Integrated Models of Cleaner Production Technologies for Maize Cultivation in China’s Black Soil Regions

Abstract

1. Introduction

2. Materials and Methods

2.1. Orthogonal Experimental Design Method

2.2. Carbon Footprint Measurement Method of Maize Farmland Ecosystems

2.3. Malmquist Index

2.4. Statistical Analysis

3. Results

3.1. Orthogonal Test Matrix of Cleaner Production Technologies for Maize Cultivation in Black Soil Regions

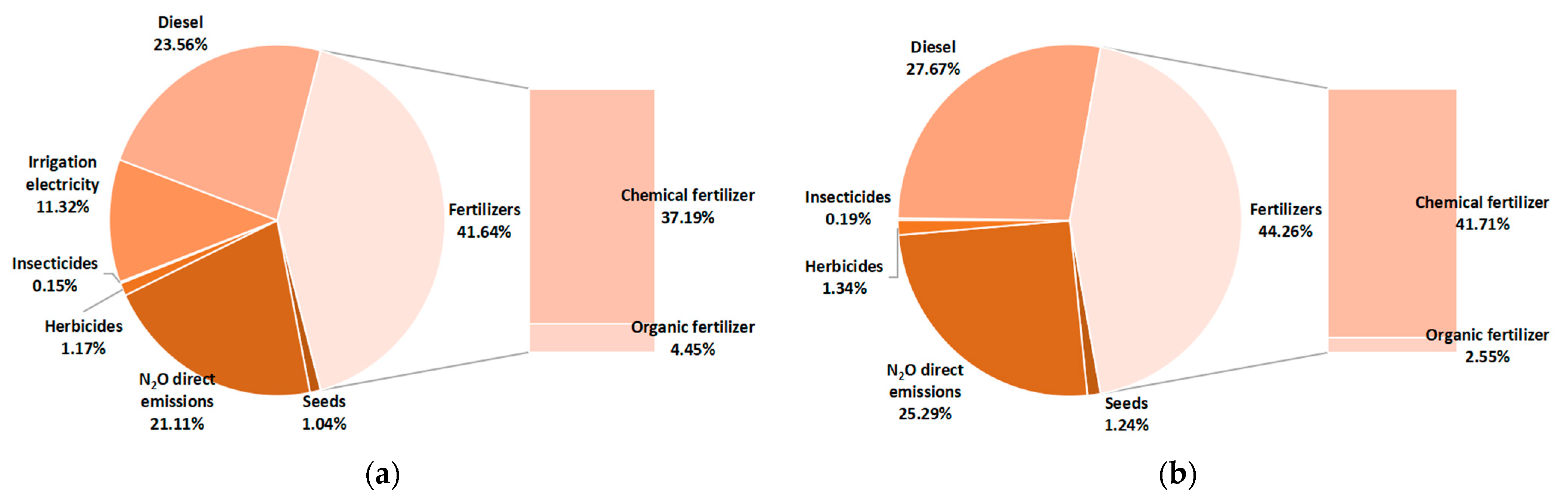

3.2. Carbon Footprint Performance of Subgroups of Orthogonal Tests of Cleaner Production Technologies for Maize Cultivation in Black Soil Regions

3.3. Evaluation of Production Efficiency of Orthogonal Test Subgroups of Cleaner Production Technology for Maize Cultivation in Black Soil Regions

3.3.1. Comprehensive Technical Efficiency Analysis

3.3.2. Tfp Index and Decomposition Analysis

4. Discussion

4.1. Analysis of Carbon Reduction Pathways of Maize Cultivation in Black Soil Regions

4.2. Identification of Integrated Models of Cleaner Production Technologies for Maize Cultivation in Black Soil Regions

5. Conclusions and Recommendations

5.1. Conclusions

- (1)

- The carbon footprint of maize cultivation in the orthogonal experimental group using cleaner production technologies was generally higher than that of the traditional control group, which showed that the application of cleaner production technologies in the black soil regions is crucial for increasing production and reducing carbon emissions and that fertilizers, diesel fuel, and direct emissions of N2O from farmland are the three main sources of carbon emissions from maize cultivation in China’s black soil regions; future focus should be placed on these three aspects to further improve maize cultivation’s carbon footprint in black soil regions.

