Simulation-Based Positioning of Circular Economy Manager’s Skills in Construction Projects

Abstract

1. Introduction

- Plastics;

- Food waste;

- Critical raw materials;

- Construction and demolition;

- Biomass and bio-based products.

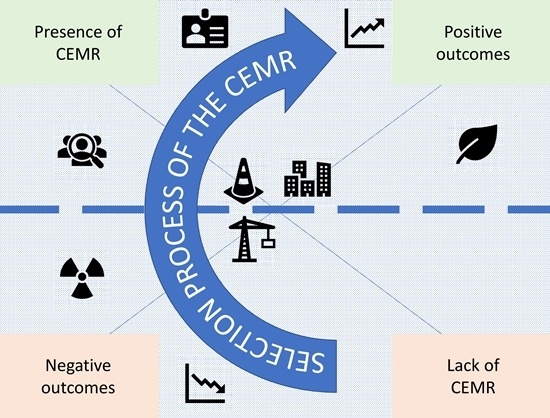

- Is it necessary to employ circular economy managers to construction projects?

- Is it possible to create one coherent model of the selection of circular economy managers in construction projects?

- Can decision-makers make more reliable decisions in a process of CEMR selection?

2. Theoretical Framework

2.1. Circular Economy (CE) in the Construction Sector

2.2. Implementation of CE in Construction Project Management (CPM)

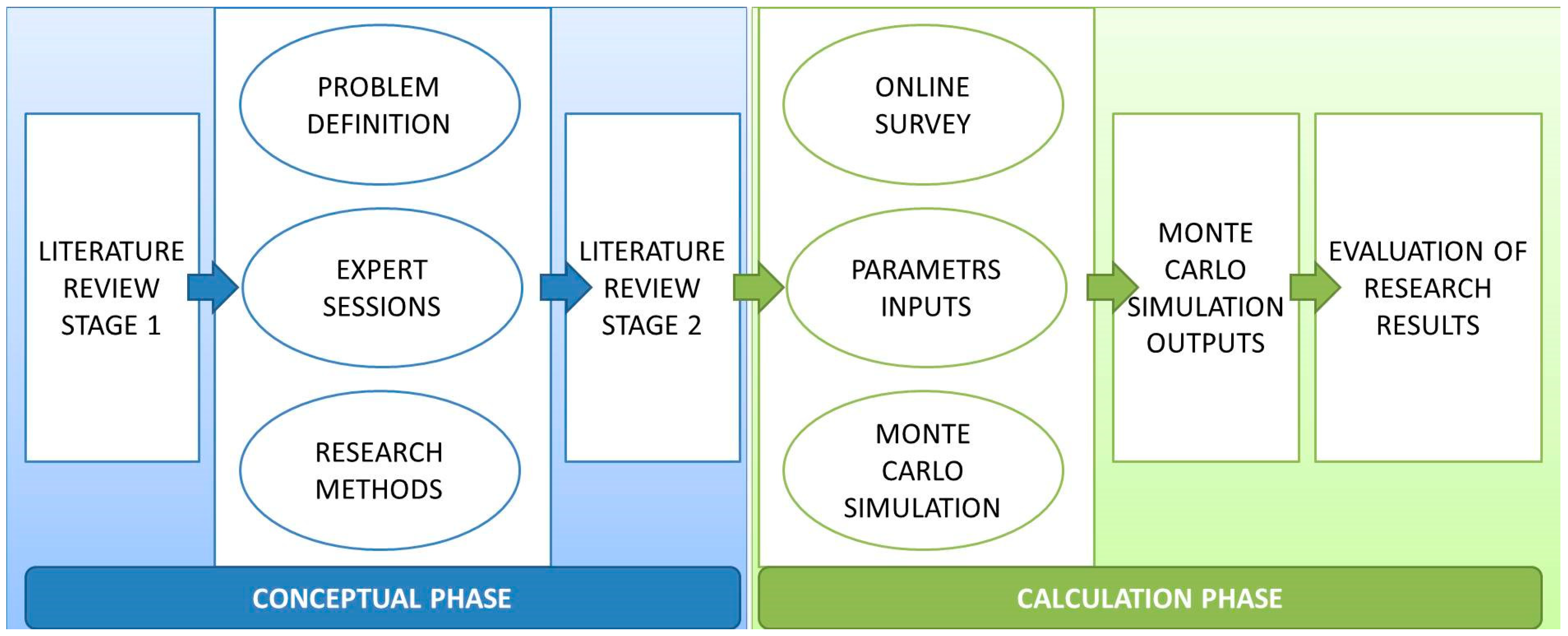

3. Methods

3.1. Overview of Methods

3.2. Description of the Selected Method

- An online survey performed on platform SurveyMonkey (www.surveymonkey.com) intended for collecting opinions about the criteria priorities and probability parameter inputs connected with particular selection criteria;

- Configuration of inputs of the model;

- Performance of simulation of the model using @Risk application (www.palisade.com).

- Developing a model—problem definition in Microsoft Excel;

- Identifying inputs and outputs—to set inputs, to specify their possible values with probability distributions, and to define outputs that should be analyzed;

- Analyzing the model with simulation—to run various scenarios with sampled values of inputs to determine the probability distributions of outputs;

- Making a decision—to make informed choices on the basis of the simulation results.

