Abstract

Control charts are considered as powerful tools in detecting any shift in a process. Usually, the Shewhart control chart is used when data follows the symmetrical property of a normal distribution. In practice, the data from the industry may follow a non-symmetrical distribution or an unknown distribution. The average run length (ARL) is a significant measure to assess the performance of the control chart. The ARL may mislead when the statistic is computed from an asymmetric distribution. To handle this issue, in this paper, an ARL-unbiased hybrid exponentially weighted moving average proportion (HEWMA-p) chart is proposed for monitoring the process variance for a non-normal distribution or an unknown distribution. The efficiency of the proposed chart is compared with the existing chart in terms of ARLs. The proposed chart is more efficient than the existing chart in terms of ARLs. A real example is given for the illustration of the proposed chart in the industry.

1. Introduction

The aim of quality refers to the quality of those product characteristics that will appeal to potential customers. It takes into account what it would cost to produce the product and what the customers are willing to pay for the product. It can be thought of as the perspective for accomplishing manufactured quality. Once the manufacturing process has started, the process does not always produce a unit in conformity with what was proposed. This may be due to causes of defects arising in materials, parts, subassemblies, assemblies, and in the final product. Due to defective or nonconforming resources, parts, assemblies, and finished products that are discarded or reworked during the manufacturing process result in increased cost and customer dissatisfaction. The waste of time and effort in manufacturing the defective or nonconforming product, the delays in delivery, and other associated costs attributable to a poorly manufactured product are the consequence of manufactured quality. If a company wishes to produce higher quality products, it usually needs higher costs for manufactured products. However, the aim should always be to offer customers good quality at a low cost. Therefore, quality is also part of the corporate approach. Understanding quality concepts leads to correct implementation and management of product quality, which adds benefits to the entire production endeavor. If an industry understands and applies quality control principles in their manufactured products, it will produce well finished products, and reduction of the costs of the products may be possible.

The control charts are effectively used for the monitoring of the process. The Shewhart control chart is designed under the assumption that the data coming from the industry follows a normal distribution. This chart is more effective in detecting a relatively large shift in a process. The Shewhart control chart cannot be applied for a monitoring process when the industrial data follow the non-normal distribution or unknown distribution. Several authors focused on designing control charts for monitoring process mean, including for example [1,2,3]. Some authors designed control charts for monitoring the process variance; see for example [4,5]. More details on control charts can be seen in [6,7,8,9,10,11,12,13].

As mentioned by [14] practitioners are often not statisticians and may have problems in implementing control charts based on non-parametric approaches. Keeping in mind this issue, several authors, including for example, references [15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41] focused on designing control charts for monitoring the process mean that were easier to apply as compared to existing charts. Later on, Yang et al. [42] worked on the extension of the chart designed in [43] to monitor the process variance using a simple arcsin transformed symmetric exponentially weighted moving average (EWMA) statistic. Yang et al. [42] further extended the work of [5] by mixing the arcsin transformed EWMA and simple EWMA statistic. Yang et al. [5] designed the arcsin transformed EWMA to monitor process variance. The average run length (ARL) is used to assess the performance of a control chart. Smaller ARL means more efficient and faster detection of a shift in the process. According to [5] “For a monitoring statistic with an asymmetrical distribution, the control chart leads to a biased ARL. That is, the in-control ARL may be smaller than any out-of-control ARL, thus taking longer to detect shifts in the parameter than to trigger a false alarm”. Lowry et al. [44] proposed a chart to tackle this issue.

