Impact-Damage Equivalency for Twisted Composite Blades with Symmetrical Configurations

Abstract

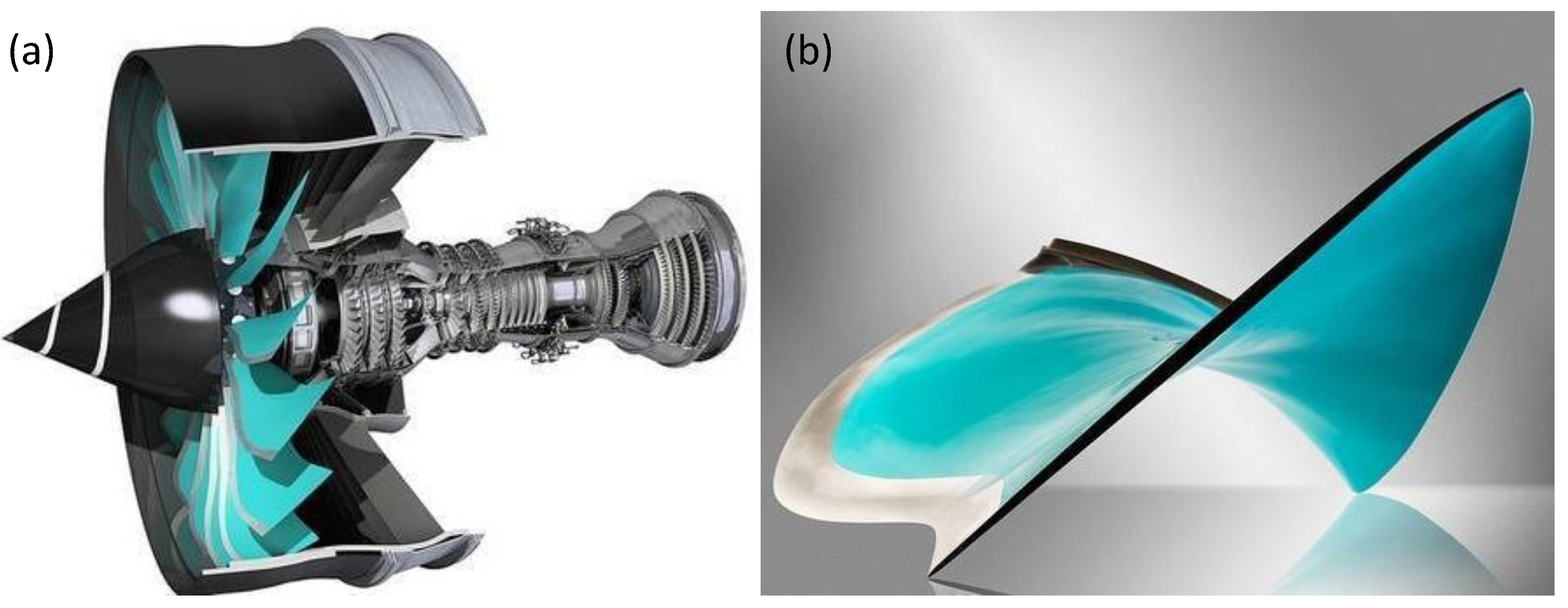

1. Introduction

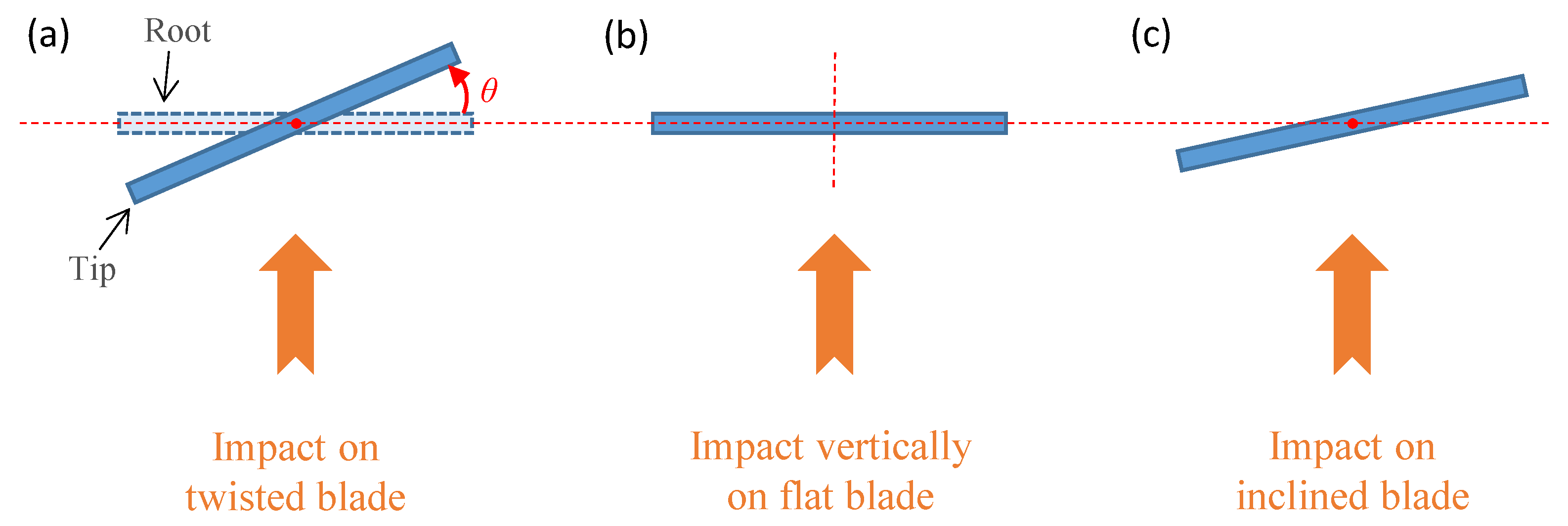

