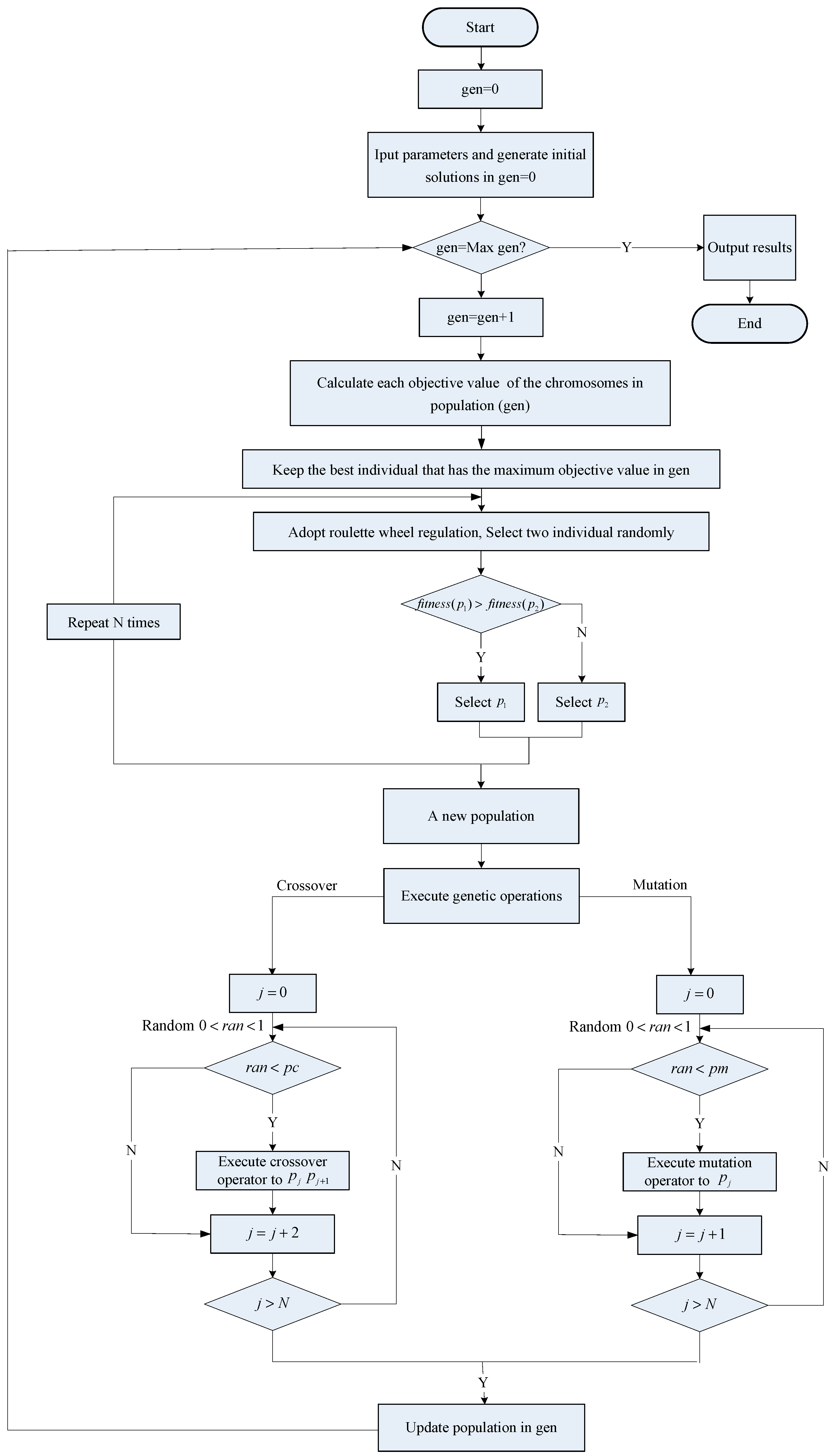

1. Introduction

Many studies have involved made-to-order or time-sensitive products (Shen et al. [

1], Shu et al. [

2], and Federgruen et al. [

3]), and finished orders are often delivered to customers immediately or shortly after production. Consequently, production and distribution are very intimately linked and must be scheduled jointly in order to achieve the desired delivery-time performance, at minimum with time-based or cost-based performance measures (Chen [

4]). In China, the newest government report noticed that, by 2020, large industrial mining enterprises and newly built logistics parks with an annual volume of over 1.5 million tons will have access to over 80% of dedicated railway lines [

5]. This shows that there is a significant benefit in practice in using optimally integrated production–distribution applications (Chen and Variraktarakis [

6] and Pundoor and Chen [

7]).

