Mechanical Behavior of Tunnel Lining with Cracks at Different Positions

Abstract

1. Introduction

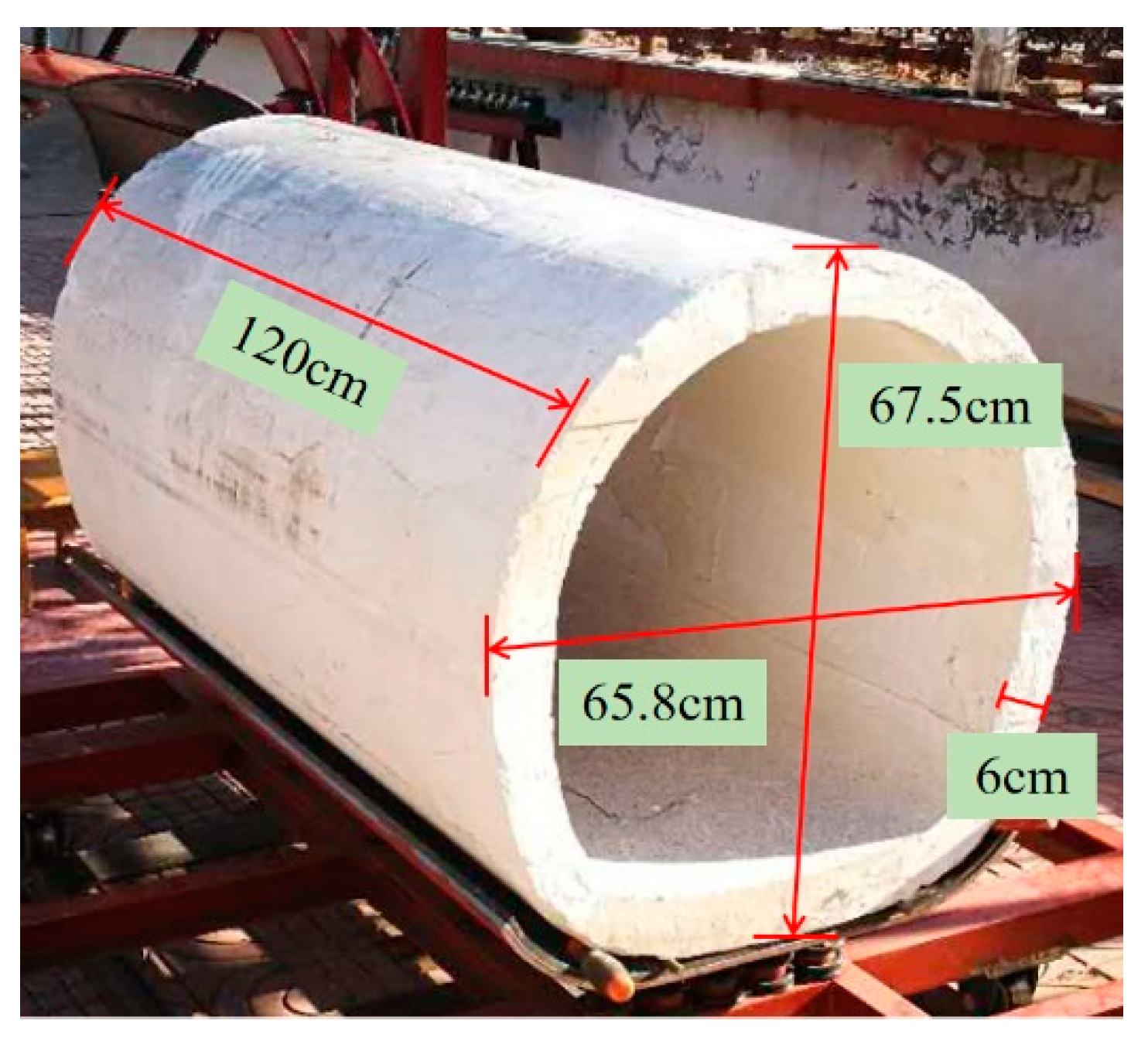

2. Laboratory Model Test

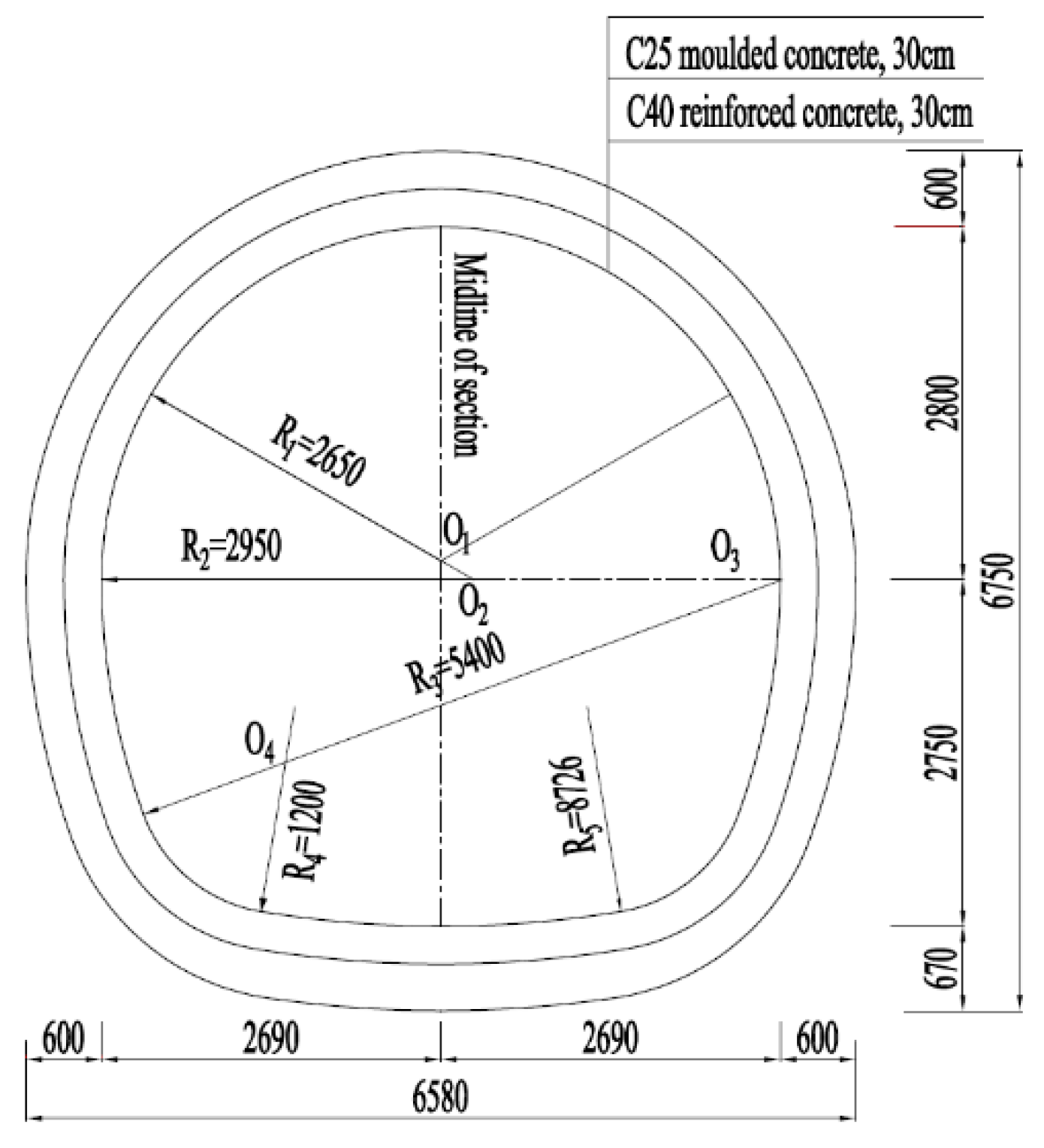

2.1. Engineering Overview

