A Novel Method for Obtaining the Loess Structural Index from Computed Tomography Images: A Case Study from the Lvliang Mountains of the Loess Plateau (China)

Abstract

:1. Introduction

2. Materials and Methods

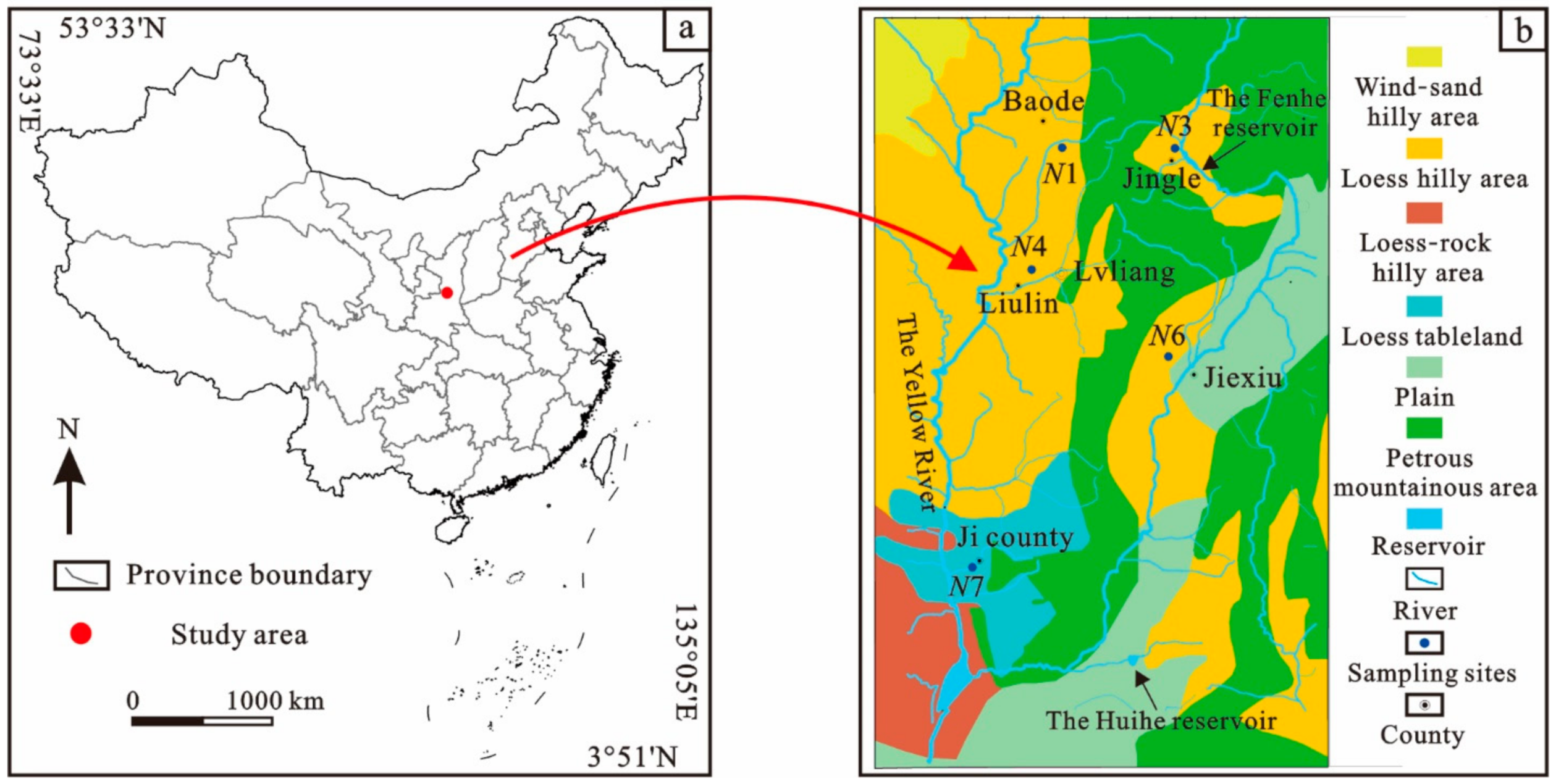

2.1. Study Area and Loess Samples

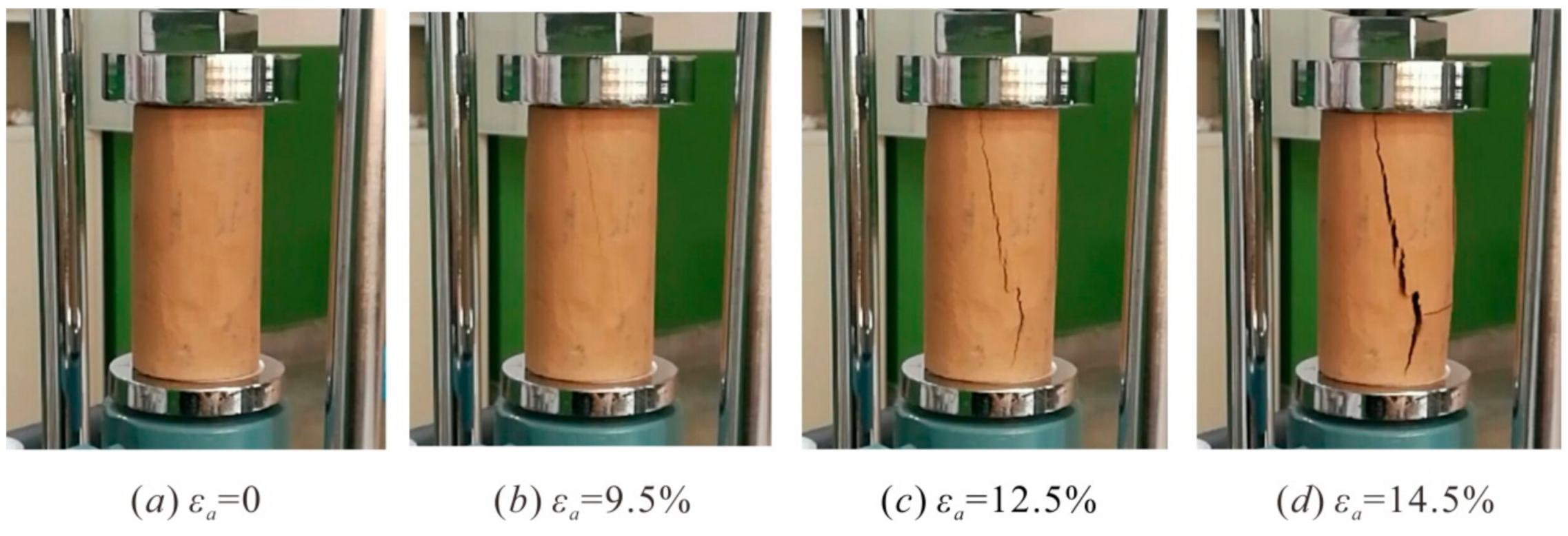

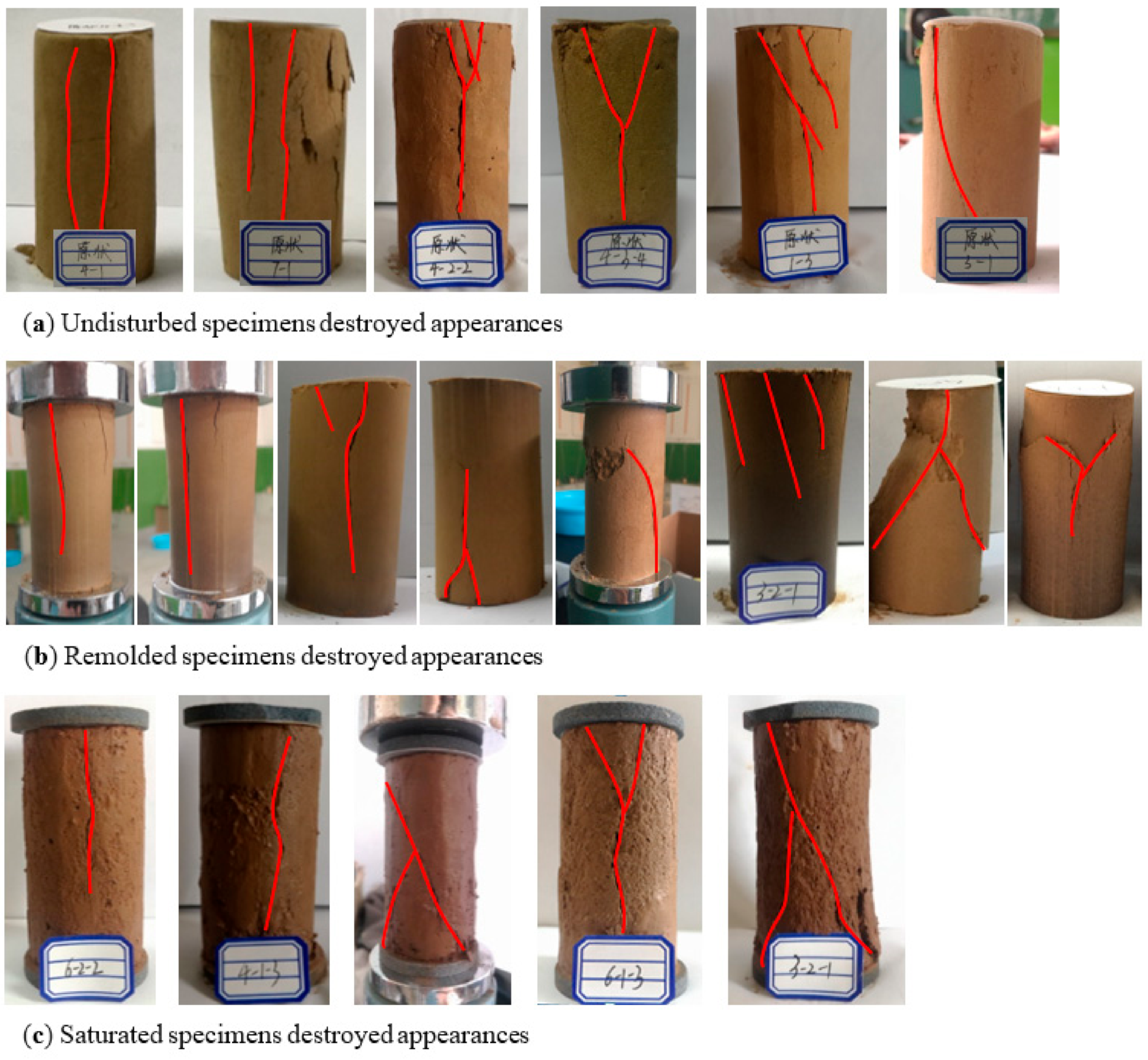

2.2. Laboratory Test

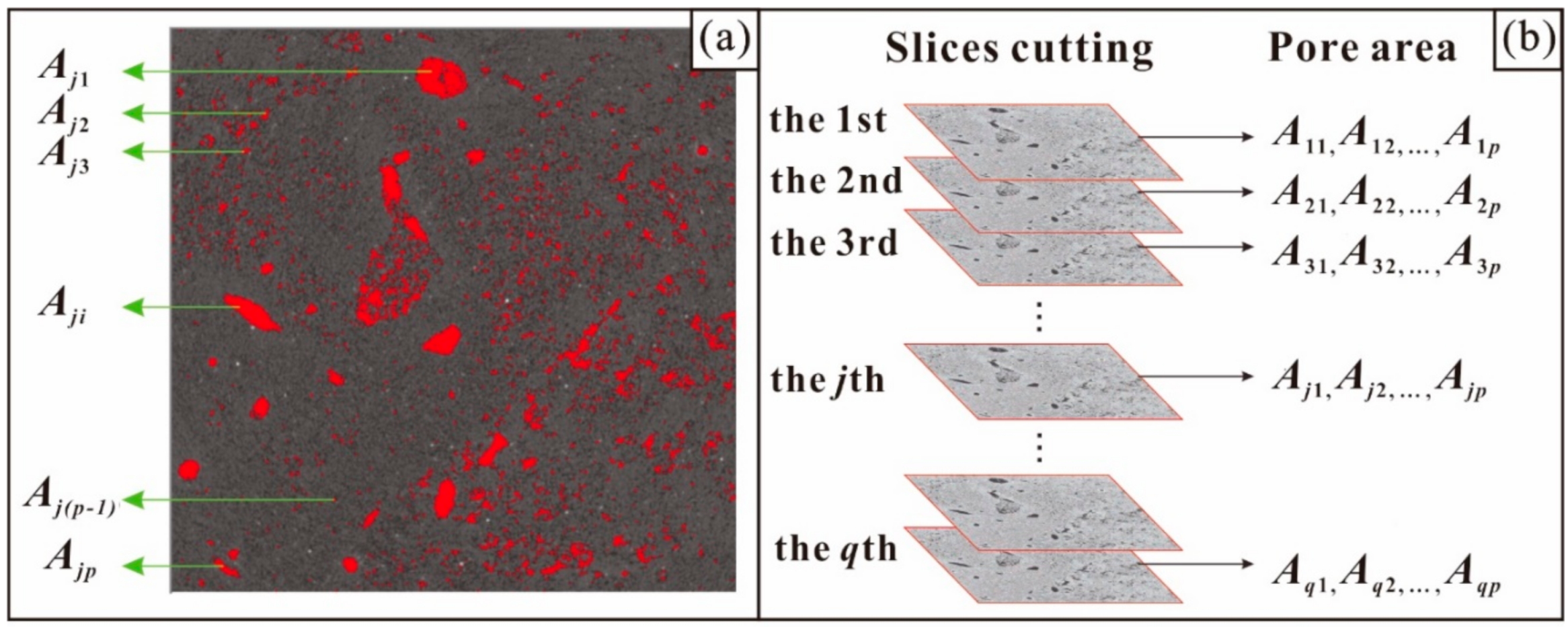