4. Criteria and Selection Model of CEMR

- Basic skills (BS): facilitate learning or self-development;

- Complex problem solving skills (CPSS): useful in solving different problems connected with a project in complex, real circumstances;

- Resource management skills (RMS): enable efficient resource allocation in a project;

- Social skills (SLS): useful for managing people in achieving project goals;

- Systems skills (SSS): facilitate understanding, monitoring and development of the whole context of a project;

- Technical skills (TS): useful for operating technical and technological aspects of a project.

5. Results

- Resource management skills;

- Complex problem solving skills;

- Systems skills;

- Social skills;

- Basic skills;

- Technical skills.

- Resource management skills;

- Systems skills;

- Complex problem solving skills;

- Basic skills;

- Social skills;

- Technical skills.

6. Discussion and Conclusions

7. Limitations and Future Research Lines

- The proposed model can be checked by other probability distribution patterns. Which of them are suitable, and how can one obtain reliable input parameters?

- There might exist some correlations between factors. How can one measure them and implement the proposed model?

- There are other methods supporting multi-criteria decision making in the personnel selection process. What other methods are suitable for the CEMR recruitment to construction projects?

- What types of difficulties can managers face in a real-life selection of CEMR?

Funding

Conflicts of Interest

Appendix A

References

- Schmelzer, M. The growth paradigm: History, hegemony, and the contested making of economic growthmanship. Ecol. Econ. 2015, 118, 262–271. [Google Scholar] [CrossRef]

- Hamilton, C. Consumerism, self-creation and prospects for a new ecological consciousness. J. Clean. Prod. 2010, 18, 571–575. [Google Scholar] [CrossRef]

- Panov, V.I. Ecological Thinking, Consciousness, Responsibility. Procedia-Soc. Behav. Sci. 2013, 86, 379–383. [Google Scholar] [CrossRef]

- Research and Degrowth. Degrowth Declaration of the Paris 2008 conference. J. Clean. Prod. 2010, 18, 523–524. [Google Scholar] [CrossRef]

- Luo, Z.; Dubey, R.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T.; Hazen, B.; Roubaud, D. Sustainable production framework for cement manufacturing firms: A behavioural perspective. Renew. Sustain. Energy Rev. 2017, 78, 495–502. [Google Scholar] [CrossRef]

- Alayón, C.; Säfsten, K.; Johansson, G. Conceptual sustainable production principles in practice: Do they reflect what companies do? J. Clean. Prod. 2017, 141, 693–701. [Google Scholar] [CrossRef]

- Górecki, J.; Swoiński, E.; Bizon-Górecka, J. Sustainable production: In search of european model for reducing environmental impact. In Innovation Management and Education Excellence Through Vision 2020; Soliman, K., Ed.; IBIMA: Milan, Italy, 2018; Volumes I–XI, pp. 1570–1578. [Google Scholar]

- Czaplicka-Kolarz, K.; Kruczek, M.; Burchart-Korol, D. Eco-Efficiency Concept for Sustainable Production Management. In Scientific Papers of Silesian University of Technology; Organization and Management Series; Silesian University of Technology: Zabrze, Poland, 2013; pp. 59–71. [Google Scholar]

- Brissaud, D.; Frein, Y.; Rocchi, V. What tracks for sustainable production systems in Europe? Procedia CIRP 2013, 7, 9–16. [Google Scholar] [CrossRef][Green Version]

- Zore, Ž.; Čuček, L.; Kravanja, Z. Synthesis of sustainable production systems using an upgraded concept of sustainability profit and circularity. J. Clean. Prod. 2018, 201, 1138–1154. [Google Scholar] [CrossRef]

- Pla-Julián, I.; Guevara, S. Is circular economy the key to transitioning towards sustainable development? Challenges from the perspective of care ethics. Futures 2018, 105, 67–77. [Google Scholar] [CrossRef]

- Gerwin, M. Sustainable Development Plan for Poland, Local Development Initiatives; Local Development Initiatives: Sopot, Poland, 2008. [Google Scholar]

- Witjes, S.; Lozano, R. Towards a more Circular Economy: Proposing a framework linking sustainable public procurement and sustainable business models. Resour. Conserv. Recycl. 2016, 112, 37–44. [Google Scholar] [CrossRef]

- Núñez-Cacho, P.; Molina-Moreno, V.; Corpas-Iglesias, F.A.; Cortés-García, F.J. Family Businesses Transitioning to a Circular Economy Model: The Case of “Mercadona”. Sustainability 2018, 10, 538. [Google Scholar] [CrossRef]

- Nuñez-Cacho, P.; Górecki, J.; Molina-Moreno, V.; Corpas-Iglesias, F. What Gets Measured, Gets Done: Development of a Circular Economy Measurement Scale for Building Industry. Sustainability 2018, 10, 2340. [Google Scholar] [CrossRef]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the Circular Economy: Evidence From the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- Suárez-Eiroa, B.; Fernández, E.; Méndez-Martínez, G.; Soto-Oñate, D. Operational principles of circular economy for sustainable development: Linking theory and practice. J. Clean. Prod. 2019, 214, 952–961. [Google Scholar] [CrossRef]

