Research on Collaborative Planning and Symmetric Scheduling for Parallel Shipbuilding Projects in the Open Distributed Manufacturing Environment

Abstract

1. Introduction

2. Literature Review

2.1. Shipbuilding Project Planning and Scheduling

2.2. Resource Constrained Project Scheduling

2.3. Symmetric Decision-Making

2.4. Conclusions on the Reviewed Literature

- (1)

- Conduct a deep analysis of the shipbuilding project planning and scheduling processes to find the relationship between tasks;

- (2)

- Define the unified mathematical model. Through mathematical methods, a unified mathematical model is constructed to link the whole project planning with the scheduling process;

- (3)

- In view of the success of MAS theory in system modeling, draw lessons from existing research and find suitable methods to build the framework of planning and scheduling with the characteristic of symmetric collaborative decision making and design the negotiation method and scheduling strategy.

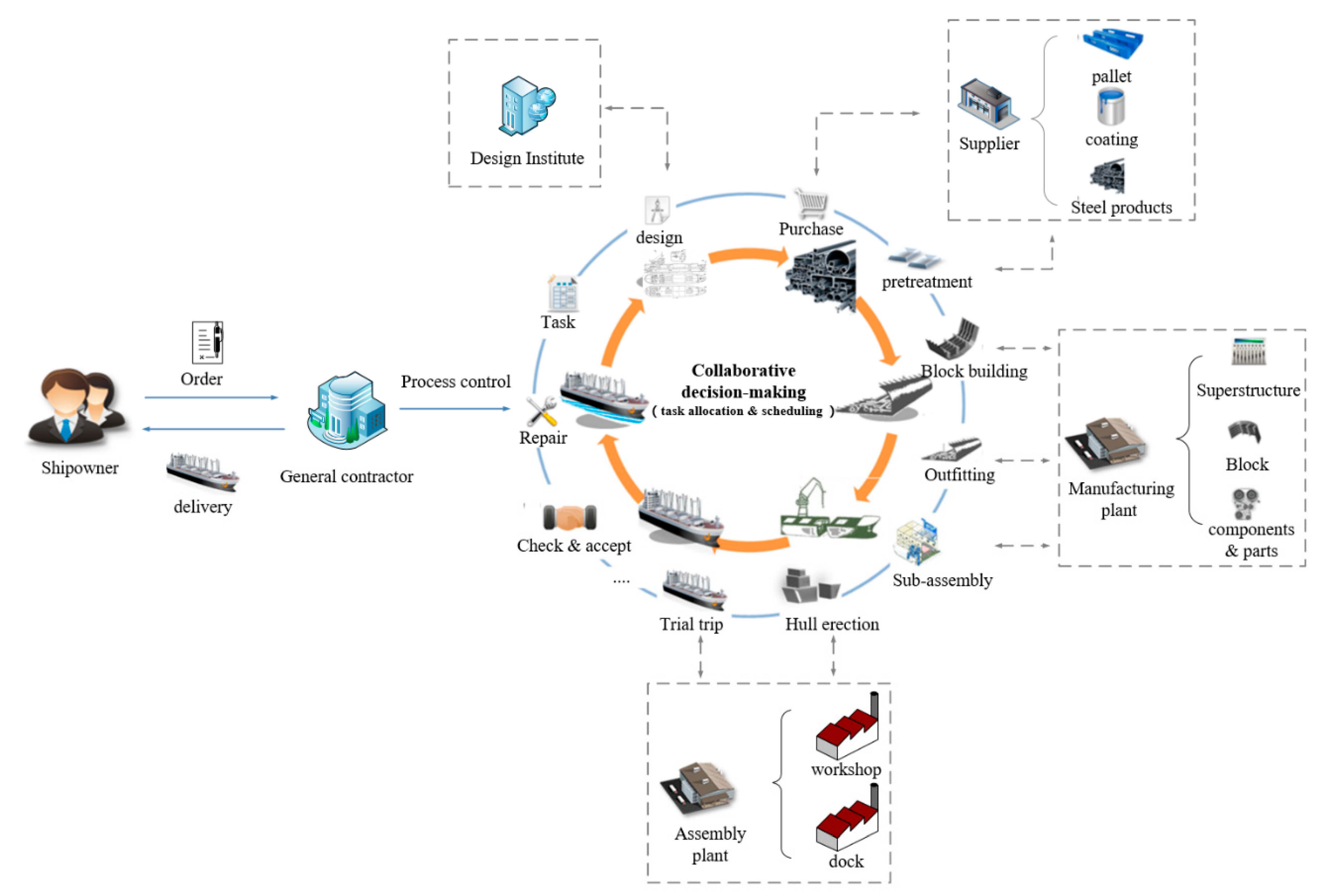

3. The Shipbuilding Projects’ Collaborative Planning and Symmetric Scheduling Process

3.1. Project Planning and Scheduling Process

- According to the requirements of the order contract, the general contractor of each project sets the overall goal of the project and breaks down the project into multiple tasks;

- The general contractor publishes the task requirements to qualified cooperative enterprises with the ability to complete the task, and negotiates with them to determine the scheduling plan for each task;

- The project planning scheme is a combination of these task scheduling schemes. The logical constraints between tasks can be considered and obtained through local scheduling optimization;

- Multiple projects are planned simultaneously, and these projects are independent of each other. Therefore, resource conflicts occur from time to time and need to be resolved by the resource owner;

- The general contractor and the cooperating enterprise conduct multiple rounds of negotiation according to their respective goals to determine the subcontractor and corresponding scheduling plan for each task.