2. Numerical Method

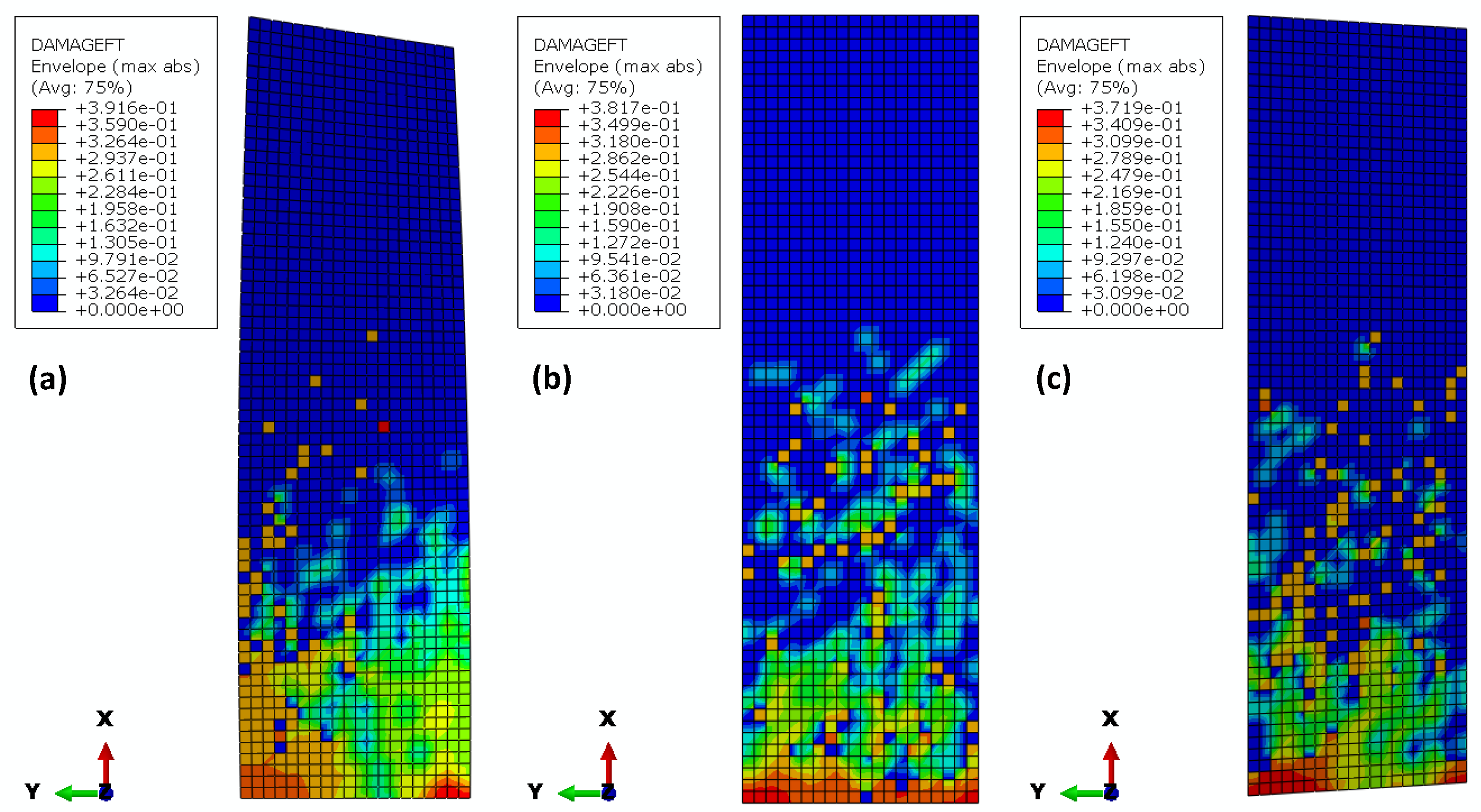

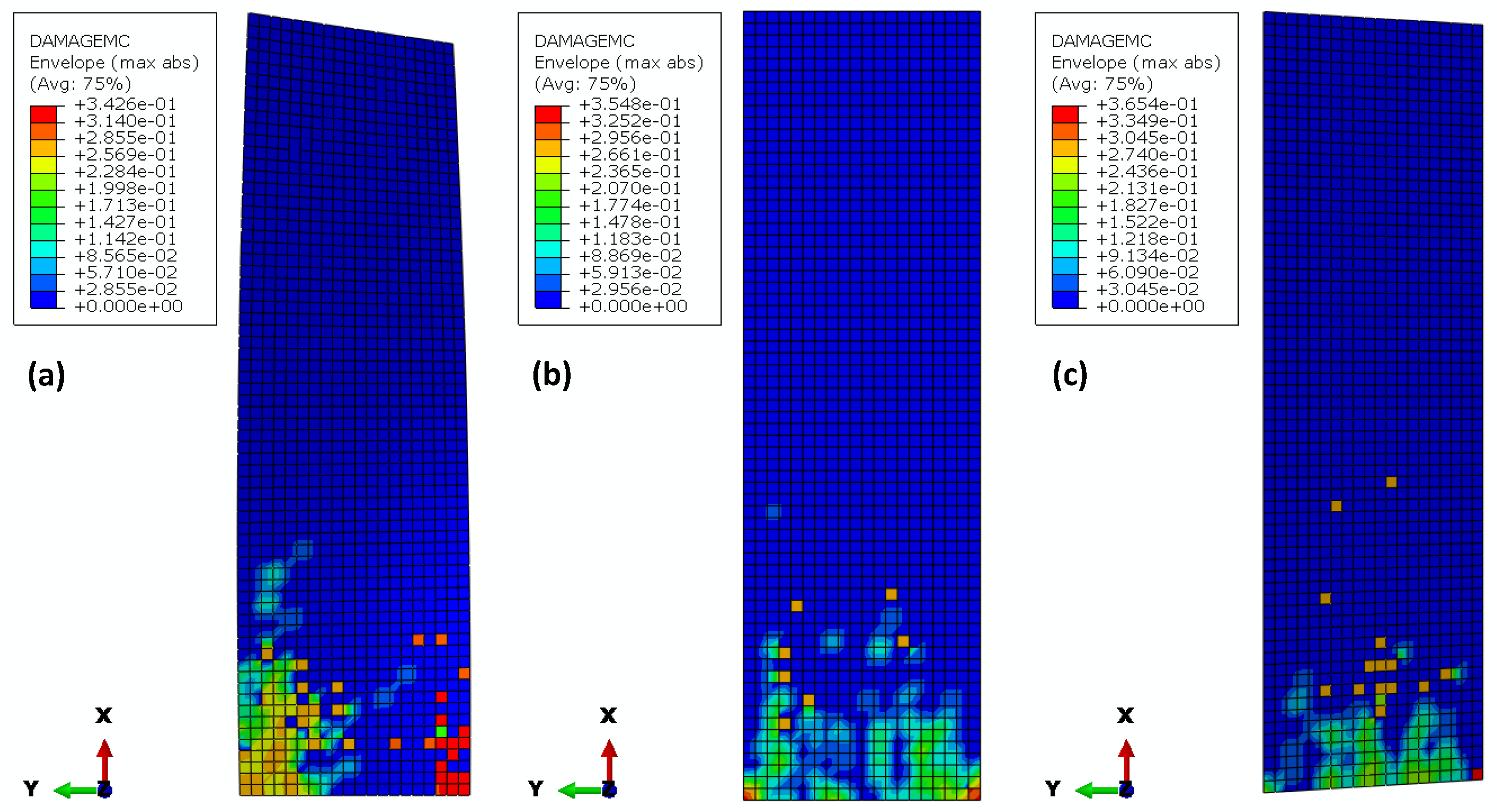

3. Results and Discussion

4. Conclusions

- ▪

