossRef]

- Upadhyaya, L.; Qian, X.; Wickramasinghe, S.R. Chemical modification of membrane surface—overview. Curr. Opin. Chem. Eng. 2018, 20, 13–18. [Google Scholar] [CrossRef]

- Yang, Z.; Ma, X.H.; Tang, C.Y. Recent development of novel membranes for desalination. Desalination 2018, 434, 37–59. [Google Scholar] [CrossRef]

- Haider, M.S.; Shao, G.N.; Imran, S.M.; Park, S.S.; Abbas, N.; Tahir, M.S.; Hussain, M.; Bae, W.; Kim, H.T. Aminated polyethersulfone-silver nanoparticles (AgNPs-APES) composite membranes with controlled silver ion release for antibacterial and water treatment applications. Mater. Sci. Eng. C 2016, 62, 732–745. [Google Scholar] [CrossRef]

- Marinescu, I.D.; Rowe, W.B.; Dimitrov, B.; Inaski, I. 16—Processed Materials. In Tribology of Abrasive Machining Processes; Marinescu, I.D., Rowe, W.B., Dimitrov, B., Inasaki, I., Eds.; William Andrew Publishing: Norwich, NY, USA, 2004; pp. 635–663. [Google Scholar]

- Shrivastava, A. 2—Polymerization. In Introduction to Plastics Engineering; Shrivastava, A., Ed.; William Andrew Publishing: Norwich, NY, USA, 2018; pp. 17–48. [Google Scholar]

- Ab Hamid, N.H.; Ye, L.; Wang, D.K.; Smart, S.; Filloux, E.; Lebouteiller, T.; Zhang, X. Evaluating the membrane fouling formation and chemical cleaning strategy in forward osmosis membrane filtration treating domestic sewage. Environ. Sci. Water Res. Technol. 2018, 4, 2092–2103. [Google Scholar] [CrossRef]

- Li, J.; Wei, M.; Wang, Y. Substrate matters: The influences of substrate layers on the performances of thin-film composite reverse osmosis membranes. Chin. J. Chem. Eng. 2017, 25, 1676–1684. [Google Scholar] [CrossRef]

- Yang, Z.; Zhou, Y.; Feng, Z.; Rui, X.; Zhang, T.; Zhang, Z. A Review on Reverse Osmosis and Nanofiltration Membranes for Water Purification. Polymers 2019, 11, 1252. [Google Scholar] [CrossRef]

- Fathizadeh, M.; Tien, H.N.; Khivantsev, K.; Song, Z.; Zhou, F.; Yu, M. Polyamide/nitrogen-doped graphene oxide quantum dots (N-GOQD) thin film nanocomposite reverse osmosis membranes for high flux desalination. Desalination 2019, 451, 125–132. [Google Scholar] [CrossRef]

- Aziz, M.; Kasongo, G. Scaling prevention of thin film composite polyamide Reverse Osmosis membranes by Zn ions. Desalination 2019, 464, 76–83. [Google Scholar] [CrossRef]

- Jamaly, S.; Darwish, N.N.; Ahmed, I.; Hasan, S.W. A short review on reverse osmosis pretreatment technologies. Desalination 2014, 354, 30–38. [Google Scholar] [CrossRef]

- Qasim, M.; Badrelzaman, M.; Darwish, N.N.; Darwish, N.A.; Hilal, N. Reverse osmosis desalination: A state-of-the-art review. Desalination 2019, 459, 59–104. [Google Scholar] [CrossRef]

- Le, N.L.; Nunes, S.P. Materials and membrane technologies for water and energy sustainability. Sustain. Mater. Technol. 2016, 7, 1–28. [Google Scholar] [CrossRef]

- Nasir, A.; Masood, F.; Yasin, T.; Hameed, A. Progress in polymeric nanocomposite membranes for wastewater treatment: Preparation, properties and applications. J. Ind. Eng. Chem. 2019, 79, 29–40. [Google Scholar] [CrossRef]

- Goh, P.S.; Matsuura, T.; Ismail, A.F.; Hilal, N. Recent trends in membranes and membrane processes for desalination. Desalination 2016, 391, 43–60. [Google Scholar] [CrossRef]

- Wen, Y.; Yuan, J.; Ma, X.; Wang, S.; Liu, Y. Polymeric nanocomposite membranes for water treatment: A review. Environ. Chem. Lett. 2019, 17, 1539–1551. [Google Scholar] [CrossRef]

- Zhu, J.; Hou, J.; Zhang, Y.; Tian, M.; He, T.; Liu, J.; Chen, V. Polymeric antimicrobial membranes enabled by nanomaterials for water treatment. J. Membr. Sci. 2018, 550, 173–197. [Google Scholar] [CrossRef]

- Tan, X.; Rodrigue, D. A Review on Porous Polymeric Membrane Preparation. Part I: Production Techniques with Polysulfone and Poly (Vinylidene Fluoride). Polymers 2019, 11, 1160. [Google Scholar] [CrossRef]

- Ashraf, M.A.; Maah, M.J.; Qureshi, A.K.; Gharibreza, M.; Yusoff, I. Synthetic polymer composite membrane for the desalination of saline water. Desalin. Water Treat. 2013, 51, 3650–3661. [Google Scholar] [CrossRef]

- Kang, G.D.; Cao, Y.M. Development of antifouling reverse osmosis membranes for water treatment: A review. Water Res. 2012, 46, 584–600. [Google Scholar] [CrossRef]

- González-Gago, C.; Pisonero, J.; Sandín, R.; Fuertes, J.F.; Sanz-Medel, A.; Bordel, N. Analytical potential of rf-PGD-TOFMS for depth profiling of an oxidized thin film composite. J. Anal. At. Spectrom. 2016, 31, 288–296. [Google Scholar] [CrossRef]

- Ismail, A.F.; Padaki, M.; Hilal, N.; Matsuura, T.; Lau, W.J. Thin film composite membrane—Recent development and future potential. Desalination 2015, 356, 140–148. [Google Scholar] [CrossRef]

- Pendergast, M.M.; Hoek, E.M. A review of water treatment membrane nanotechnologies. Energy Environ. Sci. 2011, 4, 1946–1971. [Google Scholar] [CrossRef]

- Ahmad, N.A.; Goh, P.S.; Abdul Karim, Z.; Ismail, A.F. Thin Film Composite Membrane for Oily Waste Water Treatment: Recent Advances and Challenges. Membranes 2018, 8, 86. [Google Scholar] [CrossRef] [PubMed]

- Lee, A.; Elam, J.W.; Darling, S.B. Membrane materials for water purification: Design, development, and application. Environmental Science: Water Res. Technol. 2016, 2, 17–42. [Google Scholar] [CrossRef]

