Research on an Electromagnetic Interference Test Method Based on Fast Fourier Transform and Dot Frequency Scanning for New Energy Vehicles under Dynamic Conditions

Abstract

:1. Introduction

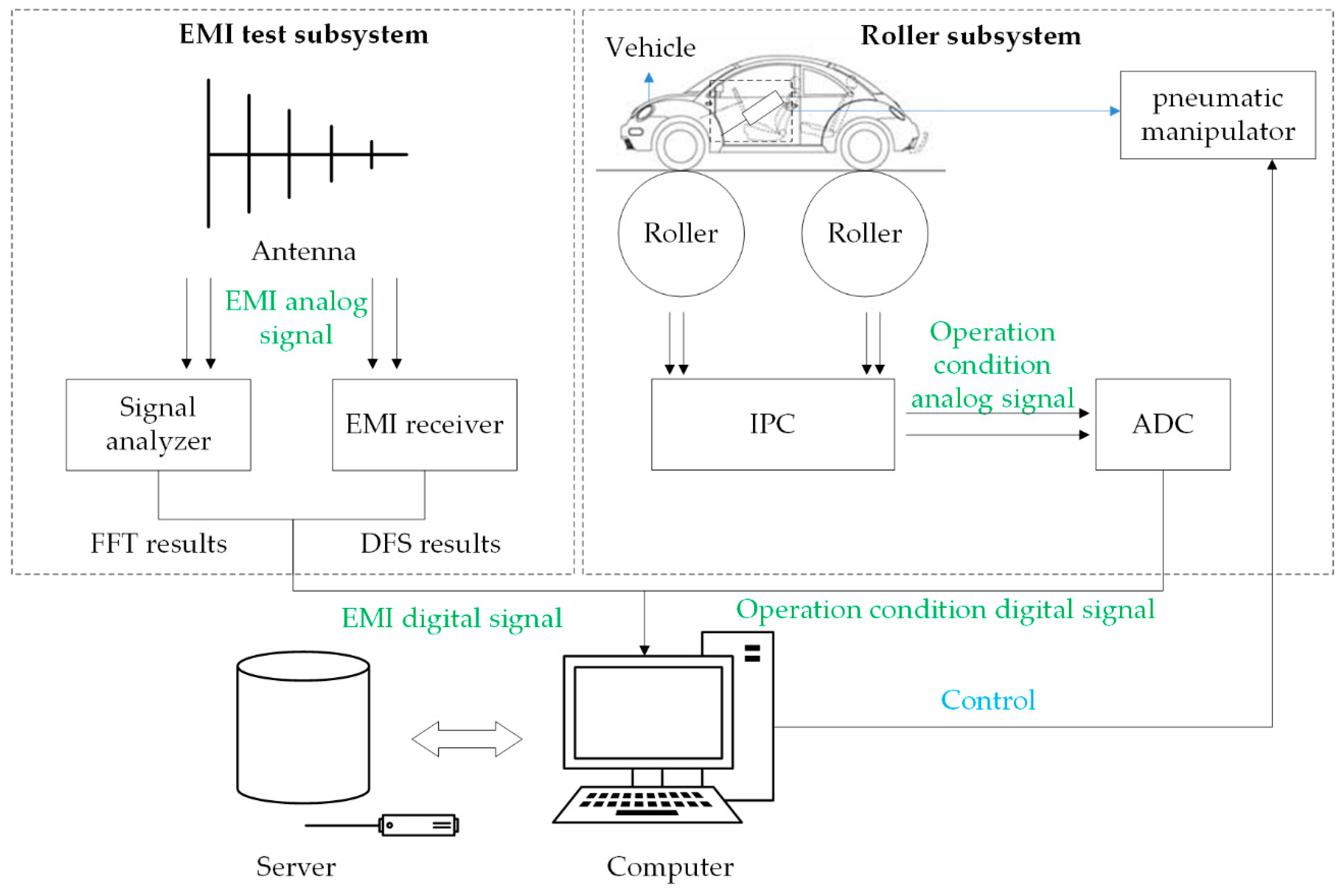

2. Framework of the Electromagnetic Interference (EMI) Test Based on Fast Fourier Transform (FFT) and Dot Frequency Scanning (DFS) for New Energy Vehicles under Dynamic Conditions