- European Commission. Communication of the Commission to the European Parliament, the Council of the European Economic and Social Committee and the Committee of the Regions, Closing the Loop—VAn EU action plan for the Circular Economy; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Kim, D.H.; Lin, S.C. Human capital and natural resource dependence. Struct. Chang. Econ. Dyn. 2017, 40, 92–102. [Google Scholar] [CrossRef]

- Shahbaz, M.; Destek, M.A.; Okumus, I.; Sinha, A. An empirical note on comparison between resource abundance and resource dependence in resource abundant countries. Resour. Policy 2019, 60, 47–55. [Google Scholar] [CrossRef]

- Barrett, J.; Cooper, T.; Hammond, G.P.; Pidgeon, N. Industrial energy, materials and products: UK decarbonisation challenges and opportunities. Appl. Therm. Eng. 2018, 136, 643–656. [Google Scholar] [CrossRef]

- Cooper, S.J.G.; Giesekam, J.; Hammond, G.P.; Norman, J.B.; Owen, A.; Rogers, J.G.; Scott, K. Thermodynamic insights and assessment of the ‘circular economy’. J. Clean. Prod. 2017, 162, 1356–1367. [Google Scholar] [CrossRef]

- Whicher, A.; Harris, C.; Beverley, K.; Swiatek, P. Design for circular economy: Developing an action plan for Scotland. J. Clean. Prod. 2018, 172, 3237–3248. [Google Scholar] [CrossRef]

- de Abreu, M.C.S.; Ceglia, D. On the implementation of a circular economy: The role of institutional capacity-building through industrial symbiosis. Resour. Conserv. Recycl. 2018, 138, 99–109. [Google Scholar] [CrossRef]

- Sousa-Zomer, T.T.; Magalhães, L.; Zancul, E.; Campos, L.M.S.; Cauchick-Miguel, P.A. Cleaner production as an antecedent for circular economy paradigm shift at the micro-level: Evidence from a home appliance manufacturer. J. Clean. Prod. 2018, 185, 740–748. [Google Scholar] [CrossRef]

- Hurlimann, A.C.; Browne, G.R.; Warren-Myers, G.; Francis, V. Barriers to climate change adaptation in the Australian construction industry–Impetus for regulatory reform. Build. Environ. 2018, 137, 235–245. [Google Scholar] [CrossRef]

- Heffernan, E.; Pan, W.; Liang, X.; de Wilde, P. Zero carbon homes: Perceptions from the UK construction industry. Energy Policy 2015, 79, 23–36. [Google Scholar] [CrossRef]

- Tam, C.M.; Tam, V.W.Y.; Tsui, W.S. Green construction assessment for environmental management in the construction industry of Hong Kong. Int. J. Proj. Manag. 2004, 22, 563–571. [Google Scholar] [CrossRef]

- Zuo, J.; Read, B.; Pullen, S.; Shi, Q. Achieving carbon neutrality in commercial building developments-Perceptions of the construction industry. Habitat Int. 2012, 36, 278–286. [Google Scholar] [CrossRef]

- De Wolf, C.; Pomponi, F.; Moncaster, A. Measuring embodied carbon dioxide equivalent of buildings: A review and critique of current industry practice. Energy Build. 2017, 140, 68–80. [Google Scholar] [CrossRef]

- Zuo, J.; Rameezdeen, R.; Hagger, M.; Zhou, Z.; Ding, Z. Dust pollution control on construction sites: Awareness and self-responsibility of managers. J. Clean. Prod. 2017, 166, 312–320. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Bilal, M.; Akinade, O.O.; Alaka, H.A.; Owolabi, H.A.; Kadiri, K.O. Waste effectiveness of the construction industry: Understanding the impediments and requisites for improvements. Resour. Conserv. Recycl. 2015, 102, 101–112. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Owolabi, H.A.; Alaka, H.A.; Kadiri, K.O. Reducing waste to landfill: A need for cultural change in the UK construction industry. J. Build. Eng. 2016, 5, 185–193. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Alaka, H.A.; Owolabi, H.A. Optimising material procurement for construction waste minimization: An exploration of success factors. Sustain. Mater. Technol. 2017, 11, 38–46. [Google Scholar] [CrossRef]

- Gbadamosi, A.-Q.; Mahamadu, A.-M.; Oyedele, L.O.; Akinade, O.O.; Manu, P.; Mahdjoubi, L.; Aigbavboa, C. Offsite Construction: Developing a BIM-Based Optimizer for Assembly. J. Clean. Prod. 2019, 215, 1180–1190. [Google Scholar] [CrossRef]

- Burger, M.; Stavropoulos, S.; Ramkumar, S.; Dufourmont, J.; van Oort, F. The heterogeneous skill-base of circular economy employment. Res. Policy 2018, 48, 248–261. [Google Scholar] [CrossRef]

- Górecki, J.; Núñez-Cacho, P.; Corpas-Iglesias, F.A.; Molina, V. How to convince players in construction market? Strategies for effective implementation of Circular Economy in construction sector. Cogent Eng. 2019, 6, 6. [Google Scholar] [CrossRef]

