Reliability Assessment of Long-Service Gravity Dams Based on Historical Water Level Monitoring Data

Abstract

1. Introduction

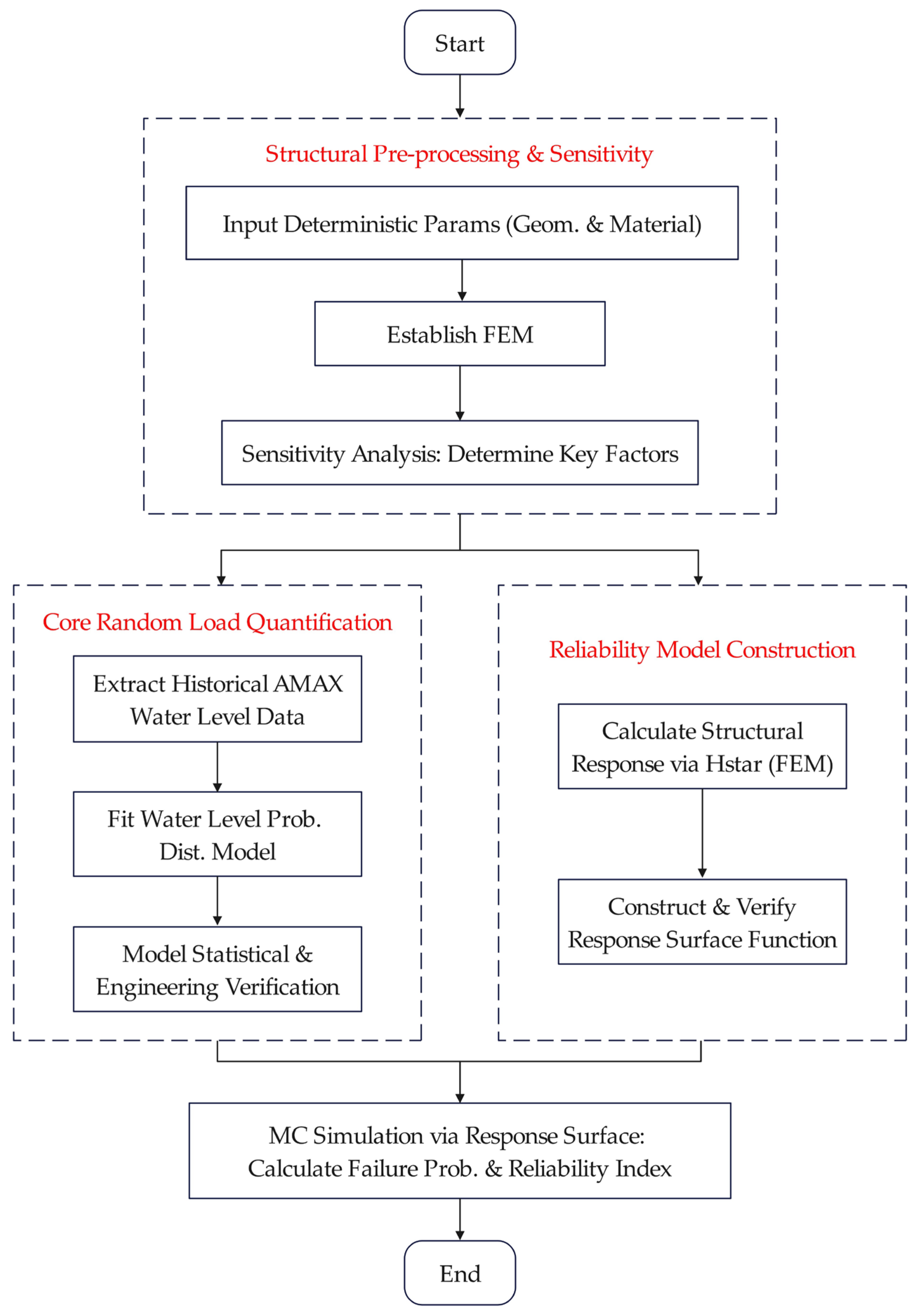

2. Water Level Load Distribution Model

