Pressure Pulsation and Energy Dissipation Mechanism of a Pump-Turbine Considering Runner Blade Leading Edge Effect

Abstract

1. Introduction

2. Numerical Model and Methodology

2.1. Governing Equations

2.1.1. Fluid Dynamics

2.1.2. Theory of Entropy Production

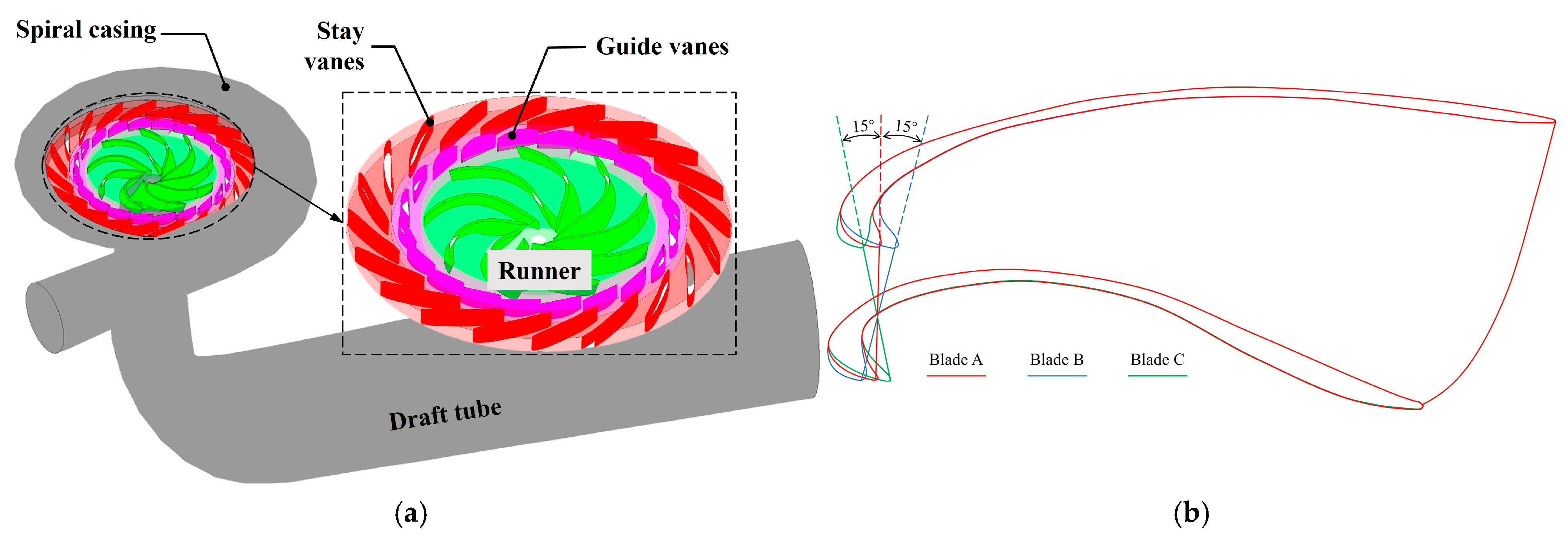

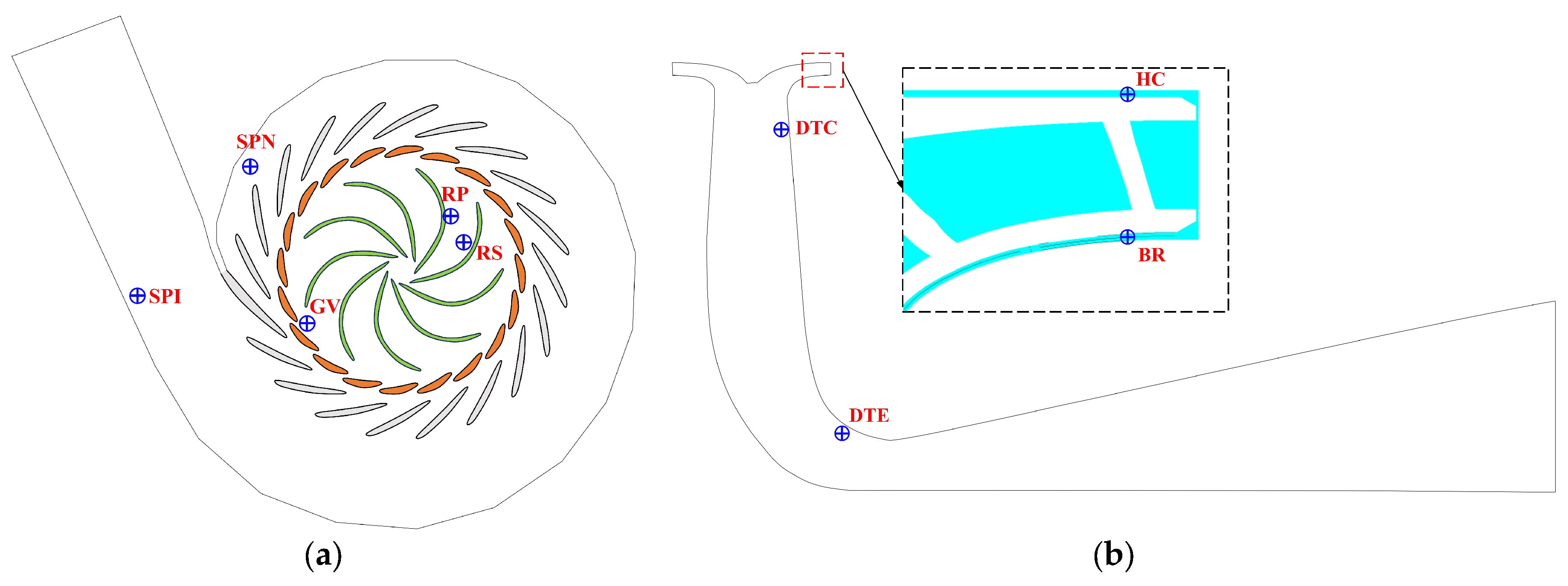

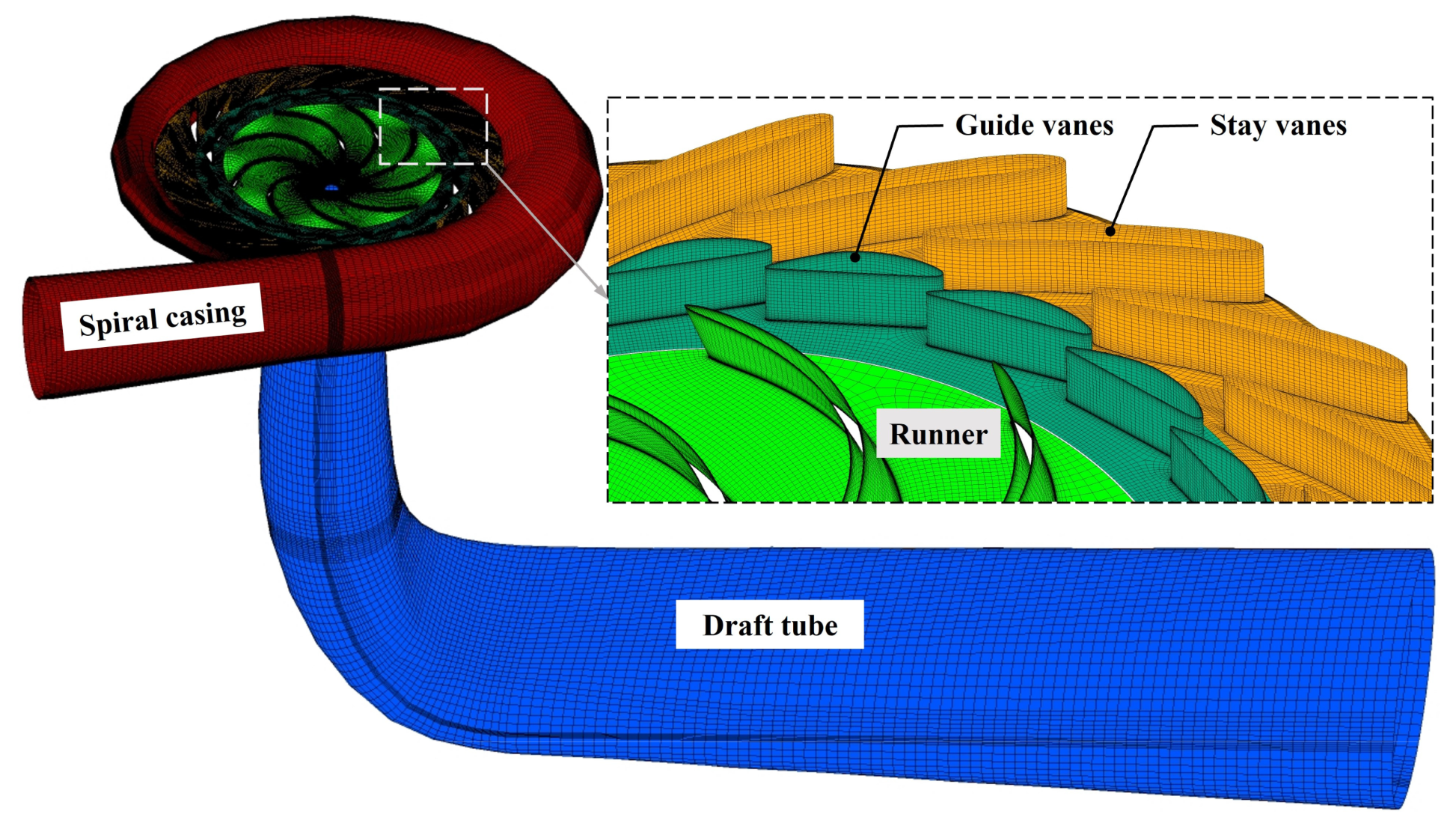

2.2. Numerical Model

2.3. Boundary Conditions

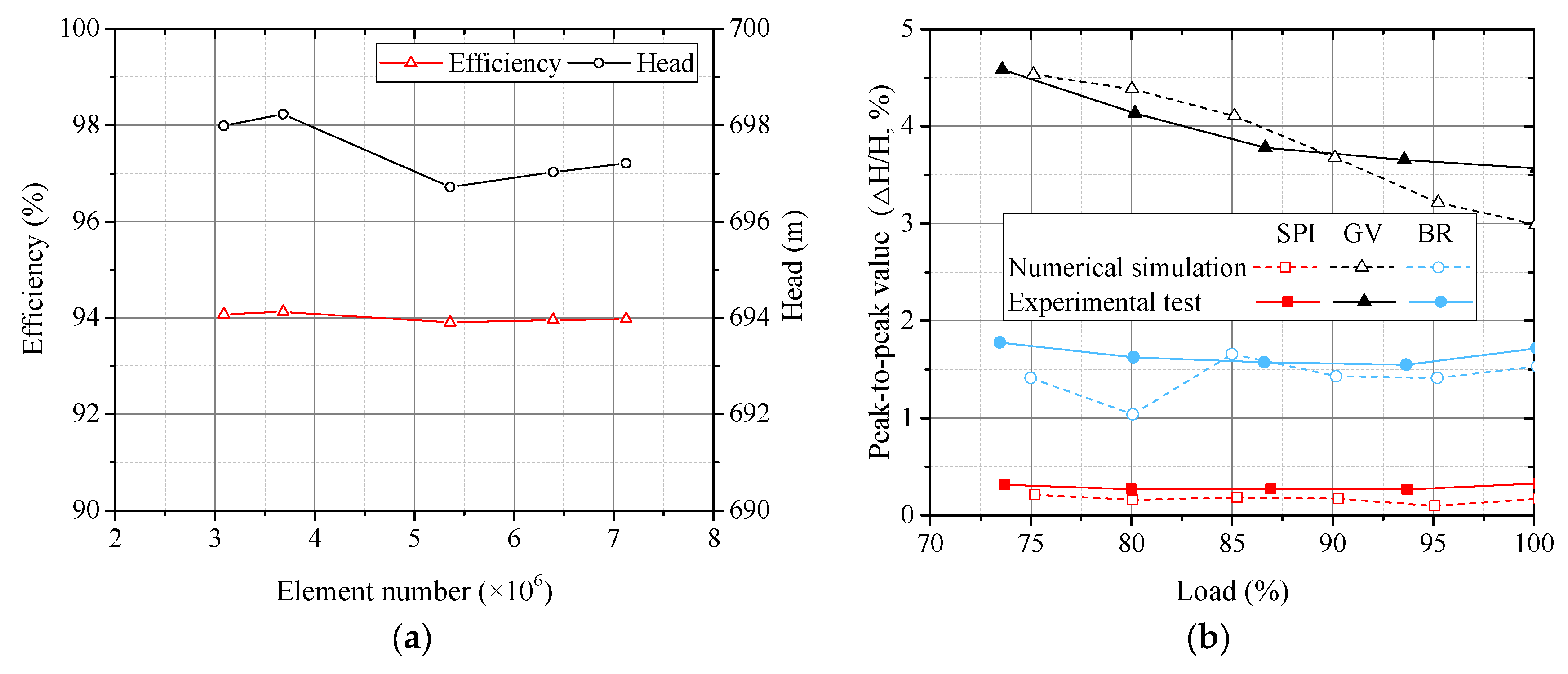

2.4. Grid-Independent Checks and Method Validation

3. Results and Discussion

3.1. Hydraulic Performance

3.1.1. Efficiency at Turbine and Pump Modes

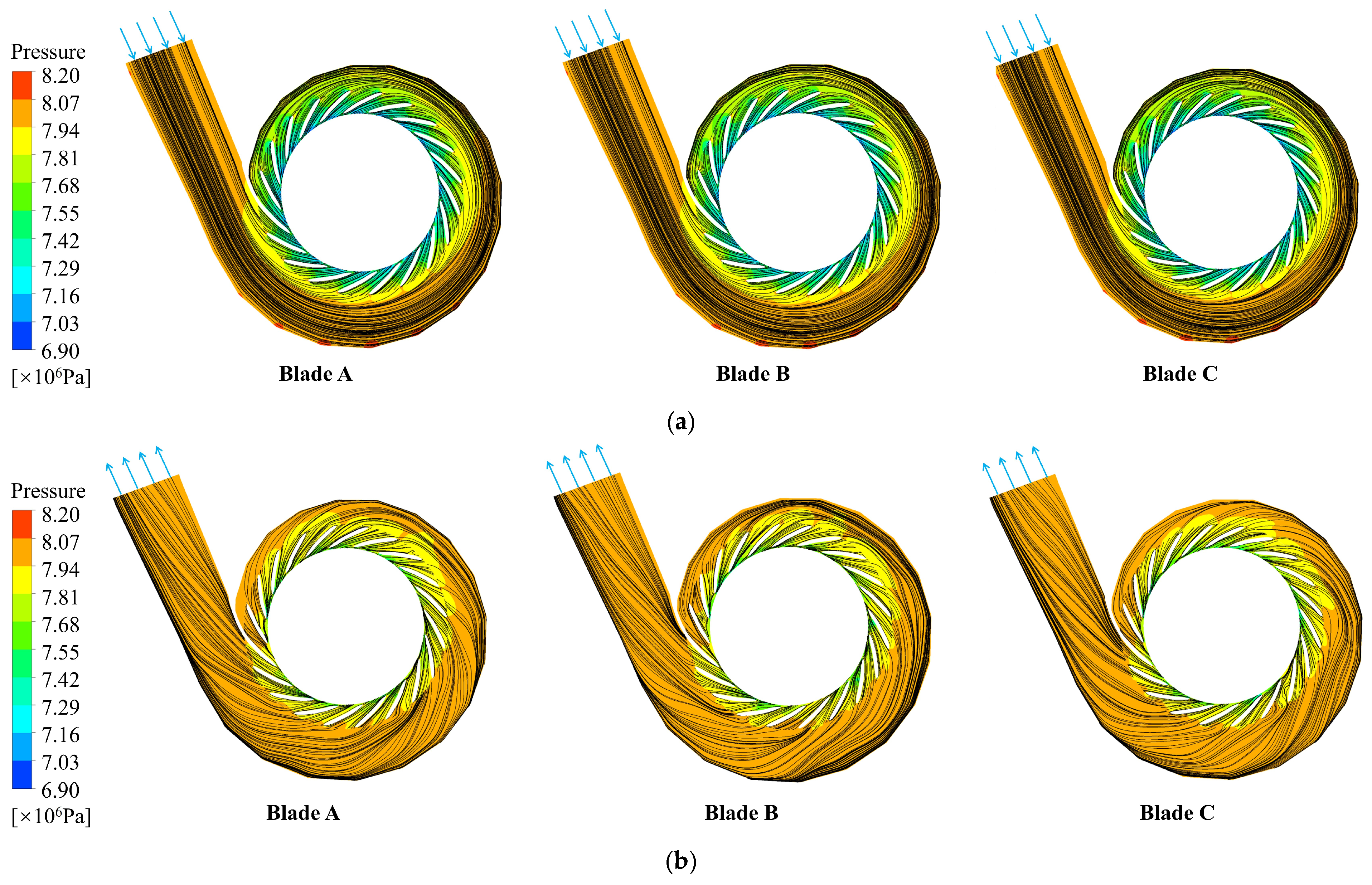

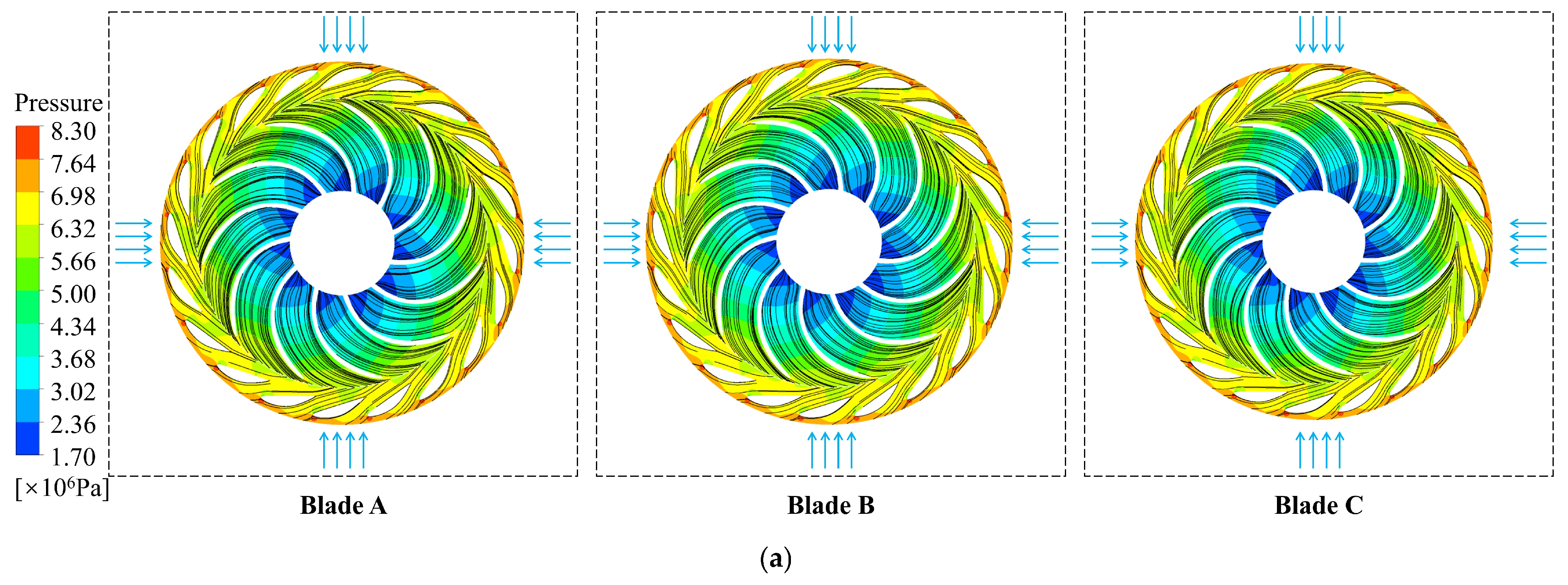

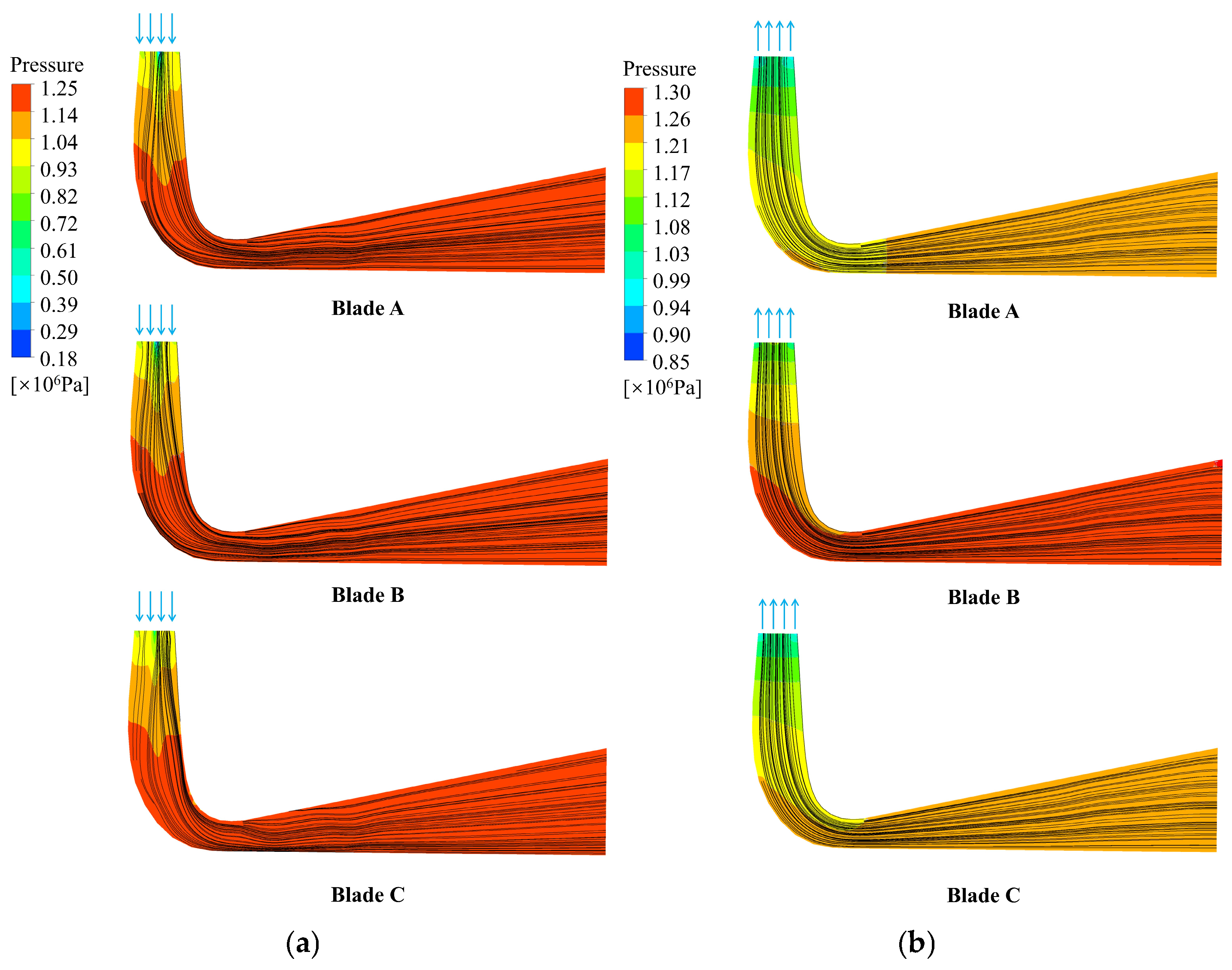

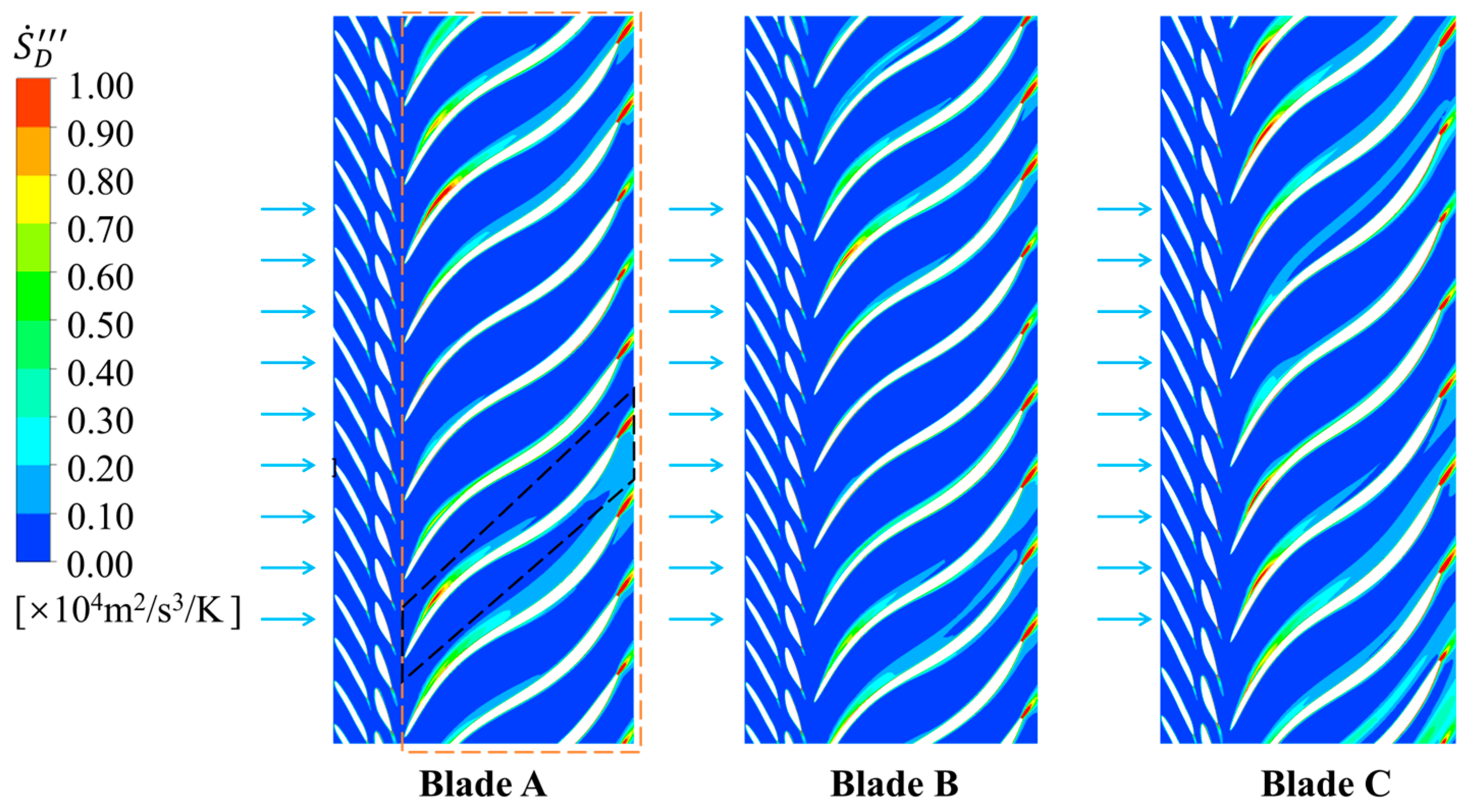

