A Novel Quality Defects Diagnosis Method for the Manufacturing Process of Large Equipment Based on Product Gene Theory

Abstract

1. Introduction

1.1. Problem Statements

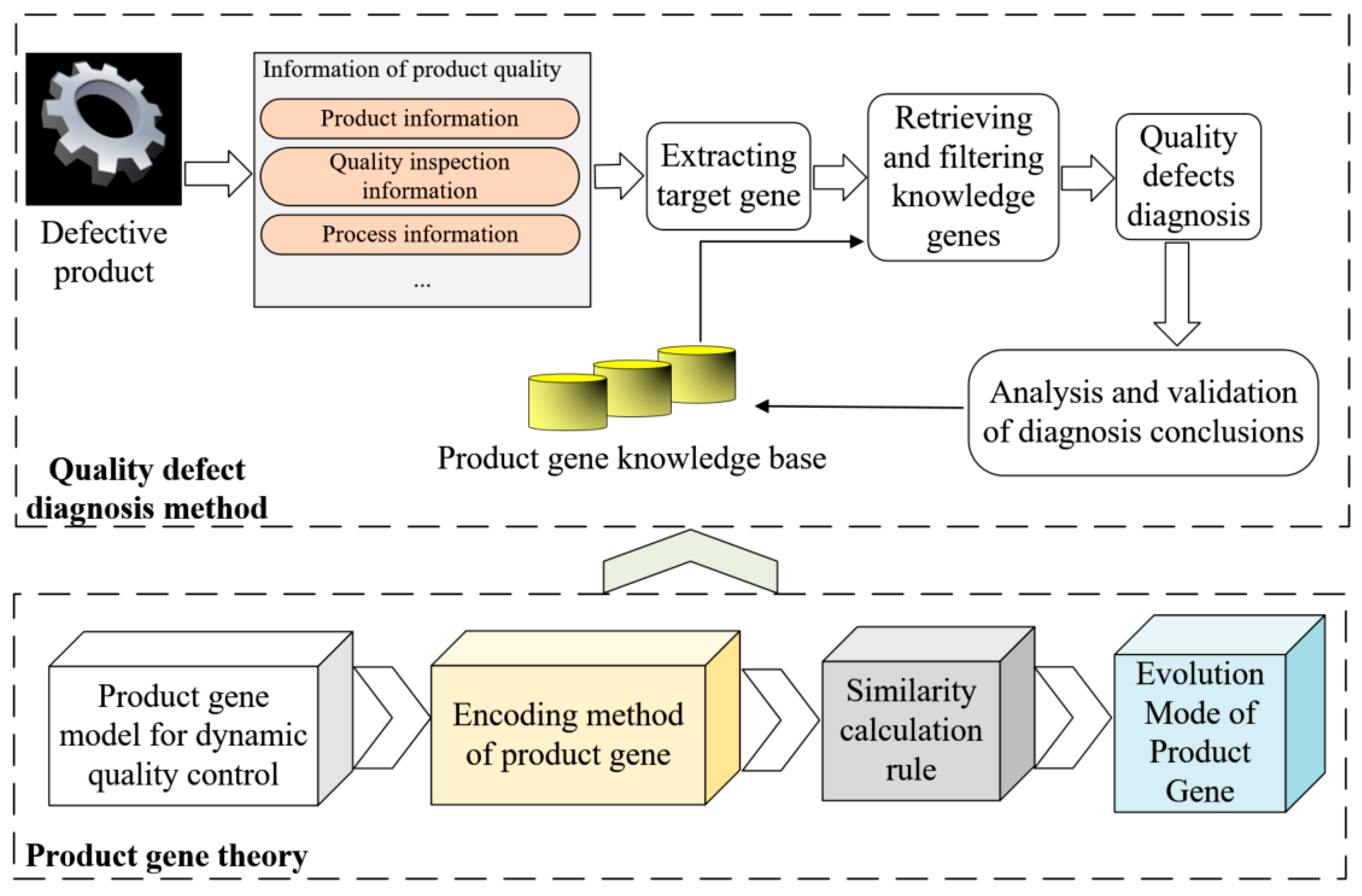

1.2. Research Framework

2. Related Work

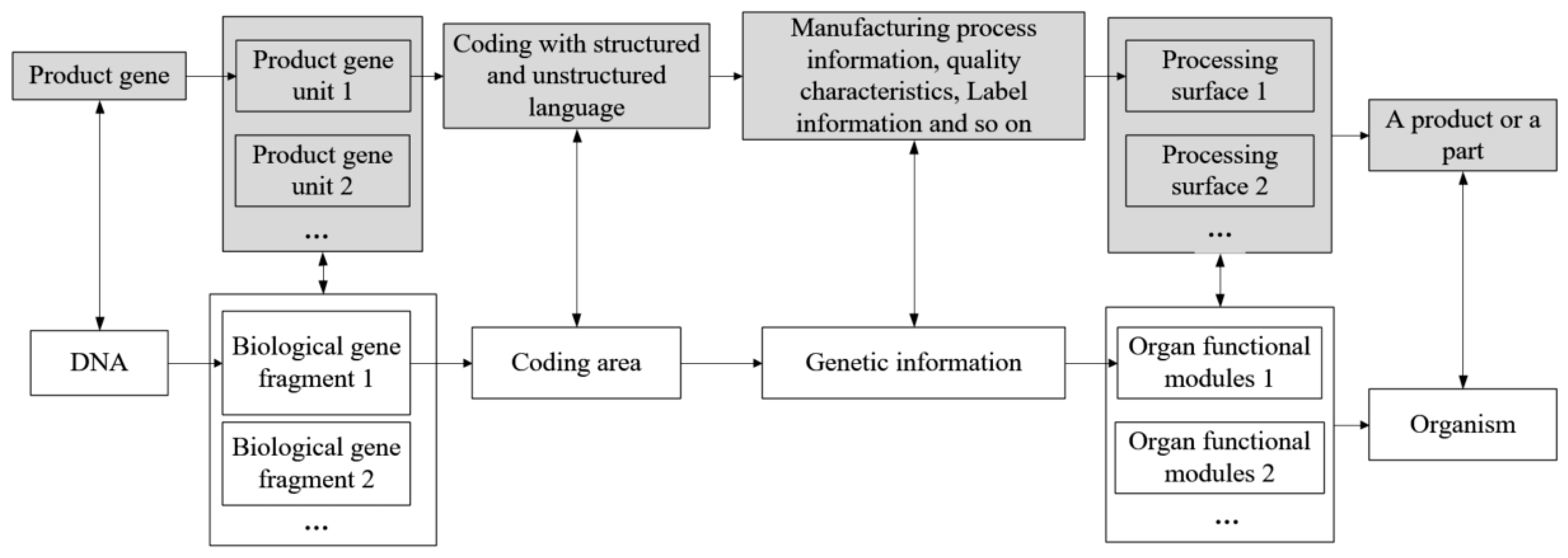

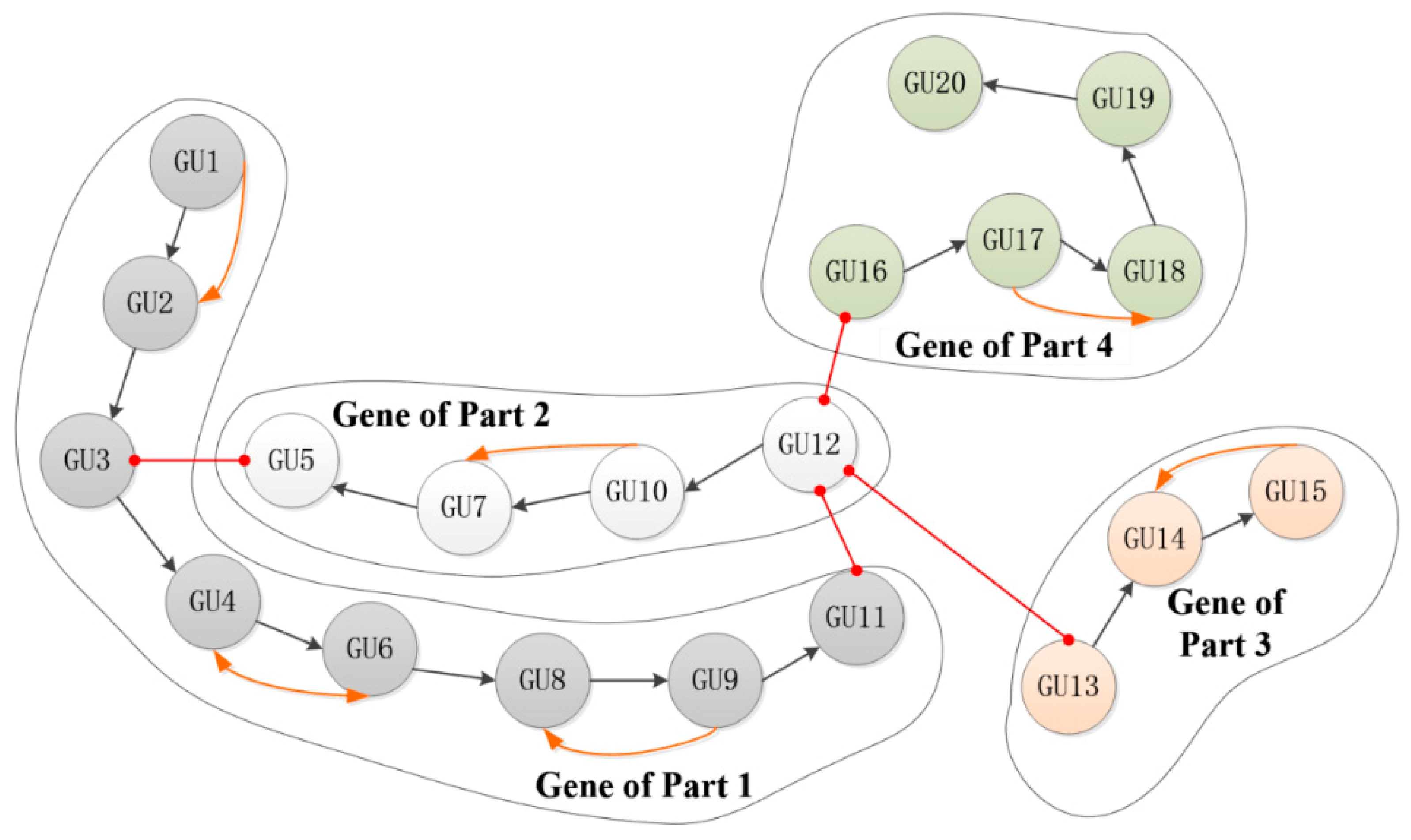

3. Product Gene Theory

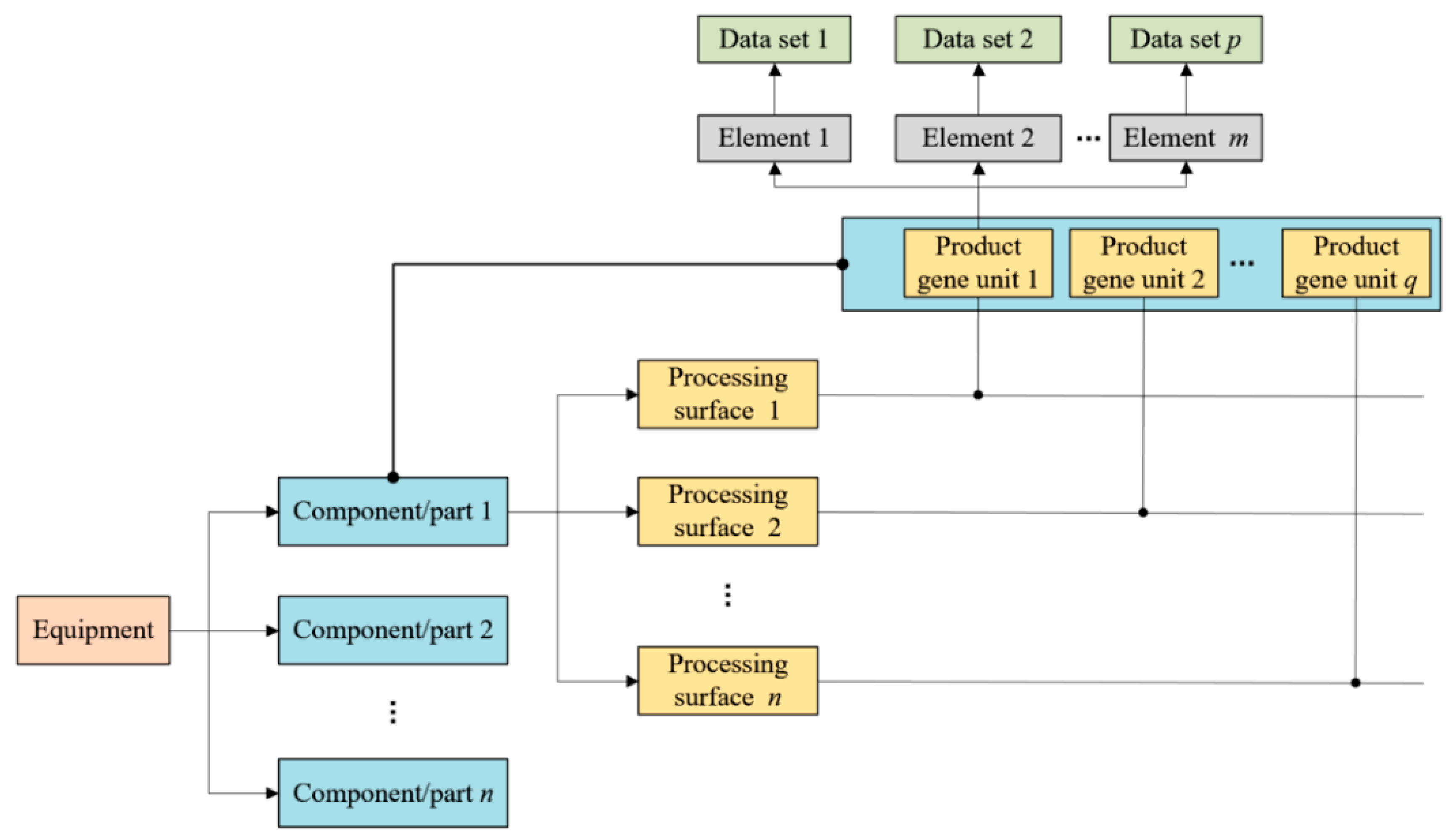

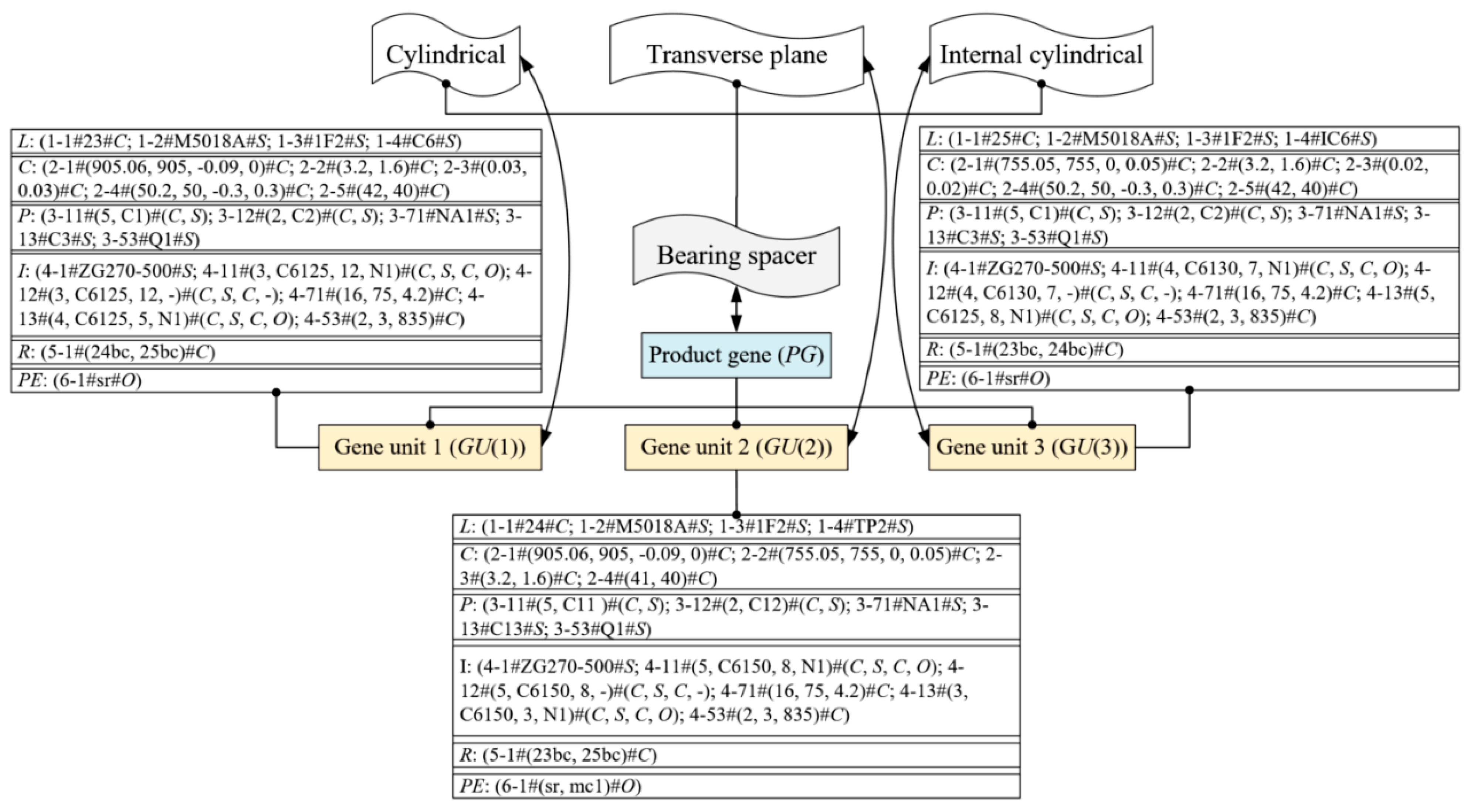

3.1. Product Gene Model for Dynamic Quality Control

3.2. Encoding Method of Product Gene

3.3. Similarity Calculation Rule

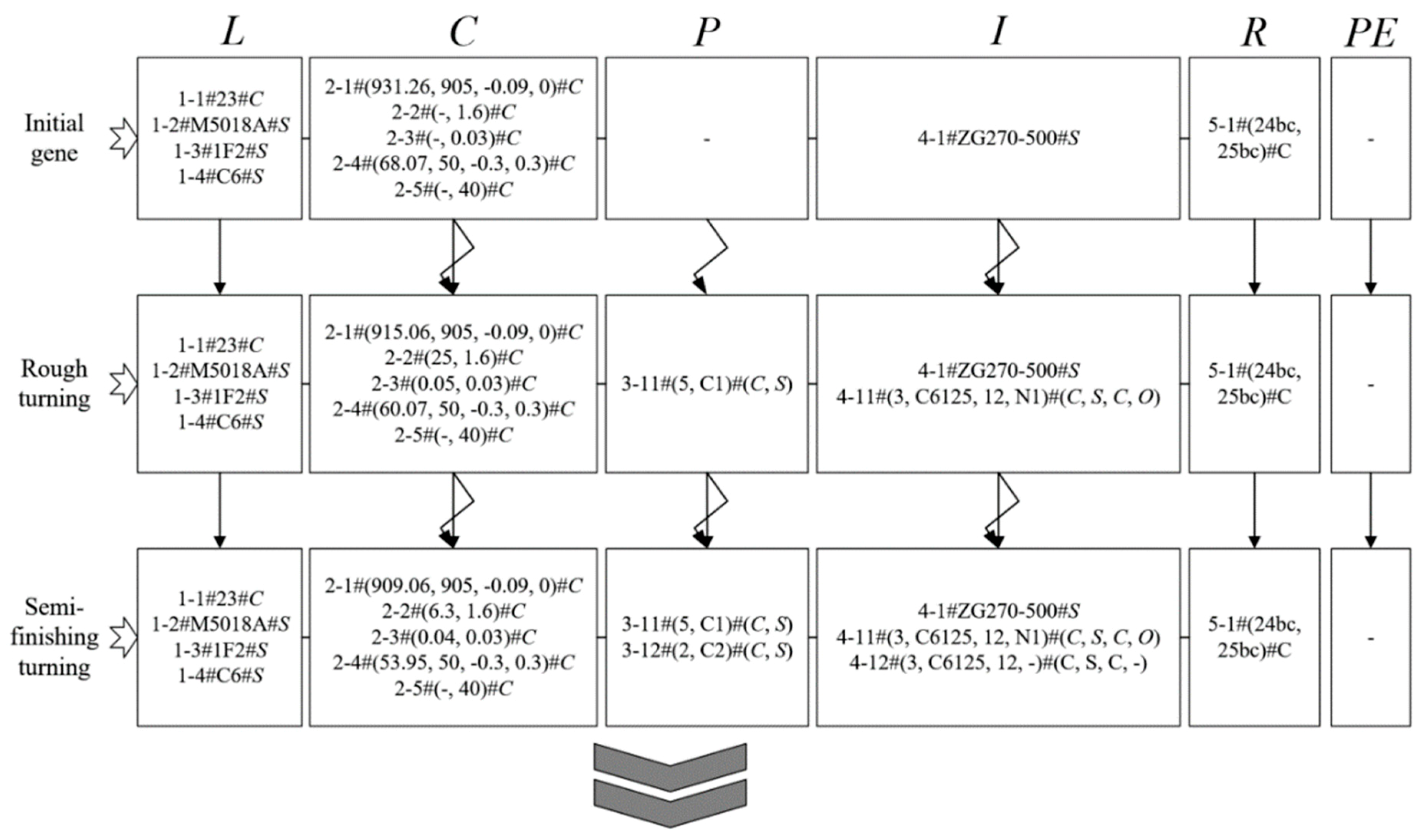

3.4. Evolution Mode of Product Gene

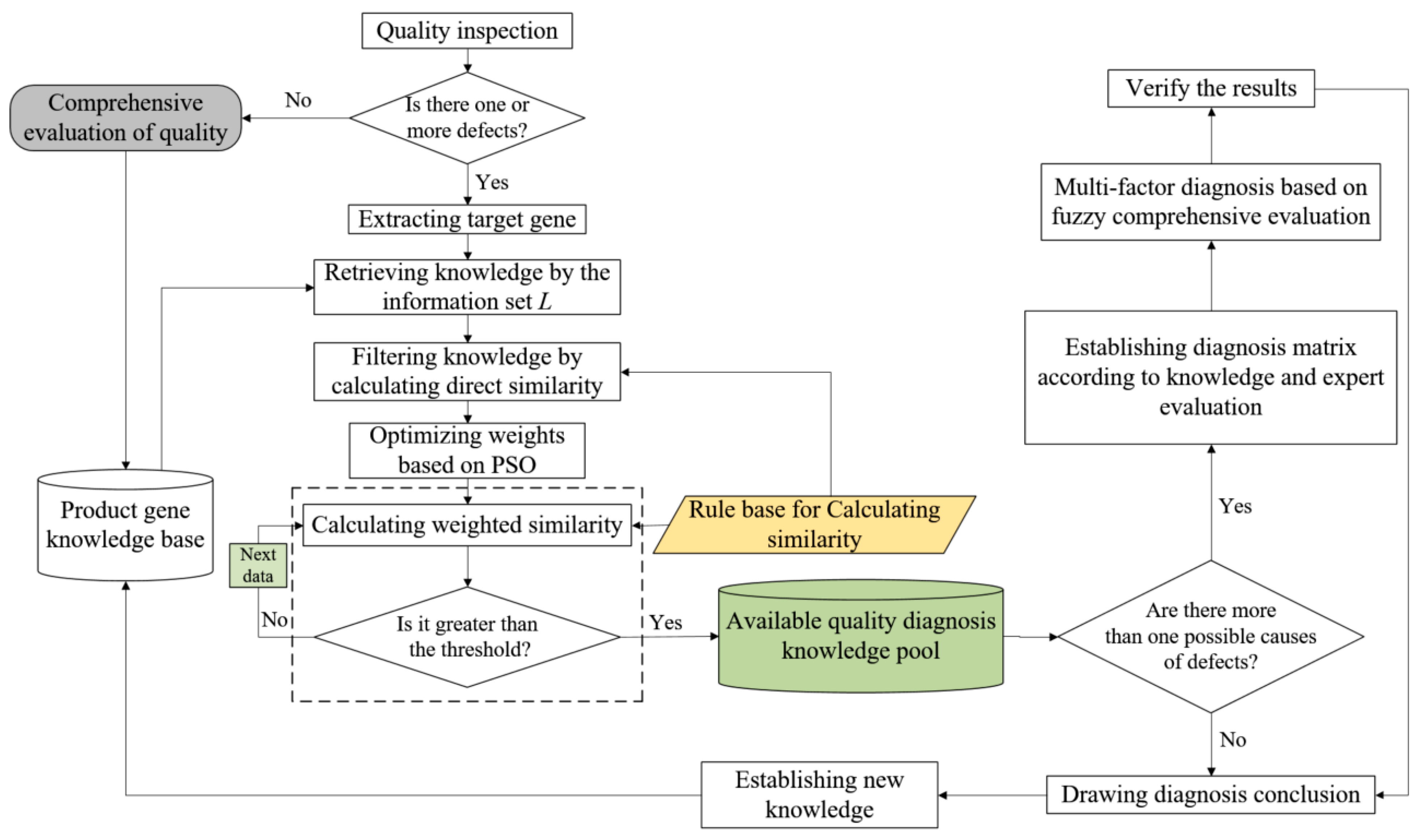

4. Quality Diagnosis Method for Manufacturing Process

4.1. Filtering Method of Product Gene Knowledge

| m | Number of related gene units |

| k | Index of a gene unit |

| nk, wk | Number of elements of gene unit k, the weight of gene unit k |

| pk, pk’, wpk | Index of an element in gene unit k, corresponding index in a knowledge gene unit, weight the element |

| n(pk) | Number of attributes of element pk |

| i(pk), i(pk’) | Index of an attribute in element pk, corresponding index in a knowledge gene unit |

| SD(PG, KPG) | Direct similarity between target gene (PG) and reference gene (KPG) |

| SD(GU(k), KGU(k)) | Direct similarity between gene unit k in PG and corresponding gene unit in KPG |

| S(PG, KPG) | Synthetic similarity between PG and KPG |

| S(GU(k), KGU(k)) | Synthetic similarity between gene unit k in PG and corresponding gene unit in KPG |

| δ(E(pk), KE(pk’)) | Similarity between element pk in PG and the corresponding element in KPG |

| δ(A(i(pk)), KA(i(pk’))) | Similarity between attribute i(pk) in PG and the corresponding element in KPG |

| TS, TSS | Threshold of direct similarity, the threshold of synthetic similarity |

| SD(GU(k)(PE), KGU(k)(PE)) | Direct similarity between the information set PE in GU(k) and corresponding information set in KGU(k) |

