1. Introduction

There are about 2000 species of fiber plants in agroecosystems globally, but only a small fraction is used practically [

1]. Annual production of key fiber crops such as cotton, flax, jute, agave, sisal, abaca, and ramie reaches 29.5 million tons [

2]. Climatic factors, especially temperature and precipitation, largely determine the yield and susceptibility to pests and diseases [

3]. In cotton cultivation, high temperatures increase water stress, while elevated CO

2 concentration can stimulate growth and development, potentially increasing yields by intensifying photosynthesis and reducing bud shedding [

4]. Uneven rainfall distribution threatens jute crops with early spring drought, which negatively affects nutrient uptake and production [

5].

Flax (

Linum usitatissimum L.), a self-pollinating annual [

1], originated in the Near East and exists mainly in cultivated fiber and oil forms. Fiber flax (60–80 cm) has a shallow root system and small seed capsules [

2], with fiber cells ranging from 6 to 65 mm and technical fiber lengths of 90–125 cm [

2,

6]. Yields are 0.4–1.2 t ha

−1 for seeds and 4.0–6.5 t ha

−1 for straw [

3,

4]. In Europe, “flax” typically refers to fiber varieties, and “linseed” to flax oil. Cultivated for over 10,000 years [

5,

6], fiber flax cultivation in Europe declined in the 20th century but rebounded in the 1990s [

7,

8]. The composition of flax fiber is approximately 75% cellulose, 5% hemicellulose, 4% lignin, 3% fats and waxes, 0.5% ash, and 12.5% water [

7,

8,

9]. Modern cultivation focuses on long-straw, high-fiber varieties [

10,

11,

12] used in various industries [

13,

14,

15,

16], including textiles and paper [

17,

18,

19,

20]. Linseed is used in food and feed [

21,

22,

23], and its oil is rich in beneficial omega-3 fatty acids [

24,

25,

26]. Flax stalks are pulled to maximize the fiber length [

27], with different parts used for varying yarn qualities. Quality assessment is vital [

28].

Flax production, despite its high energy and pesticide demand, is characterized by a relatively low impact on global warming, eutrophication, and acidification [

29]. The introduction and popularization of flax is important for the globalization of agricultural production and for counteracting the decline in crop diversity [

30]. In the context of the priority of climate protection and biodiversity over economic growth, it is necessary to slow down the chain of goods and services and minimize the transformation of ecosystems [

31]. Various fractions of flax—fiber, shive, and seeds—are used in the production of bioenergy, activated carbon, wax, bioproducts, industrial and food oils, aromatic extracts, and feed [

32]. Flax fibers are used in the production of gypsum plasterboard [

33] and reinforced concrete [

34]. Flax shives are a raw material for bioethanol production [

35], and the lignocellulose contained in them is a potential source of cellulosic ethanol [

36]. Flaxseed is key in the production of industrial and edible oils, including as a component of varnishes, paints, sealants, and waxes for wood and concrete [

37]. Chickens fed flaxseed produce eggs rich in omega-3 fatty acids [

38]. Natural flax fibers are attractive in composites due to their low cost, biodegradability, relatively high strength, low abrasion, safety, recyclability, and the possibility of waste reuse [

32]. In the context of global challenges related to climate change, which increasingly affect European agricultural systems, it is crucial to search for sustainable and resilient strategies for the production of fiber crops. Recent studies [

3,

4,

5,

39,

40] indicate significant changes in fiber yields and quality in different regions of Europe under the influence of changing atmospheric and geographical conditions.

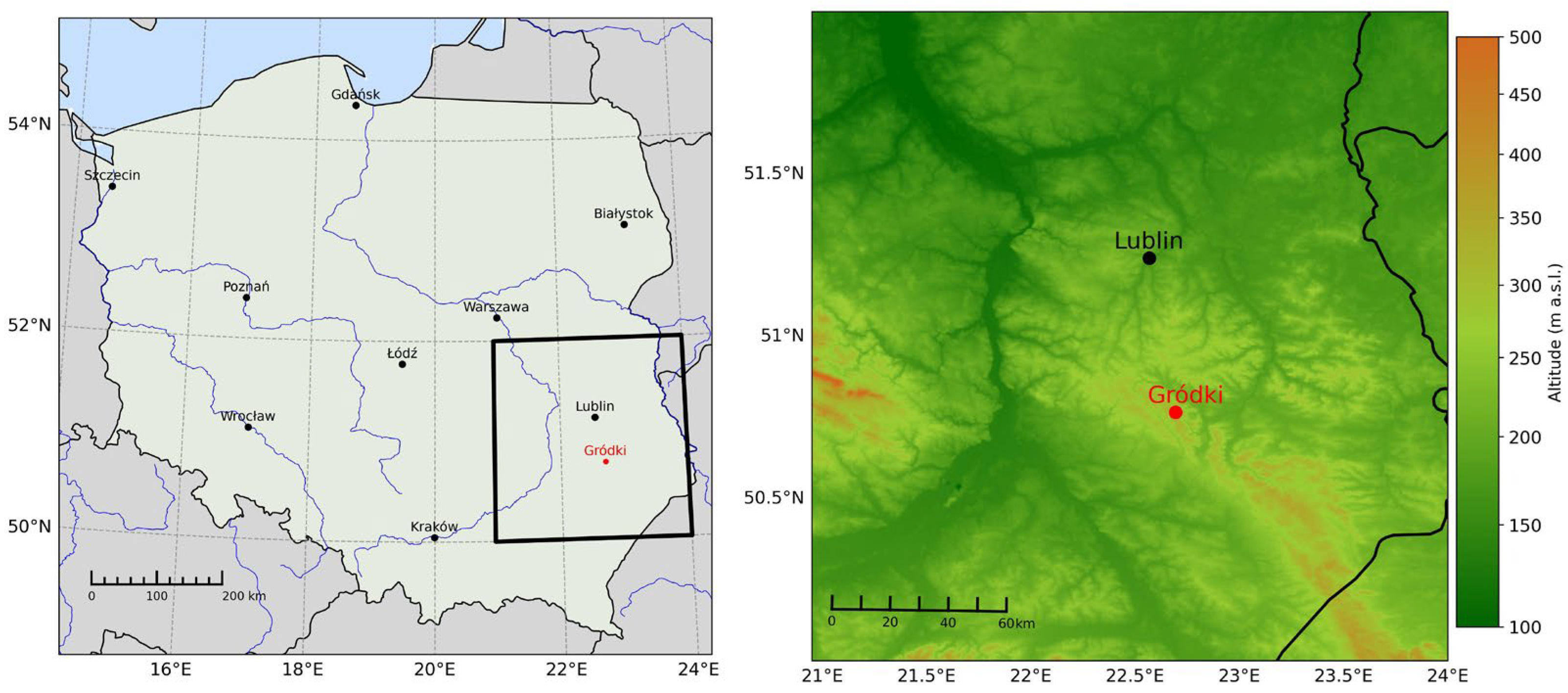

Central–eastern Poland is characterized by a more continental climate than the western part of the country, with larger annual temperature amplitudes and generally lower average precipitation, which is concentrated in the summer [

41]. This region also has a longer period of snow cover and more frosty days [

40]. These specific climatic conditions, different from other regions of Poland, are of significant importance for flax cultivation. The dominant soils of central–eastern Poland are podzols, lessives, browns, and rendzinas [

42]. These moderately fertile and permeable soils have historically been conducive to flax cultivation, which prefers moderate moisture and good drainage, shaping local agricultural traditions. Understanding this soil specificity is crucial for optimizing flax production.