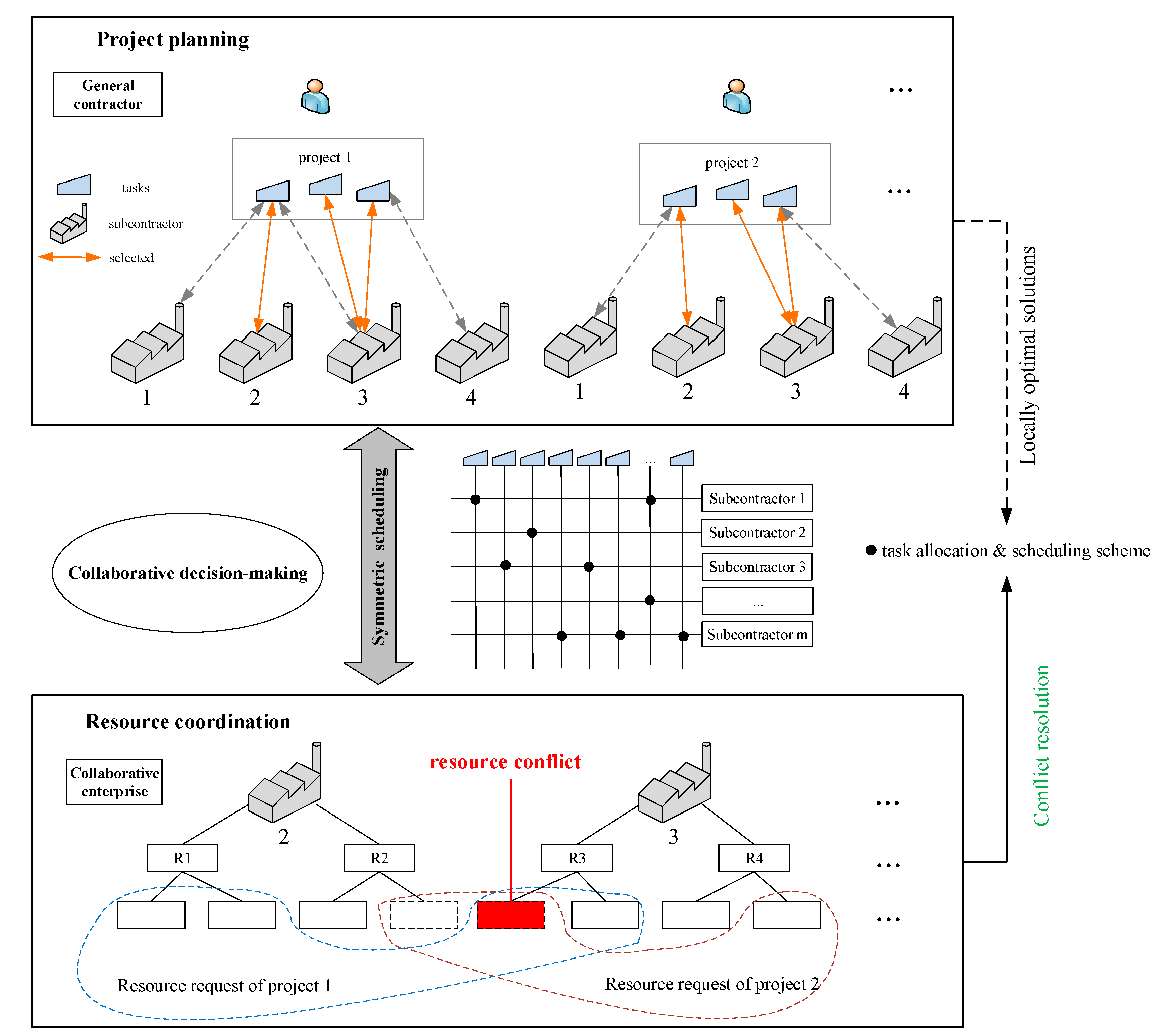

3.2. Symmetric Collaborative Decision-Making Process

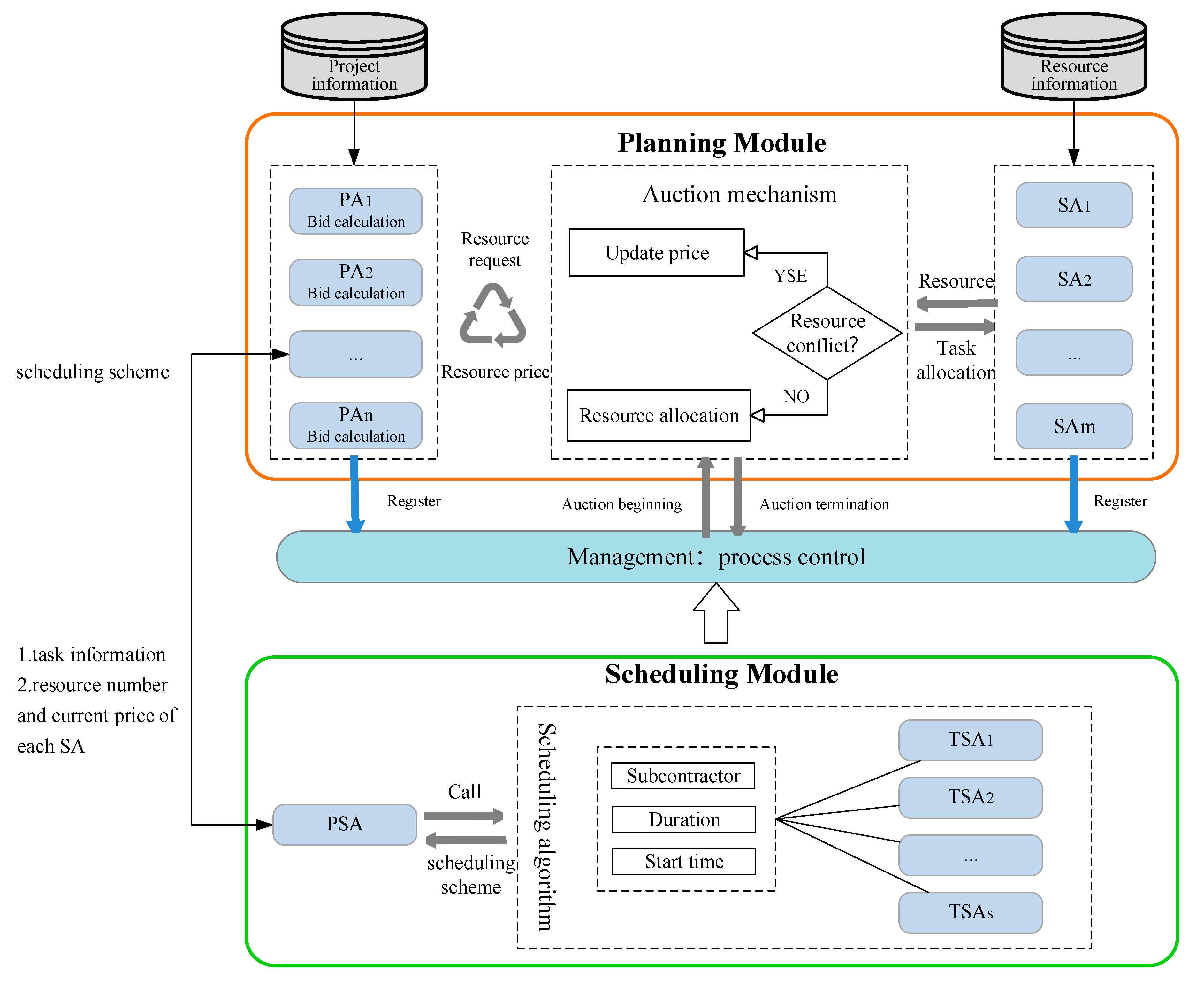

4. Symmetric Collaborative Decision-Making System

4.1. The System Framework

- Management Agent: Responsible for managing the overall system. When new projects and project plans need to be adjusted, the MA opens the project planning function of the system. In the planning process, the MA receives and verifies the PAs and SAs; then, the MA organizes the project planning and the auction process;

- Project Agent: Each project sets up one PA to complete the project planning and realize the project objective. After receiving the project information, the PA sends the registration requests to the MA, breaks the project down into numerous executable tasks by analyzing the order demand information, identifies qualified subcontractors, and inquires into the manufacturing efficiency and resource price for all tasks. Based on the auction mechanism and the project objective, PAs then adjust and finalize the project plans, determining the subcontractor and completion plan of each task;

- Subcontractor Agent: Each subcontractor sets up one SA to complete the related operations during the project, who provides the resource information to each PA, including manufacturing efficiency and resource price. Based on the auction mechanism and local objectives, SAs assist in finalizing the project plan;

- Project Schedule Agent: The PSA determines the resource use plan based on a local scheduling algorithm and sends the resource use plan to the PA.

- Task Schedule Agent: The TSA formulates the specific scheduling scheme based on the information of resources and tasks.

4.2. Project Planning Module

4.2.1. Mathematical Formulation

| Parameters | |

| Number of projects required to complete | |

| Project code | |

| Delivery date of | |

| Deadline for delivery of | |

| Fine coefficient for delay of | |

| Time window of | |

| Number of tasks of project | |

| Task code | |

| Total workload of | |

| The predecessor group of | |

| Number of qualified cooperative enterprises | |

| Enterprise code | |

| Types of available resources of | |

| Resource code | |

| Total available amount of | |

| Unit resource using cost of at time t | |

| Types of variable resources of | |

| Types of fixed resources of | |

| Candidate subcontractors group of | |

| Minimum inputs of combination resource | |

| Minimum resource input of in | |

| Workload per unit time accomplished by minimum resource inputs | |

| Duration in one scheme of completed by | |

| Start time in one scheme of completed by | |

| Resources inputs of in one scheme of | |

| Input amount of per unit time in one scheme of | |

| Variable resources inputs of in one scheme of | |

| Fixed resources inputs of in one scheme of | |

| Input amount of at the last time slot of | |

| The earliest and the latest finish time window of | |

| Quality of completed by | |

| Decision Variables | |

| If is assigned to and completed at time period t, ; else, . | |

| Production efficiency, representing the variable resource input per unit of time | |

| Objective Function | |

| The final time of project | |

| The delay penalty for project | |

| The resources cost of | |

| Total cost of project | |

| Total quality of project | |

- (1)

- If task completed by enterprise , the quality is constant;

- (2)

- The task duration is affected by the inputs of the resource, which is up to subcontractor to negotiate with the general contractor;

- (3)

- The start time is later than the end time of the predecessor tasks.