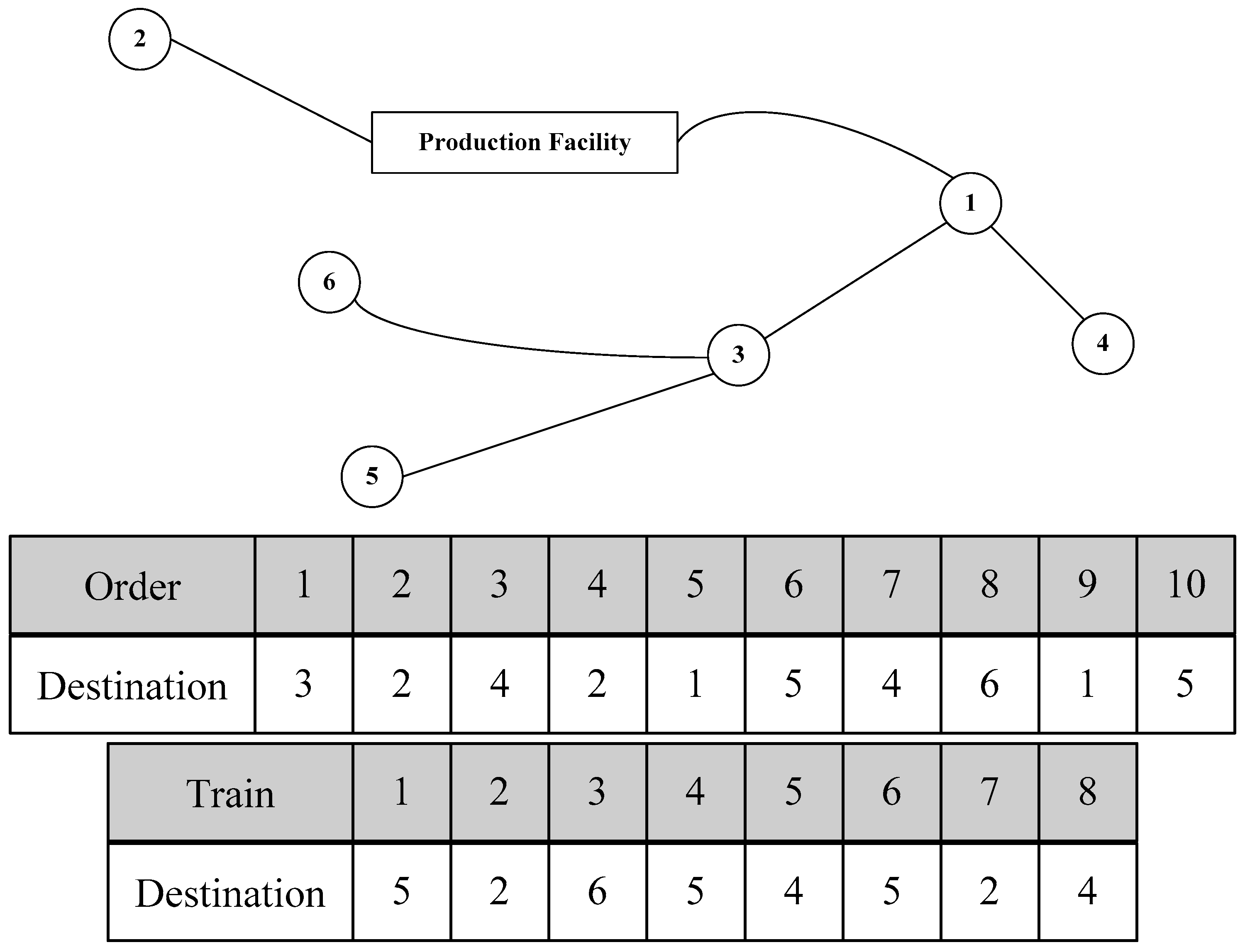

The systematic integration of different optimized operation decisions is important for providing better customer service levels at the individual order level. Three types of important challenges are faced in a production–distribution system. One is to coordinate the activities in time and space to determine the production procedure decision and train-allocated choice with the consideration of a line plan and timetable. Rail transportation has a fixed line plan, which specifies the frequency of the line services and their halting patterns (Goossens et al. [

8] and Fu et al. [

9]). However, air/road transportation uses a point-to-point service mode. Rail transportation is a one-to-many mode, and the service time at each station along the line is defined by a timetable, which specifies the arrival and departure times for each line in the form of a series of trips (Peeters [

10]; Zhang and Nie [

11]). A train can ship several orders to multiple destinations along the same passage of the railway. This problem is further complicated by the rail timetable coordination between production and rail transportation (Díaz-Madroñero et al. [

12] and Sremac et al. [

13]). In addition, there is an organizational effort required to measure earliness and tardiness penalties associated with delivery timeliness to restrict the lead times from the production line to the destinations of accessible trips in order to remain within a given time deadline. Compared with applications with fixed delivery departure dates (Li et al. [

14,

15]; Stecke and Zhao [

16]; Wang et al. [

17]), the delivery timeliness aspect of the production–rail transportation system is diversifying production procedure decisions and train-allocated choices. Furthermore, the orders must be stowed on the trains within tight time windows imposed by the production procedure decisions and the rail timetable. The importance of tight time windows is illustrated by the scope of urban rail transit (Kang et al. [

18]) and by high-speed railway catering services (Wu et al. [

19]).

This paper proposes a scheduling model to coordinate production and rail transportation to improve connections and make delivery smoother. The problem was determining the production procedure decision and train-allocated choice with the consideration of the railway timetable. The collection and delivery time analyses are the key details in this paper. The delivery earliness penalty, delivery tardiness penalty and missing connecting train penalty are considered in the optimization objective. The innovations of our study are summarized as follows.

First, a scenario analysis method is used to reveal the relationships between the production collection connecting time (PCCT) and production collection waiting time (PCWT). The time indicators can be employed to distinguish whether one order misses the trains.