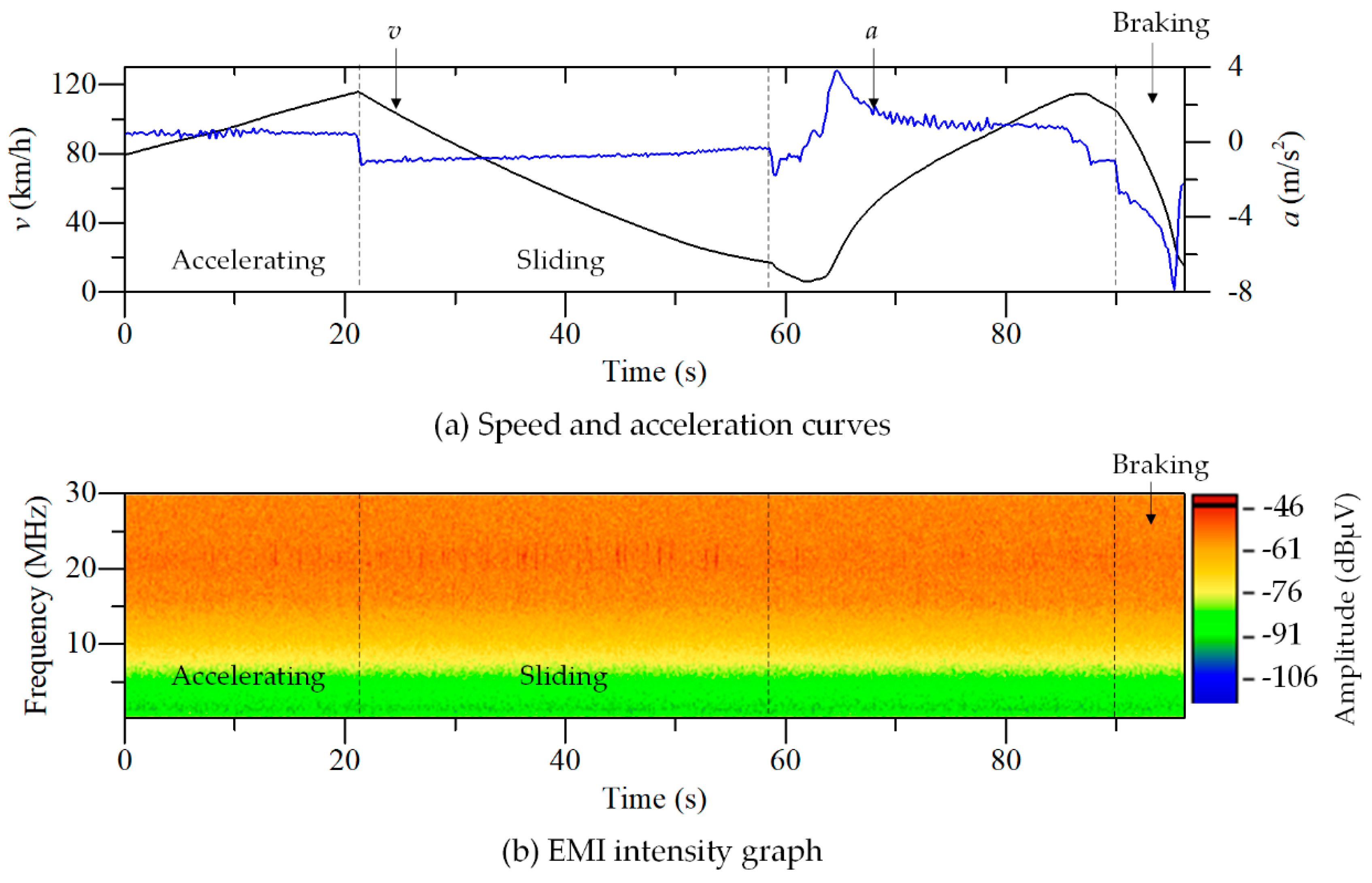

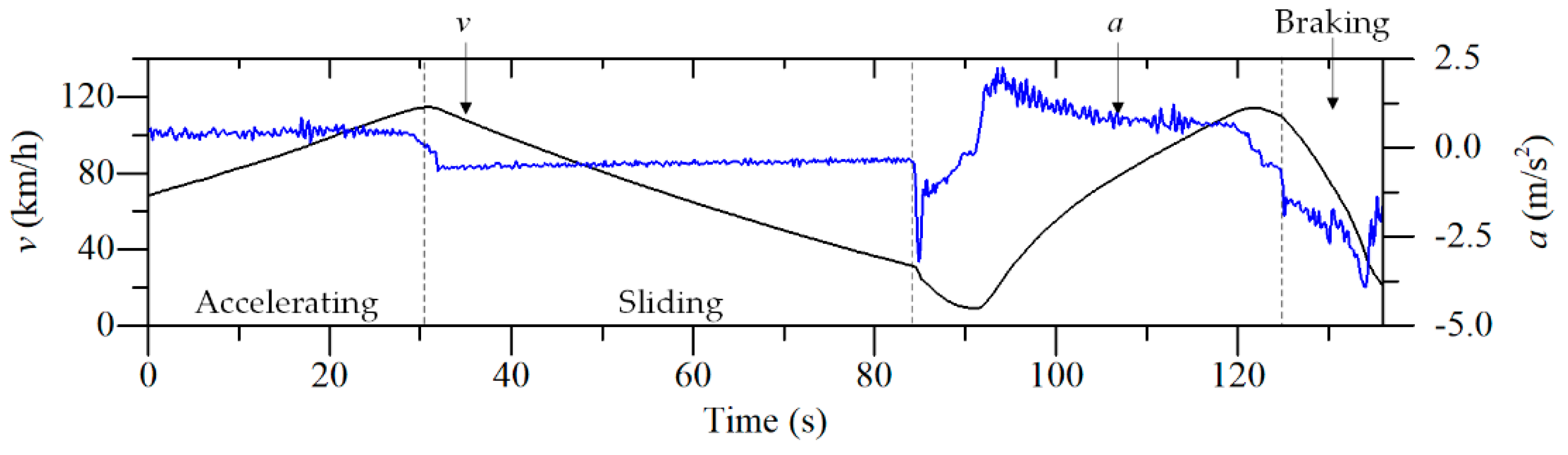

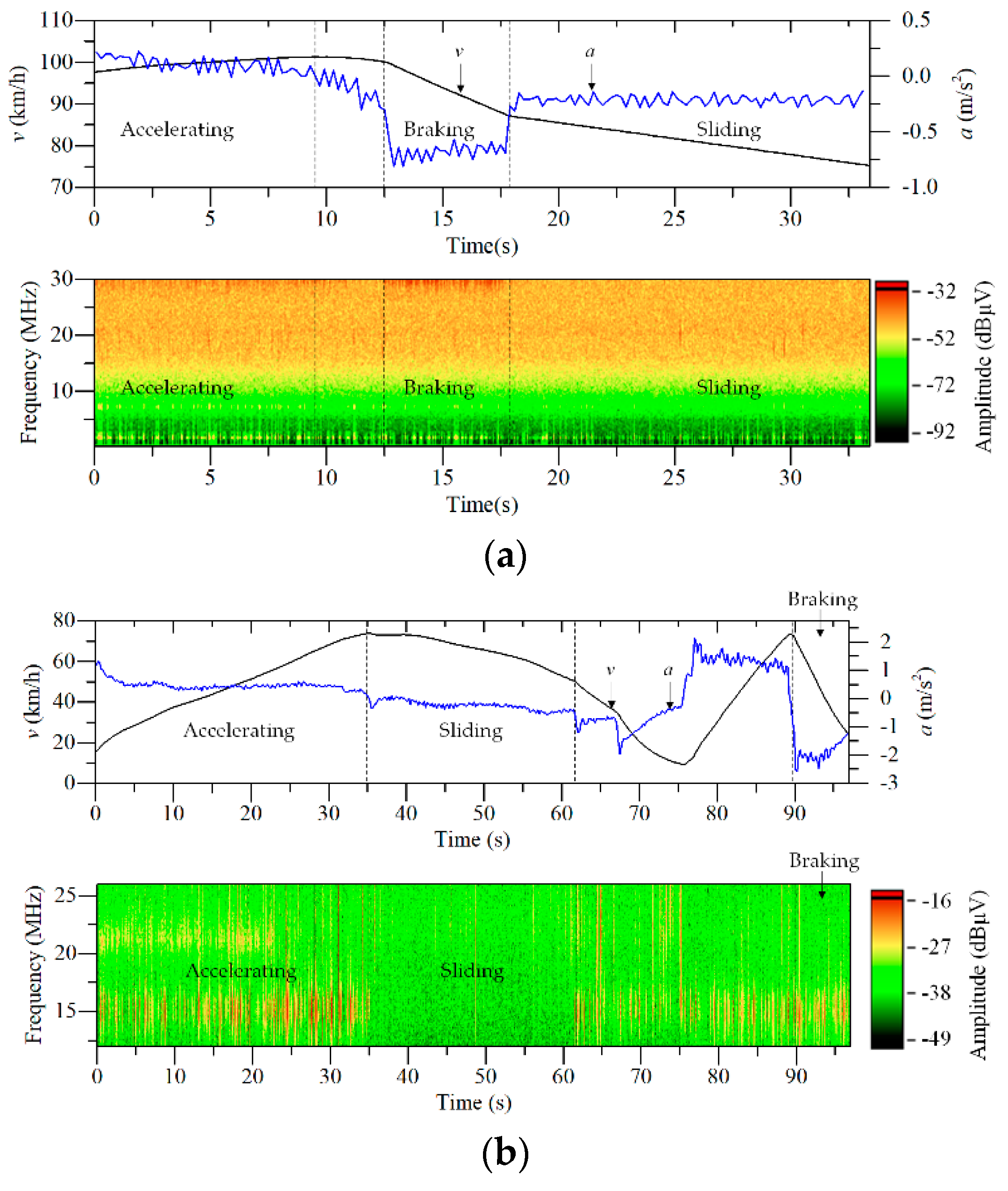

3. Identification Method for Accelerating, Sliding, and Braking Conditions

- (1)

- When the new energy vehicle is accelerating, , and then . To avoid misjudgments, a small, positive threshold, , is introduced. Therefore, . On the other hand, if the situation when is detected, it indicates that the new energy vehicle is accelerating.

- (2)

- When the new energy vehicle is sliding, and , then and . To avoid misjudgments, a small, negative threshold, , is introduced. Therefore, and . On the other hand, if the situation when and is detected, it indicates that the new energy vehicle is sliding.

- (3)

- When the new energy vehicle is braking, , then . To avoid misjudgments, a small, negative threshold, , is introduced. Therefore, . On the other hand, if the situation when is detected, it indicates that the new energy vehicle is braking.