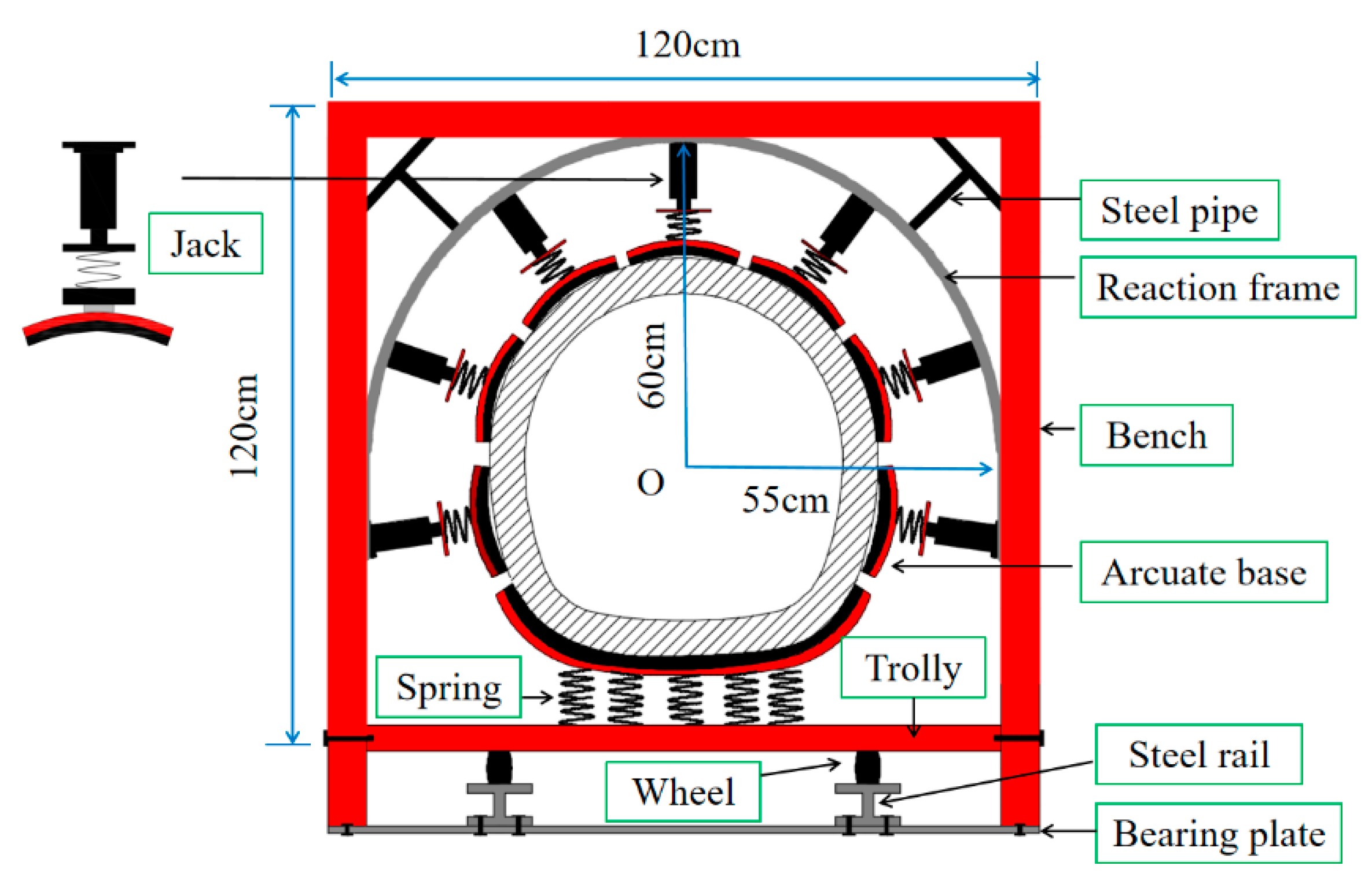

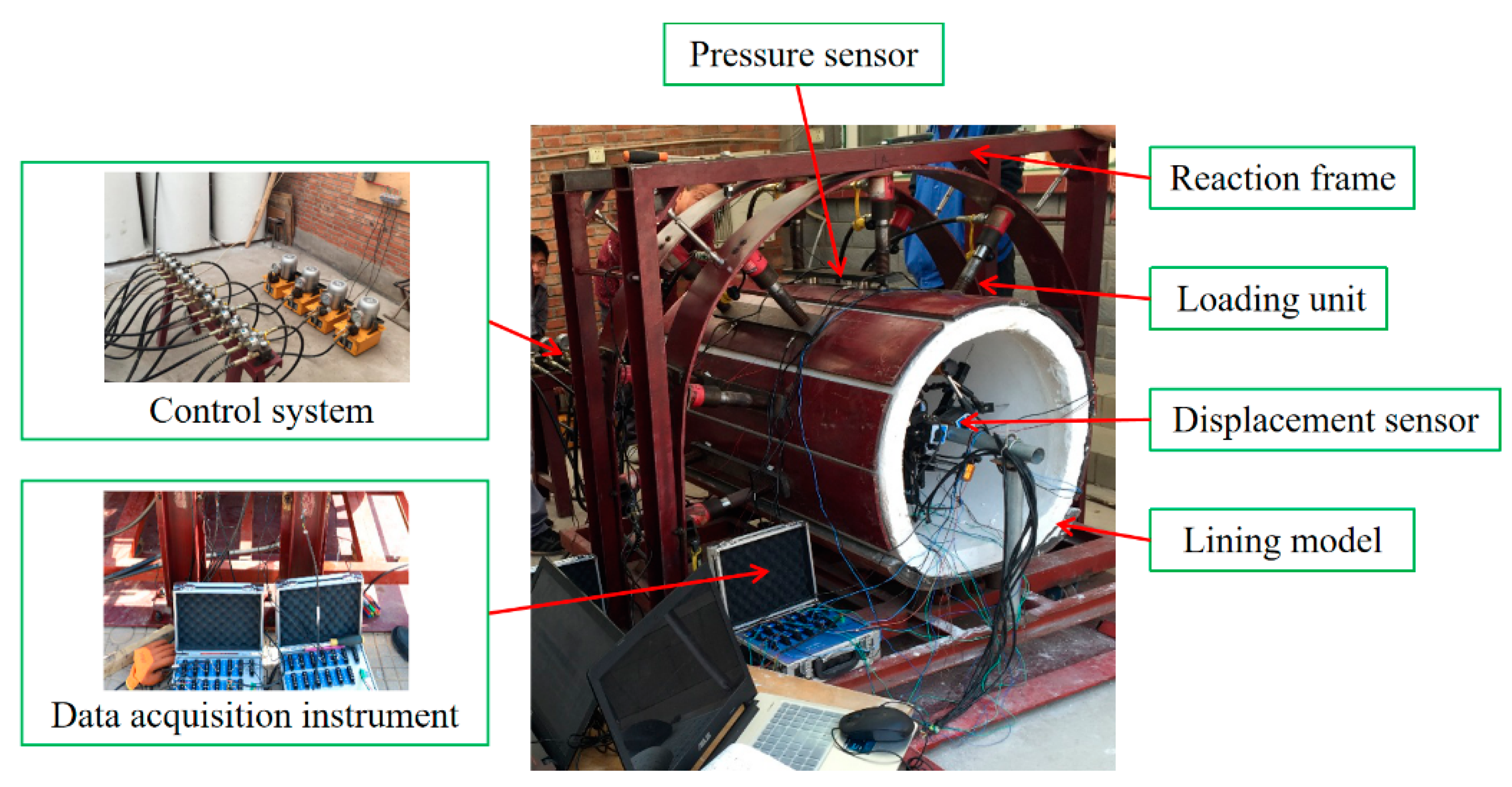

2.2. Test Platform

2.3. Similar Relations and Materials

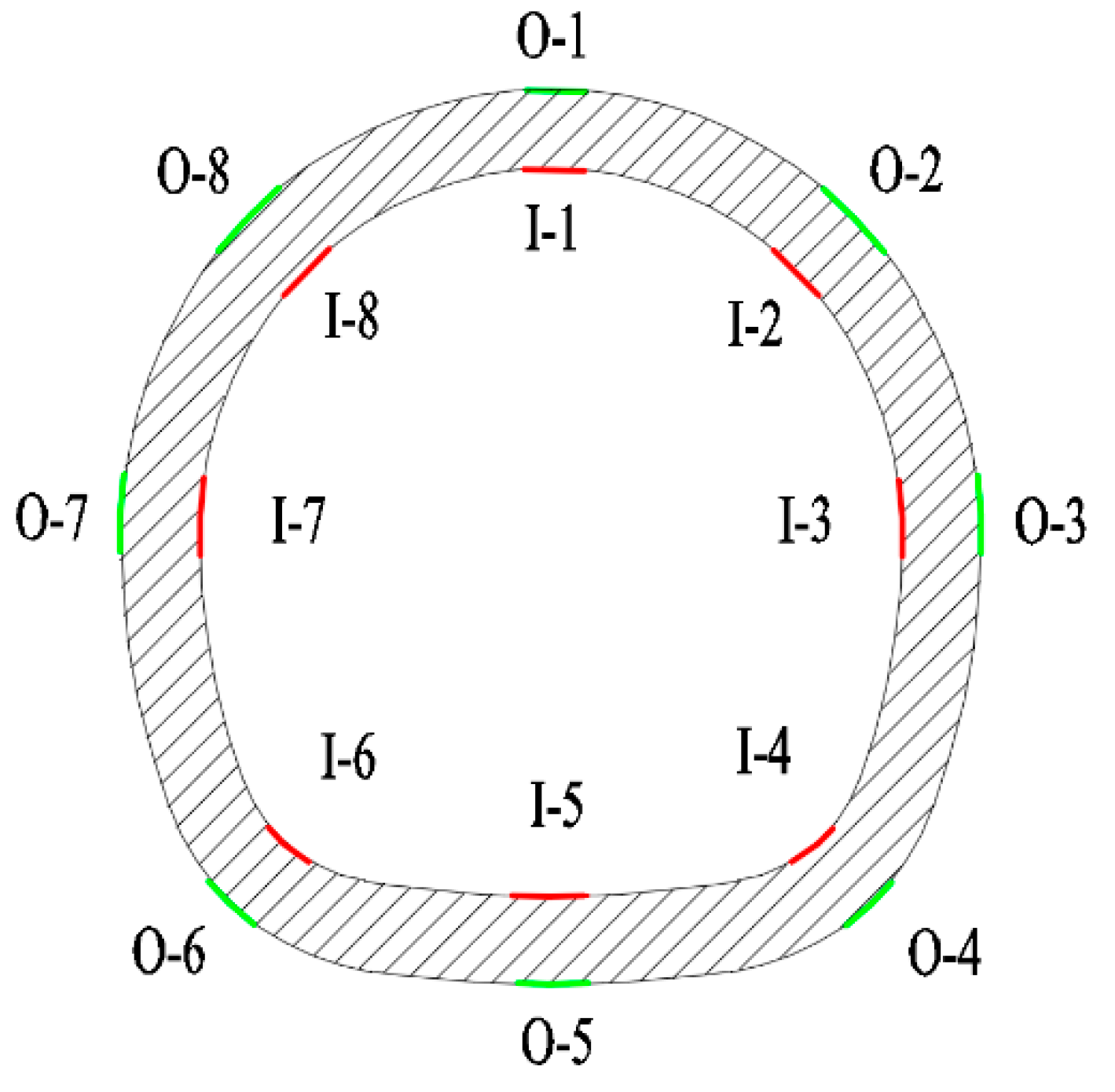

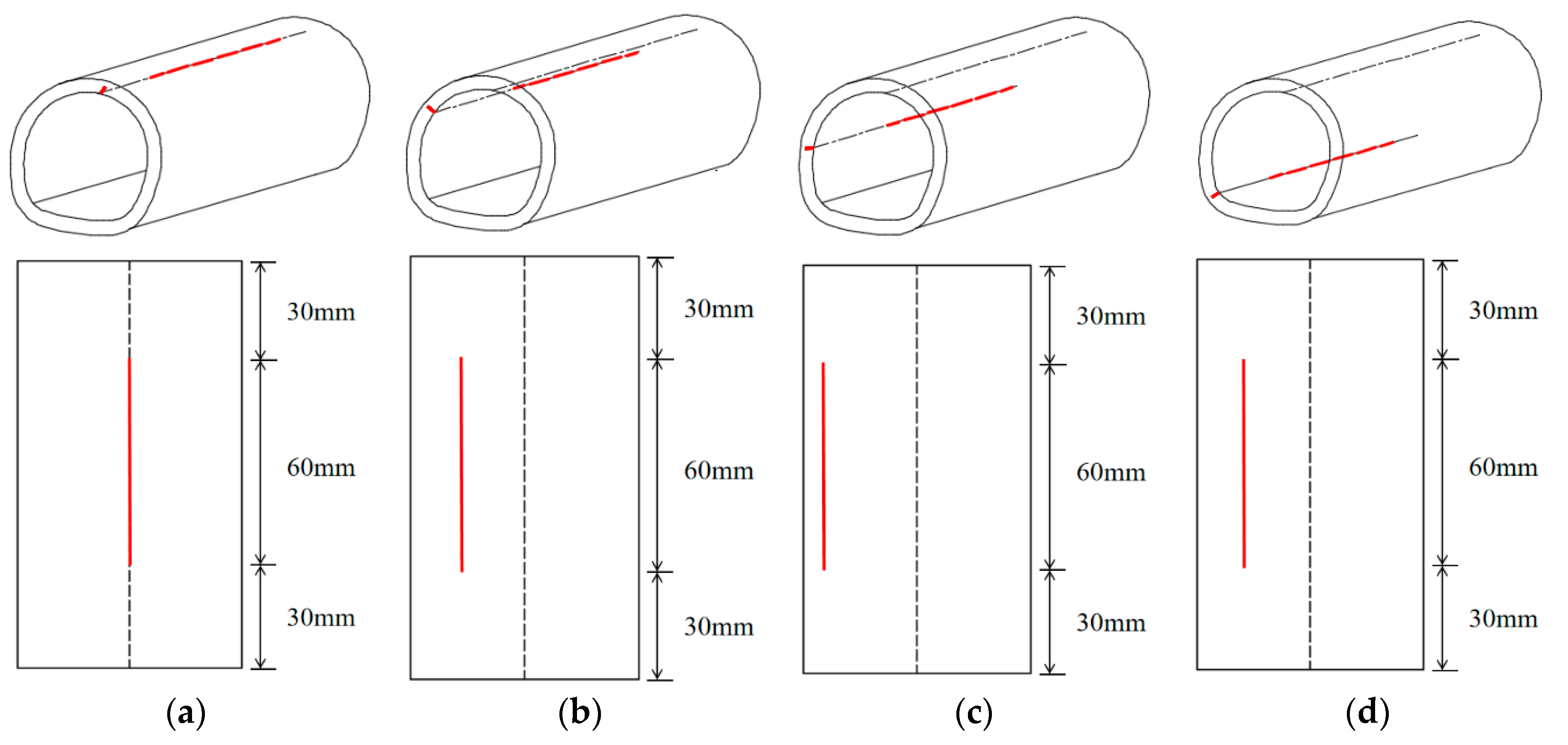