- City of Amsterdam; Circle Economy; Kate Raworth. Building Blocks for the New Strategy Amsterdam Circular 2020–2025; City of Amsterdam; Circle Economy; Kate Raworth: Amsterdam, The Netherland, 2019. [Google Scholar]

- Núñez-Cacho, P.; Górecki, J.; Molina-Moreno, V.; Corpas-Iglesias, F.A. New Measures of Circular Economy Thinking In Construction Companies. J. EU Res. Bus. 2018, 2018, 909360. [Google Scholar] [CrossRef]

- Plebankiewicz, E.; Zima, K.; Wieczorek, D. Life Cycle Cost Modelling of Buildings with Consideration of the Risk. Arch. Civ. Eng. 2016, 62, 149–166. [Google Scholar] [CrossRef][Green Version]

- Górecki, J. Circular Economy Maturity in Construction Companies. IOP Conf. Ser. Mater. Sci. Eng. 2018, 471, 112090. [Google Scholar] [CrossRef]

- Leśniak, A.; Zima, K. Cost calculation of construction projects including sustainability factors using the Case Based Reasoning (CBR) method. Sustainability 2018, 10, 1608. [Google Scholar] [CrossRef]

- Shahhosseini, V.; Sebt, M.H. Competency-based selection and assignment of human resources to construction projects. Sci. Iran. 2011, 18, 163–180. [Google Scholar] [CrossRef]

- Kabak, M. A fuzzy DEMATEL-ANP based multi criteria decision making approach for personnel selection. J. Mult.-Valued Log. Soft Comput. 2013, 20, 571–593. [Google Scholar]

- Zavadskas, E.K.; Vainiunas, P.; Turskis, Z.; Tamosaitiene, J. Multiple Criteria Decision Support system for assessment of projects managers in construction. Int. J. Inf. Technol. Decis. Mak. 2012, 11, 501–520. [Google Scholar] [CrossRef]

- Karabasevic, D.; Zavadskas, E.K.; Turskis, Z.; Stanujkic, D. The framework for the selection of personnel based on the SWARA and ARAS methods under uncertainties. Informatica 2016, 27, 49–65. [Google Scholar] [CrossRef]

- Dursun, M.; Karsak, E.E. A fuzzy MCDM approach for personnel selection. Expert Syst. Appl. 2010, 37, 4324–4330. [Google Scholar] [CrossRef]

- Polychroniou, P.V.; Giannikos, I. A fuzzy multicriteria decision-making methodology for selection of human resources in a Greek private bank. Career Dev. Int. 2009, 14, 372–387. [Google Scholar] [CrossRef]

- Safarzadegan Gilan, S.; Sebt, M.H.; Shahhosseini, V. Computing with words for hierarchical competency based selection of personnel in construction companies. Appl. Soft Comput. 2012, 12, 860–871. [Google Scholar] [CrossRef]

- Afshari, A.R.; Mojahed, M.; Yusuff, R.M. Simple Additive Weighting approach to personnel selection problem. Int. J. Innov. Manag. Technol. 2010, 1, 511–515. [Google Scholar]

- Afshari, A.R.; Yusuff, R.; Derayatifar, A.R. Project manager selection by using Fuzzy Simple Additive Weighting method. In Proceedings of the 2012 International Conference on Innovation Management and Technology Research, Malacca, Malaysia, 21–22 May 2012; pp. 412–416. [Google Scholar]

- Zavadskas, E.K.; Turskis, Z.; Tamošaitienė, J.; Marina, V. Selection of construction project managers by applying COPRAS-G method. Comput. Model. New Technol. 2008, 12, 22–28. [Google Scholar]

- Kelemenis, A.; Askounis, D. A new TOPSIS-based multi-criteria approach to personnel selection. Expert Syst. Appl. 2010, 37, 4999–5008. [Google Scholar] [CrossRef]

- Afshari, A.R. Methods for selection of construction project manager: Case study. J. Constr. Eng. Manag. 2017, 143, 06017003. [Google Scholar] [CrossRef]

- Afshari, A.R. Selection of construction project manager by using Delphi and fuzzy linguistic decision making. J. Intell. Fuzzy Syst. 2015, 28, 2827–2838. [Google Scholar] [CrossRef]

- Sadatrasool, M.; Bozorgi-Amiri, A.; Yousefi-Babadi, A. Project manager selection based on project manager competency model: PCA–MCDM Approach. J. Proj. Manag. 2016, 1, 7–20. [Google Scholar] [CrossRef]

- Liu, H.-C.; Qin, J.-T.; Mao, L.-X.; Zhang, Z.-Y. Personnel selection using interval 2-tuple linguistic VIKOR method. Hum. Factors Ergon. Manuf. 2015, 25, 370–381. [Google Scholar] [CrossRef]

- Chen, P.-C. A fuzzy Multiple Criteria Decision Making model in employee recruitment. Int. J. Comput. Sci. Netw. Secur. 2009, 9, 113–117. [Google Scholar]

- Fahmy Aly, M.; Abd El-hameed, H.M. Integrating AHP and genetic algorithm model adopted for personal selection. Int. J. Eng. Trends Technol. 2013, 6, 247–256. [Google Scholar]