Haq [45] proposed a control chart using two EWMA statistics and called it a hybrid EWMA (HEWMA) chart. He claimed that their proposed chart performed better than the usual EWMA chart. The HEWMA statistic consists of two EWMA statistics and two smoothing constants. The control chart based on HEWMA statistic has the ability to detect the shift in the process earlier than the EWMA-based control chart. The operational process of the HEWMA based control chart is the same as the EWMA control chart. Several authors worked on these statistics in the literature. There are various variable charts for joint monitoring; see for example, Nyau et al. [11], who designed the multivariate EWMA chart for the median run-length. Riaz et al. [12] proposed a mixed Tukey EWMA–CUSUM (cumulative sum) control chart and Osei-Aning et al. [13] worked on the mixed EWMA–CUSUM and mixed CUSUM–EWMA. Haq [46] presented a discussion on the HEWMA control chart. Noor-ul-Amin et al. [47] worked on the HEWMA chart for the regression estimator. Several authors proposed the attribute control chart using EWMA and HEWMA statistics. Aslam et al. [48] designed the mixed EWMA control chart. Haq [49] worked on the nonparametric EWMA chart. Riaz et al. [50] designed the nonparametric double EWMA control chart. Aslam et al. [51] worked on the HEWMA–CUSUM chart for the Weibull distribution. Aslam et al. [52] worked on the HEWMA chart for the COM–Poisson distribution.

Yang et al. [14] designed an ARL unbiased EWMA-p chart. According to the best of our knowledge, there is no work on designing a EWMA-p chart using a hybrid EWMA. The proposed methodology presents an approach to evaluate the performance using the combination of a hybrid EWMA control chart with weighted moving average proportion (EWMA-p) control chart. The hybrid EWMA and EWMA-p charts are chosen since it has been shown that these charts are efficient in detecting small but possibly detrimental shifts in the process. Aslam et al. [52] also pointed out that in a general manufacturing process, an exponentially weighted moving average EWMA control chart is more efficient in detecting small process shifts. The control chart based on the EWMA method consists of an exponential weight factor applied to the data, which gives current or recent past observations more weight than older data values. The combination of a hybrid EWMA chart and EWMA-p charts will be explored to determine the best conditions, i.e., the appropriate values of control variables for monitoring concrete strength. In this paper, we will present the enhanced hybrid exponential weighted moving average proportion (enhanced HEWMA-p) chart. The structure of the proposed chart will be presented and its efficacy will be compared with [14].

2. Design of the Enhanced HEWMA-p Chart

In this section, we will present some equations taken from [14] and present the operational procedure of the proposed control chart.

Let a random sample of size be drawn from process whose distribution is unknown with a variance to practitioners. Yang et al. [14] suggested to select an even sample size for convenience. Assuming that these samples are independently distributed with known variance, let

Then,

Define

where

Therefore, when the process is in control, is distributed as a binomial with parameters and , where the value of depends on the distribution of . Let us define . The null hypothesis is that the process is in control state at . The alternative hypothesis is that the process has been shifted at . According to [14], the statistic of has the mean of and the variance of .

We define the following two EWMA statistics:

where and are smoothing constants, and is the statistic of enhanced HEWMA-p at t.

The proposed control chart is stated as follows:

- Step 1: Select a random sample of size () from the process at time t. Compute using (3) and using (5).

- Step 2: The process is declared to be as out-of-control if or and to be in-control if , here LCL and UCL show the lower control limit and upper control limit.

The proposed control chart is the extension of the chart proposed by [14]. The proposed chart reduces to [14] chart when or = 1 or = 1. The proposed chart becomes the Shewhart chart when = 1 and = 1. It is assumed that the starting value of is the mean of , i.e., for an in control process. By following [45], the mean and variance of statistic is given by

and

Thus, the asymptotic variance of is given as

As suggested by [14] “the new variance chart may be constructed based on the distribution of the monitoring statistic , which is an asymmetric distribution having similar defects to those of the corresponding Shewhart chart”. Therefore, monitoring the process variance is the same as the monitoring process proportion , as the proportion of statistic may not be same. The control limits of the proposed control chart are given as

where are control limit coefficients.