4.2.2. Iterative Combinational Auction-Based Negotiation Method

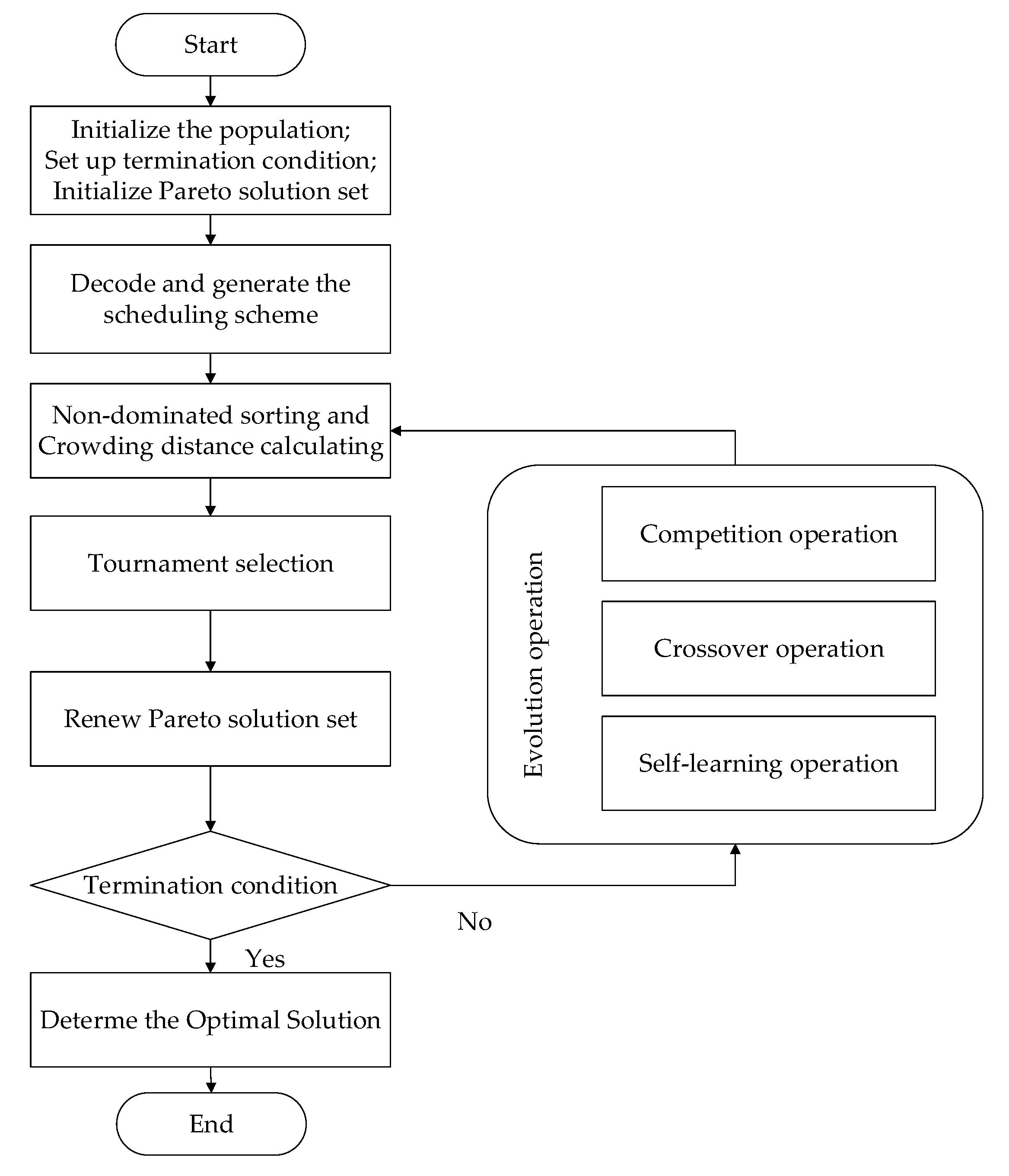

4.3. Task Scheduling Module

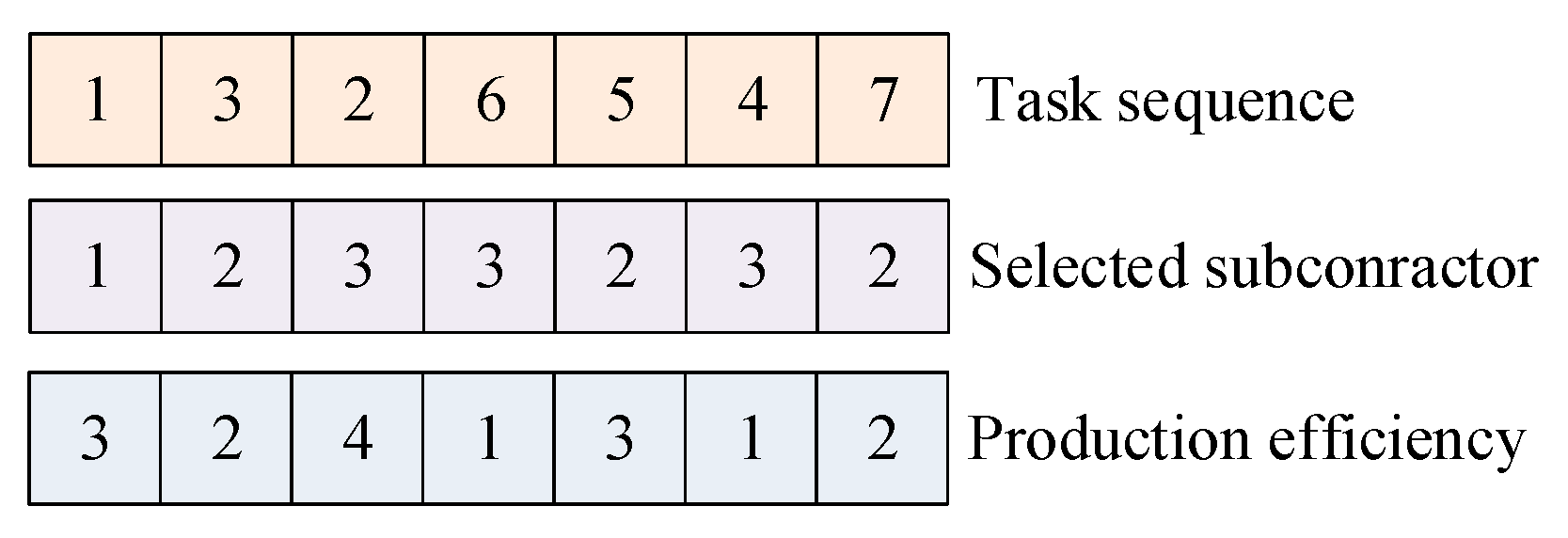

4.3.1. Encoding and Decoding

| the unscheduled task matrix order by the scheduling sequence | |

| the scheduled task matrix | |

| the task with premier order in matrix | |

| the predecessor group of task | |

| the earliest start time of task | |

| the earliest finish time of task | |

| the latest start time of task | |

| the latest finish time of task | |

| the start time of task j | |

| the finish time of task j | |

| the order of task j | |

| the selected subcontractor of task j | |

| the duration of task j | |

| the resource requirement of task j |