In this context, the application of the value chain approach (VCA) offers a comprehensive perspective on the optimization of flax production from sowing, through harvesting and processing, to the final product. VCA enables the identification of key factors influencing the yield and quality of fibers at each stage as well as the integration of the activities of different actors in the chain in order to increase the efficiency and sustainability of production [

43].

The results of this study have a significant impact on decisions regarding the sustainable development of flax cultivation in the central–eastern region of Poland and potentially in other areas with similar conditions. By identifying the optimal agrotechnical practices and flax varieties adapted to local soil and climate conditions, we will contribute to increasing the crops’ resilience to climate change and minimizing their negative impact on the environment. This study is also closely linked to the implementation of several Sustainable Development Goals of the UN Agenda 2030 [

44], in particular, the following:

- -

SDG 2 (Zero Hunger): by optimizing yields and increasing the efficiency of agricultural production.

- -

SDG 12 (Responsible Consumption and Production): by promoting sustainable flax cultivation and processing practices.

- -

SDG 13 (Climate Action): by exploring climate change adaptation strategies in agriculture [

44].

The potential beneficiaries of the results of this research are primarily farmers, who will receive practical advice on the selection of flax varieties and cultivation methods; representatives of the textile industry, who will gain access to raw material of optimal quality; and decision makers, who will be able to make more informed decisions in the field of agricultural and environmental policy.

The main objective of the study is to assess the yield and fiber quality of two selected fiber flax varieties grown in central–eastern Poland using the flax value chain approach. This objective includes identifying the impact of local soil and geographic conditions on the yield and fiber quality parameters of both varieties. Additionally, the study aims to determine the potential of each variety in the context of optimizing individual stages of the flax value chain in this region. An alternative research hypothesis was put forward to the null hypothesis.

H0 (Null Hypothesis): There are no statistically significant differences between the two studied fiber flax varieties in terms of yield and fiber quality in the climatic and soil conditions of central–eastern Poland considering individual stages of the value chain. Furthermore, there is no significant relationship between local soil and geographic conditions and the yield and fiber quality of the studied varieties.

H1; (Alternative Hypothesis): There are statistically significant differences between the two tested fiber flax varieties in terms of yield and/or fiber quality in the climatic and soil conditions of central–eastern Poland, and these differences are visible in the analysis of individual stages of the value chain.

3. Results

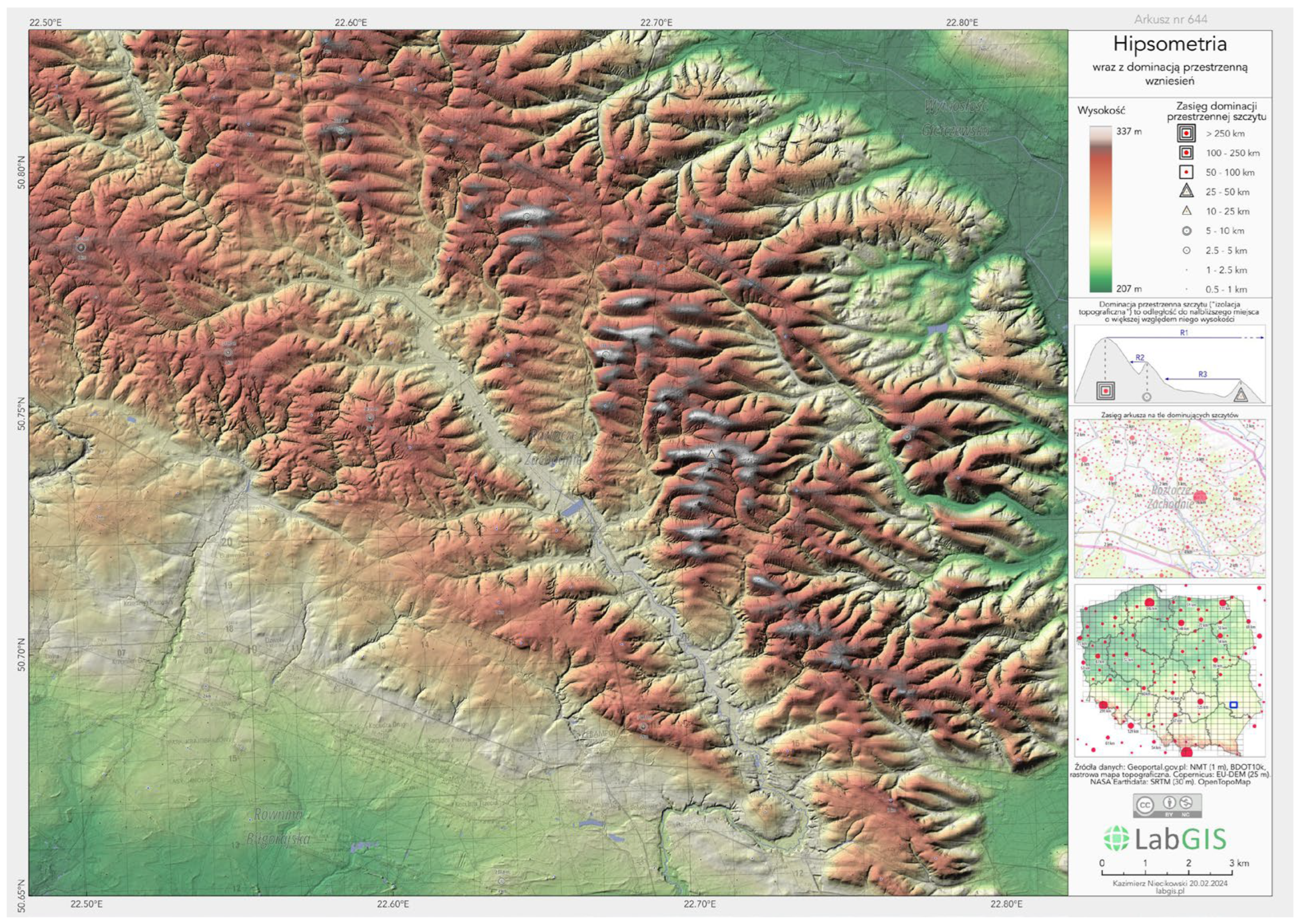

3.1. Yield of Straw

The flax straw yield was at an average level and amounted to 5.1 t ha

−1 (

Figure 5). The Artemida variety was characterized by a significantly higher straw yield than the Hermes variety.

Straw yield comparison: Artemida showed a significantly higher straw yield than Hermes in each of the three years of the study. The average yield of Artemida was 1.5 t ha−1 higher than the average yield of the Hermes variety.

Changes between years: Both varieties showed slightly higher yields in 2021–2022 than in 2023. The downward trend in 2023 may be due to unfavorable weather conditions, agrotechnical, and other environmental factors; however, Artemida still maintained an advantage over the Hermes variety (

Figure 6).

3.2. Total and Technical Length of Straw

On average, the total length of flax straw was 62.3 cm (

Table 5).

Neither variety differed significantly in terms of total straw length, but there were significant differences between the years of the study. The longest straw was recorded in 2022, while the shortest was in 2021. In 2021 and 2023, the total lengths were at similar levels (

Table 5).