3. The Average Run Length of Enhanced HEWMA-p Control Chart

The proposed enhanced hybrid exponential weighted moving average proportion (enhanced HEWMA-p) control chart performance measure can be used as the average run length (ARL). In this paper, we have limited our study to non-normal distributions with finite variance. The control limits of the enhanced HEWMA-p control chart are determined by setting the in-control ARL (ARLv0) to be a specified value, usually 370. The ARL represents the expected number of samples until a control chart signals. The proposed control chart comprises of two control coefficients, and , which are obtained by considering the desired in-control ARL. Once the coefficients and are determined, the control limits of the enhanced HEWMA-p control chart are obtained and the out-of-control ARLs (ARLv1) can be obtained according to various values of shift in proportion, pv1 = c pv0, c ≠ 1, and 0 < pv1 ≤ 1. We use the following Monte Carlo simulation procedure to compute control coefficients and , and to calculate the out-of-control ARL (ARLv1) under a specified n, pv0, and ARLv0 values.

- Step 1. Setting specified values of n, pv0, and ARLv0.

- Step 2. Evaluation of proposed control chart coefficients and for in-control process

- 2.1. Generate 10,000 possible values of control chart coefficients and .

- 2.2. When the process is in-control, from a binomial distribution with the in-control parameters a random sample of size 2000 is generated, i.e., at time t.

- 2.3. The enhanced HEWMA-p statistic HEWMA-p is computed for each subgroup of size 2000.

- 2.4. The proposed statistic HEWMA-p is plotted and in-control if go to step 2.5 and the run length for out of control process is noted.

- 2.5. Repeat 10,000 times steps 2.2 through 2.3, to compute run lengths. If the average of these run lengths (ARLs) is equal to the specified ARLv0 note the corresponding values of and , and move to step 3, otherwise select other possible values of and , and repeat the procedure from steps 2.2.

- Step 3 Evaluation of ARLv1 for proposed control chart when the process is shifted

- 3.1. Let the out-of-control proportion, pv1, be a proportion of the in-control proportion, pv0. That is, pv1 = c pv0, c ≠ 1, and 0 < pv1 ≤ 1, where c is the amount of shift in the process proportion, pv0.

- 3.2. From binomial distribution, with the in-control parameters, , a random sample of size 2000 is generated, i.e., at time t.

- 3.3. The Enhanced HEWMA-p Statistic HEWMA-p is Computed for Each Subgroup of Size 2000.

- 3.4. Using the Values of and , the proposed statistic HEWMA-p is plotted and in-control if go to step 3.5 and the run length for out of control process is noted.

- 3.5. Repeat 10,000 times steps 3.2 through 3.3, to compute run lengths. The average of run length (ARLv1) and standard error of run length (SERLv1) for each specified amount of shift is computed.

In Table 1, we present control chart coefficients and , and corresponding upper and lower control limits of the enhanced HEWMA-p control chart for n = 8 (1) 30, pv0 = 0.1, = 0.2 with ARLv0 ≈ 370. Table 2 presents ARLv1 and SERLv1 values (in second row corresponding to each n value) for pv1 = 0.025 (0.025) 0.200 at n = 8 (1) 30, pv0 = 0.1, = 0.2 with ARLv0 ≈ 370. In Table 3, we present control chart coefficients and , and corresponding upper and lower control limits of the enhanced HEWMA-p control chart for n = 8 (1) 30, pv0 = 0.3, = 0.2 with ARLv0 ≈ 370. Table 4 presents ARLv1 and SERLv1 values (in second row corresponding to each n value) for pv1 = 0.200 (0.025) 0.400 at n = 8 (1) 30, pv0 = 0.3, = 0.2 with ARLv0 ≈ 370.

Table 1.

The control limits for enhanced HEWMA-p control chart with ARL0 = 370 when = 0.2, = 0.2, and pv0 = 0.1. HEWMA-p is hybrid exponentially weighted moving average proportion, ARL is average run length, UCL is upper control limit, LCL is lower control limit.

Table 2.

The ARLs of the enhanced HEWMA-p control chart for = 0.2, = 0.2, and pv0 = 0.1.

Table 3.

The control constants with ARL0 = 370 for enhanced HEWMA-p control chart. when = 0.2, = 0.2, and pv0 = 0.3.

Table 4.