| Algorithm 1: Schedule Generation |

|

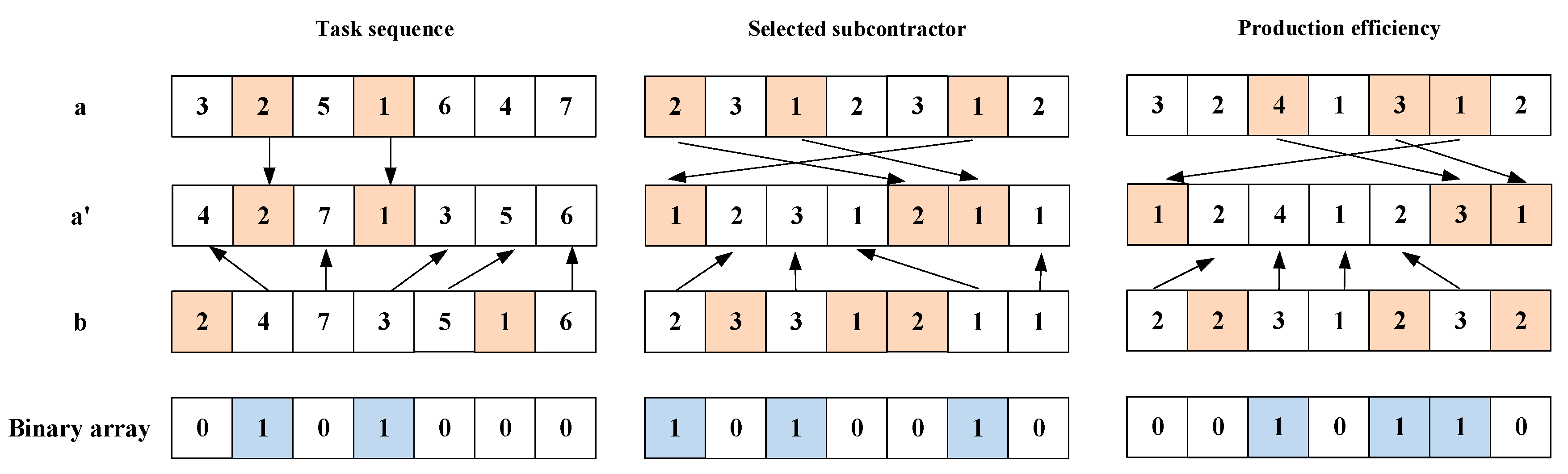

4.3.2. Initialize the Population

4.3.3. Rapid Non-Dominated Sorting and Tournament Selection

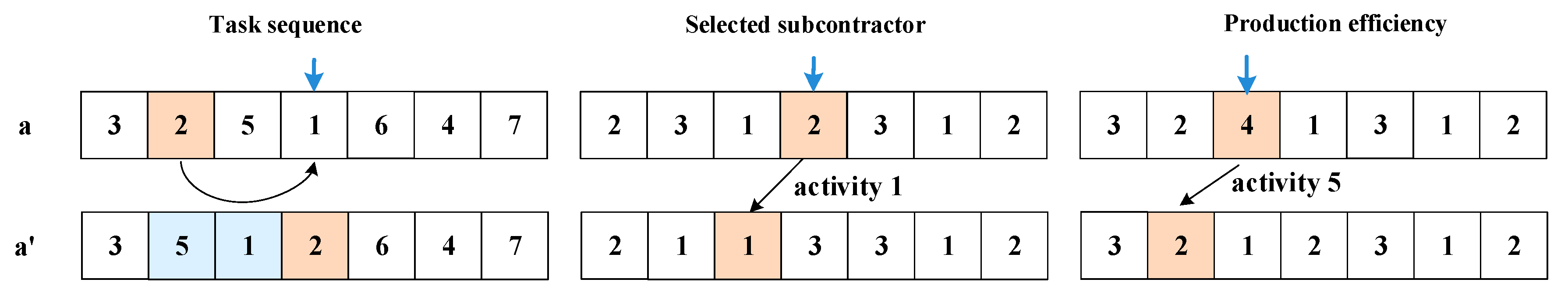

4.3.4. Evolution Operation

| Algorithm 2: Competition Operation |

|

| Algorithm 3: Collaborative Crossover Operation |

|

| Algorithm 4: Self-Learning Operation |

|

4.3.5. Determine the Optimal Scheme

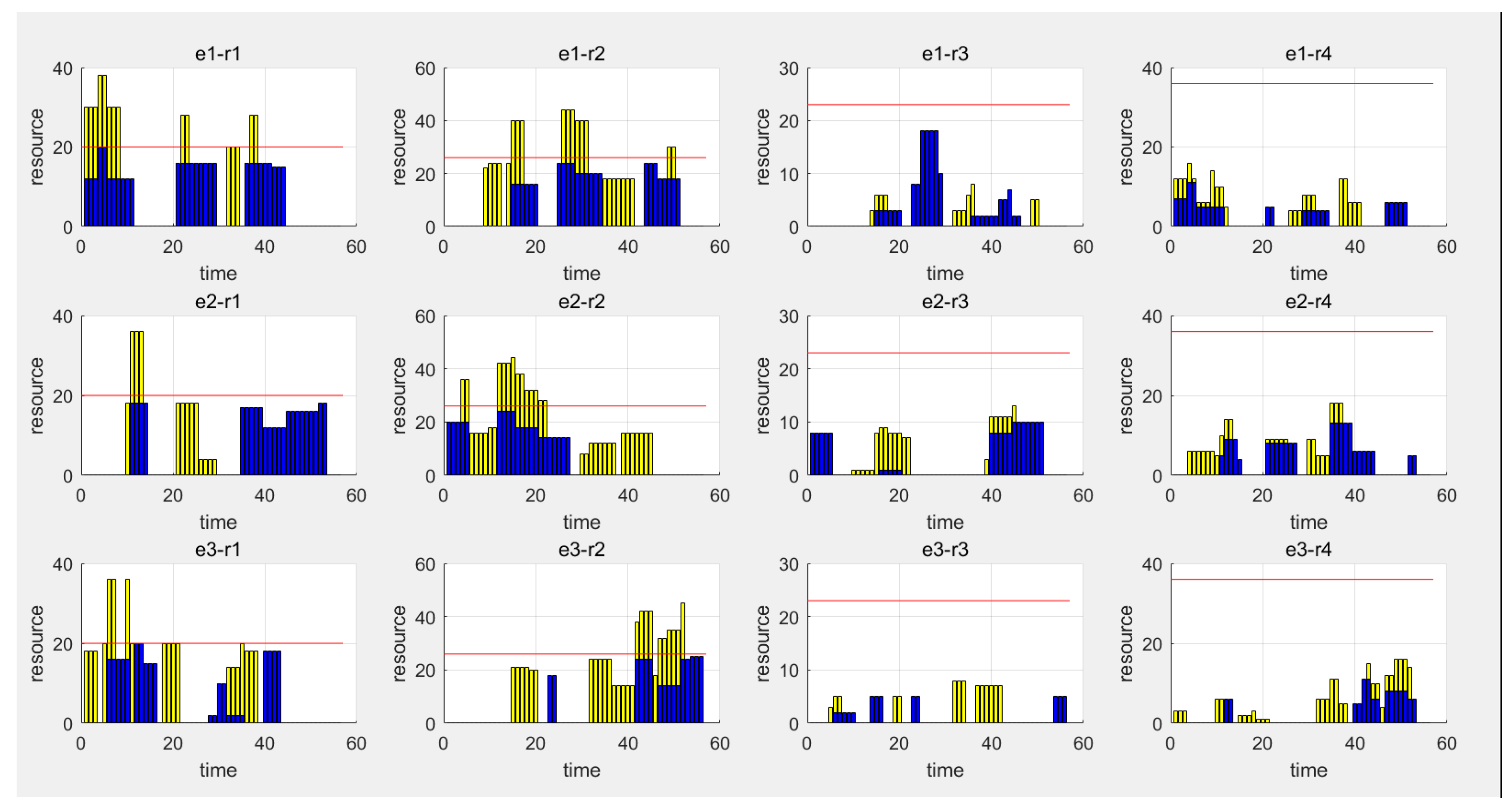

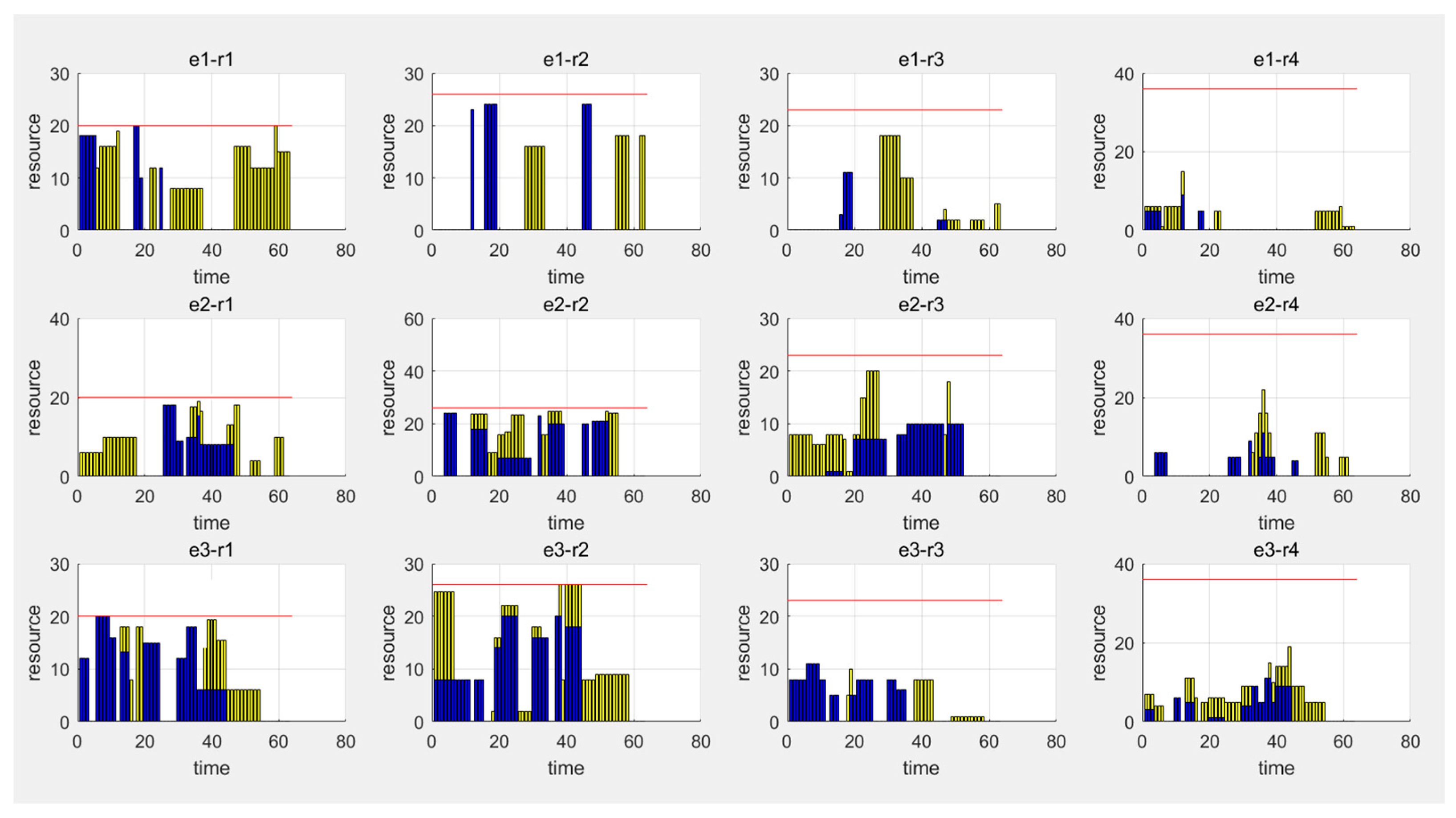

5. Experiment and Results Analysis

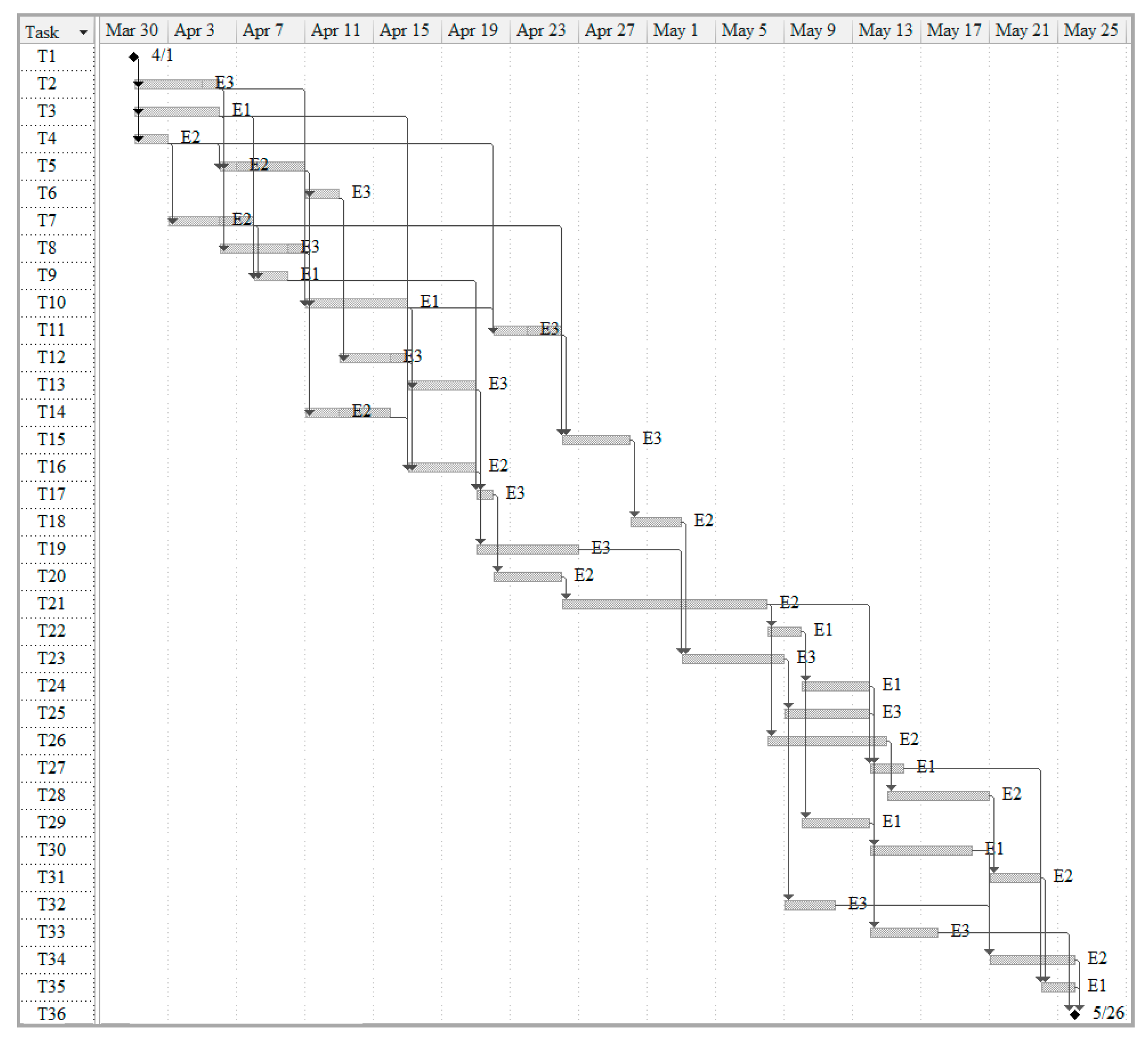

6. An Application Case

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, A.N.; Ma, B.; Loke, D.; Kumar, S.; Chan, Y.Y. Multi-project planning and optimisation for shipyard operations. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management, Hong Kong, China, 10–13 December 2012. [Google Scholar]

- Hossain, K.A.; Golam Zakaria, N.M. A Study on Global Shipbuilding Growth, Trend and Future Forecast. Procedia Eng. 2017, 194, 247–253. [Google Scholar] [CrossRef]

- Han, D.; Yang, B.; Li, J.; Wang, J.; Sun, M.; Zhou, Q. A multi-agent-based system for two-stage scheduling problem of offshore project. Advances Mech. Eng. 2017, 9, 1–17. [Google Scholar] [CrossRef]

- Lee, Y.H.; Kumara, S.R.T.; Chatterjee, K. Multi-agent based dynamic resource scheduling for distributed multiple projects using a market mechanism. J. Intell. Manuf. 2003, 14, 471–484. [Google Scholar] [CrossRef]