2.3. Computerized Tomography (CT) Scanning

3. Results

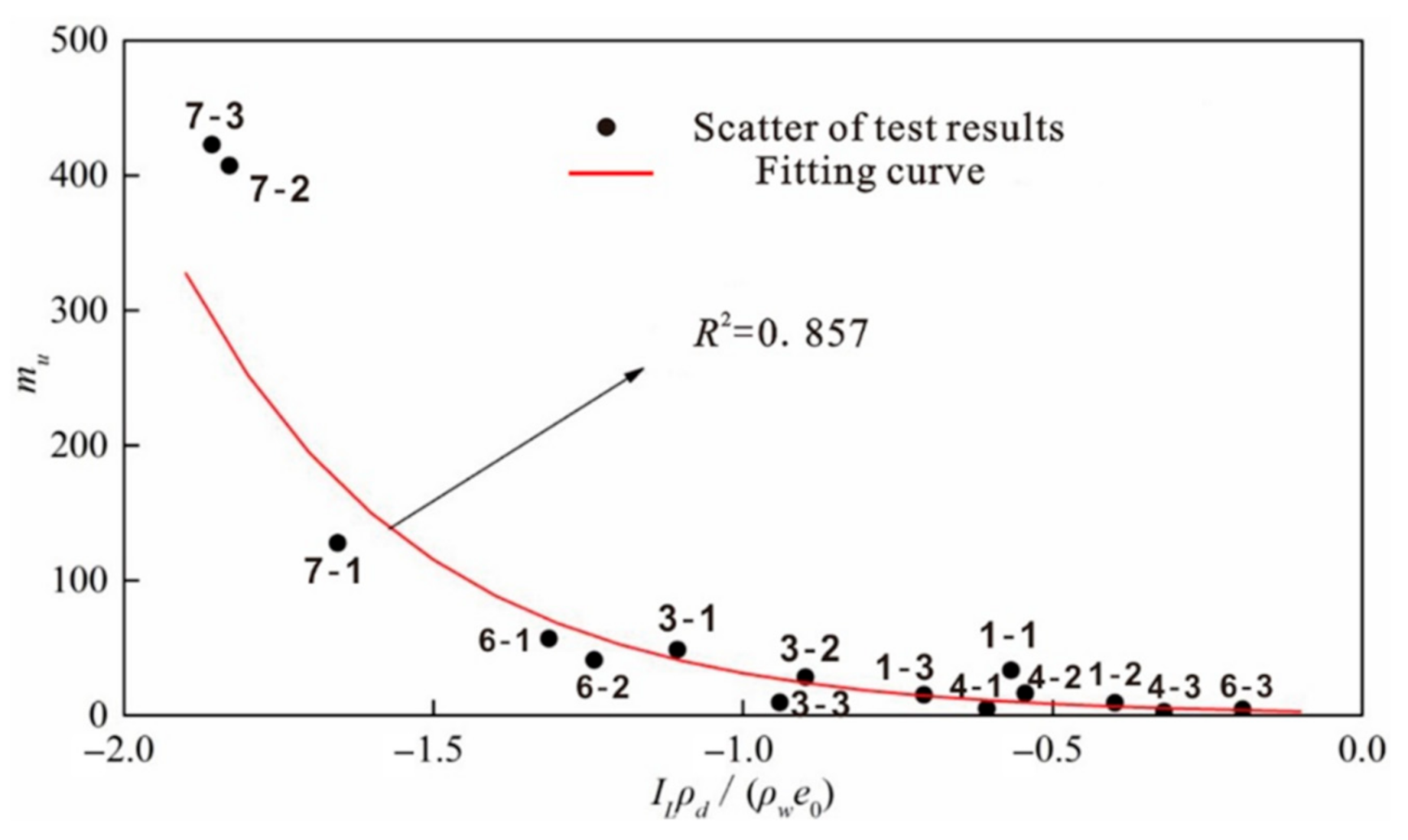

3.1. Results of Laboratory Tests

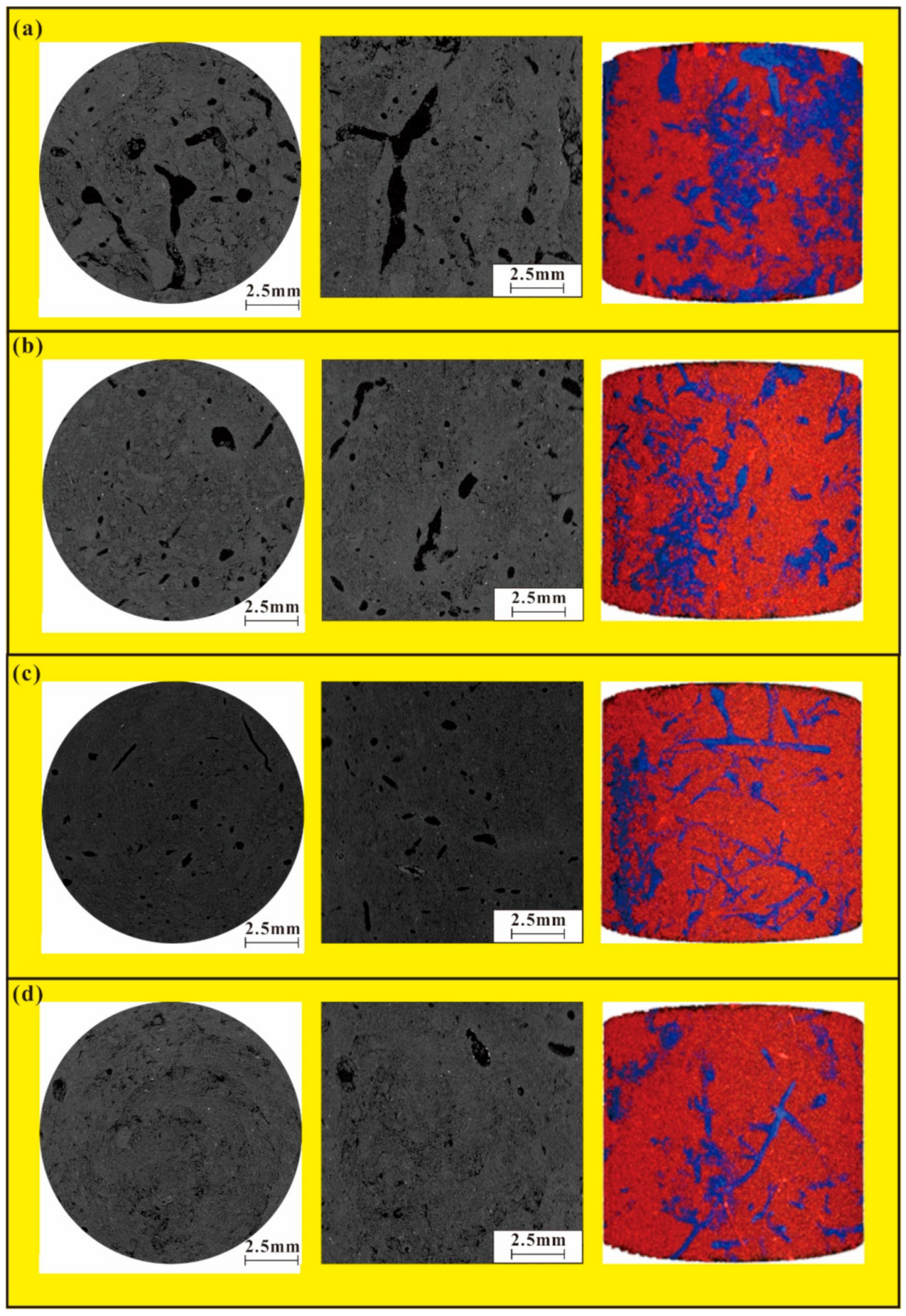

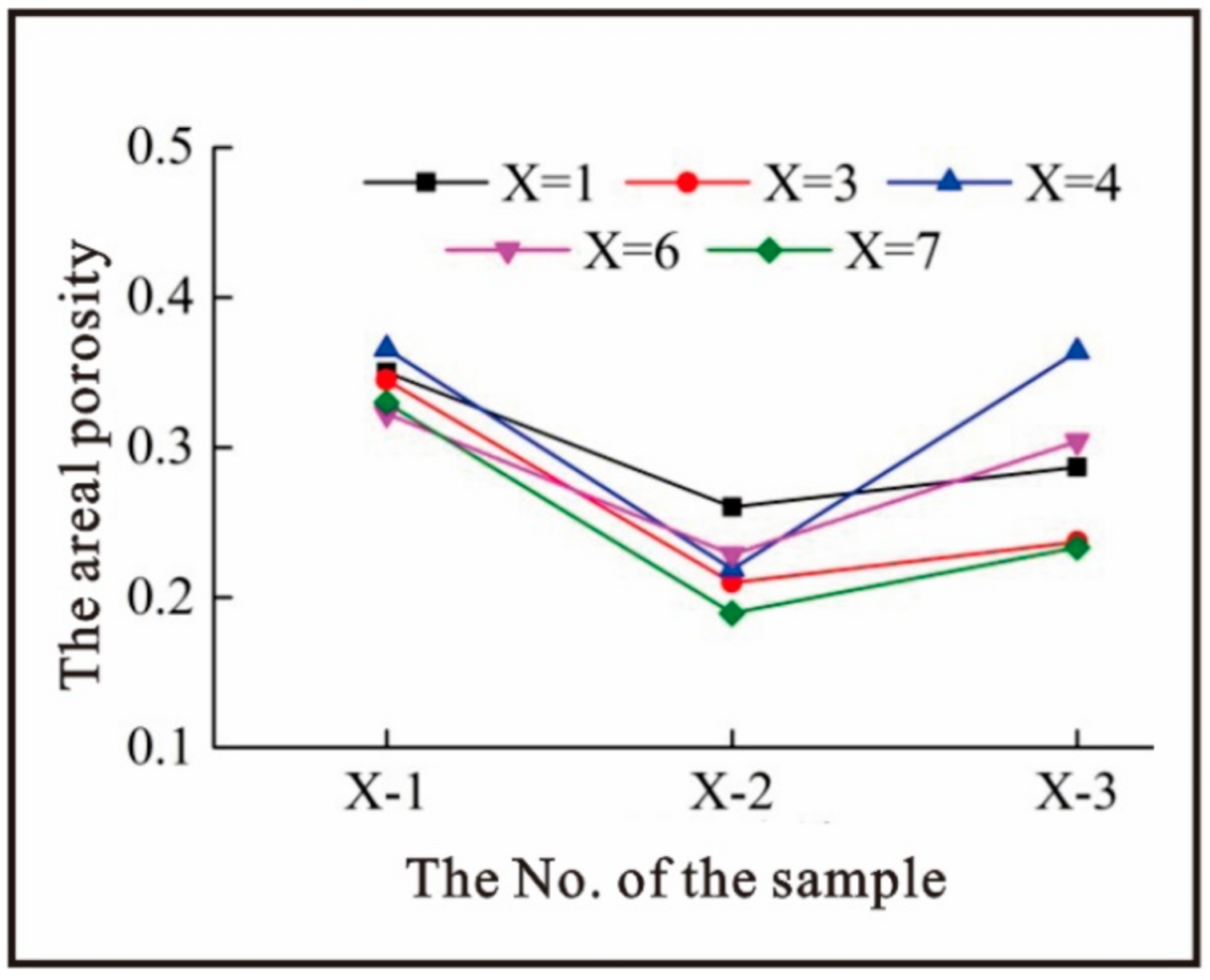

3.2. Results of CT Scanning

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ng, C.W.W.; Sadeghi, H.; Hossen, S.K.B.; Chiu, C.F.; Alonso, E.E.; Baghbanrezvan, S. Water retention and volumetric characteristics of intact and re-compacted loess. Can. Geotech. J. 2016, 53, 1258–1269. [Google Scholar] [CrossRef]

