A Novel Comprehensive Kinematic and Inverse Dynamic Model for the Flybar-Less Swashplate Mechanism: Application on a Small-Scale Unmanned Helicopter

Abstract

1. Introduction

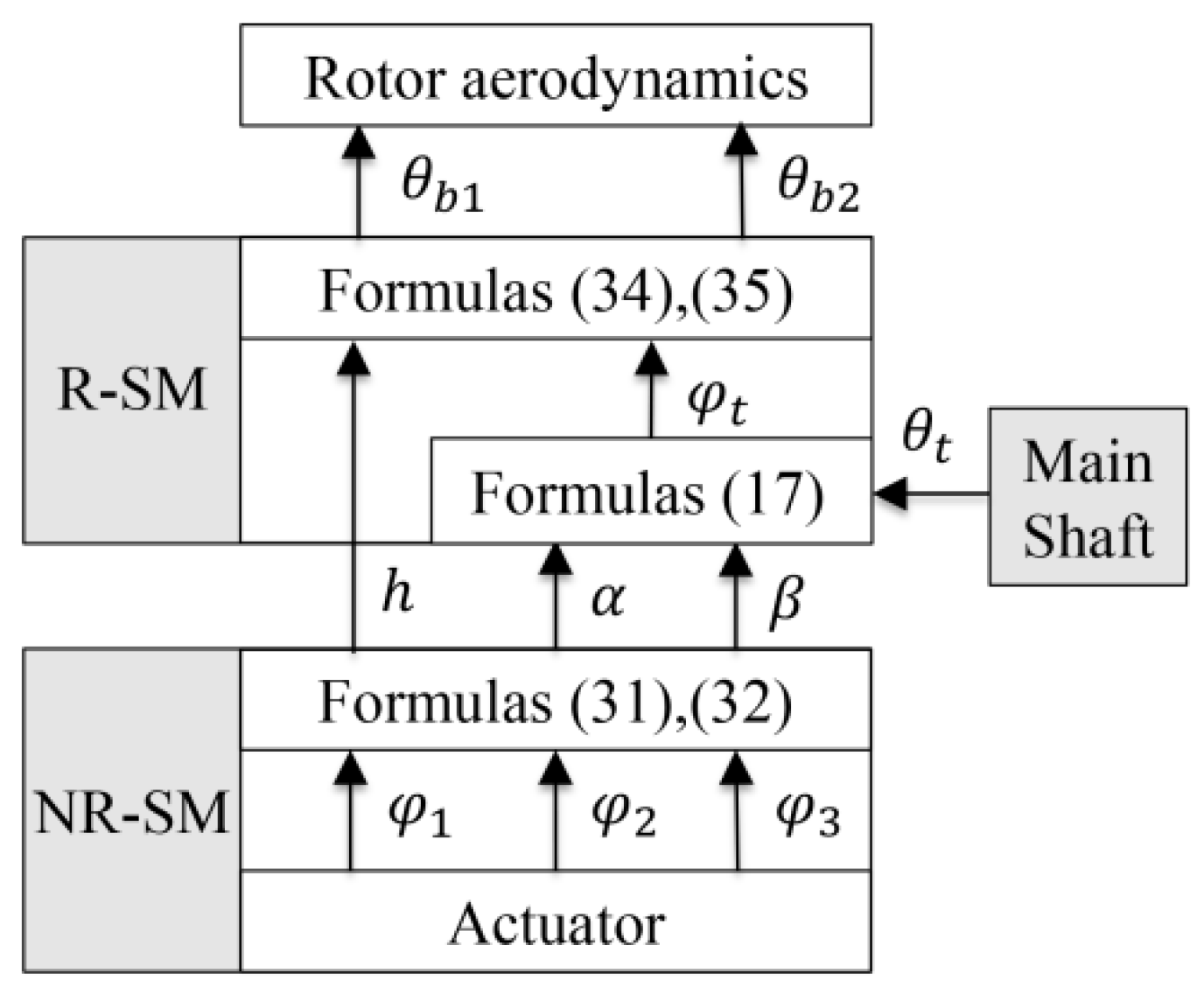

2. Methods

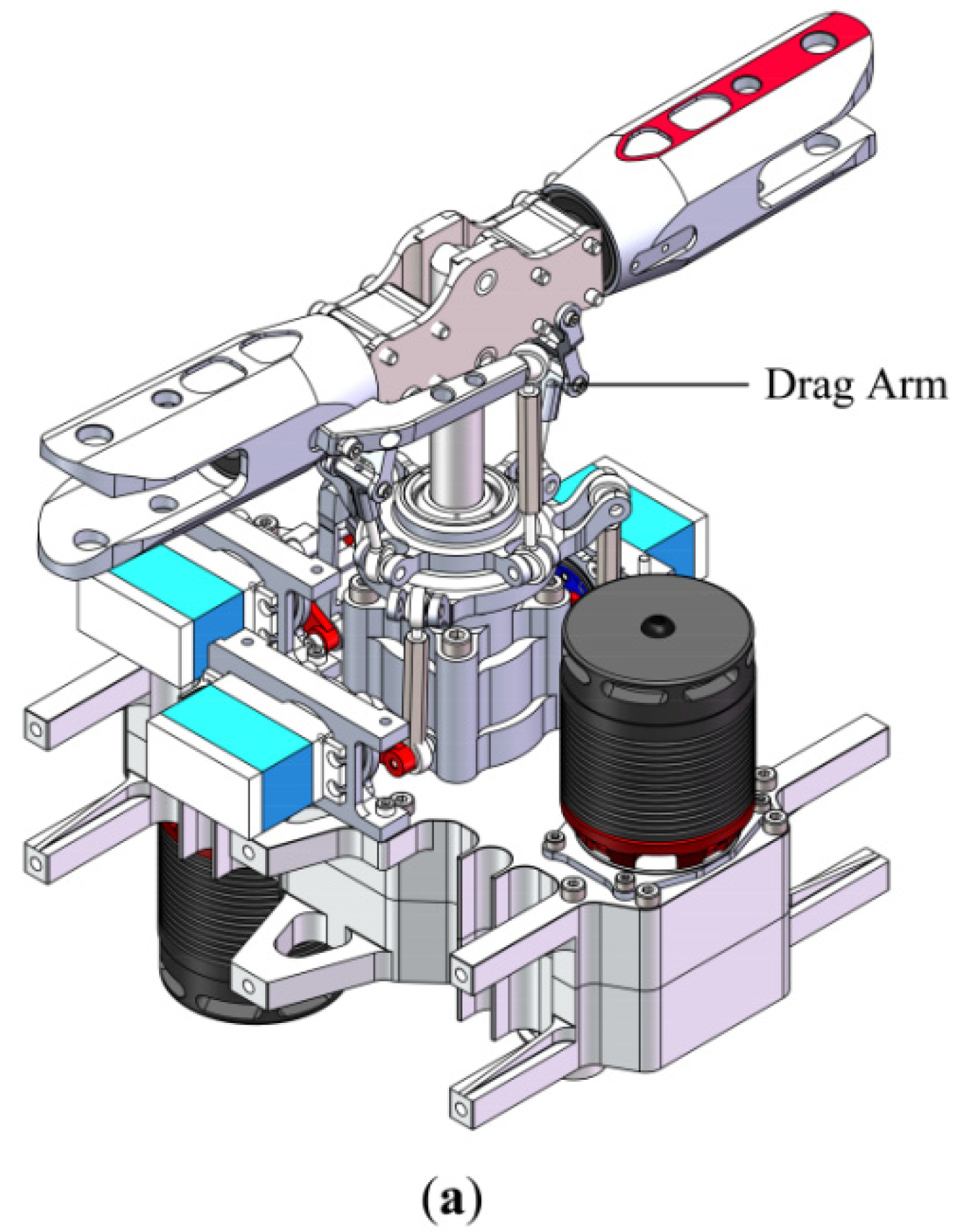

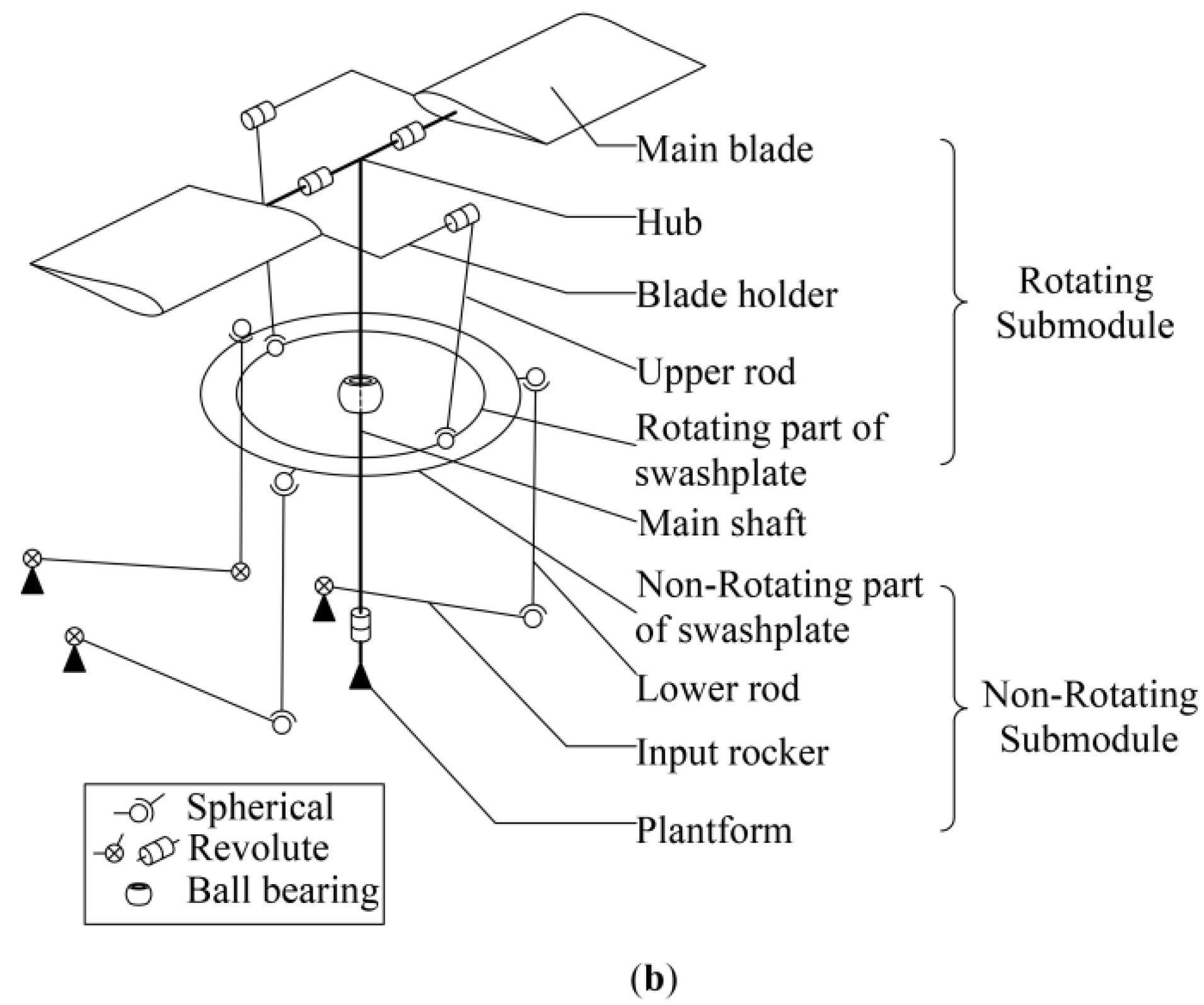

2.1. Mechanical Model

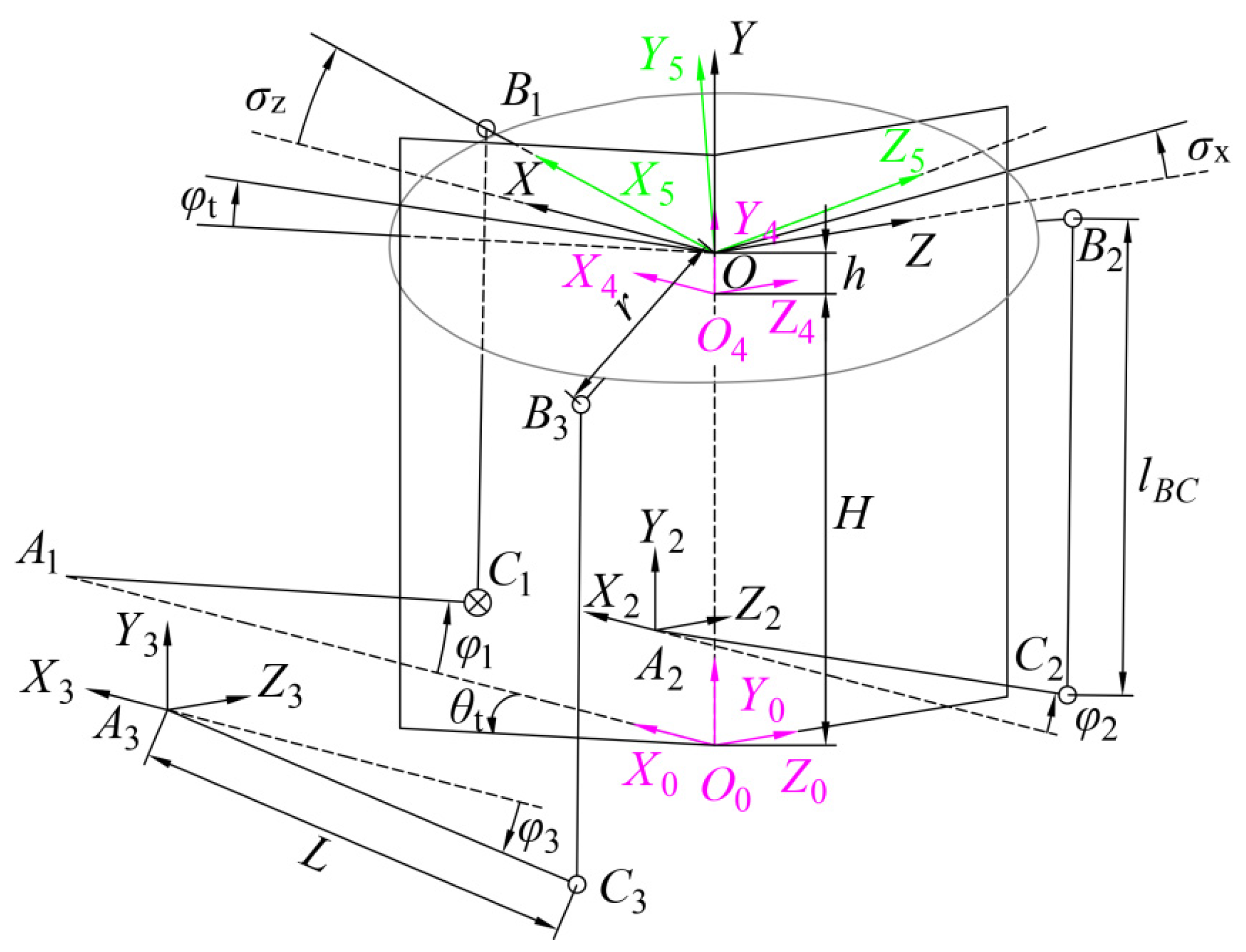