- Guo, W.; Ngo, H.H.; Li, J. A mini-review on membrane fouling. Bioresour. Technol. 2012, 122, 27–34. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.N.; Tang, C.Y. Protein fouling of nanofiltration, reverse osmosis, and ultrafiltration membranes—The role of hydrodynamic conditions, solution chemistry, and membrane properties. J. Membr. Sci. 2011, 376, 275–282. [Google Scholar] [CrossRef]

- Kim, T.S.; Park, S.H.; Park, D.; Lee, J.H.; Kang, S. Surface immobilization of chlorhexidine on a reverse osmosis membrane for in-situ biofouling control. J. Membr. Sci. 2019, 576, 17–25. [Google Scholar] [CrossRef]

- Sim, L.N.; Chong, T.H.; Taheri, A.H.; Sim, S.T.V.; Lai, L.; Krantz, W.B.; Fane, A.G. A review of fouling indices and monitoring techniques for reverse osmosis. Desalination 2018, 434, 169–188. [Google Scholar] [CrossRef]

- Chang, Y.R.; Lee, Y.J.; Lee, D.J. Membrane fouling during water or wastewater treatments: Current research updated. J. Taiwan Inst. Chem. Eng. 2019, 94, 88–96. [Google Scholar] [CrossRef]

- Ben-Sasson, M.; Zodrow, K.R.; Genggeng, Q.; Kang, Y.; Giannelis, E.P.; Elimelech, M. Surface functionalization of thin-film composite membranes with copper nanoparticles for antimicrobial surface properties. Environ. Sci. Technol. 2013, 48, 384–393. [Google Scholar] [CrossRef]

- Bucs, S.S.; Farhat, N.; Kruithof, J.C.; Picioreanu, C.; van Loosdrecht, M.C.; Vrouwenvelder, J.S. Review on strategies for biofouling mitigation in spiral wound membrane systems. Desalination 2018, 434, 189–197. [Google Scholar] [CrossRef]

- Fane, A.G. A grand challenge for membrane desalination: More water, less carbon. Desalination 2018, 426, 155–163. [Google Scholar] [CrossRef]

- Goh, P.S.; Lau, W.J.; Othman, M.H.D.; Ismail, A.F. Membrane fouling in desalination and its mitigation strategies. Desalination 2018, 425, 130–155. [Google Scholar] [CrossRef]

- Zhang, R.Y.; Liu, M.; He, Y.; Su, X.; Zhao, M. Elimelech and Z. Jiang. Antifouling membranes for sustainable water purification: Strategies and mechanisms. Chem. Soc. Rev. 2016, 45, 5888–5924. [Google Scholar] [CrossRef]

- Shahmirzadi, M.A.A.; Kargari, A. 9—Nanocomposite membranes. In Emerging Technologies for Sustainable Desalination Handbook; Gude, V.G., Ed.; Butterworth-Heinemann: Oxford UK, 2018; pp. 285–330. [Google Scholar]

- Zare, S.; Kargari, A. 4—Membrane properties in membrane distillation. In Emerging Technologies for Sustainable Desalination Handbook; Gude, V.G., Ed.; Butterworth-Heinemann: Oxford UK, 2018; pp. 107–156. [Google Scholar]

- Hu, W. Polymer Physics: A Molecular Approach. Available online: https://doi.org/10.1016/B978-0-12-815818-0.00004-7 (accessed on 20 December 2019).

- Staudinger, H. From Organic Chemistry to Macromolecules. Available online: http://agris.fao.org/agris-search/search.do?recordID=US201300469664 (accessed on 18 December 2019).

- Sarkar, A.; Carver, P.I.; Zhang, T.; Merrington, A.; Bruza, K.J.; Rousseau, J.L.; Keinath, S.E.; Dvornic, P.R. Dendrimer-based coatings for surface modification of polyamide reverse osmosis membranes. J. Membr. Sci. 2010, 349, 421–428. [Google Scholar] [CrossRef]

- Zhu, W.P.; Gao, J.; Sun, S.P.; Zhang, S.; Chung, T.S. Poly(amidoamine) dendrimer (PAMAM) grafted on thin film composite (TFC) nanofiltration (NF) hollow fiber membranes for heavy metal removal. J. Membr. Sci. 2015, 487, 117–126. [Google Scholar] [CrossRef]

- Ghasempour, A.; Pajootan, E.; Bahrami, H.; Arami, M. Introduction of amine terminated dendritic structure to graphene oxide using Poly(propylene Imine) dendrimer to evaluate its organic contaminant removal. J. Taiwan Inst. Chem. Eng. 2017, 71, 285–297. [Google Scholar] [CrossRef]

- Bao, X.; Wu, Q.; Shi, W.; Wang, W.; Yu, H.; Zhu, Z.; Zhang, X.; Zhang, Z.; Zhang, R.; Cui, F. Polyamidoamine dendrimer grafted forward osmosis membrane with superior ammonia selectivity and robust antifouling capacity for domestic wastewater concentration. Water Res. 2019, 153, 1–10. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Tang, C.Y.; Ma, J.; Liu, M.; Ping, M.; Chen, M.; Wu, Z. Modification of microfiltration membranes by alkoxysilane polycondensation induced quaternary ammonium compounds grafting for biofouling mitigation. J. Membr. Sci. 2018, 549, 165–172. [Google Scholar] [CrossRef]

- Ping, M.; Zhang, X.; Liu, M.; Wu, Z.; Wang, Z. Surface modification of polyvinylidene fluoride membrane by atom-transfer radical-polymerization of quaternary ammonium compound for mitigating biofouling. J. Membr. Sci. 2019, 570, 286–293. [Google Scholar] [CrossRef]

- Cihanoğlu, A.; Altinkaya, S.A. A facile route to the preparation of antibacterial polysulfone-sulfonated polyethersulfone ultrafiltration membranes using a cationic surfactant cetyltrimethylammonium bromide. J. Membr. Sci. 2020, 594, 117438. [Google Scholar] [CrossRef]

- Han, L.; Tan, Y.Z.; Xu, C.; Xiao, T.; Trinh, T.A.; Chew, J.W. Zwitterionic grafting of sulfobetaine methacrylate (SBMA) on hydrophobic PVDF membranes for enhanced anti-fouling and anti-wetting in the membrane distillation of oil emulsions. J. Membr. Sci. 2019, 588, 117196. [Google Scholar] [CrossRef]