- Li, J.; Li, L.; Yang, B.; Zhou, Q. Development of a Collaborative Scheduling System of Offshore Platform Project Based on Multiagent Technology. Advances Mech. Eng. 2014, 298149. [Google Scholar] [CrossRef]

- Järvenpää, E.; Lanz, M.; Siltala, N. Formal Resource and Capability Models supporting Re-use of Manufacturing Resources. Procedia Eng. 2018, 19, 87–94. [Google Scholar]

- Thomas, A.; Singh, G.; Krishnamoorthy, M.; Venkateswaran, J. Distributed optimisation method for multi-resource constrained scheduling in coal supply chains. Int. J. Prod. Res. 2013, 51, 2740–2759. [Google Scholar] [CrossRef]

- Thomas, A.; Venkateswaran, J.; Singh, G.; Krishnamoorthy, M. A resource constrained scheduling problem with multiple independent producers and a single linking constraint: A coal supply chain example. Eur. J. Oper. Res. 2014, 236, 946–956. [Google Scholar] [CrossRef]

- Singh, G.; Ernst, A.T. Resource constraint scheduling with a fractional shared resource. Oper. Res. Lett. 2011, 39, 363–368. [Google Scholar] [CrossRef]

- Tavana, M.; Abtahi, A.R.; Damghani, K.K. A new multi-objective multi-mode model for solving preemptive time-cost-quality trade-off project scheduling problems. Expert Syst. Appl. 2014, 41, 1830–1846. [Google Scholar] [CrossRef]

- Fu, N.; Lau, H.C.; Varakantham, P. Robust execution strategies for project scheduling with unreliable resources and stochastic durations. J. Sched. 2015, 18, 607–622. [Google Scholar] [CrossRef]

- Rostami, S.; Creemers, S.; Leus, R. New strategies for stochastic resource-constrained project scheduling. J. Sched. 2018, 21, 349–365. [Google Scholar] [CrossRef]

- Liu, C.; Xiang, X.; Zheng, L.; Ma, J. An integrated model for multi-resource constrained scheduling problem considering multi-product and resource-sharing. Int. J. Prod. Res. 2018, 56, 6491–6511. [Google Scholar] [CrossRef]

- Lau, J.S.; Huang, G.Q.; Mak, K.L.; Liang, L. Agent-based modeling of supply chains for distributed scheduling. IEEE Trans. Syst. Man Cybern. A Syst. Hum. 2006, 36, 847–861. [Google Scholar] [CrossRef]

- Confessore, G.; Giordani, S.; Rismondo, S. A market-based multi-agent system model for decentralized multi-project scheduling. Ann. Oper. Res. 2007, 150, 115–135. [Google Scholar] [CrossRef]

- Homberger, J. A (μ, λ)-coordination mechanism for agent-based multi-project scheduling. OR Spectr. 2007, 34, 107–132. [Google Scholar] [CrossRef]

- Adhau, S.; Mittal, M.L.; Mittal, A. A multi-agent system for decentralized multi-project scheduling with resource transfers. Int. J. Prod. Econ. 2013, 146, 646–661. [Google Scholar] [CrossRef]

- Zheng, Z.; Guo, Z.; Zhu, Y.; Zhang, X. A critical chains based distributed multi-project scheduling approach. Neurocomputing 2014, 143, 282–293. [Google Scholar] [CrossRef]

- Du, B.; Zhou, H. A robust optimization approach to the multiple allocation p-center facility location problem. Symmetry 2018, 10, 588. [Google Scholar] [CrossRef]

- Liu, L.; Su, J.; Zhao, B.; Wang, Q.; Chen, J.; Luo, Y. Towards an efficient privacy-preserving decision tree evaluation service in the Internet of Things. Symmetry 2020, 12, 103. [Google Scholar] [CrossRef]

- Zeng, S.; Hussain, A.; Mahmood, T.; Ali, M.I.; Ashraf, S.; Munir, M. Covering-based spherical fuzzy rough set model hybrid with TOPSIS for multi-attribute decision-making. Symmetry 2019, 11, 547. [Google Scholar] [CrossRef]

- Kucharska, E. Dynamic vehicle routing problem predictive and unexpected customer availability. Symmetry 2019, 11, 546. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Bausys, R.; Antucheviciene, J. Civil engineering and symmetry. Symmetry 2019, 11, 501. [Google Scholar] [CrossRef]

- Jeong, H.; CHA, K. An ecient mapreduce-based parallel processing framework for user-based collaborative filtering. Symmetry 2019, 11, 748. [Google Scholar] [CrossRef]

- Kim, B.; Byun, H.; Heo, Y.; Jeong, Y. Adaptive job load balancing scheme on mobile cloud computing with collaborative architecture. Symmetry 2017, 9, 65. [Google Scholar] [CrossRef]

- Machuca, M.D.B.; Chinthammit, W.; Huang, W.; Wasinger, R.; Duh, H. Enabling symmetric collaboration in public spaces through 3D mobile interaction. Symmetry 2018, 10, 69. [Google Scholar] [CrossRef]

- Wu, Y.; He, F.; Han, S. Collaborative CAD synchronization based on a symmetric and consistent modeling procedure. Symmetry 2017, 9, 59. [Google Scholar] [CrossRef]

- Dursun, M.; Arslan, Ö. An integrated decision framework for material selection procedure: A case study in a detergent manufacturer. Symmetry 2018, 10, 657. [Google Scholar] [CrossRef]

- Yang, W.; Hu, Y.; Hu, C.; Yang, M. An agent-based simulation of deep foundation pit emergency evacuation modeling in the presence of collapse disaster. Symmetry 2018, 10, 581. [Google Scholar] [CrossRef]

- Wang, L.; Lin, S. A multi-agent based agile manufacturing planning and control system. Comput. Ind. Eng. 2009, 57, 620–640. [Google Scholar] [CrossRef]

- Reddy, R.H.; Kumar, S.K.; Fernandes, K.J.; Tiwari, M.K. A Multi-Agent System based simulation approach for planning procurement operations and scheduling with multiple cross-docks. Comput. Ind. Eng. 2017, 107, 289–300. [Google Scholar] [CrossRef]

- Lu, L.; Wang, G. A study on multi-agent supply chain framework based on network economy. Comput. Ind. Eng. 2008, 54, 288–300. [Google Scholar] [CrossRef]

- Hsu, C.; Kao, B.; Ho, V.; Li, L.; Lai, K.R. An agent-based fuzzy constraint-directed negotiation model for solving supply chain planning and scheduling problems. Appl. Soft Comput. 2016, 48, 703–715. [Google Scholar] [CrossRef]

- Yoon, D.Y.; Kim, G.C. A concept design for development of process planning and scheduling support system. Bull. Soc. Nav. Archit. Korea 1993, 30, 37–40. [Google Scholar]

- Choi, H.R.; Ryu, K.R.; Cho, K.K.; Lim, H.S.; Hwan, J.H. A scheduling system for panel block assembly shop in shipbuilding using genetic algorithms. J. Intell. Inf. Syst. 1996, 2, 29–42. [Google Scholar]

- Cho, K.K.; Kim, Y.G. An operation scheduling system for hull fabrication shop. In Proceedings of the Korean Operations and Management Science Society Conference, Pohang, Korea, 1 April 1997; pp. 443–446. [Google Scholar]

- Woo, S.B.; Ryu, H.G.; Hahn, H.S. Heuristic algorithms for resource leveling in pre-erection scheduling and erection scheduling of shipbuilding. IE Interfaces 2003, 16, 332–343. [Google Scholar]

- Persona, A.; Regattieri, A.; Romano, P. An integrated reference model for production planning and control in SMEs. J. Manuf. Technol. Manag. 2004, 15, 626–640. [Google Scholar] [CrossRef]

- Liu, Z.; Chua, D.; Yeoh, K.W. Aggregate Production Planning for Shipbuilding with Variation-Inventory Trade-Offs. Int. J. Prod. Res. 2011, 49, 6249–6272. [Google Scholar] [CrossRef]