4. Method to Determine Characteristic Points

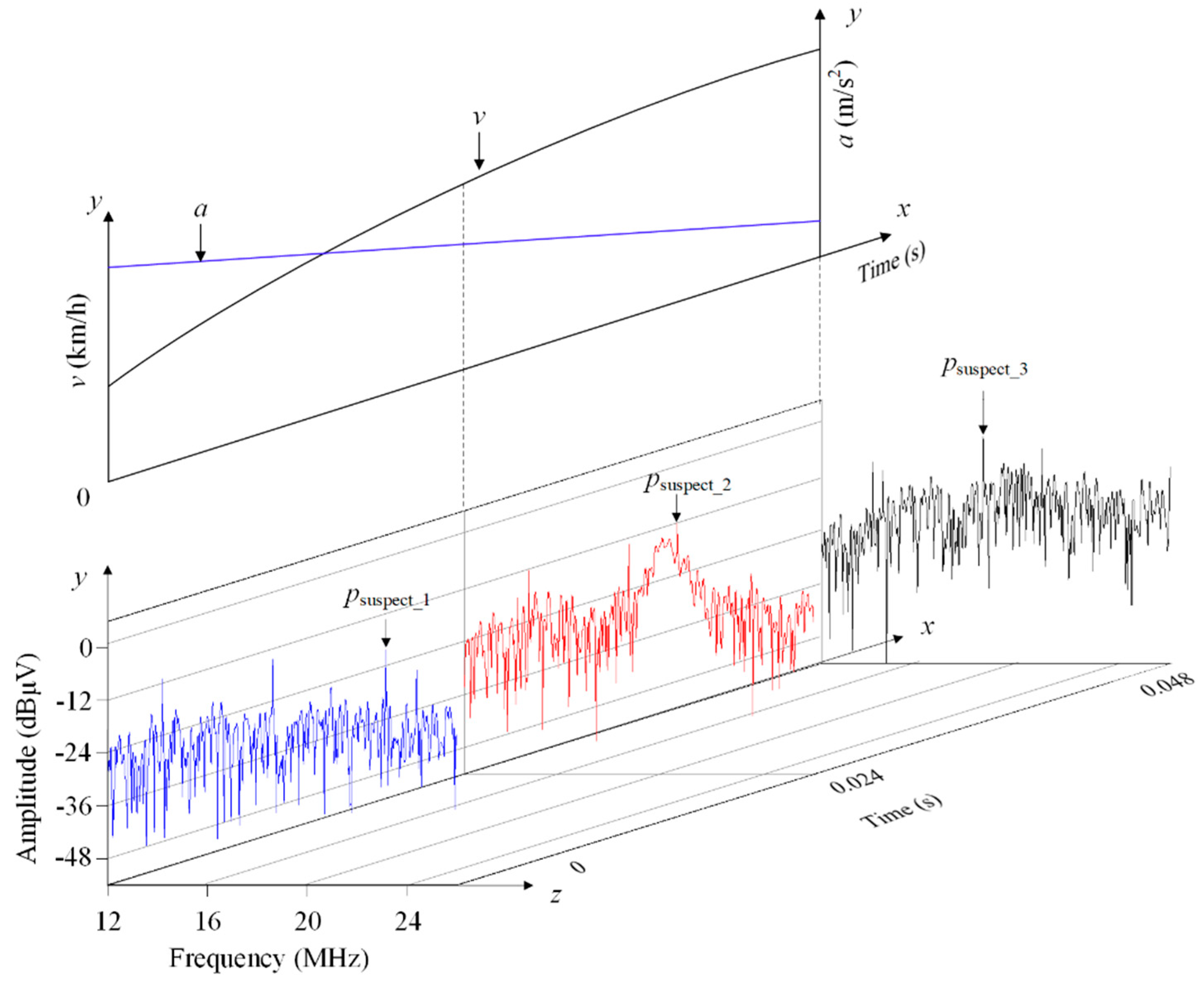

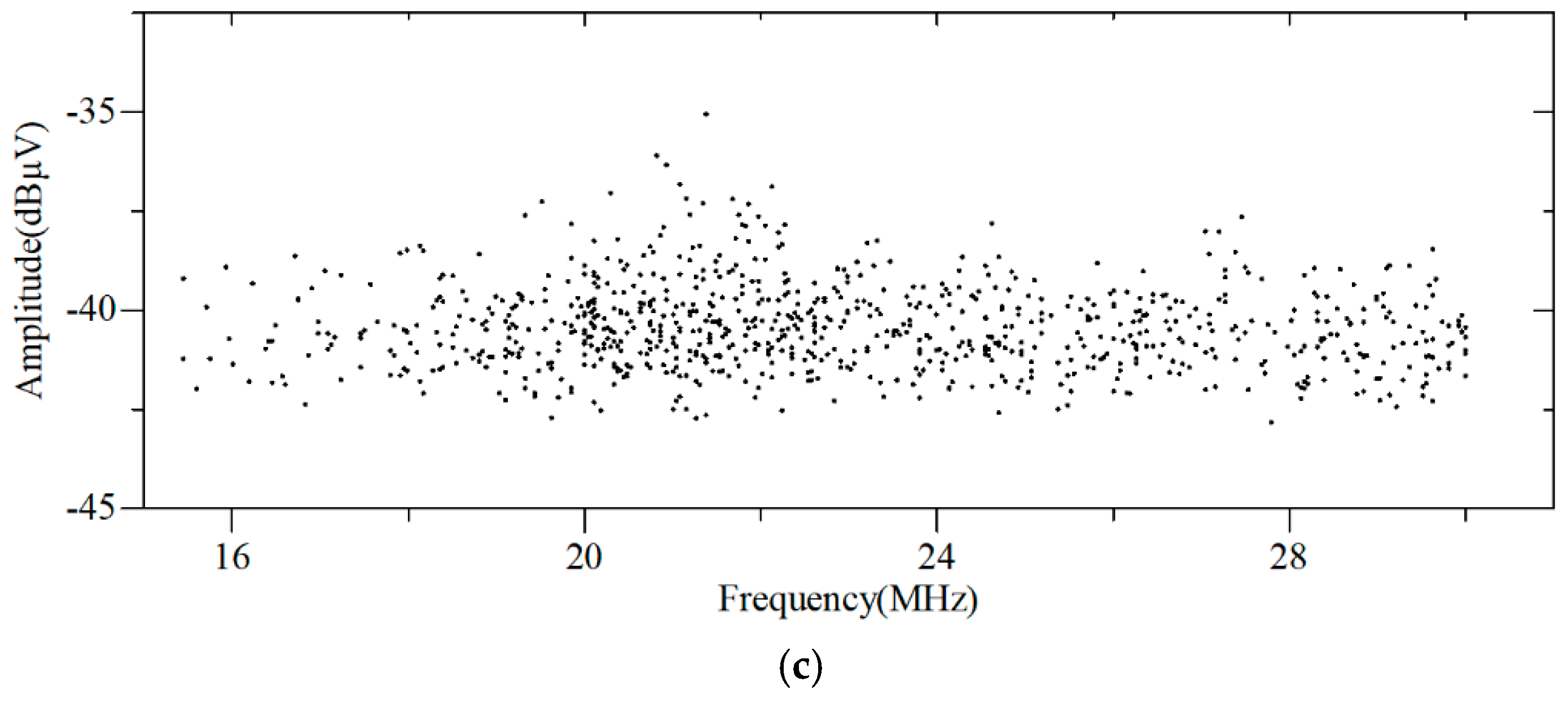

4.1. Distribution Diagram of Characteristic Points

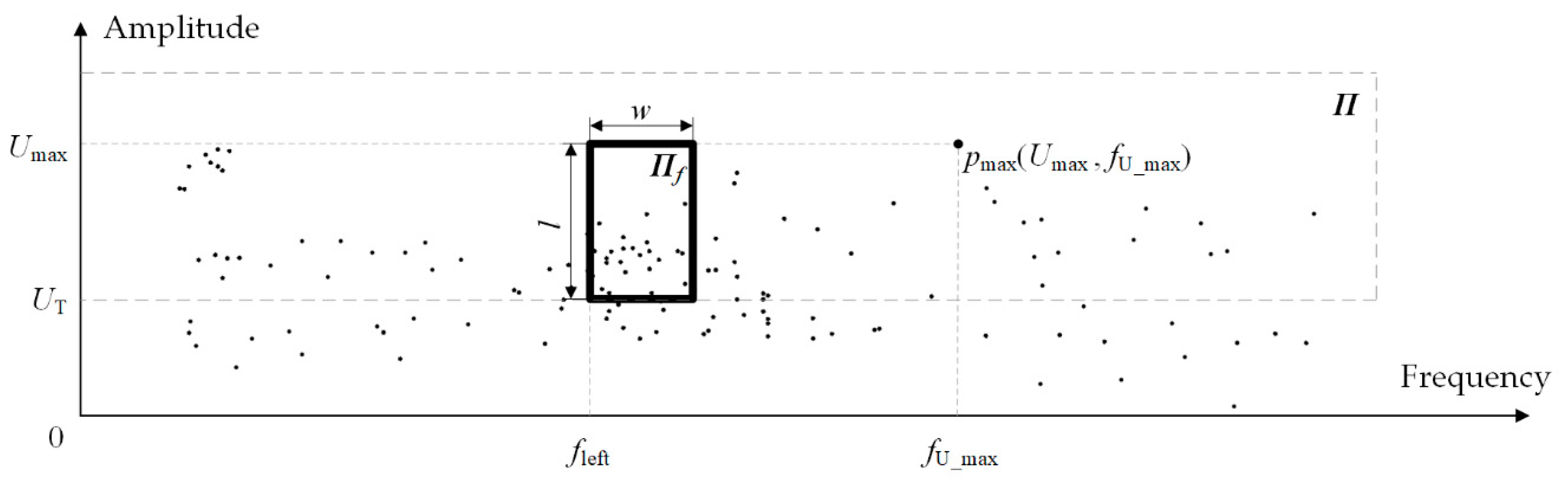

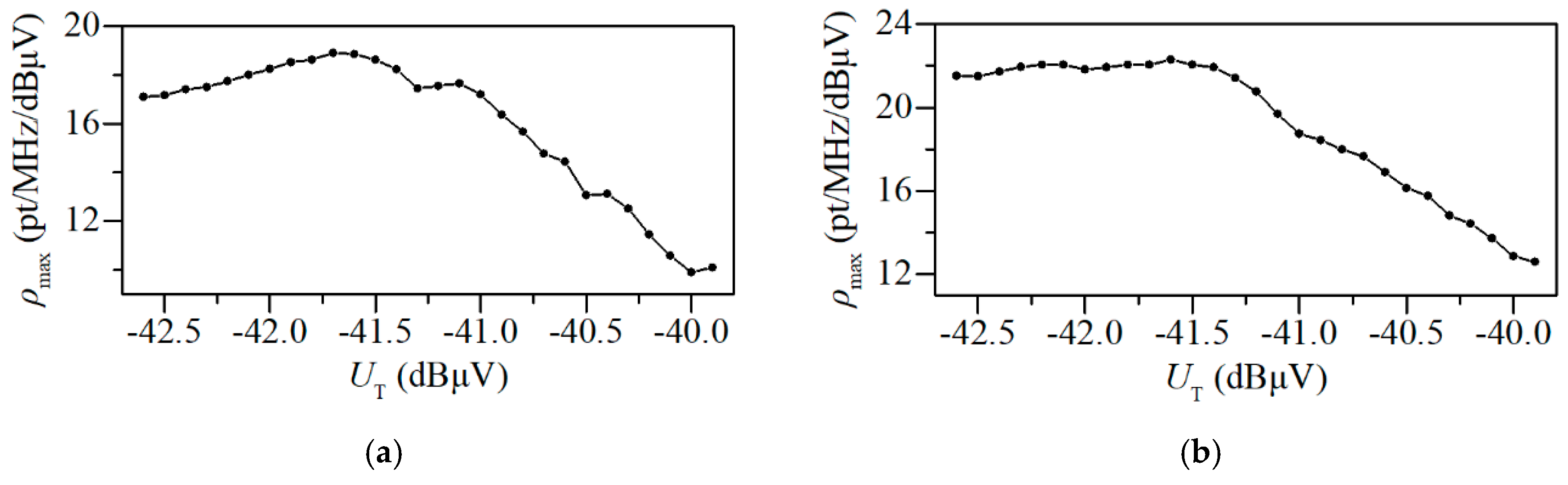

4.2. EMI Evaluation Indexes for New Energy Vehicles under Dynamic Conditions