- Chiao, Y.H.; Chen, S.T.; Patra, T.; Hsu, C.H.; Sengupta, A.; Hung, W.S.; Huang, S.H.; Qian, X.; Wickramasinghe, R.; Chang, Y.; et al. Zwitterionic forward osmosis membrane modified by fast second interfacial polymerization with enhanced antifouling and antimicrobial properties for produced water pretreatment. Desalination 2019, 469, 114090. [Google Scholar] [CrossRef]

- Zhang, X.; Tian, J.; Gao, S.; Shi, W.; Zhang, Z.; Cui, F.; Zhang, S.; Guo, S.; Yang, X.; Xie, H.; et al. Surface functionalization of TFC FO membranes with zwitterionic polymers: Improvement of antifouling and salt-responsive cleaning properties. J. Membr. Sci 2017, 544, 368–377. [Google Scholar] [CrossRef]

- Shi, J.; Kang, H.; Li, N.; Teng, K.; Sun, W.; Xu, Z.; Qian, X.; Liu, Q. Chitosan sub-layer binding and bridging for nanofiber-based composite forward osmosis membrane. Appl. Surf. Sci. 2019, 478, 38–48. [Google Scholar] [CrossRef]

- Kebria, M.R.S.; Rahimpour, A.; Bakeri, G.; Abedini, R. Experimental and theoretical investigation of thin ZIF-8/chitosan coated layer on air gap membrane distillation performance of PVDF membrane. Desalination 2019, 450, 21–32. [Google Scholar] [CrossRef]

- Elizalde, C.N.B.; Al-Gharabli, S.; Kujawa, J.; Mavukkandy, M.; Hasan, S.W.; Arafat, H.A. Fabrication of blend polyvinylidene fluoride/chitosan membranes for enhanced flux and fouling resistance. Sep. Purif. Technol. 2018, 190, 68–76. [Google Scholar] [CrossRef]

- Wang, X.; Cheng, W.; Wang, D.; Ni, X.; Han, G. Electrospun polyvinylidene fluoride-based fibrous nanocomposite membranes reinforced by cellulose nanocrystals for efficient separation of water-in-oil emulsions. J. Membr. Sci. 2019, 575, 71–79. [Google Scholar] [CrossRef]

- Moeinzadeh, R.; Ghadam, A.G.J.; Lau, W.J.; Emadzadeh, D. Synthesis of nanocomposite membrane incorporated with amino-functionalized nanocrystalline cellulose for refinery wastewater treatment. Carbohydr. Polym. 2019, 225, 115212. [Google Scholar] [CrossRef]

- Asempour, F.; Emadzadeh, D.; Matsuura, T.; Kruczek, B. Synthesis and characterization of novel Cellulose Nanocrystals-based Thin Film Nanocomposite membranes for reverse osmosis applications. Desalination 2018, 439, 179–187. [Google Scholar] [CrossRef]

- Abbasi, E.; Aval, S.F.; Akbarzadeh, A.; Milani, M.; Nasrabadi, H.T.; Joo, S.W.; Hanifehpour, Y.; Nejati-Koshki, K.; Pashaei-Asl, R. Dendrimers: Synthesis, applications, and properties. Nanoscale Res. Lett. 2014, 9, 247. [Google Scholar] [CrossRef]

- Vunain, E.; Mishra, A.K.; Mamba, B.B. Dendrimers, mesoporous silicas and chitosan-based nanosorbents for the removal of heavy-metal ions: A review. Int. J. Biol. Macromol. 2016, 86, 570–586. [Google Scholar] [CrossRef]

- Sarkar, A.; Carver, P.I.; Zhang, T.; Merrington, A.; Bruza, K.J.; Rousseau, J.L.; Keinath, S.E.; Dvornic, P.R. Surface Modification of Polyamide Reverse Osmosis Membranes with Hydrophilic Dendritic Polymers; ACS Publications: Washington, DC, USA, 2009. [Google Scholar]

- Jiao, Y.; Niu, L.N.; Ma, S.; Li, J.; Tay, F.R.; Chen, J.H. Quaternary ammonium-based biomedical materials: State-of-the-art, toxicological aspects and antimicrobial resistance. Prog. Polym. Sci. 2017, 71, 53–90. [Google Scholar] [CrossRef]

- Darling, S.B. Perspective: Interfacial materials at the interface of energy and water. J. Appl. Phys. 2018, 124, 030901. [Google Scholar] [CrossRef]

- Karatairi, E.; Darling, S.B. Crises and opportunities at the energy-water interface. MRS Bull. 2018, 43, 404–405. [Google Scholar] [CrossRef]

- Ulbricht, M. Advanced functional polymer membranes. Polymer 2006, 47, 2217–2262. [Google Scholar] [CrossRef]

- Mansourizadeh, A.; Aslmahdavi, Z.; Ismail, A.F.; Matsuura, T. Blend polyvinylidene fluoride/surface modifying macromolecule hollow fiber membrane contactors for CO2 absorption. Int. J. Greenh. Gas Control 2014, 26, 83–92. [Google Scholar] [CrossRef]

- Essalhi, M.; Khayet, M. Surface segregation of fluorinated modifying macromolecule for hydrophobic/hydrophilic membrane preparation and application in air gap and direct contact membrane distillation. J. Membr. Sci. 2012, 417, 163–173. [Google Scholar] [CrossRef]

- Prince, J.A.; Rana, D.; Singh, G.; Matsuura, T.; Kai, T.J.; Shanmugasundaram, T.S. Effect of hydrophobic surface modifying macromolecules on differently produced PVDF membranes for direct contact membrane distillation. Chem. Eng. J. 2014, 242, 387–396. [Google Scholar] [CrossRef]

- Zhang, Y.; Wan, Y.; Pan, G.; Yan, H.; Yao, X.; Shi, H.; Tang, Y.; Wei, X.; Liu, Y. Surface modification of polyamide reverse osmosis membrane with organic-inorganic hybrid material for antifouling. Appl. Surf. Sci. 2018, 433, 139–148. [Google Scholar] [CrossRef]

- Carbone, P.; Müller-Plathe, F. Molecular dynamics simulations of polyaminoamide (PAMAM) dendrimer aggregates: Molecular shape, hydrogen bonds and local dynamics. Soft Matter 2009, 5, 2638–2647. [Google Scholar] [CrossRef]

- He, L.; Wu, D.; Tong, M. The influence of different charged poly (amido amine) dendrimer on the transport and deposition of bacteria in porous media. Water Res. 2019, 161, 364–371. [Google Scholar] [CrossRef]

- Jeon, I.Y.; Noh, H.J.; Baek, J.B. Hyperbranched Macromolecules: From Synthesis to Applications. Molecules 2018, 23, 657. [Google Scholar] [CrossRef]