- (2)

- The production efficiency of each experimental group of cleaner production technology for maize cultivation in China’s black soil regions showed an overall upward trend and was higher than that of the control group, but none of them reached DEA effectiveness. The uncoordinated development of technical efficiency and the rate of technical progress are the most important reasons for low production efficiency.

- (3)

- According to the efficiency evaluation matrix of orthogonal experimental groups for cleaner production of maize cultivation in black soil regions, the integrated technical efficiency and total factor production efficiency of test group F1I2S2 in semi-arid black soil regions and test group T2F1S2 in semi-humid black soil regions were relatively optimal.

5.2. Recommendations

- (1)

- Close attention should be paid to the combined impact of carbon emissions and carbon sequestration on the carbon footprint of the black soil region, and through the application of a reasonable combination of cleaner production technology modes, the excessive carbon emissions caused by the redundancy of agricultural material inputs during the reproductive period should be reduced. At the same time, a sound system of emergency management should be established for stable production and security of supply to enhance the degree of carbon sequestration.

- (2)

- Focusing on the innovation of cleaner production technologies, strengthening technology diffusion, and bringing into play the synergistic effect of technological progress and enhancements in technological efficiency is crucial in accelerating the construction of low-carbon, high-yield, and sustainable maize cultivation.

- (3)

- In semi-arid black soil regions, efforts should be made to demonstrate and promote the integrated model (F1I2S2) of “Soil testing and formulation + Full mobile sprinkler irrigation + Straw tilling and field return” technology, which, together with effective yield-enhancement measures such as precision sowing, chemical control and anti-fall, and biological control of pests and diseases, can effectively enhance the low-carbon productivity of maize by 20.3%. In semi-humid black soil regions, efforts should be made to demonstrate and promote the “No tillage in spring + Soil testing and formulation + Straw tilling and field return” technology integrated model (T2F1S2) supplemented by the construction of high-quality maize genetic genome groups; enhance unified prevention and control and improve the coverage of green control and prevention; and reduce the number of chemical pesticides used alongside other measures, which may effectively enhance the low-carbon productivity of maize by 15.4%.

5.3. Limitations and Future Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

| 1 | Food and Agriculture Organization of the United Nations (2022). Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 6 December 2023). |

| 2 | The raw materials for organic fertilizers in this study were livestock manure such as pig manure, cow manure, sheep manure, horse manure, chicken manure, and duck manure. |

| 3 | IPCC. Climate Change 2013: The Physical Science Basis. |

References

- Li, R.; Chen, Y. A study on the conservation and use behaviour of farm land by farmers in typical black soil regions of Northeast China. J. Agric. Tech. Econ. 2017, 11, 80–91. [Google Scholar] [CrossRef]

- Hao, X.; Wang, X.; Gao, H.; Mao, Y.; Sun, L.; Ma, X.; Zhou, B.; Chi, F.; Li, W. Estimation of greenhouse gas emission and carbon footprint of farmland under different straw returning methods in songnen plain. Ecol. and Environ. Sci. 2022, 31, 318–325. [Google Scholar] [CrossRef]

- Luo, X.; Zhang, A.; Chen, H.; Feng, H. Effects of Plastic Film Mulching Patterns and Irrigation on Yield of Summer Maize and Greenhouse Gas Emissions Intensity of Field. Environ. Sci. 2018, 39, 5246–5256. [Google Scholar] [CrossRef]

- Cui, Y.; Khan, S.U.; Sauer, J.; Zhao, M. Exploring the spatiotemporal heterogeneity and influencing factors of agricultural carbon footprint and carbon footprint intensity: Embodying carbon sink effect. Sci. Total Environ. 2022, 846, 13. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Yu, J.; Yao, X. Toward cleaner production: What drives farmers to adopt eco-friendly agricultural production? J. Clean. Prod. 2018, 184, 550–558. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, X.; Lu, J.; Wu, L. Research on adoption behavior of green control techniques by family farms. Resour. Sci. 2017, 39, 934–944. [Google Scholar] [CrossRef][Green Version]