4.1.1. Filtering Knowledge by Calculating Direct Similarity

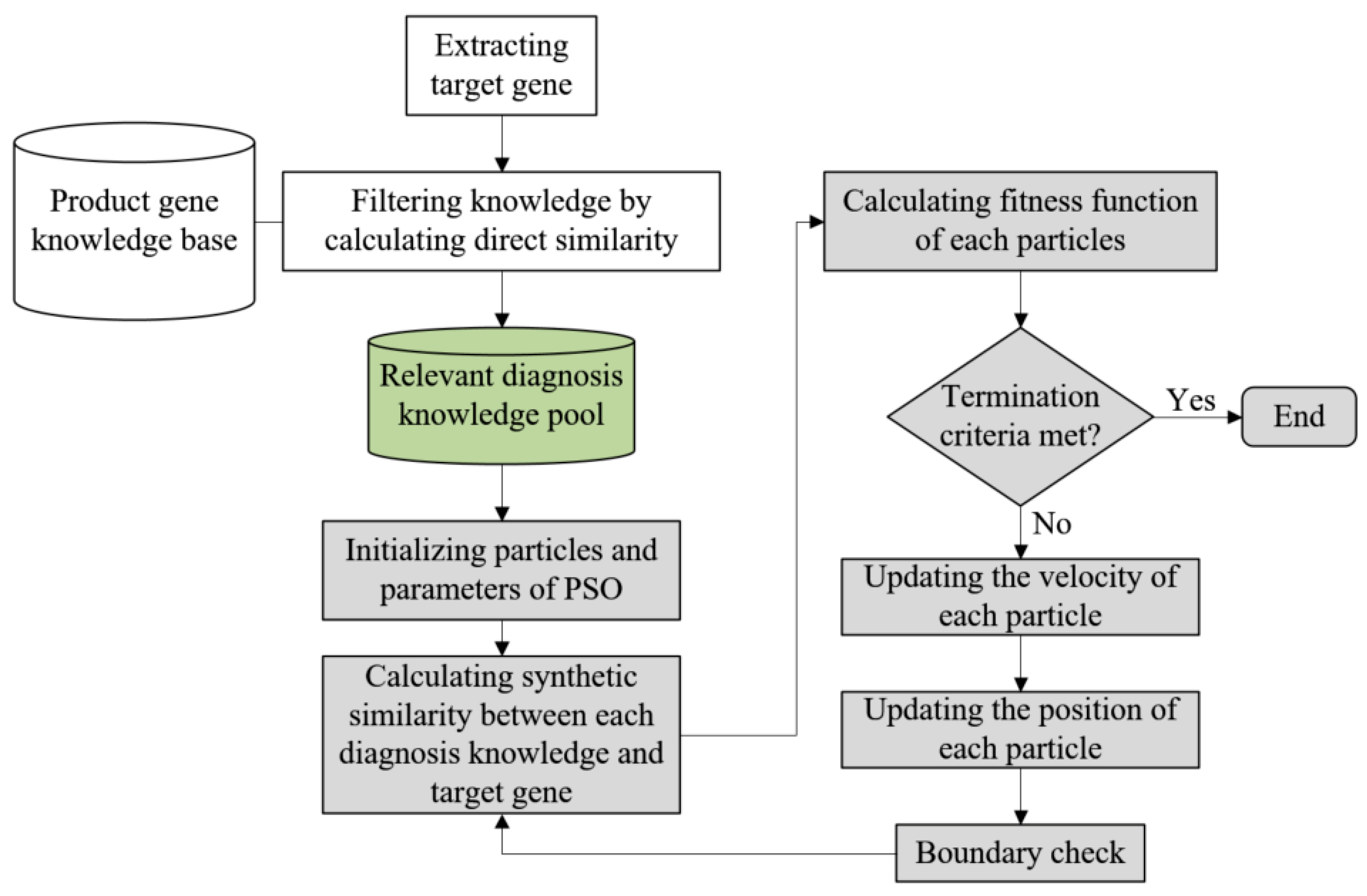

4.1.2. Filtering Knowledge by Calculating Synthetic Similarity

4.2. Fuzzy Comprehensive Evaluation for Multi-Factor Diagnosis

5. Case Study and Discussion

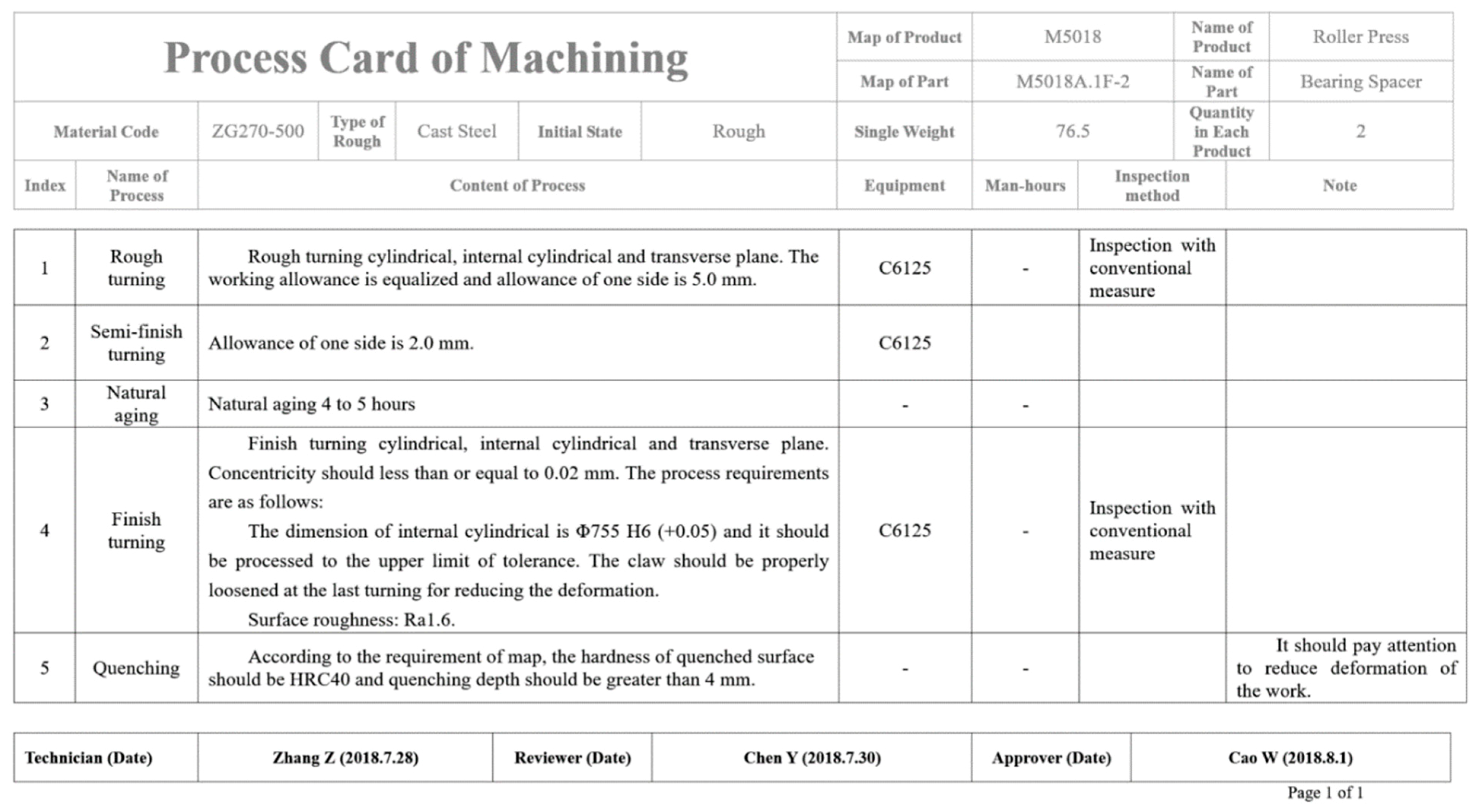

5.1. Data Preparation

5.2. Available Knowledge Acquisition

5.2.1. Filtering Knowledge Genes with Direct Similarity

5.2.2. Filtering Knowledge Genes by Calculating Synthetic Similarity

5.3. Experiment Results and Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mousavi, M.; Yap, H.J.; Musa, S.N.; Tahriri, F.; Dawal, S.Z.M. Multi-objective AGV scheduling in an FMS using a hybrid of genetic algorithm and particle swarm optimization. PLoS ONE 2017, 12, e0169817. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, G.; Yue, Q. Equipment Support Quality Management Effectiveness Evaluation based on FCE Method. Procedia Eng. 2011, 15, 4377–4381. [Google Scholar] [CrossRef]

- Li, H.; Huang, H.; Yin, Y.; Zhang, K.; Huang, P. Product Quality Evaluation Method Based on Product Gene Theory. J. Shanghai Jiaotong Univ. 2018, 23, 438–443. [Google Scholar] [CrossRef]

- Kamsu-Foguem, B.; Rigal, F.; Mauget, F. Mining association rules for the quality improvement of the production process. Expert Syst. Appl. 2013, 40, 1034–1045. [Google Scholar] [CrossRef]

- Sun, L.; Guo, S.; Tao, S.; Li, Y.; Guo, J. A quality diagnosis method for the large equipments base on quality gene similarity. Int. J. Adv. Manuf. Technol. 2013, 69, 2173–2182. [Google Scholar] [CrossRef]

- Jain, A.K.; Lad, B.K. Dynamic Optimization of Process Quality Control and Maintenance Planning. IEEE Trans. Reliab. 2017, 66, 502–517. [Google Scholar] [CrossRef]

- Liu, T.I.; Lee, J.; Liu, G.; Wu, Z. Monitoring and diagnosis of the tapping process for product quality and automated manufacturing. Int. J. Adv. Manuf. Technol. 2013, 64, 1169–1175. [Google Scholar] [CrossRef]

- Du, S.; Xi, L.; Yu, J.; Sun, J. Online intelligent monitoring and diagnosis of aircraft horizontal stabilizer assemble processes. Int. J. Adv. Manuf. Technol. 2010, 50, 377–389. [Google Scholar] [CrossRef]

- Zhang, X.H.; Deng, Z.H.; An, W.K.; Cao, H. A methodology for contour error intelligent precompensation in cam grinding. Int. J. Adv. Manuf. Technol. 2013, 64, 165–170. [Google Scholar] [CrossRef]

- Xu, F.; Liu, X.; Chen, W.; Zhou, C.; Cao, B. Ontology-Based Method for Fault Diagnosis of Loaders. Sensors 2018, 18, 729. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Dong, J.; Peng, K. A novel dynamic non-Gaussian approach for quality-related fault diagnosis with application to the hot strip mill process. J. Frankl. Inst. 2016, 354, 702–721. [Google Scholar] [CrossRef]

- Peng, K.; Zhang, K.; You, B.; Dong, J.; Wang, Z. A Quality-Based Nonlinear Fault Diagnosis Framework Focusing on Industrial Multimode Batch Processes. IEEE Trans. Ind. Electron. 2016, 63, 2615–2624. [Google Scholar] [CrossRef]

- Niu, Q. Algorithm of Multi-Causes Process Quality Diagnosis Based on Binary Tree and Intermediate Quality Indices. In Proceedings of the International Conference on Manufacturing Science and Engineering, Shenzhen, China, 30–31 March 2018. [Google Scholar]

- Xie, N.; Chen, L.; Li, A. Fault diagnosis of multistage manufacturing systems based on rough set approach. Int. J. Adv. Manuf. Technol. 2010, 48, 1239–1247. [Google Scholar] [CrossRef]

- Yaqiong, L.; Man, L.K.; Zhang, W. Fuzzy theory applied in quality management of distributed manufacturing system: A literature review and classification. Eng. Appl. Artif. Intell. 2011, 24, 266–277. [Google Scholar] [CrossRef]

- Chang, H.C.; Lin, S.C.; Kuo, C.C.; Lin, C.Y. Fuzzy Theory-Based Partial Discharge Technique for Operating State Diagnosis of High-Voltage Motor. Int. J. Fuzzy Syst. 2016, 18, 1–12. [Google Scholar] [CrossRef]

- Wan, X.; Wang, Y.; Zhao, D.; Huang, Y. A comparison of two types of neural network for weld quality prediction in small scale resistance spot welding. Mech. Syst. Signal. Process. 2017, 93, 634–644. [Google Scholar] [CrossRef]

- Kordestani, M.; Samadi, M.F.; Saif, M.; Khorasani, K. A New Fault Diagnosis of Multi-functional Spoiler System Using Integrated Artificial Neural Network and Discrete Wavelet Transform methods. IEEE Sens. J. 2018, 18, 4990–5000. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, J.; Guo, J.; Zou, Q.; Huang, Z. Vibrant fault diagnosis for hydroelectric generator units with a new combination of rough sets and support vector machine. Expert Syst. Appl. 2012, 39, 2621–2628. [Google Scholar] [CrossRef]

- Shi, J.Y.; Chen, L.; Cui, W.W. A New Hybrid Fault Diagnostic Method for Combining Dependency Matrix Diagnosis and Fuzzy Diagnosis Based on an Enhanced Inference Operator. Circuits Syst. Signal. Process. 2016, 35, 1–28. [Google Scholar] [CrossRef]

- Zhou, Q.; Yan, P.; Liu, H.; Xin, Y. A hybrid fault diagnosis method for mechanical components based on ontology and signal analysis. J. Intell. Manuf. 2017, 30, 1693–1715. [Google Scholar] [CrossRef]

- Nelson, G.; Hamlyn, P.F.; Holden, L.; McCarthy, B.J. A Species-Specific DNA Probe for Goat Fiber Identification. Text. Res. J. 1992, 62, 590–595. [Google Scholar] [CrossRef]

- Huang, J.T.; Wang, M.H.; Xu, K.K. Rolling bearing fault diagnosis fusion model based on gene expression programming. J. Inf. Comput. Sci. 2010, 7, 2437–2442. [Google Scholar]

- Ma, S.; Liu, Z.; Jiang, W.L. The application of gene techniques to multi-function radar signal analysis. Tien Tzu Hsueh Pao 2013, 41, 2374–2381. [Google Scholar]

- Hsieh, T.J. A bacterial gene recombination algorithm for solving constrained optimization problems. Appl. Math. Comput. 2014, 231, 187–204. [Google Scholar] [CrossRef]

- Chen, K.Z.; Feng, X.A. Virtual genes of manufacturing products and their reforms for product innovative design. Proc. Inst. Mech. Eng. Part C J. MEC 2004, 218, 557–574. [Google Scholar] [CrossRef]

- Sun, L.; Guo, S.; Li, Y.; Maw Htay, M. Quality Prediction Model Based on Mechanical Product Gene. Adv. Sci. 2013, 5, 1090–1096. [Google Scholar] [CrossRef]

- Libo, S. Study on Quality Control Theory for Building Materials Equipment Manufacturing Processing Based on Product Quality Gene. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2014. [Google Scholar]

- Shang, Y.; Huang, K.Z.; Zhang, Q.P. Genetic model for conceptual design of mechanical products based on functional surface. Int. J. Adv. Manuf. Technol. 2009, 42, 211–221. [Google Scholar] [CrossRef]