- Sajid, M.; Nazal, M.K.; Baig, N.; Osman, A.M. Removal of heavy metals and organic pollutants from water using dendritic polymers based adsorbents: A critical review. Sep. Purif. Technol. 2018, 191, 400–423. [Google Scholar] [CrossRef]

- Singh, B.; Saini, S.; Lohan, S.; Beg, S. Chapter 3—Systematic Development of Nanocarriers Employing Quality by Design Paradigms. In Nanotechnology-Based Approaches for Targeting and Delivery of Drugs and Genes; Mishra, V., Kesharwani, P., Mohd Amin, M.C.I., Iyer, A., Eds.; Academic Press: Pittsburgh, PA, USA, 2017; pp. 110–148. [Google Scholar]

- Sum, J.Y.; Ahmad, A.L.; Ooi, B.S. Synthesis of thin film composite membrane using mixed dendritic poly(amidoamine) and void filling piperazine monomers. J. Membr. Sci. 2014, 466, 183–191. [Google Scholar] [CrossRef]

- Mansourpanah, Y.; Jafari, Z. Efficacy of different generations and concentrations of PAMAM–NH2 on the performance and structure of TFC membranes. React. Funct. Polym. 2015, 93, 178–189. [Google Scholar] [CrossRef]

- Nikolaeva, D.; Langner, C.; Ghanem, A.; Rehim, M.A.; Voit, B.; Meier-Haack, J. Hydrogel surface modification of reverse osmosis membranes. J. Membr. Sci. 2015, 476, 264–276. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, X.; He, Y.; Zhang, D.; Feng, X.; Zhao, Y.; Chen, L. Preparation of PVDF-g-PAA-PAMAM membrane for efficient removal of copper ions. Chem. Eng. Sci. 2019, 209, 115186. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, X.; Zhao, X.T.; Li, K.; Yu, C.Y.; Liu, L.F.; Zhou, Y.F.; Gao, C.J. High flux reverse osmosis membranes fabricated with hyperbranched polymers via novel twice-crosslinked interfacial polymerization method. J. Membr. Sci. 2020, 595, 117480. [Google Scholar] [CrossRef]

- Mansourpanah, Y.; Shahebrahimi, H.; Kolvari, E. PEG-modified GO nanosheets, a desired additive to increase the rejection and antifouling characteristics of polyamide thin layer membranes. Chem. Eng. Res. Des. 2015, 104, 530–540. [Google Scholar] [CrossRef]

- Liu, M.; Yu, C.; Dong, Z.; Jiang, P.; Lü, Z.; Yu, S.; Gao, C. Improved separation performance and durability of polyamide reverse osmosis membrane in tertiary treatment of textile effluent through grafting monomethoxy-poly(ethylene glycol) brushes. Sep. Purif. Technol. 2019, 209, 443–451. [Google Scholar] [CrossRef]

- Mahdavi, H.; Shahalizade, T. Preparation, characterization and performance study of cellulose acetate membranes modified by aliphatic hyperbranched polyester. J. Membr. Sci. 2015, 473, 256–266. [Google Scholar] [CrossRef]

- Bao, X.; Wu, Q.; Shi, W.; Wang, W.; Zhu, Z.; Zhang, Z.; Zhang, R.; Zhang, B.; Guo, Y.; Cui, F. Dendritic amine sheltered membrane for simultaneous ammonia selection and fouling mitigation in forward osmosis. J. Membr. Sci. 2019, 584, 9–19. [Google Scholar] [CrossRef]

- Kong, X.; Zhang, Y.; Zeng, S.Y.; Zhu, B.K.; Zhu, L.P.; Fang, L.F.; Matsuyama, H. Incorporating hyperbranched polyester into cross-linked polyamide layer to enhance both permeability and selectivity of nanofiltration membrane. J. Membr. Sci. 2016, 518, 141–149. [Google Scholar] [CrossRef]

- Zhang, C.; Cui, F.; Zeng, G.M.; Jiang, M.; Yang, Z.Z.; Yu, Z.G.; Zhu, M.Y.; Shen, L.Q. Quaternary ammonium compounds (QACs): A review on occurrence, fate and toxicity in the environment. Sci. Total Environ. 2015, 518, 352–362. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, J.; Tang, C.Y.; Wang, Z.; Ng, H.Y.; Wu, Z. Antibiofouling polyvinylidene fluoride membrane modified by quaternary ammonium compound: Direct contact-killing versus induced indirect contact-killing. Environ. Sci. Technol. 2016, 50, 5086–5093. [Google Scholar] [CrossRef]

- Mulder, I.; Siemens, J.; Sentek, V.; Amelung, W.; Smalla, K.; Jechalke, S. Quaternary ammonium compounds in soil: Implications for antibiotic resistance development. Rev. Environ. Sci. Bio/Technol. 2018, 17, 159–185. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Chen, M.; Liu, M.; Wu, Z. Polyvinylidene fluoride membrane blended with quaternary ammonium compound for enhancing anti-biofouling properties: Effects of dosage. J. Membr. Sci. 2016, 520, 66–75. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Chen, M.; Ma, J.; Chen, S.; Wu, Z. Membrane biofouling control using polyvinylidene fluoride membrane blended with quaternary ammonium compound assembled on carbon material. J. Membr. Sci. 2017, 539, 229–237. [Google Scholar] [CrossRef]

- Fei, P.; Liao, L.; Meng, J.; Cheng, B.; Hu, X.; Song, J. Non-leaching antibacterial cellulose triacetate reverse osmosis membrane via covalent immobilization of quaternary ammonium cations. Carbohydr. Polym. 2018, 181, 1102–1111. [Google Scholar] [CrossRef]

- Zheng, L.; Sundaram, H.S.; Wei, Z.; Li, C.; Yuan, Z. Applications of zwitterionic polymers. React. Funct. Polym. 2017, 118, 51–61. [Google Scholar] [CrossRef]

- Zheng, L.; Sun, Z.; Li, C.; Wei, Z.; Jain, P.; Wu, K. Progress in biodegradable zwitterionic materials. Polym. Degrad. Stab. 2017, 139, 1–19. [Google Scholar] [CrossRef]

- Cao, Z.; Jiang, S. Super-hydrophilic zwitterionic poly (carboxybetaine) and amphiphilic non-ionic poly(ethylene glycol) for stealth nanoparticles. Nano Today 2012, 7, 404–413. [Google Scholar] [CrossRef]

- Meng, J.; Cao, Z.; Ni, L.; Zhang, Y.; Wang, X.; Zhang, X.; Liu, E. A novel salt-responsive TFC RO membrane having superior antifouling and easy-cleaning properties. J. Membr. Sci. 2014, 461, 123–129. [Google Scholar] [CrossRef]