- Shao, S.; Wang, L.; Tao, H.; Wang, Q.; Wang, S. Structural index of loess and its relation with granularity, density and humidity; in Chinese with English abstract. Chin. J. Geotech. Eng. 2014, 36, 1387–1393. [Google Scholar]

- Assallay, A.M.; Rogers, C.D.F.; Smalley, I.J. Formation and collapse of metastable particle packings and open structures in loess deposits. Eng. Geol. 1997, 48, 101–115. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, G.; Kamai, T.; Chen, W.; Zhang, D.; Yang, J. Undrained shear behavior of loess saturated with different concentrations of sodium chloride solution. Eng. Geol. 2013, 155, 69–79. [Google Scholar] [CrossRef] [Green Version]

- Wei, W.; Chen, L.; Fu, B.; Huang, Z.; Wu, D.; Gui, L. The effect of land uses and rainfall regimes on runoff and soil erosion in the semi-arid loess hilly area, China. J. Hydrol. 2007, 335, 247–258. [Google Scholar] [CrossRef]

- Wei, W.; Chen, L.; Zhang, H.; Yang, L.; Yu, Y.; Chen, J. Effects of crop rotation and rainfall on water erosion on a gentle slope in the hilly loess area, China. Catena 2014, 123, 205–214. [Google Scholar] [CrossRef]

- Derbyshire, E. Geological hazards in loess terrain, with particular reference to the loess regions of China. Earth Sci. Rev. 2001, 54, 231–290. [Google Scholar] [CrossRef]