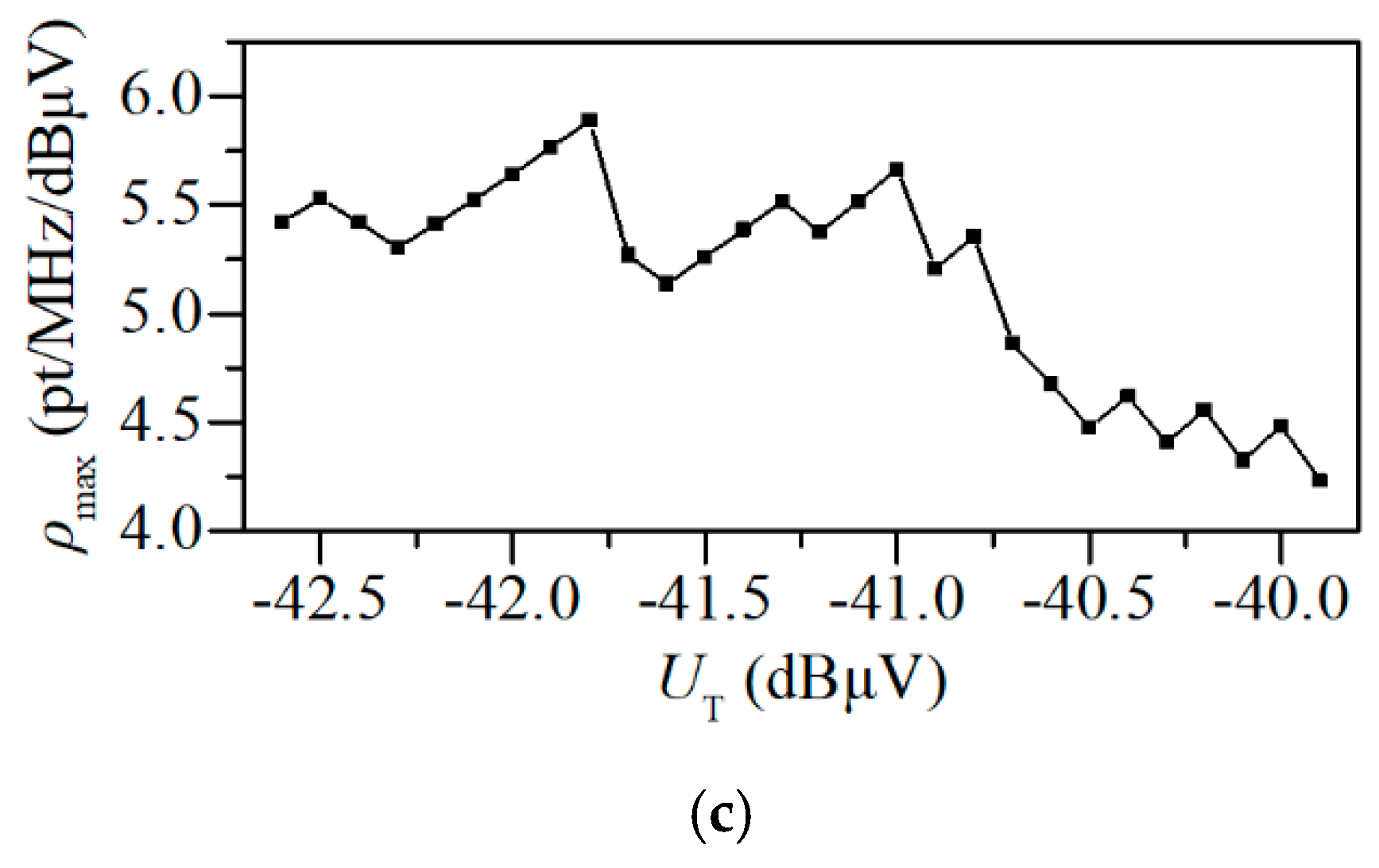

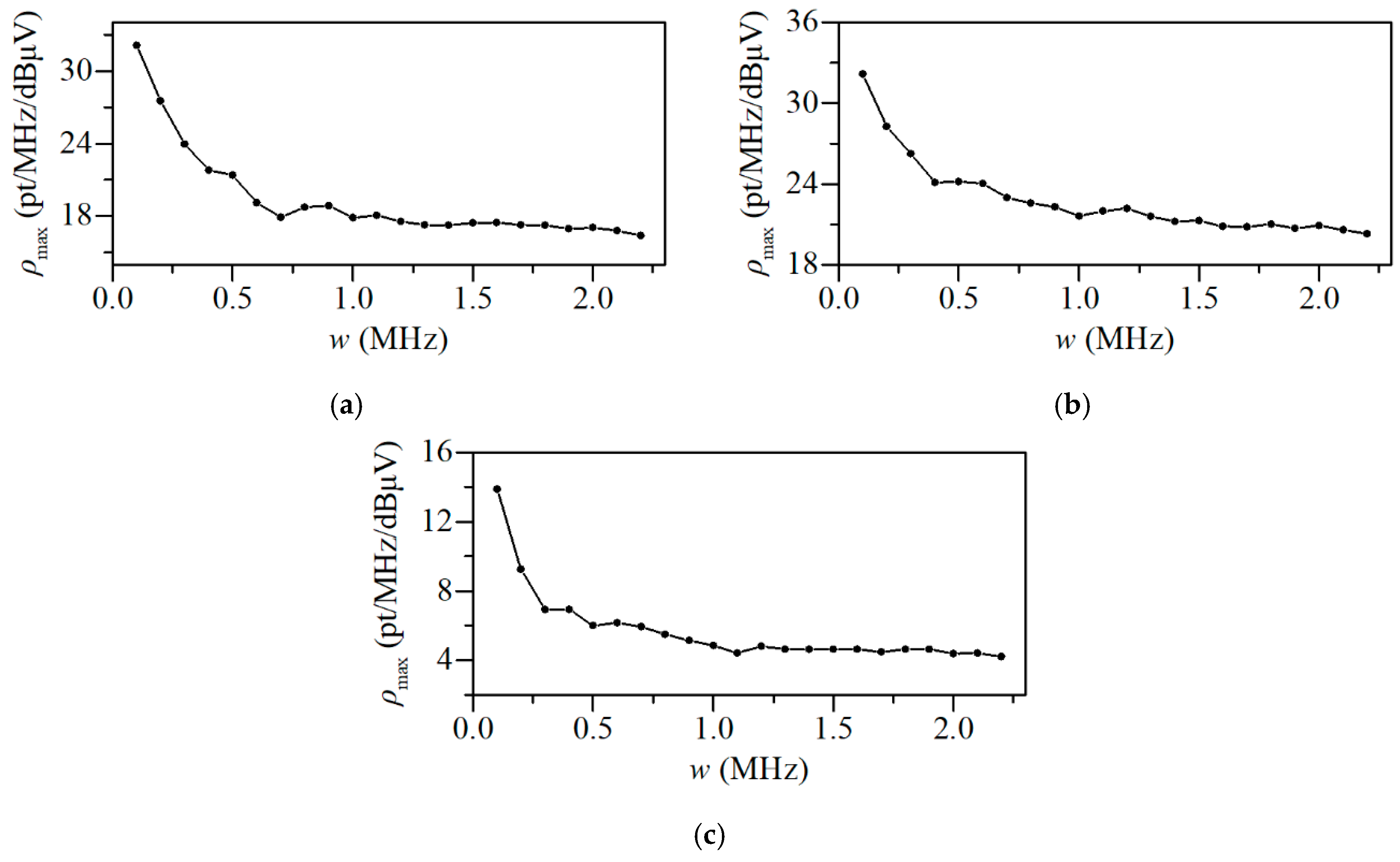

4.3. Method to Determine Characteristic Points Based on EMI Evaluation Indexes

- (1)

- , where . is a frequency concerned by the EMI test for new energy vehicles under dynamic conditions.