- Zaidi, S.J.; Mauritz, K.A.; Hassan, M.K. Membrane Surface Modification and Functionalization. In Functional Polymers; Jafar Mazumder, M.A., Sheardown, H., Al-Ahmed, A., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 1–26. [Google Scholar]

- Hadidi, M.; Zydney, A.L. Fouling behavior of zwitterionic membranes: Impact of electrostatic and hydrophobic interactions. J. Membr. Sci. 2014, 452, 97–103. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, Y.; Sadam, H.; Ma, J.; Bai, Y.; Shen, X.; Kim, J.K.; Shao, L. Novel mussel-inspired zwitterionic hydrophilic polymer to boost membrane water-treatment performance. J. Membr. Sci. 2019, 582, 1–8. [Google Scholar] [CrossRef]

- Kirschner, A.Y.; Chang, C.C.; Kasemset, S.; Emrick, T.; Freeman, B.D. Fouling-resistant ultrafiltration membranes prepared via co-deposition of dopamine/zwitterion composite coatings. J. Membr. Sci. 2017, 541, 300–311. [Google Scholar] [CrossRef]

- Ji, Y.L.; An, Q.F.; Guo, Y.S.; Hung, W.S.; Lee, K.R.; Gao, C.J. Bio-inspired fabrication of high perm-selectivity and anti-fouling membranes based on zwitterionic polyelectrolyte nanoparticles. J. Mater. Chem. A 2016, 4, 4224–4231. [Google Scholar] [CrossRef]

- You, M.; Wang, P.; Xu, M.; Yuan, T.; Meng, J. Fouling resistance and cleaning efficiency of stimuli-responsive reverse osmosis (RO) membranes. Polymer 2016, 103, 457–467. [Google Scholar] [CrossRef]

- Ma, R.; Ji, Y.L.; Weng, X.D.; An, Q.F.; Gao, C.J. High-flux and fouling-resistant reverse osmosis membrane prepared with incorporating zwitterionic amine monomers via interfacial polymerization. Desalination 2016, 381, 100–110. [Google Scholar] [CrossRef]

- Zhai, W.; Wang, M.; Song, J.; Zhang, L.; Li, X.M.; He, T. Fouling resistance of 3-[[3-(trimethoxysilane)-propyl] amino] propane-1-sulfonic acid zwitterion modified poly (vinylidene fluoride) membranes. Sep. Purif. Technol. 2020, 116589. [Google Scholar] [CrossRef]

- Rabea, E.I.; Badawy, M.E.T.; Stevens, C.V.; Smagghe, G.; Steurbaut, W. Chitosan as Antimicrobial Agent: Applications and Mode of Action. Biomacromolecules 2003, 4, 1457–1465. [Google Scholar] [CrossRef]

- Je, J.Y.; Kim, S.K. Chapter 7—Chitosan as Potential Marine Nutraceutical. In Advances in Food and Nutrition Research; Kim, S.-K., Ed.; Academic Press: Pittsburgh, PA, USA, 2012; pp. 121–135. [Google Scholar]

- Sabbah, M.; Di Pierro, P.; Cammarota, M.; Dell’Olmo, E.; Arciello, A.; Porta, R. Development and properties of new chitosan-based films plasticized with spermidine and/or glycerol. Food Hydrocoll. 2019, 87, 245–252. [Google Scholar] [CrossRef]

- Daraei, P.; Madaeni, S.S.; Salehi, E.; Ghaemi, N.; Ghari, H.S.; Khadivi, M.A.; Rostami, E. Novel thin film composite membrane fabricated by mixed matrix nanoclay/chitosan on PVDF microfiltration support: Preparation, characterization and performance in dye removal. J. Membr. Sci. 2013, 436, 97–108. [Google Scholar] [CrossRef]

- Ekambaram, K.; Doraisamy, M. Surface modification of PVDF nanofiltration membrane using Carboxymethylchitosan-Zinc oxide bionanocomposite for the removal of inorganic salts and humic acid. Colloids Surf. A Physicochem. Eng. Asp. 2017, 525, 49–63. [Google Scholar] [CrossRef]

- Ghaemi, N.; Khodakarami, Z. Nano-biopolymer effect on forward osmosis performance of cellulosic membrane: High water flux and low reverse salt. Carbohydr. Polym. 2019, 204, 78–88. [Google Scholar] [CrossRef]

- Salehi, H.; Rastgar, M.; Shakeri, A. Anti-fouling and high water permeable forward osmosis membrane fabricated via layer by layer assembly of chitosan/graphene oxide. Appl. Surf. Sci. 2017, 413, 99–108. [Google Scholar] [CrossRef]

- Shakeri, A.; Salehi, H.; Rastgar, M. Chitosan-based thin active layer membrane for forward osmosis desalination. Carbohydr. Polym. 2017, 174, 658–668. [Google Scholar] [CrossRef]

- Wang, S.; Lu, A.; Zhang, L. Recent advances in regenerated cellulose materials. Prog. Polym. Sci. 2016, 53, 169–206. [Google Scholar] [CrossRef]

- Thakur, V.K.; Voicu, S.I. Recent advances in cellulose and chitosan based membranes for water purification: A concise review. Carbohydr. Polym. 2016, 146, 148–165. [Google Scholar] [CrossRef]

- Kedia, A.; Dubey, N.K. Chapter 22—Nanoencapsulation of Essential Oils: A Possible Way for an Eco-Friendly Strategy to Control Postharvest Spoilage of Food Commodities from Pests. In Nanomaterials in Plants, Algae, and Microorganisms; Tripathi, D.K., Ahmad, P., Sharma, S., Chauhan, D.K., Duber, N.K., Eds.; Academic Press: Pittsburgh, PA, USA, 2018; pp. 501–522. [Google Scholar]

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose nanocrystals: Chemistry, self-assembly, and applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [CrossRef]

- Ullah, H.; Wahid, F.; Santos, H.A.; Khan, T. Advances in biomedical and pharmaceutical applications of functional bacterial cellulose-based nanocomposites. Carbohydr. Polym. 2016, 150, 330–352. [Google Scholar] [CrossRef]

- Sadasivuni, K.K.; Ponnamma, D.; Ko, H.U.; Kim, H.C.; Zhai, L.; Kim, J. Flexible NO2 sensors from renewable cellulose nanocrystals/iron oxide composites. Sens. Actuators B Chem. 2016, 233, 633–638. [Google Scholar] [CrossRef]

- Santamaria-Echart, A.; Ugarte, L.; García-Astrain, C.; Arbelaiz, A.; Corcuera, M.A.; Eceiza, A. Cellulose nanocrystals reinforced environmentally-friendly waterborne polyurethane nanocomposites. Carbohydr. Polym. 2016, 151, 1203–1209. [Google Scholar] [CrossRef] [PubMed]

