Criticality Assessment of Pipes in Water Distribution Networks Based on the Minimum Pressure Criterion

Abstract

1. Introduction

2. Materials and Methods

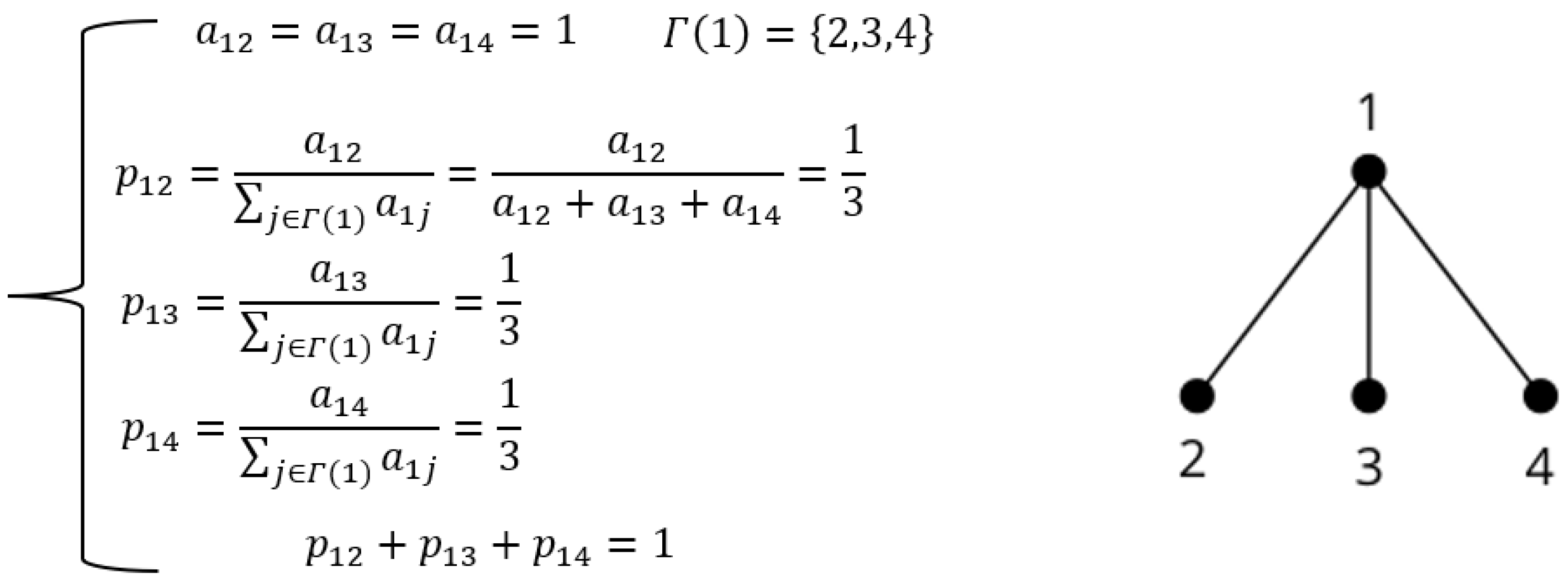

2.1. Structural Holes in Networks

2.2. Structural Hole Influence Matrix

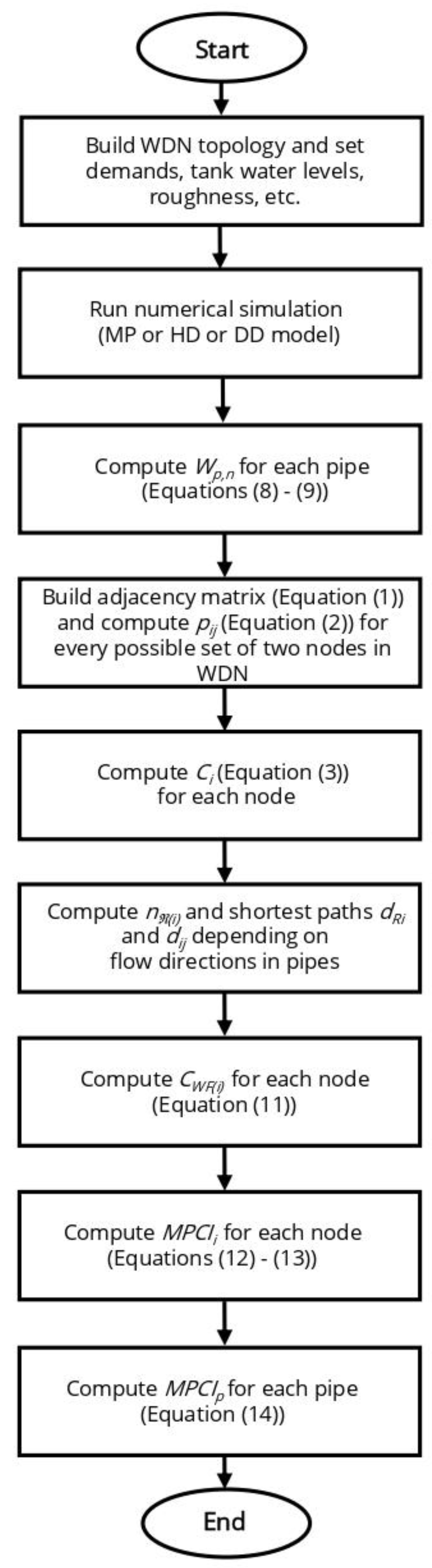

2.3. Integrated Topological–Hydraulic Minimum Pressure Criticality Indicator

2.3.1. Criticality Indicator Derived from Minimum Pressure Approach and Structural Hole Theory

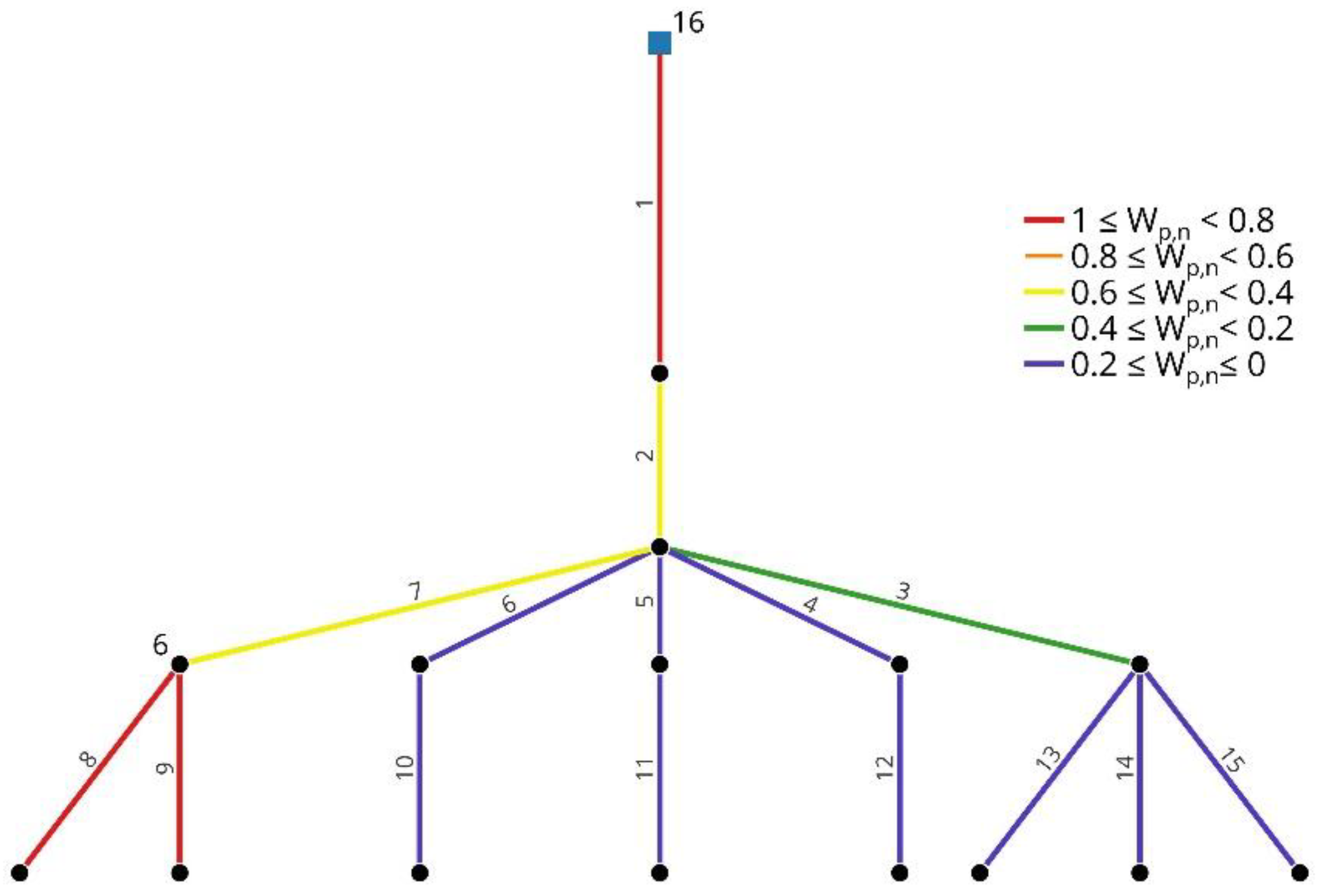

2.3.2. Computation of Weighted Adjacency Matrix by Means of Pipe Hydraulic Weights Calculation

2.3.3. Minimum Pressure Criticality Indicator

3. Results and Discussion