The varieties tested reacted differently to conditions in individual years. The Artemida variety achieved the greatest straw length, 4, in 2022, while in the other years, the value of this feature was significantly lower. In turn, Hermes was characterized by stable straw length in all years, which indicates greater resistance to changing cultivation conditions (

Table 5).

The average technical length of the straw was 53 cm, with Hermes having significantly longer technical straw than Artemida. The highest technical length was obtained in 2022, while the lowest was in the dry year 2021. Only Artemida showed significant fluctuations in technical length depending on the year—in 2022 it was the longest, and in the remaining years significantly shorter. In the case of Hermes, the technical length of the straw remained stable (

Table 5).

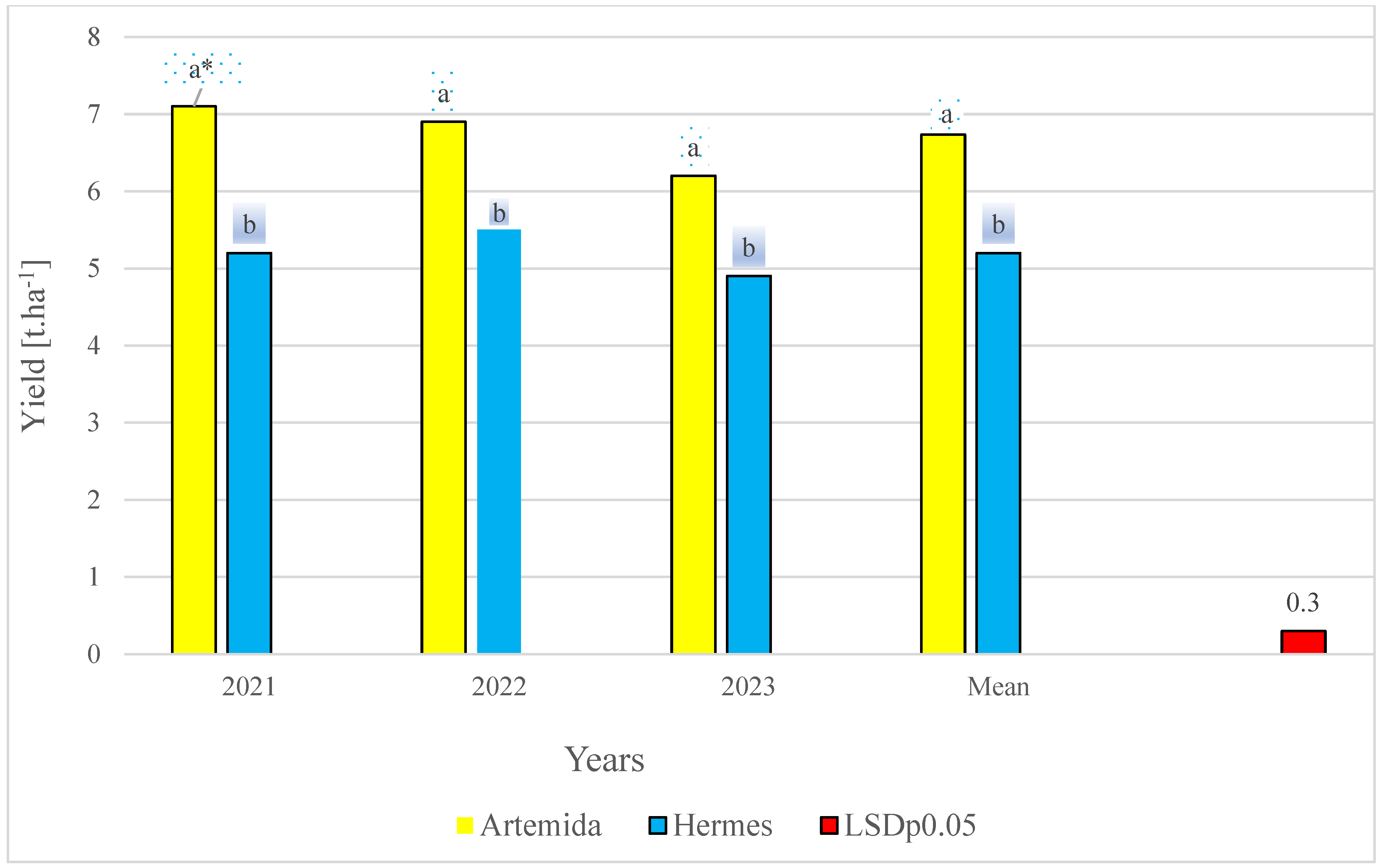

3.3. Straw Thickness

The thickness of the flax straw was, on average, 1.11 mm. At that time, the tested straw was within the norm for fiber flax [

45]. The value of this feature depended significantly on the genetic properties of the tested varieties (

Figure 7). Differences between varieties: Artemida produced thicker straw than Hermes, which may be important for its utility value, e.g., mechanical strength and suitability for various applications (e.g., textiles, biomass production). Hermes had thinner straw, which may indicate greater flexibility and easier harvesting but potentially lower durability of the material.

The value of this feature differed significantly in the years of the study. The thickest stems were in 2022, and the thinnest were in the last year of the study (

Table 6).

In summary, Artemida has significantly thicker straw than Hermes, which may affect its utility value. The thickness of the straw was the greatest in 2022, which suggests favorable growth conditions. In 2023, the straw was thinner, which may result from worse growing conditions. The research results obtained suggest that in the future, it is worth paying attention to the impact of environmental conditions and agrotechnical techniques on straw thickness and adapting the variety to a specific use (

Table 6).

3.4. Straw Color

Of the tested straw, 95% was steel-gray in color, while the remaining straw was light gray (

Table 6). The Hermes variety scored 100% steel gray in fiber throughout all years of testing. The Artemida variety, on the other hand, showed little variation in straw color, with most of the straw being steel gray, but the light-gray straw color varied slightly due to the retting conditions (temperature, moisture, and microbiological activity). In 2021, the straw had slightly more light-gray color, probably due to drier conditions affecting the microbiological retting process. In 2022, the percentage of steel-gray straw was the highest, probably due to better, more uniform retting conditions (

Table 6).

3.5. Straw Contamination

The average contamination level of the flax straw was 1.05%. This contamination was within the norm for fiber flax [

46] (

Table 7). Flax straw impurities refer to the content of impurities other than flax fiber. Most often, it includes the following:

- -

Mechanical impurities: Weed fragments (seeds, stalks, leaves), soil residues, or sand.

- -

Other plant fractions: Ears, seed capsules, or woody parts of flax stalk (shrubs) in a form imprecisely separated from the fiber.

Table 7.

Flax straw contamination level and degree of flax straw regrowth (%).

Table 7.