- Peng, B.L.; Dhar, N.; Liu, H.L.; Tam, K.C. Chemistry and applications of nanocrystalline cellulose and its derivatives: A nanotechnology perspective. Can. J. Chem. Eng. 2011, 89, 1191–1206. [Google Scholar] [CrossRef]

- Thakur, V.K.; Singha, A.S.; Thakur, M.K. Natural cellulosic polymers as potential reinforcement in composites: Physicochemical and mechanical studies. Adv. Polym. Technol. 2013, 32, E427–E435. [Google Scholar] [CrossRef]

- Nechyporchuk, O.; Belgacem, M.N.; Bras, J. Production of cellulose nanofibrils: A review of recent advances. Ind. Crops Prod. 2016, 93, 2–25. [Google Scholar] [CrossRef]

- Brigham, C. Chapter 3.22—Biopolymers: Biodegradable Alternatives to Traditional Plastics. In Green Chemistry; Török, B., Dransfield, T., Eds.; Elsevier: Amsterdam, Netherlands, 2018; pp. 753–770. [Google Scholar]

- Zhang, D.; Karkooti, A.; Liu, L.; Sadrzadeh, M.; Thundat, T.; Liu, Y.; Narain, R. Fabrication of antifouling and antibacterial polyethersulfone (PES)/cellulose nanocrystals (CNC) nanocomposite membranes. J. Membr. Sci. 2018, 549, 350–356. [Google Scholar] [CrossRef]

- Sobolčiak, P.; Tanvir, A.; Popelka, A.; Moffat, J.; Mahmoud, K.A.; Krupa, I. The preparation, properties and applications of electrospun co-polyamide 6,12 membranes modified by cellulose nanocrystals. Mater. Des. 2017, 132, 314–323. [Google Scholar] [CrossRef]

- Liu, S.; Low, Z.X.; Hegab, H.M.; Xie, Z.; Ou, R.; Yang, G.; Simon, G.P.; Zhang, X.; Zhang, L.; Wang, H. Enhancement of desalination performance of thin-film nanocomposite membrane by cellulose nanofibers. J. Membr. Sci. 2019, 592, 117363. [Google Scholar] [CrossRef]

- Jonoobi, M.; Ashori, A.; Siracusa, V. Characterization and properties of polyethersulfone/modified cellulose nanocrystals nanocomposite membranes. Polym. Test. 2019, 76, 333–339. [Google Scholar] [CrossRef]

- Arena, J.T.; McCloskey, B.; Freeman, B.D.; McCutcheon, J.R. Surface modification of thin film composite membrane support layers with polydopamine: Enabling use of reverse osmosis membranes in pressure retarded osmosis. J. Membr. Sci. 2011, 375, 55–62. [Google Scholar] [CrossRef]

- Lee, H.; Dellatore, S.M.; Miller, W.M.; Messersmith, P.B. Mussel-inspired surface chemistry for multifunctional coatings. Science 2007, 318, 426–430. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Scherer, N.F.; Messersmith, P.B. Single-molecule mechanics of mussel adhesion. Proc. Natl. Acad. Sci. USA 2006, 103, 12999–13003. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.C.; Waldman, R.Z.; Wu, M.B.; Hou, J.; Chen, L.; Darling, S.B.; Xu, Z.K. Dopamine: Just the right medicine for membranes. Adv. Funct. Mater. 2018, 28, 1705327. [Google Scholar] [CrossRef]

- Tripathi, B.P.; Das, P.; Simon, F.; Stamm, M. Ultralow fouling membranes by surface modification with functional polydopamine. Eur. Polym. J. 2018, 99, 80–89. [Google Scholar] [CrossRef]

- Ryu, J.H.; Messersmith, P.B.; Lee, H. Polydopamine Surface Chemistry: A Decade of Discovery. ACS Appl. Mater. Interfaces 2018, 10, 7523–7540. [Google Scholar] [CrossRef]

- Ding, Y.H.; Floren, M.; Tan, W. Mussel-inspired polydopamine for bio-surface functionalization. Biosurf. Biotribol. 2016, 2, 121–136. [Google Scholar] [CrossRef]

- Ball, V. Polydopamine Nanomaterials: Recent Advances in Synthesis Methods and Applications. Front. Bioeng. Biotechnol. 2018, 6, 109. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, H.C.; He, F.; Peng, S.; Li, Y.; Shao, L.; Darling, S.B. Mussel-Inspired Surface Engineering for Water-Remediation Materials. Matter 2019, 1, 115–155. [Google Scholar] [CrossRef]

- Xiong, C.; Cao, S.; Wang, Y.; Wang, X.; Long, S.; Zhang, G.; Yang, J. Surface modification of polyarylene sulfide sulfone membrane by coating with polydopamine. J. Coat. Technol. Res. 2019, 16, 643–650. [Google Scholar] [CrossRef]

- Kasemset, S.; He, Z.; Miller, D.J.; Freeman, B.D.; Sharma, M.M. Effect of polydopamine deposition conditions on polysulfone ultrafiltration membrane properties and threshold flux during oil/water emulsion filtration. Polymer 2016, 97, 247–257. [Google Scholar] [CrossRef]

- Ji, Y.L.; Ang, M.B.M.Y.; Hung, H.C.; Huang, S.H.; An, Q.F.; Lee, K.R.; Lai, J.Y. Bio-inspired deposition of polydopamine on PVDF followed by interfacial cross-linking with trimesoyl chloride as means of preparing composite membranes for isopropanol dehydration. J. Membr. Sci. 2018, 557, 58–66. [Google Scholar] [CrossRef]

- Li, Y.; Shi, S.; Cao, H.; Zhao, Z.; Su, C.; Wen, H. Improvement of the antifouling performance and stability of an anion exchange membrane by surface modification with graphene oxide (GO) and polydopamine (PDA). J. Membr. Sci. 2018, 566, 44–53. [Google Scholar] [CrossRef]

- Wang, J.; Guo, H.; Shi, X.; Yao, Z.; Qing, W.; Liu, F.; Tang, C.Y. Fast polydopamine coating on reverse osmosis membrane: Process investigation and membrane performance study. J. Colloid Interface Sci. 2019, 535, 239–244. [Google Scholar] [CrossRef] [PubMed]

- Kwon, S.J.; Park, S.H.; Shin, M.G.; Park, M.S.; Park, K.; Hong, S.; Park, H.; Park, Y.I.; Lee, J.H. Fabrication of high performance and durable forward osmosis membranes using mussel-inspired polydopamine-modified polyethylene supports. J. Membr. Sci. 2019, 584, 89–99. [Google Scholar] [CrossRef]