The ARLv1 of the enhanced HEWMA-p control chart for = 0.2, = 0.2, and pv0 = 0.3.

- 2. The ARLv1 and SERLv1 values decrease when pv1 is far away from pv0.

- 3. The ARLv1 and SERLv1 values decrease more rapidly as c increases rather than it decreases. For example, for 0.5n = 4 and pv1 = 0.05 (c = 0.5) from Table 2 we have ARLv1 = 107.03 and SERLv1 = 0.8830, whereas if pv1 = 0.15 (c = 1.5), we have ARLv1 = 47.74 and SERLv1 = 0.4055. We also observed a similar trend from Table 4.

The R codes for this study are given in the Appendix A.

4. Comparative Study

Now, we discuss the performance of the proposed control chart with the existing control charts proposed by [4,14] for = 0.2. The proposed chart reduces to [14] chart when = 0.2 (for example). We present the values of ARLv1 for the proposed control chart as well as control charts given by [4,14] in Table 5 when in-control ARLv0 ≈ 370.

Table 5.

The comparison of the proposed chart with existing charts.

From Table 5, we observe that the proposed control chart has smaller values of ARLv1 as compared to the existing two control charts. For example, when 0.5n = 6, = 0.2, pv0 = 0.3, pv1 = 0.4 the proposed control chart gives ARLv1 is 27.30, the ARLv1 from the two existing control charts are 31.36 and 34.20, respectively. Thus, the proposed control chart performs better than the existing control charts.

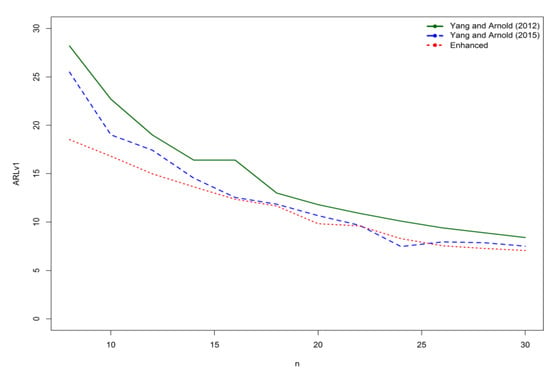

Table 5ARLv1s comparison between the chart proposed by [4,14] for = 0.2 and enhanced HEWMA-p control chart for = 0.2, = 0.2. Figure 1 depicts the ARLv1 profile comparison at pv0 = 0.1 and pv1 = 0.2 for different values of n under HEWMA-p chart and two existing charts. From Figure 1, we noticed that ARLv1 values of enhanced HEWMA-p control chart are smaller than in the two existing control charts. Hence, our proposed enhanced HEWMA-p control chart performed well as compared with existing charts.

Figure 1.

The ARLv1 profile comparison at pv0 = 0.1 and pv1 = 0.2 for different values of n under HEWMA-p chart and Yang and Arnold [4,14].

5. Example

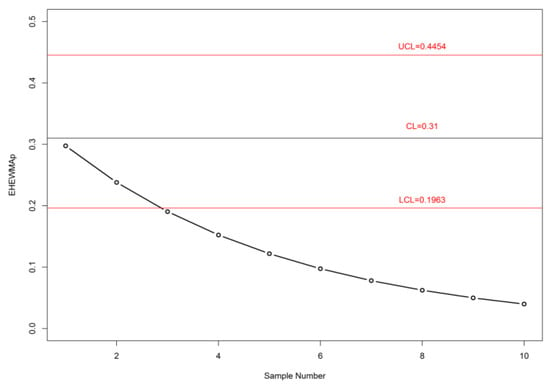

In this section, we present an example given by [14]. The service time of a bank branch in Taiwan is used to illustrate the application of the proposed enhanced HEWMA-p control chart to monitor the variability of service time. According to [14] “From the historical data, the in-control data of service times (unit: minutes) is a non-normal/unknown distribution with variance 27.805. Reference [14] illustrated that the resulting in-control probability that the service time is larger than the in-control variance is = 0.31”. To construct the enhanced HEWMA-p control chart, we also use the same value of . The upper and lower control limits of the enhanced HEWMA-p control chart with when in-control ARLv0 ≈ 370 are UCL = 0.4454 and LCL = 0.1963.