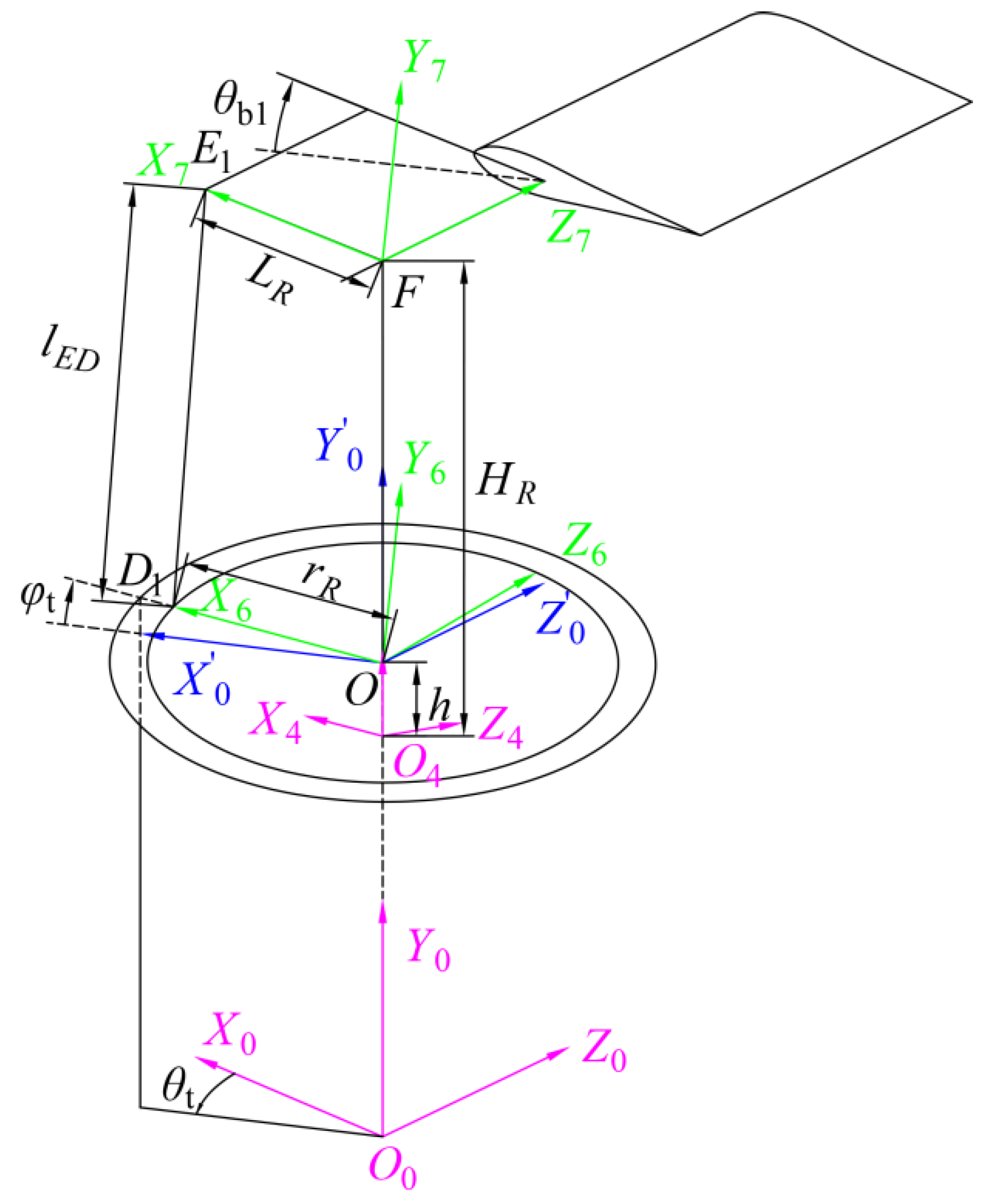

2.2. Kinematic Analysis

2.2.1. Inverse Kinematic Analysis

2.2.2. Direct Kinematic Analysis

2.2.3. Velocity Analysis

2.2.4. Acceleration Analysis

2.3. Inverse Dynamic Analysis

3. Results and Discussions

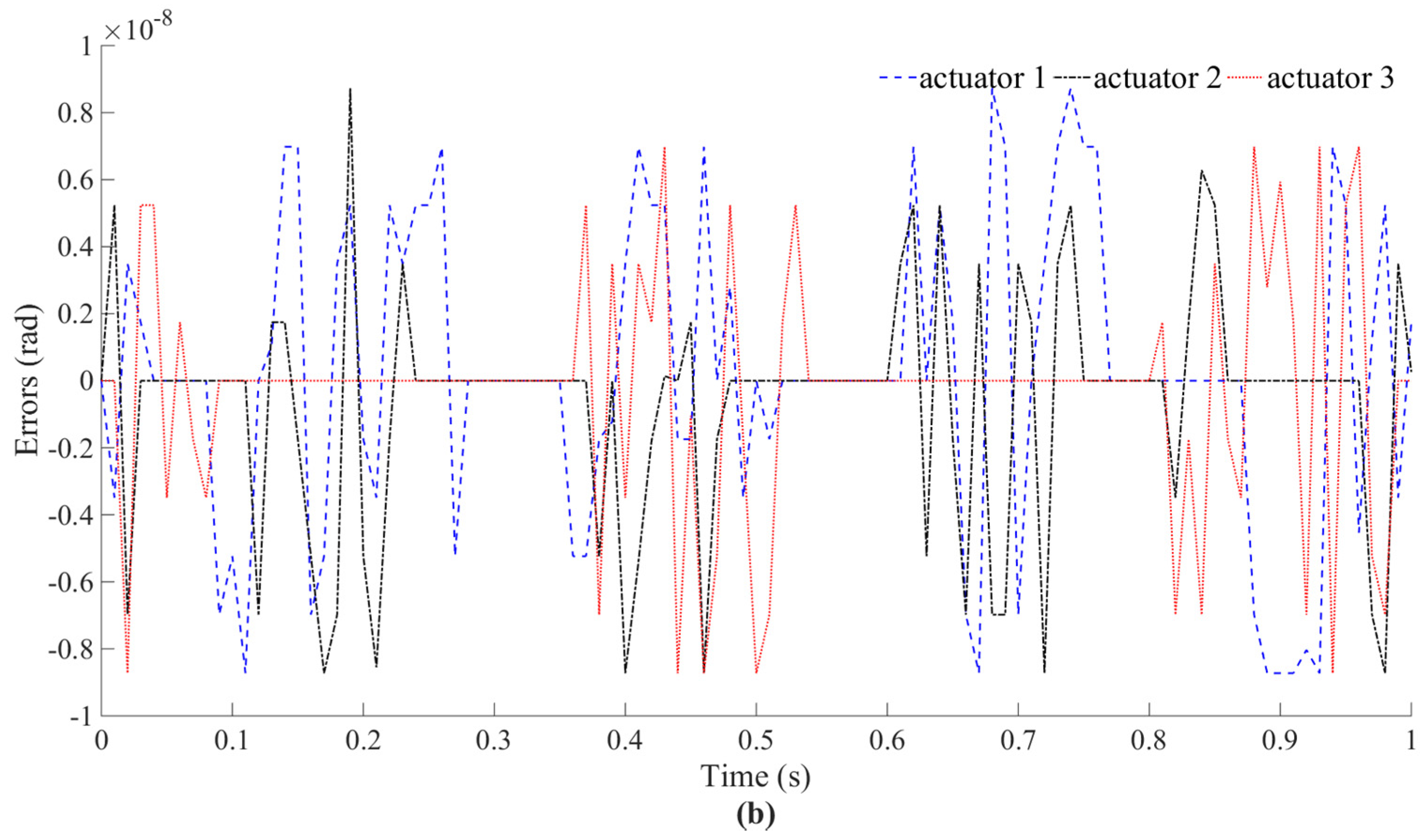

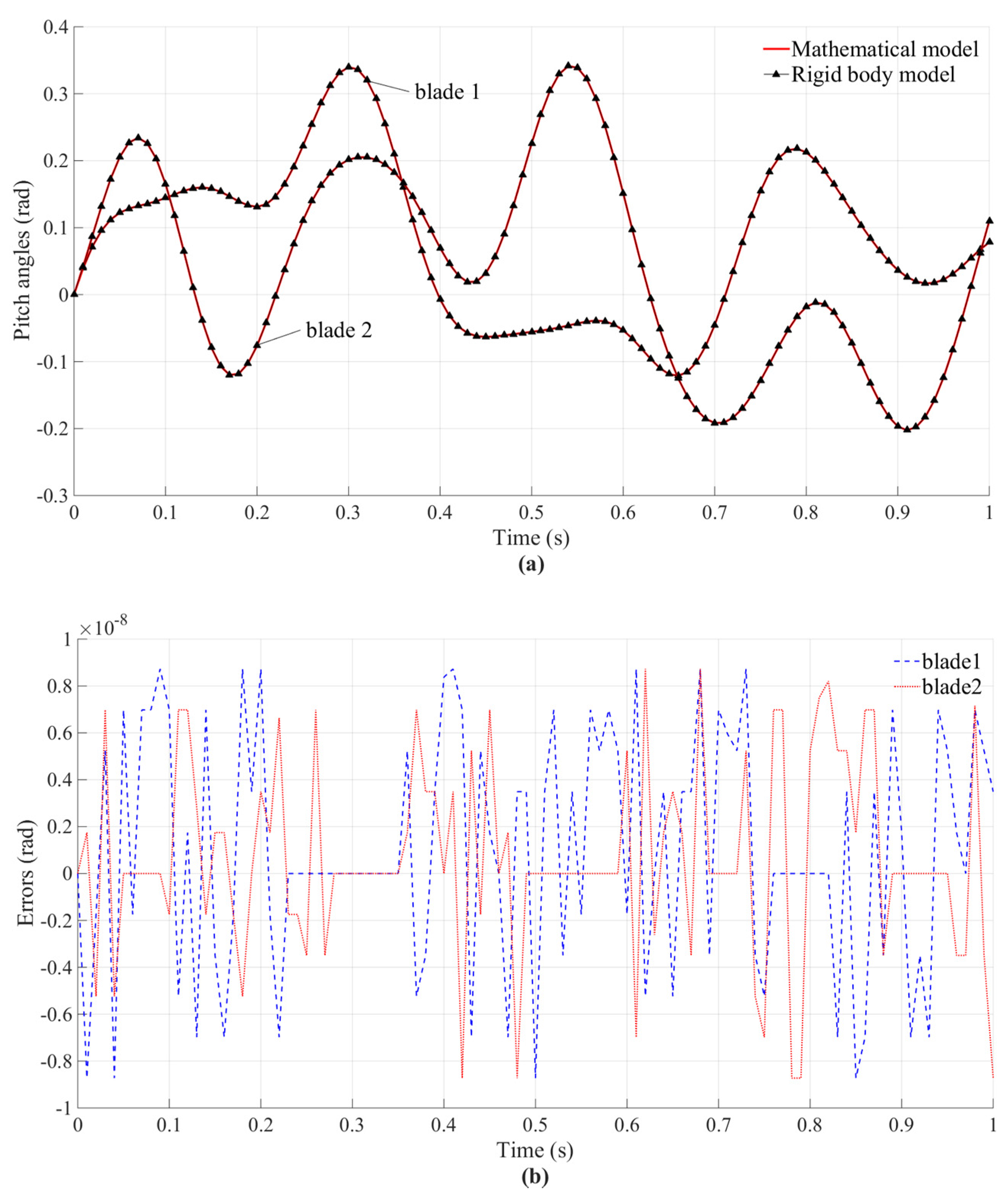

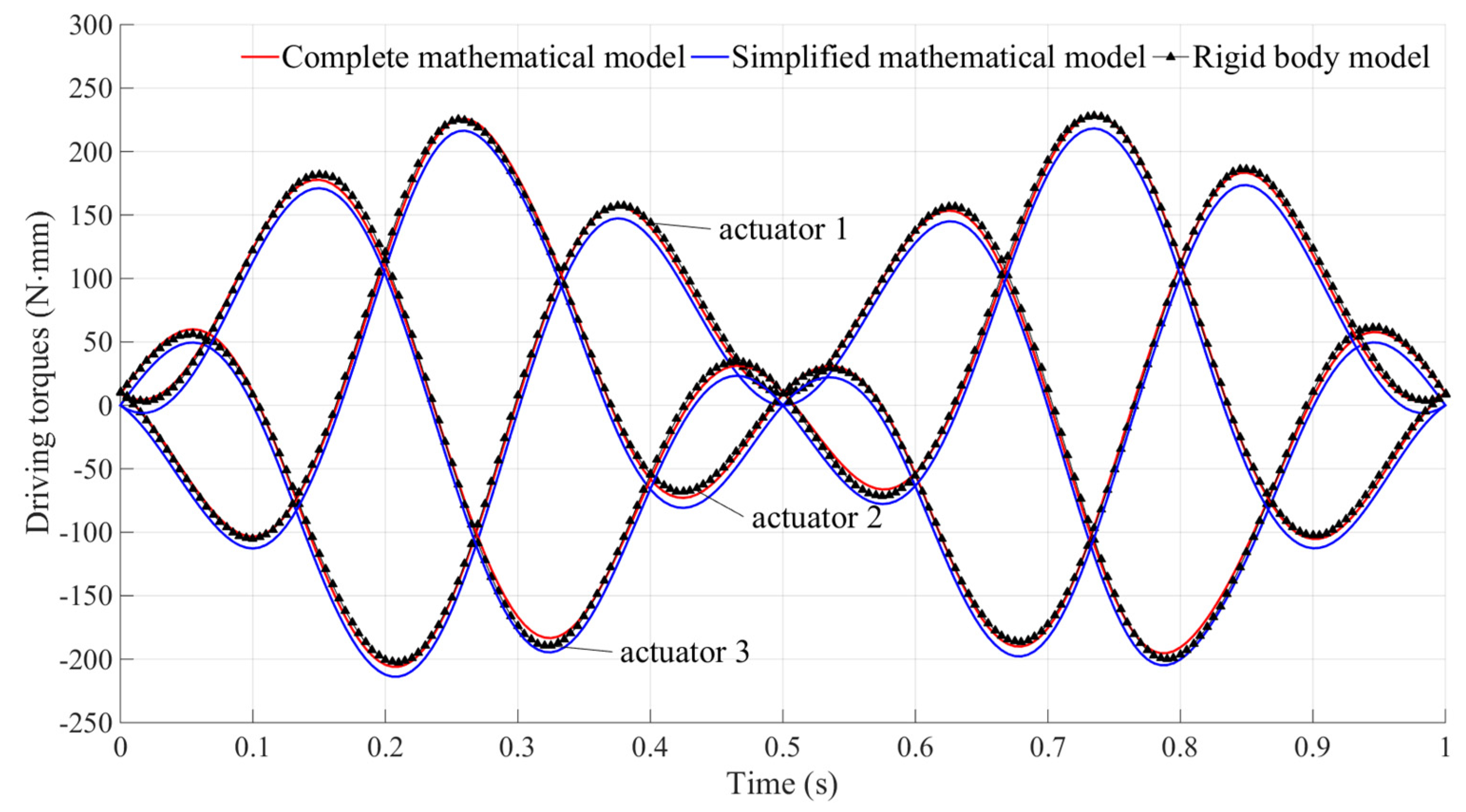

3.1. Numerical Validation