- Wu, X.; Zhang, J.; He, K.; Zhang, L. Farmer willingness to adopt rice straw returning technology and driving path. Resour. Sci. 2016, 38, 64–71. [Google Scholar] [CrossRef]

- Zhang, L. Reflections on Cleaner Production in Agriculture. Chin. Rural. Econ. 2001, 38–42. [Google Scholar]

- Chen, Z.; Zhang, J.; He, K. Technical perception, environmental awareness and adoption willingness of agricultural cleaner production technology. Chin. J. Eco-Agric. 2018, 26, 926–936. [Google Scholar] [CrossRef]

- Deng, Y.; Zhu, J. Effects of conservation tillage technology on improving grain production and environmental efficiency. China Popul. Resour. Environ. 2023, 33, 218–228. [Google Scholar] [CrossRef]

- Huang, Q.; Li, D.; Liu, K.; Ding, X.; Ye, H.; Hu, Z.; Yu, X.; Hu, Q.; Hu, H.; Xu, X. Theory and Technical Practice of Clean Production in Double-cropping Rice in Jiangxi Province. Acta Agric. Jiangxi 2020, 32, 7–12. [Google Scholar] [CrossRef]

- Song, Y.; Yu, J.; Chen, S.; Xiao, C.; Li, Y.; Su, X.; Ding, F. Effects of Reduced Chemical Fertilizer with Application of Bio organic Fertilizer on Rape Growth, Microorganism and Enzymes Activities in Soil. J. Soil. Water Conserv. 2018, 32, 352–360. [Google Scholar] [CrossRef]

- Yang, W.; Li, Q. The Impact on Less Use of Chemical Fertilizers. J. S. China Agric Univ. (Soc. Sci. Ed.) 2017, 03, 58–66. [Google Scholar] [CrossRef]

- Huang, Y.; Luo, X.; Liu, D.; Yu, W.; Tang, L. Factors Affecting Farmers’Adoption of Organic Fertilizer Instead of Chemical Fertilizer-Explaining the Phenomenon of Farmers’ Little Behavior with Strong Willingness. Resour. Environ. Yangtze Basin 2019, 28, 632–641. [Google Scholar]

- Zhou, Y.; Yin, C.; Cheng, L. Empirical Study on the Compensation Mechanism about Adoption of Agricultural Cleaner Production Technology: A Case Study on the Survey of Farmers in Eryuan County, Dali Bai Autonomous Prefecture in Yunnan Province. J. Agric. Resour. Environ. 2011, 28, 88–93+118. [Google Scholar]

- Xu, Y.; Wei, S.; Liu, E.; Yang, Y. What is the applicability of clean production technologies for maize as a countermeasure to reduce on-farm CO2 emissions and increase crop productivity? J. Clean. Prod. 2023, 428, 139462. [Google Scholar] [CrossRef]

- Rockström, J.; Williams, J.; Daily, G.; Noble, A.; Matthews, N.; Gordon, L.; Wetterstrand, H.; DeClerck, F.; Shah, M.; Steduto, P.; et al. Sustainable intensification of agriculture for human prosperity and global sustainability. Ambio 2016, 46, 4–17. [Google Scholar] [CrossRef]

- Ke, Z.; Zhao, D.; Wu, B.; Xu, H.; Chen, J. A study of constructing the agricultural cleaner production technology system of Zhejiang province. Environ. Pollut. Control. 2006, 921–924+940. [Google Scholar]

- Wang, B.; Yin, N.; Zheng, M.; Huang, Y.; Luo, Y.; Chen, S.; Cai, K.; Wang, J. Effects of Reduction of Chemical Fertilizer and Organic Manure Supplement on Vegetables Yield and Quality. Chin. Agric. Sci. Bull. 2012, 28, 242–247. [Google Scholar]

- Datta, S.; Bandyopadhyay, A.; Pal, P.K. Application of Taguchi philosophy for parametric optimization of bead geometry and HAZ width in submerged arc welding using a mixture of fresh flux and fused flux. Int. J. Adv. Manuf. Technol. 2007, 36, 689–698. [Google Scholar] [CrossRef]