- Feng, Y.; Gao, Y.; Tan, J.; Hagiwara, I. Exploratory study of mechanical kinematic innovation design based on gene recombination operation. J. Mech. Sci. Technol. 2013, 27, 721–731. [Google Scholar] [CrossRef]

- Zhao, L.; Diao, G.; Yan, P.; Yao, Y.; Chen, H. A gene recombination method for machine tools design based on complex network. Int. J. Adv. Manuf. Technol. 2016, 83, 729–741. [Google Scholar] [CrossRef]

- Zhu, H.M.; Zhang, Y.B.; Zhu, M.Z. Research on the Reverse Mold Assembly Technology Based on Product Gene. Appl. Mech. Mater. 2013, 475–476, 1463–1467. [Google Scholar] [CrossRef]

- Sun, L.; Guo, S.; Li, Y. Research on Quality Control Theory Based on Product Quality Genes. China Mech. Eng. 2013, 24, 2885–2890. [Google Scholar]

- Nicholl, D.S.T. An Introduction to Genetic Engineering; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Weckenmann, A.; Akkasoglu, G.; Werner, T. Quality management-history and trends. TQM J. 2015, 27, 281–293. [Google Scholar] [CrossRef]

- Cao, X.Y.; Teng, R.M.; Wang, X.; Gao, S.D. Integrated hybrid design and product gene-base construction for mechanical products. Chin. J. Constr. Mach. 2012, 10, 1–7. [Google Scholar]

- Wu, J.; Zhang, C.H.; Cui, N.X. PSO algorithm-based parameter optimization for HEV powertrain and its control strategy. Int. J. Automot. Technol. 2008, 9, 53–59. [Google Scholar] [CrossRef]

- Ishaque, K.; Salam, Z.; Amjad, M.; Mekhilef, S. An Improved Particle Swarm Optimization (PSO)–Based MPPT for PV With Reduced Steady-State Oscillation. IEEE Trans. Power Electr. 2012, 27, 3627–3638. [Google Scholar] [CrossRef]

- Tian, Y.; Liu, D.; Yuan, D.; Wang, K. A discrete PSO for two-stage assembly scheduling problem. Int. J. Adv. Manuf. Technol. 2013, 66, 481–499. [Google Scholar] [CrossRef]

- Bai, Y.; Zhang, H.; Hao, Y. The performance of the backpropagation algorithm with varying slope of the activation function. Chaos Soliton. Fract. 2009, 40, 69–77. [Google Scholar] [CrossRef]

- Guo, L.; Gao, J.; Yang, J.; Kang, J. Criticality evaluation of petrochemical equipment based on fuzzy comprehensive evaluation and a BP neural network. J. Loss Prevent. Proc. 2009, 22, 469–476. [Google Scholar] [CrossRef]

- Kumar, A. A tolerance allocation framework using fuzzy comprehensive evaluation and decision support processes. Int. J. Adv. Manuf. Technol. 2011, 55, 379–391. [Google Scholar] [CrossRef]

- Li, W.; Liang, W.; Zhang, L.; Tang, Q. Performance assessment system of health, safety and environment based on experts’ weights and fuzzy comprehensive evaluation. J. Loss Prevent. Proc. 2015, 35, 95–103. [Google Scholar] [CrossRef]

- Liang, B.; Cao, D. Fuzzy Mathematics and Its Application; The Science Publishing Company: Beijing, China, 2007. [Google Scholar]

- Hsiao, S.W.; Ko, Y.C. A study on bicycle appearance preference by using FCE and FAHP. Int. J. Ind. Ergonom. 2013, 43, 264–273. [Google Scholar] [CrossRef]

| Composition of Attribute Code | Type of Value | Description |

|---|---|---|

| Code of element# (values set)#(metadata set) | Boolean (B) | It can be described by a binary number. |

| Option (O) | There are multiple options to be chosen and only one option can be chosen. | |

| Discrete (D) | A discrete value is a discontinuous value or it belongs to one of several discrete intervals. | |

| Continuity (C) | A continuous value is a continuous numeric value which can be computed. | |

| String (S) | A string value is described with a string which consists of one or more characters. |

| Information Set | Code | Explanation |

|---|---|---|

| L | 1-1#23#C | The unique code of GU (1) is “23” and the type of its value is continuity. |

| 1-2#M5018A#S | The code of the equipment is “M5018A”, and the type of value is string. | |

| 1-3#1F2#S | The code of the part is “1F2” and the type of value is string. | |

| 1-4#C6#S | The code of the type of surface is “C6” and the type of value is string. | |

| C | 2-1#(905.06, 905, -0.09, 0)#C | The actual diameter is 905.06 mm, the design diameter is 905 mm, the lower deviation is −0.09 mm, the upper deviation is 0 mm. The types of values are all continuity. |

| 2-2#(3.2, 1.6)#C | The actual surface roughness is Ra3.2, the design surface roughness is Ra1.6. The types of values are both continuity. | |

| 2-3#(0.03, 0.03)#C | The actual concentricity and design concentricity are both 0.03 mm, and the type of value is continuity. | |

| 2-4#(50.2, 50, -0.3, 0.3)#C | The actual width is 50.2 mm, the design width is 50 mm, the lower deviation is -0.3 mm, the upper deviation is 0.3 mm. The types of values are all continuity. | |

| 2-5#(42, 40)#C | The actual hardness is HRC42, the design hardness is HRC40. The types of values are both continuity. | |

| P | 3-11#(5, C1)#(C, S) | The allowance of one side is 5 mm; the processing mode of rough turning is “C1”. The types of values are continuity and string, respectively. |

| 3-12#(2, C2)#(C, S) | The allowance of one side is 2 mm, the processing mode of semi-finish turning is “C2”. The types of values are continuity and string, respectively. | |

| 3-71#NA1#S | The mode of natural aging is “NA1” and the type of the value is string. | |

| 3-13#C3#S | The processing mode of finish turning is “C3” and the type of the value is string. | |

| 3-53#Q1#S | The mode of quenching is “Q1” and the type of the value is string. | |

| I | 4-1#ZG270-500#S | The material is “ZG270-500” and the type of the value is string. |

| 4-11#(3, C6125, 12, N1)#(C, S, C, O) | The capability of worker is “3” the machine type is “C6125”, the age of machine of rough turning is 12 years. The types of values are continuity, string, continuity, and option respectively. | |

| 4-12#(3, C6125, 12, -)#(C, S, C, -) | The capability of the worker is “3” the machine type is “C6125”, the age of machine of semi-finish turning is 12 years. The types of values are continuity, string, and continuity, respectively. | |

| 4-71#(16, 75, 4.2)#C | The average temperature is 16 ℃, the humidity is 75%, the time of natural aging is 4.2 hours. The types of values are all continuity. | |

| 4-13#(4, C6125, 5, N1)#(C, S, C, O) | The capability of worker is “4” the machine type is “C6125” the age of the machine is 5 years, and the inspection method of finish turning is the conventional method. The types of values are continuity, string, continuity, and option, respectively. | |

| 4-53#(2, 3, 835)#C | The capability of the worker is “2” holding time is 3 minutes, the temperature of quenching is 835 ℃. The types of values are all continuity. | |

| R | 5-1#(24bc, 25bc)#C | The unique codes of related surfaces are “24” and “25” respectively, and influence relationship and sequence relationship are included. The type of value is continuity. |

| PE | 6-1#sr#O | The defect is general surface roughness error and the type of value is option. |

| Quality Defects (Fuzzy Factors) | Diagnosis Conclusions (Fuzzy Classifications) | ||

|---|---|---|---|

| FC1 | FC2 | FC3 | |

| FF1 | 5 | 2 | 3 |

| FF2 | 1 | 3 | 4 |

| FF3 | 2 | 1 | 2 |

| Index | GU(1) | GU(2) | GU(3) |

|---|---|---|---|

| 1 | 1-1#11#C;1-2#M5018B#S;1-3#1F2#S;1-4#C6#S;2-1#(904.99,905,-0.09,0)#C;2-2#(3.2,1.6)#C;2-3#(0.02,0.03)#C;2-4#(50.33,50,-0.15,0.3)#C;2-5#(45,42)#C;3-11#(5,C1)#(C,S);3-12#(2.1,C2)#(C,S);3-71#NA2#S;3-13#C3#S;3-53#Q2#S;4-1#ZG230-450#S;4-11#(7,C6130,7,N2)#(C,S,C,O);4-12#(7,C6130,7,-)#(C,S,C,O);4-71#(13,35,4.2)#C;4-13#(4,C6130,11,N2)#(C,S,C,O);4-53#(4,3.2,830)#C;5-1#(12,3)#C;6-1#(sr,de3)#O;7-1#(om13,mat,mt)#O | 1-1#12#C;1-2#M5018B#S;1-3#1F2#S;1-4#C6#S;2-1#(905.01,905,-0.09,0)#C;2-2#(755.02,755,0,0.05)#C;2-3#(1.6,1.6)#C;2-4#(50.33,50,-0.15,0.3)#C;3-11#(4.9,C11)#(C,S);3-12#(1.8,C12)#(C,S);3-71#NA2#S;3-13#C13#S;3-53#Q2#S;4-1#ZG230-450#S;4-11#(3,C6125,11,N1)#(C,S,C,O);4-12#(3,C6125,11,-)#(C,S,C,O);4-71#(13,35,4.2)#C;4-13#(4,C6125,7,N1)#(C,S,C,O);4-53#(4,3.2,830)#C;5-1#(11,3)#C | 1-1#3#C;1-2#M5018B#S;1-3#1F2#S;1-4#C6#S;2-1#(755.02,755,0,0.05)#C;2-2#0.8,1.6#C;2-3#(0.02,0.03)#C;2-4#(45,42)#C;2-5#(40,42)#C;3-11#(4.8,C1)#(C,S);3-12#(2.1,C2)#(C,S);3-71#NA2#S;3-13#C3#S;3-53#Q2#S;4-1#ZG230-450#S;4-11#(5,C6130,7,N1)#(C,S,C,O);4-12#(5,C6130,7,-)#(C,S,C,O);4-71#(13,35,4.2)#C;4-13#(6,C6150,8,N2)#(C,S,C,O);4-53#(4,3.2,830)#C;5-1#(11,12)#C;6-1#(de3, he1)#O;7-1#(mat,ht1)#O |

| 2 | 1-1#13#C;1-2#M5018A#S;1-3#1F2A#S;1-4#C6#S;2-1#(799.97,800,-0.05,0)#C;2-2#(3.2,1.6)#C;2-3#(0.02,0.03)#C;2-4#(65.08,65,-0.15,0.15)#C;2-5#(42,42)#C;3-11#(4.9,C1)#(C,S);3-12#(2.1,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(6,C6130,10,N1)#(C,S,C,O);4-12#(6,C6130,10,N2)#(C,S,C,O);4-71#(16,15,3.9)#C;4-13#(7,C6150,11,N2)#(C,S,C,O);4-53#(3,3.2,850)#C;5-1#(14,5)#C;6-1#(sr,mc1)#O;7-1#(om11,om13,cm1, tem1)#O | 1-1#14#C;1-2#M5018A#S;1-3#1F2A#S;1-4#C6#S;2-1#(800.03,800,-0.05,0)#C;2-2#(650.01,650,0,0.07)#C;2-3#(3.2,3.2)#C;2-4#(65.08,65,-0.15,0.15)#C;3-11#(5.2,C11)#(C,S);3-12#(1.8,C12)#(C,S);3-71#NA1#S;3-13#C13#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(2,C6130,7,N1)#(C,S,C,O);4-12#(2,C6130,7,N1)#(C,S,C,O);4-71#(16,15,3.9)#C;4-13#(4,C6150,8,N1)#(C,S,C,O);4-53#(3,3.2,850)#C;5-1#(13,5)#C | 1-1#5#C;1-2#M5018A#S;1-3#1F2A#S;1-4#C6#S;2-1#(650.01,650,0,0.07)#C;2-2#0.8,1.6#C;2-3#(0.02,0.01)#C;2-4#(45,40)#C;2-5#(40,40)#C;3-11#(4.9,C1)#(C,S);3-12#(2,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(5,C6125,8,N1)#(C,S,C,O);4-12#(5,C6125,8,N2)#(C,S,C,O);4-71#(16,15,3.9)#C;4-13#(7,C6150,3,N1)#(C,S,C,O);4-53#(3,3.2,850)#C;5-1#(13,14)#C;6-1#(mc1,ce1)#O;7-1#(pw13,tem1)#O |

| 3 | 1-1#15#C;1-2#M5018A#S;1-3#1F2#S;1-4#C6#S;2-1#(905.03,905,-0.056,0)#C;2-2#(3.2,3.2)#C;2-3#(0.02,0.01)#C;2-4#(65.15,65,-0.15,0.3)#C;2-5#(42,40)#C;3-11#(5.2,C1)#(C,S);3-12#(2.1,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q2#S;4-1#ZG230-450#S;4-11#(7,C6150,5,N2)#(C,S,C,O);4-12#(7,C6150,5,N2)#(C,S,C,O);4-71#(13,35,4.2)#C;4-13#(4,C6150,3,N2)#(C,S,C,O);4-53#(7,3.5,840)#C;5-1#(16,6)#C;6-1#(ce1,de1)#O;7-1#(om13,pw13)#O | 1-1#16#C;1-2#M5018A#S;1-3#1F2#S;1-4#C6#S;2-1#(905.10,905,-0.056,0)#C;2-2#(755.08,755,0,0.08)#C;2-3#(0.8,3.2)#C;2-4#(65.15,65,-0.15,0.3)#C;3-11#(5,C11)#(C,S);3-12#(1.8,C12)#(C,S);3-71#NA1#S;3-13#C13#S;3-53#Q2#S;4-1#ZG230-450#S;4-11#(4,C6130,3,N2)#(C,S,C,O);4-12#(4,C6130,3,N1)#(C,S,C,O);4-71#(13,35,4.2)#C;4-13#(4,C6150,3,N2)#(C,S,C,O);4-53#(7,3.5,840)#C;5-1#(15,6)#C | 1-1#6#C;1-2#M5018A#S;1-3#1F2#S;1-4#C6#S;2-1#(755.08,755,0,0.08)#C;2-2#3.2,3.2#C;2-3#(0.03,0.02)#C;2-4#(44,42)#C;2-5#(45,40)#C;3-11#(5.1,C1)#(C,S);3-12#(2,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q2#S;4-1#ZG230-450#S;4-11#(4,C6150,8,N2)#(C,S,C,O);4-12#(4,C6150,8,-)#(C,S,C,O);4-71#(13,35,4.2)#C;4-13#(3,C6125,5,N1)#(C,S,C,O);4-53#(7,3.5,840)#C;5-1#(15,16)#C;6-1#(ce1)#O;7-1#(mt,pw13)#O |