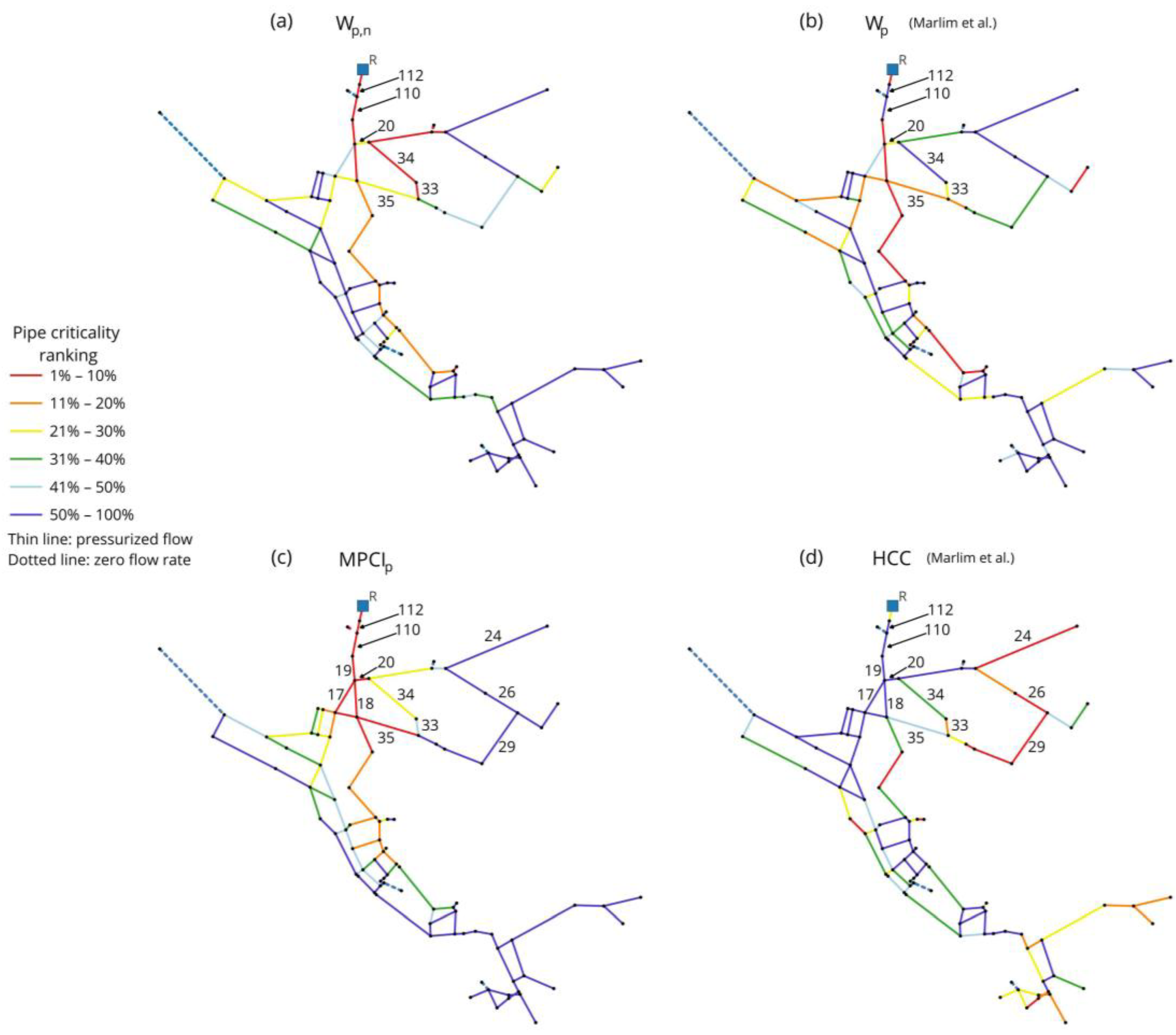

3.1. North Marin WDN

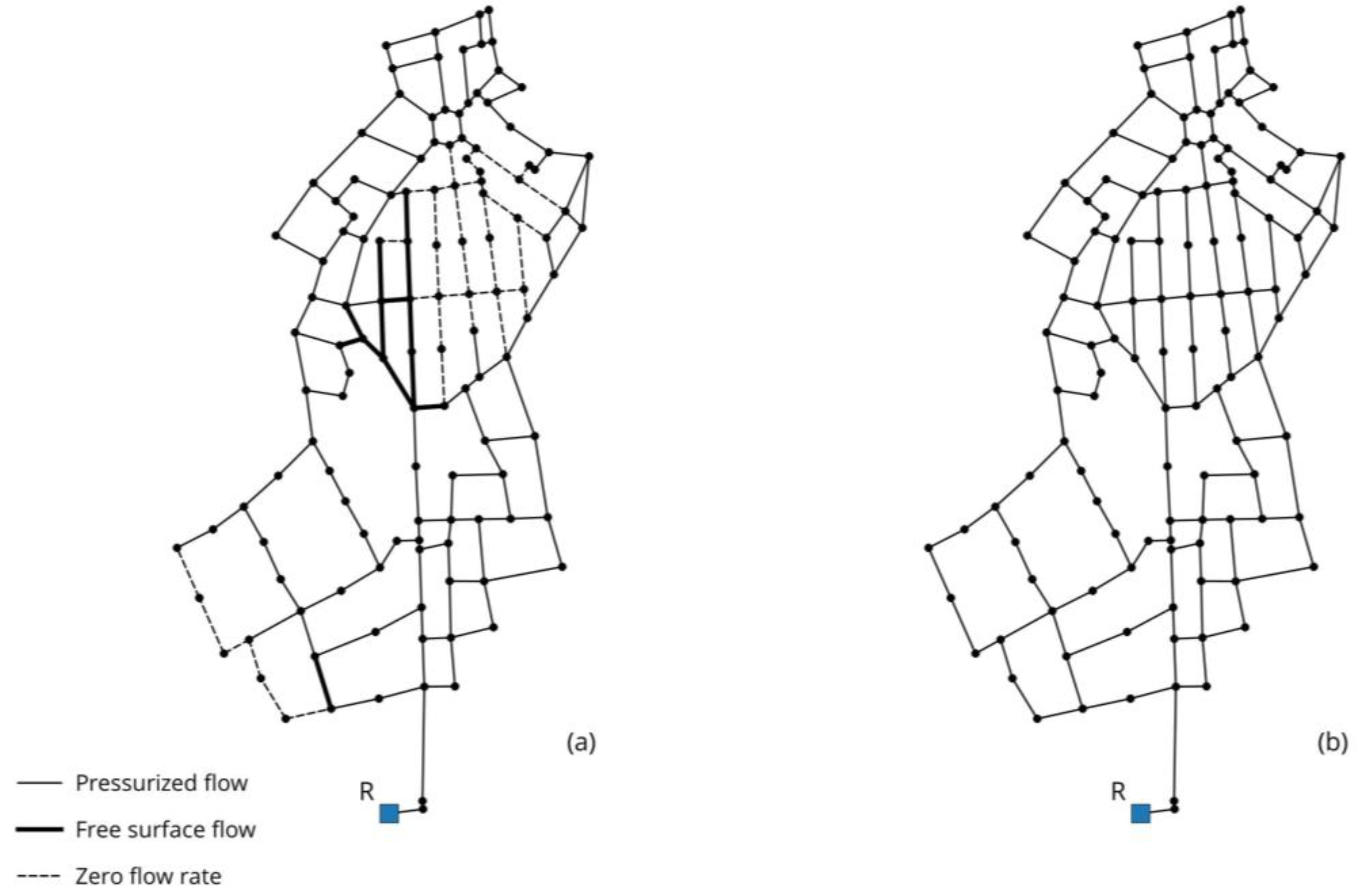

3.2. Campofelice Di Roccella WDN

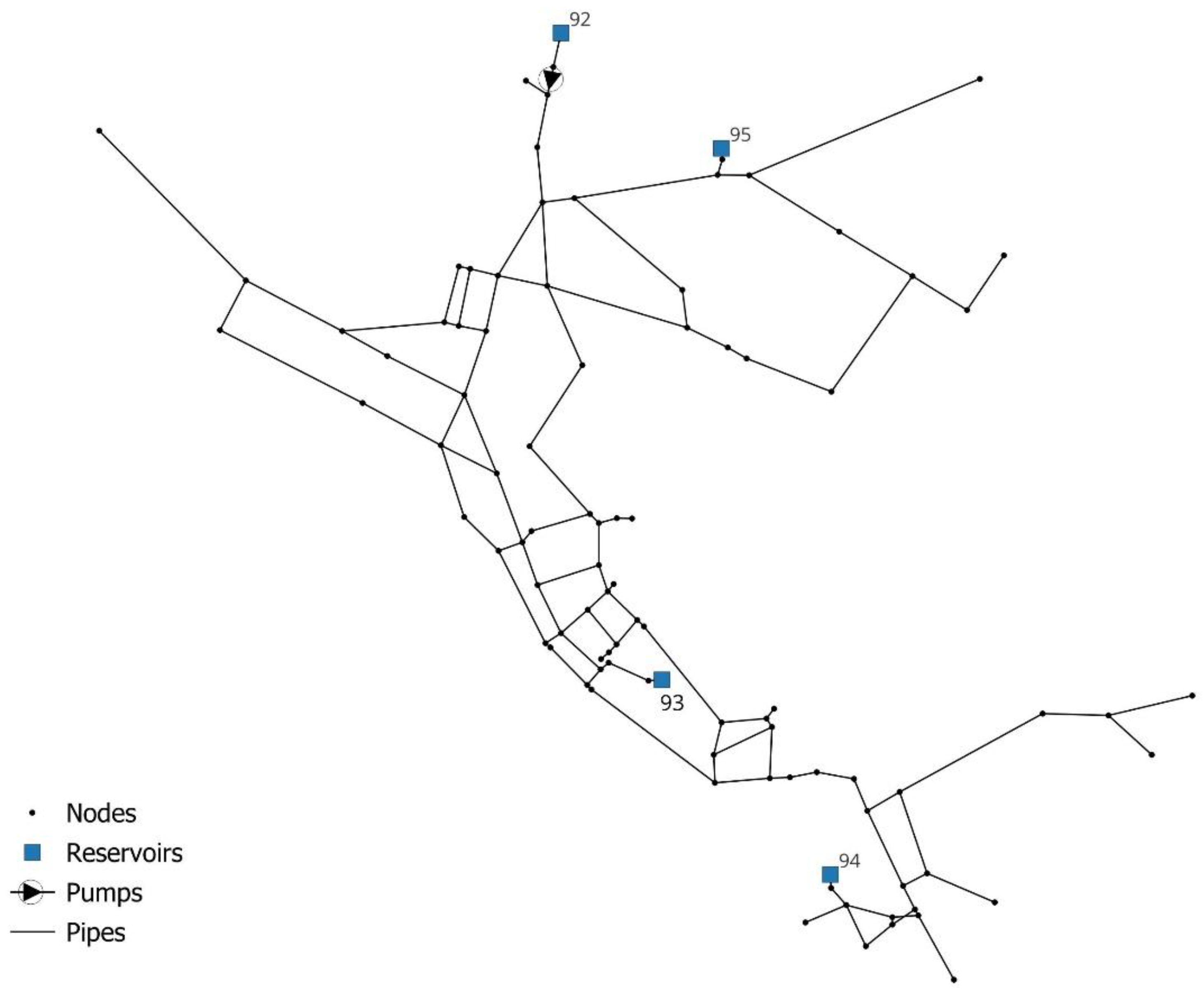

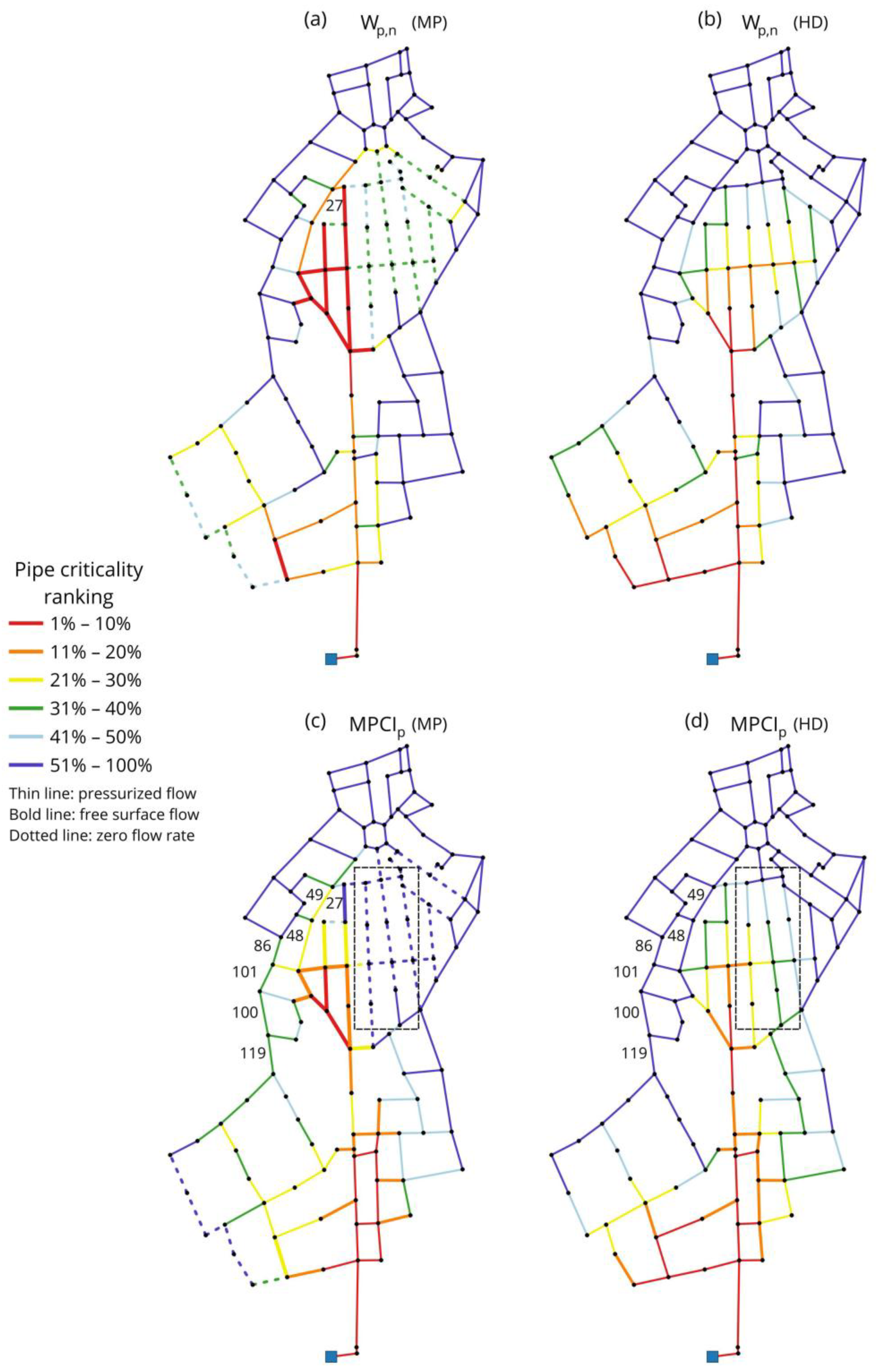

3.3. Marchi Rural WDN

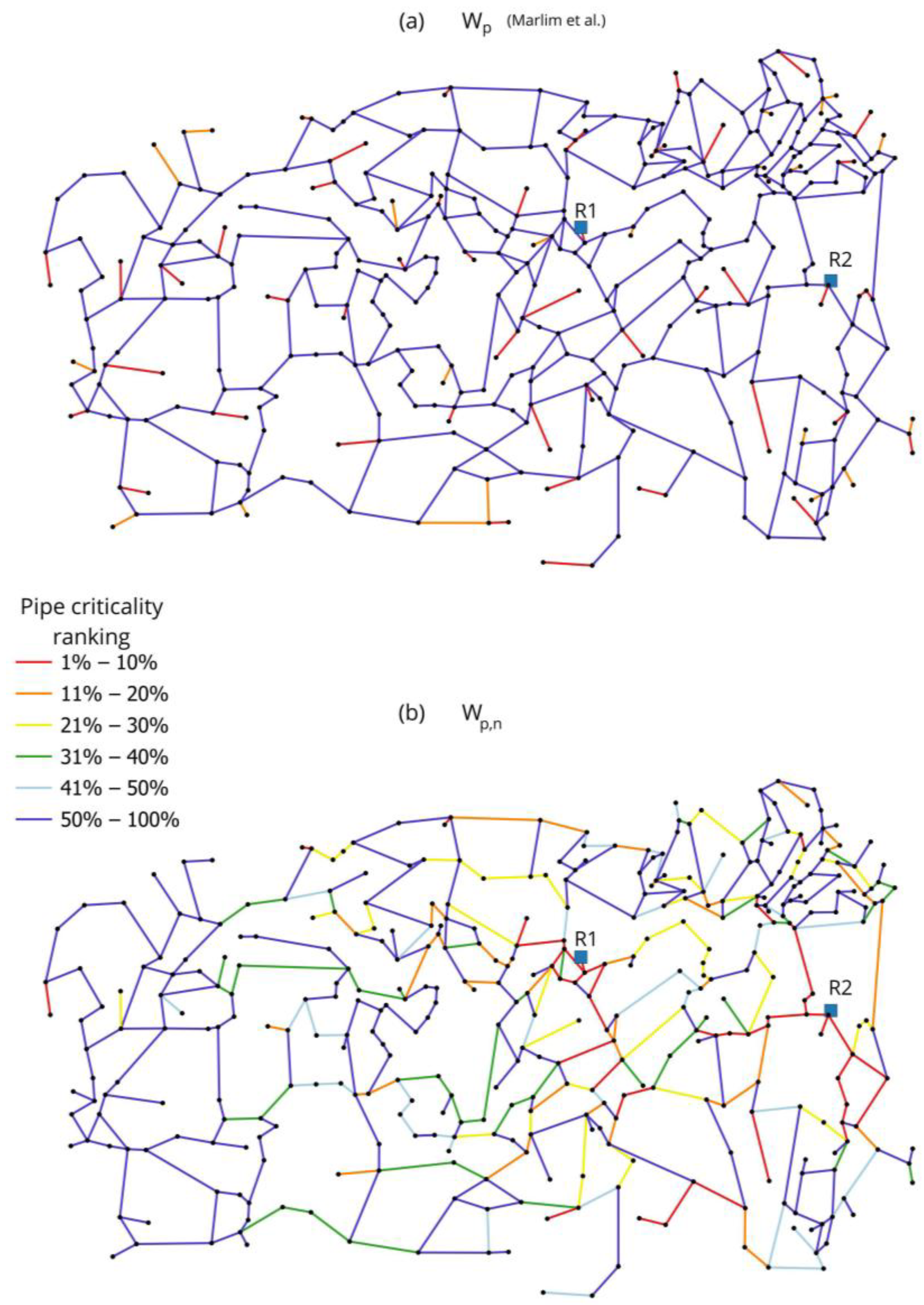

3.4. Sensitivity Analysis of Normalization Method

3.5. Global Enhancement of Network Performance via Localized Interventions Guided by MCPI

3.6. Discussion and Limitations of the Proposed Approach

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DD | Demand-Driven |

| HCC | Hydraulic Connectiveness Criticality |

| HD | Head-Driven |

| MP | Minimum Pressure |