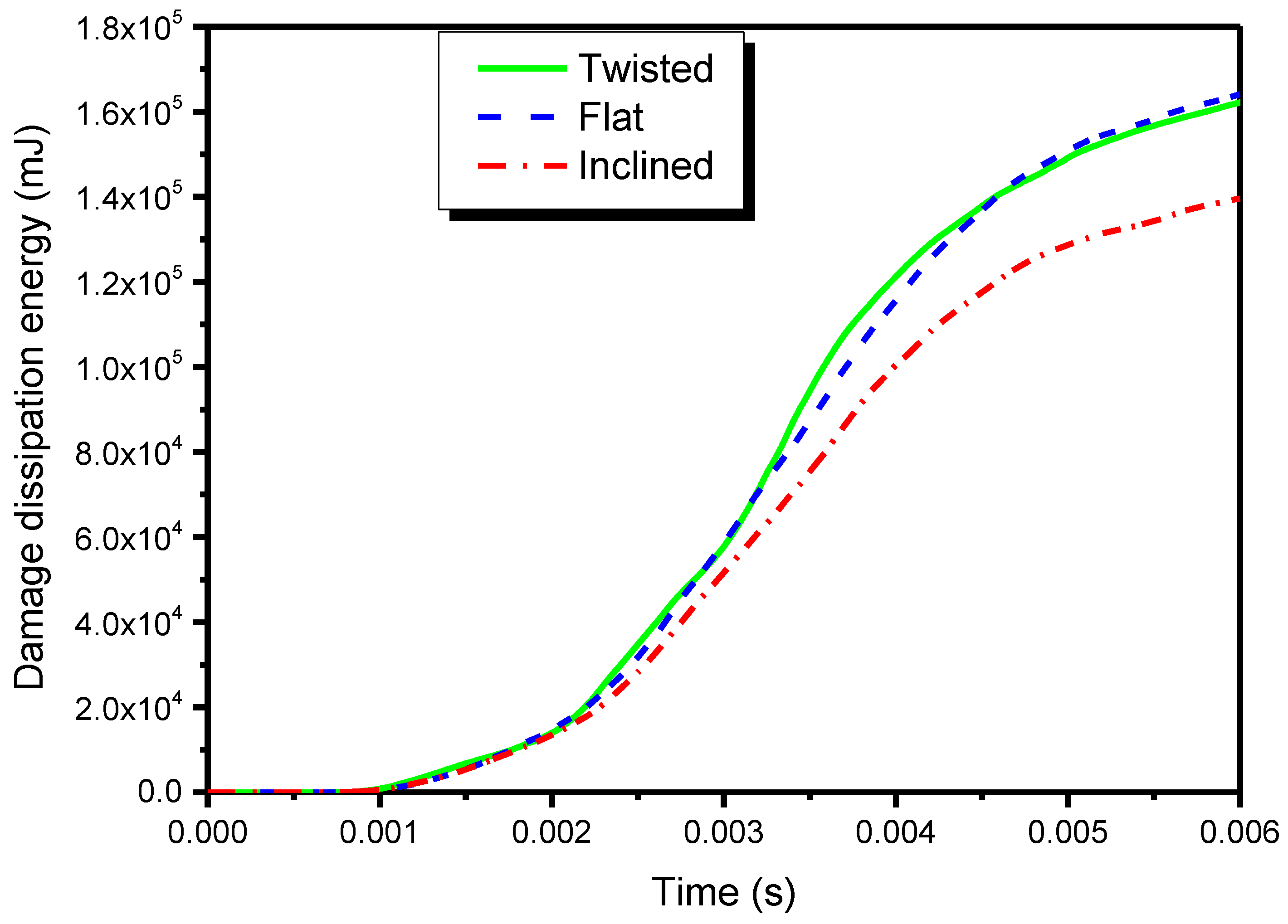

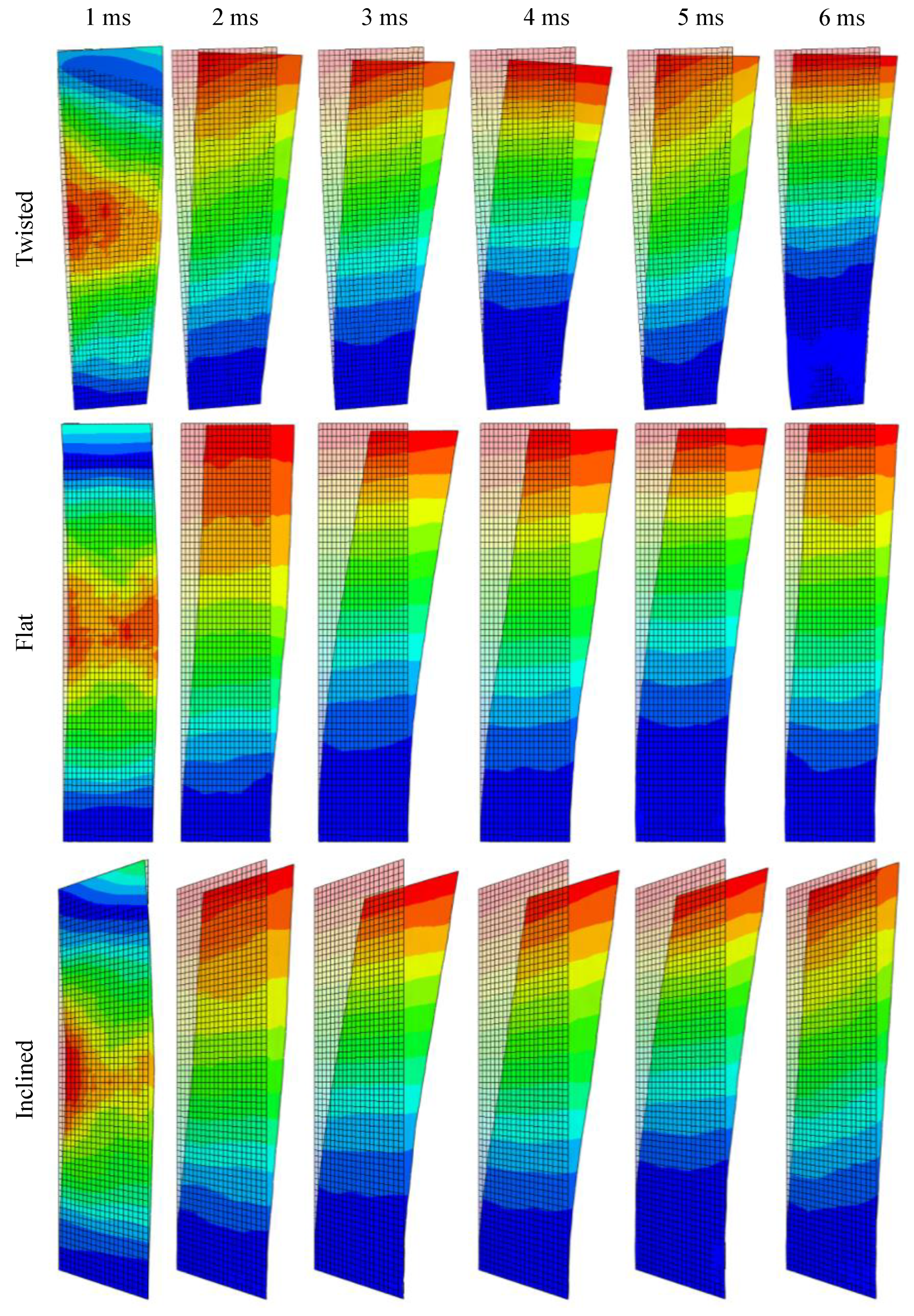

- The inclined-impacted flat blade is more equivalent to the twisted blade in terms of the fiber-tension damage and the contact force, which benefits from the similarity between the twisted and inclined configurations, such as the coupling bending and torsion deformations. On the whole, the inclined flat blade exhibits advantages over the vertically-impacted flat one in reproducing the fatal damage mode, the corner-distributed feature, and the oblique deformation.