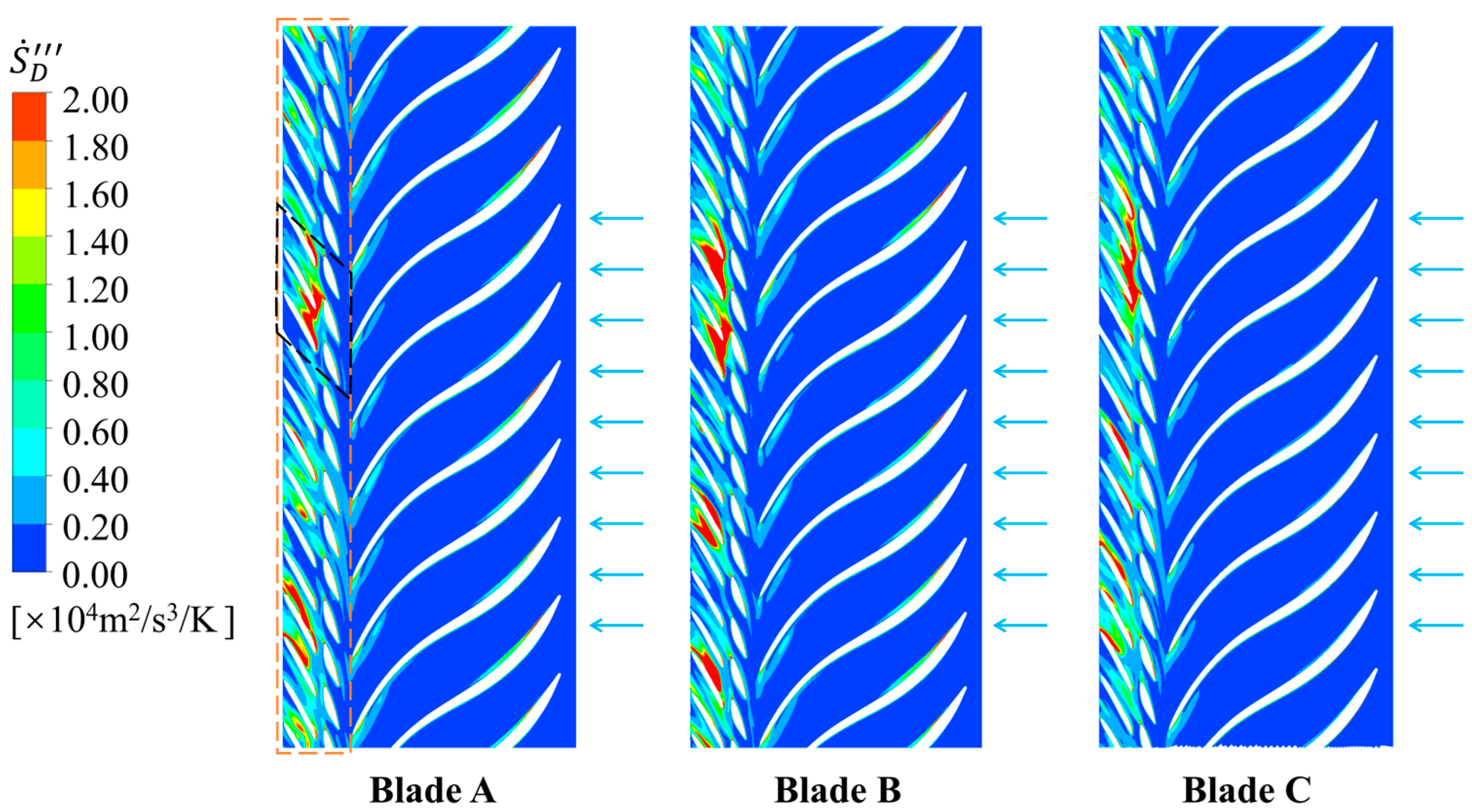

3.1.2. Flow Characteristics

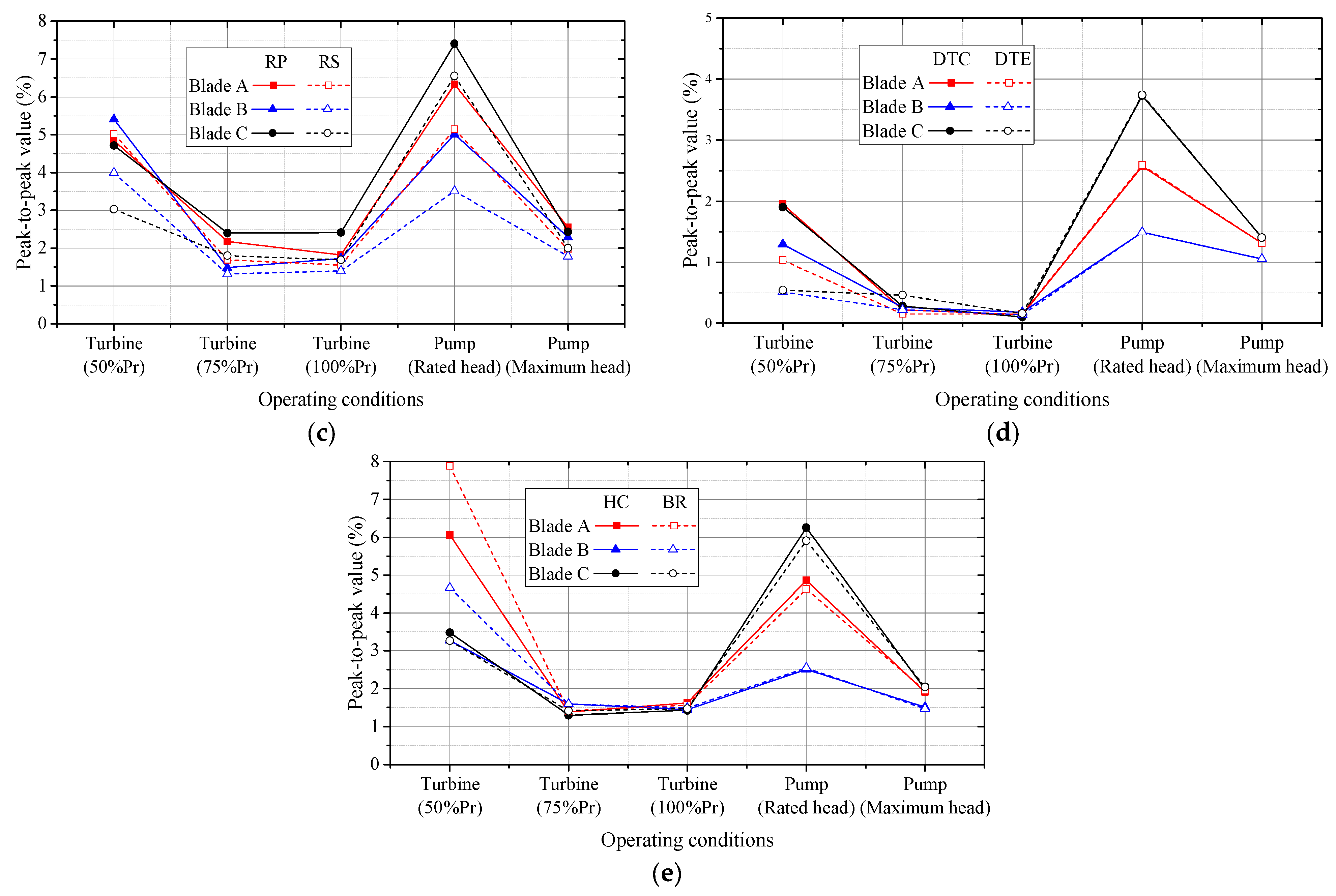

3.2. Pressure Pulsation Characteristics

3.2.1. Case Study of Blade A

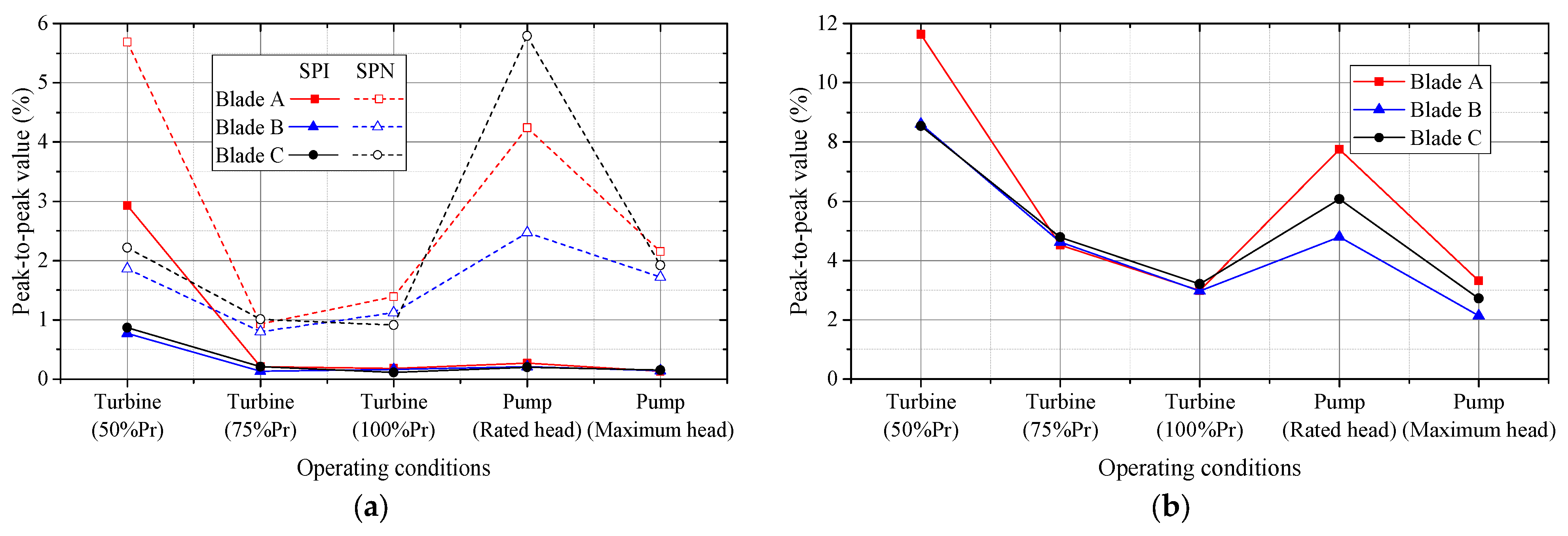

3.2.2. Statistical Analysis Under Three BLEAs

3.3. Mechanism Analysis Based on Energy Dissipation

3.4. Discussion

4. Conclusions

- (a)

- The BLEA has little effect on efficiency in different operating conditions but will affect the flow stability. Blade B, which inclines 15° to the right relative to Blade A, is better in turbine mode and pump mode in terms of efficiency and pressure pulsation.

- (b)

- The pressure pulsation in flow passage was mainly affected by the RSI at 100% in turbine mode, and the dominant frequency is mainly once or twice that of the runner blade passing frequency of 11 or 22 and of the guide vanes passing frequency of 20 .