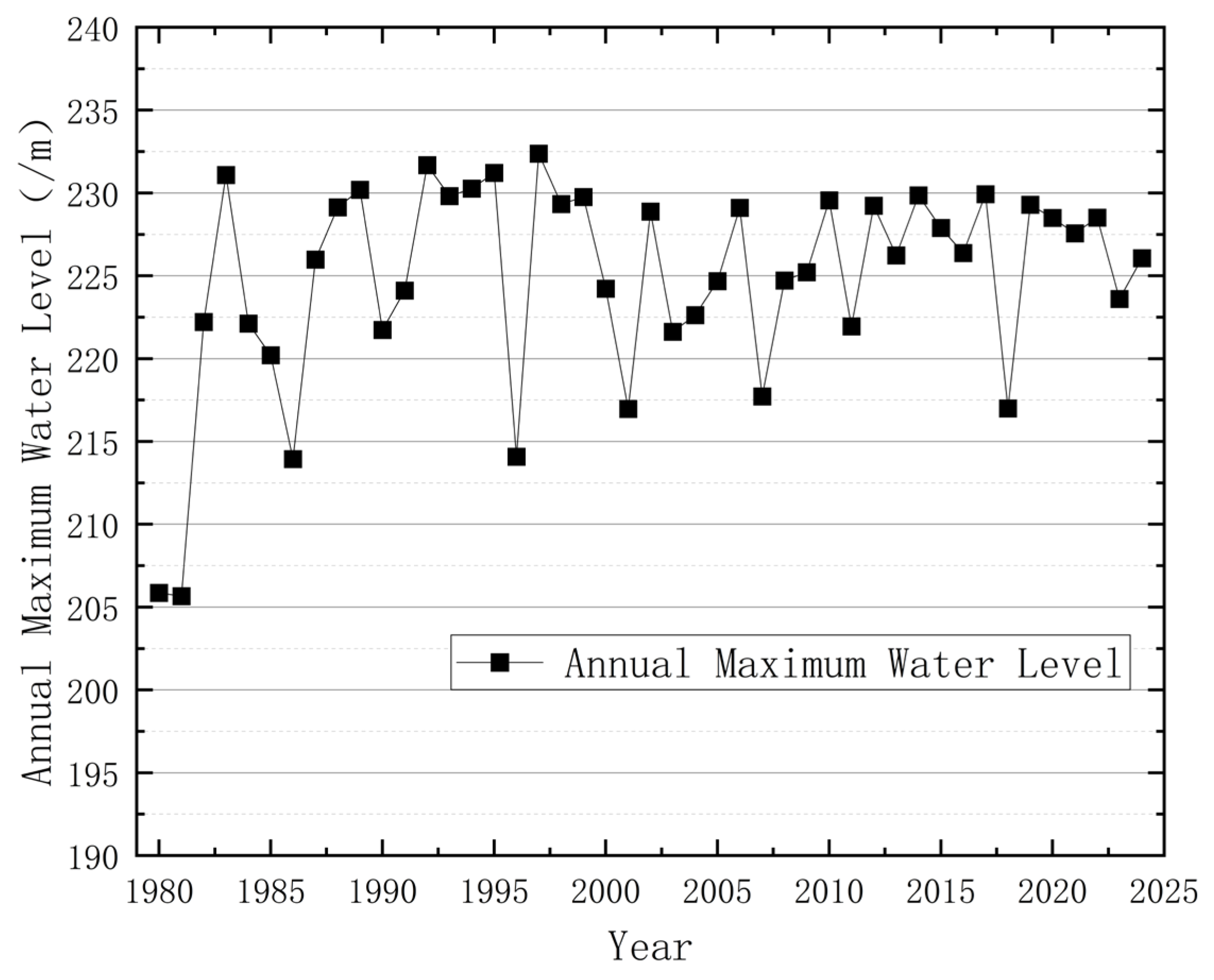

2.1. Historical Water Level Statistical Characteristic Model

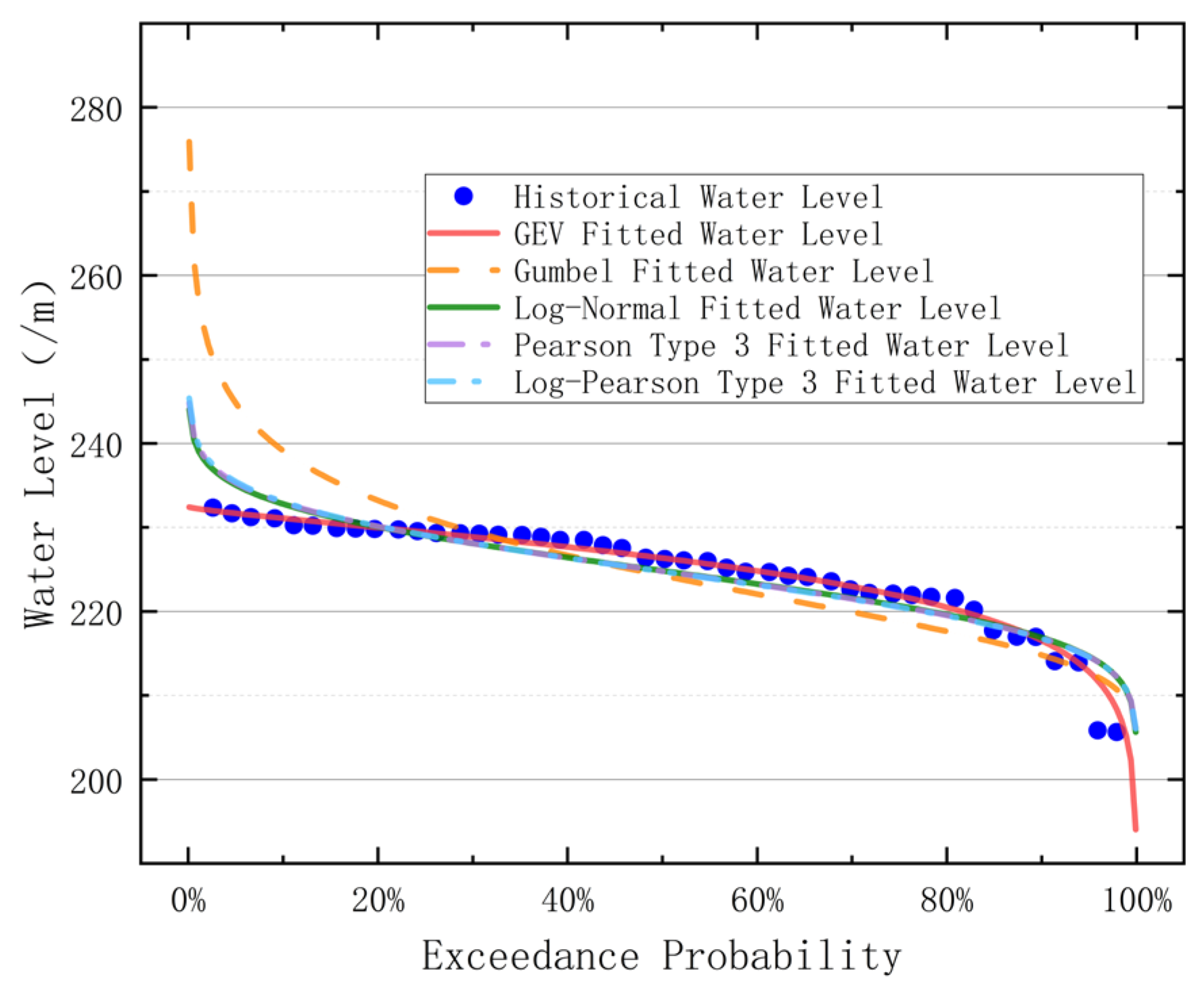

2.2. Robustness and Uncertainty Validation for Model Parameter Estimation

3. Gravity Dam Reliability Analysis Model

3.1. Failure Modes and Analysis Model

- 1.

- Failure by Cracking of the Plinth Heel:

- 2.

- Failure by Crushing of the Plinth Toe:

- 3.

- Failure by Sliding along the Foundation Plane:

3.2. Reliability Calculation Method

3.3. Integrated Reliability Analysis Framework Based on Historical Water Level Distribution

4. Engineering Application

4.1. Project Overview

4.2. Computational Model

5. Discussion

5.1. Sensitivity Analysis

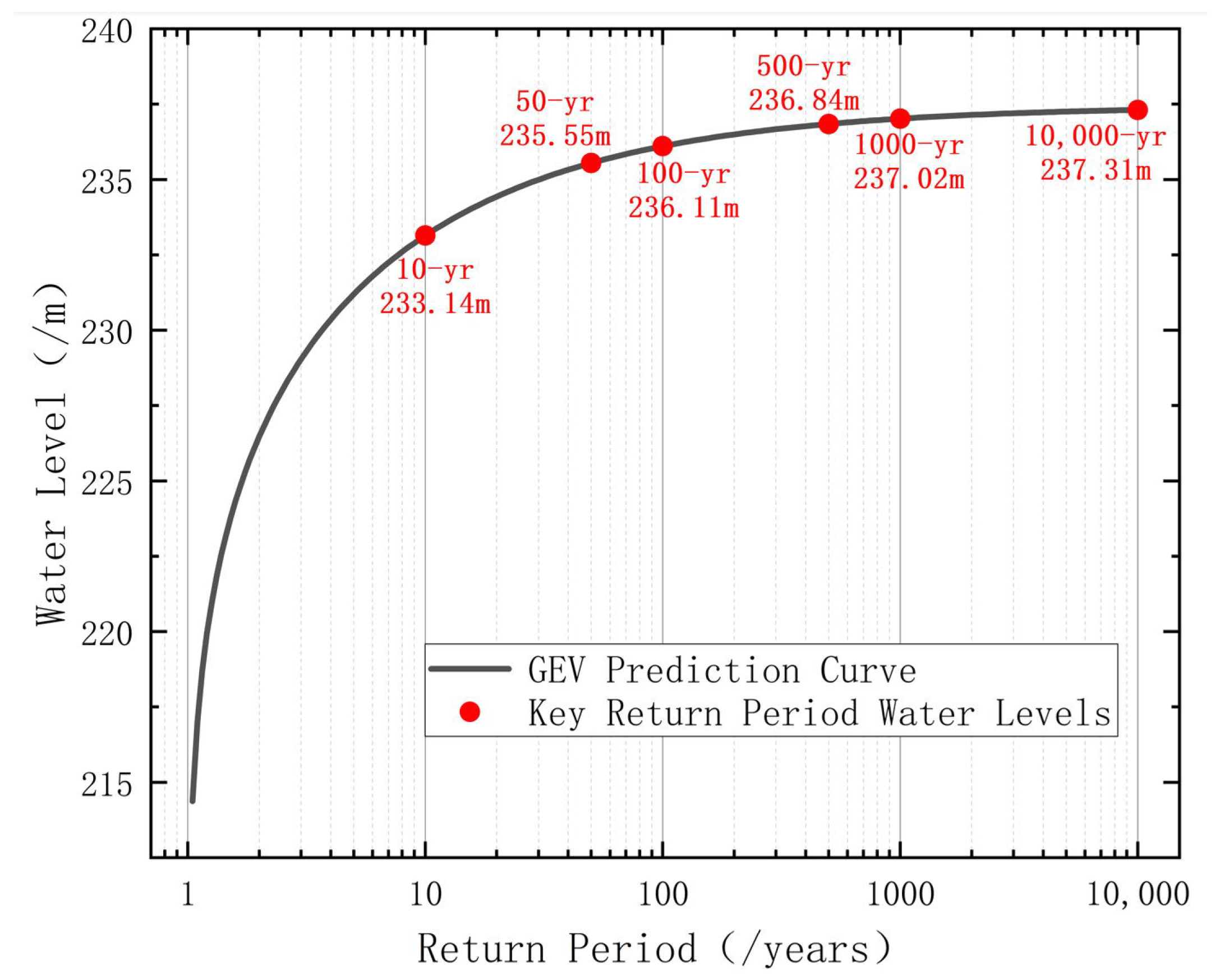

5.2. Historical Water Level Statistical Characteristic Analysis

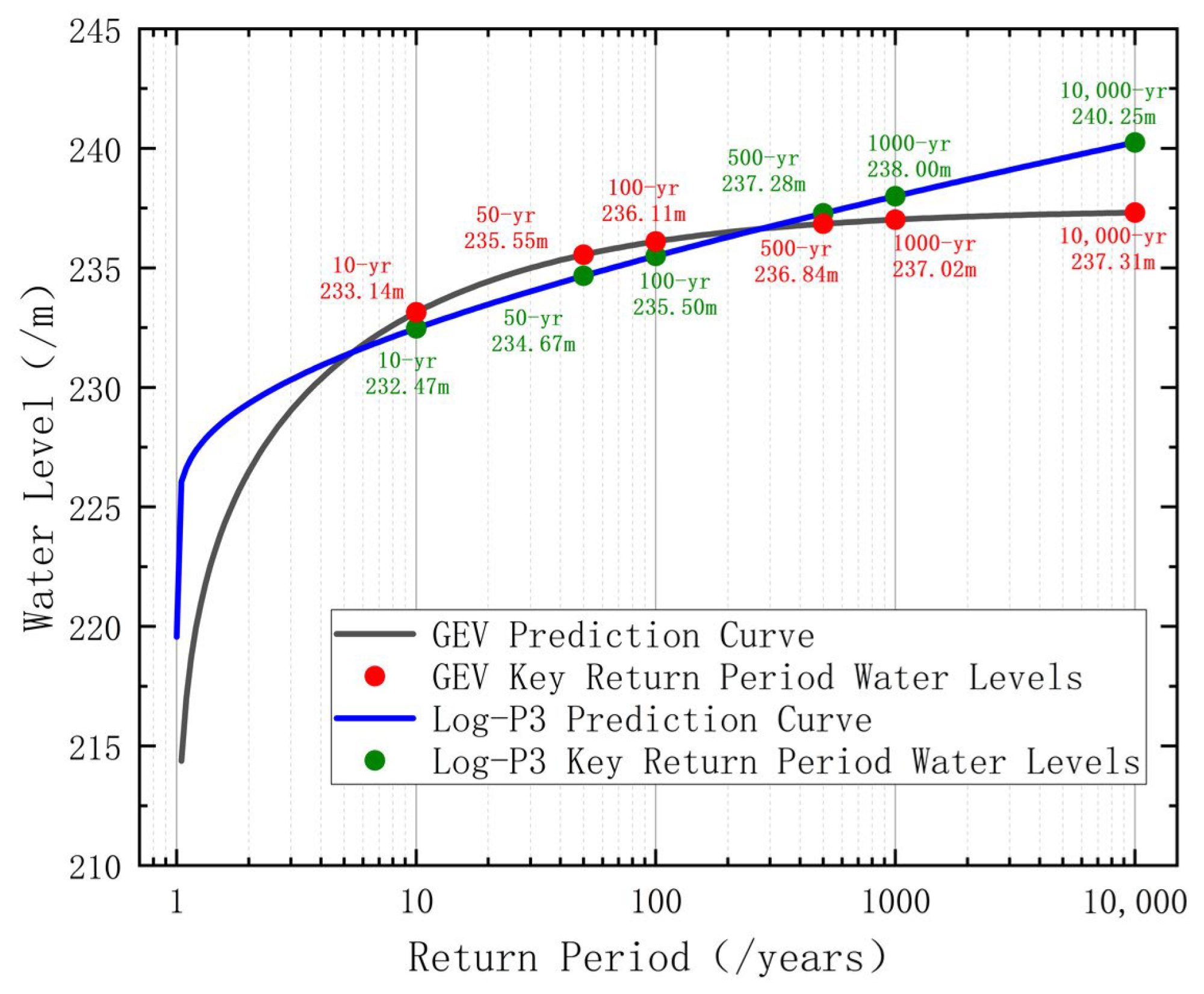

5.3. Rationale and Comparative Analysis of the GEV Water Level Model

- 1.

- Engineering System Risk Positioning of Extreme Variables

- 2.

- Robustness and Uncertainty Validation for GEV Model Parameter Estimation

- 3.

- Validation of Engineering Physical Boundary Constraints

5.4. Reliability Analysis

5.5. Reliability Result Analysis for Different Water Level Models

- Among all calculated conditions, cracking at the dam heel is the most sensitive to the water level load distribution, exhibiting the largest magnitude variation in its probability of failure, with the probability of failure differing by nearly six times between the Log-P3 model (4.3 × 10−5) and the GEV model (7.5 × 10−6). It should be noted that the current reliability assessment is based on the assumption of a linear elastic material model (Section 4.2). For the failure mode of cracking at the dam heel, which is controlled by a tensile limit state, the linear elastic assumption may potentially overestimate local tensile stresses compared to nonlinear fracture mechanics models. However, the use of a linear elastic model combined with the allowable tensile stress limit (0.1 MPa) specified in the code (SL319—2018) is a conservative practice widely adopted in preliminary reliability assessments of hydraulic structures. Future work will consider incorporating a nonlinear fracture model to further refine the tensile failure probability. While sliding along the dam base is primarily controlled by material properties such as the friction coefficient and cohesion; the crushing at the dam toe failure mode maintains an extremely low probability of failure across all models, which is due to the concrete’s compressive strength being much greater than its tensile strength, and a large safety margin being reserved in the design.