- Saber-Samandari, S.; Saber-Samandari, S.; Heydaripour, S.; Abdouss, M. Novel carboxymethyl cellulose based nanocomposite membrane: Synthesis, characterization and application in water treatment. J. Environ. Manag. 2016, 166, 457–465. [Google Scholar] [CrossRef]

| Monomers Used/Thin Film Composite(TFC) Membranes | Performance Evaluation | Features | Reference | |

|---|---|---|---|---|

| Water Permeability (L/m2 bar) | Rejection (%) | |||

| Piperazine + PAMAM/trimesoyl chloride (TMC) | 9.24 (average) | 99.0 |

| [112] |

| Piperazine + triethylamine + PAMAM/TMC | 3.0 | 90.0 |

| [113] |

| m-Phenylenediamine (MPD)/TMC (PAMAM solution was sprayed using water as solvent) | 20.40 | 98.0 |

| [114] |

| MPD/TMC/PAMAM | 1.25 | 99.4 |

| [83] |

| PAMAM was added to the surface of polyvinylidene fluoride (PVDF) membrane. | 361 | - |

| [115] |

| MPD-acyl chloride-terminated hyperbranched polyesters (HBPAC) @MPD-TMC | 3.02 | 98.9 |

| [116] |

| Piperazine + poly(ethylene glycol) + graphene oxide (GO)/TMC | 1.75 | 98.9 |

| [117] |

| Commercial polyamide thins film composite (TFC) reverse osmosis (RO) membrane grafted with monomethoxy-poly (ethylene glycol) (MPEG) brushes | 5.78 | 98.6 |

| [118] |

| QAC Compounds | Bacteria | Inhibition Rate/Growth Rate | Reference |

|---|---|---|---|

| [2-(Acryloyloxy)ethyl] trimethylammonium chloride solution (DAC) | E. coli S. aureus | ~98.3% ~98.5% | [85] |

| Dimethyloctadecyl[3-(trimethoxysilyl)propyl] ammoniumchloride (DMOTPAC) | E. coli S. aureus | ~92% ~93% | [84] |

| Dodecyl dimethyl benzyl ammonium chloride (DDBAC) | E. coli S. aureus | 0.02µ 0.02µ | [123,125] |

| Cetyl trimethyl ammonium bromide (CTAB) | E. coli S. aureus | 0.0µ 0.0µ | [126] |

| Cetyltrimethylammonium bromide (CTAB) | E. coli S. aureus | 99.84% 100% | [86] |

| 3-chloro-2-hydroxypropyl trimethyl ammonium chloride (CHPTAC) | E. coli S. aureus | 89.0% 76.6% | [127] |

| Membrane | Fabrication Method | Water Permeability | Salt Rejection (%) | Reference |

|---|---|---|---|---|

| Polyacrylonitrile (PAN)/cellulose acetate (CS)-3.5 | Hydrolyzation | 3.98 L/m2 h bar | 97.0 | 90 |

| Zeolitic imidazolate framework (ZIF)-8/CS | Dip coating | 7.2 kg/m2 h | >99.5 | 91 |

| PVDF/CS | Blend | 631.4 L/m2 h bar | - | 92 |

| PVDF/Carboxymethylchitosan-ZnO (M0.05) | Incorporate into casting dope | 13.52 L/m2 h bar | 95.01 | 145 |

| Cellulose acetate/CS | Embedding | 3.09 L/m2 h bar | 91.0 | 146 |

| CS/GO nanocomposite | Immersion (layer by layer) | 2.95 L/m2 h bar | 91.11 | 147 |

| CS/TFC (NaOH treatment) | Immersion | 2.12 L/m2 h bar | 94.52 | 148 |

| Macromolecules | Membrane Process | Applications | Polymers | Filler Concentration | Reference | |

|---|---|---|---|---|---|---|

| Dendrimers | PAMAM | NF | Evaluation of antifouling properties and removal of salts (NaCl, Na2SO4). Model foulant: BSA | PES | 0.5, 1.5, and 3 wt% | [113] |

| Removal of heavy metals such as Pb2+, Cu2+, Ni2+, Cd2+, Zn2+ and As5+ | 2.0 wt% | [81] | ||||

| RO | Evaluation of antifouling properties and protein adsorption Model foulant: BSA | 10% w/v | [114] | |||

| FO | Evaluation of ammonia-selective and anti-fouling capacities for domestic wastewater treatment | SPES | 0.1 wt%, 0.5wt%, 1wt% and 2wt% | [120] | ||

| UF | Removal of copper ions | PVDF | 3 wt% | [115] | ||

| Polyesters | RO | Desalination: Salt removal (NaCl) | PSF | 0.005wt% and 0.01wt% | [116] | |

| NF | Evaluation of antifouling properties Model foulant: BSA | CA | 2.5,5.0,7.5 and 10 wt% | [119] | ||

| Polyethylene glycol | NF | Desalination: Salt removal (NaCl and Na2SO4) | PEG | 0.5, 1.0 and 1.5 wt% | [117] | |

| RO | Evaluation of antifouling property and durability against chlorine Desalination: Salt removal (NaCl) | PA | 0.5, 1.0, 1.5 and 2.0wt% | [118] | ||

| Quaternary Ammonium Compounds (QAC) | [2-(Acryloyloxy)ethyl] trimethylammonium chloride solution (DAC) | MF | Evaluation of antibacterial property for water/wastewater treatment Model bacteria: E.coli or S. aureus | PVDF | 28 mmol | [85] |

| Dimethyloctadecyl[3-(trimethoxysilyl)propyl] ammoniumchloride (DMOTPAC) | Evaluation of antibacterial property for water/wastewater treatment Model bacteria: E. coli or S. aureus | 15 mL | [84] | |||

| Dodecyl dimethyl benzyl ammonium chloride (DDBAC) | Evaluation of antifouling and antibacterial property for water/wastewater treatment. Model foulant: BSA and SA Model bacteria: E. coli or S. aureus | 0.1, 0.2 and 0.4 wt% | [125] | |||

| Cetyl trimethyl ammonium bromide (CTAB) | UF | Evaluation of antibacterial property for water/wastewater treatment Model bacteria: E. coli or S. aureus | PSF-SPES | 0.4 wt% | [126] | |

| 3-chloro-2-hydroxypropyl trimethyl ammonium chloride (CHPTAC) | RO | Evaluation of antibacterial properties and removal of salt (NaCl). Model bacteria: E. coli, S. aureus | CTA | 0.06 mol L−1 | [127] | |