- Kim, Y.S.; Lee, D.H. A Study on Construction of Detail Integrated Scheduling System of Ship Building Process. J. Soc. Nav. Archit. Korea 2007, 44, 48–54. [Google Scholar] [CrossRef][Green Version]

- Lee, D.H.; Kim, Y.S.; Kim, J.H. A study on real-time planning system in multi progress planning environment. J. Soc. Nav. Archit. Korea 2008, 45, 547–553. [Google Scholar] [CrossRef]

- Dong, F.; Deglise-Hawkinson, J.R.; Van Oyen, M.P.; Singer, D.J. Dynamic control of a closed two-stage queueing network for outfitting process in shipbuilding. Comput. Oper. Res. 2016, 72, 1–11. [Google Scholar] [CrossRef]

- Back, M.G.; Woo, J.H.; Lee, P.; Shin, J.G. Productivity improvement strategies using simulation in offshore plant construction. J. Ship Prod. Design 2017, 33, 144–155. [Google Scholar] [CrossRef]

- Mello, M.H.; Gosling, J.; Naim, M.M.; Strandhagen, J.O.; Brett, P.O. Improving coordination in an engineer-to-order supply chain using a soft systems approach. Prod. Plan. Control 2017, 28, 89–107. [Google Scholar] [CrossRef]

- Hartmann, S.; Briskorn, D. A survey of variants and extensions of the resource constrained project scheduling problem. Eur. J. Oper. Res. 2010, 207, 1–14. [Google Scholar] [CrossRef]

- Weglarz, J.; Józefowska, J.; Mika, M.; Waligóra, G. Project scheduling with finite or infinite number of activity processing modes—A survey. Eur. J. Oper. Res. 2011, 208, 177–205. [Google Scholar] [CrossRef]

- Tritschler, M.; Naber, A.; Kolisch, R. A hybrid metaheuristic for resource-constrained project scheduling with flexible resource profiles. Eur. J. Oper. Res. 2017, 262, 262–273. [Google Scholar] [CrossRef]

- Hartmann, S. Project scheduling with multiple modes: A genetic algorithm. Ann. Oper. Res. 2001, 102, 111–135. [Google Scholar] [CrossRef]

- Alcaraz, J.; Maroto, C.; Ruiz, R. Solving the multi-mode resource constrained project scheduling problem with genetic algorithms. J. Oper. Res. Soc. 2003, 54, 614–626. [Google Scholar] [CrossRef]

- Koulinas, G.; Kotsikas, L.; Anagnostopoulos, K. A particle swarm optimization based hyper-heuristic algorithm for the classic resource constrained project scheduling problem. Inf. Sci. 2014, 277, 680–693. [Google Scholar] [CrossRef]

- Bettemir, O.H.; Sonmez, R. Hybrid genetic algorithm with simulated annealing for resource-constrained project scheduling. J. Manag. Eng. 2014, 31, 04014082. [Google Scholar] [CrossRef]

- Messelis, T.; Causmaecker, P.D. An automatic algorithm selection approach for the multi-mode resource-constrained project scheduling problem. Eur. J. Oper. Res. 2014, 233, 511–528. [Google Scholar] [CrossRef]

- Zheng, X.L.; Wang, L. A multi-agent optimization algorithm for resource constrained project scheduling problem. Expert Syst. Appl. 2015, 42, 6039–6049. [Google Scholar] [CrossRef]

- Sonmez, R.; Gurel, M. Hybrid optimization method for large-scale multimode resource-constrained project scheduling problem. J. Manag. Eng. 2016, 32, 04016020. [Google Scholar] [CrossRef]

- Dong, Z.S.; Tao, S.; Shi, Q. Coupling resource allocation and project scheduling considering resource scarcity. In Proceeding of the 2018 IISE Annual Conference, Orlando, FL, USA, 19–22 May 2018; pp. 1801–1806. [Google Scholar]

- Wang, L.; Zhan, D.; Nie, L.; Xu, X.; Zhang, Z. Optimization method for block erection scheduling with activity duration elasticity. Comput. Integr. Manuf. Syst. 2011, 17, 1478–1485. [Google Scholar]

- Confessore, G.; Giordani, S.; Rismondo, S. An auction based approach in decentralized project scheduling. In Proceeding of the PMS 2002—International Workshop on Project Management and Scheduling, Valencia, Spain, 3–5 April 2002; pp. 110–113. [Google Scholar]

- Lau, J.S.; Huang, G.Q.; Mak, K.L.; Liang, L. Distributed project scheduling with information sharing in supply chains: Part I—An agent-based negotiation model. Int. J. Prod. Res. 2005, 43, 4813–4838. [Google Scholar] [CrossRef]

- Martins, P.J. Distributed production planning and control agent-based system. Int. J. Prod. Res. 2006, 44, 3693–3709. [Google Scholar]

- Homberger, J. A multi-agent system for the decentralized resource constrained multi-project scheduling. Int. Trans. Oper. Res. 2007, 14, 565–589. [Google Scholar] [CrossRef]

- Aysegul, T.; Ihsan, S. Distributed scheduling: A review of concepts and applications. Int. J. Prod. Res. 2010, 48, 5235–5262. [Google Scholar]

- Cao, Y.; Yu, W.; Ren, W.; Chen, G. An overview of recent progress in the study of distributed multi-agent coordination. IEEE Trans. Ind. Inform. 2013, 9, 427–438. [Google Scholar] [CrossRef]

- Behnamian, J.; Ghomi, S.M.F. A survey of multi-factory scheduling. J. Intell. Manuf. 2016, 27, 231–249. [Google Scholar] [CrossRef]

- Ben-Zvi, T.; Lechler, T.G. Resource allocation in multi-project environments: Planning vs. execution strategies. Proc. PICMET 2011, 11, 1–7. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T.A.M.T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Murugan, P.; Kannan, S.; Baskar, S. NSGA-II algorithm for multi-objective generation expansion planning problem. Electr. Power Syst. Res. 2009, 79, 622–628. [Google Scholar] [CrossRef]

- Huang, B.; Buckley, B.; Kechadi, T.M. Multi-objective feature selection by using NSGA-II for customer churn prediction in telecommunications. Expert Syst. Appl. 2010, 37, 3638–3646. [Google Scholar] [CrossRef]

- Jeyadevi, S.; Baskar, S.; Babulal, C.K.; Iruthayarajan, M.W. Solving multiobjective optimal reactive power dispatch using modified NSGA-II. Int. J. Electr. Power Energy Syst. 2011, 33, 219–228. [Google Scholar] [CrossRef]

- Ramesh, S.; Kannan, S.; Baskar, S. Application of modified NSGA-II algorithm to multi-objective reactive power planning. Appl. Soft Comput. J. 2012, 12, 741–753. [Google Scholar] [CrossRef]

- Xu, Z.; Ming, X.G.; Zheng, M.; Li, M.; He, L.; Song, W. Cross-trained workers scheduling for field service using improved NSGA-II. Int. J. Prod. Res. 2015, 53, 1255–1272. [Google Scholar] [CrossRef]

- Zhong, W.; Liu, J.; Xue, M.; Jiao, L. A multiagent genetic algorithm for global numerical optimization. IEEE Trans. Syst. Man Cybern. B Cybern. 2004, 34, 1128–1141. [Google Scholar] [CrossRef]

- Ghoddousi, P.; Eshtehardian, E.; Jooybanpour, S.; Javanmardi, A. Multi-mode resource-constrained discrete time-cost-resource optimization in project scheduling using non-dominated sorting genetic algorithm. Autom. Constr. 2013, 30, 216–227. [Google Scholar] [CrossRef]

- Cao, D.; Murat, A.; Chinnam, R.B. Efficient exact optimization of multi-objective redundancy allocation problems in series-parallel systems. Reliab. Eng. Syst. Saf. 2013, 111, 154–163. [Google Scholar] [CrossRef]

- Kuo, T. A modified topsis with a different ranking index. Eur. J. Oper. Res. 2017, 260, 152–160. [Google Scholar] [CrossRef]