- (c)

- The energy dissipation is greatly affected by the flow direction, which manifested obvious energy dissipation in the runner in turbine mode and obvious energy dissipation in the stay vanes and guide vanes in pump mode. The energy dissipation in pump mode is larger than that in turbine mode, and the maximum value of local total entropy production in pump mode is about double of that in turbine mode. In addition, the energy dissipation of Blade B is lower in turbine mode, but larger in pump mode.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, P.; Li, Y.; Sun, L. Dynamic behavior and energy dissipation analysis of pump turbine in unstable S characteristic zone. J. Energy Storage 2024, 102, 114275. [Google Scholar] [CrossRef]

- Zhang, F.; Xiao, R.; Zhu, D.; Liu, W.; Tao, R. Pressure pulsation reduction in the draft tube of pump turbine in turbine mode based on optimization design of runner blade trailing edge profile. J. Energy Storage 2023, 59, 106541. [Google Scholar] [CrossRef]

- Shi, G.; Wang, N.; Liu, H.; Wen, H.; Huang, Z.; Wu, J. Study on the flow and pressure pulsation characteristics in the hump region of pump-turbine based on C-shaped blade design. J. Energy Storage 2025, 119, 116246. [Google Scholar] [CrossRef]

- Olimstad, G.; Nielsen, T.; Børresen, B. Dependency on Runner Geometry for Reversible-Pump Turbine Characteristics in Turbine Mode of Operation. J. Fluids Eng. 2012, 134, 121102. [Google Scholar] [CrossRef]

