1. Introduction

With the development of the economy and the increase in the population, the demand for water resources is increasing. However, due to the irrational exploitation and unitization of water resources, many countries, especially developing countries, such as India, China, Mexico, and South Africa, experience different levels of water shortage. In response to the issue of water resource allocation and optimization, many scholars have studied and addressed this issue based on operation research studies. To date, these studies can be divided into linear programming (LP) and nonlinear programming (NLP) according to the function relationships. Similarly, these studies can be distinguished by crisp models and uncertain models. However, uncertainty is an important factor that could highly affect water resources allocation [

1]. For example, there is a peak period and bottom period for just one day of water consumption; the seasonality of water resources is also an important factor of volatility. In fact, very few water resources remain at a constant amount. In addition, other human controlled conditions of the social economy and environmental policy are constantly changing year to year. These issues require uncertain methods to address such complex inputs. Consequently, inexact, fuzzy, and stochastic models or algorithms have been preferred to consider uncertainty beyond the conventional planning methods. In agricultural water resource management, uncertainty is frequently considered because of incomplete data records. Therefore, this study mainly provides a relatively in-depth understanding of water resources management of local agriculture combined with discussions of the relevant regulations and various related optimal planning studies in the world; the results of this study can provide powerful decision support for water resources allocation in the southern Min River basin. Moreover, a new

α-representation fuzzy sets (FS) optimization model is proposed in this study. This study also provides a valuable analysis of the economic development and optimal utilization of the limited water resources in this area.

Regarding the uncertainty of water resources management, many research studies have been conducted on this issue. In 2000, Huang et al. [

2] developed an inexact two-stage stochastic programming (ITSP) model for water resources management. This algorithm can reflect not only uncertainties that are expressed as probability distributions, but also those made available as interval numbers. In 2005, Maqsood et al. [

3] presented an interval-parameter fuzzy two-stage stochastic programming (IFTSP) method for the planning of water resources management; the authors used an optimization framework to represent predefined water policies and then applied discrete interval numbers with the possibility and probability distribution in their solution process, resulting in an efficient policy to use the water. Li et al. [

4], in 2008, developed an inexact multistage stochastic integer programming (IMSIP) method for the management of water resources; this method can use probabilities and dynamics methods to reflect a complete scenario set over a multistage context. In 2017, Liu et al. [

5] introduced a two-stage regional multi-water source allocation model (TRMSA) to determine the water supply that consisted of surface water, ground water, and transit water. This model can optimize water supply for a shortage year of water and satisfy requirements of each targets in the water systems. In general, these studies could address uncertainty by using interval numbers, probability degrees and the two-stage programming (TSP) model; however, none of the aforementioned studies considered the type-2 (T2) fuzzy sets model, which has been used extensively to capture linguistic uncertainty in decision-making problems [

6].

Recently, studies of the optimal fuzzy linear programming have been conducted. As an extension of the conventional FS concept, the higher levels of fuzzy sets, the T2FSs, have been coupled into the water model to handle more uncertainty and hence to produce more accurate and robust results [

7,

8] because of the introduction of the T2FSs into the optimal process. This approach has been widely used because T2FSs can consider more uncertainty in various areas. Çebi and Otay [

9] proposed an approach using the interval T2FSs method. The suggested approach has been applied to a site selection problem of a cement factory. The interval T2FSs method is a special version of the general T2FSs method. IT2FSs are the most applicable T2FSs because of the reduced computational effort in comparison with normal T2FSs. Mehdi et al. [

10] integrated both IT2FSs and multiple criteria decision making (MCDM) problems, in which there is done an intensive research concerning the application of other fuzzy sets to solve it [

11,

12,

13,

14,

15]. This MCDM can be transferred into a new approach based on the weight aggregated sum product assessment (WASPAS) method. The WASPAS method can help increase the stability of the uncertain issues. Runkler et al. [

16] extended type 1 fuzzy sets (T1FSs) to IT2FSs in a decision-making situation by considering the risk associated with the decision making; they revealed that the T2 approach contains a larger solution space to enable a better decision. Suo et al. [

17] developed a T2 fuzzy chance-constrained programming (TFCP) method for energy systems planning under uncertainty. Roy and Bhaumik [

18] considered a triangular T2FSs intuitionistic fuzzy matrix game to treat policy-management toward the free and fair accession of water against its limited resources. In their study, the T2FSs mathematic programming reduced the time of calculation to obtain the final results in water resource management.

However, these aforementioned research studies had obvious limitations in terms of the reduction of the calculated intensity and accuracy of T2FSs. These studies cannot reflect the features of the primary variable of a T2FSs, which is especially useful in the problems of the engineering planning. If the application of T2FSs is to reflect the “level of uncertainty” of a problem, but the solution process in the engineering scope does oversimplify the feature of the T2FSs regarding the operability. The definitions of T2FSs are given by Mendel [

19].

is a mapping

defined over a nonempty universe, where

is a linguistic word,

indicates the uncertainty of

, and

is the class of all FSs over the

; the corresponding

is the class of all T2FSs over the

. Previously, the

α-cut, which is defined as

, was the most commonly used solution method for functions of T2FSs, especially in the interval type-2 fuzzy sets (IT2FSs) problems. The

α-cut mapping

is the union of all fulfilled requirements of the FSs. However, this method is incapable of reflecting the uncertainty of the third dimension membership function of the T2FSs. Consequently, the

α-plane was introduced for a general T2FS [

20]. The

α-plane denotes a T2 fuzzy set of

, which is the union of all first memberships of

, whose secondary grades are greater or equal to

α . Both methods are usually given by experts who may use their perceptions. The flaws are very obvious in these complex engineering problems. Therefore, based on these studies either on

α-cuts or

α-planes, none of the algorithms can precisely reflect the characteristic of the general T2FSs. Thus, although the decision managers are willing to receive a higher profit in the existing water resources, the results that were obtained from uncertain analysis based on experts’ experience often lead to more confusion and subjectivity. The advantages of applying T2FSs in the practical problems have not been proved by optimal controllers [

21]. The T2FSs are better able to handle uncertainties than the traditional type-1 fuzzy sets. Thus, to achieve a better solution, the concepts of

α-cuts and

α-planes can be combined and defined to produce a small uncertainty area of the decision space. The inexact T2FSs programming algorithm containing the

α-representation can achieve more accurate results for fuzzy optimization and fuzzy equations.

This study aims to develop an α-representation model that offers advantages on both α-cuts and α-planes/z-slices for the general T2FSs as the complementary measures. The α-representation method can combine α-cuts and α-planes into a smaller space over a particular . This double cut algorithm, which corresponds to the cuts both in two-dimensional and three-dimensional spaces, can certainly produce a small uncertainty decision area. Clearly, the larger cuts of the α-cut and z-slice will result in less uncertainty. Thus, the union of all for cut and plane provides a better result for the decision maker. The α-RITF2S programming model can integrate the α-representation method in a general optimal framework. This new innovative method is capable of reflecting the uncertainty of the parameter constraints expressed as T2FSs and offers an accurate decision support. This developed model will be applied to a real case study of management of the irrigation water system of the southern Min River Basin located in southeastern China. The study is based on the predecessor’s study of fuzzy linear programming and inexact linear programming methods, and the developed model is combined with the carrying capacity of agricultural environmental resources. This study attempts to establish a water system allocation model with uncertain factors that provides a valuable reference for the sustainable development of the Southern Min river basin. The results from the α-RITF2S programming model support the less uncertain results that were obtained from the in-depth uncertainty among volatility of water resources, the changes in supply and demand, and the perceptions between water authority and users; the results will benefit the local residents and descendants in this area for a long time and provide a reference for environmentally sustainable development in other regions. However, in this paper, many factors are considered to reflect the actual situation in this area; as a result, a certain one-sidedness may exist. The participants should make the corresponding adjustments according to the specific conditions when referring to the results of this paper.