- Duan, H.; Zhang, Y.; Zhao, J.; Bian, X. Carbon Footprint Analysis of Farmland Ecosystem in China. J. Soil. Water Conserv. 2011, 25, 203–208. [Google Scholar] [CrossRef]

- Fare, R.; Grosskopf, S.; Norris, M.; Zhang, Z. Productivity growth, technical progress, and efficiency change in industrialized countries. Am. Econ. Rev. 1994, 84, 66–83. [Google Scholar]

- Zhu, X.; Shi, Q.; Gai, Q. Misallocation and TEP in Rural China. Econ. Res. J. 2011, 46, 86–98. [Google Scholar]

- Zhou, J.; Wang, Y.; Liu, X.; Shi, X.; Cai, C. Spatial Temporal Differences of Carbon Emissions and Carbon Compensationin in China Based on Land Use Change. Scie Geogr. Sin. 2019, 39, 1955–1961. [Google Scholar] [CrossRef]

- Jiao, Y.; Huang, Y.; Zong, L.; Zhou, Q.L.; Sass, R. Impact of Different Levels of Nitrogen Fertilizer on N2O Emission from Different Soils. Environ. Sci. 2008, 29, 2094–2098. [Google Scholar] [CrossRef]

- He, Q.; Zhang, J.; Zhang, H. Impact of Agricultural Mechanisation on Agricultural Carbon Emissions--Empirical Evidence from Main Grain Producing Areas. Stat. Decis. 2023, 39, 88–92. [Google Scholar] [CrossRef]

- Li, Y.; Ge, Y.; Liu, A.; Liang, Y. Research on agro-ecological compensation mechanism based on the carbon sink function of food crops. Issues. Agric. Econ. 2014, 35, 33–40. [Google Scholar] [CrossRef]

- Zhao, R.; Qin, M. Temporospatial Variation of Partial Carbon Source/Sink of Farmland Ecosystem in Coastal China. J. Ecol. Rural. Environ. 2007, 23, 1–6+11. [Google Scholar]

| Test Level | Semi-Arid Black Soil Regions | Semi-Humid Black Soil Regions | ||||

|---|---|---|---|---|---|---|

| F | I | S | T | F | S | |

| 1 | F1 | I1 | S1 | T1 | F1 | S1 |

| 2 | F2 | I2 | S2 | T2 | F2 | S2 |

| Economic Coefficients | Carbon Sequestration | Water Content | |

|---|---|---|---|

| Maize | 0.40 | 0.47 | 0.13 |

| Agricultural Materials | Emission Parameters | Parameter Sources |

|---|---|---|

| Maize seeds | 1.93 kgCO2eq/kg | Ecoinvent 2.2 |

| Composite fertilizers | 1.77 kgCO2eq/kg | CLCD 0.7 |

| Herbicides | 10.15 kgCO2eq/kg | Ecoinvent 2.2 |

| Insecticides | 16.61 kgCO2eq/kg | Ecoinvent 2.2 |

| Diesel fuel usage process | 4.10 kgCO2eq/kg | Ecoinvent 2.2 |

| Organic fertilizers (N) | 9.18 kgCO2eq/kg | SimaPro 9.5.0 |

| Organic fertilizers (P) | 1.18 kgCO2eq/kg | SimaPro 9.5.0 |

| Organic fertilizers (K) | 0.67 kgCO2eq/kg | SimaPro 9.5.0 |

| Irrigation electricity | 1.23 kgCO2eq/kWh | CLCD 0.7 |

| Direct on-farm N2O emissions | 0.01 kgN/kg | IPCC |

| Semi-Arid Black Soil Regions | Semi-Humid Black Soil Regions | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| No. | F | I | S | Treatment | No. | T | F | S | Treatment |