| 4 | … | … | … |

| Element Code | Abbreviation | Explanation |

|---|---|---|

| 6-1 | sr | It indicates that the surface roughness is too large. |

| mc1 | It indicates the existence of microcracks on the surface. | |

| ce1 | It indicates that the concentricity error is too large. | |

| de1 | It indicates that the diameter error is greater than the upper deviation. | |

| de2 | It indicates that the diameter error is less than the lower deviation. | |

| de3 | It indicates that the width error is greater than the upper deviation. | |

| de4 | It indicates that the width error is less than the lower deviation. | |

| bh | It indicates the existence of blowholes on the surface. | |

| imp | It indicates the existence of impurities on the surface. | |

| he1 | It indicates that the surface hardness is lower than its design value. | |

| 7-1 | om11 | It indicates that the machine of rough turning or semi-finish turning is too old. |

| om13 | It indicates that the machine of finish turning is too old. | |

| mat | It indicates that the material is inappropriate or unqualified | |

| mt | It indicates that the error of measuring tools is too large. | |

| pw11 | It indicates that the worker who carries out rough turning is not skilled enough. | |

| pw13 | It indicates that the worker who carries out finish turning is not skilled enough. | |

| pw53 | It indicates that the worker who carries out quenching is not skilled enough. | |

| cm1 | It indicates that the structure of casting mold is unreasonable. | |

| cm2 | It indicates that the casting mold has not been cleaned up. | |

| ht1 | It indicates that the holding time of quenching is too short. | |

| ht2 | It indicates that the holding time of quenching is too long. | |

| tem1 | It means that the temperature of quenching is too high. | |

| tem2 | It means that the temperature of quenching is too low. |

| Index | GU(1) | GU(2) | GU(3) |

|---|---|---|---|

| 1 | 1-1#11#C;1-2#M5018B#S;1-3#1F2#S;1-4#C6#S;2-1#(904.99,905,-0.09,0)#C;2-2#(3.2,1.6)#C;2-3#(0.02,0.03)#C;2-4#(50.33,50,-0.15,0.3)#C;2-5#(45,42)#C;3-11#(5,C1)#(C,S);3-12#(2.1,C2)#(C,S);3-71#NA2#S;3-13#C3#S;3-53#Q2#S;4-1#ZG230-450#S;4-11#(7,C6130,7,N2)#(C,S,C,O);4-12#(7,C6130,7,-)#(C,S,C,O);4-71#(13,35,4.2)#C;4-13#(4,C6130,11,N2)#(C,S,C,O);4-53#(4,3.2,830)#C;5-1#(12,3)#C;6-1#(sr,de3)#O;7-1#(om13,mat,mt)#O | 1-1#12#C;1-2#M5018B#S;1-3#1F2#S;1-4#C6#S;2-1#(905.01,905,-0.09,0)#C;2-2#(755.02,755,0,0.05)#C;2-3#(1.6,1.6)#C;2-4#(50.33,50,-0.15,0.3)#C;3-11#(4.9,C11)#(C,S);3-12#(1.8,C12)#(C,S);3-71#NA2#S;3-13#C13#S;3-53#Q2#S;4-1#ZG230-450#S;4-11#(3,C6125,11,N1)#(C,S,C,O);4-12#(3,C6125,11,-)#(C,S,C,O);4-71#(13,35,4.2)#C;4-13#(4,C6125,7,N1)#(C,S,C,O);4-53#(4,3.2,830)#C;5-1#(11,3)#C | 1-1#3#C;1-2#M5018B#S;1-3#1F2#S;1-4#C6#S;2-1#(755.02,755,0,0.05)#C;2-2#0.8,1.6#C;2-3#(0.02,0.03)#C;2-4#(45,42)#C;2-5#(40,42)#C;3-11#(4.8,C1)#(C,S);3-12#(2.1,C2)#(C,S);3-71#NA2#S;3-13#C3#S;3-53#Q2#S;4-1#ZG230-450#S;4-11#(5,C6130,7,N1)#(C,S,C,O);4-12#(5,C6130,7,-)#(C,S,C,O);4-71#(13,35,4.2)#C;4-13#(6,C6150,8,N2)#(C,S,C,O);4-53#(4,3.2,830)#C;5-1#(11,12)#C;6-1#(de3, he1)#O;7-1#(mat,ht1)#O |

| 2 | 1-1#13#C;1-2#M5018A#S;1-3#1F2A#S;1-4#C6#S;2-1#(799.97,800,-0.05,0)#C;2-2#(3.2,1.6)#C;2-3#(0.02,0.03)#C;2-4#(65.08,65,-0.15,0.15)#C;2-5#(42,42)#C;3-11#(4.9,C1)#(C,S);3-12#(2.1,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(6,C6130,10,N1)#(C,S,C,O);4-12#(6,C6130,10,N2)#(C,S,C,O);4-71#(16,15,3.9)#C;4-13#(7,C6150,11,N2)#(C,S,C,O);4-53#(3,3.2,850)#C;5-1#(14,5)#C;6-1#(sr,mc1)#O;7-1#(om11,om13,cm1,tem1)#O | 1-1#14#C;1-2#M5018A#S;1-3#1F2A#S;1-4#C6#S;2-1#(800.03,800,-0.05,0)#C;2-2#(650.01,650,0,0.07)#C;2-3#(3.2,3.2)#C;2-4#(65.08,65,-0.15,0.15)#C;3-11#(5.2,C11)#(C,S);3-12#(1.8,C12)#(C,S);3-71#NA1#S;3-13#C13#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(2,C6130,7,N1)#(C,S,C,O);4-12#(2,C6130,7,N1)#(C,S,C,O);4-71#(16,15,3.9)#C;4-13#(4,C6150,8,N1)#(C,S,C,O);4-53#(3,3.2,850)#C;5-1#(13,5)#C | 1-1#5#C;1-2#M5018A#S;1-3#1F2A#S;1-4#C6#S;2-1#(650.01,650,0,0.07)#C;2-2#0.8,1.6#C;2-3#(0.02,0.01)#C;2-4#(45,40)#C;2-5#(40,40)#C;3-11#(4.9,C1)#(C,S);3-12#(2,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(5,C6125,8,N1)#(C,S,C,O);4-12#(5,C6125,8,N2)#(C,S,C,O);4-71#(16,15,3.9)#C;4-13#(7,C6150,3,N1)#(C,S,C,O);4-53#(3,3.2,850)#C;5-1#(13,14)#C;6-1#(mc1,ce1)#O;7-1#(pw13,tem1)#O |

| 5 | 1-1#19#C;1-2#SLC301#S;1-3#1F2R#S;1-4#C6#S;2-1#(774.99,775,-0.08,0)#C;2-2#(0.8,1.6)#C;2-3#(0.03,0.03)#C;2-4#(69.81,70,-0.15,0.15)#C;2-5#(43,40)#C;3-11#(5,C1)#(C,S);3-12#(1.8,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q1#S;4-1#ZG230-450#S;4-11#(3,C6150,8,N1)#(C,S,C,O);4-12#(3,C6150,8,N2)#(C,S,C,O);4-71#(16,50,4.2)#C;4-13#(2,C6130,3,N1)#(C,S,C,O);4-53#(7,3.8,850)#C;5-1#(21,9)#C;6-1#(sr,mc1,de4)#O;7-1#(mt,pw11,pw13,cm1,tem1)#O | 1-1#21#C;1-2#SLC301#S;1-3#1F2R#S;1-4#C6#S;2-1#(775.02,775,-0.08,0)#C;2-2#(625.04,625,0,0.44)#C;2-3#(1.6,1.6)#C;2-4#(69.91,70,-0.15,0.15)#C;3-11#(5.2,C11)#(C,S);3-12#(2.1,C12)#(C,S);3-71#NA1#S;3-13#C13#S;3-53#Q1#S;4-1#ZG230-450#S;4-11#(3,C6130,8,N2)#(C,S,C,O);4-12#(3,C6130,8,N2)#(C,S,C,O);4-71#(16,50,4.2)#C;4-13#(6,C6130,11,N2)#(C,S,C,O);4-53#(7,3.8,850)#C;5-1#(19,9)#C;6-1#(sr,mc1)#O;7-1#(om13,mt,pw11,cm1,tem1)#O | 1-1#9#C;1-2#SLC301#S;1-3#1F2R#S;1-4#C6#S;2-1#(625.04,625,0,0.44)#C;2-2#3.2,3.2#C;2-3#(0.02,0.02)#C;2-4#(42,40)#C;2-5#(44,42)#C;3-11#(5.1,C1)#(C,S);3-12#(2.2,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q1#S;4-1#ZG230-450#S;4-11#(6,C6125,10,N1)#(C,S,C,O);4-12#(6,C6125,10,N1)#(C,S,C,O);4-71#(16,50,4.2)#C;4-13#(5,C6150,10,N2)#(C,S,C,O);4-53#(7,3.8,850)#C;5-1#(19,21)#C;6-1#(sr,mc1)#O;7-1#(mt,cm1,ht2,tem1)#O |

| 11 | 1-1#66#C;1-2#TRMC202#S;1-3#1F2#S;1-4#C6#S;2-1#(904.99,905,-0.056,0)#C;2-2#(3.2,1.6)#C;2-3#(0.02,0.05)#C;2-4#(64.83,65,-0.15,0.3)#C;2-5#(41,40)#C;3-11#(4.8,C1)#(C,S);3-12#(2.1,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q2#S;4-1#ZG230-450#S;4-11#(5,C6125,7,N1)#(C,S,C,O);4-12#(5,C6125,7,N2)#(C,S,C,O);4-71#(21,75,4.2)#C;4-13#(6,C6125,8,N2)#(C,S,C,O);4-53#(7,3.2,850)#C;5-1#(62,34)#C;6-1#(sr,de4)#O;7-1#(mat,mt,cm1)#O | 1-1#62#C;1-2#TRMC202#S;1-3#1F2#S;1-4#C6#S;2-1#(905.01,905,-0.056,0)#C;2-2#(755.02,755,0,0.08)#C;2-3#(3.2,1.6)#C;2-4#(65.13,65,-0.15,0.3)#C;3-11#(5.2,C11)#(C,S);3-12#(2.2,C12)#(C,S);3-71#NA1#S;3-13#C13#S;3-53#Q2#S;4-1#ZG230-450#S;4-11#(5,C6150,7,N2)#(C,S,C,O);4-12#(5,C6150,7,-)#(C,S,C,O);4-71#(21,75,4.2)#C;4-13#(6,C6125,11,N1)#(C,S,C,O);4-53#(7,3.2,850)#C;5-1#(66,34)#C;6-1#(sr)#O;7-1#(om13)#O | 1-1#34#C;1-2#TRMC202#S;1-3#1F2#S;1-4#C6#S;2-1#(755.02,755,0,0.08)#C;2-2#3.2,1.6#C;2-3#(0.03,0.03)#C;2-4#(44,42)#C;2-5#(42,42)#C;3-11#(5,C1)#(C,S);3-12#(2.2,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q2#S;4-1#ZG230-450#S;4-11#(6,C6125,7,N1)#(C,S,C,O);4-12#(6,C6125,7,N2)#(C,S,C,O);4-71#(21,75,4.2)#C;4-13#(5,C6150,3,N1)#(C,S,C,O);4-53#(7,3.2,850)#C;5-1#(66,62)#C;6-1#(sr)#O;7-1#(mt)#O |

| 14 | 1-1#71#C;1-2#M5018R#S;1-3#1F2R#S;1-4#C6#S;2-1#(775.02,775,-0.05,0)#C;2-2#(3.2,1.6)#C;2-3#(0.01,0.02)#C;2-4#(69.95,70,-0.15,0.3)#C;2-5#(40,42)#C;3-11#(5.1,C1)#(C,S);3-12#(2,C2)#(C,S);3-71#NA2#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(5,C6130,8,N2)#(C,S,C,O);4-12#(5,C6130,8,N1)#(C,S,C,O);4-71#(21,75,3.9)#C;4-13#(6,C6150,3,N2)#(C,S,C,O);4-53#(7,3.8,850)#C;5-1#(73,45)#C;6-1#(sr,de1,he1)#O;7-1#(mt,tem1)#O | 1-1#73#C;1-2#M5018R#S;1-3#1F2R#S;1-4#C6#S;2-1#(775.08,775,-0.05,0)#C;2-2#(625.05,625,0,0.07)#C;2-3#(1.6,1.6)#C;2-4#(69.95,70,-0.15,0.3)#C;3-11#(4.8,C11)#(C,S);3-12#(2.2,C12)#(C,S);3-71#NA2#S;3-13#C13#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(7,C6150,10,N2)#(C,S,C,O);4-12#(7,C6150,10,-)#(C,S,C,O);4-71#(21,75,3.9)#C;4-13#(4,C6125,8,N2)#(C,S,C,O);4-53#(7,3.8,850)#C;5-1#(71,45)#C | 1-1#45#C;1-2#M5018R#S;1-3#1F2R#S;1-4#C6#S;2-1#(625.05,625,0,0.07)#C;2-2#3.2,1.6#C;2-3#(0.02,0.03)#C;2-4#(41,40)#C;2-5#(45,40)#C;3-11#(5.1,C1)#(C,S);3-12#(2.1,C2)#(C,S);3-71#NA2#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(3,C6125,11,N2)#(C,S,C,O);4-12#(3,C6125,11,N1)#(C,S,C,O);4-71#(21,75,3.9)#C;4-13#(5,C6130,3,N1)#(C,S,C,O);4-53#(7,3.8,850)#C;5-1#(71,73)#C;6-1#(sr)#O;7-1#(om11,pw11)#O |