2. Methodology

Consider a problem in which a water manager is charged with supplying water from various sources during a dry season to multiple users. The users are expanding their activities and determine how much water they can expect. If an insufficient amount of water is available, then they will curtail their expansion plans. In a real-life problem, parameter B on the right side of model denotes a higher level of an uncertain situation that can be treated as a T2FS. Prior to proposing the α-RITF2S programming model, the following definition gives the background information of Type-2 fuzzy sets (T2FSs).

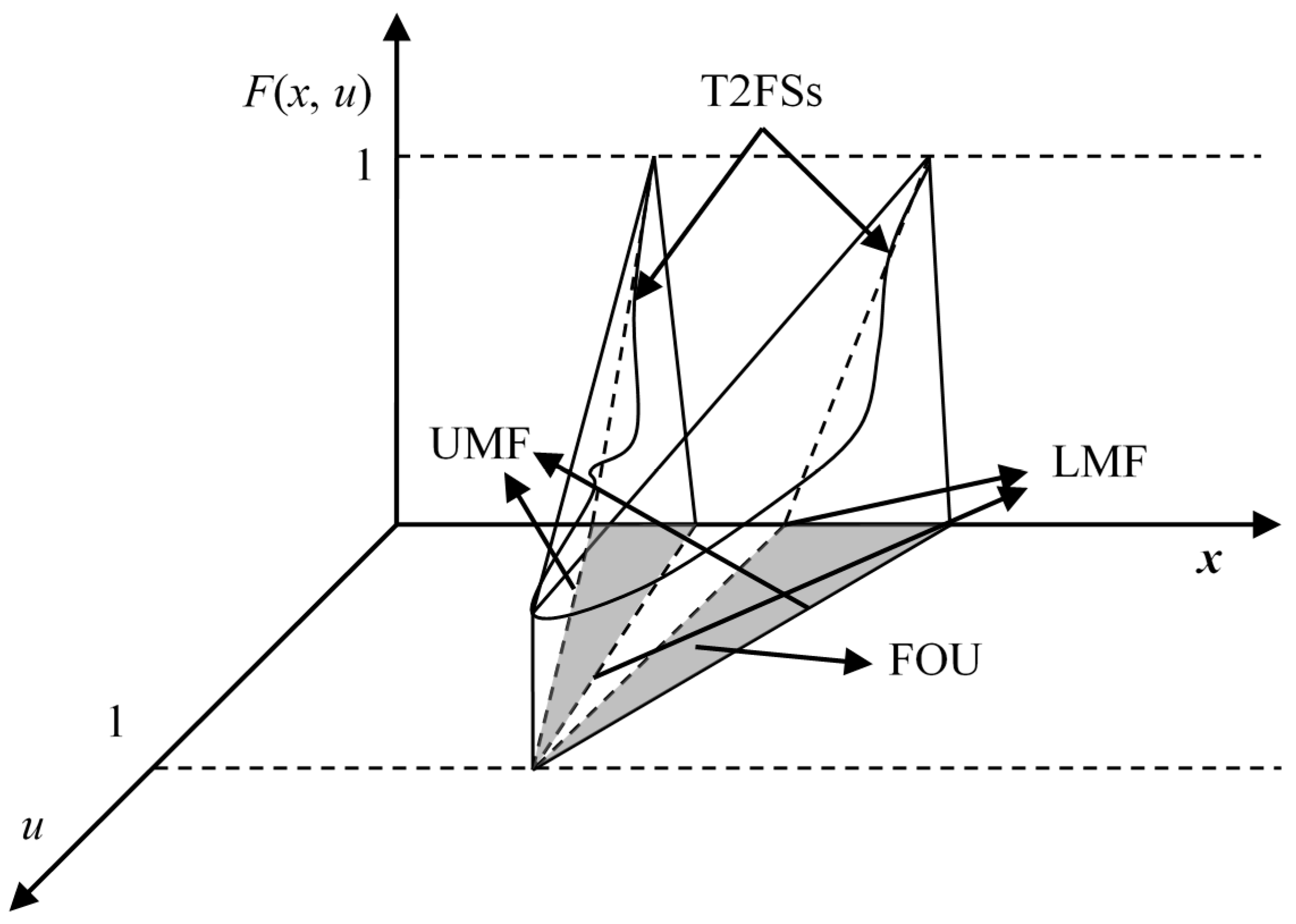

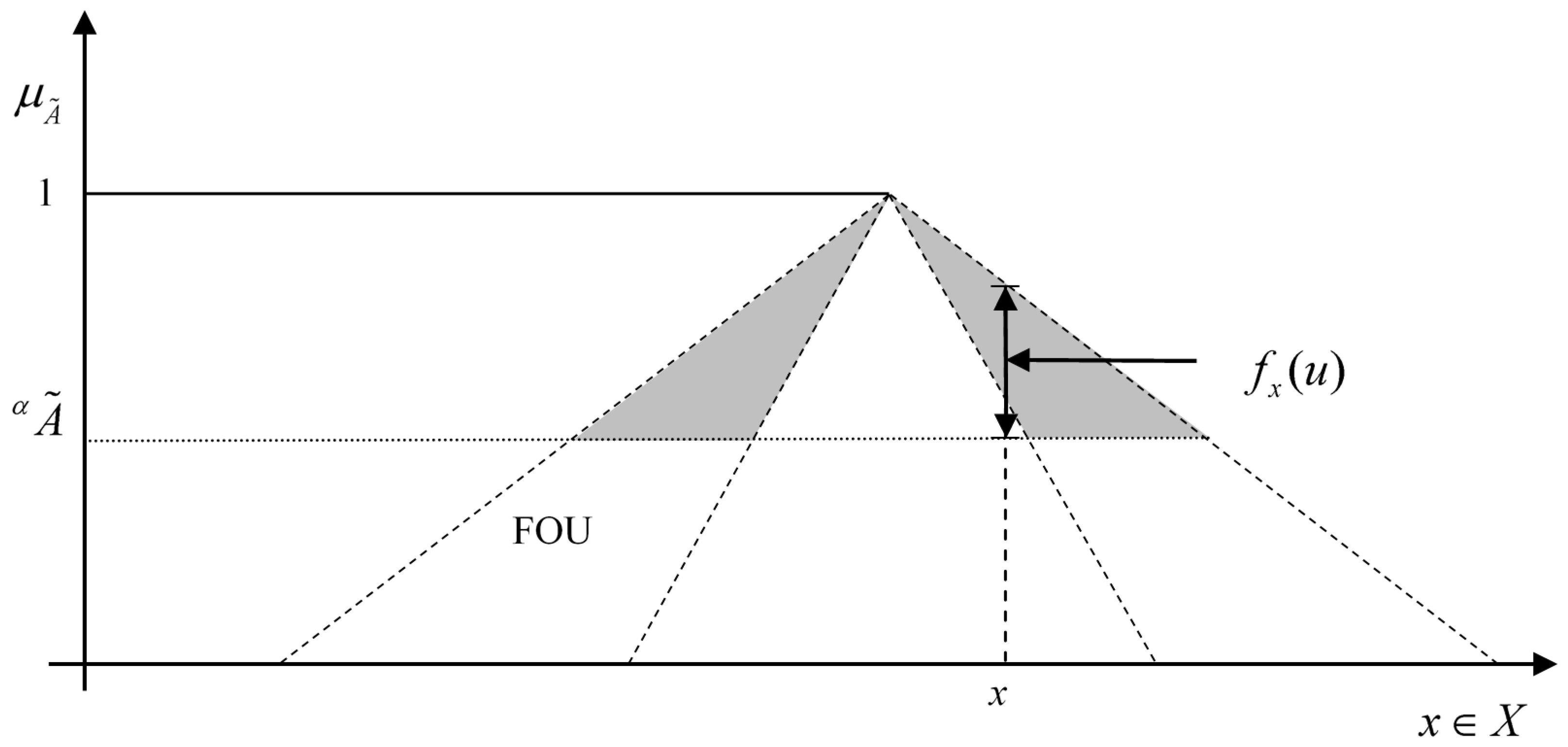

Definition 1. A T2FS(as shown Figure 1) in the universe of discourse X can be represented by a type-2 membership function[22] as follows:wheredenotes an interval in [0, 1], anddenotes the union over all admissible x and u. The LMF denotes the lower membership function of T2FS; the UMF represents the upper membership function of T2FS. Fuzzy sets can be represented through α-cuts (also known as α level), which basically are horizontal slices over its membership function. The α-cut of A is defined as. f (x) represents the secondary membership function of T2FSs. This approach simplifies the computation of any function f (x) in presence of fuzzy sets. Figure 2 shows a particular value overfor α = 0.6. The concept of footprint of uncertainty (FOU) of an interval Type-2 fuzzy set (IT2FS) can be extended to

α-planes [

23], which are represented by a T2FS through

α-planes that are z-slices over the secondary membership

. An

α-plane for a general T2FS

, denoted as

, is the union of all primary memberships of

whose secondary grades are greater than or equal to

α, (

), i.e.,

To reduce the uncertainty of fuzzy coefficients, Figuroa [

24] presented a method of T2FSs that is based on the existing

α-cuts and

α-planes algorithm.