- Cao, J.; Luo, Y.; Mirza Umar, B.; Wang, W.; Wang, Z. Influence of structural parameters on the modal characteristics of a Francis runner. Eng. Fail. Anal. 2022, 131, 105853. [Google Scholar] [CrossRef]

- Binama, M.; Su, W.-T.; Cai, W.-H.; Li, X.-B.; Muhirwa, A.; Li, B.; Bisengimana, E. Blade trailing edge position influencing pump as turbine (PAT) pressure field under part-load conditions. Renew. Energy 2019, 136, 33–47. [Google Scholar] [CrossRef]

- Wang, W.; Tai, G.; Shen, J.; Pei, J.; Yuan, S. Experimental investigation on pressure fluctuation characteristics of a mixed-flow pump as turbine at turbine and runaway conditions. J. Energy Storage 2022, 55, 105562. [Google Scholar] [CrossRef]

- Gao, B.; Zhang, N.; Li, Z.; Ni, D.; Yang, M. Influence of the Blade Trailing Edge Profile on the Performance and Unsteady Pressure Pulsations in a Low Specific Speed Centrifugal Pump. J. Fluids Eng. 2016, 138, 051106. [Google Scholar] [CrossRef]

- Li, D.; Qin, Y.; Wang, J.; Zhu, Y.; Wang, H.; Wei, X. Optimization of blade high-pressure edge to reduce pressure fluctuations in pump-turbine hump region. Renew. Energy 2022, 181, 24–38. [Google Scholar] [CrossRef]

- Yulin, F.; Xuhe, W.; Baoshan, Z.; Dongyue, Z.; Xijun, Z. Mechanism study on pressure fluctuation of pump-turbine runner with large blade lean angle. IOP Conf. Ser. Earth Environ. Sci. 2016, 49, 42006. [Google Scholar] [CrossRef]

- Lu, J.; Tao, R.; Xiao, W.; Gui, Z.; Zhu, D.; Xiao, R.; Liu, W. Analysis of flow and energy dissipation in pump turbine with small guide vane opening. Eng. Appl. Comput. Fluid Mech. 2024, 18, 2421481. [Google Scholar] [CrossRef]