- Güngör, Z.; Serhadlıoğlu, G.; Kesen, S.E. A fuzzy AHP approach to personnel selection problem. Appl. Soft Comput. 2009, 9, 641–646. [Google Scholar] [CrossRef]

- Taylor, F.A.; Ketcham, A.F.; Hoffman, D. Personnel evaluation with AHP. Manag. Decis. 1998, 36, 679–685. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Turskis, Z.; Tamošaitienė, J.; Marina, V. Multicriteria selection of project managers by applying grey criteria. Technol. Econ. Dev. Econ. 2008, 14, 462–477. [Google Scholar] [CrossRef]

- Boran, S.; Göztepe, K.; Yavuz, E. A study on election of personnel based on performance measurement by using Analytic Network Process (ANP). Int. J. Comput. Sci. Netw. Secur. 2008, 8, 333–338. [Google Scholar]

- Varajão, J.; Cruz-Cunha, M.M. Using AHP and the IPMA Competence Baseline in the project managers selection process. Int. J. Prod. Res. 2013, 51, 3342–3354. [Google Scholar] [CrossRef]

- Zhao, L.; Guo, Y.; Cui, W. The application of fuzzy comprehensive evaluation methods in the selection of a project manager. In Proceedings of the 2009 Fourth International Conference on Computer Sciences and Convergence Information Technology, Seoul, Korea, 24–26 November 2009; pp. 1387–1391. [Google Scholar]

- Rashidi, A.; Jazebi, F.; Brilakis, I. Neurofuzzy Genetic System for Selection of Construction Project Managers. J. Constr. Eng. Manag. 2011, 137, 17–29. [Google Scholar] [CrossRef]

- Jazebi, F.; Rashidi, A. An automated procedure for selecting project managers in construction firms. J. Civ. Eng. Manag. 2013, 19, 97–106. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, X.-Q.; Yu, G.; Zhang, L.-F. Study on engineering project manager selection. In Proceedings of the 2008 4th International Conference on Wireless Communications, Networking and Mobile Computing, Dalian, China, 12–17 October 2008; pp. 1–4. [Google Scholar]

- Hadad, Y.; Keren, B.; Laslo, Z. A decision-making support system module for project manager selection according to past performance. Int. J. Proj. Manag. 2013, 31, 532–541. [Google Scholar] [CrossRef]

- Lin, H.-T. Personnel selection using analytic network process and fuzzy data envelopment analysis approaches. Comput. Ind. Eng. 2010, 59, 937–944. [Google Scholar] [CrossRef]

- Turskis, Z.; Zavadskas, E.K. A novel method for multiple criteria analysis: Grey Additive Ratio Assessment (ARAS-G) method. Informatica 2010, 21, 597–610. [Google Scholar]

- Baležentis, A.; Baležentis, T.; Brauers, W.K.M. Personnel selection based on computing with words and fuzzy MULTIMOORA. Expert Syst. Appl. 2012, 39, 7961–7967. [Google Scholar] [CrossRef]

- Kabak, M.; Burmaoǧlu, S.; Kazançoǧlu, Y. A fuzzy hybrid MCDM approach for professional selection. Expert Syst. Appl. 2012, 39, 3516–3525. [Google Scholar] [CrossRef]

- Dağdeviren, M. A hybrid multi-criteria decision-making model for personnel selection in manufacturing systems. J. Intell. Manuf. 2010, 21, 451–460. [Google Scholar] [CrossRef]

- Jafarnejad Chaghooshi, A.; Arab, A.; Hosseini Dehshiri, S.J. A fuzzy hybrid approach for project manager selection. Decis. Sci. Lett. 2016, 5, 447–460. [Google Scholar] [CrossRef]

- Mohammadi, F.; Sadi, M.K.; Nateghi, F.; Abdullah, A.; Skitmore, M. A hybrid Quality Function Deployment and Cybernetic Analytic Network Process model for project manager selection. J. Civ. Eng. Manag. 2014, 20, 795–809. [Google Scholar] [CrossRef]

- Kazan, H.; Özçelik, S.; Hobikoğlu, E.H. Election of deputy candidates for nomination with AHP-Promethee methods. Procedia-Soc. Behav. Sci. 2015, 195, 603–613. [Google Scholar] [CrossRef]

- Keršuliene, V.; Zavadskas, E.K.; Turskis, Z. Selection of rational dispute resolution method by applying new step-wise weight assessment ratio analysis (SWARA). J. Bus. Econ. Manag. 2010, 11, 243–258. [Google Scholar] [CrossRef]

- Karabasevic, D.; Stanujkic, D.; Urosevic, S.; Maksimovic, M. Selection of candidates in the mining industry based on the application of the SWARA and the MULTIMOORA methods. Acta Montan. Slovaca 2015, 20, 116–124. [Google Scholar]

- Karabašević, D.; Stanujkić, D.; Urošević, S.; Maksimović, M. An approach to personnel selection based on SWARA and WASPAS methods. J. Econ. Manag. Inform. 2016, 7, 1–11. [Google Scholar]