Definition 2. Letbe the α-cut, andbe the α-plane of. Denotingand, therepresentation of, namely,, is the union of allandof:

This definition combines both the α-cut and the α-plane of into a single representation. This definition is also useful to examine the effect of decomposing into slices, and it can be useful for computing functions of fuzzy sets via a fuzzy extension principle. Thus, any Type-2 fuzzy set A can be recomposed using , as defined as follows. This part given the definition of representation algorithm.

Definition 3. Letbe the α-cut andbe the α-plane of A. Thus, the fuzzy setcan be composed as the union of alland:

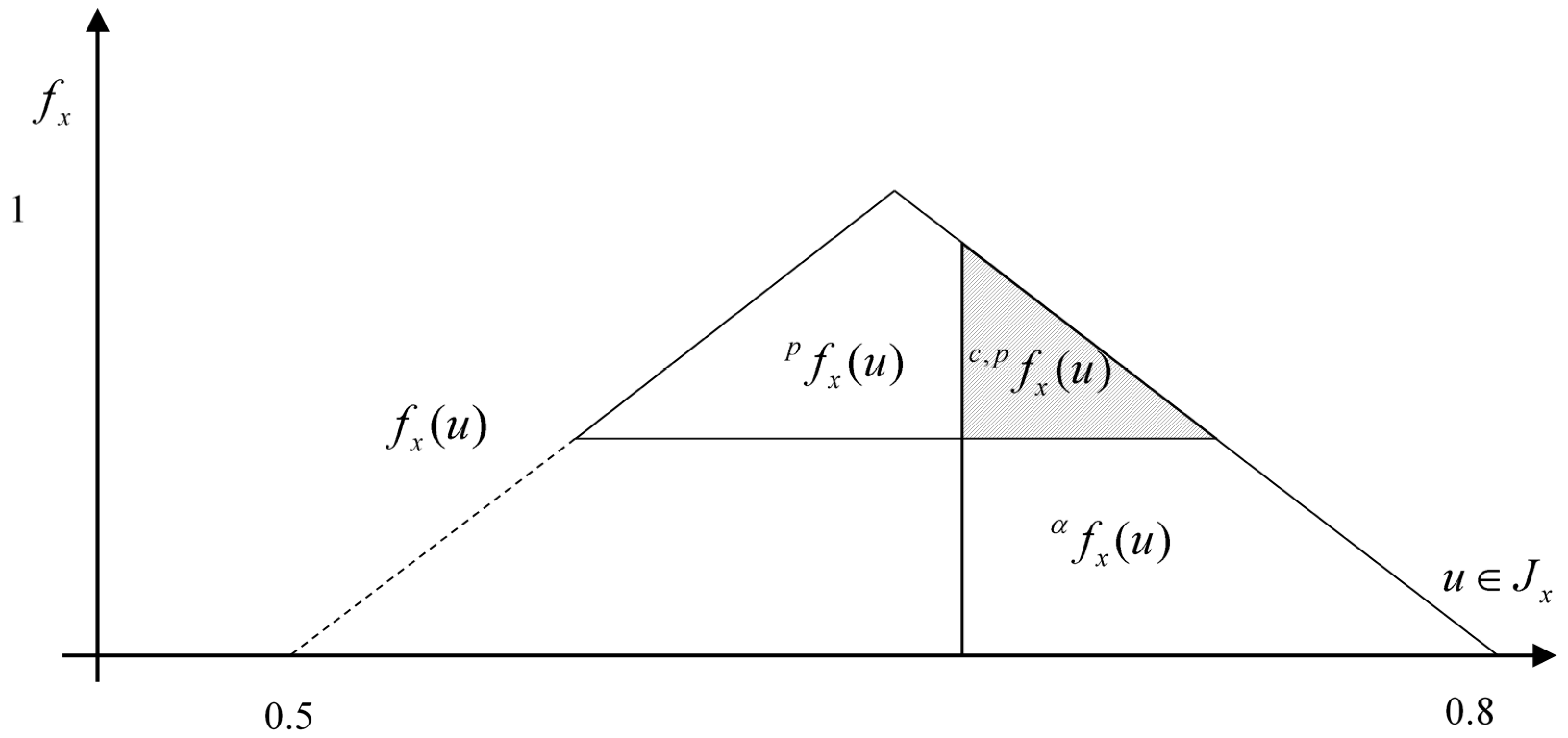

Definition 4. Letbe the α-cut andbe the α-plane of. The boundaries ofgiven, namelyand, are defined as:

The above definition given the solution of representation algorithm, In

Figure 3, the larger solid triangle in the right side shows a vertical slice of

X where

cuts

over

α = 0.6. Moreover, the

for the p-cut value of

(

p = 0.5) is shown as the solid triangle at the top of

Figure 3.

The solutions from the above equations can be combined into

for

over a particular

, leading to

, as shown in

Figure 3. Consequently, the intersection of all

for

is organized as

over

c = 0.6,

p = 0.5, as shown in the shadow part of

Figure 3. According to the figure, this double cut produces a small uncertainty area, i.e., a larger

c,

p of the cut corresponds to less uncertainty.

Thus, according to the inexact linear programming (ILP) [

25], the T2FS programming model can be rewritten, as follows:

subject to

where

and

represent interval parameters,

and

, respectively, and

where

is a T2FSs coefficient.

According to the arithmetic operations on the T2FS coefficients introduced above, a

α-representation level

is selected for all T2FS coefficients. Thus, model (6) can be rewritten as:

subject to

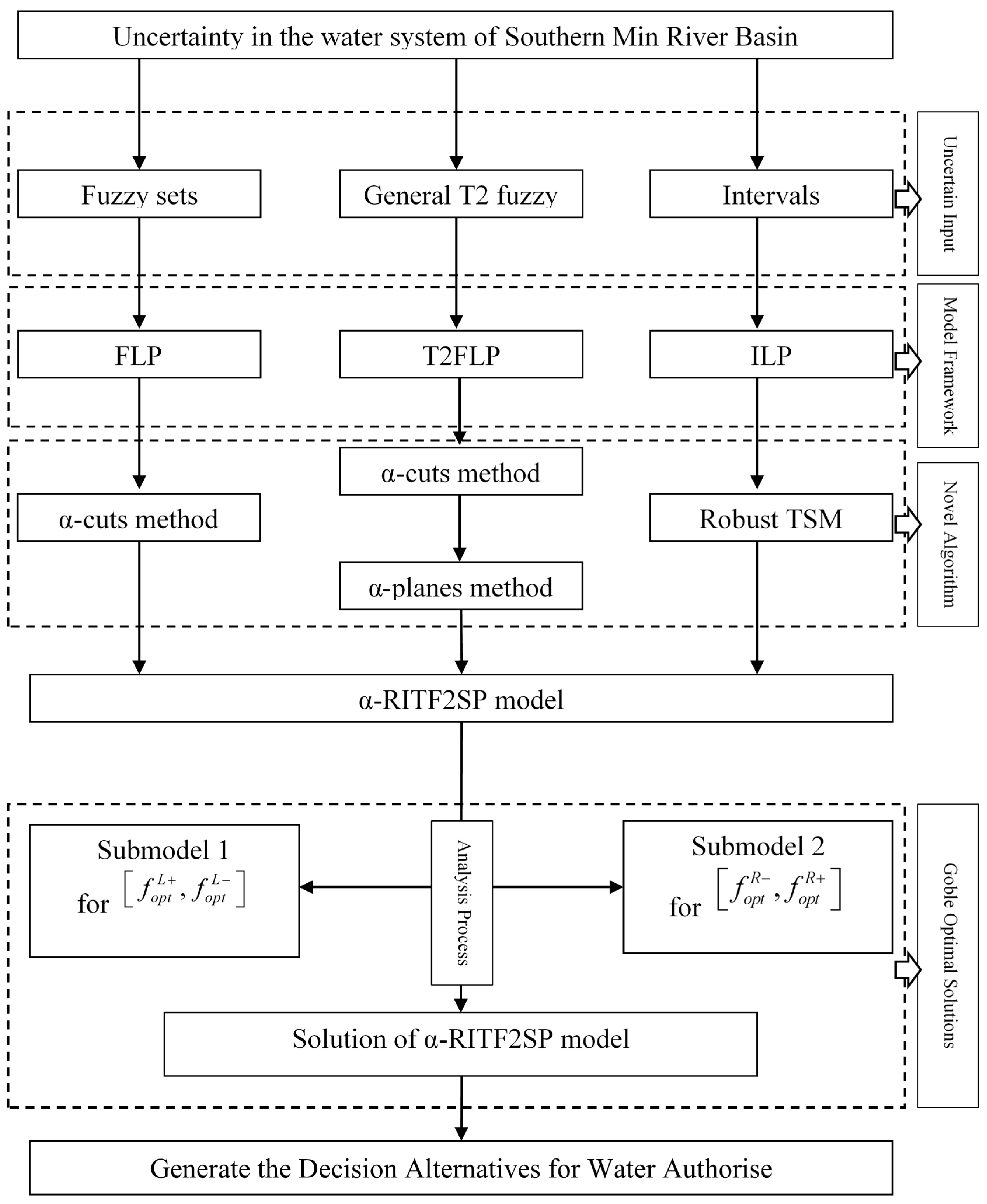

To solve model (7), it can be transferred into two boundary models by using a robust two-step-method (RTSM), as follows:

subject to

and

subject to

According to Chinneck and Ramadan [

26], we convert each boundary model into two LP models corresponding to upper and lower approximation intervals. Thus, the optimal solutions for model (6) are as follows (

Figure 4 shows the relevant flow chart of the proposed approach from a linear programming perspective).

Briefly, the procedure for solving the α-RITF2SP approach can be summarized, as follows:

- Step 1

Formulate the inexact linear programming T2 model.

- Step 2

Apply the α-cuts and α-planes methods over the higher degrees of uncertainty.

- Step 3

Obtain two more specific inexact LP submodels.

- Step 4

Solve these two T2FSsLP functions by applying the RTSM algorithm.

- Step 5

Obtain the optimal solutions and .

3. Water Resources Management under Uncertainty

3.1. Overview of the Water System

The developed model is applied to a real case study of water resources management for the agriculture area.

Figure 5 (the picture was obtained from wikimedia.org) [

27] shows the location map of the southern Min River basin. The river basin is located in the South Asian subtropics; the area mainly refers to the areas of Xiamen, Zhangzhou, and Quanzhou, including the Jiulong River. The river basin has superior climatic conditions, adequate light and heat resources, fertile land, and abundant products. In the southern Min agricultural basin, there are more than five million people, and the land accounts for 13% of the province. Although the southern Min River basin has superior climatic conditions, natural disasters occur frequently because of the unstable monsoon climate. Although adequate light and heat resources are favorable conditions for agricultural development, these conditions have not been fully utilized. The spatial and temporal distributions of rainfall are uneven, making this basin vulnerable to natural disasters, such as floods and droughts. These phenomena provide the most basic information on the status of water resources in the region.

This river basin has a variety of landforms, such as plains, hills, mesas, basins, and mountains. These geomorphological features are conducive to the comprehensive development of agriculture. However, the per capita arable land is small, at only 0.8 acres. This arable land area is less than the average (1.5 acres) and it is even lower than the world’s per capita arable land area (4.7 acres). Moreover, most of the land resources available for cultivation have been used; this situation restricts the development of crop farming to some extent. However, the water treatment cost of arable land has not been considered in this model due to the currently local environmental and agricultural regulations.

Because of its advantageous geographical location, adequate resources, and a strong rainforest landscape, this natural environment is suitable for a variety of living creatures. Rich biological resources have created excellent conditions for agriculture, animal husbandry, forestry, fishery, and other industries. However, these conditions have not been effectively and reasonably used and developed; in addition, many rare wild animal resources, forest resources, and various economic fish resources have been destroyed to varying degrees, resulting in low efficiency, and the ecological environment has also been destroyed. The water resources in the southern Min River basin are relatively abundant, but the current utilization rate is low and thus has great development potential in a model of planning patter. In addition to considering water supply in Xiamen and other places, it is also possible to consider the rational planning and construction of hydroelectric power stations.

The water basin has a long history and pleasant scenery; this situation has created rich tourism resources in this area. For example, in Xiamen City, with its strong subtropical climate, graceful and clean city bay style, passionate and simple overseas Chinese customs, delicious tropical fruits, and fresh seafood products, is a nationally famous tourist city, attracting tourists from all over the country. The large number of tourists visiting Xiamen has exerted great pressure on its water supply, water use, water treatment, and garbage disposal as an increase in the cost of water treatment.

3.2. Analysis of the Environmental Issues of Southern Min Area

3.2.1. Ecological Issues

Floods are an historical problem in this watershed. As a result of typhoons, rainstorms, climate change, and soil erosion, flood disasters are frequent. The causes of more serious soil erosion are as follows: (1) overexploitation of orchards and tea plantation, and (2) overexploitation of mines and rivers and planting inappropriate trees in large areas, destroying vegetation on the ground. The increasing severity of soil erosion has also contributed to the occurrence of floods. As a result, a vicious cycle has been formed. Ecological problems can reduce the ability of natural water bodies to degrade pollutions, thereby increasing the cost of water treatment for this region.