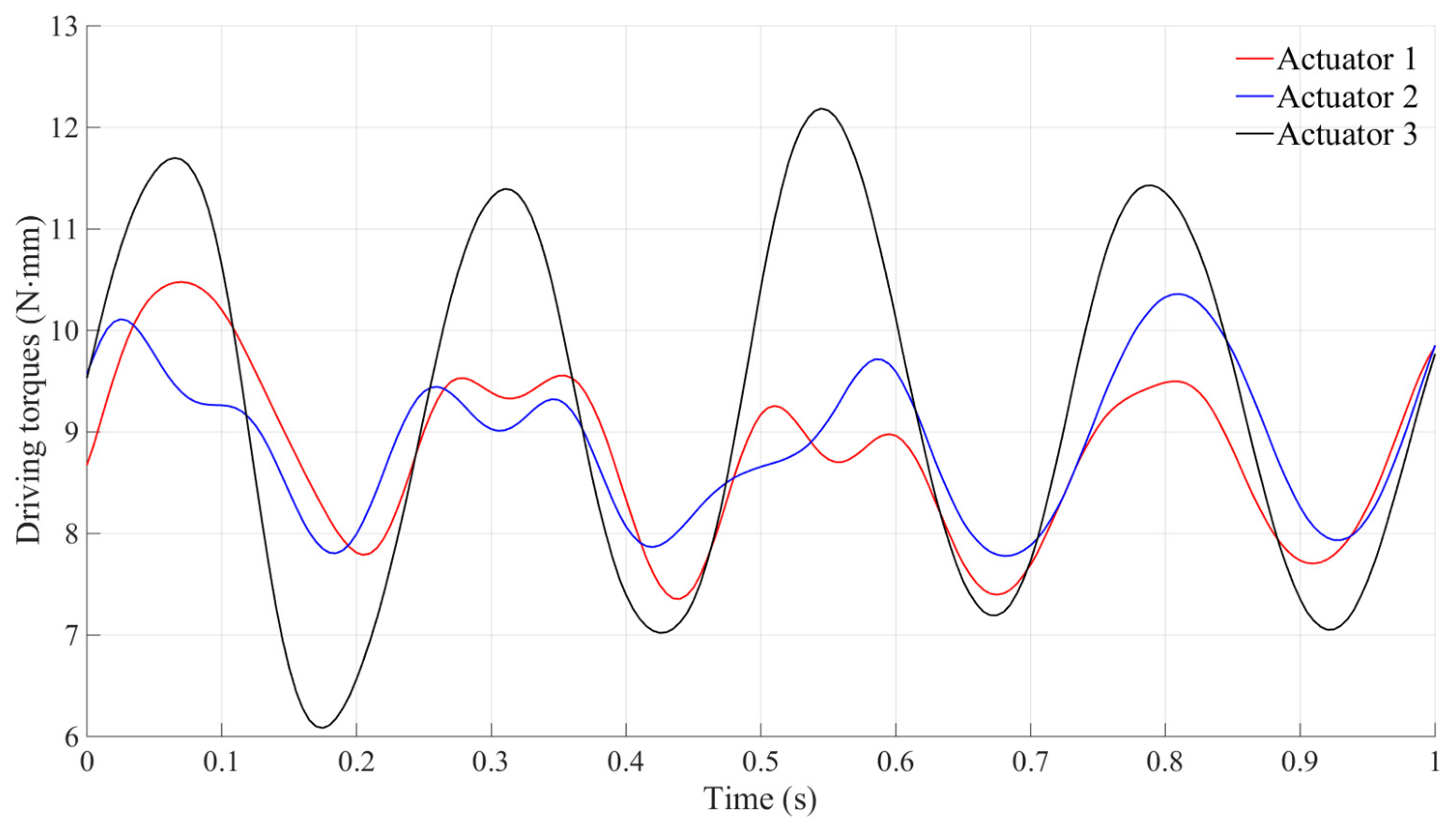

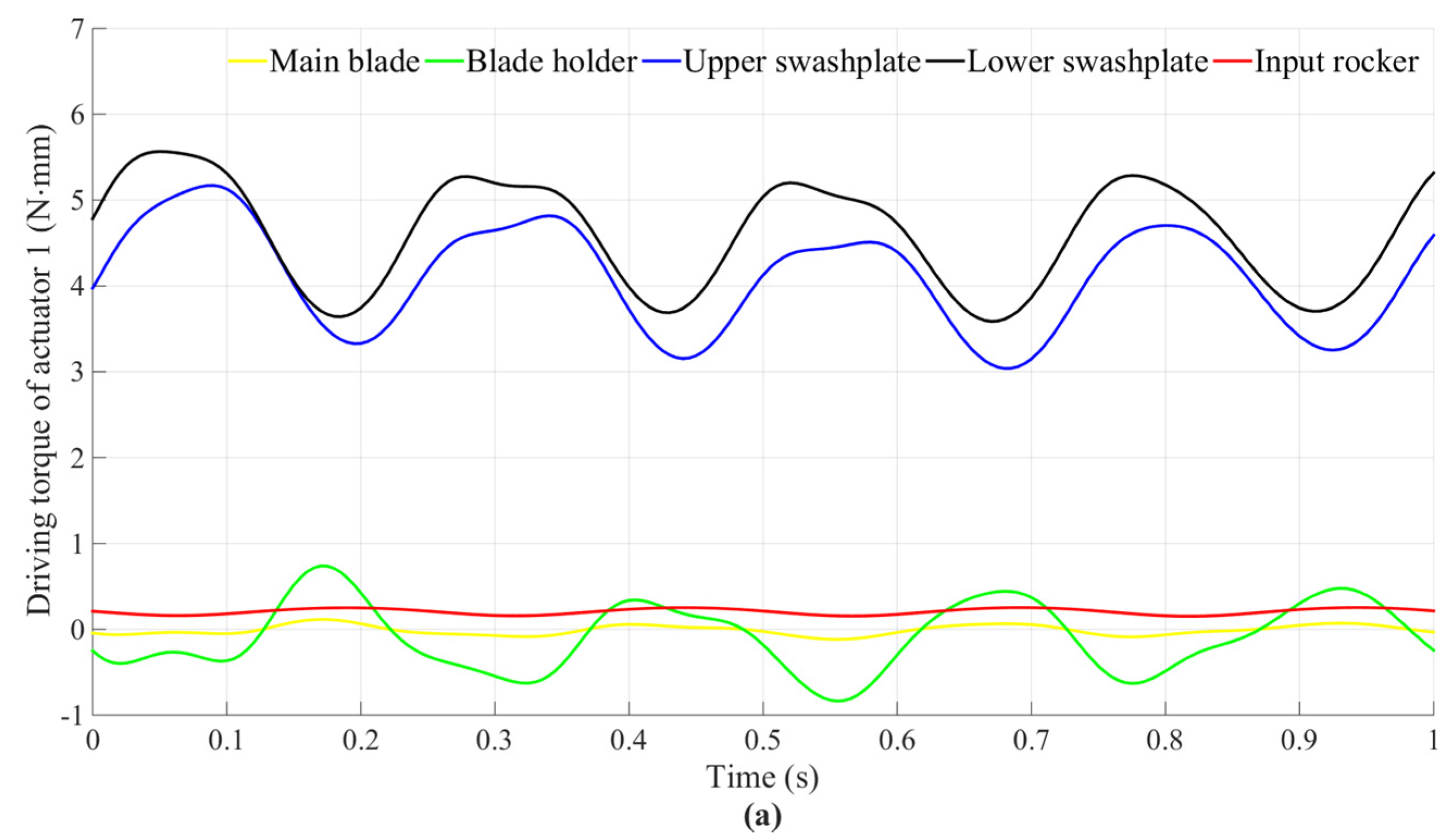

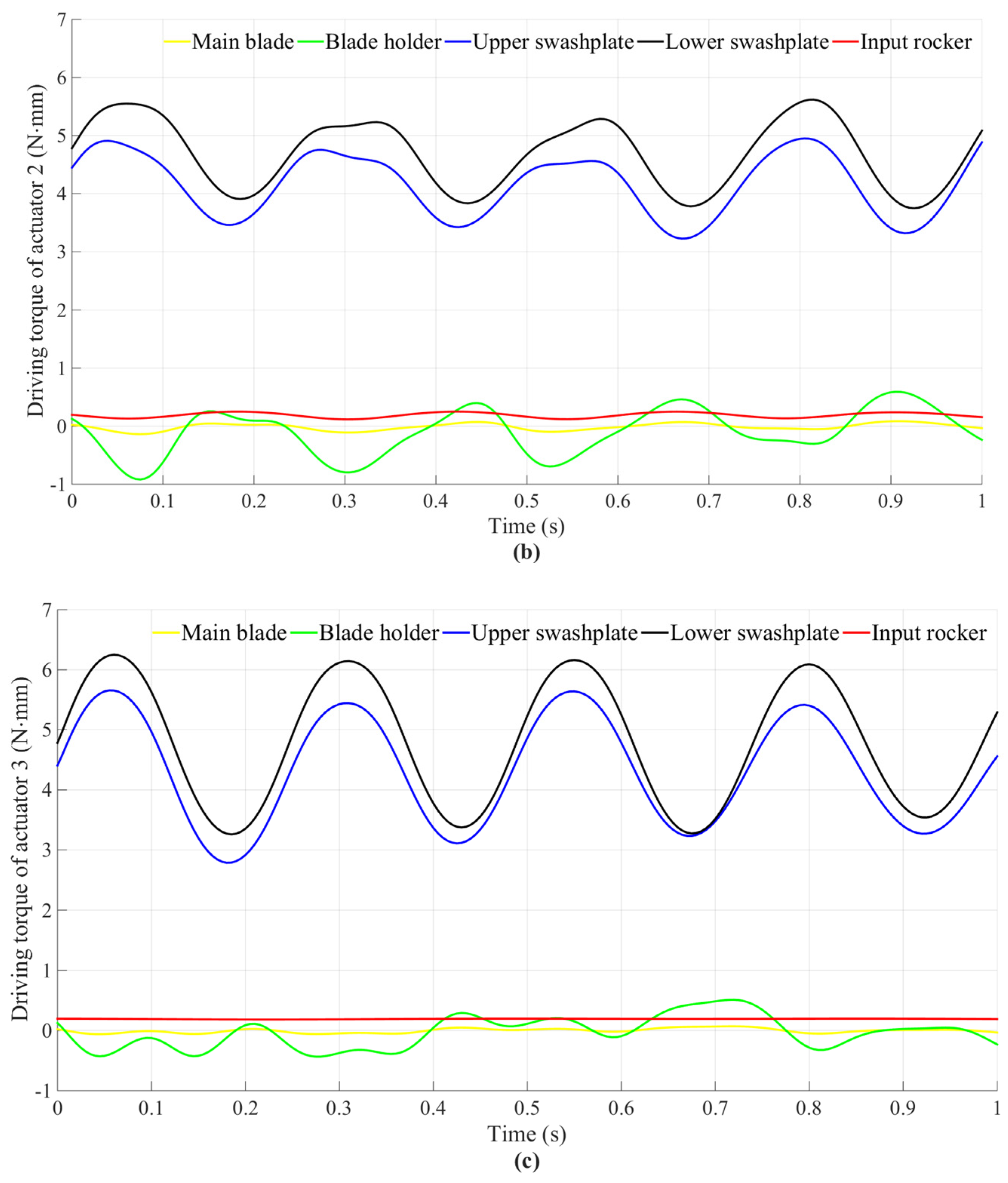

3.2. Simulation Results and Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Raptis, I.A.; Valavanis, K.P. Linear and Nonlinear Control of Small-Scale Unmanned Helicopters; Springer: Heidelberg, Germany, 2011. [Google Scholar]