| Polyzwitterions | poly (4-(2-sulfoethyl)-1-(4-vinylbenzyl) pyridinium betaine) (PSVBP) | RO | Evaluation of antifouling properties and removal of salt (NaCl). Mixture model: BSA | PA | 2 mmol L−1 | [131] |

| poly (sulfobetaine methacrylate) (PSBMA), poly (4-(2-Sulfoethyl)-1-(4-vinyl- benzyl) pyridinium betain) (PSVBP) and poly (N-isopropylacrylamide) (PNIPAM) | Evaluating of antifouling and easy-cleaning properties. Model foulants: BSA and CaCO3 | 4 mmol L−1 | [137] | |||

| N-aminoethyl piperazine propane sulfonate (AEPPS) | UF | Evaluation of antifouling properties and removal of salt (NaCl and Na2SO4). Model foulants: BSA, SA or HA | PSF | 2.0, 10.0, 20.0 mg·mL−1 | [34] | |

| RO | Evaluation of antifouling properties and removal of salt (NaCI) for water treatment Model foulants: TA and NaAlg | 0%, 5%, 10%, 25% and 50% in aqueous solution. | [138] | |||

| Catechol-functionalized zwitterionic PEG | UF | Evaluation of antifouling property and removal of BSA for water treatment. | PVDF | 0.5, 1.0, 1.5 wt% | [134] | |

| 3-dimethyl (methacryloyloxyethyl) ammonium propane sulfonate (DMAPS) | NF | Evaluation of antifouling properties and removal of salt (NaCl/Na2SO4) Model foulants: BSA | PSF | 35, 55, and 75 wt% | [136] | |

| 2-(Methacryloyloxy) ethyl dimethyl (3-sulfopropyl)-ammonium hydroxide | MD | Evaluation of anti-fouling and anti-wetting of oil emulsions. Model foulant: hexadecane emulsion and soy bean oil emulsion | PVDF | 2, 5, 10 wt% | [87] | |

| Poly(2-methacryloyloxyethyl phosphorylcholine) (PMPC) | UF | Evaluation of antifouling properties for oil-water separations. Model foulants: soybean oil emulsion | PSF | 2 g/L | [135] | |

| Chitosan | FO | Desalination and water treatment | PAN | 2%, 2.5%, 3%, 3.5%, 4%, 4.5% and 5% (wt) | [90] | |

| Water desalination | CA | 0.2, 0.8, 1.6, 3.2 and 4.8 wt% | [145] | |||

| Evaluation of antifouling properties removal of salt (Na2SO4) Model foulants: SA | SPES-PES | 0.1 wt% | [146] | |||

| Desalination: Salt removal (NaCl and Na2SO4) | PA | 0.5, 1.0, and 2.0 wt%. | [147] | |||

| MD | Evaluation of antifouling properties and removal of salt (NaCl) | PVDF | 0.5g | [91] | ||

| MF | Evaluation of antifouling properties for water treatment Model foulants: BSA | 0.5, 1.0, 1.5, 2.0 and 2.5% (w/w) | [92] | |||

| NF | Removal of inorganic salts and humic acid and evaluation of antifouling Inorganic salts: Na2SO4, MgSO4, NaCl, MgCl2, LiCl | 0.05, 0.15 and 0.2 wt% | [144] | |||

| Cellulose | Nanocrystalline cellulose (NCs) | UF | Evaluation of antifouling resistance against oil molecules deposition for wastewater treatment | PSF | 0.5, 1.0, and 2.0 wt%. | [94] |

| Evaluation of antifouling and antibacterial property for water treatment. Model foulant: BSA Model bacteria: E. coli and S. aureus | PES | 0.02, 0.08, 0.15 and 0.75 wt% | [159] | |||

| RO | Evaluation of antifouling properties and removal of salt (NaCl) Model foulant: BSA | PSF | 0.05%, 0.1%, 0.2% w/v | [95] | ||

| MF | Separation of water-in-oil emulsions (soya-bean oil) | PVDF | 2, 4 or 6wt% | [93] | ||

| Separation of water-in-oil emulsions for wastewater treatment (vegetable oil and diesel oil) | PA | 0.2, 0.5, 1.0, 2.5, 5.0 wt% | [160] | |||

| cellulose nanofibers (CNFs) | RO | Evaluation of antifouling properties and chlorine resistance for water desalination | PSF | 0.002%, 0.02% and 0.2% | [161] | |

| carboxymethyl cellulose | - | Removal of dye and heavy metal for water treatment (crystal violet (CV) and cadmium (Cd (II)) ions) | PAA | 1.25% W/V | [178] | |

| Polydopamine | UF | Evaluation of antifouling properties Model foulant: BSA | PSF | 2 mg·mL−1 | [167] | |

| Evaluation of antifouling properties during oil/water emulsion filtration | 0.1, 0.5, 2, and 8 mg/mL | [173] | ||||

| Organic wastewater treatment Organic solvent: acetone, ether, and formic acid | PASS | 1, 2, 3 g/L | [172] | |||

| NF | Separation of water from isopropanol | PVDF | 0.1, 0.3, 0.5 0.7 and 0.9wt% | [174] | ||

| FO | Removal of salt (NaCl) for water treatment | PE | 2.0 g·L−1 | [177] | ||

| RO | Evaluation of antifouling properties and desalination Model foulant: soybean oil | - | 2.0 g/L | [175] | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagandran, S.; Goh, P.S.; Ismail, A.F.; Wong, T.-W.; Binti Wan Dagang, W.R.Z. The Recent Progress in Modification of Polymeric Membranes Using Organic Macromolecules for Water Treatment. Symmetry 2020, 12, 239. https://doi.org/10.3390/sym12020239

Nagandran S, Goh PS, Ismail AF, Wong T-W, Binti Wan Dagang WRZ. The Recent Progress in Modification of Polymeric Membranes Using Organic Macromolecules for Water Treatment. Symmetry. 2020; 12(2):239. https://doi.org/10.3390/sym12020239

Chicago/Turabian StyleNagandran, Saraswathi, Pei Sean Goh, Ahmad Fauzi Ismail, Tuck-Whye Wong, and Wan Rosmiza Zana Binti Wan Dagang. 2020. "The Recent Progress in Modification of Polymeric Membranes Using Organic Macromolecules for Water Treatment" Symmetry 12, no. 2: 239. https://doi.org/10.3390/sym12020239

APA StyleNagandran, S., Goh, P. S., Ismail, A. F., Wong, T.-W., & Binti Wan Dagang, W. R. Z. (2020). The Recent Progress in Modification of Polymeric Membranes Using Organic Macromolecules for Water Treatment. Symmetry, 12(2), 239. https://doi.org/10.3390/sym12020239