- Peng, J.; Leng, Y.; Zhu, X.; Wu, D.; Tong, X. Development of a loess-mudstone landslide in a fault fracture zone. Environ. Earth Sci. 2016, 75, 658–668. [Google Scholar] [CrossRef]

- Tang, Y.; Feng, F.; Guo, Z.; Feng, W.; Li, Z.; Wang, J.; Sun, Q.; Ma, H.; Li, Y. Integrating principal component analysis with statistically-based models for analysis of causal factors and landslide susceptibility mapping: A comparative study from the loess plateau area in Shanxi (China). J. Clean. Prod. 2020, 277, 124159. [Google Scholar] [CrossRef]

- Zhou, J.; Zhu, C.; Zheng, J.; Wang, X.; Liu, Z. Landslide disaster in the loess area of China. J. For. Res. 2002, 13, 157–161. [Google Scholar]

- Wang, R.; Dong, Z.; Zhou, Z.; Wang, P. Temporal variation in preferential water flow during natural vegetation restoration on abandoned farmland in the Loess Plateau of China. Land 2019, 8, 186. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Liang, Y.; Zhang, H.; Wu, Y.; Lin, X. A loess landslide induced by excavation and rainfall. Landslides 2014, 11, 141–152. [Google Scholar] [CrossRef]

- Zhuang, J.; Peng, J. A coupled slope cutting—A prolonged rainfall-induced loess landslide: A 17 October 2011 case study. Bull. Eng. Geol. Environ. 2014, 73, 997–1011. [Google Scholar] [CrossRef]

- Tang, Y.; Xue, Q.; Li, Z.; Feng, W. Three modes of rainfall infiltration inducing loess landslide. Nat. Hazards. 2015, 79, 137–150. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, J. Controlling factors of loess landslides in western China. Environ. Earth Sci. 2010, 59, 1671–1680. [Google Scholar] [CrossRef]

- Ma, F.; Yang, J.; Bai, X. Water sensitivity and microstructure of completed loess. Transp. Geotech. 2017, 11, 41–56. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; Li, Y. Land engineering consolidates degraded sandy land for agricultural development in the largest sandy land of China. Land 2020, 9, 199. [Google Scholar] [CrossRef]

- Keesstra, S.D.; Bouma, J.; Wallinga, J.; Tittonell, P.; Smith, P.; Cerdà, A.; Montanarella, L.; Quinton, J.N.; Pachepsky, Y.; van der Putten, W.H.; et al. The significance of soils and soil science towards realization of the United Nations Sustainable Development Goals. Soil 2016, 2, 111–128. [Google Scholar] [CrossRef] [Green Version]

- Visser, S.; Keesstra, S.; Maas, G.; De Cleen, M. Soil as a Basis to Create Enabling Conditions for Transitions Towards Sustainable Land Management as a Key to Achieve the SDGs by 2030. Sustainability 2019, 11, 6792. [Google Scholar] [CrossRef] [Green Version]

- Keesstra, S.; Mol, G.; De Leeuw, J.; Okx, J.; De Cleen, M.; Visser, S. Soil-related sustainable development goals: Four concepts to make land degradation neutrality and restoration work. Land 2018, 7, 133. [Google Scholar] [CrossRef] [Green Version]

- Koliji, A.; Vulliet, L.; Laloui, L. Structural characterization of unsaturated aggregated soil. Can. Geotech. J. 2010, 47, 297–311. [Google Scholar] [CrossRef]

- Mitchell, J.K. Fundamentals of Soil Behavior; John Wiley & Sons: New York, NY, USA, 1993. [Google Scholar]

- Chen, H.; Jiang, Y.; Gao, Y.; Yuan, X. Structural characteristics and its influencing factors of typical loess. Bull. Eng. Geol. Environ. 2018, 78, 4893–4905. [Google Scholar] [CrossRef]

- Zhang, W.; Sun, Y.; Chen, W.; Song, Y.; Zhang, J. Collapsibility, composition, and microfabric of the coastal zone loess around the Bohai Sea, China. Eng. Geol. 2019, 257, 105142. [Google Scholar] [CrossRef]

- Li, P.; Xie, W.; Pak, R.Y.S.; Vanapalli, S.K. Microstructural evolution of loess soils from the Loess Plateau of China. Catena 2019, 173, 276–288. [Google Scholar] [CrossRef]

- Mokritskaya, T.P.; Tushev, A.V.; Samoylich, K.A.; Baranov, P.N. Deformations of loess soils caused by changes in the microaggregate structure. Bull. Eng. Geol. Environ. 2019, 78, 3729–3739. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, T.; Zhang, Y.; Xu, Q. Geometrical appearance and spatial arrangement of structural blocks of the Malan loess in NW China: Implications for the formation of loess columns. J. Asian Earth Sci. 2018, 158, 18–28. [Google Scholar] [CrossRef]

- Baudet, B.; Stallebrass, S. A constitutive model for structured clays. Geotechnique 2004, 54, 269–278. [Google Scholar] [CrossRef]

- Suebsuk, J.; Horpibulsuk, S.; Liu, M. A critical state model for overconsolidated structured clays. Comput. Geotech. 2011, 38, 648–658. [Google Scholar] [CrossRef]

- Robin, V.; Javadi, A.A.; Cuisinier, O.; Masrouri, F. An effective constitutive model for lime treated soils. Comput. Geotech. 2015, 66, 189–202. [Google Scholar] [CrossRef]

- Shao, S.; Zhou, F.; Long, J. Structural properties of loess and its quantitative parameter; in Chinese with English abstract. Chin. J. Geotech. Eng. 2004, 26, 531–536. [Google Scholar]