- The probability of failure calculated by the Uniform Distribution model is significantly lower than the other two models. This result quantitatively proves that the Uniform Distribution has an inherent statistical flaw due to its inability to accurately reflect the extreme characteristics of the annual maximum water level, leading to a severe underestimation of the high-water-level risk.

- The probability of failure for the GEV model (actual operational risk) is significantly lower than the Log-P3 model (design risk). This difference stems from the distinct characterization of the extreme value probability density by the models: The Log-P3 curve (natural sequence) has a steeper tail, assigning higher weight to high water levels that approach the structural limit state. Given that gravity dam failure occurs in the extremely small probability region of high water load, the conservative estimation of the dangerous tail by Log-P3 directly increases the number of failure samples. Therefore, the higher reliability index of the GEV model is rational, as it precisely reflects the risk reduction effect of human control. This strongly proves the scientific validity of the GEV model for assessing the true safety level of long-service dams under long-term control.

- Finally, it should be noted that this reliability analysis focuses on quantifying the uncertainty of the water level load. For other material parameters, although they were treated as random variables, a more complex probability density function (PDF) fitting was not performed. Future work will incorporate the uncertainty of material and geometric parameters more comprehensively to enhance the comprehensiveness of the system reliability assessment.

6. Conclusions

- This study is the first to systematically utilize long-term operational monitoring data to construct a GEV model-based probability distribution of systemic operational extremes for human-controlled reservoirs. The model’s rationality and reliability are statistically proven through the K-S test and Bootstrap robustness analysis, providing a new paradigm for transforming long-term dam monitoring data into scientific risk input.

- By comparison with the commonly used Uniform Distribution model in engineering, the GEV model is confirmed to be able to more accurately capture high-water-level uncertainty, effectively overcoming the inherent risk underestimation problem of simple distributions, and providing a more refined basis for risk quantification.