3.2.2. Air Pollution Issues

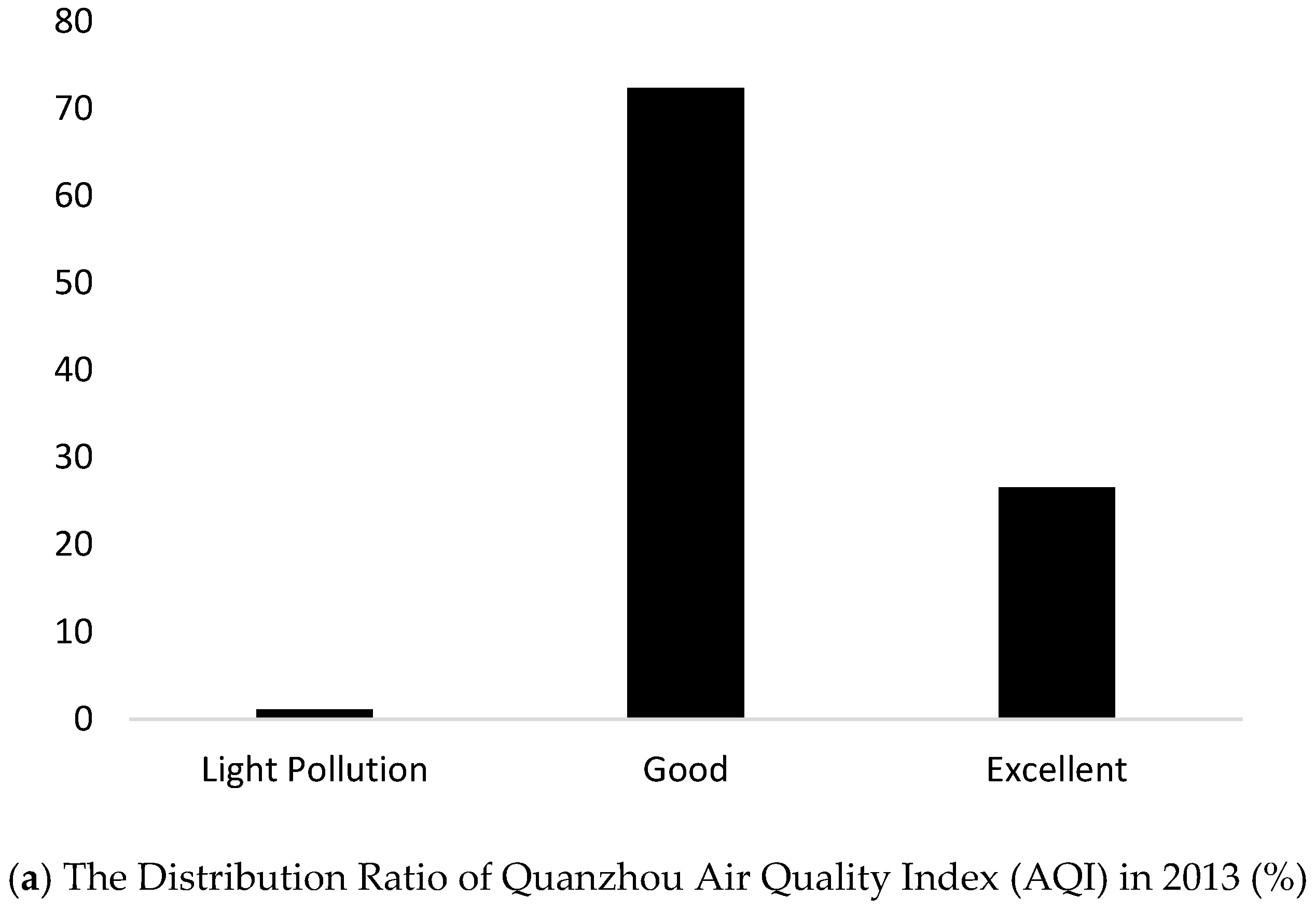

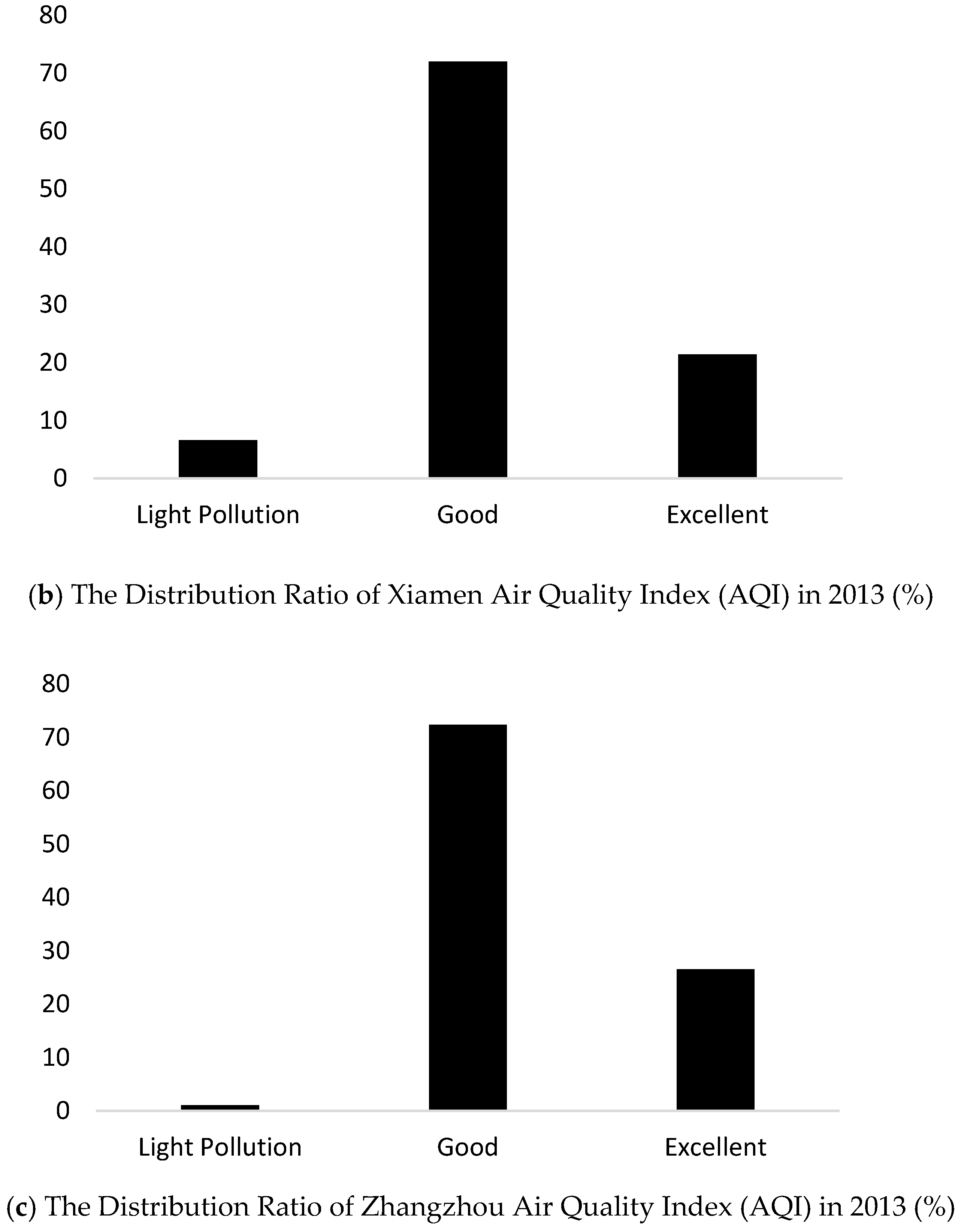

There is a strong correlation between atmospheric deposition and water quality. But, the air pollution in the southern Min River basin is much better than that in many other cities of China.

Figure 6 represents the air quality of index for this area. However, many problems have been raised in recent years. The severe air pollution has caught the attention of the regional environmental protection office. Recently, Xiamen City has taken some measures to improve air quality of the city, such as strengthening the treatment of exhaust pollution from motor vehicles, the control of fume pollution in the catering industry, and the prevention of dust. In contrast, for the cities of Quanzhou and Zhangzhou, the supervision and control requirements must be strengthened in the future. The issues of air pollution among cities should be redefined and monitored more clearly. Thus, this strengthening will improve water quality and reduce water treatment costs.

3.2.3. Water Pollution Issues

The excessive and unsustainable construction of hydropower stations led to the drought and low flow conditions in the tributaries and main stream of the Jiulong River. “Lake servitization” increases the hydraulic retention time and easily leads to water bloom and water eutrophication in the reservoir area. In 2009, there were algal bloom incidents in the area of the North-Stream Reservoir that caused the pollution of drinking water in Xiamen City, severely affecting daily lives. This example represents just one of the causes of water pollution; the author believes that the main reason may be the discharges of various pollution sources of wastewater. As a result, overall reasonable planning of the construction of hydropower stations should be implemented to amplify the advantages and reduce the disasters that are caused by the hydropower stations.

Because eighty percent of Xiamen’s drinking water comes from the Jiulong River, the pollution of Jiulong River is an extremely important issue. Affected by industries such as the Longyan Paper Mill and the Zhangzhou Sugar Mill, the north-stream and west-stream of Jiulong River have suffered from various levels of pollution. However, in the wet season, the water flow is large and the dilution effect is more obvious; as a result, the water quality of the watershed will be better than that in the dry season. Therefore, a summary of the water pollutants in the area is as follows: (1) the pollution that is caused by the breeding of livestock and poultry from upstream of this river. There is a large amount of pig breeding in the basin, with most of the farms experiencing serious pollution problems, and their treatment facilities are incomplete, with some farms even directly discharging the wastewater into the river. As a result, the nitrogen, phosphorus, and other indicators in the relevant water areas and land in the basin have been seriously exceeded. (2) The construction of the hydropower station is unreasonable, with the distribution density being excessively high, thereby preventing the natural purification of water quality to proceed normally. As a result, the water resources are prone to algae blooms and eutrophication. (3) Although the discharge amounts from the industries (such as paper mills, sugar factories, pharmaceutical factories, and metal processing plants) were not very high, the pollutants from these plants accounted for more than 90% of the watershed. These companies must rectify the situation, as economic conditions permit, and minimize the total amount of pollution. Excessive usages of chemical fertilizers and pesticides also pollute nearby waters resources and land to a certain extent, thereby directly or indirectly endangering the cities welfare. (4) The quantity and scale of wastewater and waste treatment facilities do not meet the corresponding needs in this area.