| MPCI | Minimum Pressure Criticality Indicator |

| WDN | Water Distribution Network |

| WPI | Water Performance Indicator |

References

- Alegre, H.; Baptista, J.M.; Cabrera, E.; Cubillo, F.; Duarte, P.; Hirner, W.; Merkel, W.; Parena, R. Performance Indicators for Water Supply Services, 3rd ed.; IWA Publishing: London, UK, 2016; Volume 15, ISBN 9781780406336. [Google Scholar] [CrossRef]

- Li, P.-H.; Kao, J.-J. Segment-Based Vulnerability Analysis System for a Water Distribution Network. Civ. Eng. Environ. Syst. 2008, 25, 41–58. [Google Scholar] [CrossRef]

- Walski, T.M. Water Distribution Valve Topology for Reliability Analysis. Reliab. Eng. Syst. Saf. 1993, 42, 21–27. [Google Scholar] [CrossRef]

- Yazdani, A.; Jeffrey, P. Water Distribution System Vulnerability Analysis Using Weighted and Directed Network Models. Water Resour. Res. 2012, 48, W06517. [Google Scholar] [CrossRef]

- Abdel-Mottaleb, N.; Walski, T. Evaluating Segment and Valve Importance and Vulnerability. J. Water Resour. Plan. Manag. 2021, 147, 04021020. [Google Scholar] [CrossRef]

- Liu, J.; Kang, Y. Segment-Based Resilience Response and Intervention Evaluation of Water Distribution Systems. AQUA—J. Water Supply Res. Technol. 2021, 71, 100–119. [Google Scholar] [CrossRef]

- Tornyeviadzi, H.M.; Neba, F.A.; Mohammed, H.; Seidu, R. Nodal Vulnerability Assessment of Water Distribution Networks: An