2.4. Experimental Scheme

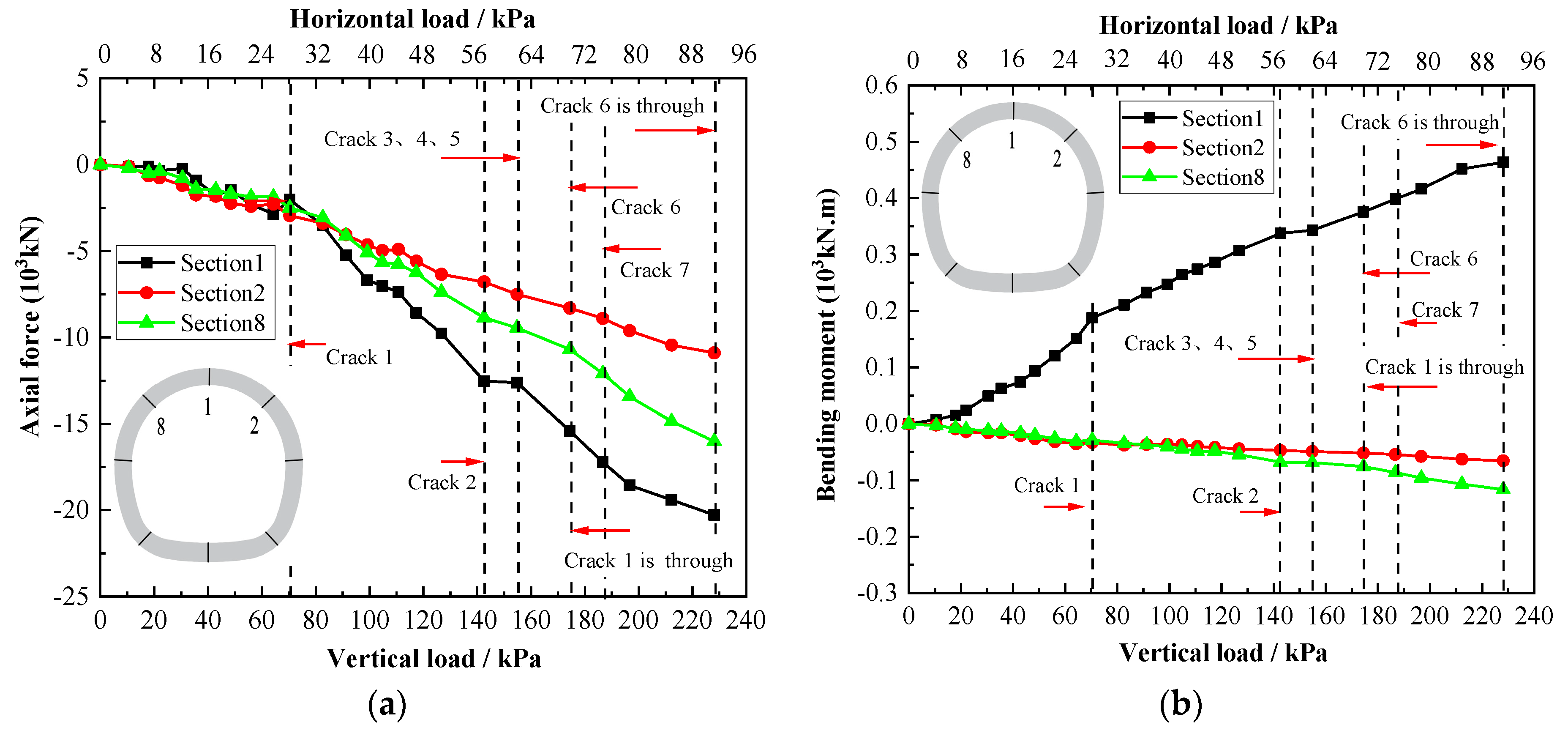

3. Test Results Analysis

3.1. Results Analysis of Lining with No Prefabricated Crack

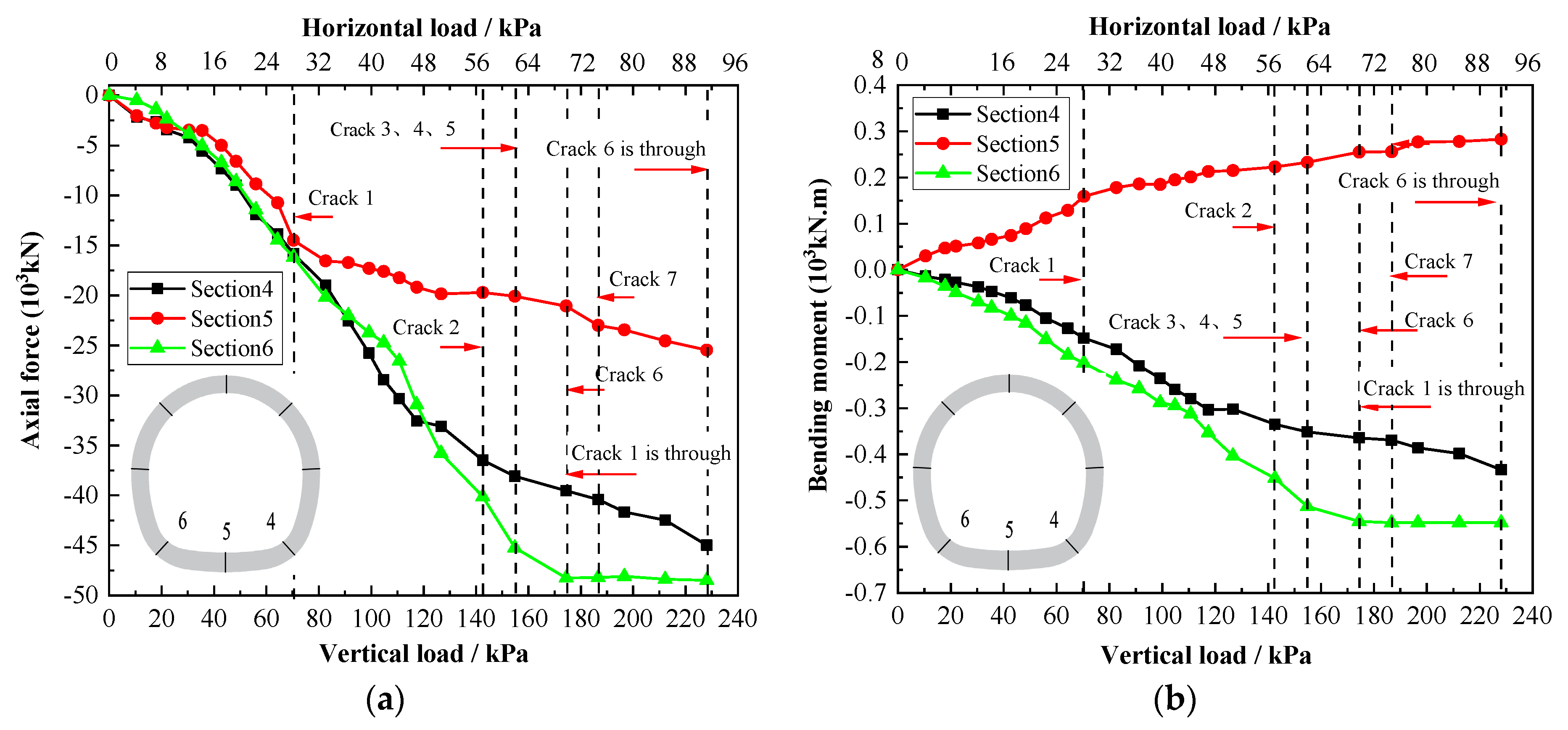

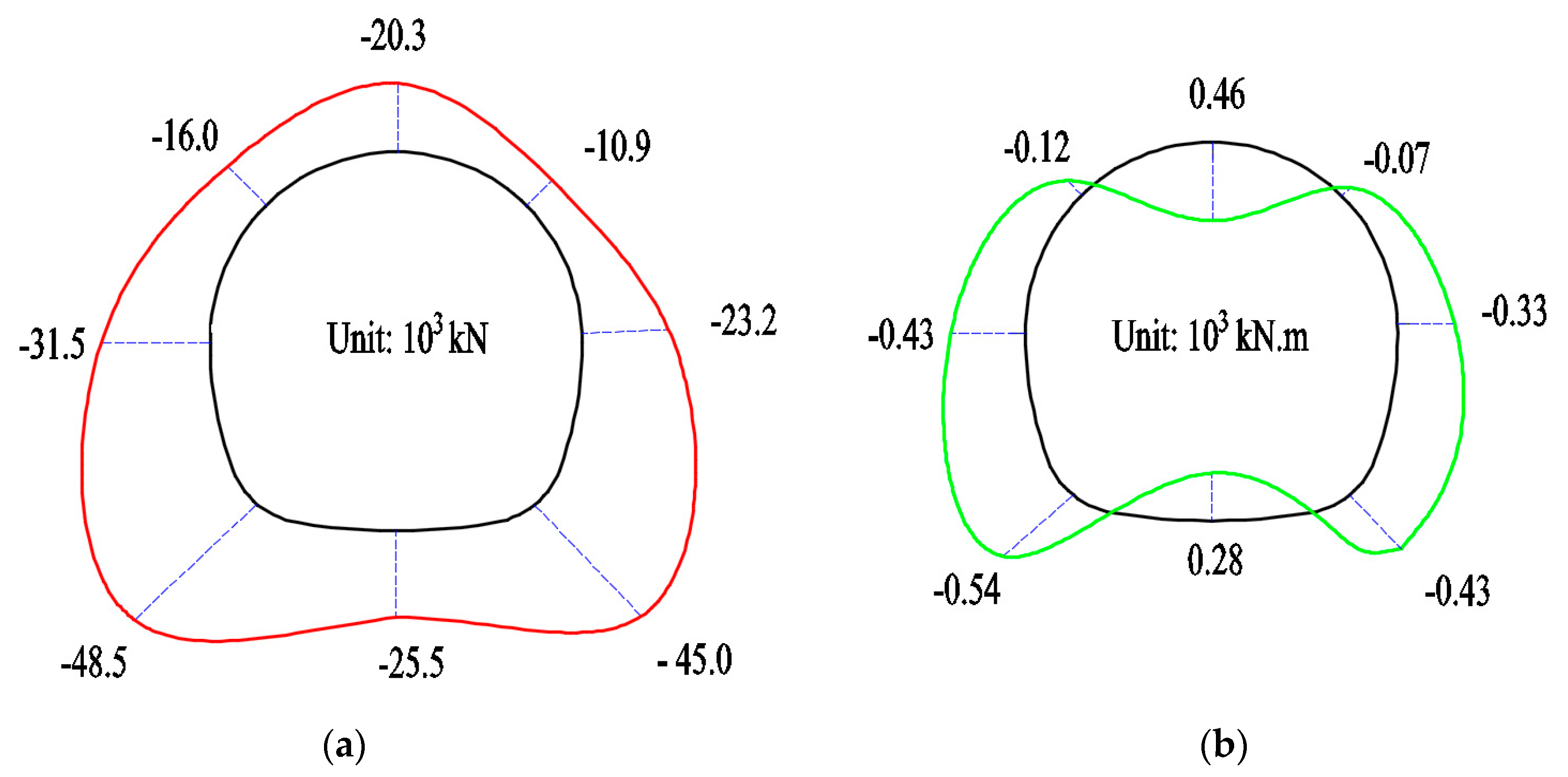