Table 1 and

Table 2 show the pollution discharges from the sources. Therefore, in this rapid economic development, if decision makers want to develop and maintain a green economy or/and recycling economy, the environmental protection facilities, policies, and regulations should also develop rapidly to match the pace of social and economic developments.

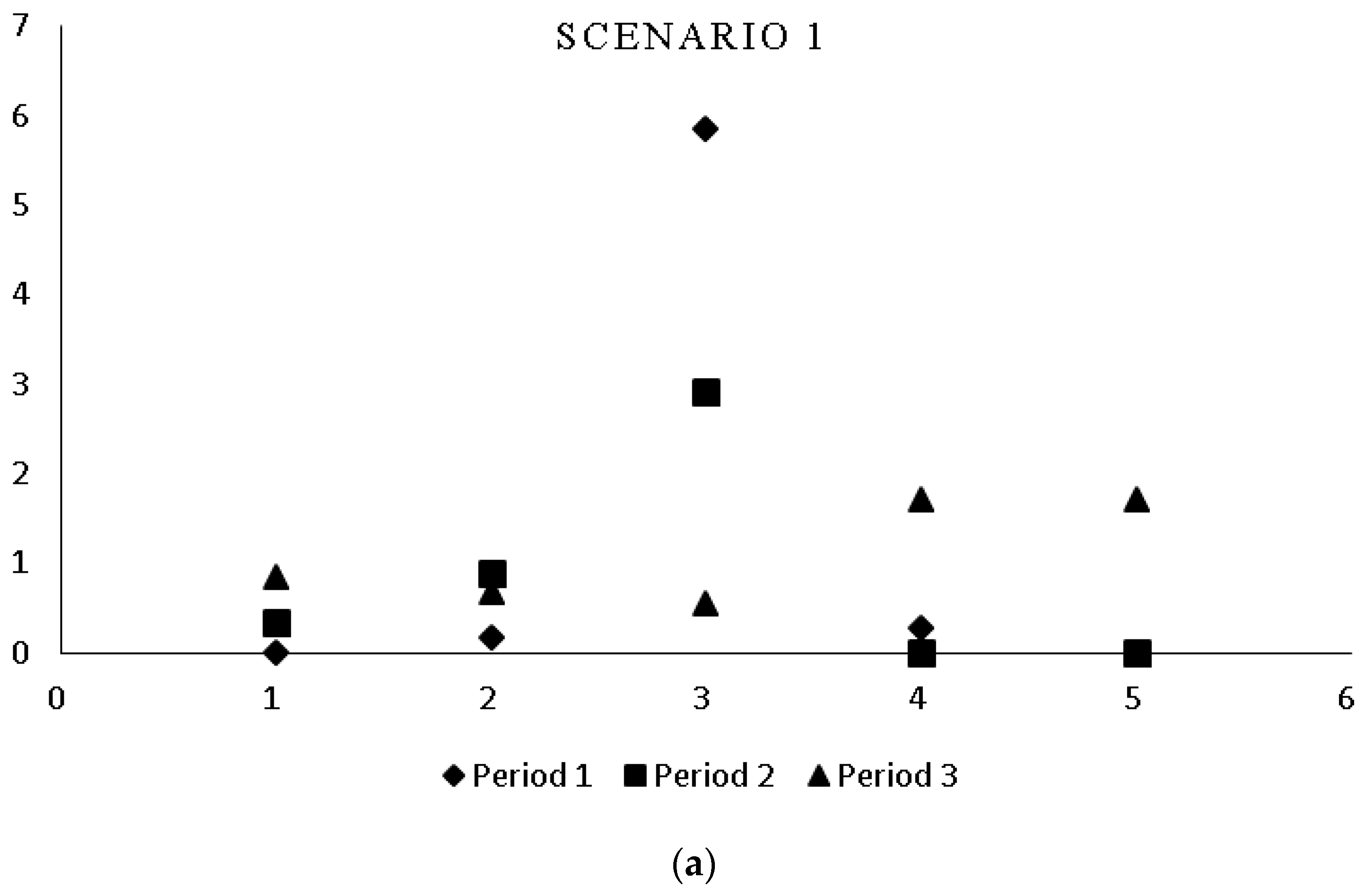

3.3. Modeling Formulation

The maximum profit of the water resources system is inevitably guided by the industries that make reasonable usage of water resources. However, these industries will discharge waste water and therefore generate corresponding treatment costs. Consequently, the maximum profit should be received under a reasonable manufacturing process. The largest profit is equal to the net profit minus both the water cost and the cost of treatment of pollution. However, the manufacturing process must satisfy every constraint: the total amount of water usages should not exceed the carrying capacity of the local environmental resources; the total amount of sewage treatment should remain within the capacity of the wastewater treatment plants; the industrial scale constraint on production should consider the economic factors and equipment constraints for every industry; and, the expenditure of investments cannot exceed the government budget. It is also obvious that the water system must be profitable; thus, all input values are considered to be nonnegative. In this study, the planning horizon covers 15 years with five years per period, i.e., 2018–2022, 2022–2027, and 2027–2032. During the planning horizon, Fujian will upgrade its industrial structure. However, limited by water resource, the size of population will be controlled strictly. According to the future economic and social development of Fujian, and considering uncertain events, the forecasted water demand for each end-user is uncertain with three possible scenarios, i.e., low, medium and high, with the corresponding probability of 0.25, 0.6, and 0.15, respectively. Therefore, the

α-RITF2SP model can be formulated, as follows:

- (1)

Water utilization benefits

- (2)

- (3)

- (4)

- (5)

Constraints:

- (1)

Water availability constraints:

- (2)

Seawater desalinization constraints:

- (3)

Water recycling constraints:

- (4)

Water supply and demand balance constraints:

- (5)

Nonnegative constraints:

where the index of model (11) is given as follows:

| total system profit; |

| t | the period; |

| h | petrochemical industry, h = 1, 2 for different companies; |

| i | marine chemical industry, h = 1, 2 for different companies; |

| j | fine chemical industry, j = 1, ..., 9 for different companies; |

| m | water source, m = 1, 2, 3, 4, 5 for surface water, underground water, transferred water, desalination water and reused water, respectively; |

| s | water level; |

| T2 fuzzy set; |

| scenario probability; |

| water utilization benefit from petrochemical industry h in period t (million ¥/106 m3); |

| water utilization benefit from marine chemical industry i in period t (million ¥/106 m3); |

| water utilization benefit from fine chemical industry j in period t (million ¥/106 m3); |

| water utilization benefit from energy industry in period t (million ¥/106 m3); |

| water utilization benefit from steel industry in period t (million ¥/106 m3); |

| water consumed by petrochemical industry h in period t under scenario s (106 m3); |

| water consumed by marine chemical industry i in period t under scenario s (106 m3); |

| water consumed by fine chemical industry j in period t under scenario s (106 m3); |

| water consumed by energy industry in period t under scenario s (106 m3); |

| water consumed by steel industry in period t under scenario s (106 m3); |

| water supply cost from source m in period t (million ¥/106 m3); |

| extra cost from water source m in period t (million ¥/106 m3); |

| provided amount from water source m to petrochemical industry h in period t (106 m3); |

| provided amount from water source m to marine chemical industry i in period t (106 m3); |

| provided amount from water source m to fine chemical industry j in period t (106 m3); |

| provided amount from water source m to energy industry in period t (106 m3); |

| provided amount from water source m to steel industry in period t (106 m3); |

| extra supply from water source m to petrochemical industry h under scenario s in period t (106 m3); |