- The probability of failure for the Historical Operational GEV model is significantly lower than the Design Code Log-P3 model. For the most sensitive failure mode (cracking at the dam heel), the GEV model’s probability of failure is approximately six times lower than that of the Log-P3 model. This quantitative result reveals that the Log-P3 model yields overly conservative assessment results due to its conservative estimation of the probability density of the extreme tail risk. The comparison powerfully demonstrates that the GEV model can precisely reflect the risk reduction effect of human control, providing a more scientific basis for true operational risk assessment of long-service gravity dams. From a practical standpoint, the GEV-RSM-MC framework established in this study offers decision support for operational management. It allows managers to perform an operational recalibration of the design safety margin based on actual running data, guiding more scientific risk prevention and resource allocation. For example, when the GEV model demonstrates that the actual risk is significantly lower than the design risk, it can inform the optimization of operating rules or maintenance budgets.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gu, C.S.; Su, H.Z.; Liu, H.Z. Review of Research on Dam Service Risk Analysis and Management. J. Hydraul. Eng. 2018, 49, 26–35. [Google Scholar]

- Yan, L. Research on Dam Operation Safety Risk Analysis Methods. Ph.D. Thesis, Tianjin University, Tianjin, China, 2013. [Google Scholar]

- Song, S.B. Research Progress in Stochastic Modeling of Hydrological Non-Stationary Heteroscedastic Series Under Changing Watershed Environments. J. Water Resour. Water Eng. 2023, 34, 1–6. [Google Scholar]

- Bai, T.; Xu, Y.; Sun, X.G.; Wei, J.; Pan, X. Study on Multi-Objective Operation Rules and Schemes of Guanting Reservoir. Water Resour. Prot. 2023, 39, 101–108, 124. [Google Scholar]

- Crozier, H.; Jiang, L. Uncertainty in Dam Failure Probability Assessment. Express Water Resour. Hydropower Inf. 2005, 6, 23–25. [Google Scholar]

- Li, Y.; Zhao, H.; Wei, Y.; Bao, T.; Li, T.; Wang, Q.; Wang, N.; Zhao, M. Vision-guided crack identification and size quantification framework for dam underwater concrete structures. Struct. Health Monit. 2024, 24, 2125–2148. [Google Scholar] [CrossRef]

- Li, Y.; Bao, T.; Huang, X.; Chen, H.; Xu, B.; Shu, X.; Zhou, Y.; Cao, Q.; Tu, J.; Wang, R.; et al. Underwater crack pixel-wise identification and quantification for dams via lightweight semantic segmentation and transfer learning. Autom. Constr. 2022, 144, 104600. [Google Scholar] [CrossRef]

- Li, Y.; Bao, T.; Li, T.; Wang, R. A robust real-time method for identifying hydraulic tunnel structural defects using deep learning and computer vision. Comput.-Aided Civ. Infrastruct. Eng. 2023, 38, 1381–1399. [Google Scholar] [CrossRef]

- Li, Y.; Bao, T.; Huang, X.; Wang, R.; Shu, X.; Xu, B.; Tu, J.; Zhou, Y.; Zhang, K. An integrated underwater structural multi-defects automatic identification and quantification framework for hydraulic tunnel via machine vision and deep learning. Struct. Health Monit. 2023, 22, 2360–2383. [Google Scholar] [CrossRef]

- U.S. Bureau of Reclamation (USBR); U.S. Army Corps of Engineers (USACE). Best Practices in Dam and Levee Safety Risk Analysis; U.S. Bureau of Reclamation: Denver, CO, USA, 2019. [Google Scholar]

- GB 51247-2018; Seismic Design Standard for Hydraulic Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2018.

- Dai, L. Impact Analysis of Cascade Reservoir Operation on Downstream Reservoir Flood Control and Power Generation. Ph.D. Thesis, Huazhong University of Science and Technology, Wuhan, China, 2023. [Google Scholar]

- Chen, L.C.; Chen, J.K.; Gui, Z.; Dai, P.; Zi, J.J.; Huang, H.J.; Wang, J.T. Dynamic Reliability Analysis of RCC Gravity Dam Based on Response Spectrum Method. China Rural Water Hydropower 2009, 9, 118–120. [Google Scholar]

- Jiang, S.H.; Hou, J.G.; He, Y.M. Reliability Analysis of Deep Anti-sliding Stability System for Gravity Dam Based on Weighted Response Surface Method. J. Hydraul. Eng. 2011, 42, 337–343. [Google Scholar]

- Jiang, S.H.; Zhang, M.; Li, D.Q. Reliability Analysis of Gravity Dam Based on Hermite Orthogonal Polynomial Approximation Method. Eng. J. Wuhan Univ. 2011, 44, 170–174. [Google Scholar]