Second, a scenario analysis method is used to reveal the relationships between the production delivery connecting time (PDCT) and production delivery waiting time (PDWT). These formulas can be used to estimate the relationship between the order arrival time and delivery time window.

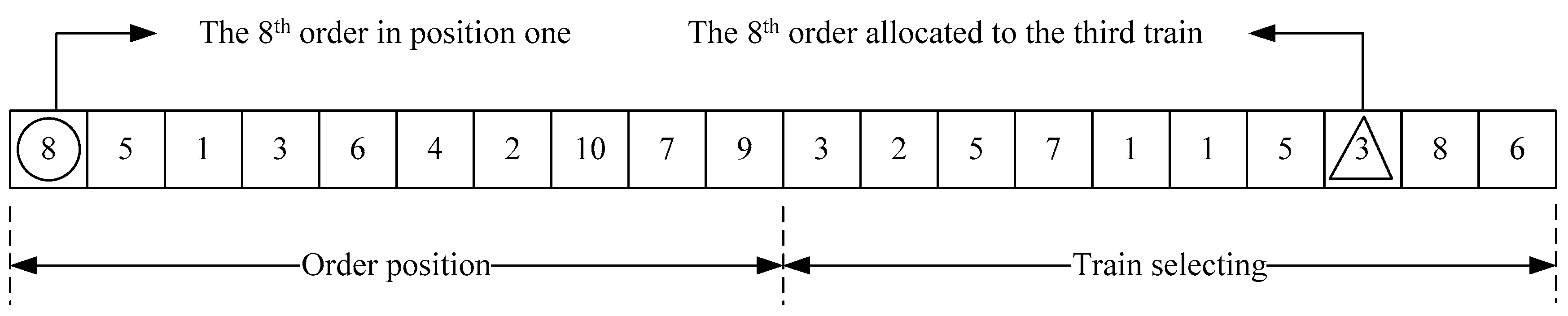

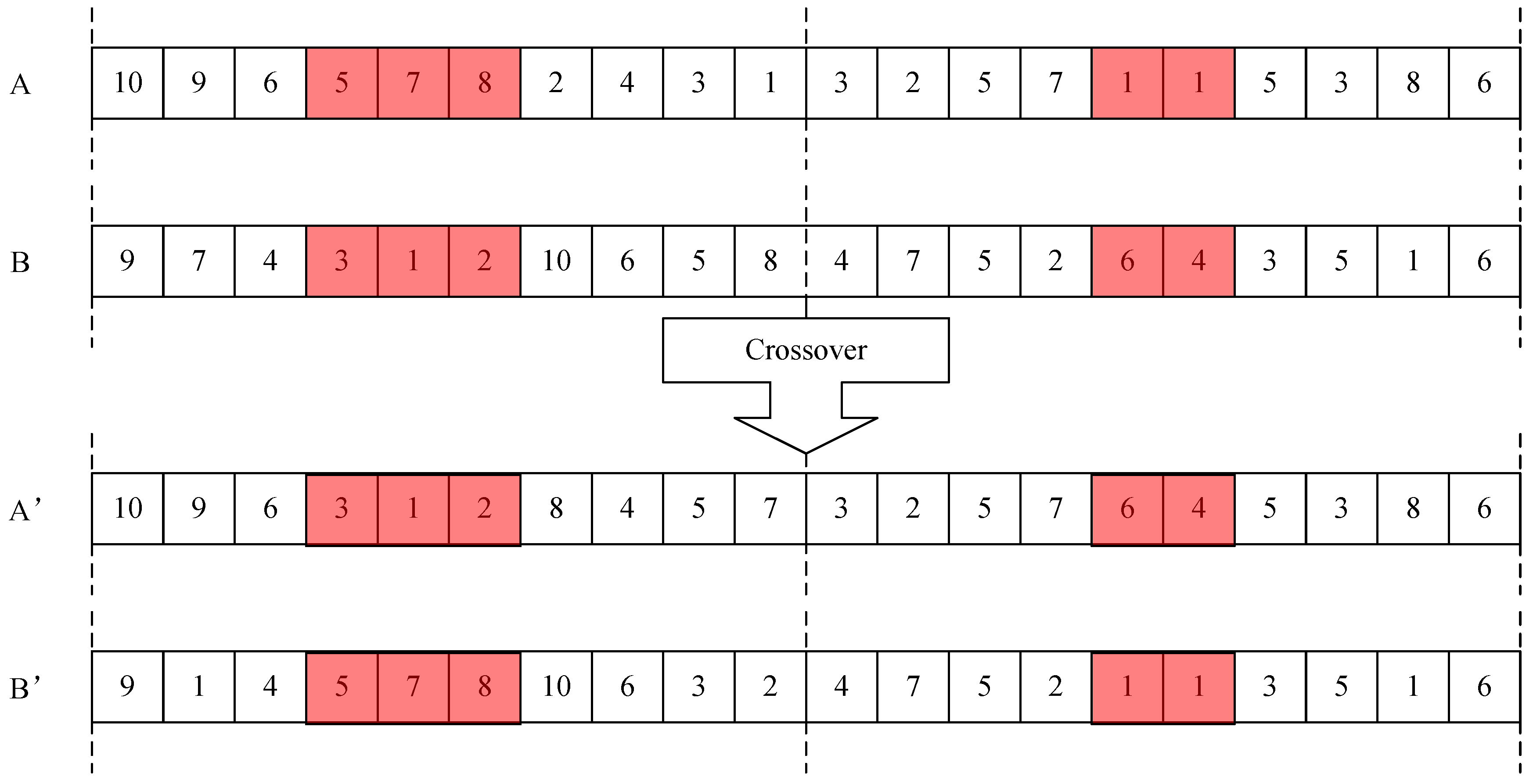

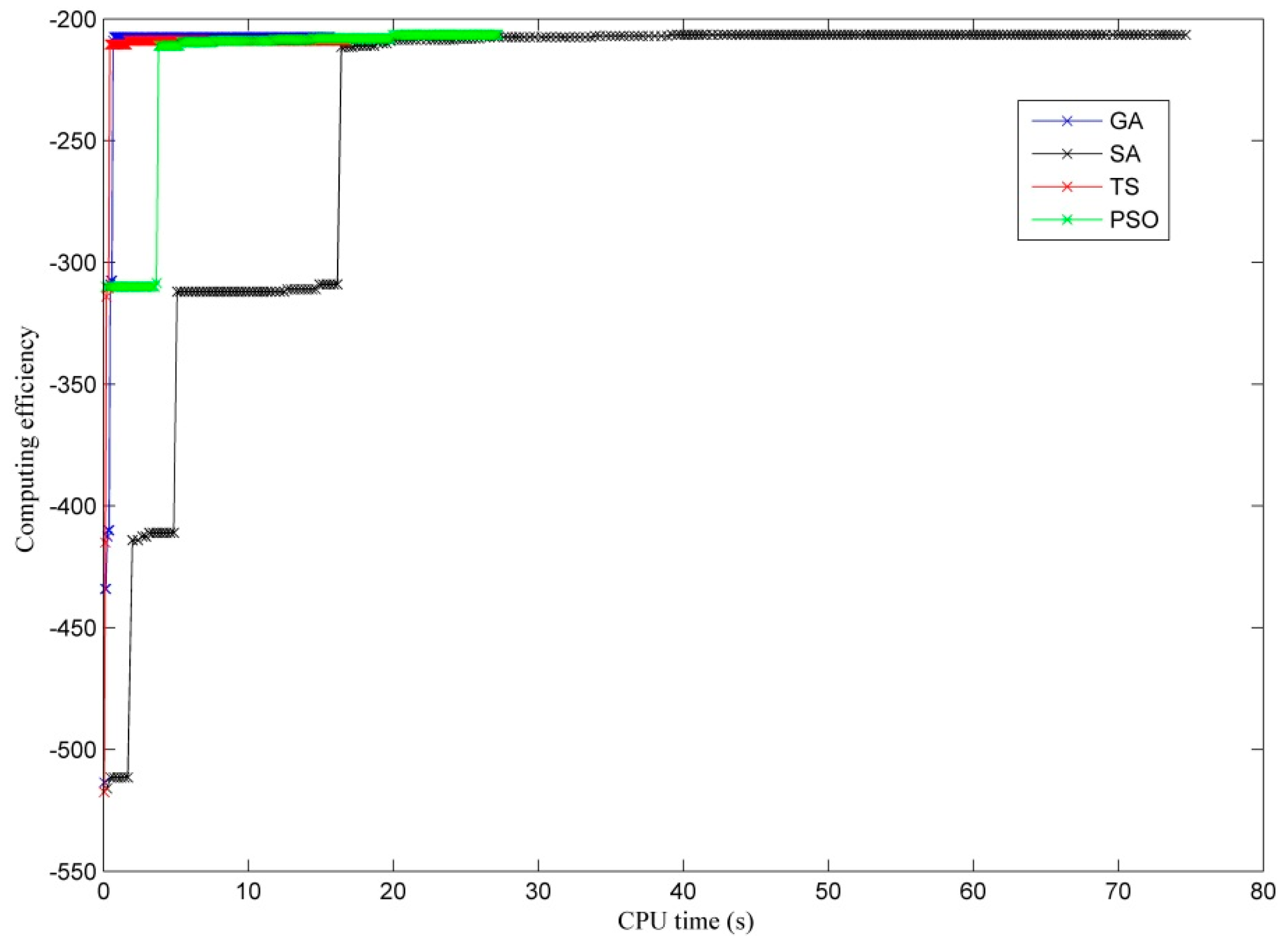

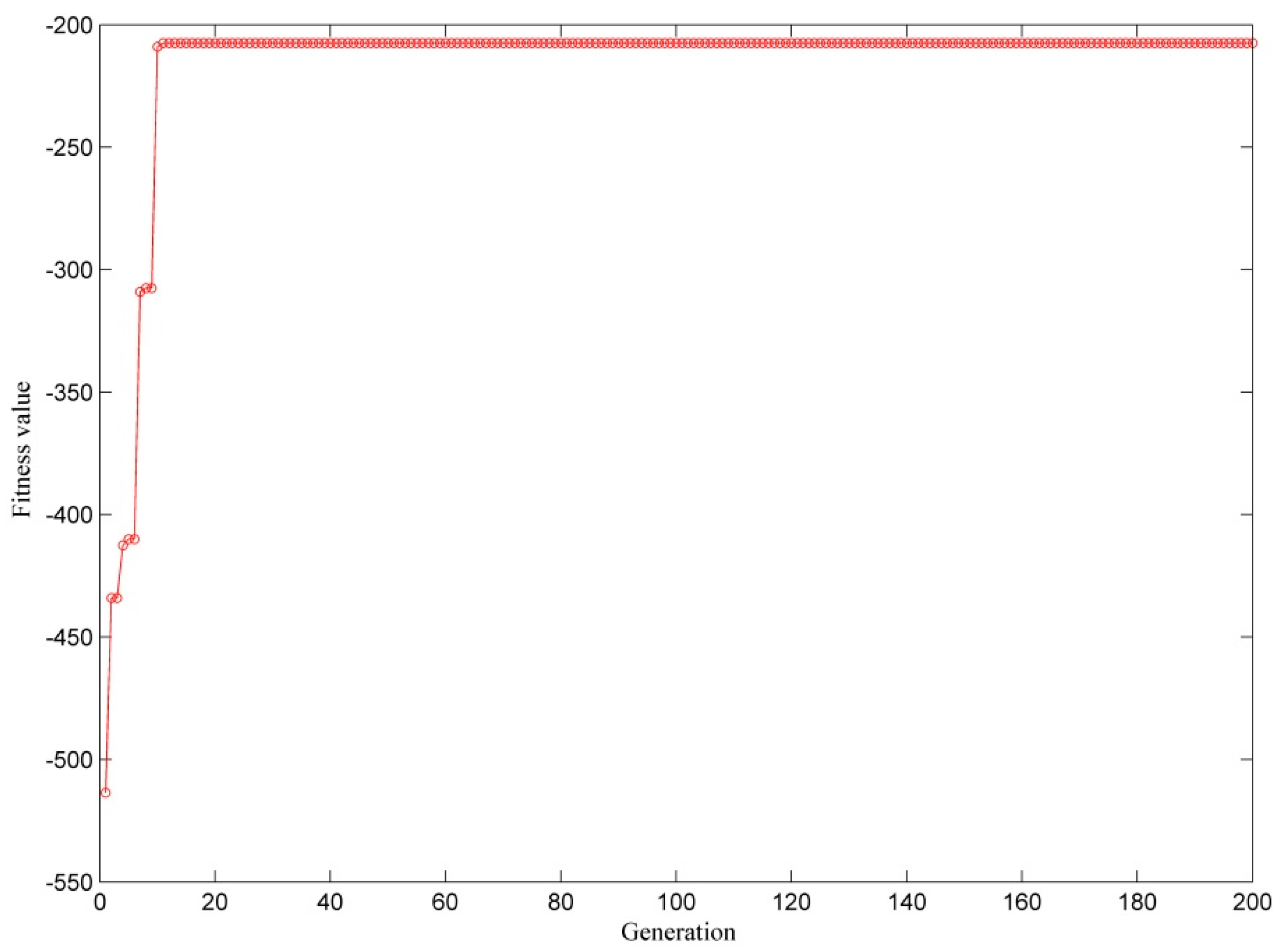

Moreover, a mathematical programming method is developed to solve the problem based on connecting and waiting time. The highlight of our research mainly focused on the time coordination between production and rail transportation. GA is employed to address the model.

2. Literature Review