| 15 | 1-1#83#C;1-2#TRMC202#S;1-3#1F2#S;1-4#C6#S;2-1#(904.91,905,-0.056,0)#C;2-2#(1.6,1.6)#C;2-3#(0.02,0.02)#C;2-4#(49.92,50,-0.15,0.15)#C;2-5#(43,40)#C;3-11#(5,C1)#(C,S);3-12#(2,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(2,C6130,3,N1)#(C,S,C,O);4-12#(2,C6130,3,N2)#(C,S,C,O);4-71#(13,15,4.7)#C;4-13#(5,C6150,5,N1)#(C,S,C,O);4-53#(3,3.2,830)#C;5-1#(77,46)#C;6-1#(de2)#O;7-1#(pw11,tem2)#O | 1-1#77#C;1-2#TRMC202#S;1-3#1F2#S;1-4#C6#S;2-1#(905.10,905,-0.056,0)#C;2-2#(755.08,755,0,0.08)#C;2-3#(0.8,3.2)#C;2-4#(49.92,50,-0.15,0.15)#C;3-11#(5.2,C11)#(C,S);3-12#(2,C12)#(C,S);3-71#NA1#S;3-13#C13#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(7,C6130,5,N1)#(C,S,C,O);4-12#(7,C6130,5,N2)#(C,S,C,O);4-71#(13,15,4.7)#C;4-13#(5,C6125,8,N1)#(C,S,C,O);4-53#(3,3.2,830)#C;5-1#(83,46)#C | 1-1#46#C;1-2#TRMC202#S;1-3#1F2#S;1-4#C6#S;2-1#(755.09,755,0,0.08)#C;2-2#3.2,1.6#C;2-3#(0.03,0.01)#C;2-4#(44,42)#C;2-5#(44,40)#C;3-11#(5,C1)#(C,S);3-12#(2.2,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(2,C6125,5,N2)#(C,S,C,O);4-12#(2,C6125,5,-)#(C,S,C,O);4-71#(13,15,4.7)#C;4-13#(6,C6130,11,N1)#(C,S,C,O);4-53#(3,3.2,830)#C;5-1#(83,77)#C;6-1#(sr,ce1,de1)#O;7-1#(om13,pw11,tem2)#O |

| 16 | 1-1#85#C;1-2#M5018R#S;1-3#1F2A#S;1-4#C6#S;2-1#(799.97,800,-0.08,0)#C;2-2#(1.6,1.6)#C;2-3#(0.03,0.03)#C;2-4#(50.21,50,-0.3,0.3)#C;2-5#(43,42)#C;3-11#(5.1,C1)#(C,S);3-12#(2.2,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q2#S;4-1#ZG270-500#S;4-11#(2,C6150,3,N1)#(C,S,C,O);4-12#(2,C6150,3,N1)#(C,S,C,O);4-71#(13,35,5.5)#C;4-13#(3,C6150,10,N2)#(C,S,C,O);4-53#(7,3.2,835)#C;5-1#(80,48)#C;6-1#(bh,imp)#O;7-1#(pw11,cm2)#O | 1-1#80#C;1-2#M5018R#S;1-3#1F2A#S;1-4#C6#S;2-1#(800.03,800,-0.08,0)#C;2-2#(650.01,650,0,0.44)#C;2-3#(3.2,1.6)#C;2-4#(50.21,50,-0.3,0.3)#C;3-11#(4.9,C11)#(C,S);3-12#(2.2,C12)#(C,S);3-71#NA1#S;3-13#C13#S;3-53#Q2#S;4-1#ZG270-500#S;4-11#(3,C6150,3,N2)#(C,S,C,O);4-12#(3,C6150,3,N1)#(C,S,C,O);4-71#(13,35,5.5)#C;4-13#(5,C6150,3,N1)#(C,S,C,O);4-53#(7,3.2,835)#C;5-1#(85,48)#C;6-1#(sr,imp)#O;7-1#(mt,pw11,cm2)#O | 1-1#48#C;1-2#M5018R#S;1-3#1F2A#S;1-4#C6#S;2-1#(650.01,650,0,0.44)#C;2-2#3.2,1.6#C;2-3#(0.02,0.05)#C;2-4#(42,42)#C;2-5#(43,42)#C;3-11#(4.8,C1)#(C,S);3-12#(2.2,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q2#S;4-1#ZG270-500#S;4-11#(7,C6130,8,N1)#(C,S,C,O);4-12#(7,C6130,8,N1)#(C,S,C,O);4-71#(13,35,5.5)#C;4-13#(3,C6125,5,N2)#(C,S,C,O);4-53#(7,3.2,835)#C;5-1#(85,80)#C;6-1#(sr,bh,imp)#O;7-1#(pw13,cm2)#O |

| 17 | 1-1#86#C;1-2#TRM113#S;1-3#1F2A#S;1-4#C6#S;2-1#(799,98,800,-0.08,0)#C;2-2#(3.2,1.6)#C;2-3#(0.02,0.02)#C;2-4#(65.17,65,-0.3,0.3)#C;2-5#(43,40)#C;3-11#(4.8,C1)#(C,S);3-12#(1.8,C2)#(C,S);3-71#NA2#S;3-13#C3#S;3-53#Q1#S;4-1#ZG230-450#S;4-11#(7,C6130,5,N1)#(C,S,C,O);4-12#(7,C6130,5,N2)#(C,S,C,O);4-71#(16,75,4.2)#C;4-13#(5,C6125,7,N1)#(C,S,C,O);4-53#(7,3,840)#C;5-1#(81,51)#C;6-1#(sr,imp)#O;7-1#(cm2,ht1)#O | 1-1#81#C;1-2#TRM113#S;1-3#1F2A#S;1-4#C6#S;2-1#(800.02,800,-0.08,0)#C;2-2#(650.03,650,0,0.44)#C;2-3#(3.2,1.6)#C;2-4#(65.17,65,-0.3,0.3)#C;3-11#(4.9,C11)#(C,S);3-12#(1.9,C12)#(C,S);3-71#NA2#S;3-13#C13#S;3-53#Q1#S;4-1#ZG230-450#S;4-11#(6,C6150,7,N1)#(C,S,C,O);4-12#(6,C6150,7,-)#(C,S,C,O);4-71#(16,75,4.2)#C;4-13#(3,C6150,5,N1)#(C,S,C,O);4-53#(7,3,840)#C;5-1#(86,51)#C;6-1#(sr,imp,he1)#O;7-1#(cm2,ht1)#O | 1-1#51#C;1-2#TRM113#S;1-3#1F2A#S;1-4#C6#S;2-1#(650.03,650,0,0.44)#C;2-2#0.8,3.2#C;2-3#(0.02,0.02)#C;2-4#(40,42)#C;2-5#(41,40)#C;3-11#(5.2,C1)#(C,S);3-12#(1.8,C2)#(C,S);3-71#NA2#S;3-13#C3#S;3-53#Q1#S;4-1#ZG230-450#S;4-11#(6,C6150,10,N1)#(C,S,C,O);4-12#(6,C6150,10,N1)#(C,S,C,O);4-71#(16,75,4.2)#C;4-13#(4,C6150,10,N1)#(C,S,C,O);4-53#(7,3,840)#C;5-1#(86,81)#C;6-1#(imp)#O;7-1#(om11,om13,cm2)#O |

| 19 | 1-1#90#C;1-2#M5018B#S;1-3#1F2#S;1-4#C6#S;2-1#(904.99,905,-0.09,0)#C;2-2#(0.8,3.2)#C;2-3#(0.02,0.03)#C;2-4#(64.95,65,-0.15,0.3)#C;2-5#(45,40)#C;3-11#(4.9,C1)#(C,S);3-12#(1.9,C2)#(C,S);3-71#NA2#S;3-13#C3#S;3-53#Q1#S;4-1#ZG230-450#S;4-11#(2,C6130,8,N2)#(C,S,C,O);4-12#(2,C6130,8,-)#(C,S,C,O);4-71#(21,35,4.2)#C;4-13#(6,C6130,10,N2)#(C,S,C,O);4-53#(2,3.2,835)#C;5-1#(91,56)#C;6-1#(mc1)#O;7-1#(pw11,cm1)#O | 1-1#91#C;1-2#M5018B#S;1-3#1F2#S;1-4#C6#S;2-1#(905.01,905,-0.09,0)#C;2-2#(755.02,755,0,0.05)#C;2-3#(0.8,3.2)#C;2-4#(64.82,65,-0.15,0.3)#C;3-11#(4.9,C11)#(C,S);3-12#(1.9,C12)#(C,S);3-71#NA2#S;3-13#C13#S;3-53#Q1#S;4-1#ZG230-450#S;4-11#(5,C6130,7,N1)#(C,S,C,O);4-12#(5,C6130,7,N1)#(C,S,C,O);4-71#(21,35,4.2)#C;4-13#(7,C6150,11,N1)#(C,S,C,O);4-53#(2,3.2,835)#C;5-1#(90,56)#C;6-1#(mc1)#O;7-1#(om13,cm1)#O | 1-1#56#C;1-2#M5018B#S;1-3#1F2#S;1-4#C6#S;2-1#(755.02,755,0,0.05)#C;2-2#3.2,1.6#C;2-3#(0.03,0.01)#C;2-4#(45,42)#C;2-5#(42,42)#C;3-11#(5.2,C1)#(C,S);3-12#(1.8,C2)#(C,S);3-71#NA2#S;3-13#C3#S;3-53#Q1#S;4-1#ZG230-450#S;4-11#(6,C6125,5,N2)#(C,S,C,O);4-12#(6,C6125,5,N2)#(C,S,C,O);4-71#(21,35,4.2)#C;4-13#(5,C6130,11,N1)#(C,S,C,O);4-53#(2,3.2,835)#C;5-1#(90,91)#C;6-1#(sr,mc1,ce1,de4)#O;7-1#(om13,mat,mt,cm1)#O |

| 21 | 1-1#94#C;1-2#M5018B#S;1-3#1F2R#S;1-4#C6#S;2-1#(774.93,775,-0.05,0)#C;2-2#(0.8,3.2)#C;2-3#(0.03,0.02)#C;2-4#(65.15,65,-0.15,0.15)#C;2-5#(41,40)#C;3-11#(5,C1)#(C,S);3-12#(2.1,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(3,C6125,5,N2)#(C,S,C,O);4-12#(3,C6125,5,-)#(C,S,C,O);4-71#(26,15,4.5)#C;4-13#(3,C6125,3,N2)#(C,S,C,O);4-53#(2,3.8,840)#C;5-1#(95,60)#C;6-1#(ce1,de2)#O;7-1#(pw11,pw13)#O | 1-1#95#C;1-2#M5018B#S;1-3#1F2R#S;1-4#C6#S;2-1#(775.08,775,-0.05,0)#C;2-2#(625.05,625,0,0.07)#C;2-3#(1.6,1.6)#C;2-4#(64.80,65,-0.15,0.15)#C;3-11#(4.8,C11)#(C,S);3-12#(2.2,C12)#(C,S);3-71#NA1#S;3-13#C13#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(5,C6150,5,N2)#(C,S,C,O);4-12#(5,C6150,5,N2)#(C,S,C,O);4-71#(26,15,4.5)#C;4-13#(2,C6125,10,N2)#(C,S,C,O);4-53#(2,3.8,840)#C;5-1#(94,60)#C | 1-1#60#C;1-2#M5018B#S;1-3#1F2R#S;1-4#C6#S;2-1#(625.05,625,0,0.07)#C;2-2#1.6,1.6#C;2-3#(0.02,0.02)#C;2-4#(41,40)#C;2-5#(42,42)#C;3-11#(5,C1)#(C,S);3-12#(1.9,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(3,C6150,10,N2)#(C,S,C,O);4-12#(3,C6150,10,-)#(C,S,C,O);4-71#(26,15,4.5)#C;4-13#(6,C6125,5,N1)#(C,S,C,O);4-53#(2,3.8,840)#C;5-1#(94,95)#C;6-1#(de4)#O;7-1#(om11,pw11)#O |

| 25 | 1-1#106#C;1-2#M5018R#S;1-3#1F2#S;1-4#C6#S;2-1#(904.99,905,-0.09,0)#C;2-2#(0.8,1.6)#C;2-3#(0.02,0.05)#C;2-4#(50.20,50,-0.15,0.15)#C;2-5#(40,40)#C;3-11#(4.8,C1)#(C,S);3-12#(2.2,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q2#S;4-1#ZG230-450#S;4-11#(6,C6125,5,N1)#(C,S,C,O);4-12#(6,C6125,5,N1)#(C,S,C,O);4-71#(21,50,3.9)#C;4-13#(2,C6125,11,N2)#(C,S,C,O);4-53#(5,3,850)#C;5-1#(107,72)#C;6-1#(de3,bh)#O;7-1#(om13,pw13,tem1)#O | 1-1#107#C;1-2#M5018R#S;1-3#1F2#S;1-4#C6#S;2-1#(905.01,905,-0.09,0)#C;2-2#(755.02,755,0,0.05)#C;2-3#(1.6,3.2)#C;2-4#(50.20,50,-0.15,0.15)#C;3-11#(4.9,C11)#(C,S);3-12#(2.2,C12)#(C,S);3-71#NA1#S;3-13#C13#S;3-53#Q2#S;4-1#ZG230-450#S;4-11#(5,C6150,10,N1)#(C,S,C,O);4-12#(5,C6150,10,-)#(C,S,C,O);4-71#(21,50,3.9)#C;4-13#(4,C6150,11,N1)#(C,S,C,O);4-53#(5,3,850)#C;5-1#(106,72)#C;6-1#(bh,he1)#O;7-1#(om11,om13,tem1)#O | 1-1#72#C;1-2#M5018R#S;1-3#1F2#S;1-4#C6#S;2-1#(755.02,755,0,0.05)#C;2-2#3.2,1.6#C;2-3#(0.02,0.05)#C;2-4#(40,42)#C;2-5#(45,42)#C;3-11#(5.1,C1)#(C,S);3-12#(2,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q2#S;4-1#ZG230-450#S;4-11#(2,C6150,10,N1)#(C,S,C,O);4-12#(2,C6150,10,-)#(C,S,C,O);4-71#(21,50,3.9)#C;4-13#(6,C6130,10,N1)#(C,S,C,O);4-53#(5,3,850)#C;5-1#(106,107)#C;6-1#(sr,de3,bh)#O;7-1#(om11,om13,pw11,tem1)#O |