Integrated Fuzzy AHP-TOPSIS Approach. Int. J. Crit. Infrastruct. Prot. 2021, 34, 100434. [Google Scholar] [CrossRef]

- Marlim, M.S.; Jeong, G.; Kang, D. Identification of Critical Pipes Using a Criticality Index in Water Distribution Networks. Appl. Sci. 2019, 9, 4052. [Google Scholar] [CrossRef]

- Giustolisi, O.; Ridolfi, L.; Simone, A. Tailoring Centrality Metrics for Water Distribution Networks. Water Resour. Res. 2019, 55, 2348–2369. [Google Scholar] [CrossRef]

- Prasad, R.K. Identification of Critical Pipes for Water Distribution Network Rehabilitation. Water Resour. Manag. 2021, 35, 5187–5204. [Google Scholar] [CrossRef]

- Hajibabaei, M.; Yousefi, A.; Hesarkazzazi, S.; Minaei, A.; Jenewein, O.; Shahandashti, M.; Sitzenfrei, R. Resilience Enhancement of Water Distribution Networks under Pipe Failures: A Hydraulically Inspired Complex Network Approach. AQUA—Water Infrastruct. Ecosyst. Soc. 2023, 72, 2358–2376. [Google Scholar] [CrossRef]

- Raspati, G.S.; Bruaset, S.; Bosco, C.; Mushom, L.; Johannessen, B.; Ugarelli, R. A Risk-Based Approach in Rehabilitation of Water Distribution Networks. Int. J. Environ. Res. Public Health 2022, 19, 1594. [Google Scholar] [CrossRef] [PubMed]

- Marlim, M.S.; Kang, D. Hydraulic Connectiveness Metric for the Analysis of Criticality in Water Distribution Networks. Water 2024, 16, 1498. [Google Scholar] [CrossRef]