Research on the integration of scheduling models of production and distribution has been relatively recent and is known as integrated production–distribution planning or scheduling, with studies such as Pundoor et al. [

7], Pronsing et al. [

20], Zhong et al. [

21], Russel et al. [

22], Kishimoto et al. [

23], and Ma et al. [

24]. In many applications including made-to-order or time-sensitive (e.g., perishable, seasonal) products, finished orders are often delivered to customers immediately or shortly after the production. Therefore, the need for integration between supply chain partners is inevitable for these products. Chen [

4] summarized the existing integrated production and distribution scheduling models. These models aim to optimize one or a combination of the time-based, cost-based, and revenue-based performance measures [

24,

25,

26,

27,

28,

29,

30,

31,

32] by taking into account relevant fleet size, trucks’ routes, job processing or batching, e.g., Cheng et al. [

33], Devapriya et al. [

34], and Noroozi et al. [

35]. For instance, Hajiaghaei-Keshteli et al. [

26] adopt a mathematical modeling method to study the production and transportation system and capacity and cost of rail transportation, which are the highlights of the article. Job delivery and release dates are two importation issues considered in the research by Lu et al. [

29]. Ma Y. et al. [

24] developed an integrated production–distribution planning model using bi-level programming for supply chain management. Bock [

31] addressed time-critical routing on a given path under release dates and deadline restrictions, while the minimization of the total weighted completion time is pursued.