- ▪

- For the fiber-compression damage mode, both the axisymmetric and centrosymmetric configurations can relatively well describe the damage distribution of the twisted case. However, in terms of the matrix-compression damage, the two flat blades both failed to adequately reflect the damage distribution of the twisted blade. It can be indicated that the flat laminates cannot perfectly reproduce the local compressive deformations that the twisted laminate experiences.

- ▪

- The three configurations showed similar matrix-tension damage maps, which were globally distributed. The vertically-impacted flat blade is quite adequate to reflect the real damage history in the twisted blade case, while the inclined flat case performs inadequately.

Author Contributions

Funding

Conflicts of Interest

References

- Abrate, S. Soft impacts on aerospace structures. Prog. Aerosp. Sci. 2016, 81, 1–17. [Google Scholar] [CrossRef]

- Zhang, D.; Fei, Q. Effect of bird geometry and impact orientation in bird striking on a rotary Jet-Engine fan analysis using SPH method. Aerosp. Sci. Technol. 2016, 54, 320–329. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, L.; Zhang, D. Effect of arbitrary yaw/pitch angle in bird strike numerical simulation using SPH method. Aerosp. Sci. Technol. 2018, 81, 284–293. [Google Scholar] [CrossRef]

- Meguid, S.A.; Mao, R.H.; Ng, T.Y. FE analysis of geometry effects of an artificial bird striking an aeroengine fan blade. Int. J. Impact Eng. 2008, 35, 487–498. [Google Scholar] [CrossRef]

- Mohagheghian, I.; Wang, Y.; Zhou, J.; Yu, L.; Guo, X.; Yan, Y.; Charalambides, M.N.; Dear, J.P. Deformation and damage mechanisms of laminated glass windows subjected to high velocity soft impact. Int. J. Solids Struct. 2017, 109, 46–62. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, J.; Zhang, X.; Yan, Y.; Jiang, L.; Mohagheghian, I.; Dear, J.P.; Charalambides, M.N. Experimental and numerical investigation of high velocity soft impact loading on aircraft materials. Aerosp. Sci. Technol. 2019, 90, 44–58. [Google Scholar] [CrossRef]

- Grimaldi, A.; Sollo, A.; Guida, M.; Marulo, F. Parametric study of a SPH high velocity impact analysis—A birdstrike windshield application. Compos. Struct. 2013, 96, 616–630. [Google Scholar] [CrossRef]

- Hedayati, R.; Ziaei-Rad, S.; Eyvazian, A.; Hamouda, A.M. Bird strike analysis on a typical helicopter windshield with different lay-ups. J. Mech. Sci. Technol. 2014, 28, 1381–1392. [Google Scholar] [CrossRef]

- Riccio, A.; Cristiano, R.; Saputo, S.; Sellitto, A. Numerical methodologies for simulating Bird-Strike on composite wings. Compos. Struct. 2018, 202, 590–602. [Google Scholar] [CrossRef]

- Yu, Z.; Xue, P.; Yao, P.; Zahran, M.S. Analytical determination of the critical impact location for wing leading edge under birdstrike. Lat. Am. J. Solids Struct. 2019, 16, 1–17. [Google Scholar] [CrossRef]

- Di Caprio, F.; Cristillo, D.; Saputo, S.; Guida, M.; Riccio, A. Crashworthiness of wing leading edges under bird impact event. Compos. Struct. 2019, 216, 39–52. [Google Scholar] [CrossRef]

- Smojver, I.; Ivančević, D. Numerical simulation of bird strike damage prediction in airplane flap structure. Compos. Struct. 2010, 92, 2016–2026. [Google Scholar] [CrossRef]

- Orlando, S.; Marulo, F.; Guida, M.; Timbrato, F. Bird strike assessment for a composite wing flap. Int. J. Crashworthiness 2018, 23, 219–235. [Google Scholar] [CrossRef]

- Vignjevic, R.; Orłowski, M.; De Vuyst, T.; Campbell, J.C. A parametric study of bird strike on engine blades. Int. J. Impact Eng. 2013, 60, 44–57. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Gao, X. Bird strike on a flat plate: Experiments and numerical simulations. Int. J. Impact Eng. 2014, 70, 21–37. [Google Scholar] [CrossRef]