- Stanujkic, D.; Karabasevic, D.; Zavadskas, E.K. A new approach for selecting alternatives based on the adapted Weighted Sum and the SWARA methods: A case of personnel selection. Econ. Comput. Econ. Cybern. Stud. Res. 2017, 51, 39–56. [Google Scholar]

- Zavadskas, E.K.; Turskis, Z.; Antucheviciene, J.; Zakarevicius, A. Optimization of weighted aggregated sum product assessment. Elektron. ir Elektrotechnika 2012, 122, 3–6. [Google Scholar] [CrossRef]

- Kosareva, N.; Kazimieras Zavadskas, E.; Krylovas, A.; Dadelo, S. Personnel ranking and selection problem solution by application of KEMIRA method. Int. J. Comput. Commun. Control 2015, 11, 51. [Google Scholar] [CrossRef]

- Xu, X. The SIR method: A superiority and inferiority ranking method for multiple criteria decision making. Eur. J. Oper. Res. 2001, 131, 587–602. [Google Scholar] [CrossRef]

- Rezaei, J. Best-worst multi-criteria decision-making method. Omega 2015, 53, 49–57. [Google Scholar] [CrossRef]

- Müller, R.; Turner, R. Leadership competency profiles of successful project managers. Int. J. Proj. Manag. 2010, 28, 437–448. [Google Scholar] [CrossRef]

- Tabassi, A.A.; Roufechaei, K.M.; Ramli, M.; Bakar, A.H.A.; Ismail, R.; Pakir, A.H.K. Leadership competences of sustainable construction project managers. J. Clean. Prod. 2016, 124, 339–349. [Google Scholar] [CrossRef]

- De los Rios, I.C.; Charnley, F.J.S. Skills and capabilities for a sustainable and circular economy: The changing role of design. J. Clean. Prod. 2017, 160, 109–122. [Google Scholar] [CrossRef]

- Lambrechts, W.; Gelderman, C.J.; Semeijn, J.; Verhoeven, E. The role of individual sustainability competences in eco-design building projects. J. Clean. Prod. 2019, 208, 1631–1641. [Google Scholar] [CrossRef]

- Sahakian, M.; Seyfang, G. A sustainable consumption teaching review: From building competencies to transformative learning. J. Clean. Prod. 2018, 198, 231–241. [Google Scholar] [CrossRef]

| Method | References | Method | References |

|---|---|---|---|

| ANFIS | [43] | (Fuzzy) DEMATEL | [44] |

| ARAS | [45,46] | Fuzzy MCDM | [47,48] |

| Computing with words | [49] | (Fuzzy) SAW | [50,51] |

| COPRAS-G | [52] | (Fuzzy) TOPSIS | [53] |

| Delphi and fuzzy linguistic | [54,55] | (Fuzzy) VIKOR | [56,57] |

| (Fuzzy) AHP | [43,58,59,60,61] | Grey Relational Analysis | [62] |

| (Fuzzy) ANP | [44,63] | IPMA Competence Baseline | [64] |

| Fuzzy Comprehensive Evaluation | [65] | Neuro-fuzzy Genetic System | [66] |

| Fuzzy curves | [67] | Principal Component Analysis | [68] |

| (Fuzzy) Data Envelopment Analysis | [69,70] | Hybrid methods | [43,44,54,55,71,72,73,74,75,76] |

| Group | Name of Criterion | Type of Criterion | References |

|---|---|---|---|

| Basic skills (BS) | Active learning | UC | [36] |

| Active listening | UC | [36] | |

| Critical thinking | UC | [36] | |

| Emotional resilience | UC | [86] | |

| Learning strategies | UC | [36] | |

| Mathematics | UC | [36] | |

| Monitoring | UC | [36] | |

| Motivation | UC | [86] | |

| Reading comprehension | UC | [36] | |

| Science (applicability to solve problems) | UC | [36] | |

| Self-awareness | UC | [86] | |

| Speaking | UC | [36] | |

| Writing | UC | [36] | |

| Complex problem solving skills (CPSS) | Achieving (management) | UC | [86,87] |

| Complex problem solving | UC | [36] | |

| Intuitiveness | UC | [86] | |

| Solve aesthetic and structural problems with limited supplied components | UC | [88] | |

| Strategic management competence and action competence | UC | [89,90] | |

| Strategic perspective | UC | [86,87] | |

| Understand failure mode and maintenance procedures | UC | [88] | |

| Vision and imagination | UC | [86,87] | |

| Resource management skills (RMS) | Management of financial resources | UC | [36] |