| 26 | 1-1#109#C;1-2#M5018R#S;1-3#1F2R#S;1-4#C6#S;2-1#(774.98,775,-0.08,0)#C;2-2#(1.6,3.2)#C;2-3#(0.02,0.05)#C;2-4#(50.10,50,-0.3,0.15)#C;2-5#(44,42)#C;3-11#(5,C1)#(C,S);3-12#(1.9,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(7,C6130,8,N2)#(C,S,C,O);4-12#(7,C6130,8,N2)#(C,S,C,O);4-71#(13,75,5.5)#C;4-13#(7,C6150,5,N2)#(C,S,C,O);4-53#(7,3.8,840)#C;5-1#(108,75)#C | 1-1#108#C;1-2#M5018R#S;1-3#1F2R#S;1-4#C6#S;2-1#(775.02,775,-0.08,0)#C;2-2#(625.04,625,0,0.44)#C;2-3#(0.8,3.2)#C;2-4#(50.10,50,-0.3,0.15)#C;3-11#(5.1,C11)#(C,S);3-12#(2.2,C12)#(C,S);3-71#NA1#S;3-13#C13#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(7,C6130,8,N1)#(C,S,C,O);4-12#(7,C6130,8,N2)#(C,S,C,O);4-71#(13,75,5.5)#C;4-13#(6,C6125,5,N2)#(C,S,C,O);4-53#(7,3.8,840)#C;5-1#(109,75)#C | 1-1#75#C;1-2#M5018R#S;1-3#1F2R#S;1-4#C6#S;2-1#(625.04,625,0,0.44)#C;2-2#1.6,1.6#C;2-3#(0.02,0.02)#C;2-4#(42,42)#C;2-5#(40,42)#C;3-11#(4.9,C1)#(C,S);3-12#(1.9,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(2,C6125,11,N2)#(C,S,C,O);4-12#(2,C6125,11,-)#(C,S,C,O);4-71#(13,75,5.5)#C;4-13#(6,C6130,10,N1)#(C,S,C,O);4-53#(7,3.8,840)#C;5-1#(109,108)#C;6-1#(he1)#O;7-1#(mat)#O |

| 27 | 1-1#110#C;1-2#M5018B#S;1-3#1F2A#S;1-4#C6#S;2-1#(799.98,800,-0.05,0)#C;2-2#(0.8,3.2)#C;2-3#(0.03,0.03)#C;2-4#(65.08,65,-0.15,0.15)#C;2-5#(42,40)#C;3-11#(5,C1)#(C,S);3-12#(2,C2)#(C,S);3-71#NA2#S;3-13#C3#S;3-53#Q1#S;4-1#ZG230-450#S;4-11#(5,C6150,5,N2)#(C,S,C,O);4-12#(5,C6150,5,N1)#(C,S,C,O);4-71#(26,50,4.2)#C;4-13#(2,C6130,8,N2)#(C,S,C,O);4-53#(4,3.8,835)#C;5-1#(111,78)#C;6-1#(mc1)#O;7-1#(mat,cm1)#O | 1-1#111#C;1-2#M5018B#S;1-3#1F2A#S;1-4#C6#S;2-1#(800.02,800,-0.05,0)#C;2-2#(650.03,650,0,0.07)#C;2-3#(1.6,3.2)#C;2-4#(65.08,65,-0.15,0.15)#C;3-11#(4.8,C11)#(C,S);3-12#(1.8,C12)#(C,S);3-71#NA2#S;3-13#C13#S;3-53#Q1#S;4-1#ZG230-450#S;4-11#(6,C6125,5,N2)#(C,S,C,O);4-12#(6,C6125,5,-)#(C,S,C,O);4-71#(26,50,4.2)#C;4-13#(4,C6130,7,N1)#(C,S,C,O);4-53#(4,3.8,835)#C;5-1#(110,78)#C;6-1#(mc1)#O;7-1#(mat,cm1)#O | 1-1#78#C;1-2#M5018B#S;1-3#1F2A#S;1-4#C6#S;2-1#(650.03,650,0,0.07)#C;2-2#1.6,3.2#C;2-3#(0.02,0.03)#C;2-4#(43,42)#C;2-5#(45,42)#C;3-11#(5.1,C1)#(C,S);3-12#(2.1,C2)#(C,S);3-71#NA2#S;3-13#C3#S;3-53#Q1#S;4-1#ZG230-450#S;4-11#(3,C6125,3,N1)#(C,S,C,O);4-12#(3,C6125,3,N2)#(C,S,C,O);4-71#(26,50,4.2)#C;4-13#(4,C6150,10,N2)#(C,S,C,O);4-53#(4,3.8,835)#C;5-1#(110,111)#C;6-1#(mc1)#O;7-1#(mat,cm1)#O |

| 32 | 1-1#122#C;1-2#M5018B#S;1-3#1F2A#S;1-4#C6#S;2-1#(799.97,800,-0.08,0)#C;2-2#(3.2,1.6)#C;2-3#(0.02,0.03)#C;2-4#(49.80,50,-0.15,0.15)#C;2-5#(42,40)#C;3-11#(5,C1)#(C,S);3-12#(1.8,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q2#S;4-1#ZG270-500#S;4-11#(2,C6150,11,N1)#(C,S,C,O);4-12#(2,C6150,11,-)#(C,S,C,O);4-71#(21,75,4.5)#C;4-13#(7,C6130,5,N2)#(C,S,C,O);4-53#(3,3.8,850)#C;5-1#(123,103)#C;6-1#(sr,de4)#O;7-1#(om11,mt,pw11)#O | 1-1#123#C;1-2#M5018B#S;1-3#1F2A#S;1-4#C6#S;2-1#(800.03,800,-0.08,0)#C;2-2#(650.01,650,0,0.44)#C;2-3#(1.6,3.2)#C;2-4#(50.05,50,-0.15,0.15)#C;3-11#(5.2,C11)#(C,S);3-12#(1.8,C12)#(C,S);3-71#NA1#S;3-13#C13#S;3-53#Q2#S;4-1#ZG270-500#S;4-11#(3,C6150,7,N2)#(C,S,C,O);4-12#(3,C6150,7,N1)#(C,S,C,O);4-71#(21,75,4.5)#C;4-13#(3,C6130,7,N2)#(C,S,C,O);4-53#(3,3.8,850)#C;5-1#(122,103)#C | 1-1#103#C;1-2#M5018B#S;1-3#1F2A#S;1-4#C6#S;2-1#(649.99,650,0,0.44)#C;2-2#1.6,1.6#C;2-3#(0.03,0.03)#C;2-4#(42,40)#C;2-5#(43,40)#C;3-11#(4.9,C1)#(C,S);3-12#(2.1,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q2#S;4-1#ZG270-500#S;4-11#(5,C6125,3,N1)#(C,S,C,O);4-12#(5,C6125,3,N1)#(C,S,C,O);4-71#(21,75,4.5)#C;4-13#(3,C6150,10,N1)#(C,S,C,O);4-53#(3,3.8,850)#C;5-1#(122,123)#C;6-1#(de2)#O;7-1#(om13,pw13)#O |

| 33 | 1-1#125#C;1-2#M5018B#S;1-3#1F2#S;1-4#C6#S;2-1#(904.94,905,-0.09,0)#C;2-2#(3.2,3.2)#C;2-3#(0.02,0.03)#C;2-4#(70.08,70,-0.3,0.15)#C;2-5#(40,42)#C;3-11#(5,C1)#(C,S);3-12#(1.8,C2)#(C,S);3-71#NA2#S;3-13#C3#S;3-53#Q1#S;4-1#ZG230-450#S;4-11#(4,C6125,7,N2)#(C,S,C,O);4-12#(4,C6125,7,N1)#(C,S,C,O);4-71#(32,50,5.5)#C;4-13#(4,C6130,7,N1)#(C,S,C,O);4-53#(2,3,835)#C;5-1#(124,105)#C;6-1#(imp,he1)#O;7-1#(mat,cm1,cm2,ht1)#O | 1-1#124#C;1-2#M5018B#S;1-3#1F2#S;1-4#C6#S;2-1#(905.06,905,-0.09,0)#C;2-2#(755.05,755,0,0.05)#C;2-3#(1.6,3.2)#C;2-4#(70.08,70,-0.3,0.15)#C;3-11#(5,C11)#(C,S);3-12#(2.1,C12)#(C,S);3-71#NA2#S;3-13#C13#S;3-53#Q1#S;4-1#ZG230-450#S;4-11#(5,C6130,3,N2)#(C,S,C,O);4-12#(5,C6130,3,-)#(C,S,C,O);4-71#(32,50,5.5)#C;4-13#(2,C6130,11,N1)#(C,S,C,O);4-53#(2,3,835)#C;5-1#(125,105)#C;6-1#(imp)#O;7-1#(mat,cm1,cm2)#O | 1-1#105#C;1-2#M5018B#S;1-3#1F2#S;1-4#C6#S;2-1#(755.05,755,0,0.05)#C;2-2#1.6,3.2#C;2-3#(0.03,0.03)#C;2-4#(44,42)#C;2-5#(43,42)#C;3-11#(4.9,C1)#(C,S);3-12#(2.2,C2)#(C,S);3-71#NA2#S;3-13#C3#S;3-53#Q1#S;4-1#ZG230-450#S;4-11#(4,C6125,8,N1)#(C,S,C,O);4-12#(4,C6125,8,N1)#(C,S,C,O);4-71#(32,50,5.5)#C;4-13#(2,C6150,11,N2)#(C,S,C,O);4-53#(2,3,835)#C;5-1#(125,124)#C;6-1#(imp)#O;7-1#(mat,cm1,cm2)#O |

| 35 | 1-1#128#C;1-2#M5018A#S;1-3#1F2R#S;1-4#C6#S;2-1#(774.98,775,-0.08,0)#C;2-2#(3.2,1.6)#C;2-3#(0.02,0.01)#C;2-4#(64.94,65,-0.15,0.15)#C;2-5#(40,42)#C;3-11#(4.9,C1)#(C,S);3-12#(2,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q2#S;4-1#ZG270-500#S;4-11#(7,C6150,8,N1)#(C,S,C,O);4-12#(7,C6150,8,-)#(C,S,C,O);4-71#(21,75,4.2)#C;4-13#(3,C6125,5,N1)#(C,S,C,O);4-53#(2,3,830)#C;5-1#(129,121)#C;6-1#(sr,ce1,bh,he1)#O;7-1#(pw13,pw53,ht1,tem2)#O | 1-1#129#C;1-2#M5018A#S;1-3#1F2R#S;1-4#C6#S;2-1#(775.02,775,-0.08,0)#C;2-2#(625.04,625,0,0.44)#C;2-3#(1.6,1.6)#C;2-4#(64.94,65,-0.15,0.15)#C;3-11#(5,C11)#(C,S);3-12#(2.2,C12)#(C,S);3-71#NA1#S;3-13#C13#S;3-53#Q2#S;4-1#ZG270-500#S;4-11#(4,C6130,5,N2)#(C,S,C,O);4-12#(4,C6130,5,-)#(C,S,C,O);4-71#(21,75,4.2)#C;4-13#(5,C6130,8,N1)#(C,S,C,O);4-53#(2,3,830)#C;5-1#(128,121)#C;6-1#(he1)#O;7-1#(pw53,ht1,tem2)#O | 1-1#121#C;1-2#M5018A#S;1-3#1F2R#S;1-4#C6#S;2-1#(625.04,625,0,0.44)#C;2-2#3.2,3.2#C;2-3#(0.02,0.03)#C;2-4#(41,42)#C;2-5#(40,42)#C;3-11#(5.1,C1)#(C,S);3-12#(2,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q2#S;4-1#ZG270-500#S;4-11#(3,C6150,8,N1)#(C,S,C,O);4-12#(3,C6150,8,-)#(C,S,C,O);4-71#(21,75,4.2)#C;4-13#(7,C6125,7,N1)#(C,S,C,O);4-53#(2,3,830)#C;5-1#(128,129)#C;6-1#(bh,he1)#O;7-1#(pw53,cm1,ht1,tem2)#O |

| 36 | 1-1#133#C;1-2#TRM113#S;1-3#1F2A#S;1-4#C6#S;2-1#(799.98,800,-0.05,0)#C;2-2#(3.2,3.2)#C;2-3#(0.02,0.02)#C;2-4#(49.82,50,-0.3,0.15)#C;2-5#(43,40)#C;3-11#(4.8,C1)#(C,S);3-12#(2,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(6,C6125,5,N1)#(C,S,C,O);4-12#(6,C6125,5,N1)#(C,S,C,O);4-71#(26,75,4.2)#C;4-13#(6,C6130,5,N2)#(C,S,C,O);4-53#(4,3.2,835)#C;5-1#(130,131)#C | 1-1#130#C;1-2#TRM113#S;1-3#1F2A#S;1-4#C6#S;2-1#(800.02,800,-0.05,0)#C;2-2#(650.03,650,0,0.07)#C;2-3#(0.8,1.6)#C;2-4#(49.82,50,-0.3,0.15)#C;3-11#(4.8,C11)#(C,S);3-12#(1.8,C12)#(C,S);3-71#NA1#S;3-13#C13#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(5,C6130,5,N2)#(C,S,C,O);4-12#(5,C6130,5,N2)#(C,S,C,O);4-71#(26,75,4.2)#C;4-13#(4,C6125,5,N1)#(C,S,C,O);4-53#(4,3.2,835)#C;5-1#(133,131)#C | 1-1#131#C;1-2#TRM113#S;1-3#1F2A#S;1-4#C6#S;2-1#(650.03,650,0,0.07)#C;2-2#1.6,1.6#C;2-3#(0.03,0.02)#C;2-4#(45,42)#C;2-5#(44,40)#C;3-11#(4.9,C1)#(C,S);3-12#(2.2,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(3,C6130,8,N1)#(C,S,C,O);4-12#(3,C6130,8,-)#(C,S,C,O);4-71#(26,75,4.2)#C;4-13#(5,C6125,11,N1)#(C,S,C,O);4-53#(4,3.2,835)#C;5-1#(133,130)#C;6-1#(ce1)#O;7-1#(om13,pw11)#O |