Flax straw contamination level and degree of flax straw regrowth (%).

| Variety | Contamination Level | Degree of Straw Growth |

|---|

| Years | Mean | Properly | Undergrown | Overgrown |

|---|

| Years | Mean | Years | Mean | Years | Mean |

|---|

| 2021 | 2022 | 2023 | 2021 | 2022 | 2023 | 2021 | 2022 | 2023 | 2021 | 2022 | 2023 |

|---|

| Artemida | 0.50a * | 0.50a | 0.60a | 0.53b | 90.0a | 84.0a | 81.0a | 85.0b | 0.0c | 0.0c | 0.0c | 0.0b | 10.0c | 16.0b | 19.0a | 15.0a |

| Hermes | 1.50b | 1.20c | 2.00a | 1.57a | 93.0a | 92.0a | 93.0a | 92.7a | 7.0b | 8.0a | 7.0b | 7.3a | 0.0d | 0.0d | 0.0d | 0.00b |

| LSDp0.05 | | 0.20 | | 0.10 | 13.0 | 5.0 | 0.6 | 0.2 | 1.2 | 0.4 |

| Mean | 1.00b | 0.85c | 1.30a | 1.05 | 91.5a | 88.8a | 87.0a | 88. | 3.5b | 4.0a | 3.5b | 3.7 | 5.0c | 8.0b | 9.5a | 7.5 |

| LSDp0.05 | | 0.10 | | | 6.5 | | 0.3 | | 0.6 | |

Artemida showed a significantly lower level of straw contamination (average 0.53%) compared with the Hermes variety (1.57%). Hermes, therefore, proved to be a variety more susceptible to contamination with plant debris, weed seeds, or other foreign materials, which may result from differences in the structure of the plant or the method of ripening. The cleanest flax straw was obtained in 2022 (average 0.85%), while the most contaminated was obtained in 2023 (1.30%). These differences may result from weather conditions, e.g., higher humidity in 2023, which could have promoted the deposition of contaminants or caused more difficult harvesting (

Table 7).

The stability of the varieties in the years of the study turned out to be varied. Artemida had a relatively stable level of contamination, in the range of 0.50–0.60%, which indicates its better resistance to factors influencing straw contamination. The Hermes variety, on the other hand, showed greater fluctuations: the lowest contamination was in 2022 (1.20%) and the highest in 2023 (2.00%). This may indicate that its straw is more susceptible to external conditions and requires more careful post-harvest processing. A lower level of contamination in the raw material means higher-quality straw and less expenditure on its cleaning before further processing. Artemida may be a more desirable variety in terms of raw material purity, especially where minimizing losses and additional processing is key (

Table 7).

3.6. Straw Retting

Straw retting analysis showed that 88.8% was properly retted fiber, 3.7% was under-retted, and 7.5% was over-retted (

Table 7). The genetic properties of the varieties studied had a significant impact on the degree of retting. The French variety Hermes was characterized by better retting than Artemida, although 7.3% of under-retted straw was recorded. In the case of Artemida, as much as 15% of straw showed signs of over-retting (

Table 7). However, it should be emphasized that the degrees of under-retting and over-retting were within the applicable standard [

41,

42,

43]. In the years 2021–2023, significant differences were observed in the degree of proper straw development depending on the variety (

Table 7). Well-developed straw: Hermes consistently maintained a high proportion of well-developed straw (92–93% per year), which was statistically significantly higher than for Artemida. Artemida showed a decreasing trend (from 90% in 2021 to 81% in 2023), which may suggest its greater sensitivity to environmental conditions.

Underdeveloped straw: Hermes showed a higher proportion of underdeveloped straw (7–8%), while Artemida practically did not (0%). This may indicate a slightly greater susceptibility of Hermes to growth-limiting factors.

Overgrown straw: Artemida showed a significantly higher proportion of overgrown straw compared with Hermes, which did not show this phenomenon. This suggests a potential agronomic problem or a genetic tendency of Artemida to overgrowth.

Agronomic recommendations: For the Artemida variety, it may be necessary to adjust fertilization and sowing dates to limit overgrowing. In the case of the Hermes variety, attention should be paid to factors limiting growth to minimize cases of undergrowth.

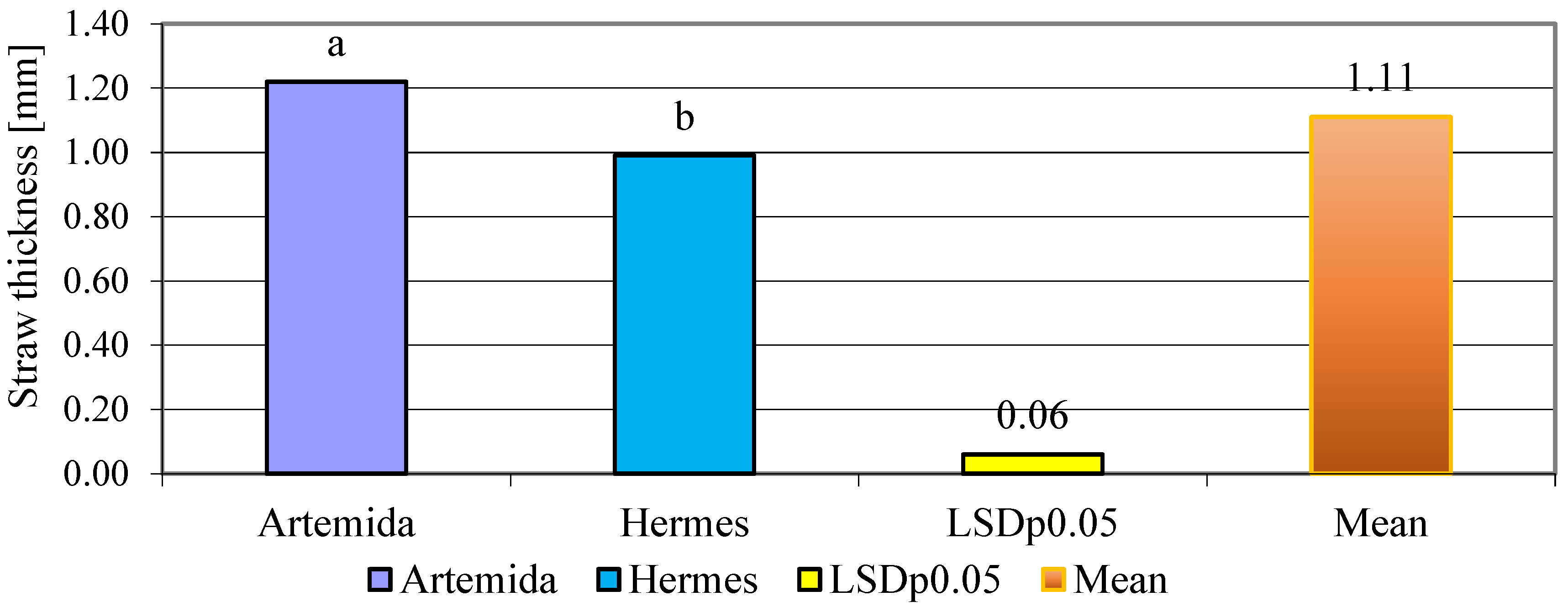

3.7. Fiber Yield

Flax fiber yield is a key parameter for assessing the utility value of fiber flax varieties. Total fiber yield ranged from 1.71 to 2.19 t ha

−1 (

Table 8). In COBORU experiments in Poland, total fiber yields ranged from 1.0 to 2.5 t ha

−1. The best varieties in COBORU experiments achieve yields of 2.0–2.5 t ha

−1.

Statistically significant differences in fiber yields were noted in the years studied (

Table 8). The Hermes variety consistently achieved higher and more stable yields of both total and long fiber compared with the Artemida variety.

Total Fiber Yield:

Artemida: Yields ranged from 1.71 t ha

−1 (2023) to 2.11 t ha

−1 (2022), with an average of 1.90 t ha

−1. The lowest yield of this variety was recorded in 2023. Hermes: Yields were more stable, ranging from 1.99 t ha

−1 (2023) to 2.19 t ha

−1 (2021). Hermes achieved higher yields than Artemida in all years studied (

Table 8).