- Luo, H.; Tao, R.; Yang, J.; Wang, Z. Influence of Blade Leading-Edge Shape on Rotating-Stalled Flow Characteristics in a Centrifugal Pump Impeller. Appl. Sci. 2020, 10, 5635. [Google Scholar] [CrossRef]

- Cao, J.; Yang, G.; Luo, Y.; Chen, J.; Liao, R.; Wang, Z. Failure investigation of a Kaplan turbine blade lever. Eng. Fail. Anal. 2022, 142, 106840. [Google Scholar] [CrossRef]

- Zhu, D.; Xiao, R.; Liu, W. Influence of leading-edge cavitation on impeller blade axial force in the pump mode of reversible pump-turbine. Renew. Energy 2021, 163, 939–949. [Google Scholar] [CrossRef]

- Tao, R.; Jin, F.; Wu, Y.; Lu, Z.; Xiao, R.; Zhu, D.; Liu, W. Analyses of the spatial and temporal features of the blade pressure-side cavitation in a pump-turbine runner in the pump mode. Energy Sci. Eng. 2022, 10, 3125–3137. [Google Scholar] [CrossRef]

- Xiang, R.; Wang, T.; Fang, Y.; Yu, H.; Zhou, M.; Zhang, X. Effect of blade curve shape on the hydraulic performance and pressure pulsation of a pump as turbine. Phys. Fluids 2022, 34, 085130. [Google Scholar] [CrossRef]

- Li, Y.; Hao, P.; Zhang, Z.; Zhang, L.; Hai, H.; Zhang, H.; Wang, X.; Wang, J.; Zhao, Z.; Peng, P. Characterization of Pressure Pulsation Propagation in a Pump-Turbine Based on the Same-Frequency Tracking Method. Energy Sci. Eng. 2025, 13, 3588–3604. [Google Scholar] [CrossRef]

- Gao, Z.; Zhu, W.; Meng, L.; Zhang, J.; Zhang, F.; Pan, L.; Lu, L. Experimental Study of the Francis Turbine Pressure Fluctuations and the Pressure Fluctuations Superposition Phenomenon Inside the Runner. J. Fluids Eng. 2017, 140, 041208. [Google Scholar] [CrossRef]

- Pei, J.; Shen, J.; Wang, W.; Yuan, S.; Zhao, J. Evaluating hydraulic dissipation in a reversible mixed-flow pump for micro-pumped hydro storage based on entropy production theory. Renew. Energy 2024, 225, 120271. [Google Scholar] [CrossRef]

- Lu, Z.; Tao, R.; Yao, Z.; Liu, W.; Xiao, R. Effects of guide vane shape on the performances of pump-turbine: A comparative study in energy storage and power generation. Renew. Energy 2022, 197, 268–287. [Google Scholar] [CrossRef]

- Deng, Y.; Xu, J.; Li, Y.; Zhang, Y.; Kuang, C. Research on Energy Loss Characteristics of Pump-Turbine during Abnormal Shutdown. Processes 2022, 10, 1628. [Google Scholar] [CrossRef]

- Li, G.; Wang, Y.; Cao, P.; Zhang, J.; Mao, J. Effects of the Splitter Blade on the Performance of a Pump-Turbine in Pump Mode. Math. Probl. Eng. 2018, 2018, 2403179. [Google Scholar] [CrossRef]

- Chen, T.P.; Wei, X.Z.; Bie, R.S.; Li, Y.; Zhang, T.; Liu, Y.X. A Numerical Study on the Energy Dissipation Mechanisms of a Two-Stage Vertical Pump as Turbine Using Entropy Generation Theory. J. Appl. Fluid Mech. 2024, 17, 159–175. [Google Scholar] [CrossRef]

- Favrel, A.; Nicolle, J.; Morissette, J.-F.; Giroux, A.-M. On the correlation between runner blade dynamic stresses and pressure fluctuations in a prototype Francis turbine. IOP Conf. Ser. Earth Environ. Sci. 2022, 1079, 12115. [Google Scholar] [CrossRef]

- Li, X.-B.; Binama, M.; Su, W.-T.; Cai, W.-H.; Muhirwa, A.; Li, B.; Li, F.-C. Runner blade number influencing RPT runner flow characteristics under off-design conditions. Renew. Energy 2020, 152, 876–891. [Google Scholar] [CrossRef]

- Ouyang, J.; Luo, Y.; Tao, R. Influence of blade leaning on hydraulic excitation and structural response of a reversible pump turbine. Proc. Inst. Mech. Eng. Part A J. Power Energy 2021, 236, 241–259. [Google Scholar] [CrossRef]

- Ono, K.; Tsuru, W.; Yokota, K. Influence of runner leading edge radius on the pump-turbine performance. J. Phys. Conf. Ser. 2022, 2217, 12062. [Google Scholar] [CrossRef]

- Zhu, D.; Yan, W.; Guang, W.; Wang, Z.; Tao, R. Influence of Guide Vane Opening on the Runaway Stability of a Pump-Turbine Used for Hydropower and Ocean Power. J. Mar. Sci. Eng. 2023, 11, 1218. [Google Scholar] [CrossRef]

- Tao, R.; Xiao, R.; Wang, Z. Influence of Blade Leading-Edge Shape on Cavitation in a Centrifugal Pump Impeller. Energies 2018, 11, 2588. [Google Scholar] [CrossRef]

- Ruan, H.; Chao, W.; Li, X.; Zhang, Q.; Qing, L.; Wei, C. The Influence of the Installation Angle of a Blade’s Low-Pressure Edge on the Cavitation Performance of Francis Pump-Turbines. Fluids 2025, 10, 248. [Google Scholar] [CrossRef]

- Ru, S.; Zhang, S.; Zhou, K.; Huang, X.; Huang, W.; Wang, Z. Numerical Study on the Flow and Structural Characteristics of a Large High Head Prototype Pump-Turbine under Different Operating Conditions. Processes 2023, 11, 2970. [Google Scholar] [CrossRef]

- Lu, J.; Tao, R.; Yao, Z.; Xiao, R.; Liu, W. Transient simulation energy study of fast opening of guide vane during start-up of pump turbine in energy storage mode. Energy 2025, 324, 135964. [Google Scholar] [CrossRef]

- Ono, K.; Tsuru, W.; Yokota, K. Effects of Leading Edge of a Pump-Turbine on Turbine Performance. In Proceedings of the Conference of Kanto Branch, Online, 24 February 2021; Volume 2021.27, p. 1100. [Google Scholar]

- Jin, F.; Luo, Y.; Wang, H.; Wang, Z.; Lin, K.; Lei, X.; Yang, X. Dynamic response of a pump-turbine runner during turbine’s mode starting up. J. Energy Storage 2023, 74, 109339. [Google Scholar] [CrossRef]

- Yi, C.; Lu, Y.; Li, X.; Zhao, Y.; Sun, C.; Wang, Z. Study on the influence of guide vane opening on pressure pulsation of pump-turbine under zero flow pump condition. J. Phys. Conf. Ser. 2024, 2854, 12063. [Google Scholar] [CrossRef]

- Cui, B.L.; Sun, F.Y.; Zhang, Y.L.; Liu, J.X.; Xiao, J.J. Influence of blade trailing edge profile on unsteady pressure pulsations in a multistage centrifugal pump. Energy Sci. Eng. 2023, 11, 1471–1483. [Google Scholar] [CrossRef]