The coordinating and scheduling issues involve both machine scheduling (for order processing) and vehicle scheduling and routing (for order delivery). Delivery in particular is the focus of our article. Trucks are an important transport mode for most orders to reach their destination. A few studies have focused on coordinating the relationship between production and truck scheduling. Chang et al. [

25], Chen et al. [

4], Zhong et al. [

21], Moons [

36], Wang et al. [

37], Xuan [

38], Zhong et al. [

39], Seyedhosseini et al. [

40], Kang and Lee [

41], Ganesan [

14], Hajiaghaei-Keshteli et al. [

26], Zandieh [

42], and Delavar et al. [

43] proposed mathematical models to optimize the production and road and air transportation coordinating problem. For instance, an integrated production and distribution scheduling problem is considered by Devapriya et al. [

34], and in this research, the trucks’ routes and the fleet size are the important decisions. Moons et al. [

36] developed a study on a production and distribution system, and decisions on vehicle routing received considerable attention. Sawik [

44] discussed the production and distribution scheduling problem in supply chains with regional and local disruption risks. Azadian et al. [

45] researched the order contract producing problem from a manager’s perspective and proposed an integrated scheduling model on the coordination of production and transportation planning. It is not difficult to see that this class of problems define delivery shipments that are allowed to visit multiple customers. Hence, it is necessary to find a route (i.e., sequence of customers to visit) for each delivery shipment. Such a routing problem alone is already intractable in many cases because it contains the strongly NP-hard traveling salesman problem (TSP) as a special case (Chen [

4]).

Although there are many works on the study of production–distribution issues as mentioned above, the coordination between production and rail transportation in an operational time dimension is one of the less focused-upon aspects. Several similar versions of this problem, termed the production road/air transportation problem, have been studied in Moons et al. [

36] and Li et al. [

46]. Compared with the airline transportation problem, air transportation is also apparently affected by the flight plan and aircrafts used (Pemberton [

47]; Liang et al. [

48]; Ho et al. [

49]), but the loading required by each flight is usually satisfied at its origin port. Nevertheless, in the rail transportation problem, a train can either be loaded at a trip’s origin or at its other passing station. At any rate, the difficulty degree of the airline transportation problem is reduced on this point alone. Hence, the distribution system design integrated the knowledge of path selecting, and the time window caused by the rail timetable makes our issue more novel and interesting. In addition to this, according to the schedule, the connecting trains provide a very important as well as unique opportunity for orders to reach their final destinations in time (Kang et al. [

18] and Wu et al. [

19]). Producers and customers tend to complain more when orders miss the connecting trains to their destinations. These characteristics lead to some difficulties to apply the off-the-shelf technologies in a production–distribution system. To the best of our knowledge, few studies have been conducted to investigate these topics in the context of railway timetables.

In conclusion, our method not only takes relevant accessibility into account, but also takes delivery timeliness as a time window constraint into account. Of course, this is more common in other articles. However, more importantly, not only the delivery timeliness (customer service levels at the individual order level) is guaranteed by the tight delivery time window, but also a comprehensive formula is introduced to measure delivery timeliness or customer service levels at the individual order level. The comprehensive formula can be used to distinguish between the last feasible connecting train and the non-last ones and be used to judge whether the feasible connecting trains will be missed. Meanwhile, the comprehensive formula is employed to improve the connecting relationship between the production line and trains. This comprehensive formula is summarized from the scenario analysis introduced in our research.

3. Integrated Scheduling Coordination Model

3.1. Basic Assumptions

To facilitate the model formulation, we consider the following assumptions throughout this paper:

Assumption 1. The transfer operating time () and delivery operating time () are known and fixed for all orders. Although not all orders have the same quantity, and are assumed constant for simplification.

Assumption 2. It can be assumed that the production line and related rail station are at the same geographical position. The same assumption applies for the order destination and the related train.

Assumption 3. We regard the production line as a single machine, and no free time is allowed.

3.2. Production Connecting Connection Time (PCCT) and Waiting Time (PCWT)

The PCCT could be evaluated by , where represents the departure time of the last feasible connecting train from station ; represents the completion time of the order at station on production line , and it is determined by its production sequence; represents the operating time from to at station . If , the order can connect to the feasible train successfully. However, the order fails to connect when .

Regarding the PCWT, , is defined as the waiting time when the order transfers from the production line to the selected connecting train . If orders fail to transfer to a feasible connecting train, PCWT is defined as a sufficiently large value.

As mentioned above,

and

can be calculated by Equation (1), where

represents a sufficiently large positive value.