- Allaeys, F.; Luyckx, G.; Van Paepegem, W.; Degrieck, J. Characterization of real and substitute birds through experimental and numerical analysis of momentum, average impact force and residual energy in bird strike on three rigid targets: A flat plate, a wedge and a splitter. Int. J. Impact Eng. 2017, 99, 1–13. [Google Scholar] [CrossRef]

- Dar, U.A.; Zhang, W.; Xu, Y. FE Analysis of Dynamic Response of Aircraft Windshield against Bird Impact. Int. J. Aerosp. Eng. 2013, 2013, 1–12. [Google Scholar] [CrossRef]

- Mao, R.H.; Meguid, S.A.; Ng, T.Y. Transient three dimensional finite element analysis of a bird striking a fan blade. Int. J. Mech. Mater. Des. 2008, 4, 79–96. [Google Scholar] [CrossRef][Green Version]

- Dar, U.A.; Awais, M.; Mian, H.H.; Sheikh, M.Z. The effect of representative bird model and its impact direction on crashworthiness of aircraft windshield and canopy structure. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2019, 233, 5150–5163. [Google Scholar] [CrossRef]

- Georgiadis, S.; Gunnion, A.J.; Thomson, R.S.; Cartwright, B.K. Bird-Strike simulation for certification of the Boeing 787 composite moveable trailing edge. Compos. Struct. 2008, 86, 258–268. [Google Scholar] [CrossRef]

- Mohagheghian, I.; Charalambides, M.N.; Wang, Y.; Jiang, L.; Zhang, X.; Yan, Y.; Kinloch, A.J.; Dear, J.P. Effect of the polymer interlayer on the High-Velocity soft impact response of laminated glass plates. Int. J. Impact Eng. 2018, 120, 150–170. [Google Scholar] [CrossRef]

- Hedayati, R.; Sadighi, M. Effect of Using an Inner Plate between Two Faces of a Sandwich Structure in Resistance to Bird-Strike Impact. J. Aerosp. Eng. 2016, 29, 04015020. [Google Scholar] [CrossRef]

- Hu, D.; Song, B.; Wang, D.; Chen, Z. Experiment and numerical simulation of a Full-Scale helicopter composite cockpit structure subject to a bird strike. Compos. Struct. 2016, 149, 385–397. [Google Scholar] [CrossRef]

- Wang, J.; Xu, Y.; Zhang, W. Finite element simulation of PMMA aircraft windshield against bird strike by using a rate and temperature dependent nonlinear viscoelastic constitutive model. Compos. Struct. 2014, 108, 21–30. [Google Scholar] [CrossRef]

- Roberts, G.D.; Revilock, D.M.; Binienda, W.K.; Nie, W.Z.; Mackenzie, S.B.; Todd, K.B. Impact Testing and Analysis of Composites for Aircraft Engine Fan Cases. J. Aerosp. Eng. 2002, 15, 104–110. [Google Scholar] [CrossRef]

- Higuchi, R.; Okabe, T.; Yoshimura, A.; Tay, T.E. Progressive failure under High-Velocity impact on composite laminates: Experiment and phenomenological mesomodeling. Eng. Fract. Mech. 2017, 178, 346–361. [Google Scholar] [CrossRef]

- Minak, G.; Abrate, S.; Ghelli, D.; Panciroli, R.; Zucchelli, A. Low-Velocity impact on carbon/epoxy tubes subjected to torque–Experimental results, analytical models and FEM analysis. Compos. Struct. 2010, 92, 623–632. [Google Scholar] [CrossRef]

- Saghafi, H.; Minak, G.; Zucchelli, A. Effect of preload on the impact response of curved composite panels. Compos. Part B Eng. 2014, 60, 74–81. [Google Scholar] [CrossRef]

- Heimbs, S.; Bergmann, T. High-Velocity Impact Behaviour of Prestressed Composite Plates under Bird Strike Loading. Int. J. Aerosp. Eng. 2012, 2012, 1–11. [Google Scholar] [CrossRef]

- Guida, M.; Sellitto, A.; Marulo, F.; Riccio, A. Analysis of the Impact Dynamics of Shape Memory Alloy Hybrid Composites for Advanced Applications. Materials 2019, 12, 153. [Google Scholar] [CrossRef] [PubMed]

- Friedrich, L.A. Impact Resistance of Hybrid Composite Fan Blade Materials; NASA: Washington, DC, USA, 1974. [Google Scholar]