Ten new samples of size 10 each from new automatic service system of the bank branch under study were considered [14] and listed in Table 6. To illustrate the out-of-control detection ability, for each sample in Table 6, the statistic, Vt and the monitoring statistic where at time t, t = 1, 2, …, 10, were computed. The corresponding enhanced HEWMA-p control chart detected out-of-control variance signals from the third sample onward (samples 3–10 on the enhanced HEWMA-p control chart) (Figure 2). By comparing Figure 2 with the chart in [14], it can be seen that the existing chart indicated a shift at the 4th sample. Therefore, the proposed chart was more efficient in detecting a shift in the process as compared to existing chart of Yang and Arnold [14]. The same performance was also shown by the results in Table 2 and Table 4. For this study, we can conclude that the proposed chart shows better performance than the existing two charts.

Table 6.

The new service times from 10 counters in a bank branch. EWMA is exponentially weighted moving average.

Figure 2.

The enhanced HEWMA-p chart for the example.

6. Concluding Remarks

In this paper, an enhanced hybrid EWMA-p chart is proposed for monitoring the process variance. A simulation procedure is presented for calculating its average run lengths (ARLs). Some tables are presented for practical use. The simulation study supports that the proposed chart is more efficient in detecting a shift in the process. A real example is presented for illustration purposes. The proposed control chart can be used in the industry for the monitoring of processes when the distribution is unknown in practice. The limitation of the proposed chart is that it can be used for only a fixed sample size. The variable sample size enhanced hybrid EWMA-p chart will be considered as our future research. In addition, the proposed control chart for a variable sample size can be considered as future research. The proposed chart using autocorrelation can be considered as future research.

Author Contributions

Conceived and designed the experiments, M.A., G.S.R., A.H.A.-M., C.-H.J. Performed the experiments, M.A. and A.H.A.-M. Analyzed the data, M.A. and A.H.A.-M. Contributed reagents/materials/analysis tools, M.A. Wrote the paper, M.A.

Funding

This article was funded by the Deanship of Scientific Research (DSR) at King Abdulaziz University, Jeddah. The authors, therefore, acknowledge and thank DSR for technical and financial support.

Acknowledgments

The authors are deeply thankful to the editor and reviewers for their valuable suggestions to improve the quality of this manuscript.

Conflicts of Interest

The authors declare no conflict of interest regarding this paper.

Nomenclature

| ARL | Average run length |

| HEWMA-p | Hybrid exponentially weighted moving average proportion |

| EWMA | Exponentially weighted moving average |

| HEWMA | Hybrid exponentially weighted moving average |

| EWMA–CUSUM | Exponentially weighted moving average–Cumulative sum |

| LCL | Lower control limit |

| UCL | Upper control limit |

| SERL | Standard error of run length |

Appendix A

1. R code to obtain chart coefficients

2. ARL.EHEWMAp<-function(r0,n,la1,la2,p0) {

3. # r0 is specified in-control ARL (ARLv0)

4. # la1 is lamda1

5. # la2 is lamda2

6. # p0 is specified in control p value

7. options(digits =6)

8. N<-10,000

9. rl<-c()

10. vt<-c()

11. G<-c()

12. H<-c()

13. set.seed(5577)

14. m<-n/2

15. v<-la1*la2*p0*(1-p0)/((2-la1)*(2-la2)*m)

16. q<-seq(2.65,7.09, by =0.1)

17. for (k1 in q){

18. for (k2 in q)

19. {

20. if(k1>k2) {

21. l<-p0-k2*sqrt(v)