- (2)

- When () and w are constant, the larger ρ is, the more EMI that is generated by new energy vehicles. Therefore, the frequencies in the area whose ρ is larger than the threshold (especially the area whose ρ is maximum) should be included in the EMI test for new energy vehicles under dynamic conditions.

5. Implementations and Experiments

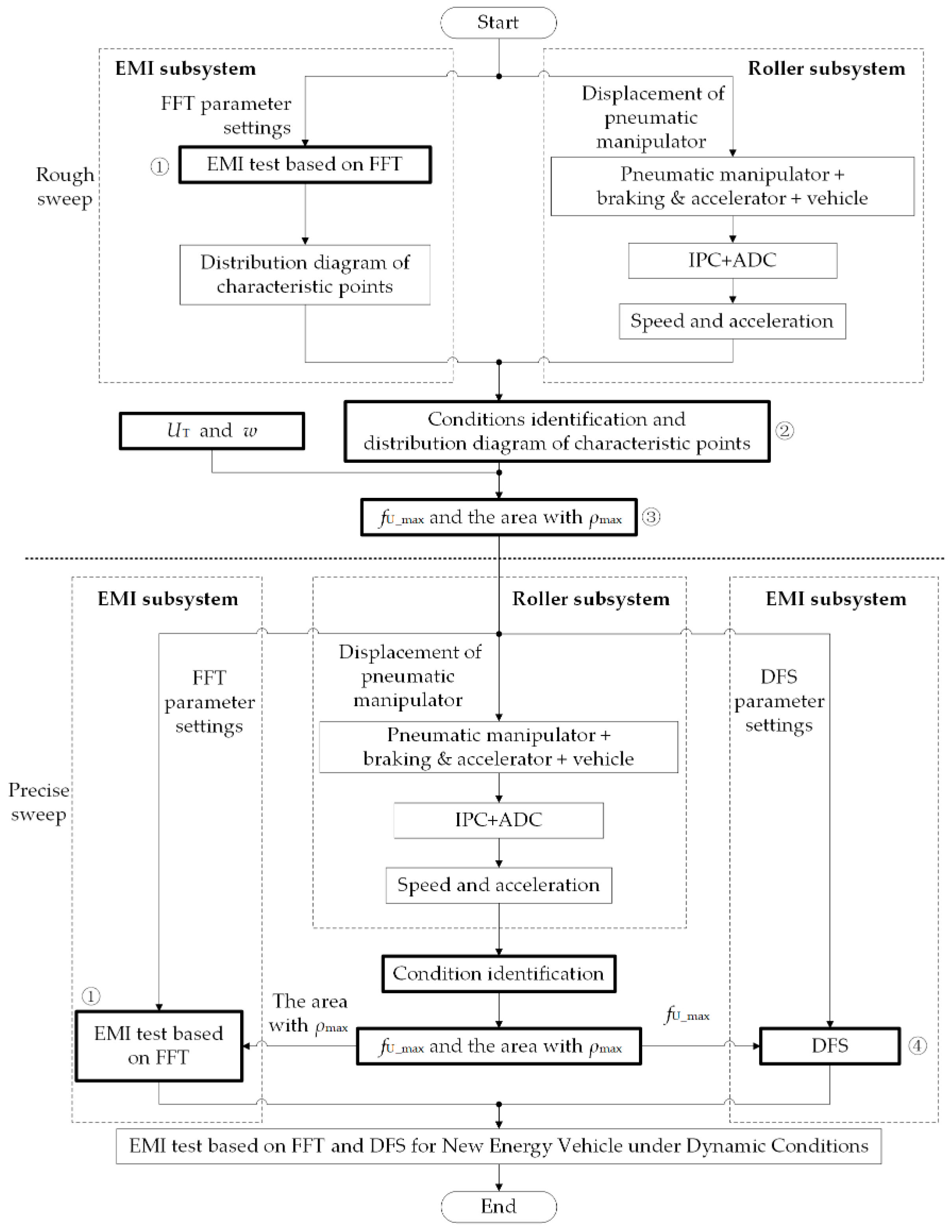

5.1. Implementation Flow

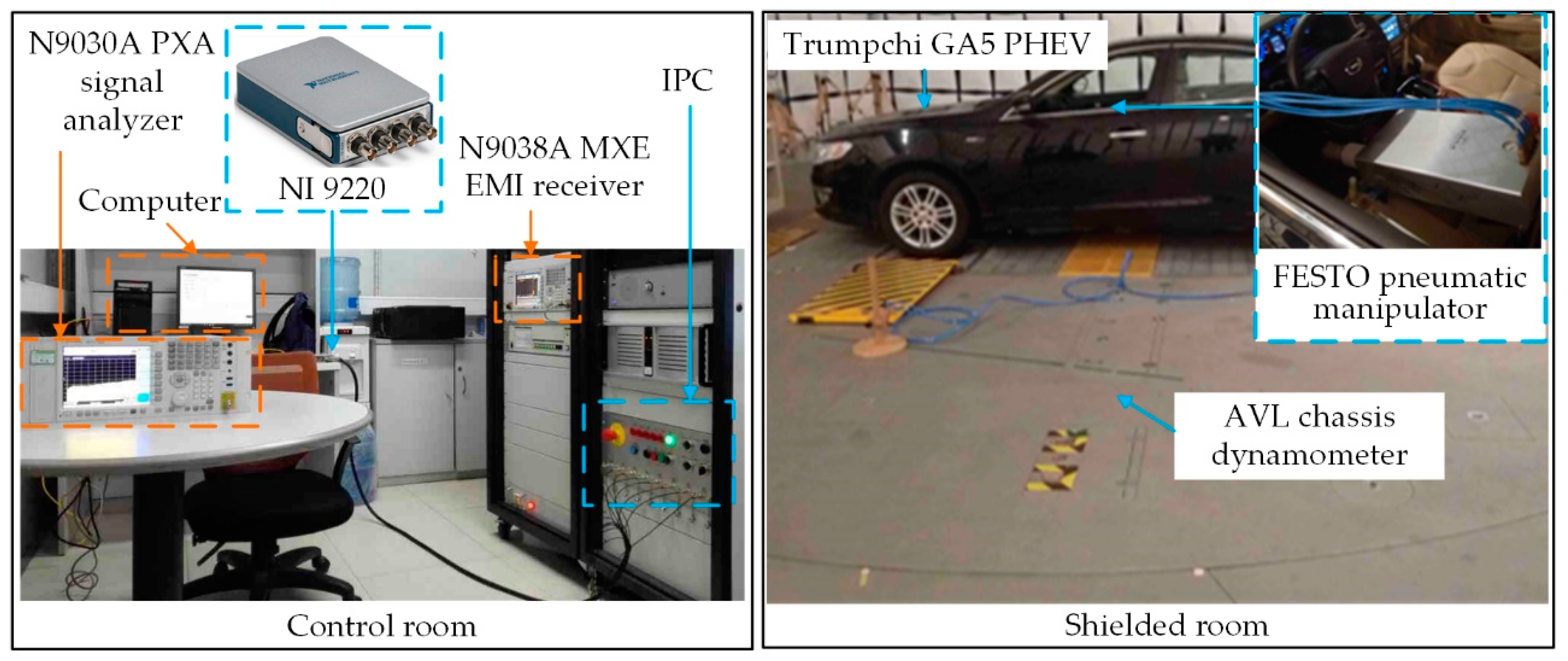

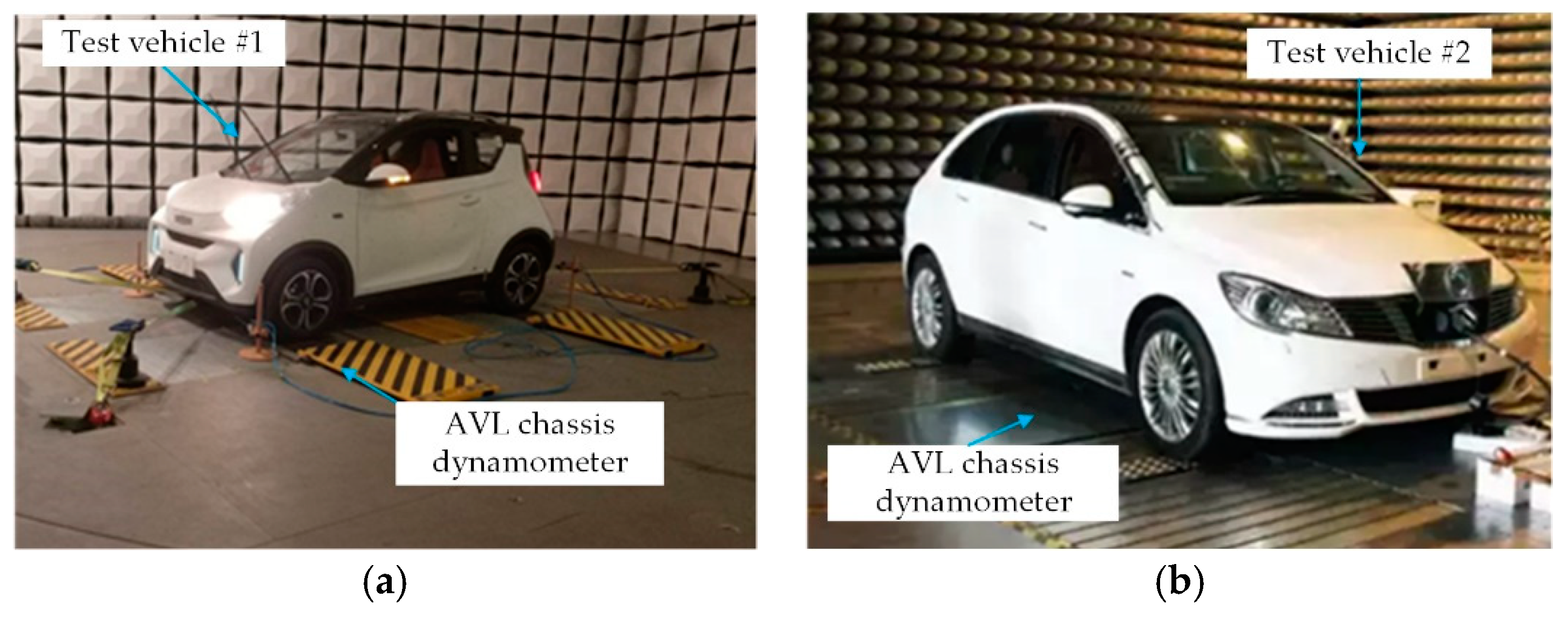

5.2. Construction of the Experimental System

5.3. Experimental Process and Results

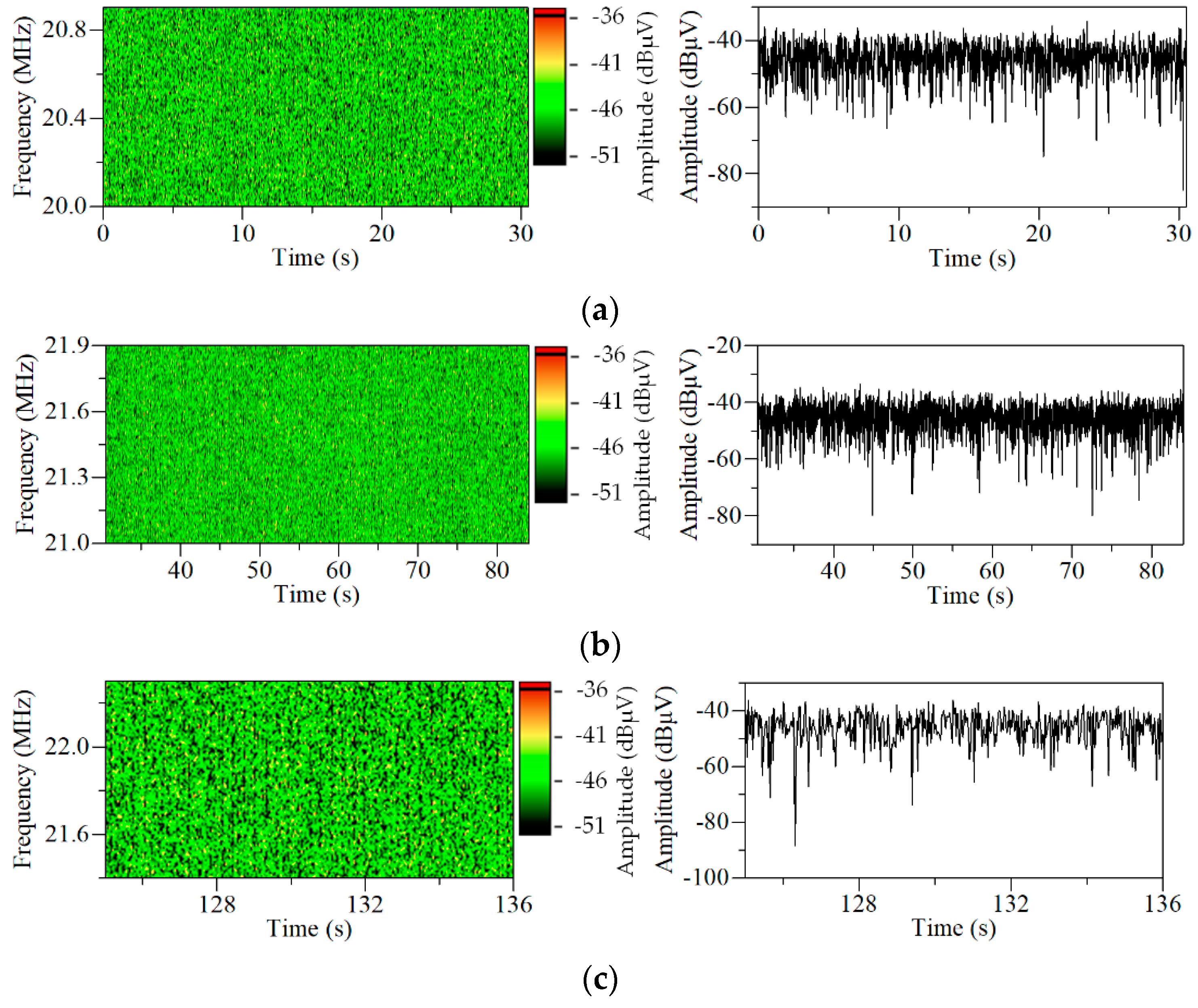

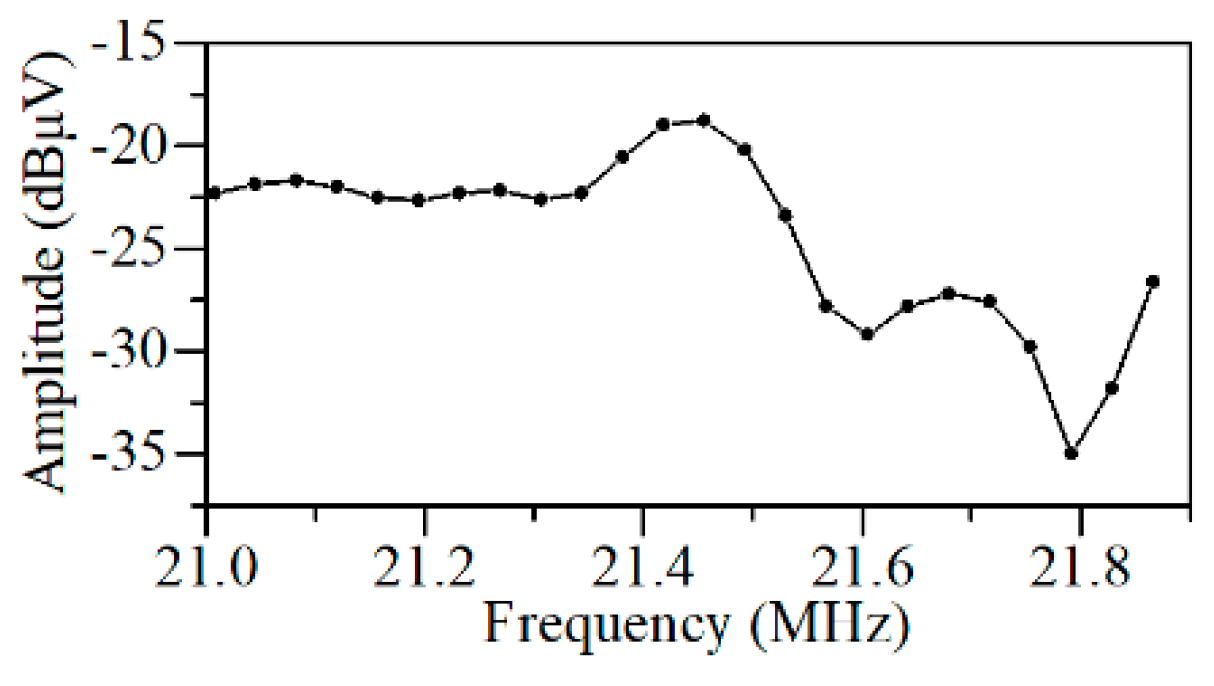

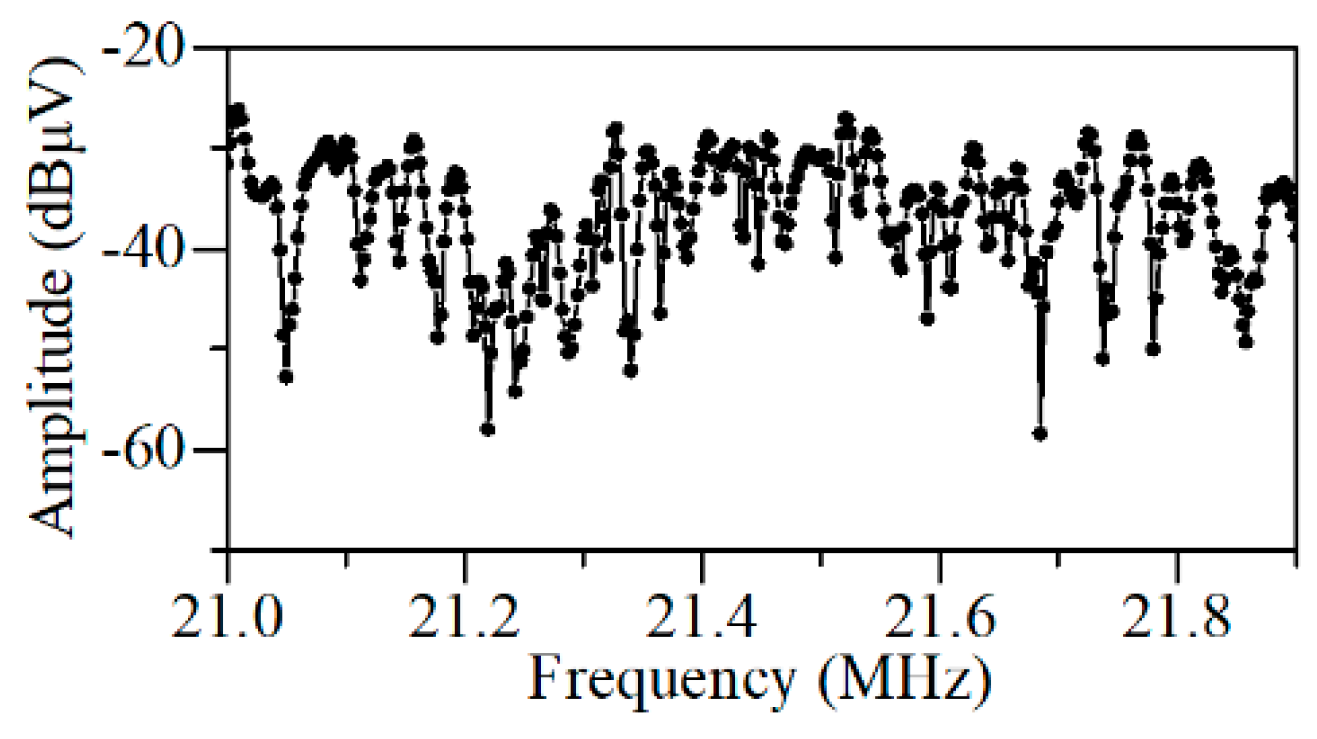

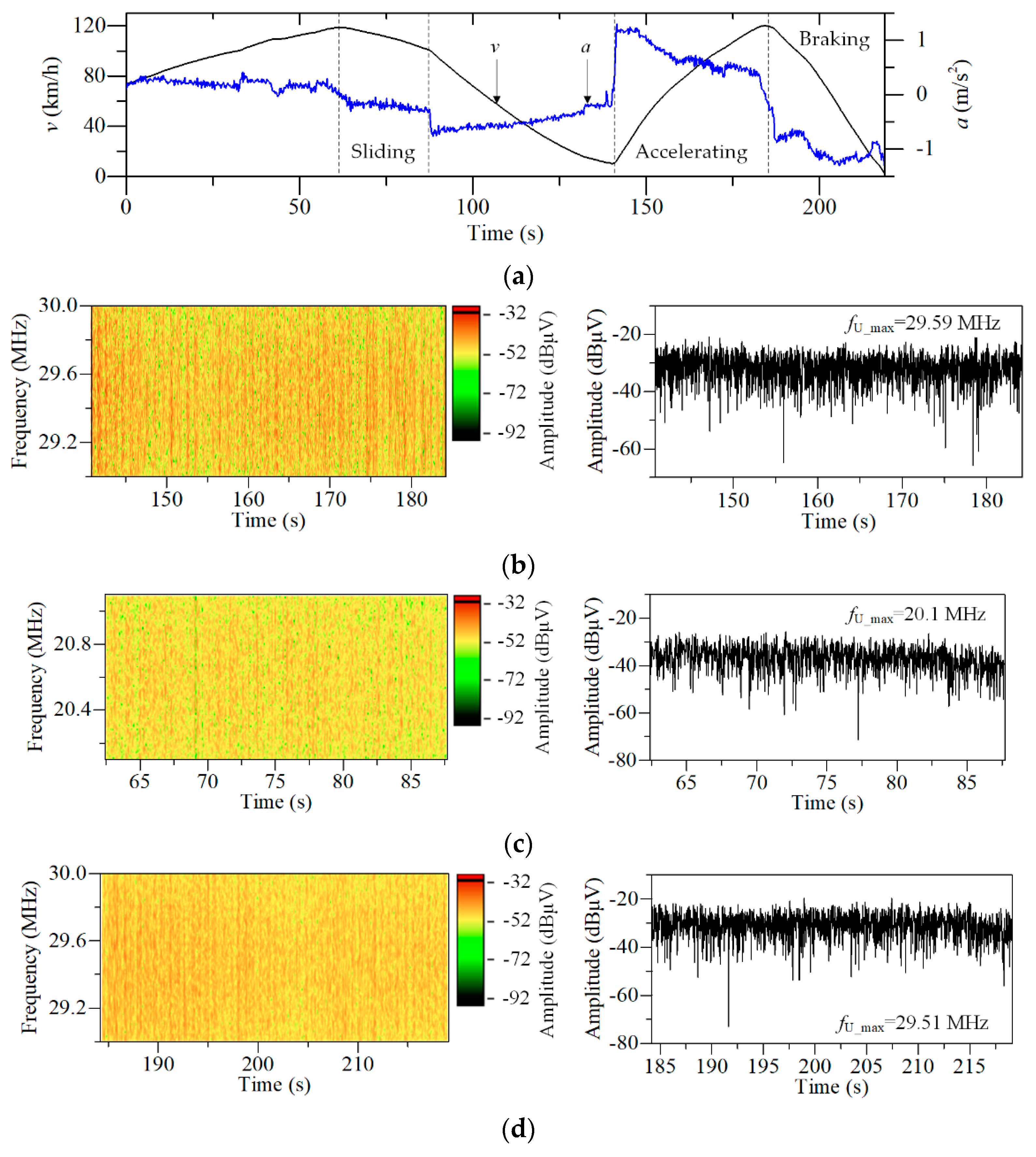

5.3.1. Experiments of GA5 PHEV

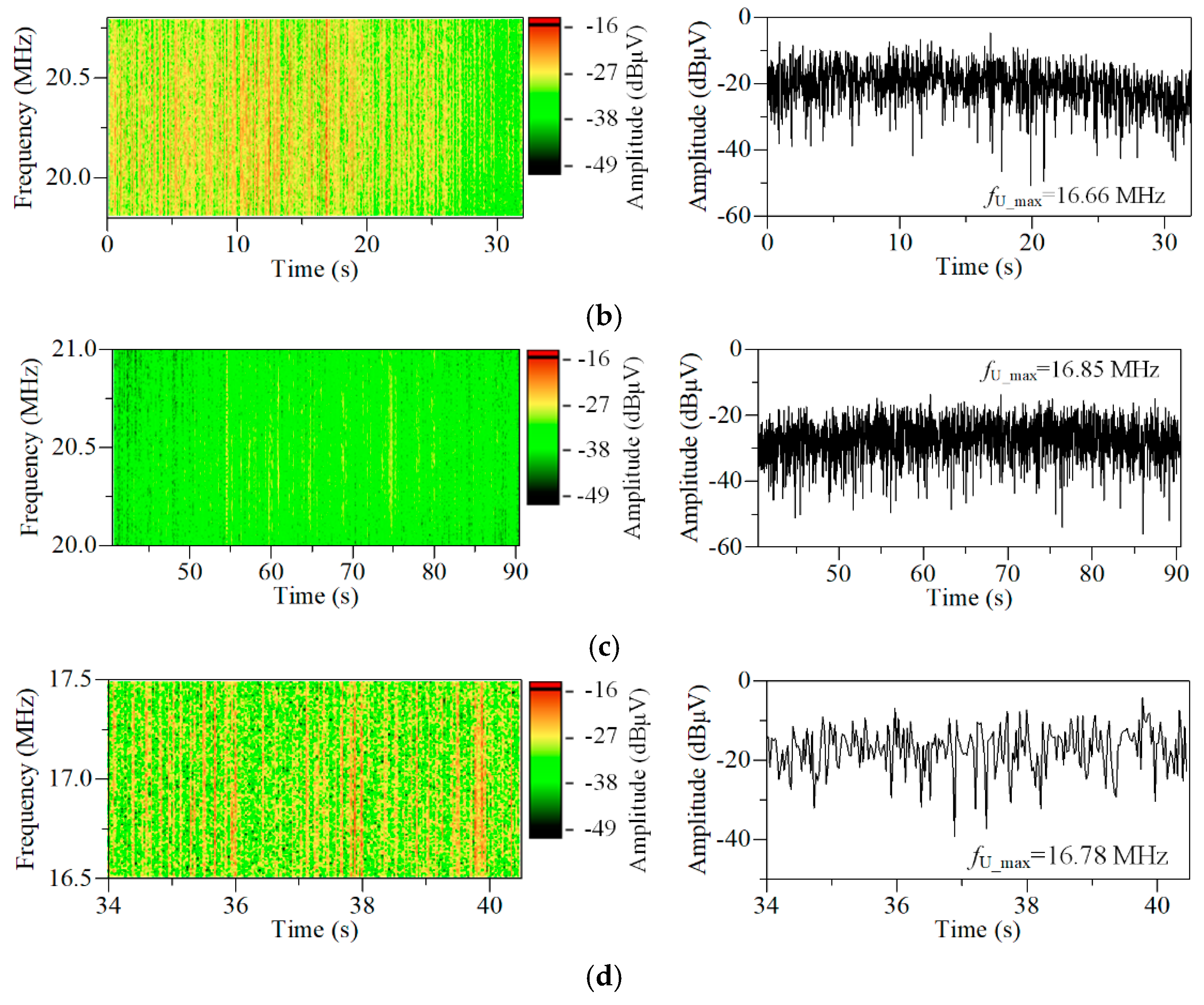

5.3.2. Test Results of Other Test Vehicles

5.4. Comparison Among Different EMI Test Methods

6. Conclusions and Prospects

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yan, L.; Zhang, Y.; He, Y.; Gao, S.; Zhu, D.; Ran, B.; Wu, Q. Hazardous traffic event detection using Markov Blanket and sequential minimal optimization (MB-SMO). Sensors 2016, 16, 1084. [Google Scholar] [CrossRef]

- Yuan, X.; Liu, X.; Zuo, J. The development of new energy vehicles for a sustainable future: A review. Renew. Sustain. Energy Rev. 2015, 42, 298–305. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, Q. Estimation of parasitic parameters and EMI improvement of a full-bridge PWM converter system in the electric vehicle. Electron. World 2016, 122, 24–29. [Google Scholar]