| Management of material resources | SC | [36] | |

| Management of personnel resources | SC | [36] | |

| Resource management | SC | [86,87] | |

| Time management | UC | [36] | |

| Understand logistics and distribution processes | SC | [88] | |

| Understand processes for reverse and re-manufacturing | SC | [88] | |

| Social skills (SLS) | Conscientiousness | UC | [86] |

| Coordination | UC | [36] | |

| Developing (management) | UC | [86,87] | |

| Developing followers into leaders | UC | [87] | |

| Empowering (management) | UC | [86,87] | |

| Engaging communication | UC | [86,87] | |

| Influence | UC | [86] | |

| Inspire followers to go beyond their own interest | UC | [87] | |

| Instructing | UC | [36] | |

| Interpersonal competence | UC | [89,90] | |

| Interpersonal sensitivity | UC | [86] | |

| Negotiation | UC | [36] | |

| Normative competence | UC | [89,90] | |

| Persuasion | UC | [36] | |

| Service orientation | UC | [36] | |

| Social perceptiveness | UC | [36] | |

| System skills (SSS) | Critical analysis and judgement | UC | [86,87] |

| Embracing diversity and interdisciplinary competence | UC | [89] | |

| Foresighted thinking or anticipatory competence | UC | [89,90] | |

| Judgment and decision making | UC | [36] | |

| Systems analysis | UC | [36] | |

| Systems evaluation | UC | [36] | |

| Systems thinking competence | UC | [89,90] | |

| Understand factors of the use experience | SC | [88] | |

| Understand product wear by use | SC | [88] | |

| Understand user expectations and perception of value | SC | [88] | |

| Technical skills (TS) | Assess material physical and chemical properties | SC | [88] |

| Equipment maintenance | SC | [36] | |

| Equipment selection | SC | [36] | |

| Installation | SC | [36] | |

| Operation and control | SC | [36] | |

| Operation monitoring | SC | [36] | |

| Operations analysis | SC | [36] | |

| Programming (IT skills) | UC | [36] | |

| Quality control analysis | SC | [36] | |

| Repairing (ability) | SC | [36] | |

| Technology design | SC | [36] | |

| Troubleshooting (with operating errors) | SC | [36] | |

| Understand engineering functions of the product | SC | [88] | |

| Understand the service experience and how to design services | SC | [88] |

| Factor | Name of Criterion | Weighted Average | Min | Max | Rank | Reliability |

|---|---|---|---|---|---|---|

| X1,1 | Motivation | 4.41 | 1 | 5 | 1 | 81,48 |

| X1,2 | Critical thinking | 4.37 | 1 | 5 | 2 | 81,11 |

| X1,3 | Active learning | 4.19 | 1 | 5 | 3 | 81,11 |

| X1,4 | Monitoring | 4.04 | 3 | 5 | 4 | 75,93 |

| X1,5 | Active listening | 3.96 | 1 | 5 | 5–6 | 75,19 |

| X1,6 | Learning strategies | 3.96 | 1 | 5 | 5–6 | 76,67 |

| X1,7 | Science (applicability to solve problems) | 3.89 | 1 | 5 | 7 | 79,26 |

| X1,8 | Self-awareness | 3.85 | 2 | 5 | 8 | 74,07 |

| X1,9 | Reading comprehension | 3.81 | 2 | 5 | 9 | 71,85 |

| X1,10 | Emotional resilience | 3.74 | 2 | 5 | 10 | 71,48 |

| X1,11 | Speaking | 3.70 | 1 | 5 | 11 | 68,89 |

| X1,12 | Mathematics | 3.56 | 1 | 5 | 12 | 71,48 |

| X1,13 | Writing | 3.52 | 1 | 5 | 13 | 68,15 |

| X2,1 | Vision and imagination | 4.48 | 2 | 5 | 1 | 78 |

| X2,2 | Strategic perspective | 4.4 | 2 | 5 | 2 | 78 |

| X2,3 | CompleXproblem solving | 4.36 | 3 | 5 | 3 | 78,8 |

| X2,4 | Achieving (management) | 4.32 | 3 | 5 | 4 | 82,4 |

| X2,5 | Understand failure mode and maintenance procedures | 4.16 | 1 | 5 | 5 | 82 |

| X2,6 | Strategic management competence and action competence | 4.08 | 2 | 5 | 6 | 74,8 |

| X2,7 | Intuitiveness | 4 | 2 | 5 | 7 | 73,2 |

| X2,8 | Solve aesthetic and structural problems with limited supplied components | 3.76 | 1 | 5 | 8 | 69,2 |

| X3,1 | Management of material resources | 4.45 | 3 | 5 | 1–2 | 87,27 |

| X3,2 | Resource management | 4.45 | 3 | 5 | 1–2 | 83,64 |

| X3,3 | Time management | 4.32 | 3 | 5 | 3 | 81,82 |

| X3,4 | Management of personnel resources | 4.27 | 3 | 5 | 4 | 83,64 |

| X3,5 | Management of financial resources | 4.18 | 2 | 5 | 5–6 | 82,73 |

| X3,6 | Understand processes for reverse and re-manufacturing | 4.18 | 1 | 5 | 5–6 | 78,64 |

| X3,7 | Understand logistics and distribution processes | 4.14 | 2 | 5 | 7 | 76,36 |

| X4,1 | Developing (management) | 4.21 | 3 | 5 | 1 | 78,42 |

| X4,2 | Inspire followers to go beyond their own interest | 4.11 | 2 | 5 | 2 | 74,21 |