- Chen, S.; Lin, C.; Gu, Y.; Sheng, J.; Hariri-Ardebili, M.A. Dam Deformation Data Preprocessing with Optimized Variational Mode Decomposition and Kernel Density Estimation. Remote Sens. 2025, 17, 718. [Google Scholar] [CrossRef]

- Chen, S.; Gu, C.; Lin, C.; Zhang, K.; Zhu, Y. Multi-kernel optimized relevance vector machine for probabilistic prediction of concrete dam displacement. Eng. Comput. 2021, 37, 1943–1959. [Google Scholar] [CrossRef]

- Lin, C.; Li, T.; Chen, S.; Yuan, L.; van Gelder, P.; Yorke-Smith, N. Long-term viscoelastic deformation monitoring of a concrete dam: A multi-output surrogate model approach for parameter identification. Eng. Struct. 2022, 266, 114553. [Google Scholar] [CrossRef]

- Lin, C.; Du, X.; Chen, S.; Li, T.; Zhou, X.; van Gelder, P.H.A.J.M. On the multi-parameters identification of concrete dams: A novel stochastic inverse approach. Int. J. Numer. Anal. Methods Geomech. 2024, 48, 3792–3810. [Google Scholar] [CrossRef]

- Lin, C.; Chen, S.; Hariri-Ardebili, M.A.; Li, T. An explainable probabilistic model for health monitoring of concrete dam via optimized sparse bayesian learning and sensitivity analysis. Struct. Control Health Monit. 2023, 2023, 2979822. [Google Scholar] [CrossRef]

- Li, T.C.; Li, D.D.; Wang, Z.Q. Reliability Analysis of Tensile Strength of Gravity Dam Based on Finite Element Response Surface Method. Hydro-Sci. Eng. 2009, 4, 100–104. [Google Scholar]

- Cheng, J.; Ma, X.Y.; Zhang, L.; Li, Z.Y.; Hu, Z.L. Time-Varying Reliability Calculation and Analysis of Gravity Dam Based on Stochastic Finite Element Method. Yellow River 2020, 42, 100–103. [Google Scholar]

- Yang, G.; Cai, Y.J.; Ma, Y.F.; Wu, Q.; Liu, X.J.; Zhang, L.Y. Efficient Reliability Analysis of Gravity Dam Stability and Stress Considering Seepage Effects. J. Civ. Environ. Eng. 2024, 47, 145–154. [Google Scholar]

- Zeng, B.; Wang, K.; Deng, L.S.; Liu, Z. Seismic Reliability Analysis of Gravity Dams Based on Non-stationary Stochastic Ground Motion Model. Chin. J. Earthq. Eng. 2017, 39, 467–474. [Google Scholar]

- Zhu, B.F.; Xu, P. Temperature Stress and Temperature Control of Roller Compacted Concrete Gravity Dams. Water Resour. Hydropower Eng. 1996, 4, 18–25. [Google Scholar]

- Li, S.Q.; Song, Z.Q.; Yao, Q.R.; Liu, K.; Liu, Y.H. Reliability Analysis of Anti-sliding Stability of Gravity Dams with Double Randomness of Ground Motion and Structural Parameters. J. Water Resour. Water Eng. 2022, 33, 148–153. [Google Scholar]

- Liu, Y.Y.; Lin, C.N.; Liu, X.Q.; Du, X.H.; Zhou, X.B. Rapid Solution Method for Static and Dynamic Reliability of Gravity Dam Anti-sliding Stability Based on Finite Element Method. J. China Three Gorges Univ. (Nat. Sci.) 2023, 45, 8–13. [Google Scholar]

- SL 44-2006; Water Conservancy and Hydropower Engineering Design Flood Calculation Standard. China Water Power Press: Beijing, China, 2006.

- Zhang, H.; Kang, F. Based on Bootstrap Multiple Mediation Effect Analysis Method. Stat. Decis. 2016, 5, 75–78. [Google Scholar]

- Coles, S. An Introduction to Statistical Modeling of Extreme Values; Springer: London, UK, 2001. [Google Scholar]

- Hosking, J.R.M.; Wallis, J.R.; Wood, E.F. Estimation of the generalized extreme-value distribution by the method of probability-weighted moments. Technometrics 1985, 27, 251–261. [Google Scholar] [CrossRef]

- Hosking, J.R.M.; Wallis, J.R. Regional Frequency Analysis: An Approach Based on L-Moments; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- SL 319-2018; Concrete Gravity Dam Design. China Water Power Press: Beijing, China, 2018.