- Walczak, D.; Rutkowska, A. Project rankings for participatory budget based on the fuzzy TOPSIS method. Eur. J. Oper. Res. 2017, 260, 706–714. [Google Scholar] [CrossRef]

- Chauhan, R.; Singh, T.; Tiwari, A.; Patnaik, A.; Thakur, N.S. Hybrid entropy-TOPSIS approach for energy performance prioritization in a rectangular channel employing impinging air jets. Energy 2017, 134, 360–368. [Google Scholar] [CrossRef]

- Huang, W.; Shuai, B.; Wang, Y.; Antwi, E. Using entropy-TOPSIS method to evaluate urban rail transit system operation performance: The China case. Transp. Res. A 2018, 111, 292–303. [Google Scholar] [CrossRef]

| Project | Task | Workload | Predecessors | Candidate Scheme | ||

|---|---|---|---|---|---|---|

| Enterprise | Quality | Resources | ||||

| Project code: Complete windows: 2019.4.01–2019.5.20 Deadline: 2019.5.31 Fine coefficient: US$10,000 | -- | -- | -- | -- | -- | |

| 10 | 6 | 0,2,2,0 | ||||

| 15 | 10 | 6,0,0,5 | ||||

| 3 | 0,10,5,0 | |||||

| 2 | 0,10,0,4 | |||||

| 14 | 5 | 3,0,8,0 | ||||

| 15 | , | 1 | 10,0,6,0 | |||

| 15 | 7 | 9,0,0,8 | ||||

| 2 | 6,0,0,5 | |||||

| 6 | 0,2,0,5 | |||||

| 12 | 9 | 0,8,0,6 | ||||

| … | … | … | … | … | … | |

| 12 | 1 | 6,0,0,5 | ||||

| 8 | 8,0,10,0 | |||||

| 9 | 0,7,7,0 | |||||

| 14 | , | 1 | 10,0,6,0 | |||

| 10 | , | 4 | 0,2,0,5 | |||

| 8 | 0,5,5,0 | |||||

| -- | ,, | -- | -- | -- | ||

| Project code: Complete windows: 2019.4.11–2019.5.30 Deadline: 2019.6.10 Fine coefficient: US$10,000 | -- | -- | -- | -- | -- | |

| 14 | 6 | 6,0,0,1 | ||||

| 6 | 0,10,8,0 | |||||

| 10 | 8 | 0,10,5,0 | ||||

| 8 | 0,10,0,4 | |||||

| 15 | 4 | 3,0,0,7 | ||||

| 7 | 3,0,8,0 | |||||

| 3 | 3,0,0,3 | |||||

| 14 | , | 1 | 10,0,6,0 | |||

| 12 | 6 | 0,2,0,5 | ||||

| … | … | … | … | … | … | |

| 10 | 2 | 6,0,0,5 | ||||

| 4 | 8,0,10,0 | |||||

| 6 | 0,7,7,0 | |||||

| 11 | , | 8 | 5,0,0,1 | |||

| 1 | 0,7,10,0 | |||||

| 4 | 0,7,0,8 | |||||

| 13 | , | 6 | 0,2,5,0 | |||

| -- | ,, | -- | -- | -- | ||

| Enterprise | ||||||||

|---|---|---|---|---|---|---|---|---|

| 20 | 1000 | 23 | 1000 | 26 | 1000 | 36 | 1000 | |

| 20 | 1000 | 23 | 1000 | 26 | 1000 | 36 | 1000 | |

| 20 | 1000 | 23 | 1000 | 26 | 1000 | 36 | 1000 | |

| Task | Subcontractor | Duration | Start Time | Start Time | Resources |

|---|---|---|---|---|---|

| -- | 0 days | 2019/4/1 | 2019/4/1 | -- | |

| 5 days | 2019/4/1 | 2019/4/6 | 0,16,8,0 | ||

| 5 days | 2019/4/1 | 2019/4/6 | 18,0,0,5 | ||

| 2 days | 2019/4/1 | 2019/4/3 | 15,0,8,0 | ||

| 5 days | 2019/4/6 | 2019/4/11 | 20,0,6,0 | ||

| 2 days | 2019/4/11 | 2019/4/13 | 0,16,0,5 | ||

| 5 days | 2019/4/3 | 2019/4/8 | 0,24,0,6 | ||

| 5 days | 2019/4/6 | 2019/4/11 | 15,0,3,0 | ||

| 2 days | 2019/4/8 | 2019/4/10 | 18,0,0,7 | ||

| 6 days | 2019/4/11 | 2019/4/17 | 0,20,0,5 | ||

| 4 days | 2019/4/22 | 2019/4/26 | 0,9,6,0 | ||

| 4 days | 2019/4/13 | 2019/4/17 | 0,18,2,0 | ||

| 4 days | 2019/4/17 | 2019/4/21 | 0,21,0,2 | ||

| 5 days | 2019/4/11 | 2019/4/16 | 6,0,6,0 | ||

| 4 days | 2019/4/26 | 2019/4/30 | 18,0,0,5 | ||

| 4 days | 2019/4/17 | 2019/4/21 | 0,21,0,8 | ||

| 1 day | 2019/4/21 | 2019/4/22 | 0,26,5,0 | ||

| 3 days | 2019/4/30 | 2019/5/3 | 5,0,0,0 | ||

| 6 days | 2019/4/21 | 2019/4/27 | 2,0,0,0 | ||

| 4 days | 2019/4/22 | 2019/4/26 | 18,0,0,1 | ||

| 12 days | 2019/4/26 | 2019/5/8 | 6,0,0,5 | ||

| 2 days | 2019/5/8 | 2019/5/10 | 18,0,0,3 | ||

| 6 days | 2019/5/3 | 2019/5/9 | 20,0,6,0 | ||

| 4 days | 2019/5/10 | 2019/5/14 | 0,8,0,5 | ||

| 5 days | 2019/5/9 | 2019/5/14 | 0,16,0,6 | ||

| 7 days | 2019/5/8 | 2019/5/15 | 16,0,0,6 | ||

| 2 days | 2019/5/14 | 2019/5/16 | 16,0,0,6 | ||

| 6 days | 2019/5/15 | 2019/5/21 | 0,20,0,5 | ||

| 4 days | 2019/5/10 | 2019/5/14 | 0,9,6,0 | ||

| 6 days | 2019/5/14 | 2019/5/20 | 0,12,2,0 | ||

| 3 days | 2019/5/21 | 2019/5/24 | 10,0,0,5 | ||

| 3 days | 2019/5/9 | 2019/5/12 | 15,0,6,0 | ||

| 4 days | 2019/5/14 | 2019/5/18 | 0,21,7,0 | ||

| 5 days | 2019/5/21 | 2019/5/26 | 0,14,10,0 | ||

| 2 days | 2019/5/24 | 2019/5/26 | 0,18,5,0 | ||

| -- | 0 days | 2019/5/26 | 2019/5/26 | -- |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, X.; Li, J.; Guo, H.; Wu, X. Research on Collaborative Planning and Symmetric Scheduling for Parallel Shipbuilding Projects in the Open Distributed Manufacturing Environment. Symmetry 2020, 12, 161. https://doi.org/10.3390/sym12010161

Mao X, Li J, Guo H, Wu X. Research on Collaborative Planning and Symmetric Scheduling for Parallel Shipbuilding Projects in the Open Distributed Manufacturing Environment. Symmetry. 2020; 12(1):161. https://doi.org/10.3390/sym12010161

Chicago/Turabian StyleMao, Xuezhang, Jinghua Li, Hui Guo, and Xiaoyuan Wu. 2020. "Research on Collaborative Planning and Symmetric Scheduling for Parallel Shipbuilding Projects in the Open Distributed Manufacturing Environment" Symmetry 12, no. 1: 161. https://doi.org/10.3390/sym12010161

APA StyleMao, X., Li, J., Guo, H., & Wu, X. (2020). Research on Collaborative Planning and Symmetric Scheduling for Parallel Shipbuilding Projects in the Open Distributed Manufacturing Environment. Symmetry, 12(1), 161. https://doi.org/10.3390/sym12010161