| A1 | F1 | I1 | S1 | F1I1S1 | H1 | T1 | F1 | S1 | T1F1S1 |

| A2 | F1 | I2 | S2 | F1I2S2 | H2 | T1 | F2 | S2 | T1F2S2 |

| A3 | F2 | I1 | S2 | F2I1S2 | H3 | T2 | F1 | S2 | T2F1S2 |

| A4 | F2 | I2 | S1 | F2I2S1 | H4 | T2 | F2 | S1 | T2F2S1 |

| A-CK | F3 | I3 | S3 | F3I3S3 | H-CK | T3 | F3 | S3 | T3F3S3 |

| No. | Treatment | 2019 | 2020 | 2021 | 2022 | 2023 | Mean | |

|---|---|---|---|---|---|---|---|---|

| A1 | F1I1S1 | 3323.86 | 4345.70 | 4340.05 | 4231.31 | 4385.11 | 4125.21 | |

| A2 | F1I2S2 | 4166.29 | 4542.26 | 4360.34 | 4351.88 | 4388.32 | 4361.82 | |

| A3 | F2I1S2 | 4126.94 | 5156.16 | 5059.06 | 6337.14 | 5866.61 | 5309.18 | |

| A4 | F2I2S1 | 4320.85 | 5236.17 | 5092.04 | 5992.89 | 5648.97 | 5258.18 | |

| A-CK | F3I3S3 | 3560.40 | 4515.52 | 4521.57 | 4689.63 | 4744.14 | 4406.25 | |

| H1 | T1F1S1 | 4145.71 | 4028.63 | 4126.46 | 3731.00 | 3691.58 | 3944.68 | |

| H2 | T1F2S2 | 3684.85 | 4043.61 | 3858.24 | 4059.43 | 4683.76 | 4065.98 | |

| H3 | T2F1S2 | 4178.86 | 4181.98 | 4288.40 | 3782.34 | 3842.85 | 4054.89 | |

| H4 | T2F2S1 | 4163.37 | 5349.61 | 5129.80 | 5143.94 | 5219.16 | 5001.18 | |

| H-CK | T3F3S3 | 5260.01 | 4558.65 | 4549.10 | 4573.35 | 4524.44 | 4693.11 | |

| A1 | F1I1S1 | 6817.37 | 8598.69 | 8244.94 | 6527.88 | 8754.19 | 7788.61 | |

| A2 | F1I2S2 | 7163.47 | 8005.95 | 7620.02 | 4875.83 | 7784.24 | 7089.90 | |

| A3 | F2I1S2 | 7270.01 | 7837.77 | 8207.28 | 6995.73 | 8524.20 | 7767.10 | |

| A4 | F2I2S1 | 7438.14 | 8232.58 | 7570.32 | 6882.30 | 8319.04 | 7688.48 | |

| A-CK | F3I3S3 | 5924.15 | 7771.67 | 7908.17 | 5589.47 | 6295.16 | 6697.72 | |

| H1 | T1F1S1 | 7788.03 | 8868.12 | 9067.09 | 5411.83 | 7884.67 | 7803.95 | |

| H2 | T1F2S2 | 8177.15 | 9299.21 | 9395.90 | 9131.71 | 9405.14 | 9081.82 | |

| H3 | T2F1S2 | 7396.33 | 8454.23 | 8728.17 | 7349.48 | 8017.50 | 7989.14 | |

| H4 | T2F2S1 | 8423.55 | 9525.58 | 9740.03 | 9834.02 | 8683.05 | 9241.25 | |

| H-CK | T3F3S3 | 8475.99 | 8475.99 | 8391.36 | 6535.13 | 7212.31 | 7818.16 | |

| A1 | F1I1S1 | 3493.51 | 4252.99 | 3904.89 | 2296.57 | 4369.08 | 3663.41 | |

| A2 | F1I2S2 | 2997.18 | 3463.69 | 3259.68 | 523.95 | 3395.92 | 2728.08 | |

| A3 | F2I1S2 | 3143.08 | 2681.61 | 3148.22 | 658.58 | 2657.59 | 2457.82 | |

| A4 | F2I2S1 | 3117.29 | 2996.41 | 2478.28 | 889.41 | 2670.07 | 2430.29 | |