- Xia, L.-S.; Zhang, C.-Z.; Li, H. Influences of runner blade shape on the transient behaviours of pump-turbines in load rejection. J. Hydraul. Res. 2020, 59, 462–476. [Google Scholar] [CrossRef]

- Xu, L.; Liu, D.; Li, Z.; Zhao, X.; Liu, X. Experimental and numerical simulation research on flow characteristics of model pump-turbine in four-quadrant operating quadrants. J. Energy Storage 2022, 54, 105083. [Google Scholar] [CrossRef]

- Wang, D.; Li, Z.; Zhao, Q.; Li, D.; Deng, W.; Ji, L.; Shengyang, P. Pressure pulsation analysis of runner and draft tube of pump turbine under different working conditions. IOP Conf. Ser. Earth Environ. Sci. 2022, 1037, 012036. [Google Scholar] [CrossRef]

- Zhang, D.; Quan, Q.; Huang, X.; Wang, Z.; Wang, B.; Xiao, Y. Transient Flow-Induced Stress Investigation on a Prototype Reversible Pump–Turbine Runner. Energies 2024, 17, 3026. [Google Scholar] [CrossRef]

- Shi, G.; Li, B.; Xiao, Y.; Tang, M.; Yang, X. Effect of Speed Linear Decrease on Internal Flow Characteristics and Pressure Pulsations of Variable-Speed Pump Turbine in Turbine Mode. J. Mar. Sci. Eng. 2024, 12, 2243. [Google Scholar] [CrossRef]

- Terentiev, L. The Turbulence Closure Model Based on Linear Anisotropy Invariant Analysis; Friedrich-Alexander University Erlangen-Nuremberg: Erlangen, Germany, 2006. [Google Scholar]

- Cao, J.; Luo, Y.; Shi, Y.; Liu, X.; Xu, D.; Wang, Y.; Zhai, L.; Wang, Z. A review of hydro-turbine unit rotor system dynamic behavior: Multi-field coupling of a three-dimensional model. Phys. Fluids 2024, 36, 121304. [Google Scholar] [CrossRef]

- Menter, F.; Rumsey, C. Assessment of two-equation turbulence models for transonic flows. In Proceedings of the Fluid Dynamics Conference, Bangalore, India, 11–15 July 1994; pp. 1–18. [Google Scholar]

- Li, D.; Wang, H.; Qin, Y.; Han, L.; Wei, X.; Qin, D. Entropy production analysis of hysteresis characteristic of a pump-turbine model. Energy Convers. Manag. 2017, 149, 175–191. [Google Scholar] [CrossRef]

- Yu, Z.-F.; Wang, W.-Q.; Yan, Y.; Liu, X.-S. Energy loss evaluation in a Francis turbine under overall operating conditions using entropy production method. Renew. Energy 2021, 169, 982–999. [Google Scholar] [CrossRef]

- Xu, Z.; Zheng, Y.; Kan, K.; Chen, H. Flow instability and energy performance of a coastal axial-flow pump as turbine under the influence of upstream waves. Energy 2023, 272, 127121. [Google Scholar] [CrossRef]

- Song, X.; Jin, Y.; Wang, Z.; Presas, A.; Tang, F.; Liu, C. Energy dissipation and time–frequency analysis of characteristics induced by vortex breakdown in an axial flow pump. Phys. Fluids 2024, 36, 065102. [Google Scholar] [CrossRef]

- Cao, J.; Luo, Y.; Zhuang, J.; Li, X.; Wang, Z. Effect of the pressure balance device on the flow characteristics of a pump-turbine. Proc. Inst. Mech. Eng. Part A J. Power Energy 2022, 236, 1533–1543. [Google Scholar] [CrossRef]

- Pan, J.; Liu, Q.; Pang, J.; Zhang, F.; Tao, R.; Xiao, R.; Zhou, L.; Liu, W. Comparative evaluation of sand erosion in reversible turbine at pump mode and turbine mode. J. Energy Storage 2024, 79, 110185. [Google Scholar] [CrossRef]

- Li, S.; Yao, B.; Pang, J.; Liu, D.; Chengmei, D.; Jiang, D.; Wang, H.; Gang, Y.; Cheng, H.; Liu, X. Research on the technical improvement of the turbine runner of a power station based on improving stability. Energy Sci. Eng. 2024, 12, 4582–4597. [Google Scholar] [CrossRef]

- Hu, Z.; Cheng, Y.; Liu, D.; Chen, H.; Ji, B.; Ding, J. Broadening the operating range of pump-turbine to deep-part load by runner optimization. Renew. Energy 2023, 207, 73–88. [Google Scholar] [CrossRef]

- Hu, J.; Yang, J.; He, X.; Zeng, W.; Zhao, Z.; Yang, J. Transition of amplitude–frequency characteristic in rotor–stator interaction of a pump-turbine with splitter blades. Renew. Energy 2023, 205, 663–677. [Google Scholar] [CrossRef]

- Rusanov, A.; Subotin, V.; Khoryev, O.; Lynnyk, O.; Bykov, Y.; Korotaiev, P.; Ahibalov, Y. Experimental Studies of Pressure Pulsations in Draft Tube Diffuser of Pump-Turbine Models for Heads up to 200 m. Sci. Innov. 2024, 20, 53–66. [Google Scholar] [CrossRef]

- Xiao, W.; Gui, Z.; Lu, Z.; Xiao, R.; Tao, R. Pressure pulsation of pump turbine at runaway condition based on Hilbert Huang transform. Front. Energy Res. 2024, 12, 1344676. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, Z.; Zhao, Y.; Wang, Z.; Presas, A. Study on evolution characteristics of energy dissipation and vortex in pump-turbine during load rejection transition process. Phys. Fluids 2025, 37, 025104. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.; Luo, Y.; Ouyang, J.; Chen, X.; Liu, S.; Zhang, H. Pressure Pulsation and Energy Dissipation Mechanism of a Pump-Turbine Considering Runner Blade Leading Edge Effect. Water 2025, 17, 3184. https://doi.org/10.3390/w17223184

Liu B, Luo Y, Ouyang J, Chen X, Liu S, Zhang H. Pressure Pulsation and Energy Dissipation Mechanism of a Pump-Turbine Considering Runner Blade Leading Edge Effect. Water. 2025; 17(22):3184. https://doi.org/10.3390/w17223184

Chicago/Turabian StyleLiu, Bin, Yongyao Luo, Jinhui Ouyang, Xupeng Chen, Shizhe Liu, and Han Zhang. 2025. "Pressure Pulsation and Energy Dissipation Mechanism of a Pump-Turbine Considering Runner Blade Leading Edge Effect" Water 17, no. 22: 3184. https://doi.org/10.3390/w17223184

APA StyleLiu, B., Luo, Y., Ouyang, J., Chen, X., Liu, S., & Zhang, H. (2025). Pressure Pulsation and Energy Dissipation Mechanism of a Pump-Turbine Considering Runner Blade Leading Edge Effect. Water, 17(22), 3184. https://doi.org/10.3390/w17223184