| 37 | 1-1#138#C;1-2#M5018A#S;1-3#2FR#S;1-4#C6#S;2-1#(699.97,700,-0.05,0)#C;2-2#(0.8,3.2)#C;2-3#(0.03,0.03)#C;2-4#(70.05,70,-0.15,0.3)#C;2-5#(45,40)#C;3-11#(4.8,C1)#(C,S);3-12#(2.2,C2)#(C,S);3-71#NA2#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(2,C6150,10,N1)#(C,S,C,O);4-12#(2,C6150,10,N2)#(C,S,C,O);4-71#(21,15,5.5)#C;4-13#(5,C6130,8,N2)#(C,S,C,O);4-53#(5,3,840)#C;5-1#(139,132)#C | 1-1#139#C;1-2#M5018A#S;1-3#2FR#S;1-4#C6#S;2-1#(700.03,700,-0.05,0)#C;2-2#(550.01,550,0,0.07)#C;2-3#(3.2,3.2)#C;2-4#(70.05,70,-0.15,0.3)#C;3-11#(5,C11)#(C,S);3-12#(2.1,C12)#(C,S);3-71#NA2#S;3-13#C13#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(7,C6150,5,N1)#(C,S,C,O);4-12#(7,C6150,5,N1)#(C,S,C,O);4-71#(21,15,5.5)#C;4-13#(2,C6125,5,N1)#(C,S,C,O);4-53#(5,3,840)#C;5-1#(138,132)#C | 1-1#132#C;1-2#M5018A#S;1-3#2FR#S;1-4#C6#S;2-1#(550.01,550,0,0.07)#C;2-2#3.2,1.6#C;2-3#(0.02,0.03)#C;2-4#(42,42)#C;2-5#(40,42)#C;3-11#(4.9,C1)#(C,S);3-12#(1.9,C2)#(C,S);3-71#NA2#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(7,C6150,7,N1)#(C,S,C,O);4-12#(7,C6150,7,N1)#(C,S,C,O);4-71#(21,15,5.5)#C;4-13#(7,C6150,5,N1)#(C,S,C,O);4-53#(5,3,840)#C;5-1#(138,139)#C;6-1#(sr,he1)#O;7-1#(mat,mt,ht1)#O |

| 38 | 1-1#140#C;1-2#M5018R#S;1-3#1F2A#S;1-4#C6#S;2-1#(800.01,800,-0.05,0)#C;2-2#(0.8,3.2)#C;2-3#(0.03,0.02)#C;2-4#(50.06,50,-0.15,0.15)#C;2-5#(43,42)#C;3-11#(5,C1)#(C,S);3-12#(2,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(4,C6125,8,N2)#(C,S,C,O);4-12#(4,C6125,8,-)#(C,S,C,O);4-71#(26,50,5.5)#C;4-13#(6,C6150,5,N1)#(C,S,C,O);4-53#(2,3.5,840)#C;5-1#(141,135)#C;6-1#(mc1,ce1,de1)#O;7-1#(mat,mt,pw53,cm1)#O | 1-1#141#C;1-2#M5018R#S;1-3#1F2A#S;1-4#C6#S;2-1#(800.03,800,-0.05,0)#C;2-2#(650.01,650,0,0.07)#C;2-3#(1.6,1.6)#C;2-4#(50.06,50,-0.15,0.15)#C;3-11#(5,C11)#(C,S);3-12#(2.1,C12)#(C,S);3-71#NA1#S;3-13#C13#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(4,C6130,10,N1)#(C,S,C,O);4-12#(4,C6130,10,N2)#(C,S,C,O);4-71#(26,50,5.5)#C;4-13#(4,C6130,8,N2)#(C,S,C,O);4-53#(2,3.5,840)#C;5-1#(140,135)#C;6-1#(mc1,he1)#O;7-1#(mat,pw53,cm1)#O | 1-1#135#C;1-2#M5018R#S;1-3#1F2A#S;1-4#C6#S;2-1#(650.01,650,0,0.07)#C;2-2#0.8,1.6#C;2-3#(0.03,0.02)#C;2-4#(41,42)#C;2-5#(41,42)#C;3-11#(5.2,C1)#(C,S);3-12#(2.2,C2)#(C,S);3-71#NA1#S;3-13#C3#S;3-53#Q1#S;4-1#ZG270-500#S;4-11#(4,C6130,11,N2)#(C,S,C,O);4-12#(4,C6130,11,N2)#(C,S,C,O);4-71#(26,50,5.5)#C;4-13#(7,C6125,3,N2)#(C,S,C,O);4-53#(2,3.5,840)#C;5-1#(140,141)#C;6-1#(mc1,ce1,he1)#O;7-1#(mat,mt,pw53,cm1)#O |

| Index | 1 | 2 | 5 | 11 | 14 | 15 | 16 | 17 | 19 | 21 |

| SD(PG, KPG) | 0.71 | 0.73 | 0.70 | 0.72 | 0.74 | 0.71 | 0.72 | 0.72 | 0.73 | 0.72 |

| SD(PG(PE), KPG(PE)) | 0.50 | 0.50 | 1.83 | 1.50 | 1.33 | 0.33 | 0.33 | 0.50 | 1.25 | 0.00 |

| Index | 25 | 26 | 27 | 32 | 33 | 35 | 36 | 37 | 38 | |

| SD(PG, KPG) | 0.71 | 0.71 | 0.70 | 0.73 | 0.72 | 0.73 | 0.71 | 0.70 | 0.74 | |

| SD(PG(PE), KPG(PE)) | 0.33 | 0.00 | 1.00 | 0.50 | 0.00 | 0.25 | 0.00 | 0.50 | 0.67 |

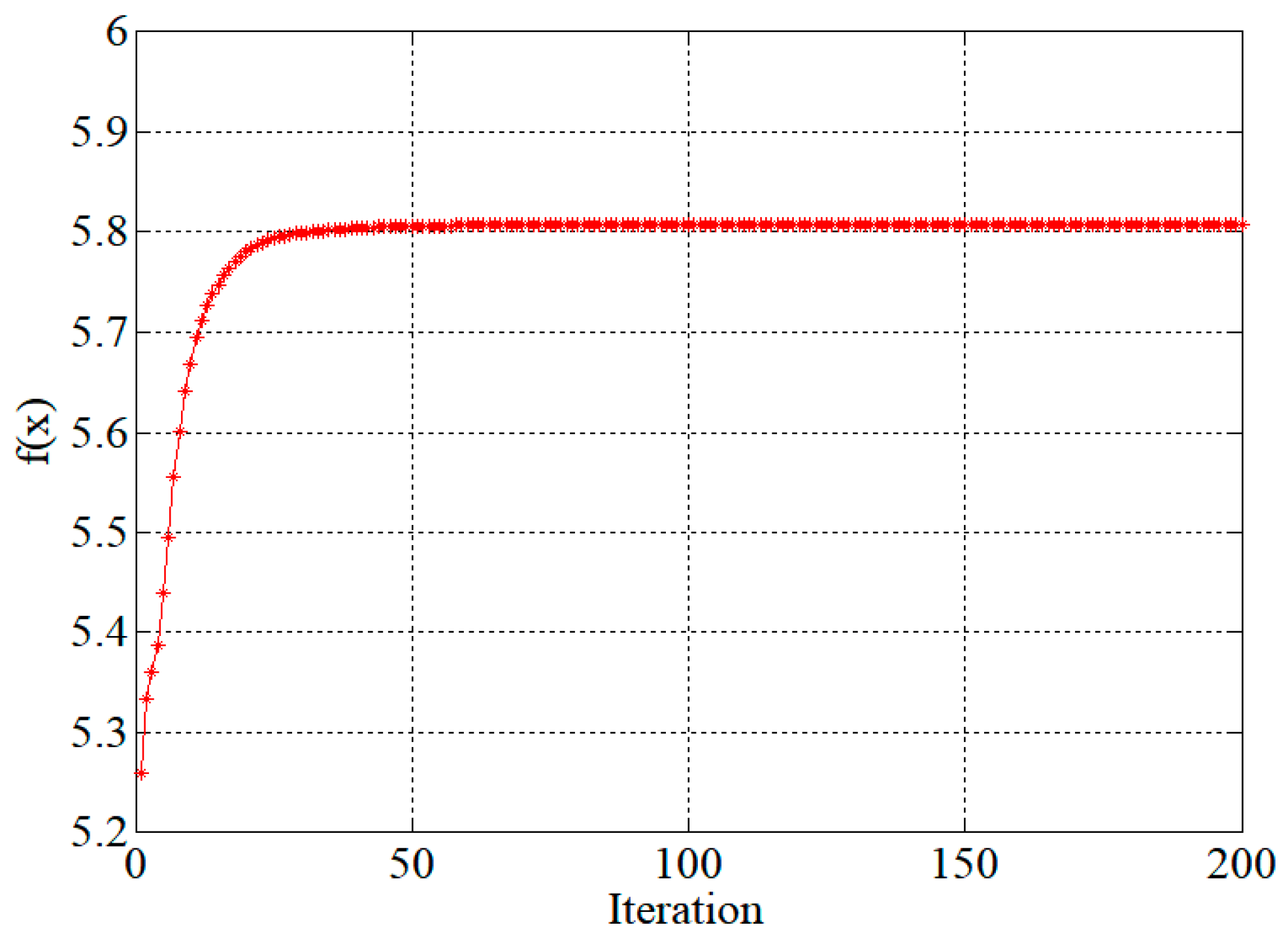

| Number of Dimensions | Population Size | Number of Iterations | Self-Confidence | Swarm Confidence | Inertia Weight |

|---|---|---|---|---|---|

| 59 | 200 | 200 | C1 = 0.01 | C2 = 0.9 | ωmin = 0.01 ωmax = 0.5 |

| Index | 1 | 2 | 5 | 11 | 14 | 15 | 16 | 17 | 19 | 21 |

| S(PG, KPG) | 0.79 | 0.84 | 0.79 | 0.79 | 0.82 | 0.79 | 0.82 | 0.80 | 0.80 | 0.82 |

| Index | 25 | 26 | 27 | 32 | 33 | 35 | 36 | 37 | 38 | |

| S(PG, KPG) | 0.81 | 0.80 | 0.80 | 0.82 | 0.82 | 0.82 | 0.83 | 0.80 | 0.82 |

| Quality Defects | Causes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| om11 | om13 | mat | mt | pw11 | pw13 | pw53 | cm1 | cm2 | ht1 | ht2 | tem1 | tem2 | |

| sr | 4 | 3 | 2 | 5 | 4 | 2 | 1 | 2 | 4 | 4 | 0 | 3 | 1 |

| mc1 | 1 | 3 | 7 | 3 | 1 | 1 | 3 | 10 | 0 | 0 | 0 | 2 | 0 |

| ce1 | 0 | 2 | 3 | 3 | 2 | 3 | 3 | 3 | 0 | 1 | 0 | 1 | 1 |

| de1 | 0 | 0 | 1 | 2 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 1 | 0 |

| de2 | 0 | 1 | 0 | 0 | 1 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| de3 | 1 | 2 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 2 | 0 |

| de4 | 2 | 1 | 1 | 2 | 2 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| bh | 2 | 3 | 0 | 0 | 2 | 3 | 2 | 1 | 2 | 2 | 0 | 3 | 2 |

| imp | 1 | 1 | 3 | 1 | 2 | 1 | 0 | 3 | 9 | 3 | 0 | 0 | 0 |

| he1 | 1 | 1 | 5 | 3 | 0 | 1 | 5 | 4 | 2 | 6 | 0 | 2 | 3 |

| Cause | Analysis and Conclusion |

|---|---|

| om11 | The ages of machines of rough turning (or semi-finish turning) in GU(1) is 12 years, GU(2) is 7 years, and GU(3) is 8 years. Generally, the processing capacity of a machine older than 10 years will be greatly affected in building material equipment enterprise. Therefore, the “om11” is one of the causes of “sr” in GU(1). |

| om13 | The ages of machines of finish turning in GU(1) is 5 years, GU(2) is 8 years, and GU(3) is 3 years. Therefore, the “om13” should be excluded. |

| mat, mt | These two causes can be verified by inspecting the quality of material and measuring tools. In this experiment, the material is qualified, while some of measuring tools are unqualified. Therefore, the “mat” should be excluded and the ‘mt’ should be one of the causes of defects. |

| pw11 | The capabilities of workers of rough turning (or semi-finish turning) in GU(1), GU(2) and GU(3) are 3, 4, 5, where 4 is the median. Therefore, the “pw11” is also one of the causes of “sr” in GU(1). |

| cm1 | The structure of the casting mold is found to be unreasonable. Therefore, the “cm1” is one of the causes of defects. |

| cm2 | No impurities are found on the part, therefore, the “cm2” should be excluded. |

| ht1 | Generally, the holding time of quenching of the part should be about 3.5 minutes. Therefore, the “ht1” should be one of the causes of defects. |

| tem1 | The temperature of quenching is reasonable, therefore, the “tem1” should be excluded. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, W.; Guo, C.; Guo, S.; Li, X. A Novel Quality Defects Diagnosis Method for the Manufacturing Process of Large Equipment Based on Product Gene Theory. Symmetry 2019, 11, 685. https://doi.org/10.3390/sym11050685

Xu W, Guo C, Guo S, Li X. A Novel Quality Defects Diagnosis Method for the Manufacturing Process of Large Equipment Based on Product Gene Theory. Symmetry. 2019; 11(5):685. https://doi.org/10.3390/sym11050685

Chicago/Turabian StyleXu, Wenxiang, Chen Guo, Shunsheng Guo, and Xixing Li. 2019. "A Novel Quality Defects Diagnosis Method for the Manufacturing Process of Large Equipment Based on Product Gene Theory" Symmetry 11, no. 5: 685. https://doi.org/10.3390/sym11050685

APA StyleXu, W., Guo, C., Guo, S., & Li, X. (2019). A Novel Quality Defects Diagnosis Method for the Manufacturing Process of Large Equipment Based on Product Gene Theory. Symmetry, 11(5), 685. https://doi.org/10.3390/sym11050685