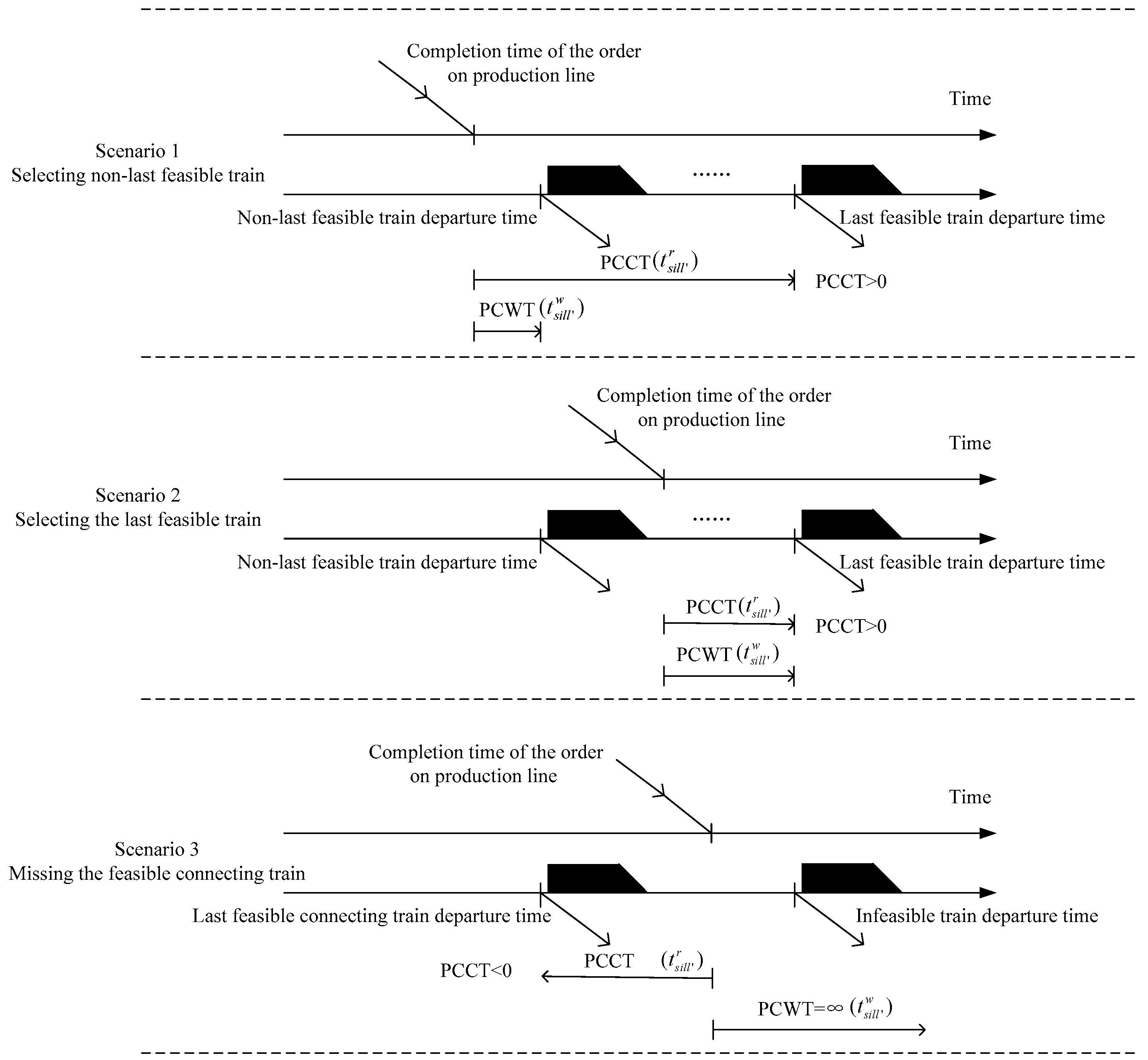

Three different relationships based on the orders’ completion times and train departure times are shown in

Figure 1. The timeline above represents the completion time of the order at station

on production line

, while the below timeline captures the departure times of connecting trains at station

on line

.

- (1)

As scenario 1 shows, if PCCT > PCWT, orders will choose the non-last feasible connecting train instead of the last feasible one, in which .

- (2)

As scenario 2 shows, if PCCT = PCWT, orders will choose the last feasible connecting train; that is, .

- (3)

However, if no feasible train can be chosen, as shown in scenario 3, PCCT is defined as a negative value, and PCWT is a sufficiently large positive value; that is, PCCT < PCWT. Orders will fail to connect; that is, . We let to simplify the numerical calculation. is defined as the penalty value of missing the feasible connecting train.

From the above, we propose a composite indicator as production connection time (PCT,

) in Equation (2). Orders can connect successfully between

and

when

, otherwise,

.

3.3. Production Delivery Connection Time (PDCT) and Waiting Time (PDWT)

At each delivery destination , the PDCT is decided by the selected train arrival time and the end time of the time window for the order because the delivery time from line to the customers is constant, as assumed. Thus, PDCT is calculated by , where M is a sufficiently large positive value, represents the arrival time of the selected train to its delivery destination; represents the end delivery time for the order ; and represents the order delivery operating time from line to customers. Orders can deliver successfully between rail transportation and customers when . However, orders fail to transfer when .

The PDWT,

, is the waiting time for the order until the delivery service allowed by the time window. If the train arrival time is beyond the due time, orders may not successfully be delivered, and PDWT approaches an infinite positive number. Therefore,

and

can be calculated by Equation (3).