22. cl<-p0

23. u<-p0+k1*sqrt(v)

a. for(j in 1:2000)

b. {

i. G[1]<-p0

ii. H[1]<-p0

iii. for(i in 2:N)

iv. {

v. vt[i]<-rbinom(1, m, p0)

vi. G[i]<-la2*vt[i]/m+(1-la2)*G[i-1]

vii. H[i]<-la1*G[i]+(1-la1)*H[i-1]

viii. if ((H[i]<l) | (H[i]>u)){rl[j]=i;break;}else{rl[j]=0;}

ix. }

c. }

d. arl<-mean(rl)

e. if ((arl>=r0) && (arl<=r0+5)) {

i. print(c(n,la1,la2,p0,k1,k2,arl))}

f. sdarl<-sd(rl)

g. searl<-sdarl/sqrt(N)

24. }

25. }

26. }

27. }

References

- Chakraborti, S.; Van der Laan, P.; Bakir, S. Nonparametric control charts: An overview and some results. J. Qual. Technol. 2001, 33, 304. [Google Scholar] [CrossRef]

- Chakraborti, S.; Eryilmaz, S. A nonparametric Shewhart-type signed-rank control chart based on runs. Commun. Stat. Simul. Comput. 2007, 36, 335–356. [Google Scholar] [CrossRef]

- Li, S.-Y.; Tang, L.-C.; Ng, S.-H. Nonparametric CUSUM and EWMA control charts for detecting mean shifts. J. Qual. Technol. 2010, 42, 209. [Google Scholar] [CrossRef]

- Yang, S.F.; C. Arnold, B. Signal detection for process with unknown distribution. In Advanced Materials Research; Trans Tech Publications: Zurich, Switzerland, 2012; pp. 1472–1475. [Google Scholar]

- Yang, S.-F.; Arnold, B.C. A simple approach for monitoring business service time variation. Sci. World J. 2014, 2014. [Google Scholar] [CrossRef] [PubMed]

- Avinadav, T.; Perlman, Y.; Cheng, T. Economic design of control charts for monitoring batch manufacturing processes. Int. J. Comput. Integr. Manuf. 2016, 29, 212–221. [Google Scholar] [CrossRef]

- Chen, F.-L.; Huang, H.-J. A synthetic control chart for monitoring process dispersion with sample range. Int. J. Adv. Manuf. Technol. 2005, 26, 842–851. [Google Scholar] [CrossRef]

- Aslam, M.; Khan, N.; Azam, M.; Jun, C.-H. Designing of a new monitoring t-chart using repetitive sampling. Inf. Sci. 2014, 269, 210–216. [Google Scholar] [CrossRef]

- Aslam, M.; Azam, M.; Jun, C.H. A control chart for COM–poisson distribution using resampling and exponentially weighted moving average. Qual. Reliab. Eng. Int. 2016, 32, 727–735. [Google Scholar] [CrossRef]

- Aslam, M.; Azam, M.; Jun, C.-H. A new exponentially weighted moving average sign chart using repetitive sampling. J. Process. Control. 2014, 24, 1149–1153. [Google Scholar] [CrossRef]

- Nyau, S.Y.; Lee, M.H.; Wong, M.D. Optimal statistical design of variable sample size multivariate exponentially weighted moving average control chart based on median run-length. Qual. Technol. Quant. Manag. 2017, 14, 478–495. [Google Scholar] [CrossRef]

- Riaz, M.; Khaliq, Q.-U.-A.; Gul, S. Mixed Tukey EWMA-CUSUM control chart and its applications. Qual. Technol. Quant. Manag. 2017, 14, 378–411. [Google Scholar] [CrossRef]

- Osei-Aning, R.; Abbasi, S.A.; Riaz, M. Mixed EWMA-CUSUM and mixed CUSUM-EWMA modified control charts for monitoring first order autoregressive processes. Qual. Technol. Quant. Manag. 2017, 14, 429–453. [Google Scholar] [CrossRef]

- Yang, S.F.; Arnold, B.C. Monitoring process variance using an ARL-unbiased EWMA-p control chart. Qual. Reliab. Eng. Int. 2015. [Google Scholar] [CrossRef]