- CISPR 12:2009. Vehicles, Boats and Internal Combustion Engines—Radio Disturbance Characteristics—Limits and Methods of Measurement for the Protection of off-Board Receivers; Council of Standards Australia: Sydney, Australia, 2009. [Google Scholar]

- ECE 10.05. Uniform Provisions Concerning the Approval of Vehicles with Regard to Electromagnetic Compatibility; The United Nations Economic Commission for Europe: Geneva, Switzerland, 2014. [Google Scholar]

- SAE J551-5-2012. Performance Levels and Methods of Measurement of Magnetic and Electric Field Strength from Electric Vehicles, 150 kHz to 30 MHz; Society of Automotive Engineers: New York, NY, USA, 2012. [Google Scholar]

- GB/T 18387-2017. Limits and Test Method of Magnetic and Electric Field Strength from Electric Vehicles; Standardization Administration of the People’s Republic of China: Beijing, China, 2017.

- Zeng, B.; Deng, J.; Lin, D.; Lin, Q.; Liu, G. Comparison of below 30 MHz electric vehicle EMI measurements method standard. China Meas. Test 2016, 42, 11–14. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, L.; Liao, C. Modeling and Analysis of Conducted Electromagnetic Interference in Electric Vehicle Power Supply System. Prog. Electromagn. Res. 2013, 139, 193–209. [Google Scholar] [CrossRef]

- Tondato, F.; Bazzell, J.; Schwartz, L.; Mc Donald, B.W.; Fisher, R.; Anderson, S.S.; Galindo, A.; Dueck, A.C.; Scott, L.R. Safety and interaction of patients with implantable cardiac defibrillators driving a hybrid vehicle. Int. J. Cardiol. 2016, 227, 318–324. [Google Scholar] [CrossRef] [PubMed]