Long-Fiber Yield:

Artemida: Yields ranged from 0.92 t ha

−1 (2023) to 1.39 t ha

−1 (2022). Hermes: Yields were more stable, ranging from 1.76 t ha

−1 (2023) to 1.92 t ha

−1 (2021), reaching significantly higher average values than Artemida (

Table 8).

Influence of Crop Year:

Overall, the highest average yields of both total fiber (2.11 t ha

−1) and long fiber (1.59 t ha

−1) were recorded in 2022, while the lowest were in 2023 (1.85 t ha

−1 and 1.34 t ha

−1, respectively). Differences between years were statistically significant (

Table 8).

In summary, the Hermes variety proved to be a more productive and stable variety in terms of both total and long-fiber yield.

As 2021 was generally wet, this led to flax lodging in a significant area of the cultivated flax while still in the green–yellow phase. The French variety Hermes had significantly higher fiber yield than the Polish variety Artemida (

Figure 8).

Table 9 shows the share of long and short fibers. Hermes achieved a significantly higher yield of long fibers compared with the Artemida variety. Artemida had a higher share of short fibers than Hermes. Significant differences indicate a clear advantage of the Hermes variety in the production of high-quality fiber, making it a better choice for the textile industry.

Influence of the years of research on fiber yield: Long-fiber yield did not show significant differences between years—values for the entire sample were similar. Artemida achieved the highest long-fiber yield in 2022 (20.20%), suggesting favorable growing conditions that year. Hermes had the lowest result in 2022, but it was still significantly better than Artemida. The yield of short fibers was the highest in 2023, which may indicate more difficult harvesting conditions leading to more brittle fibers (

Table 9).

Variety stability over the years: Hermes maintained a relatively stable yield of long fibers, indicating greater resistance to environmental conditions. Artemida showed greater fluctuations, especially in the case of short fibers, with the highest yield obtained in 2022 and the lowest in 2023 (

Table 9).

Importance for the textile industry: Hermes proved to be a much better choice for producing high-quality long fiber, which is more valuable in the textile industry. Artemida produced more short fiber, which may be less desirable for producers of high-quality yarn but may find applications in the paper or technical industry (

Table 9).

The best years for long-fiber quality were 2022 for Artemida and 2021 and 2023 for Hermes (

Table 9).

3.8. Fiber Efficiency

Flax fiber yield, measured as its percentage share in straw, was high or medium-high and constituted 34.3% of straw mass (

Table 10). Long fiber constituted, on average, 26.0%, while short fiber constituted 8.4% of the total straw mass. Genetic features differentiated both the share of long and short fibers. The Hermes variety was characterized by a significantly higher share of long fibers and a lower share of short fibers than the Artemida variety (

Table 10).

To estimate fiber yield for 2021–2023, we considered the average fiber efficiency of the two flax varieties (Artemida and Hermes), along with climate and soil conditions from those years (

Table 10).

The fiber efficiency by variety and environmental conditions (2021–2023) is presented in

Table 11.

The analysis of fiber efficiency showed that Hermes consistently provided higher yields, especially in long fiber, making it more suitable for the production of high-quality textiles. In contrast, Artemida, characterized by higher yields in short fiber, is better suited for blended fabrics or technical applications.

The slight variations observed in the yields between years (

Table 11) are in line with expectations and are due to the following factors:

2021: Slightly lower yields due to drier conditions in June and July (low hydrothermal coefficient), which affected fiber development.

2022: Optimal rainfall and temperatures contributed to improved overall fiber yield.

2023: Slightly higher total yield owing to improved soil conditions (higher pH and nutrient availability, as confirmed by soil analyses). The experiment provided a realistic assessment of fiber efficiency trends based on the weather conditions, soil properties, and agrotechnical conditions observed during those years.

3.9. Fiber Quality Assessment

The results of the tensile strength and elongation of flax fibers extracted from the two flax varieties tested are presented in

Table 12.

The tested flax fibers, assessed according to the [

47] standard, were characterized by features appropriate for long and short fibers. The short fibers of the Hermes variety were characterized by a compact, medium fine, buttery, medium heavy structure, which indicates their good quality and elasticity. The fibers of the Artemida cultivar were characterized by a medium thick structure with moderate resistance to spontaneous cracking and a distinct sound when broken, which suggests a higher stiffness of the material (

Table 12).

Destructive force and elongation of fibers: The highest destructive force was recorded for the samples of the S25 (10.15 N) and S45 (10.56 N) series, which indicates high mechanical resistance of these fibers. The M25 samples showed the highest elongation (6.40%), which may indicate a higher elasticity of these fibers. The A series fibers had lower values of breaking force and moderate elongation, which may indicate their greater susceptibility to cracking compared with the S and M series. The Hermes variety was distinguished by greater cohesion and mechanical resistance, while Artemida was characterized by medium strength and a more rigid fiber structure (

Table 12).

The analyzed flax varieties, Artemida and Hermes, differed in terms of the structure and mechanical properties of the fiber (

Table 13).

Long fibers: Artemida was characterized by a medium-thick, medium-delicate fiber with moderate resistance to breaking and a distinct breaking sound. This may suggest a fiber of good quality but with slightly higher stiffness. The Hermes variety showed a compact, technical fiber with a medium-thick, medium-fine, buttery, and medium-heavy structure. This structure may indicate greater uniformity and better suitability for spinning (

Table 13).

Short fibers: Artemida produced a fiber that was less divisible, not very delicate, with medium strength and medium resistance to breaking, which may limit its use in the high-quality textile industry. The Hermes variety, on the other hand, was characterized by fiber with medium divisibility, medium delicacy, and medium resistance to breaking, with a distinct breaking sound. This indicates greater flexibility and better processability (

Table 13).

3.10. Descriptive Statistics

Table 14 presents statistics describing the tested flax features.

Statistical analysis of flax traits showed varied variability and data distributions (

Table 14).

Most of the analyzed traits were characterized by low or moderate variability.

Straw yield: Average 6.0 t ha−1, moderate variability (SD 0.9), almost symmetrical distribution (skewness 0.2).

Straw length (technical and total): High stability (averages 53.0 and 62.3, low deviations), distributions close to normal.

Straw thickness: Average 1.1, low variability (SD 0.1), slightly right-skewed distribution (skewness 0.5).

Straw color: Dominant steel gray (average 95.0), symmetrical distribution (skewness 0).

Fiber purity: Average 1.1% impurities, moderate variability (SD 0.6), right-skewed distribution (skewness 0.5).

Fiber maturity: Most fibers are well developed (average 88.8%, SD 5.2), left-skewed distribution (skewness −0.6).

Fiber proportions: Long fiber predominance over short fiber, moderate variability (V ~40%).

Total fiber yield: Average 34.3, moderate variability (SD 6.5), symmetrical distribution (skewness 0).

The exceptions were the immature and overgrown fiber traits, which, despite low average shares (3.7% and 7.5%), showed high variability (V% > 110) (

Table 14).

Overall, the distributions of most traits were close to normal, with only minor deviations in skewness.

3.11. Interaction of Straw and Fiber Characteristics

A simple Pearson correlation analysis was performed between the straw and flax fiber characteristics of the tested varieties (

Table 15).