- Bakir, S.T.; Reynolds, M.R. A nonparametric procedure for process control based on within-group ranking. Technometrics 1979, 21, 175–183. [Google Scholar] [CrossRef]

- Amin, R.W.; Searcy, A.J. A nonparametric exponentially weighted moving average control scheme. Commun. Stat. Simul. Comput. 1991, 20, 1049–1072. [Google Scholar] [CrossRef]

- Amin, R.W.; Reynolds, M.R., Jr.; Saad, B. Nonparametric quality control charts based on the sign statistic. Commun. Stat. Theory Methods 1995, 24, 1597–1623. [Google Scholar] [CrossRef]

- Qiu, P.; Hawkins, D. A rank-based multivariate CUSUM procedure. Technometrics 2001, 43, 120–132. [Google Scholar] [CrossRef]

- Zamba, K.; Hawkins, D.M. A multivariate change-point model for statistical process control. Technometrics 2006, 48, 539–549. [Google Scholar] [CrossRef]

- Bakir, S.T. A distribution-free Shewhart quality control chart based on signed-ranks. Qual. Eng. 2004, 16, 613–623. [Google Scholar] [CrossRef]

- Bakir, S.T. Distribution-free quality control charts based on signed-rank-like statistics. Commun. Stat. Theory Methods 2006, 35, 743–757. [Google Scholar] [CrossRef]

- Zhou, C.; Zou, C.; Zhang, Y.; Wang, Z. Nonparametric control chart based on change-point model. Stat. Pap. 2009, 50, 13–28. [Google Scholar] [CrossRef]

- Qiu, P.; Zou, C.; Wang, Z. Nonparametric profile monitoring by mixed effects modeling. Technometrics 2010, 52, 265–277. [Google Scholar] [CrossRef]

- Hawkins, D.M.; Deng, Q. A nonparametric change-point control chart. J. Qual. Technol. 2010, 42, 165–173. [Google Scholar] [CrossRef]

- Human, S.; Chakraborti, S.; Smit, C. Nonparametric Shewhart-type sign control charts based on runs. Commun. Stat. Theory Methods 2010, 39, 2046–2062. [Google Scholar] [CrossRef]

- Graham, M.A.; Chakraborti, S.; Human, S.W. A nonparametric exponentially weighted moving average signed-rank chart for monitoring location. Comput. Stat. Data Anal. 2011, 55, 2490–2503. [Google Scholar] [CrossRef]

- Graham, M.A.; Chakraborti, S.; Human, S.W. A nonparametric EWMA sign chart for location based on individual measurements. Qual. Eng. 2011, 23, 227–241. [Google Scholar] [CrossRef]

- Yang, S.F.; Cheng, S.W. A new non-parametric CUSUM mean chart. Qual. Reliab. Eng. Int. 2011, 27, 867–875. [Google Scholar] [CrossRef]

- Yang, S.-F.; Lin, J.-S.; Cheng, S.W. A new nonparametric EWMA sign control chart. Expert Syst. Appl. 2011, 38, 6239–6243. [Google Scholar] [CrossRef]

- Bakir, S.T. A nonparametric shewhart-type quality control chart for monitoring broad changes in a process distribution. Int. J. Qual. Stat. Reliab. 2012, 2012. [Google Scholar] [CrossRef]

- Ghute, V.; Shirke, D. A nonparametric signed-rank control chart for bivariate process location. Qual. Technol. Quant. Manag. 2012, 9, 317–328. [Google Scholar] [CrossRef]

- Yang, S.-F. An improved distribution free EWMA mean chart. Commun. Stat. Simul. Comput. 2016, 45, 1410–1427. [Google Scholar] [CrossRef]

- Lu, S.L. An extended nonparametric exponentially weighted moving average sign control chart. Qual. Reliab. Eng. Int. 2015, 31, 3–13. [Google Scholar] [CrossRef]

- Mukherjee, A.; Sen, R. Comparisons of Shewhart-type rank based control charts for monitoring location parameters of univariate processes. Int. J. Prod. Res. 2015, 53, 4414–4445. [Google Scholar] [CrossRef]