- Chun, Y.; Park, S.; Kim, J.; Kim, H.; Hwang, K.; Kim, J.; Ahn, S. Electromagnetic Compatibility of Resonance Coupling Wireless Power Transfer in On-Line Electric Vehicle System. IEICE Trans. Commun. 2014, 2, 416–423. [Google Scholar] [CrossRef]

- Jeschke, S.; Hirsch, H. Investigations on the EMI of an electric vehicle traction system in dynamic operation. In Proceedings of the 2014 International Symposium on Electromagnetic Compatibility (EMC Europe), Gothenburg, Sweden, 1–4 September 2014; pp. 420–425. [Google Scholar]

- Peng, H.; Hu, J.; Jiang, C.; Liu, Q.; Xu, H.; He, Z. Analysis for the EMI measurement and propagation path in Hybrid Electric Vehicle. In Proceedings of the 1st IEEE Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chongqing, China, 20–22 May 2016; pp. 1087–1090. [Google Scholar]

- Vassilev, A.; Ferber, A.; Wehrmann, C.; Pinaud, O.; Schilling, M.; Ruddle, A.R. Magnetic Field Exposure Assessment in Electric Vehicles. IEEE Trans. Electromagn. Compat. 2015, 57, 35–43. [Google Scholar] [CrossRef]

- Zhong, S.; Huang, J.; Wu, J.; Jiang, C.; Liu, G. Frame design and key technical analysis of EMI test system for new energy vehicle dynamic condition. China Meas. Test 2017, 8, 76–79. [Google Scholar]

| Acceleration | Sliding | Braking | |

|---|---|---|---|

| Features of speed and acceleration | , |

| Parameter | Acceleration | Sliding | Braking |

|---|---|---|---|

| (pt/MHz/dBμV) | 18.9 | 22.3 | 5.1 |

| The frequency range of the area with (MHz) | 20.0~20.9 | 21.0~21.9 | 21.4~22.3 |

| Parameter | Test Vehicle #1 | Test Vehicle #2 | ||||

|---|---|---|---|---|---|---|