The correlation coefficients indicate the strength and direction of the relationship between different flax traits. Here are the most important, spherical relationships:

Straw yield (y1) showed a positive correlation with straw thickness (x3) (r = 0.93) →. Thicker straw is associated with higher yield. A strong negative correlation occurred with the steel-gray straw color (x4) (−0.92) and fiber contamination (x6) (−0.94) →. Higher straw yield is associated with lower steel-gray color and lower fiber contamination. A negative correlation with straw yield also occurred with properly retted fiber (x7) (−0.77), and here, the higher straw yield may contribute to the share of properly retted fiber, probably due to uneven retting (

Table 15).

Straw thickness and total straw yield were found to be strongly correlated and to influence the final fiber properties (

Table 15. Correct retting is crucial, as a balance between correctly retted fiber (x7) and avoiding overgrown fiber (x9) leads to higher fiber yield.

Long-fiber yield (x10) was found to be the most important factor for total fiber production (x12), while short fibers (x11) had a negative effect on this trait (

Table 15).

Straw color (x4, x5) significantly influenced fiber properties, probably due to retting effects. Optimum flax fiber production therefore requires careful control of retting, thickness, and straw quality to maximize long-fiber yield while minimizing contamination (

Table 15).

4. Discussion

4.1. Flax Production

Flax is a key industrial plant, and the quality of its fiber depends on proper management at each stage of production. The optimal harvest date is at the green–yellow maturity stage (BBCH 83), when the stems turn yellow to 1/3 of their height, and the leaves and seed pods fall off. The right harvest time ensures high fiber quality [

13,

76,

77].

Retting flax straw, which is crucial for obtaining fiber, consists of the biological decomposition of the pectins that bind the fiber to the wood. It can be carried out using the field method (dominant in Poland) or by soaking in pools [

78,

79]. In the retting method, it is necessary to turn the straw after 2–3 weeks to ensure even retting [

80,

81,

82].

Straw is harvested after it has turned gray or steel gray, and characteristic mycelium spots appear. In unfavorable weather conditions, the straw may become overgrown, which reduces the quality of the fiber. After harvesting, the straw is bailed or bundled and then transported to storage facilities where it must be protected from moisture [

29,

83].

Straw processing involves scutching, which produces scutched (long) fiber, a raw material for high-quality combed yarns, and scutchings, containing short fibers mixed with shives. Further processing produces the following:

Tow—a raw material for carded yarns,

Shive—used in the production of boards,

Retting waste—for the paper industry,

Production dust—the only waste from the process [

9,

84].

Local flax production could fill the gaps in high-quality fiber, the production of which is currently limited in northwestern Europe. In Normandy, where the full flax value chain operates, it is planned to adapt it also for hemp [

9,

77,

84].

4.2. Influence of Variety and Environmental Factors on Flax Straw Yield

The three-year research shows that the Artemida flax variety significantly outperformed Hermes in straw yield (above LSD), primarily due to variety, though environment also played a role. Artemida’s stability and adaptability, potentially from deeper roots and better water use, were noted.

Modern flax varieties like Artemida exhibit better abiotic stress resistance, maintaining stable yields even under drought (20–30% higher than older varieties like Hermes). Climate change, with rising temperatures and irregular rainfall, underscores the advantage of heat- and water shortage-resistant varieties like Artemida [

47,

48,

84].

Optimized agrotechnical practices, including precise fertilization, efficient water management (drip irrigation), and biostimulants/soil microorganisms (e.g., mycorrhiza) [

48,

56,

80], further enhance Artemida’s yield more than Hermes.

Current flax breeding focuses on increased fiber content, higher straw quality, and climate resilience, with genetic studies identifying key stress-resistance genes [

3,

4,

80].

In conclusion, variety choice is critical for high flax yields, especially with climate change. Artemida surpasses Hermes in yield and response to intensive cultivation, making it more effective across conditions. Future breeding should prioritize high-yielding, climate-resilient varieties that respond well to modern technologies.

4.3. Fiber Deglutination

Regardless of agricultural practices, bast fiber degumming significantly impacts flax fiber quality. Various methods exist, including physical, chemical, and biological processes [

56], which differ in workload, cost, environmental impact, and fiber quality. Monomorphic fiber production in Poland has improved, with new refinement methods simplifying production but requiring optimized raw material preparation.

Traditional biological methods like soaking (used in the studies) and water retting [

8,

73] prepare flax straw for mechanical fiber separation. Soaking relies on anaerobic bacteria to decompose pectic substances, easing bast separation. Warm-water resting accelerates this and allows quality control, but it involves costs for basins and heating.

Chemical degumming, using substances like sodium hydroxide, shortens processing but can reduce fiber quality and has environmental drawbacks [

85]. Enzymatic retting uses pectinolytic enzymes to enhance fiber laminarization and cleaning, offering quality control, but is expensive due to enzyme isolation [

86,

87].

Physical methods employ electromagnetic waves, ultrasound, steam treatment, and osmosis [

88]. Steam treatment in autoclaves hydrolyzes pectins [

89] but is costly. Osmotic degumming uses water diffusion to swell the stem, cracking it and releasing hydrated pectins [

87].

Each degumming method influences the fiber quality differently based on the physical, chemical, and biological processes involved as well as processing time, economics, and environmental impact [

85,

86,

87].

4.4. Flax Straw Commodity Evaluation

Retting, crucial for flax fiber quality before scutching, traditionally involves field exposure for pectin degradation by soil microorganisms. This eco-friendly, low-cost method is weather-dependent; over-retting weakens fibers, while insufficient retting yields stiff, low-quality fibers [

27,

78,

79].

Uniform fiber quality is essential for commodity evaluation. Scutched fiber should be suitable for combing and combed fiber for spinning [

27]. Flax fiber grades (56, 50, 40) prohibit defects like musty smells or spots, while lower grades allow minimal defects.

The key fiber assessment parameters include technical fiber arrangement (parallel and even), scutched fiber length (min. 40 cm), and moisture (15%) [

85,

88]. Organoleptic assessment covers divisibility, “butteriness”, fineness, tensile strength, weight, color, and appearance, often confirmed by lab tests. Processed fiber is bundled, tied, and labeled.

Tow is similarly assessed organoleptically for color uniformity, tensile strength, impurities, fineness, and divisibility [

89,

90,

91].

Our research confirmed that raw material from the tested flax varieties met all quality standards, indicating effective retting and processing. Optimizing these processes, especially with changing climate, can further enhance flax fiber quality and production efficiency.

4.5. Straw Quality

The quality of flax straw is a complex trait influenced by both genetics and environmental factors like rainfall, temperature, sunlight, and cultivation [

45,

46,

48].The minimum straw length should be 43 cm, and the bundles should be tied with natural materials. The straw must meet specific density requirements: for retted straw, it’s ≥2 kg, and for raw straw, it’s 2.5–4 kg. Impurities in raw straw should not exceed specified percentages, for example, a maximum of 15% weeds. For retted straw, a key quality indicator is the percentage of improperly grown stalks, which should also be limited (e.g., below 5–10%, though the exact value depends on the specific standard and intended use).

Steel gray was the dominant straw color (94–96%), indicating proper ripening, which is desirable for textile fiber quality. Light-gray straw (4–6%), possibly influenced by weather and ripening, was less frequent. The year 2022 showed the best color intensity. Research confirms straw color as a key quality indicator [

67,

68,

69,

70], with steel gray linked to better fiber properties. Environmental factors like moisture and temperature can affect the prevalence of light-gray straw.