- Shen, J.W.; Chopra, I. Swashplateless Helicopter Rotor with Trailing-Edge Flaps. J. Aircraft. 2004, 41, 208–214. [Google Scholar] [CrossRef]

- Song, B.; Mills, J.K.; Liu, Y.; Fan, C.Z. Nonlinear dynamic modeling and control of a small-scale helicopter. Int. J. Control Autom. Syst. 2010, 8, 534–543. [Google Scholar]

- Lange, C.; Ranjbaran, F.; Angeles, J.; Goritschnig, G. The kinematics of the swashplate mechanism of a VTOL unmanned aerial vehicle. Multibody Syst. Dyn. 1999, 3, 333–365. [Google Scholar] [CrossRef]

- Akbarzadeh, A.; Enferadi, J.; Sharifnia, M. Dynamics analysis of a 3-RRP spherical parallel manipulator using the natural orthogonal complement. Multibody Syst. Dyn. 2013, 29, 361–380. [Google Scholar] [CrossRef]

- Lange, C.; Ranjbaran, F.; Angeles, J.; Goritschnig, G. The dynamics of the swashplate mechanism of a VTOL unmanned aerial vehicle. Multibody Syst. Dyn. 2001, 5, 105–131. [Google Scholar]

- Sabaapour, M.R.; Zohoor, H. Analysis of a swashplate mechanism of the hingeless rotor hub with the flybar in a model helicopter, Part I: Kinematics. Trans. Jpn. Soc. Mech. Eng. 2010, 4, 616–631. [Google Scholar] [CrossRef][Green Version]

- Sabaapour, M.R.; Zohoor, H. Analysis of a swashplate mechanism of the hingeless rotor hub with the flybar in a model helicopter, Part II: Dynamics. Trans. Jpn. Soc. Mech. Eng. 2010, 4, 258–296. [Google Scholar] [CrossRef][Green Version]

- Tsai, L.W. Solving the Inverse Dynamics of a Stewart-Gough Manipulator by the Principle of Virtual Work. J. Mech. Des. 1999, 122, 3–9. [Google Scholar]