- Wasserman, S.; Faust, K. Social Network Analysis: Methods and Applications; Cambridge University Press: Cambridge, UK, 1994. [Google Scholar]

- Tucciarelli, T.; Puleo, D.; Nasello, C.; Sinagra, M. Air intrusion in water distribution network (WDN) modelling. J. Hydroinform. 2025, 27, 1371–1389. [Google Scholar] [CrossRef]

- Shin, G.; Kwon, S.H.; Lee, S. Designing Isolation Valve System to Prevent Unexpected Water Quality Incident. Sustainability 2023, 16, 153. [Google Scholar] [CrossRef]

- Husband, S.; Boxall, J. Understanding and Managing Discolouration Risk in Trunk Mains. Water Res. 2016, 107, 127–140. [Google Scholar] [CrossRef]

- Boxall, J.B.; Saul, A.J. Modeling Discoloration in Potable Water Distribution Systems. J. Environ. Eng. 2005, 131, 716–725. [Google Scholar] [CrossRef]

- Zhu, C.; Wang, X.; Zhu, L. A Novel Method of Evaluating Key Nodes in Complex Networks. Chaos Solitons Fractals 2017, 96, 43–50. [Google Scholar] [CrossRef]

- Burt, R.S. Structural Holes: The Social Structure of Competition; Harvard University Press: Cambridge, MA, USA, 1992. [Google Scholar]

- Lazega, E.; Burt, R.S. Structural Holes: The Social Structure of Competition. Rev. Française Sociol. 1995, 36, 779. [Google Scholar] [CrossRef]

- Burt, R.S. The Network Structure of Social Capital. Res. Organ. Behav. 2000, 22, 345–423. [Google Scholar] [CrossRef]

- Burt, R.S. Structural Holes versus Network Closure as Social Capital. In Social Capital; Routledge: New York, NY, USA, 2017; pp. 31–56. [Google Scholar]

- Todini, E. Looped Water Distribution Networks Design Using a Resilience Index Based Heuristic Approach. Urban Water 2000, 2, 115–122. [Google Scholar] [CrossRef]

- Yang, E.; Faust, K.M. Quantifying the Impact of Population Dynamics on the Structural Robustness of Water Infrastructure Using a Structural Hole Influence Matrix Approach. ACS EST Water 2022, 2, 1161–1173. [Google Scholar] [CrossRef]

- Clark, R.M.; Rossman, L.A.; Wymer, L.J. Modeling Distribution System Water Quality: Regulatory Implications. J. Water Resour. Plan. Manag. 1995, 121, 423–428. [Google Scholar] [CrossRef]

- Braga, A.S.; Saulnier, R.; Filion, Y.; Cushing, A. Dynamics of Material Detachment from Drinking Water Pipes under Flushing Conditions in a Full-Scale Drinking Water Laboratory System. Urban Water J. 2020, 17, 745–753. [Google Scholar] [CrossRef]

- Caldarola, F.; Maiolo, M. Local Indices within a Mathematical Framework for Urban Water Distribution Systems. Cogent Eng. 2019, 6, 1643057. [Google Scholar] [CrossRef]