| Accelerating (0~9.3 s) | Sliding (17.7~33.7 s) | Braking (12.5~17.7 s) | Accelerating (0s~35 s) | Sliding (35~62 s) | Braking (90~97 s) | |

| (MHz) | 29.59 | 20.10 | 29.51 | 16.66 | 16.85 | 16.78 |

| (dBμV) | −32.54 | −32.94 | −30.51 | −2.72 | −7.82 | −6.86 |

| η | 0.78 | 0.67 | 0.90 | 0.94 | 0.87 | 0.87 |

| The frequency range of the area with (MHz) | 29.0~30.0 | 20.1~21.1 | 29.0~30.0 | 19.8~20.8 | 20.0~21.0 | 16.5~17.5 |

| /t (pt/MHz/dBμV/min) | 91.6 | 30.8 | 132.7 | 32.1 | 27.8 | 48.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Zhong, S. Research on an Electromagnetic Interference Test Method Based on Fast Fourier Transform and Dot Frequency Scanning for New Energy Vehicles under Dynamic Conditions. Symmetry 2019, 11, 1092. https://doi.org/10.3390/sym11091092

Liu G, Zhong S. Research on an Electromagnetic Interference Test Method Based on Fast Fourier Transform and Dot Frequency Scanning for New Energy Vehicles under Dynamic Conditions. Symmetry. 2019; 11(9):1092. https://doi.org/10.3390/sym11091092

Chicago/Turabian StyleLiu, Guixiong, and Senming Zhong. 2019. "Research on an Electromagnetic Interference Test Method Based on Fast Fourier Transform and Dot Frequency Scanning for New Energy Vehicles under Dynamic Conditions" Symmetry 11, no. 9: 1092. https://doi.org/10.3390/sym11091092

APA StyleLiu, G., & Zhong, S. (2019). Research on an Electromagnetic Interference Test Method Based on Fast Fourier Transform and Dot Frequency Scanning for New Energy Vehicles under Dynamic Conditions. Symmetry, 11(9), 1092. https://doi.org/10.3390/sym11091092