| extra supply from water source m to marine chemical industry i under scenario s in period t (106 m3); |

| extra supply from water source m to fine chemical industry j under scenario s in period t (106 m3); |

| extra supply from water source m to energy industry under scenario s in period t (106 m3); |

| extra supply from water source m to steel industry under scenario s in period t (106 m3); |

| discharge ratio of wastewater per unit water consumption j during period t; |

| sewage treatment ratio of emission from during period t; |

| sewage treatment cost for petrochemical industry h in period t (million ¥/106 m3); |

| sewage treatment cost for marine chemical industry i in period t (million ¥/106 m3); |

| sewage treatment cost for fine chemical industry j in period t (million ¥/106 m3); |

| sewage treatment cost for energy industry in period t (million ¥/106 m3); |

| sewage treatment cost for steel industry in period t (million ¥/106 m3); |

| penalty cost for water shortage for petrochemical industry h in period t (million ¥/106 m3); |

| penalty cost for water shortage for marine chemical industry i in period t (million ¥/106 m3); |

| penalty cost for water shortage for fine chemical industry j in period t (million ¥/106 m3); |

| penalty cost for water shortage for energy industry in period t (million ¥/106 m3); |

| penalty cost for water shortage for steel industry in period t (million ¥/106 m3); |

| water demand for petrochemical industry h during period t under scenario s (106 m3); |

| water demand for marine chemical industry i during period t under scenario s (106 m3); |

| water demand for fine chemical industry j during period t under scenario s (106 m3); |

| water demand for energy industry during period t under scenario s (106 m3); |

| water demand for steel industry during period t under scenario s (106 m3); |

| maximum available water (106 m3); |

| average working days (days/year); |

| production efficiency; |

| the capacity of sea water desalinization (106 m3/day); |

| recycling ratio during period t; |

| transmission loss ratio during period t; and, |

| maximum tolerance of water shortage during period t. |

3.4. Data Source

Combing the specific circumstances of the southern Min River basin, the enterprises or factories that must be analyzed and optimized are divided into petrochemicals, marine chemicals, fine chemicals, energy utilization industry, and steel industry. Taking into account the current study of the southern Min River basin, this paper focused on the major pollution sources as the objects of modeling that are typically represented in the three cities of Xiamen, Zhangzhou, and Quanzhou. However, because of the changes of the industries, these data do not represent the entire industries but represent only part of them.

Table 3 and

Table 4 list the parameter data from the relevant area obtained from the Environmental Status Bulletin of Fujian Province [

28] and the Statistical Bulletin and the local market price in 2013 that are required for the model calculations [

29]. By considering that there are too many small chemical companies in this area to consider, in this study, we selected only nine of them to represent this chemical industry. In the future, if more data can be found, all of the chemical companies should be considered. The data show the approximate price range of the respective products of the companies or factories in various industries in each term. The uncertain changes in prices are affected by many factors, such as demand relations, seasonal changes, international market prices, and domestic policy implications.