- Shao, S.; Zheng, W.; Wang, Z.; Wang, S. Structural index of loess and its testing method; in Chinese with English abstract. Rock Soil Mech. 2010, 31, 15–19. [Google Scholar]

- Wang, L.; Shao, S.; Lu, Z. Influence of physical properties on the initial structure of loess. Rock Soil Mech. 2017, 38, 3484–3490. [Google Scholar]

- Qin, P.; Shao, S.; An, Z.; Zhu, F.; Zheng, X. The initial state of the soil structural quantitative research and verification; in Chinese with English abstract. J. Xi’an Univ. Technol. 2015, 31, 448–453. [Google Scholar]

- Yue, Z.; Chen, S.; Tham, L.G. Finite element modeling of geomaterials using digital image processing. Comput. Geotech. 2003, 30, 375–397. [Google Scholar] [CrossRef]

- Sasanian, S.; Newson, T.A. Use of mercury intrusion porosimetry for microstructural investigation of reconstituted clays at high water contents. Eng. Geol. 2013, 158, 15–22. [Google Scholar] [CrossRef]

- Gomez-Gonzalez, M.A.; Garcia-Guinea, J.; Laborda, F.; Garrido, F. Thallium occurrence and partitioning in soils and sediments affected by mining activities in Madrid province (Spain). Sci. Total Environ. 2015, 536, 268–278. [Google Scholar] [CrossRef] [Green Version]

- Herrmann, K.H.; Pohlmeier, A.; Gembris, D.; Vereecken, H. Three-dimensional imaging of pore water diffusion and motion in porous media by nuclear magnetic resonance imaging. J. Hydrol. 2002, 267, 244–257. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Wu, Y.; Lin, C.; Zhang, B. Experimental study on meso-damage cracking characteristics of RSA by CT test. Environ. Earth Sci. 2015, 73, 5545–5558. [Google Scholar] [CrossRef]

- Xu, W.; Yue, Z.; Hu, R. Study on the mesostructure and mesomechanical characteristics of the soil-rock mixture using digital image processing based finite element method. Int. J. Rock Mech. Min. Sci. 2008, 45, 749–762. [Google Scholar] [CrossRef]

- Razavi, M.; Muhunthan, B.; Hattamleh, O. Representative elementary volume analysis of sands using X-ray computed tomography. Geotech. Test. J. 2007, 30, 478–490. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, W.; Yu, Y. Triaxial tests of soil–rock mixtures with different rock block distributions. Soils Found. 2016, 56, 44–56. [Google Scholar] [CrossRef] [Green Version]

- Matsushima, T.; Katagiri, J.; Uesugi, K.; Tsuchiyama, A.; Nakano, T. 3D shape characterization and image-based DEM simulation of the lunar soil simulant FJS-1. J. Aerosp. Eng. 2009, 22, 15–23. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; He, S.; Deng, X.; Xu, Y. Characterization of macropore structure of Malan loess in NW China based on 3D pipe models constructed by using computed tomography technology. J. Asian Earth Sci. 2018, 154, 271–279. [Google Scholar] [CrossRef]

- Lehmkuhl, F.; Zens, J.; Krauß, L.; Schulte, P.; Kels, H. Loess-paleosol sequences at the northern European loess belt in Germany: Distribution, geomorphology and stratigraphy. Quat. Sci. Rev. 2016, 153, 11–30. [Google Scholar] [CrossRef]

- Shao, T.; Wang, R.; Xu, Z.; Wei, P.; Zhao, J.; Niu, J.; Song, D. Permeability and Groundwater Enrichment Characteristics of the Loess-Paleosol Sequence in the Southern Chinese Loess Plateau. Water 2020, 12, 870. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.; Ebach, M.C.; Triantafilis, J. Cladistic analysis of Chinese Soil Taxonomy. Geoderma Reg. 2017, 10, 11–20. [Google Scholar] [CrossRef]

- Jiang, J.; Xiang, W.; Rohn, J.; Schleier, M.; Pan, J.; Zhang, W. Research on mechanical parameters of coarse-grained sliding soil based on CT scanning and numerical tests. Landslides 2016, 13, 1261–1272. [Google Scholar] [CrossRef]

- Monnet, J.M.; Bourrier, F.; Dupire, S.; Berger, F. Suitability of airborne laser scanning for the assessment of forest protection effect against rockfall. Landslides 2017, 14, 299–310. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Tang, H.; Liu, X.; Tan, Q.; Xiahou, Y. Seepage and Instability Characteristics of Slope Based on Spatial Variation Structure of Saturated Hydraulic Conductivity; in Chinese with English abstract. Earth Sci. 2018, 43, 622–634. [Google Scholar]

- Rodrigo-Comino, J.; Terol, E.; Mora, G.; Giménez-Morera, A.; Cerdà, A. Vicia sativa Roth. Can Reduce Soil and Water Losses in Recently Planted Vineyards (Vitis vinifera L.). Earth. Syst. Environ. 2020, 4, 827–842. [Google Scholar] [CrossRef]

- Novara, A.; Cerda, A.; Barone, E.; Gristina, L. Cover crop management and water conservation in vineyard and olive orchards. Soil Tillage Res. 2021, 208, 104896. [Google Scholar] [CrossRef]