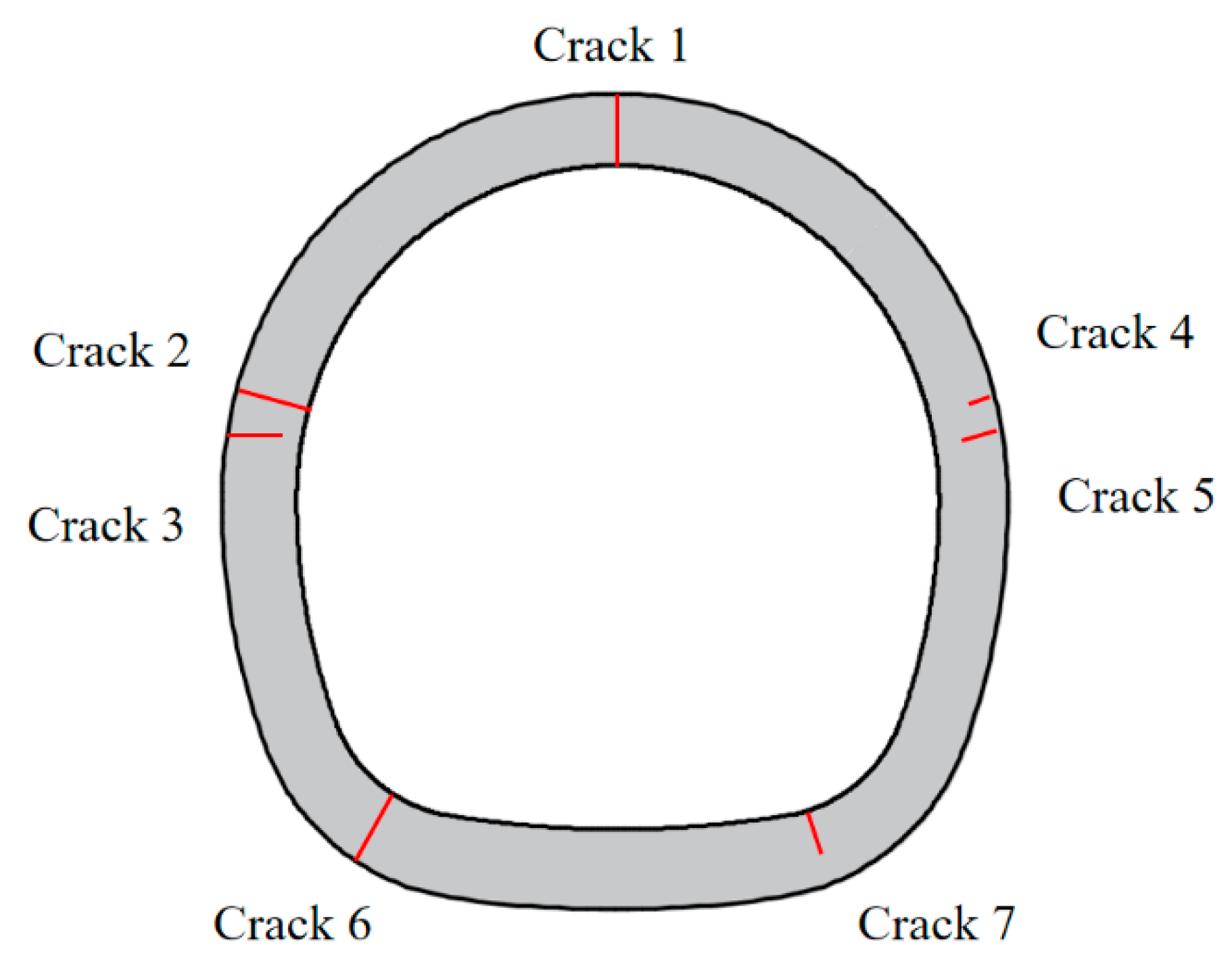

3.1.1. Mechanical behavior of the lining

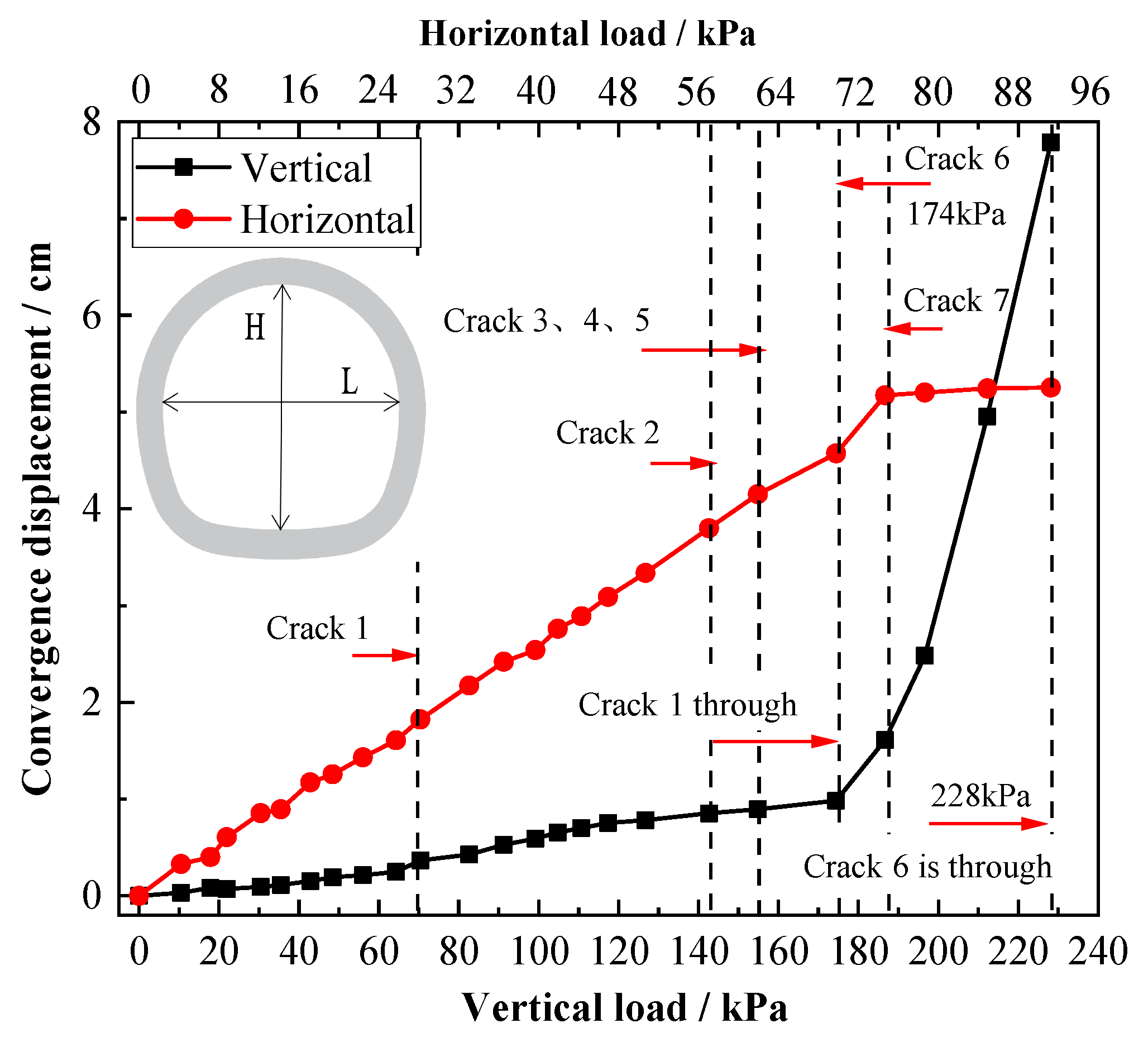

3.1.2. Deformation behavior of lining

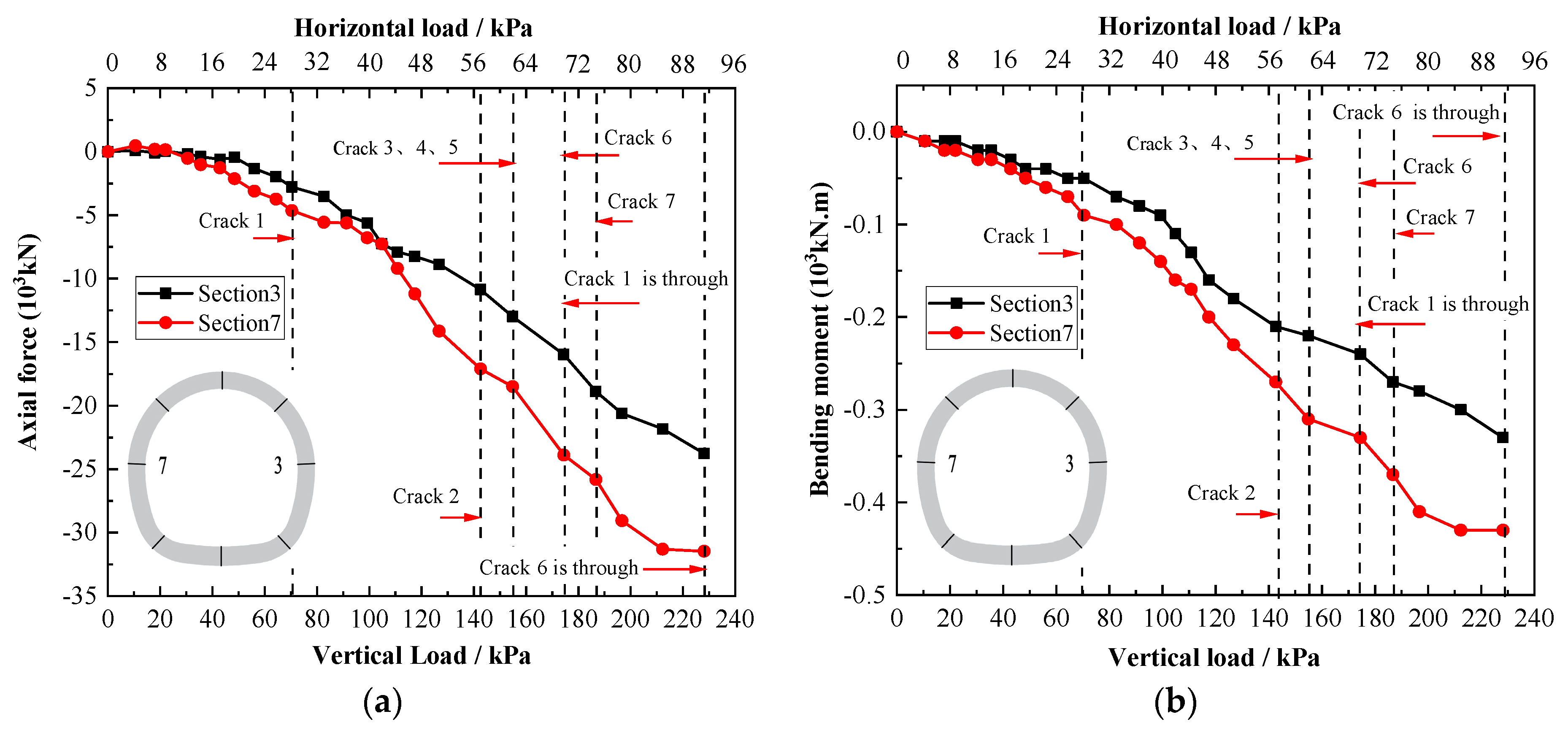