Moisture of raw straw should be ≤20% and that of retted ≤18%. Commercial weight is adjusted for impurities. Retted straw weight is classified by quality [

46]. Fiber yield is proportional to straw quality (e.g., ~15% from first class). The studied straw had an average length of 607 mm, technical length of 530 mm, and thickness of 1.11 mm. Degumming methods impact fiber yield and quality.

The subjective assessment of straw quality considers maturity, retting, decortication ease, fiber divisibility, purity, and color [

92]. Retting alters straw composition (N, lipids, ash) and increases fibrous fractions. Stem diameter correlates positively with fiber diameter but negatively with tensile strength [

93].

Genetic factors significantly influence straw and fiber quality [

55]. Genome-wide association studies identified genetic variants associated with fiber traits, suggesting polygenic control. Stable variants showed consistent effects over three years, offering the potential for market-assisted selection.

4.6. Yield and Quality of Flax Fiber

The flax varieties tested met the quality standards for fiber flax, with a minimum required technical straw length of 43 cm. The Hermes variety was distinguished by a greater straw length (total and technical) than that of Artemida. The fiber length variability was 5.1%, which, according to [

18,

19,

26], did not depend significantly on straw quality. The coefficient of variation of long fibers, in the range of 5.3–5.9%, indicates their high stability [

27,

29].

The results of COBORU [

47] and our own studies indicate a strong dependence of straw yield on location. Comparing the results of the Artemida variety from Bezek (COBORU) [

47] with our own studies, a lower straw length (620 mm total, 540 mm technical) was noted in this study, but a higher straw yield (5.1 t ha

−1 vs. 3.5 t ha

−1 in Bezek). Fiber efficiency in 2021 was also more favorable in our own research (total fiber 28.2%, long fiber 16.7%), with a long fiber quality assessment of Ns 25, while in Bezek it was Ns 23 [

47].

The soil requirements of flax are divergent in the literature: Mańkowska et al. [

94] observed a higher straw yield on class V soils than on class II soils, while Rólski [

95] found a higher straw yield on class III than on class V. Heller [

56] emphasizes a 25% increase in yield on soils with good structure and moisture. Our own research has shown an improvement in plant development with an increase in soil pH, although Rólski [

95] warns against sowing flax on acidic soils. Woszczka et al. [

96] noted a significant increase in straw and seed yield at pH 7.0 compared with pH 4.2. Conversely, Mańkowska and Mańkowski [

94] observed an increase in straw yield below pH 5.5 and a decrease above 6.6, and Buranji et al. [

97] found the highest percentage of emergence at pH 5.5.

Proper nutrition has a significant effect on the quality and yield of flax. Studies by Kruska et al. [

98] showed a beneficial effect of humic acids and nitrogen on plant parameters. Abdelmasieh et al. [

67] observed that nitrogen and biological fertilizers increased the length and diameter of the stem, straw yield, and fiber yield and quality. Trukhachev et al. [

99] emphasized the importance of crop rotation and organic mineral fertilization for high yields. Mureșan et al. [

100] indicated a positive effect of phacelia and mustard fertilization on flax yield.

The quality of flax fiber, consisting mainly of polysaccharides and lignin, is influenced by many environmental and agrotechnical factors, including sowing density, crop rotation, maintenance treatments, retting conditions, and harvest date [

7,

80,

81,

82]. The retting process is critical and directly affects fiber quality [

27,

78,

82]. Studies by Sharma and Faughey [

27] and Coroller et al. [

90] (for the Hermes variety, with a fiber diameter of 14.7–22.5 µm) identify parameters such as fiber strength, fineness, ash, and lignin content as key quality indicators.

The Hermes variety in this study achieved higher straw and fiber yields than did Artemida (average 40% total fiber, 35% long fiber), and its fiber was more compact, elastic, and uniform, which made it better suited for textile processing. Artemida’s fiber was stiffer and less separable, which may limit its use.

In summary, modern Western European flax varieties adapt well to the climatic conditions of the Western Roztocze region, achieving satisfactory straw and long-fiber yields. Although the Polish variety in these studies was characterized by higher yields, its lower quality often leads to its replacement with high-quality Western European varieties. The key is to strive to select varieties that provide high yields of fiber of optimal quality.

4.7. The Influence of Abiotic Factors on the Quality of Flax Fiber

Flax fiber quality is determined by a complex interplay of biotic and abiotic factors.

4.7.1. Morphological Characteristics and Variety Selection

Plant morphology significantly influences fiber quality. Key traits include technical stem length, number of internodes, and stem diameter. Longer stems generally yield compact, dense bast bundles with long elementary fibers. Long internodes and fewer leaves lead to higher quality and less breakage. Thicker stems, however, can result in thicker, less elastic fiber with lower spinning quality due to the larger, more lignified fiber bundles. A cylindrical stem indicates fiber distribution [

81,

85].

Our research found Hermes variety straw to be superior to that of Artemida, being thinner, more delicate, and having a compact, delicate, medium-heavy fiber structure. Artemida fiber showed medium resistance to self-tearing. This highlights the crucial role of flax variety selection for fiber quality. Additionally, plant age and maturity at harvest are vital, as immature plants yield shorter, weaker fibers [

10,

88,

90].

4.7.2. Environmental and Agronomic Influences

Soil conditions (composition, structure) and agrotechnical practices such as fertilization profoundly impact fiber quality. Appropriate fertilization, combining mineral fertilizers with manure, can enhance fiber properties. However, excessive use of fertilizers or plant protection products can be detrimental [

54,

101].

Harvesting and storage techniques, along with post-harvest processing, are also critical for maintaining fiber quality.

Climatic conditions (temperature, humidity, sunlight) are significant abiotic factors. Flax thrives in cool temperatures (max 18–20 °C) and high humidity, especially during early growth. It prefers fertile, humus, clay–sandy soils. Extreme weather, like drought, hail, or strong winds, can damage plants and reduce fiber quality [

13,

76,

77].

4.7.3. Climate Change and Future Considerations

Research by Čeh et al. [

39] in Slovenia and Casa et al. [

84] in Italy demonstrated a strong correlation between climatic conditions, production year, and flax yield/quality. High summer temperatures, water deficits, and cold, wet spring soil negatively impacted seed yield and oil quality. These studies underscore the increasing influence of climate change and extreme weather on flax cultivation [

98].

Recent research emphasizes the need for stress-resistant varieties and adaptive agrotechnical strategies to mitigate negative climate impacts. Drought can decrease seed yields and alter fatty acid composition [

102], while high temperatures can negatively affect oil content and fiber quality [

5,

103]. Therefore, identifying flax genotypes with greater phenotypic plasticity and resistance to abiotic stresses is crucial for the future stability and profitability of flax cultivation [

39,

84].

In conclusion, achieving high-quality flax fiber necessitates comprehensive management of all contributing factors, including variety selection, optimal agronomic practices, and environmental control.

4.8. Correlation Relationships

Pearson correlation analysis confirms the key relationships between flax morphological traits, the retting process, and the final yield and fiber quality. A strong positive correlation was found between stem thickness and straw yield (r = 0.93), which highlights the importance of vegetative plant traits for overall biomass. Additionally, technical and total straw length correlated positively with the content of properly retted fiber, suggesting that longer plants are more susceptible to effective retting and produce better-quality fiber.