| A-CK | F3I3S3 | 2363.75 | 3256.15 | 3386.59 | 899.84 | 1551.03 | 2291.47 | |

| H1 | T1F1S1 | 3642.32 | 4839.49 | 4940.63 | 1680.83 | 4193.09 | 3859.27 | |

| H2 | T1F2S2 | 4492.30 | 5255.60 | 5537.66 | 5072.27 | 4721.38 | 5015.84 | |

| H3 | T2F1S2 | 3217.47 | 4272.25 | 4439.77 | 3567.15 | 4174.66 | 3934.26 | |

| H4 | T2F2S1 | 4260.19 | 4175.98 | 4610.23 | 4690.09 | 3463.89 | 4240.08 | |

| H-CK | T3F3S3 | 3215.98 | 3917.34 | 3842.26 | 1961.78 | 2687.88 | 3125.05 |

| No. | Treatment | 2019 | 2020 | 2021 | 2022 | 2023 | Mean |

|---|---|---|---|---|---|---|---|

| A1 | F1I1S1 | 0.924 | 0.958 | 0.958 | 0.953 | 0.959 | 0.950 |

| A2 | F1I2S2 | 0.965 | 0.982 | 0.976 | 0.991 | 0.984 | 0.980 |

| A3 | F2I1S2 | 0.942 | 0.962 | 0.959 | 0.941 | 0.971 | 0.955 |

| A4 | F2I2S1 | 0.935 | 0.946 | 0.948 | 0.952 | 0.970 | 0.950 |

| A-CK | F3I3S3 | 0.880 | 0.894 | 0.898 | 0.907 | 0.963 | 0.908 |

| H1 | T1F1S1 | 0.845 | 0.895 | 0.897 | 0.909 | 0.938 | 0.896 |

| H2 | T1F2S2 | 0.821 | 0.974 | 0.970 | 0.972 | 0.966 | 0.939 |

| H3 | T2F1S2 | 0.877 | 0.944 | 0.947 | 0.965 | 0.969 | 0.940 |

| H4 | T2F2S1 | 0.864 | 0.945 | 0.930 | 0.944 | 0.951 | 0.926 |

| H-CK | T3F3S3 | 0.840 | 0.844 | 0.850 | 0.860 | 0.898 | 0.858 |

| No. | Treatment | Effch | Techch | Pech | Sech | Tfp |

|---|---|---|---|---|---|---|

| A1 | F1I1S1 | 0.942 | 1.098 | 1.010 | 0.933 | 1.034 |

| A2 | F1I2S2 | 1.171 | 1.028 | 1.005 | 1.164 | 1.203 |

| A3 | F2I1S2 | 0.474 | 1.023 | 1.008 | 0.471 | 0.486 |

| A4 | F2I2S1 | 0.709 | 1.019 | 1.010 | 0.702 | 0.723 |

| A-CK | F3I3S3 | 0.527 | 0.928 | 1.025 | 0.514 | 0.489 |

| H1 | T1F1S1 | 1.067 | 1.004 | 1.030 | 1.036 | 1.071 |

| H2 | T1F2S2 | 1.016 | 0.979 | 1.046 | 0.972 | 0.995 |

| H3 | T2F1S2 | 1.116 | 1.034 | 1.027 | 1.087 | 1.154 |

| H4 | T2F2S1 | 0.462 | 1.003 | 1.026 | 0.450 | 0.463 |

| H-CK | T3F3S3 | 0.541 | 1.100 | 1.021 | 0.530 | 0.595 |

| No. | Treatment | Year | Effch | Techch | Tfp | No. | Treatment | Year | Effch | Techch | Tfp |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | F1I1S1 | 2019–2020 | 0.890 | 1.383 | 1.230 | H1 | T1F1S1 | 2019–2020 | 1.240 | 1.177 | 1.459 |

| 2020–2021 | 0.105 | 1.008 | 0.105 | 2020–2021 | 0.871 | 1.175 | 1.023 | ||||

| 2021–2022 | 0.019 | 1.053 | 0.020 | 2021–2022 | 0.001 | 0.808 | 0.001 | ||||

| 2022–2023 | 445.093 | 0.990 | 440.780 | 2022–2023 | 1751.561 | 0.910 | 1593.960 | ||||