- Riaz, M. A sensitive non-parametric EWMA control chart. J. Chin. Inst. Eng. 2015, 38, 208–219. [Google Scholar] [CrossRef]

- Chakraborty, N.; Chakraborti, S.; Human, S.W.; Balakrishnan, N. A generally weighted moving average signed-rank control chart. Qual. Reliab. Eng. Int. 2016, 32, 2835–2845. [Google Scholar] [CrossRef]

- Haq, A.; Khoo, M.B. A new synthetic control chart for monitoring process mean using auxiliary information. J. Stat. Comput. Simul. 2016, 86, 3068–3092. [Google Scholar] [CrossRef]

- Abid, M.; Nazir, H.Z.; Riaz, M.; Lin, Z. An efficient nonparametric EWMA Wilcoxon signed-rank chart for monitoring location. Qual. Reliab. Eng. Int. 2017, 33, 669–685. [Google Scholar] [CrossRef]

- Petcharat, K. Sensitive non-parametric control charts for monitoring process variation. Int. J. Sci. Technol. Res. 2017, 6, 23–25. [Google Scholar]

- Lu, S.-L. Non parametric double generally weighted moving average sign charts based on process proportion. Commun. Stat. Theory Methods 2018, 47, 2684–2700. [Google Scholar] [CrossRef]

- Haq, A.; Khoo, M.B. A new double sampling control chart for monitoring process mean using auxiliary information. J. Stat. Comput. Simul. 2018, 88, 869–899. [Google Scholar] [CrossRef]

- Yang, S.-F.; Arnold, B.C. A simple approach for monitoring process mean and variance simultaneously. In Frontiers in Statistical Quality Control 11; Springer: Berlin, Germany, 2015; pp. 135–149. [Google Scholar]

- Yang, S.F.; Cheng, T.C.; Hung, Y.C.; W. Cheng, S. A new chart for monitoring service process mean. Qual. Reliab. Eng. Int. 2012, 28, 377–386. [Google Scholar] [CrossRef]

- Lowry, C.A.; Champ, C.W.; Woodall, W.H. The performance of control charts for monitoring process variation. Commun. Stat. Simul. Comput. 1995, 24, 409–437. [Google Scholar] [CrossRef]

- Haq, A. A new hybrid exponentially weighted moving average control chart for monitoring process mean. Qual. Reliab. Eng. Int. 2013, 29, 1015–1025. [Google Scholar] [CrossRef]

- Haq, A. A new hybrid exponentially weighted moving average control chart for monitoring process mean: Discussion. Qual. Reliab. Eng. Int. 2017, 33, 1629–1631. [Google Scholar] [CrossRef]

- Noor-ul-Amin, M.; Khan, S.; Sanaullah, A. HEWMA control chart using auxiliary information. Iran. J. Sci. Technol. Trans. A Sci. 2018, 1–13. [Google Scholar] [CrossRef]

- Aslam, M.; Khan, N.; Aldosari, M.S.; Jun, C.-H. Mixed control charts using EWMA statistics. IEEE Access 2016, 4, 8286–8293. [Google Scholar] [CrossRef]

- Haq, A. A new nonparametric EWMA control chart for monitoring process variability. Qual. Reliab. Eng. Int. 2017, 33, 1499–1512. [Google Scholar] [CrossRef]

- Riaz, M.; Abbasi, S.A. Nonparametric double EWMA control chart for process monitoring. Revist. Colomb. Estad. 2016, 39, 167–184. [Google Scholar] [CrossRef]

- Aslam, M.; Azam, M.; Jun, C.-H. A HEWMA-CUSUM control chart for the Weibull distribution. Commun. Stat. Theory Methods 2018, 47, 5973–5985. [Google Scholar] [CrossRef]

- Aslam, M.; Khan, N.; Jun, C.-H. A hybrid exponentially weighted moving average chart for COM-Poisson distribution. Trans. Inst. Meas. Control 2018, 40, 456–461. [Google Scholar] [CrossRef]

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).