| X4,3 | Coordination | 4.05 | 2 | 5 | 3–5 | 76,32 |

| X4,4 | Empowering (management) | 4.05 | 2 | 5 | 3–5 | 76,84 |

| X4,5 | Negotiation | 4.05 | 3 | 5 | 3–5 | 78,95 |

| X4,6 | Engaging communication | 4 | 2 | 5 | 6 | 74,74 |

| X4,7 | Conscientiousness | 3.95 | 3 | 5 | 7–9 | 76,84 |

| X4,8 | Interpersonal competence | 3.95 | 3 | 5 | 7–9 | 70 |

| X4,9 | Persuasion | 3.95 | 3 | 5 | 7–9 | 74,74 |

| X4,10 | Influence | 3.89 | 1 | 5 | 10–11 | 75,26 |

| X4,11 | Instructing | 3.89 | 2 | 5 | 10–11 | 76,84 |

| X4,12 | Developing followers into leaders | 3.84 | 1 | 5 | 12 | 75,26 |

| X4,13 | Interpersonal sensitivity | 3.79 | 2 | 5 | 13–14 | 68,95 |

| X4,14 | Normative competence | 3.79 | 3 | 5 | 13–14 | 76,32 |

| X4,15 | Service orientation | 3.74 | 2 | 5 | 15 | 71,58 |

| X4,16 | Social perceptiveness | 3.68 | 1 | 5 | 16 | 68,42 |

| X5,1 | Systems evaluation | 4.32 | 3 | 5 | 1 | 80,53 |

| X5,2 | Critical analysis and judgement | 4.26 | 3 | 5 | 2–3 | 78,42 |

| X5,3 | Systems analysis | 4.26 | 2 | 5 | 2–3 | 77,89 |

| X5,4 | Foresighted thinking –or anticipatory– competence | 4.16 | 2 | 5 | 4–5 | 78,42 |

| X5,5 | Systems thinking competence | 4.16 | 2 | 5 | 4–5 | 75,79 |

| X5,6 | Judgment and decision making | 4.11 | 2 | 5 | 6 | 80 |

| X5,7 | Understand user expectations and perception of value | 4.05 | 2 | 5 | 7 | 75,79 |

| X5,8 | Embracing diversity and interdisciplinary competence | 3.89 | 1 | 5 | 8–9 | 73,16 |

| X5,9 | Understand factors of the use experience | 3.89 | 1 | 5 | 8–9 | 74,74 |

| X5,10 | Understand product wear by use | 3.84 | 1 | 5 | 10 | 74,74 |

| X6,1 | Operation monitoring | 4.05 | 1 | 5 | 1 | 77,37 |

| X6,2 | Equipment selection | 3.95 | 1 | 5 | 2 | 72,11 |

| X6,3 | Operation and control | 3.89 | 2 | 5 | 3–4 | 74,21 |

| X6,4 | Operations analysis | 3.89 | 2 | 5 | 3–4 | 77,37 |

| X6,5 | Quality control analysis | 3.84 | 2 | 5 | 5–6 | 73,68 |

| X6,6 | Technology Design | 3.84 | 1 | 5 | 5–6 | 68,42 |

| X6,7 | Programming (IT skills) | 3.79 | 2 | 5 | 7–9 | 78,42 |

| X6,8 | Troubleshooting (with operating errors) | 3.79 | 2 | 5 | 7–9 | 72,11 |

| X6,9 | Understand engineering functions of the product | 3.79 | 1 | 5 | 7–9 | 77,37 |

| X6,10 | Understand the service experience and how to design services | 3.74 | 1 | 5 | 10 | 74,74 |

| X6,11 | Assess material physical and chemical properties | 3.53 | 1 | 5 | 11–12 | 64,74 |

| X6,12 | Installation | 3.53 | 1 | 5 | 11–12 | 70,53 |

| X6,13 | Equipment maintenance | 3.47 | 1 | 5 | 13 | 67,89 |

| X6,14 | Repairing (ability) | 3.37 | 1 | 5 | 14 | 70,53 |

| Factors | Cut-Off Score Group | Deterministic | Probabilistic | ||

|---|---|---|---|---|---|

| Mean | Min | Max | Median | ||

| XBS,j | Basic skills | 3.923 | 0.895 | 3.923 | 3.023 |

| XCPSS,j | Complex problem solving skills | 4.195 | 1.100 | 4.195 | 3.180 |

| XRMS,j | Resource management skills | 4.284 | 1.194 | 4.284 | 3.667 |

| XSL:S,j | Social skills | 3.934 | 1.487 | 3.934 | 2.954 |

| XSSS,j | Systems skills | 4.094 | 1.610 | 4.094 | 3.263 |

| XTS,j | Technical skills | 3.748 | 1.324 | 3.748 | 2.703 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Górecki, J. Simulation-Based Positioning of Circular Economy Manager’s Skills in Construction Projects. Symmetry 2020, 12, 50. https://doi.org/10.3390/sym12010050

Górecki J. Simulation-Based Positioning of Circular Economy Manager’s Skills in Construction Projects. Symmetry. 2020; 12(1):50. https://doi.org/10.3390/sym12010050

Chicago/Turabian StyleGórecki, Jarosław. 2020. "Simulation-Based Positioning of Circular Economy Manager’s Skills in Construction Projects" Symmetry 12, no. 1: 50. https://doi.org/10.3390/sym12010050

APA StyleGórecki, J. (2020). Simulation-Based Positioning of Circular Economy Manager’s Skills in Construction Projects. Symmetry, 12(1), 50. https://doi.org/10.3390/sym12010050