3.2. Analysis of Prefabricated Cracks at Different Positions

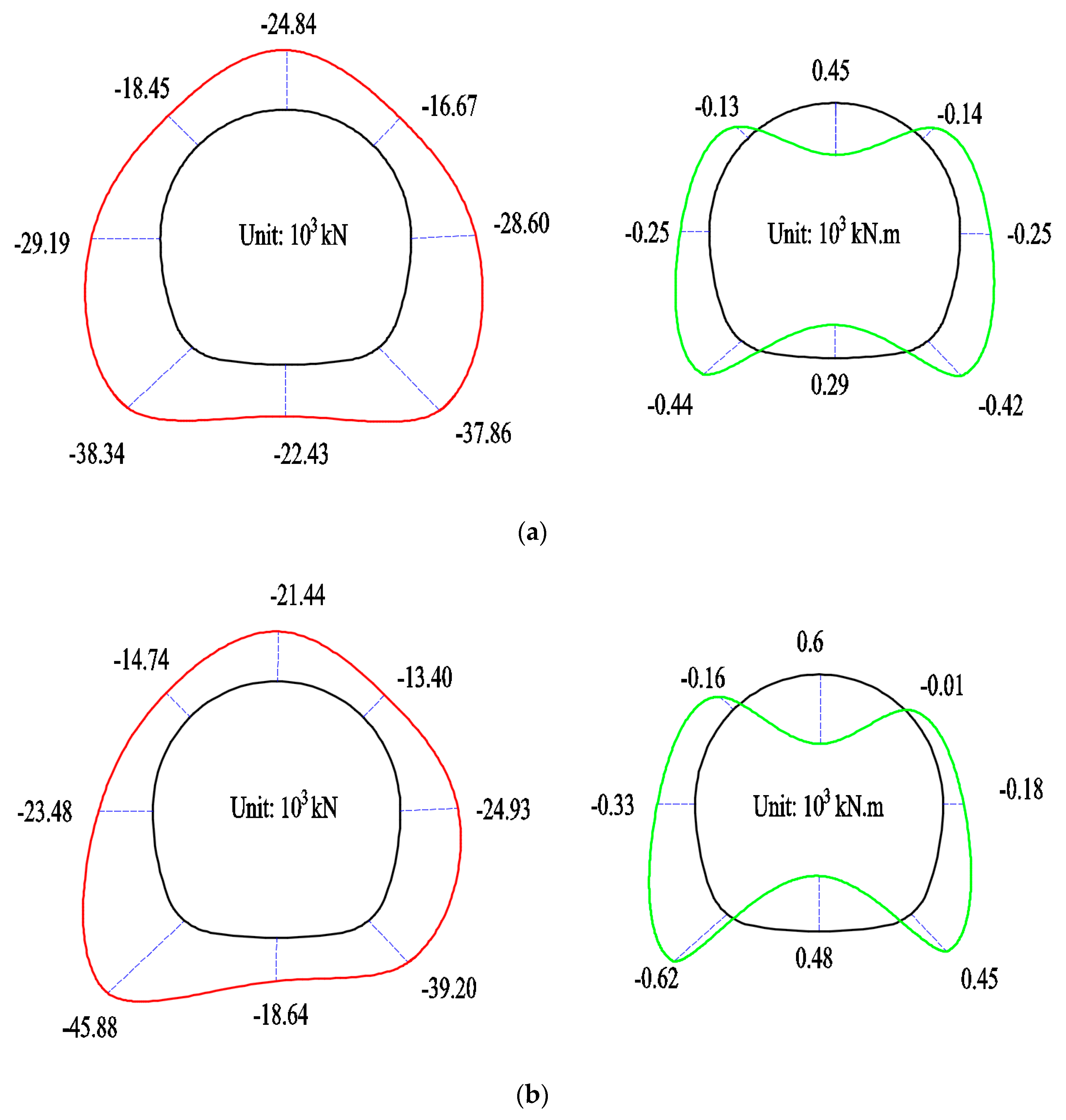

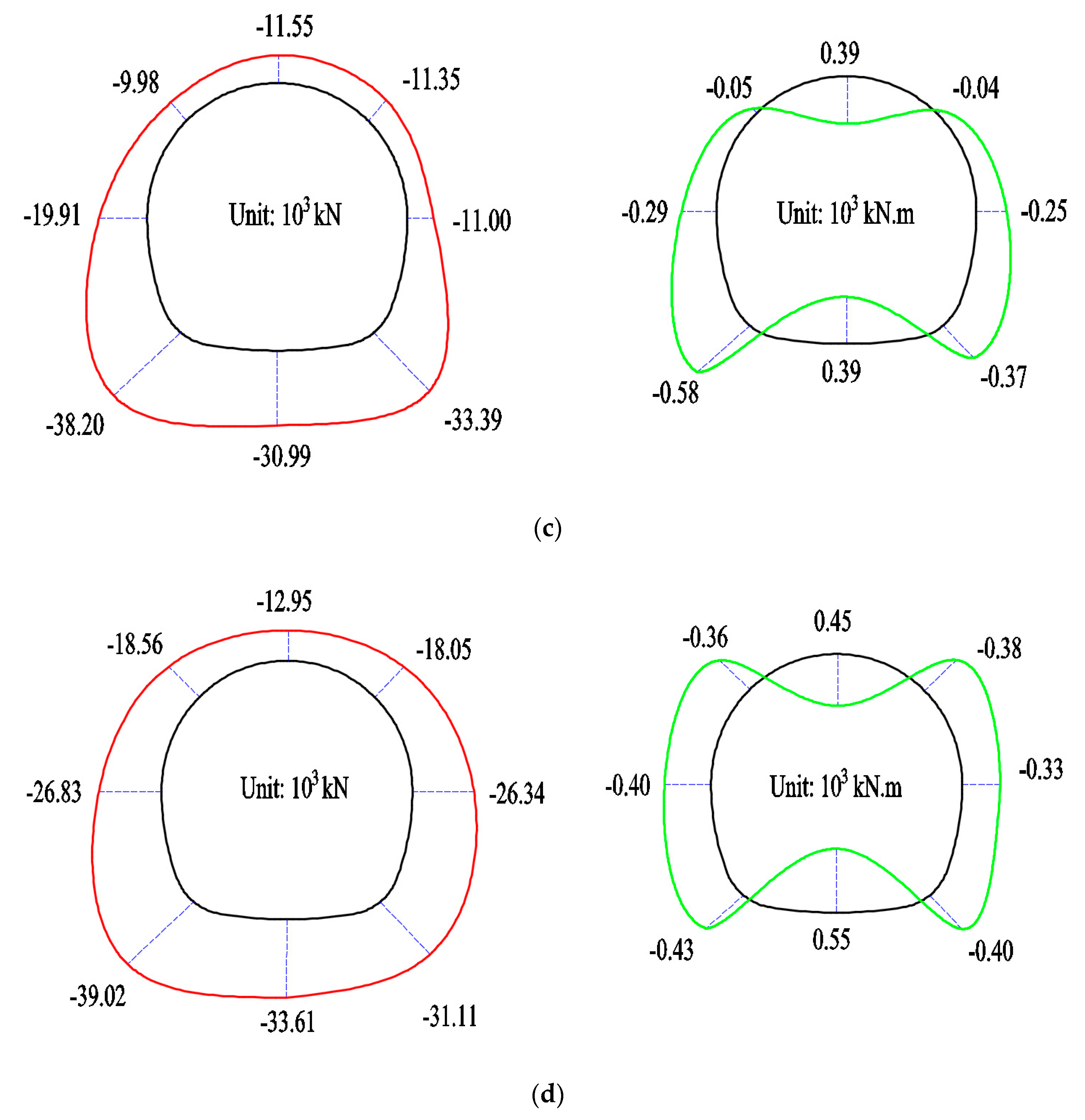

3.2.1. Mechanical Behavior Analysis

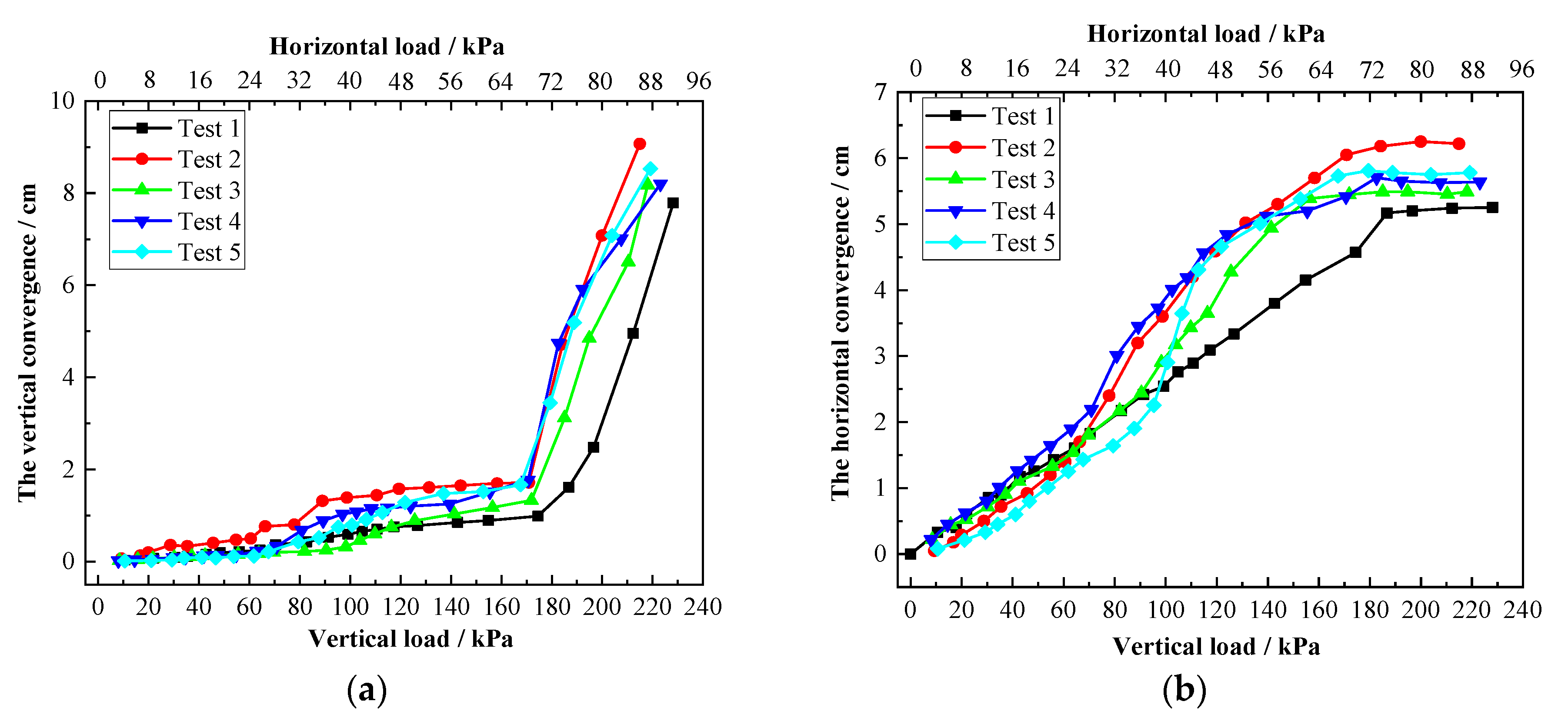

3.2.2. Deformation Behavior Analysis

4. Analysis of Carrying Capacity of Lining

5. Conclusions

- (1)

- The carrying capacity of the lining with prefabricated cracks was reduced, and the deformation of the lining structure increased. Cracks located at the vault fully extended along longitudinal direction accelerated the speed of lining damage. When the crack located at the left arch spring extended along longitudinal direction, the tunnel lining failed.