Straw color proved to be a particularly important indicator of the retting process: a steel-gray color strongly negatively correlated with fiber yield (−0.91), while light gray showed a strong positive correlation (0.93). This suggests that excessive darkening of straw may indicate problems with retting, leading to fiber degradation. This is also confirmed by the negative correlation between a high percentage of retted fiber and properly retted fiber (−0.92), which indicates that too long a retting process reduces the quality of the raw material.

The key parameter determining the processing value of flax is the yield of long fibers, which shows an almost perfect correlation with the total fiber yield (r = 0.99). Conversely, an increase in the share of short fibers negatively correlates with long fibers (−0.99), which reduces the overall quality of the yarn. These observations emphasize the need to strive for the optimization of harvesting and retting technology in order to minimize the short-fiber fraction.

In the light of contemporary research, the importance of these correlations is confirmed by the development of precise techniques for assessing plant characteristics and the retting process. The use of multispectral imaging and artificial intelligence to analyze straw color and other physical indicators allows for the non-destructive and rapid assessment of retting progress and the prediction of fiber quality [

94,

98]. In addition, advances in genomics and plant breeding enable the selection of flax varieties with optimized stem traits (length, thickness) and a genetic predisposition to efficient rating, which translates into higher yield and quality of long fiber [

7,

10,

18]. Integration of these data with predictive models allows for the improvement of cultivation and processing systems, leading to more sustainable and economically efficient production of flax fiber [

104].

These results provide a solid basis for further research on the optimization of technological processes and the selection of flax varieties that will provide the highest quality raw material for the textile industry.

4.9. Indications for Agricultural Practice and Processing

Monitoring weather conditions: In years with unfavorable conditions (e.g., high humidity), it is worth considering delaying harvesting to allow full maturation of the straw.

Adequate fertilization: Balanced fertilization (especially with nitrogen) can improve straw quality and color intensity.

Cultivar selection: Selecting cultivars with a stable steel-gray color feature can ensure higher quality of the raw material regardless of weather conditions.

The latest research confirms that the steel-gray color of flax straw is a key indicator of its quality and maturity. The stability of this feature in different years of cultivation indicates the high suitability of fiber flax for industrial purposes. The impact of weather conditions on the share of light-gray straw indicates the need for further research on the optimization of agrotechnics to minimize the negative effects of unfavorable weather conditions. The 2022 results confirm that favorable weather conditions are crucial for obtaining the highest quality raw material.

- -

Recommendations for farmers: In the case of growing flax for fiber, it is worth choosing the Hermes variety, which is characterized by higher and more stable yield.

- -

Recommendations for breeders: It is worth continuing work on improving the yield of varieties such as Artemida, especially in terms of yield stability in various environmental conditions.

- -

Recommendations for processors: The Hermes variety may be more profitable due to the higher yield of long fiber, which is more valuable in processing.

4.10. Limitations of the Study

The presented study, although providing valuable information, has some limitations resulting from its scope and methodology, which require caution when interpreting and generalizing the results:

Location and representativeness: The study was conducted in a limited number of specific locations in Roztocze. The diversity of the soil and microclimatic conditions in the region means that the results may not be fully representative of the entire area or of other crop types (e.g., [

5,

6]).

Duration: A three-year observation period may be too short to capture long-term trends in soil pH and fertilization responses under variable weather conditions and with different agricultural practices.

Sample size: The limited number of soil samples collected, and crop varieties analyzed may affect the statistical strength and generalizability of the conclusions.

Scope of parameters analyzed: The study focused on pH and available forms of P, K, and Mg, omitting other important soil parameters (e.g., organic matter, microelements, biological activity) that also affect crop performance.

External factors and agricultural practices: The influence of unexplored external factors (e.g., climate change, local pollution) and specific historical agricultural practices in the fields studied may not have been fully controlled and may have influenced the obtained results.

Therefore, caution is suggested in generalizing the results to the whole Roztocze region and other cropping systems, and the need for further studies in more locations and over longer periods of time is emphasized.

5. New Trends and Challenges

In flax production, the use of biostimulants and precise flax irrigation is important to increase yields while reducing environmental impact [

31,

48,

84]. In regions such as Normandy, a comprehensive value chain is developing, covering all stages, from cultivation to processing [

11,

50,

51]. Breeding varieties resistant to abiotic stresses is key to yield stability [

49]. The production of high-quality flax fiber requires precise management from harvest to processing. The development of sustainable practices, modern technologies, and local value chains can increase the competitiveness of flax fiber on the global market [

4,

31]. New perspectives for the use of flax fiber, such as biocomposites, bioremediation, biofuels, pharmaceuticals, and medicine indicate the growing importance of this versatile fiber plant in various fields of industry and science. However, to maximize the potential of flax and to meet the challenges of its improvement, continuously evolving knowledge and new molecular breeding tools are necessary. It is expected that better knowledge of the genes involved in flax productivity and quality will allow breeders to select and obtain varieties with more desirable traits. Modern molecular technologies, such as DNA sequencing techniques, functional genomics, and associative genomics, can accelerate the process of identifying important genes and their relationships with phenotypic traits [

28,

55]. Another important aspect is a better understanding of the development of the cell wall in relation to the properties of flax fiber. The cell wall plays a key role in the formation and characterization of flax fiber. Better knowledge of the biosynthetic processes and the structure of the cell wall can help to understand how it affects the mechanical properties, strength, and elasticity of the fiber. In addition, the developing knowledge of the chemical composition of flax fiber, such as the content of cellulose, hemicellulose, lignin, protein, and other substances, can provide information regarding the various applications of flax in various fields. Analysis of the chemical composition can also help in the pursuit of obtaining fiber with the right properties for specific industrial purposes [

35,

36,

80].

Further research on molecular breeding, genomics, biochemistry, and molecular biology of flax is crucial to achieving progress in this field. It will enable breeders and scientists to develop new varieties of flax with increased productivity and better fiber quality adapted to the specific requirements of different industries. Improving the knowledge of flax and its use in novel applications can contribute to sustainable development, reduce dependence on chemical raw materials, and contribute to the protection of the natural environment.

The improved knowledge and understanding of flax genetics, biology, and biochemistry supported by modern molecular technologies can ensure the development of a variety of products based on flax fibers and contribute to the growing importance of this versatile plant in today’s world.

6. Conclusions

This study revealed clear varietal differences between Artemida and Hermes in terms of straw yield and fiber characteristics. Artemida produced higher straw biomass, while Hermes yielded a higher proportion of long fibers with better mechanical properties, including finer structure and greater compactness—qualities desirable for technical applications.

Fiber quality was influenced by multiple factors, including genotype, environmental conditions, and post-harvest processes. Notably, straw thickness and yield were closely linked to long-fiber output, while short-fiber content showed a negative relationship. Retting effectiveness, indicated by straw color, also played a key role, reinforcing the need for precise harvest and processing timing.

These findings have practical implications for flax growers. Selecting suitable varieties for local conditions, optimizing retting, and managing straw quality can improve fiber yield and quality. Moreover, integrating these practices across the flax value chain, from field to processing, can support greater efficiency and economic viability.

Future research should explore how to further refine value chain operations, especially through automation and sustainable practices, to reduce production costs and environmental impact. Promoting inter-sector collaboration and supporting policies can facilitate knowledge transfer, stimulate innovation, and strengthen the economic potential of flax cultivation.

Finally, fiber flax offers a viable crop alternative for small-scale farms in Eastern Poland and similar regions in the EU, contributing to rural development, cultural heritage preservation, and sustainable land use.