- Hou, J.P.; Ruiz, C. Soft body impact on laminated composite materials. Compos. Part A Appl. Sci. Manuf. 2007, 38, 505–515. [Google Scholar] [CrossRef]

- Liu, L.; Luo, G.; Chen, W.; Zhao, Z.; Huang, X. Dynamic Behavior and Damage Mechanism of 3D Braided Composite Fan Blade under Bird Impact. Int. J. Aerosp. Eng. 2018, 2018, 1–16. [Google Scholar] [CrossRef]

- Nishikawa, M.; Hemmi, K.; Takeda, N. Finite-Element simulation for modeling composite plates subjected to soft-body, High-Velocity impact for application to bird-strike problem of composite fan blades. Compos. Struct. 2011, 93, 1416–1423. [Google Scholar] [CrossRef]

- Zhou, Y.; Sun, Y.; Cai, W. Bird-Striking damage of rotating laminates using SPH-CDM method. Aerosp. Sci. Technol. 2019, 84, 265–272. [Google Scholar] [CrossRef]

- Ten Years of “Twisting” a Fan Blade, This Innovative Technology Is about to Affect Your Airplane. 2018. Available online: http://www.sohu.com/a/234993331_660773 (accessed on 27 July 2019).

- Heimbs, S. Computational methods for bird strike simulations: A review. Comput. Struct. 2011, 89, 2093–2112. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Yu, X.; Tang, Z.; Gao, X.; Lv, J.; Zhang, Z. A novel design for reinforcing the aircraft tail leading edge structure against bird strike. Int. J. Impact Eng. 2017, 105, 89–101. [Google Scholar] [CrossRef]

- Taddei, L.; Awoukeng Goumtcha, A.; Roth, S. Smoothed particle hydrodynamics formulation for penetrating impacts on ballistic gelatine. Mech. Res. Commun. 2015, 70, 94–101. [Google Scholar] [CrossRef]

- Hashin, Z.; Rotem, A. A Fatigue Failure Criterion for Fiber Reinforced Materials. J. Compos. Mater. 1973, 7, 448–464. [Google Scholar] [CrossRef]

- Riccio, A.; Ricchiuto, R.; Saputo, S.; Raimondo, A.; Caputo, F.; Antonucci, V.; Lopresto, V. Impact behaviour of omega stiffened composite panels. Prog. Aerosp. Sci. 2016, 81, 41–48. [Google Scholar] [CrossRef]

- Smojver, I.; Ivančević, D. Bird strike damage analysis in aircraft structures using Abaqus/Explicit and coupled Eulerian Lagrangian approach. Compos. Sci. Technol. 2011, 71, 489–498. [Google Scholar] [CrossRef]

| Ply Angles | Ply Number | Total Thickness (mm) | In-Plane Dimensions (mm × mm) |

|---|---|---|---|

| [0/45/0/-45/-45/0/45/0]s | 16 | 48 | 500 × 150 |

| Properties | Value |

|---|---|

| Mass density | 1600 kg/m3 |

| Orthotropic elastic properties | E11 = 181,000 MPa; E22 = 10,300 MPa; ν12 = 0.28; G12 = 7170 MPa; G13 = 1000 MPa; G23 = 500 MPa |

| Strength properties | XT = XC = 1500 MPa; YT = 40 MPa; YC = 246 MPa; S12 = 200 MPa; S13 = 123 MPa |

| Fracture energies | = 11.5 kJ/m2; = 4.1 kJ/m2; = 0.35 kJ/m2; = 3.2 kJ/m2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Sun, Y.; Huang, T. Impact-Damage Equivalency for Twisted Composite Blades with Symmetrical Configurations. Symmetry 2019, 11, 1292. https://doi.org/10.3390/sym11101292

Zhou Y, Sun Y, Huang T. Impact-Damage Equivalency for Twisted Composite Blades with Symmetrical Configurations. Symmetry. 2019; 11(10):1292. https://doi.org/10.3390/sym11101292

Chicago/Turabian StyleZhou, Yadong, Youchao Sun, and Tianlin Huang. 2019. "Impact-Damage Equivalency for Twisted Composite Blades with Symmetrical Configurations" Symmetry 11, no. 10: 1292. https://doi.org/10.3390/sym11101292

APA StyleZhou, Y., Sun, Y., & Huang, T. (2019). Impact-Damage Equivalency for Twisted Composite Blades with Symmetrical Configurations. Symmetry, 11(10), 1292. https://doi.org/10.3390/sym11101292