- Khaligh, S.P.; Fahimi, F.; Koch, C.R. A fast inverse kinematic solution for the nonlinear actuating mechanisms of a small-scale helicopter. Multibody Syst. Dyn. 2015, 35, 257–275. [Google Scholar] [CrossRef]

- Saffarian, M.; Fahimi, F. A comprehensive kinematic analysis of a model helicopter’s actuating mechanism. In Proceedings of the AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 7–10 January 2008. [Google Scholar]

- Kim, S.K.; Tilbury, D.M. Mathematical modeling and experimental identification of an unmanned helicopter robot with flybar dynamics. J. Intell. Robot. Syst. 2004, 21, 95–116. [Google Scholar] [CrossRef]

- Ren, B.; Sarabia, M.; Chen, C.; Fua, C.H.; Lee, T.H. Modeling, Control and Coordination of Helicopter Systems; Springer: New York, NY, USA, 2012. [Google Scholar]

- AI-Sharman, M.; Abdel-Hafez, M.; AI-Omari, M. State Estimation for a Small Scale Flybar-less Helicopter. Proc. Technol. 2014, 15, 258–267. [Google Scholar] [CrossRef]

- Ding, L.; Wu, H.T.; Yao, Y. Chaotic Artificial Bee Colony Algorithm for System Identification of a Small-Scale Unmanned Helicopter. Int. J. Aerosp. Eng. 2015, 2015, 801874. [Google Scholar] [CrossRef]

- Yuan, X.; Zhu, J.; Chen, Z.; Lu, X.; Meng, J. Inverse dynamic modeling and analysis of a coaxial helicopter’s swashplate mechanism. Mech. Mach. Theory 2017, 113, 208–230. [Google Scholar] [CrossRef]

- Merlet, J.P. Parallel Robots; Springer: Heidelberg, Germany, 2006. [Google Scholar]

- Dasgupta, B.; Choudhury, P. A general strategy based on the Newton–Euler approach for the dynamic formulation of parallel manipulators. Mech. Mach. Theory 1999, 34, 801–824. [Google Scholar] [CrossRef]

- Hwang, Y. Recursive Newton-Euler formulation for flexible dynamic manufacturing analysis of open-loop robotic systems. Int. J. Adv. Manuf. Technol. 2006, 29, 598–604. [Google Scholar]

- Abdellatif, H.; Heimann, B. Computational efficient inverse dynamics of 6-DOF fully parallel manipulators by using the Lagrangian formalism. Mech. Mach. Theory 2009, 44, 192–207. [Google Scholar] [CrossRef]

- Zandron, O.S. Superconducting State in the Lagrangian Formalism of the Generalized Hubbard Model. Int. J. Theor. Phys. 2003, 42, 2103–2113. [Google Scholar] [CrossRef]

- Pedrammehr, S.; Nahavandi, S.; Abdi, H. Closed-form dynamics of a hexarot parallel manipulator by means of the principle of virtual work. Acta Mech. Sin. 2018, 34, 883–895. [Google Scholar] [CrossRef]

- Enferadi, J.; Akbarzadeh Tootoonchi, A. Inverse dynamics analysis of a general spherical star-triangle parallel manipulator using principle of virtual work. Nonlinear Dyn. 2010, 61, 419–434. [Google Scholar] [CrossRef]

- Rao, A.B.K.; Saha, S.K.; Rao, P.V.M. Dynamics Modelling of Hexaslides using the Decoupled Natural Orthogonal Complement Matrices. Multibody Syst. Dyn. 2006, 15, 159–180. [Google Scholar] [CrossRef]

- Tu, T.W. First-order form, Lagrange’s form, and Gibbs–Appell’s form of Kane’s equations. Acta Mech. 2016, 227, 1885–1901. [Google Scholar] [CrossRef]

- Gallardo-Alvarado, J.; Aguilar-Nájera, C.R.; Casique-Rosas, L. Solving the kinematics and dynamics of a modular spatial hyper-redundant manipulator by means of screw theory. Multibody Syst. Dyn. 2008, 20, 307–325. [Google Scholar] [CrossRef]

- Lin, C.-J.; Chen, C.-T. Reconfiguration for the Maximum Dynamic Wrench Capability of a Parallel Robot. Appl. Sci. 2016, 6, 80. [Google Scholar] [CrossRef]

- Tsai, L.W. Robot. Analysis: The Mechanics of Serial and Parallel Manipulators; Wiley: New York, NY, USA, 1999. [Google Scholar]

| Parameters | Moment of Inertia (× 10−6 Kg·m2) | Parameters | Length (mm) | Parameters | Weight ( Kg) |

|---|---|---|---|---|---|

| 13.403 | 25 | 1.776 | |||

| 26.591 | 12.02 | 1.702 | |||

| 13.403 | 11.73 | 1.702 | |||

| 9.462 | 11.73 | 85.56 | |||

| 19.117 | 44.5 | 52.32 | |||

| 9.793 | 60 | 58.53 | |||

| 23.282 | 30 | ||||

| 26.780 | 30 | ||||

| 6.316 | 1.68 | ||||

| 793.943 | 54.74 | ||||

| 794.929 | 60 | ||||

| 1.048 | 60 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Guan, R.; Yao, Y.; Wang, H.; Hu, L. A Novel Comprehensive Kinematic and Inverse Dynamic Model for the Flybar-Less Swashplate Mechanism: Application on a Small-Scale Unmanned Helicopter. Symmetry 2020, 12, 1849. https://doi.org/10.3390/sym12111849

Liu J, Guan R, Yao Y, Wang H, Hu L. A Novel Comprehensive Kinematic and Inverse Dynamic Model for the Flybar-Less Swashplate Mechanism: Application on a Small-Scale Unmanned Helicopter. Symmetry. 2020; 12(11):1849. https://doi.org/10.3390/sym12111849

Chicago/Turabian StyleLiu, Jianbo, Rongqiang Guan, Yongming Yao, Hui Wang, and Linqiang Hu. 2020. "A Novel Comprehensive Kinematic and Inverse Dynamic Model for the Flybar-Less Swashplate Mechanism: Application on a Small-Scale Unmanned Helicopter" Symmetry 12, no. 11: 1849. https://doi.org/10.3390/sym12111849

APA StyleLiu, J., Guan, R., Yao, Y., Wang, H., & Hu, L. (2020). A Novel Comprehensive Kinematic and Inverse Dynamic Model for the Flybar-Less Swashplate Mechanism: Application on a Small-Scale Unmanned Helicopter. Symmetry, 12(11), 1849. https://doi.org/10.3390/sym12111849