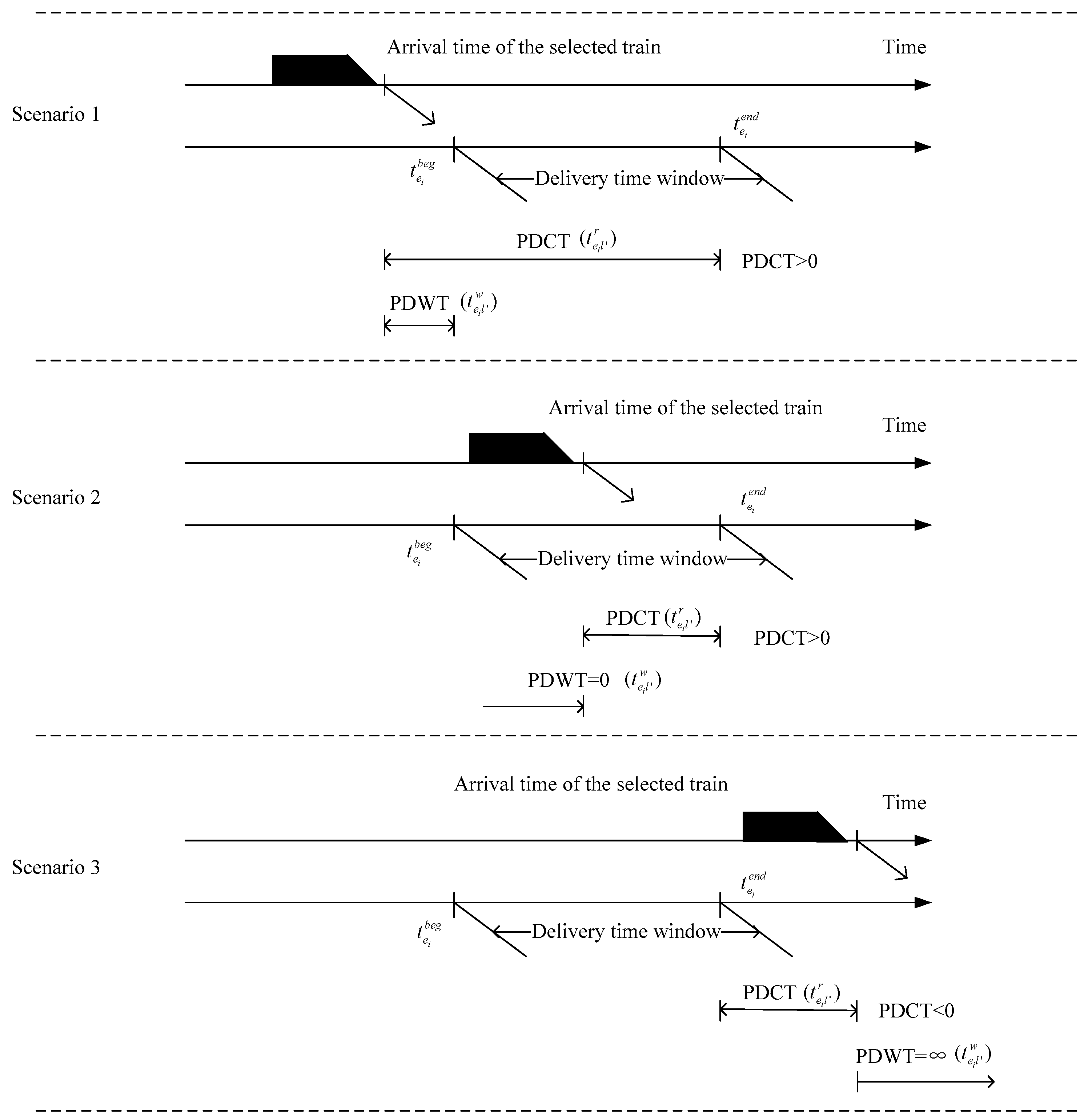

Three different relationships based on the selected train arrival time and delivery time window are shown in

Figure 2. The timeline above shows the selected train arrival time to the order’s destination, while the arrows below capture the delivery time window of the order.

- (1)

If PDCT − PDWT > 0 and PDWT > 0 (scenario 1), orders will be delivered early to the destination, in which case . We let , and this means the penalty value of delivering early.

- (2)

If PDCT − PDWT > 0 and PDWT = 0 (scenario 2), orders can be delivered as soon as the connecting train arrives, in which . We let to facilitate the numerical calculation.

- (3)

However, if PDCT − PDWT < 0, and PDCT < 0 (scenario 3), orders will fail to deliver, and . In this case, is a sufficiently large positive value, and is a negative value, implying . We let , and the meaning of is the penalty value of delivering late. Let .

Here, we define a production delivery time (PDT,

) in formula (4).

3.4. Model Formulation

In the integrated scheduling coordination model, the objective function contains two aspects. On one hand, the model is intended to maximize PCCT and PDCT. If PCCT > 0, orders can choose one feasible connecting train successfully. Otherwise, orders fail to connect. Similarly, if PDCT > 0, orders can be delivered successfully. Otherwise, orders fail to deliver. However, some orders may fail to transfer and deliver because of production procedure decisions. On the other hand, the model expects to minimize PCWT and PDWT. From Equations (2) and (4), two integrative variables are defined here (PCT and PDT). Thus, the objective function is to maximize

and

to increase successful connections /deliveries and reduce waiting time.

(1) For any order

in the production line

, Equation (6) is given to determine the completion time of the order

at station

on production line

.

(2) Some equipment requirements that set limits on the capacity for connecting trains should be satisfied.

(3) From Equations (2) and (4), we define

and

.

5. Conclusions

There are many studies on the study of production–distribution issues, but few works focus on the coordinating timetable of rail transportation with the production sequence. This paper focuses on procedure decisions and train-allocated choices with the consideration of railway timetables.

A scenario analysis method is used to reveal the relationships between PCCT and PCWT in the production process and the relationships between PDCT and PDWT in the delivery process. An integrated scheduling coordination model is established to maximize the production connecting time (PCT) and production delivery time (PDT). The model and GA are applicable and easy to implement. The results indicate that the more successful connections and deliveries in the network that are achieved are attributed to our model.

Our research can be furthered in several areas. First, considering both ordinary trains and charter trains in the problem makes the problem more interesting, because the timetable for charter trains can be personalized to meet order demand. Moreover, actual trains in service may miss their scheduling because of unexpected incidents, so it is worth discussing how a dynamic rescheduling strategy which aims to eliminate the negative effects could be made.