| Mean | 0.942 | 1.098 | 1.034 | Mean | 1.067 | 1.004 | 1.071 | ||||

| A2 | F1I2S2 | 2019–2020 | 1.975 | 1.065 | 2.104 | H2 | T1F2S2 | 2019–2020 | 1.062 | 1.187 | 1.261 |

| 2020–2021 | 0.769 | 0.827 | 0.636 | 2020–2021 | 1.162 | 0.899 | 1.045 | ||||

| 2021–2022 | 0.983 | 0.857 | 0.842 | 2021–2022 | 0.841 | 0.956 | 0.804 | ||||

| 2022–2023 | 1.261 | 1.479 | 1.865 | 2022–2023 | 1.028 | 0.900 | 0.925 | ||||

| Mean | 1.171 | 1.028 | 1.203 | Mean | 1.016 | 0.979 | 0.995 | ||||

| A3 | F2I1S2 | 2019–2020 | 0.115 | 1.099 | 0.127 | H3 | T2F1S2 | 2019–2020 | 1.202 | 1.227 | 1.475 |

| 2020–2021 | 0.806 | 0.985 | 0.793 | 2020–2021 | 1.009 | 0.980 | 0.989 | ||||

| 2021–2022 | 0.001 | 0.880 | 0.001 | 2021–2022 | 0.140 | 1.019 | 0.143 | ||||

| 2022–2023 | 430.357 | 1.153 | 495.992 | 2022–2023 | 9.149 | 0.933 | 8.533 | ||||

| Mean | 0.474 | 1.023 | 0.486 | Mean | 1.116 | 1.034 | 1.154 | ||||

| A4 | F2I2S1 | 2019–2020 | 0.613 | 1.235 | 0.757 | H4 | T2F2S1 | 2019–2020 | 1.093 | 0.952 | 1.041 |

| 2020–2021 | 0.106 | 0.976 | 0.103 | 2020–2021 | 1.158 | 0.994 | 1.151 | ||||

| 2021–2022 | 0.002 | 0.918 | 0.002 | 2021–2022 | 0.909 | 1.152 | 1.047 | ||||

| 2022–2023 | 1915.691 | 0.972 | 1862.819 | 2022–2023 | 0.040 | 0.928 | 0.037 | ||||

| Mean | 0.709 | 1.019 | 0.723 | Mean | 0.462 | 1.003 | 0.463 | ||||

| A-CK | F3I3S3 | 2019–2020 | 0.981 | 2.219 | 2.176 | H-CK | T3F3S3 | 2019–2020 | 3.904 | 1.328 | 5.184 |

| 2020–2021 | 1.399 | 1.013 | 1.417 | 2020–2021 | 1.005 | 0.969 | 0.974 | ||||

| 2021–2022 | 0.000 | 0.498 | 0.000 | 2021–2022 | 0.003 | 0.826 | 0.003 | ||||

| 2022–2023 | 149.639 | 0.661 | 98.949 | 2022–2023 | 6.785 | 1.376 | 9.337 | ||||

| Mean | 0.527 | 0.928 | 0.489 | Mean | 0.541 | 1.100 | 0.595 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Xu, Y. Integrated Models of Cleaner Production Technologies for Maize Cultivation in China’s Black Soil Regions. Land 2024, 13, 731. https://doi.org/10.3390/land13060731

Yang Y, Xu Y. Integrated Models of Cleaner Production Technologies for Maize Cultivation in China’s Black Soil Regions. Land. 2024; 13(6):731. https://doi.org/10.3390/land13060731

Chicago/Turabian StyleYang, Yinsheng, and Ying Xu. 2024. "Integrated Models of Cleaner Production Technologies for Maize Cultivation in China’s Black Soil Regions" Land 13, no. 6: 731. https://doi.org/10.3390/land13060731

APA StyleYang, Y., & Xu, Y. (2024). Integrated Models of Cleaner Production Technologies for Maize Cultivation in China’s Black Soil Regions. Land, 13(6), 731. https://doi.org/10.3390/land13060731