- Cerdà, A.; Daliakopoulos, I.N.; Terol, E.; Novara, A.; Fatahi, Y.; Moradi, E.; Salvati, L.; Pulido, M. Long-term monitoring of soil bulk density and erosion rates in two Prunus Persica (L) plantations under flood irrigation and glyphosate herbicide treatment in La Ribera district, Spain. J. Environ. Manag. 2021, 282, 111965. [Google Scholar] [CrossRef] [PubMed]

| Sample ID | Dry Density ρd (g/cm3) | Pore Ratio e0 | Liquidity Index IL | Physical Index ILρd/(ρwe0) | Unconfined Compressive Strength (kPa) | Structural Index mu | ||

|---|---|---|---|---|---|---|---|---|

| Undisturbed q0 | Remolded qr | Saturated qs | ||||||

| 1-1 | 1.35 | 0.99 | −0.81 | −1.10 | 226.39 | 40.39 | 26.15 | 48.52 |

| 1-2 | 1.52 | 0.78 | −0.85 | −1.66 | 437.82 | 99.04 | 15.18 | 127.48 |

| 1-3 | 1.49 | 0.84 | −1.05 | −1.86 | 458.96 | 78.61 | 6.34 | 422.76 |

| 3-1 | 1.33 | 1.03 | −0.73 | −0.94 | 112.84 | 51.65 | 26.15 | 9.43 |

| 3-2 | 1.52 | 0.78 | −0.46 | −0.90 | 166.98 | 80.35 | 12.28 | 28.26 |

| 3-3 | 1.35 | 0.98 | −0.41 | −0.56 | 303.88 | 99.02 | 28.01 | 33.30 |

| 4-1 | 1.33 | 1.03 | −0.55 | −0.71 | 213.81 | 120.78 | 24.76 | 15.29 |

| 4-2 | 1.55 | 0.75 | −0.60 | −1.24 | 388.89 | 268.30 | 13.78 | 40.91 |

| 4-3 | 1.44 | 0.97 | −0.13 | −0.19 | 51.11 | 96.62 | 6.09 | 4.44 |

| 6-1 | 1.35 | 1.00 | −0.45 | −0.61 | 55.56 | 24.76 | 25.55 | 4.88 |

| 6-2 | 1.45 | 0.86 | −0.19 | −0.32 | 75.46 | 70.07 | 28.99 | 2.80 |

| 6-3 | 1.45 | 0.87 | −0.24 | −0.40 | 115.79 | 57.02 | 25.35 | 9.27 |

| 7-1 | 1.25 | 1.15 | −0.50 | −0.54 | 101.42 | 32.96 | 19.02 | 16.41 |

| 7-2 | 1.45 | 0.87 | −1.10 | −1.83 | 365.34 | 129.31 | 2.54 | 407.10 |

| 7-3 | 1.39 | 0.94 | −0.89 | −1.32 | 102.22 | 71.27 | 2.58 | 56.92 |

| Sample | Sampling Depth/m | Total Volume/μm3 | Porosity/% | Volume of the Soil Particles/μm3 | Volume of the Pores/μm3 | Amount of the Pores |

|---|---|---|---|---|---|---|

| 1-1 | 3 | 4214.33 | 16.28 | 3528.24 | 686.09 | 102,685 |

| 1-2 | 5 | 4214.33 | 13.40 | 3649.61 | 564.72 | 103,452 |

| 1-3 | 10 | 4214.33 | 11.58 | 3726.31 | 488.02 | 110,246 |

| 3-1 | 3 | 4214.33 | 11.66 | 3722.94 | 491.39 | 108,795 |

| 3-2 | 7 | 4214.33 | 12.34 | 3694.28 | 520.05 | 104,335 |

| 3-3 | 9 | 4214.33 | 10.61 | 3767.19 | 447.14 | 105,324 |

| 4-1 | 3 | 4214.33 | 9.89 | 3797.53 | 416.80 | 156,039 |

| 4-2 | 14 | 4214.33 | 8.96 | 3836.73 | 377.60 | 135,986 |

| 4-3 | 16.5 | 4214.33 | 7.12 | 3914.27 | 300.06 | 184,345 |

| 6-1 | 3 | 4214.33 | 10.24 | 3782.78 | 431.55 | 144,770 |

| 6-2 | 3.5 | 4214.33 | 6.23 | 3951.78 | 262.55 | 177,705 |

| 6-3 | 4.5 | 4214.33 | 8.93 | 3837.99 | 376.34 | 119,389 |

| 7-1 | 3 | 4214.33 | 11.92 | 3711.98 | 502.35 | 129,583 |

| 7-2 | 7.5 | 4214.33 | 13.25 | 3655.93 | 558.40 | 149,248 |

| 7-3 | 13.5 | 4214.33 | 10.06 | 3790.37 | 423.96 | 159,328 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Y.; Bi, Y.; Guo, Z.; Li, Z.; Feng, W.; Wang, J.; Li, Y.; Ma, H. A Novel Method for Obtaining the Loess Structural Index from Computed Tomography Images: A Case Study from the Lvliang Mountains of the Loess Plateau (China). Land 2021, 10, 291. https://doi.org/10.3390/land10030291

Tang Y, Bi Y, Guo Z, Li Z, Feng W, Wang J, Li Y, Ma H. A Novel Method for Obtaining the Loess Structural Index from Computed Tomography Images: A Case Study from the Lvliang Mountains of the Loess Plateau (China). Land. 2021; 10(3):291. https://doi.org/10.3390/land10030291

Chicago/Turabian StyleTang, Yaming, Yinqiang Bi, Zizheng Guo, Zhengguo Li, Wei Feng, Jiayun Wang, Yane Li, and Hongna Ma. 2021. "A Novel Method for Obtaining the Loess Structural Index from Computed Tomography Images: A Case Study from the Lvliang Mountains of the Loess Plateau (China)" Land 10, no. 3: 291. https://doi.org/10.3390/land10030291