| Node ID | C(i) | CWF(i) | MPCI(i) | Node ID | C(i) | CWF(i) | MPCI(i) |

|---|---|---|---|---|---|---|---|

| 1 | 0.500 | 0.001 | 0.004 | 47 | 0.333 | 0.011 | 0.102 |

| 2 | 0.333 | 0.002 | 0.012 | 48 | 0.333 | 0.013 | 0.126 |

| 3 | 0.333 | 0.004 | 0.033 | 49 | 0.500 | 0.013 | 0.066 |

| 4 | 1.000 | 0.000 | 0.000 | 50 | 1.000 | 0.000 | 0.037 |

| 5 | 0.333 | 0.002 | 0.012 | 51 | 0.250 | 0.019 | 0.121 |

| 6 | 0.333 | 0.003 | 0.022 | 52 | 0.333 | 0.015 | 0.077 |

| 7 | 1.000 | 0.000 | 0.000 | 53 | 0.500 | 0.016 | 0.080 |

| 8 | 0.333 | 0.001 | 0.006 | 54 | 0.500 | 0.019 | 0.093 |

| 9 | 0.333 | 0.000 | 0.002 | 55 | 0.333 | 0.013 | 0.065 |

| 10 | 1.000 | 0.000 | 0.000 | 56 | 0.500 | 0.012 | 0.065 |

| 11 | 0.333 | 0.007 | 0.053 | 57 | 0.250 | 0.016 | 0.107 |

| 12 | 0.500 | 0.008 | 0.039 | 58 | 0.333 | 0.014 | 0.069 |

| 13 | 0.500 | 0.001 | 0.007 | 59 | 0.500 | 0.020 | 0.096 |

| 14 | 0.333 | 0.003 | 0.020 | 60 | 0.333 | 0.022 | 0.164 |

| 15 | 0.333 | 0.002 | 0.014 | 61 | 0.334 | 0.021 | 0.158 |

| 16 | 0.333 | 0.017 | 0.132 | 62 | 0.500 | 0.000 | 0.003 |

| 17 | 0.333 | 0.010 | 0.049 | 63 | 0.333 | 0.070 | 0.830 |

| 18 | 0.333 | 0.011 | 0.052 | 64 | 1.000 | 0.000 | 0.000 |

| 19 | 0.333 | 0.023 | 0.115 | 65 | 0.500 | 0.001 | 0.005 |

| 20 | 0.333 | 0.024 | 0.118 | 66 | 0.333 | 0.002 | 0.013 |

| 21 | 0.333 | 0.017 | 0.084 | 67 | 1.000 | 0.000 | 0.000 |

| 22 | 0.333 | 0.025 | 0.325 | 68 | 1.000 | 0.000 | 0.001 |

| 23 | 0.250 | 0.000 | 0.003 | 69 | 0.500 | 0.072 | 0.749 |

| 24 | 1.000 | 0.000 | 0.000 | 70 | 1.000 | 0.000 | 0.000 |

| 25 | 0.500 | 0.024 | 0.116 | 71 | 1.000 | 0.000 | 0.000 |

| 26 | 0.333 | 0.026 | 0.191 | 72 | 1.000 | 0.000 | 0.023 |

| 27 | 0.500 | 0.000 | 0.000 | 73 | 1.000 | 0.000 | 0.000 |

| 28 | 0.500 | 0.013 | 0.114 | 74 | 0.500 | 0.001 | 0.005 |

| 29 | 0.333 | 0.014 | 0.068 | 75 | 0.333 | 0.002 | 0.010 |

| 30 | 0.500 | 0.001 | 0.004 | 76 | 0.500 | 0.004 | 0.021 |

| 31 | 1.000 | 0.000 | 0.000 | 77 | 0.500 | 0.003 | 0.015 |

| 32 | 1.000 | 0.000 | 0.000 | 78 | 0.333 | 0.006 | 0.067 |

| 33 | 0.333 | 0.016 | 0.203 | 79 | 0.333 | 0.007 | 0.125 |

| 34 | 0.250 | 0.023 | 0.323 | 80 | 0.500 | 0.003 | 0.017 |

| 35 | 0.333 | 0.031 | 0.349 | 81 | 1.000 | 0.000 | 0.000 |

| 36 | 0.500 | 0.032 | 0.293 | 82 | 0.320 | 0.067 | 0.861 |

| 37 | 0.500 | 0.001 | 0.005 | 83 | 0.320 | 0.033 | 0.198 |

| 38 | 0.333 | 0.028 | 0.338 | 84 | 0.333 | 0.016 | 0.174 |

| 39 | 0.333 | 0.007 | 0.056 | 85 | 0.500 | 0.069 | 0.823 |

| 40 | 0.500 | 0.005 | 0.028 | 86 | 0.334 | 0.023 | 0.120 |

| 41 | 0.500 | 0.033 | 0.375 | 87 | 0.458 | 0.020 | 0.071 |

| 42 | 0.500 | 0.008 | 0.121 | 88 | 0.320 | 0.057 | 0.725 |

| 43 | 0.500 | 0.009 | 0.045 | 89 | 0.333 | 0.030 | 0.235 |

| 44 | 0.333 | 0.012 | 0.088 | 90 | 0.333 | 0.001 | 0.004 |

| 45 | 0.500 | 0.008 | 0.042 | 91 | 1.000 | 0.000 | 0.000 |

| 46 | 0.333 | 0.009 | 0.048 | 92 | 1.000 | 0.068 | 1.000 |

| Wp,n-Wp (Figure 6a,b) | Wp,n-MPCIp (Figure 6a–c) | Wp-HCC (Figure 6b–d) | MPCIp-HCC (Figure 6c,d) |

|---|---|---|---|

| 0.536 | 0.477 | 0.386 | −0.446 |

| Wp,n (MP)-Wp,n (HD) (Figure 8a,b) | Wp,n (MP)-MPCIp (MP) (Figure 8a–c) | Wp,n (HD)-MPCIp (HD) (Figure 8b–d) | MPCIp (MP)-MPCIp (HD) (Figure 8c,d) |

|---|---|---|---|

| 0.703 | 0.478 | 0.903 | 0.651 |

| North Marin WDN | Campofelice di Roccella WDN | Marchi Rural WDN | |||

|---|---|---|---|---|---|

| Maximum Norm-L1 Norm | Maximum Norm-L2 Norm | Maximum Norm-L1 Norm | Maximum Norm-L2 Norm | Maximum Norm-L1 Norm | Maximum Norm-L2 Norm |

| 0.984 | 0.994 | 0.980 | 0.994 | 0.999 | 0.999 |

| Ir (Design Conditions) | Ir (50 mm Increased Diameters in ~1024 m of Pipes Belonging to First Criticality Group of Figure 10) | Ir (50 mm Increased Diameters in ~1024 m of Pipes Belonging to Last Criticality Group of Figure 10) |

|---|---|---|

| 0.206 | 0.244 (+18%) | 0.209 (+1.75%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Puleo, D.; Sinagra, M.; Picone, C.; Tucciarelli, T. Criticality Assessment of Pipes in Water Distribution Networks Based on the Minimum Pressure Criterion. Water 2025, 17, 3185. https://doi.org/10.3390/w17223185

Puleo D, Sinagra M, Picone C, Tucciarelli T. Criticality Assessment of Pipes in Water Distribution Networks Based on the Minimum Pressure Criterion. Water. 2025; 17(22):3185. https://doi.org/10.3390/w17223185

Chicago/Turabian StylePuleo, Daniele, Marco Sinagra, Calogero Picone, and Tullio Tucciarelli. 2025. "Criticality Assessment of Pipes in Water Distribution Networks Based on the Minimum Pressure Criterion" Water 17, no. 22: 3185. https://doi.org/10.3390/w17223185

APA StylePuleo, D., Sinagra, M., Picone, C., & Tucciarelli, T. (2025). Criticality Assessment of Pipes in Water Distribution Networks Based on the Minimum Pressure Criterion. Water, 17(22), 3185. https://doi.org/10.3390/w17223185