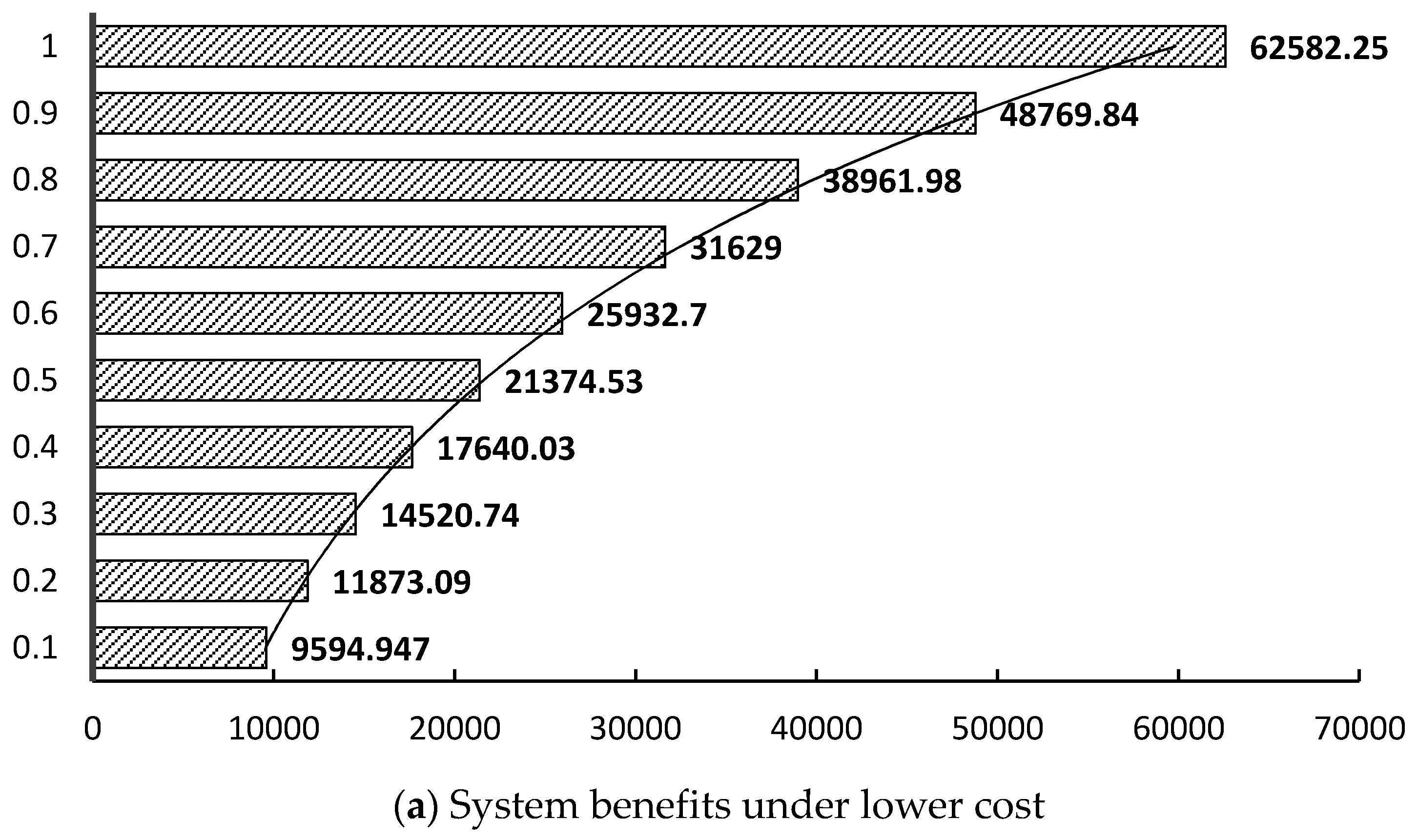

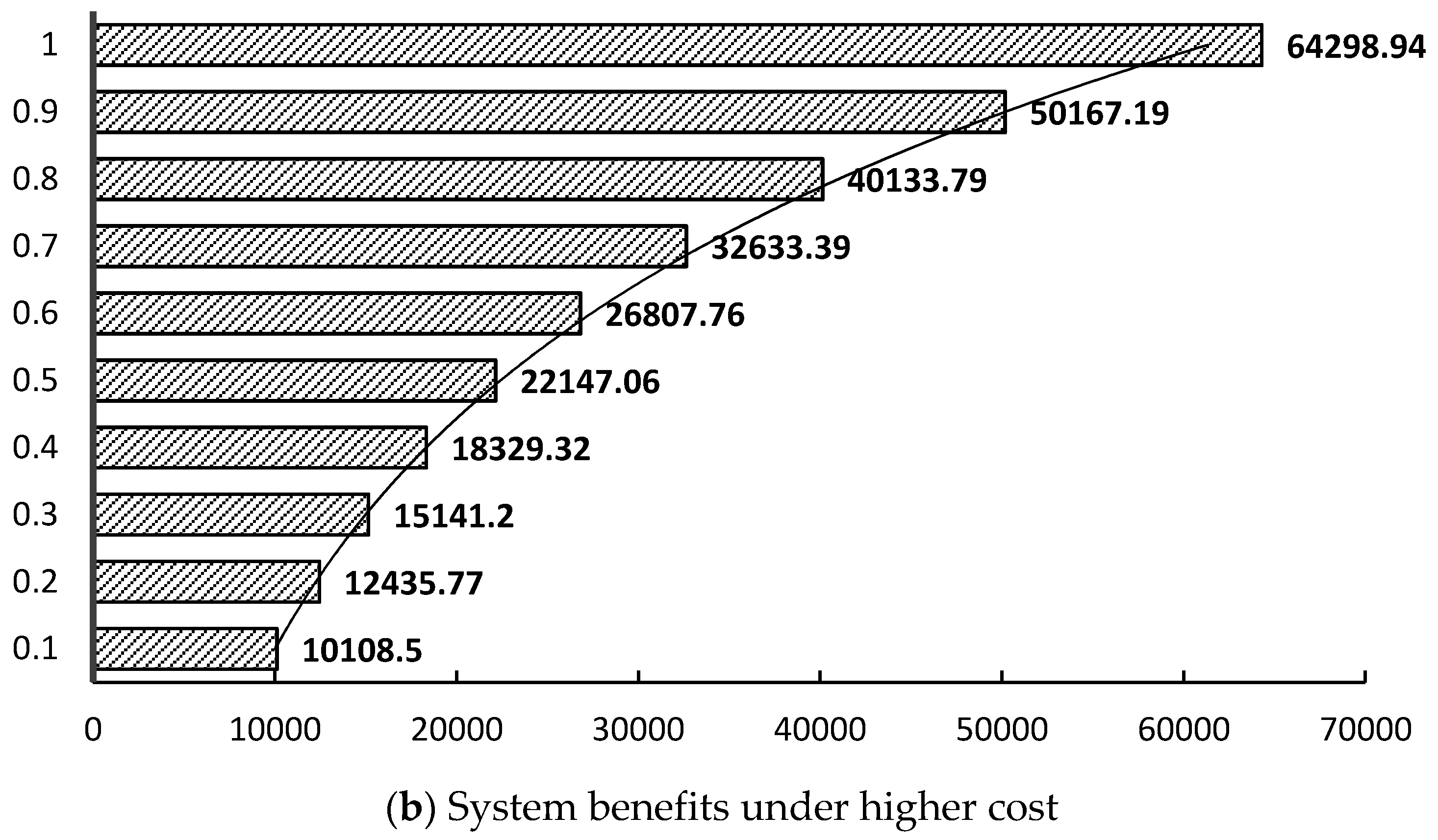

5. Conclusions

Through integrating the advantages of both α-cuts and α-plane into the interval optimal framework, an α-representation of the inexact T2 fuzzy sets programming method (α-RITF2SP) was developed. The α-RITF2SP is based on interval programming, and Type-2 fuzzy sets linear programming under uncertainty. The method addresses the higher level uncertainty in function constraints to obtain more accurate results than other fuzzy linear programming models. The method uses the α-plane to solve the problems in the third dimension of uncertainty; these problems are expressed as T2FSs in the function. The inexact linear programming is useful to indicate the fluctuation of environmental resources and data changes after the uncertain events occur to accurately determine the water system uncertainty.

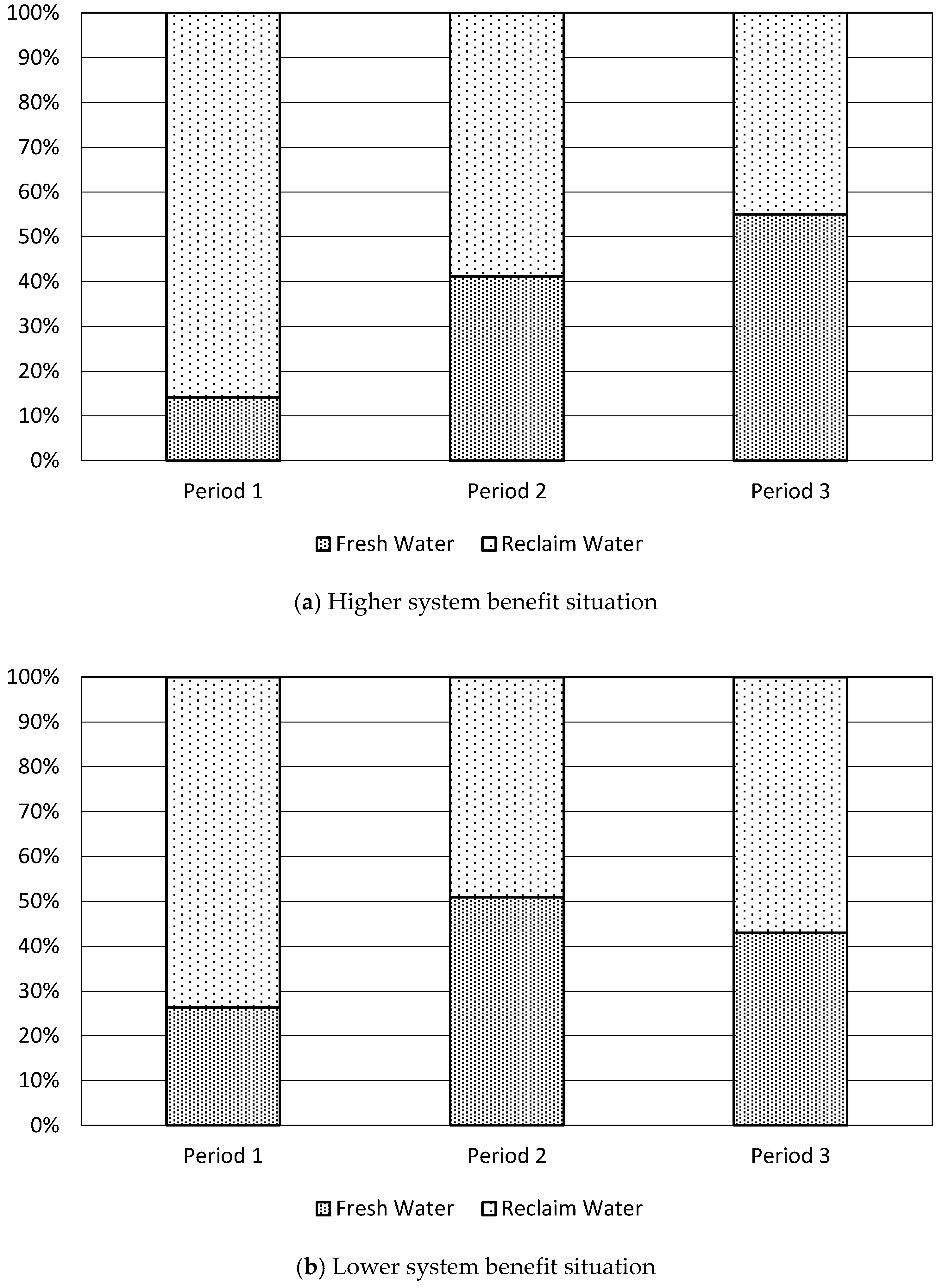

The proposed method was applied to the real case study of the southern Min River basin water resources management system. The α-RITF2SP provided water authorities with input under experts’ perceptions or linguistic uncertainty with the following advantages: (1) the α-represent method, which can effectively implement membership function uncertainty into the optimization process, is an alternative perspective to indicate the general T2FSs; (2) the method obtains a more specific representation of a T2FS, while α-cuts have been well used among classical fuzzy sets and α-planes also have been well utilized for T2FSs; (3) both the input uncertainty and linguistic uncertainty are solved through two different cuts and planes, in which the α-cuts approach is desirable for the decision makers, whereas the α-planes approach is desirable in constrained water resources; (4) the developed method is applied to a practical issue in the Southern Min River basin; and, (5) it provides the desired water resources management plans with maximum system benefit under limited natural resources to the decision makers of this area.

The α-RITF2SP approach was introduced for the first time in this study to the optimization field of water resources management. This approach enables an extended application of linear programming of T2FSs to other resources and environmental management problems based on the fields of interest of researchers.