- Chen, Y.F.; Zhou, C.B. Inversion of Elastoplastic Mechanical Parameters of Geheyan Dam Foundation Rock Mass During Operation Period. J. Rock Mech. Eng. 2002, 7, 968–975. [Google Scholar]

- Zhu, H.B.; He, L.J. Research on Applicable Conditions for Consistency Tests of Normal Distribution Using One-Sample K-S Test in SPSS. J. Cap. Inst. Phys. Educ. 2009, 21, 466–470. [Google Scholar]

- Li, B.; Zhou, X.B.; Sun, P. Influence of Shear Strength Parameters on Reliability Index of Anti-Sliding Stability. Adv. Sci. Technol. Water Resour. 2014, 34, 31–35. [Google Scholar]

- Zhang, J.Z.; Li, G.Q. Discussion on System Reliability and Probabilistic Life of Service Gravity Dam. J. Hydraul. Eng. 2000, 4, 40–45. [Google Scholar]

| Material | Elastic Modulus (GPa) | Poisson’s Ratio | Unit Weight (kN/m3) |

|---|---|---|---|

| Dam Body | 24 | 0.167 | 24 |

| Dam Foundation | 20 | 0.25 | 26 |

| Control Indices | Unit Weight of Dam Body | Unit Weight of Dam Foundation | Elastic Modulus of Dam Body | Elastic Modulus of Dam Foundation | Poisson’s Ratio of Dam Body | Poisson’s Ratio of Dam Foundation | Upstream Water Level | Coefficient of Friction | Cohesion |

|---|---|---|---|---|---|---|---|---|---|

| Cracking at Plinth Heel | 0.1380 | 0.0017 | 0.0586 | −0.0704 | 0.0271 | −0.0279 | −0.7047 | / | / |

| Crushing at Plinth Toe | 0.0385 | 0.0019 | 0.0388 | −0.0466 | 0.0140 | −0.0150 | 0.3842 | / | / |

| Sliding along Foundation Plane | 0.0389 | 0.0012 | −0.0047 | 0.0056 | −0.0356 | 0.0118 | −0.0921 | 0.3869 | 0.0003 |

| Model | p-Value |

|---|---|

| GEV | 0.8246 |

| Gumbel | 0.0215 |

| Log-Normal | 0.2796 |

| Pearson3 | 0.2841 |

| Log-Pearson3 | 0.2876 |

| Random Variable | Unit | Distribution Type | Mean Value | Coefficient of Variation |

|---|---|---|---|---|

| Unit Weight of Dam Body | kN/m3 | Normal Distribution | 24 | 0.03 |

| Coefficient of Friction | Dimensionless | Normal Distribution | 1.2 | 0.22 |

| Compressive Strength of Concrete | MPa | Normal Distribution | 25 | 0.16 |

| Failure by Cracking of the Plinth Heel | Failure by Crushing of the Plinth Toe | Failure by Sliding Along the Foundation Plane |

|---|---|---|

| 0.99662 | 0.99878 | 0.99266 |

| Water Level Model | Cracking at Plinth Heel | Crushing at Plinth Toe | Sliding Along Foundation Plane | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Number of Failures | Probability of Failure | Reliability Index | Number of Failures | Probability of Failure | Reliability Index | Number of Failures | Probability of Failure | Reliability Index | |

| Uniform Distribution | 45 | 4.5 × 10−6 | 4.44 | 5 | 5.0 × 10−7 | 4.89 | 23 | 2.3 × 10−6 | 4.55 |

| Historical Data GEV | 75 | 7.5 × 10−6 | 4.33 | 6 | 6.0 × 10−7 | 4.83 | 88 | 8.8 × 10−6 | 4.29 |

| Design Condition Log-P3 | 432 | 4.3 × 10−5 | 3.93 | 6 | 6.0 × 10−7 | 4.83 | 89 | 8.9 × 10−6 | 4.28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Qi, H.; Li, Z.; Du, X.; Lin, C.; Sheng, T.; Li, T. Reliability Assessment of Long-Service Gravity Dams Based on Historical Water Level Monitoring Data. Water 2025, 17, 3374. https://doi.org/10.3390/w17233374

Lu Y, Qi H, Li Z, Du X, Lin C, Sheng T, Li T. Reliability Assessment of Long-Service Gravity Dams Based on Historical Water Level Monitoring Data. Water. 2025; 17(23):3374. https://doi.org/10.3390/w17233374

Chicago/Turabian StyleLu, Yuzhou, Huijun Qi, Ziwei Li, Xiaohu Du, Chaoning Lin, Taozhen Sheng, and Tongchun Li. 2025. "Reliability Assessment of Long-Service Gravity Dams Based on Historical Water Level Monitoring Data" Water 17, no. 23: 3374. https://doi.org/10.3390/w17233374

APA StyleLu, Y., Qi, H., Li, Z., Du, X., Lin, C., Sheng, T., & Li, T. (2025). Reliability Assessment of Long-Service Gravity Dams Based on Historical Water Level Monitoring Data. Water, 17(23), 3374. https://doi.org/10.3390/w17233374