- (2)

- The internal force of the lining was greatly affected by the positions of prefabricated cracks. The internal forces of the lining structure decreased with the existence of prefabricated cracks. Whether or not a prefabricated crack existed, the outer fiber of the vault and inverted arch were under compression and the inner fiber was under tension, so a tension crack appeared at the inside fiber of the vault and inverted arch, while compressive stress concentration appeared at both sides of the arch springs.

- (3)

- The deformation of the lining structure with the existence of prefabricated cracks increased. When the prefabricated crack was located at the vault, the deformation was the largest, followed by the arch spring, side wall, and arch shoulder. Vertical deformation was greatly affected by the crack at the vault; however, the appearance of cracks in other parts had little influence on vertical deformation. The through-crack at the tunnel vault indicated failure of the vault of the lining. At this time, the load transferring from the arch to the sidewall decreased in order to reduce horizontal deformation, while vertical deformation increased greatly until the structure was damaged.

- (4)

- The ultimate carrying capacity of the lining was reduced due to the existence of prefabricated cracks, and the carrying capacity of the lining structure was greatly reduced when the prefabricated crack was located at the vault. It can be concluded that the crack at the vault was the most damaging under the stress and deformation of the lining structure, so treatment of longitudinal cracks at the vault should be strengthened and receive more attention during projects.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, C.P.; Han, K.H.; Zhang, D.L. Face stability analysis of shallow circular tunnels in cohesive-frictional soils. Tunn. Undergr. Space Technol. 2015, 50, 345–357. [Google Scholar] [CrossRef]

- Zhang, C.P.; Li, W.; Zhu, W.J.; Tan, Z.B. Face stability analysis of a shallow horseshoe-shaped shield tunnel in clay with a linearly increasing shear strength with depth. Tunn. Undergr. Space Technol. 2020, 97, 103291. [Google Scholar] [CrossRef]

- Han, K.H.; Zhang, C.P.; Zhang, D.L. Upper-bound solutions for the face stability of a shield tunnel in multilayered cohesive–frictional soils. Comput. Geotech. 2016, 79, 1–9. [Google Scholar] [CrossRef]

- Li, W.; Zhang, C.P. Face Stability Analysis for a Shield Tunnel in Anisotropic Sands. Int. J. Geomech. 2020. [Google Scholar] [CrossRef]

- Zhang, C.P.; Zhang, X.; Fang, Q. Behaviors of existing twin subway tunnels due to new subway station excavation below in close vicinity. Tunn. Undergr. Space Technol. 2018, 81, 121–128. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, C.P.; Wang, J.C. Effect of closely spaced twin tunnel construction beneath an existing subway station: A case study. J. Test. Eval. 2018, 46, 1559–1573. [Google Scholar] [CrossRef]

- Briffaut, M.; Benboudjema, F.; D’Aloia, L. Effect of fibres on early age cracking of concrete tunnel lining. Part I: Laboratory ring test. Tunn. Undergr. Space Technol. 2016, 59, 215–220. [Google Scholar] [CrossRef]

- Ansell, A. Investigation of shrinkage cracking in shotcrete on tunnel drains. Tunn. Undergr. Space Technol. 2010, 25, 607–613. [Google Scholar] [CrossRef]

- Kamel, T.; Limam, A.; Silvani, C. Residual strength of underground structures in service. Can. Geotech. J. 2016, 53, 988–999. [Google Scholar] [CrossRef]

- Carvalho, J.P.; Lehmann, H.; Bartelt, H.; Magalhães, F.; Amezcua-Correa, R.; Santos, J.L.; Knight, J.C. Structural diagnosis of a concrete dam with cracking and high nonrecoverable displacements. J. Perform. Construct. Facil. 2016, 30, 04016021. [Google Scholar]

- Kong, C.; Gao, X.Q.; Cao, L.; Liu, K. Analysis of the failure of primary support of a deep-buried railway tunnel in silty clay. Eng. Fail. Anal. 2016, 66, 259–273. [Google Scholar] [CrossRef]

- Zhou, L.; Zhu, Z.; Dong, Y.; Ying, P.; Wang, M. Study of the fracture behavior of mode I and mixed mode I/II cracks in tunnel under impact loads. Tunn. Undergr. Space Technol. 2019, 84, 11–21. [Google Scholar] [CrossRef]

- Song, W.; Lai, H.; Liu, Y.; Yang, W.; Zhu, Z. Field and laboratory study of cracking and safety of secondary lining for an existing highway tunnel in loess ground. Tunn. Undergr. Space Technol. 2019, 88, 35–46. [Google Scholar] [CrossRef]

- Zhang, X.P.; Jiang, Y.J.; Sugimoto, S. Seismic damage assessment of mountain tunnel: A case study on the Tawarayama tunnel due to the 2016 Kumamoto Earthquake. Tunn. Undergr. Space Technol. 2018, 71, 138–148. [Google Scholar] [CrossRef]

- Xu, G.; He, C.; Lu, D.; Wang, S. The influence of longitudinal crack on mechanical behavior of shield tunnel lining in soft-hard composite strata. Thin-Walled Struct. 2019, 144, 106282. [Google Scholar] [CrossRef]

- Li, Y.J.; Wang, M.S.; Xu, H.J.; Zhang, Y. Study on the Damage Classification Criterion and Reinforcement Strategies of Mine Construction Subway. Urban Rapid Rail Transit. 2014, 27, 86–89. (In Chinese) [Google Scholar]

- Feng, X.Y. Study on Tunnel Damage Classification and Lining Crack Control Technology. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2012. (In Chinese). [Google Scholar]

- Zhang, S.L. Study on Health Diagnosis and Evaluation of Tunnel Lining Structure. Ph.D. Thesis, Beijing Jiaotong University, Beijing, China, 2012. (In Chinese). [Google Scholar]

- He, C.; Tang, Z.C.; Wang, B.; She, J. Research on effect of inner surface reinforcing on structure bearing capacity by model test in defective tunnel. Rock Soil Mech. 2009, 30, 406–412. (In Chinese) [Google Scholar]

- Li, X.Z.; Li, W.Y.; Song, Y.L.; Gu, Y.C. Experiment on the influence of cracking characteristics under unsymmetrical load on stresses or forces in tunnel lining. China Civ. Eng. J. 2015, 48, 119–128. (In Chinese) [Google Scholar]

| Elastic Modulus (GPa) | Compressive Strength (GPa) | Poisson’s Ratio | |

|---|---|---|---|

| Prototype lining | 30 | 30 | 0.2 |

| Model lining | 2.9 | 3.1 | 0.2 |

| Scheme | Position of Crack |

|---|---|

| Test 1 | None (baseline case) |

| Test 2 | Vault |

| Test 3 | Shoulder |

| Test 4 | Sidewall |

| Test 5 | Arch spring |

| Scheme | Load When Crack at Vault is Through (kPa) | Failure Load (kPa) | Carrying Capacity Reduction Ratio |

|---|---|---|---|

| Test 1 | 174 | 228 | – |

| Test 2 | 144 | 215 | 5.7% |

| Test 3 | 156 | 218 | 4.4% |

| Test 4 | 171 | 223 | 2.2% |

| Test 5 | 179 | 219 | 3.9% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, J.; Jie, Y.; Niu, X.; Liu, C.; Liu, X. Mechanical Behavior of Tunnel Lining with Cracks at Different Positions. Symmetry 2020, 12, 194. https://doi.org/10.3390/sym12020194

Su J, Jie Y, Niu X, Liu C, Liu X. Mechanical Behavior of Tunnel Lining with Cracks at Different Positions. Symmetry. 2020; 12(2):194. https://doi.org/10.3390/sym12020194

Chicago/Turabian StyleSu, Jie, Yinming Jie, Xiaokai Niu, Chang Liu, and Xuan Liu. 2020. "Mechanical Behavior of Tunnel Lining with Cracks at Different Positions" Symmetry 12, no. 2: 194. https://doi.org/10.3390/sym12020194

APA StyleSu, J., Jie, Y., Niu, X., Liu, C., & Liu, X. (2020). Mechanical Behavior of Tunnel Lining with Cracks at Different Positions. Symmetry, 12(2), 194. https://doi.org/10.3390/sym12020194