Numerical and Experimental Analysis of Internal Flow Characteristics of Four-Way Opposing Diaphragm Pump

Abstract

1. Introduction

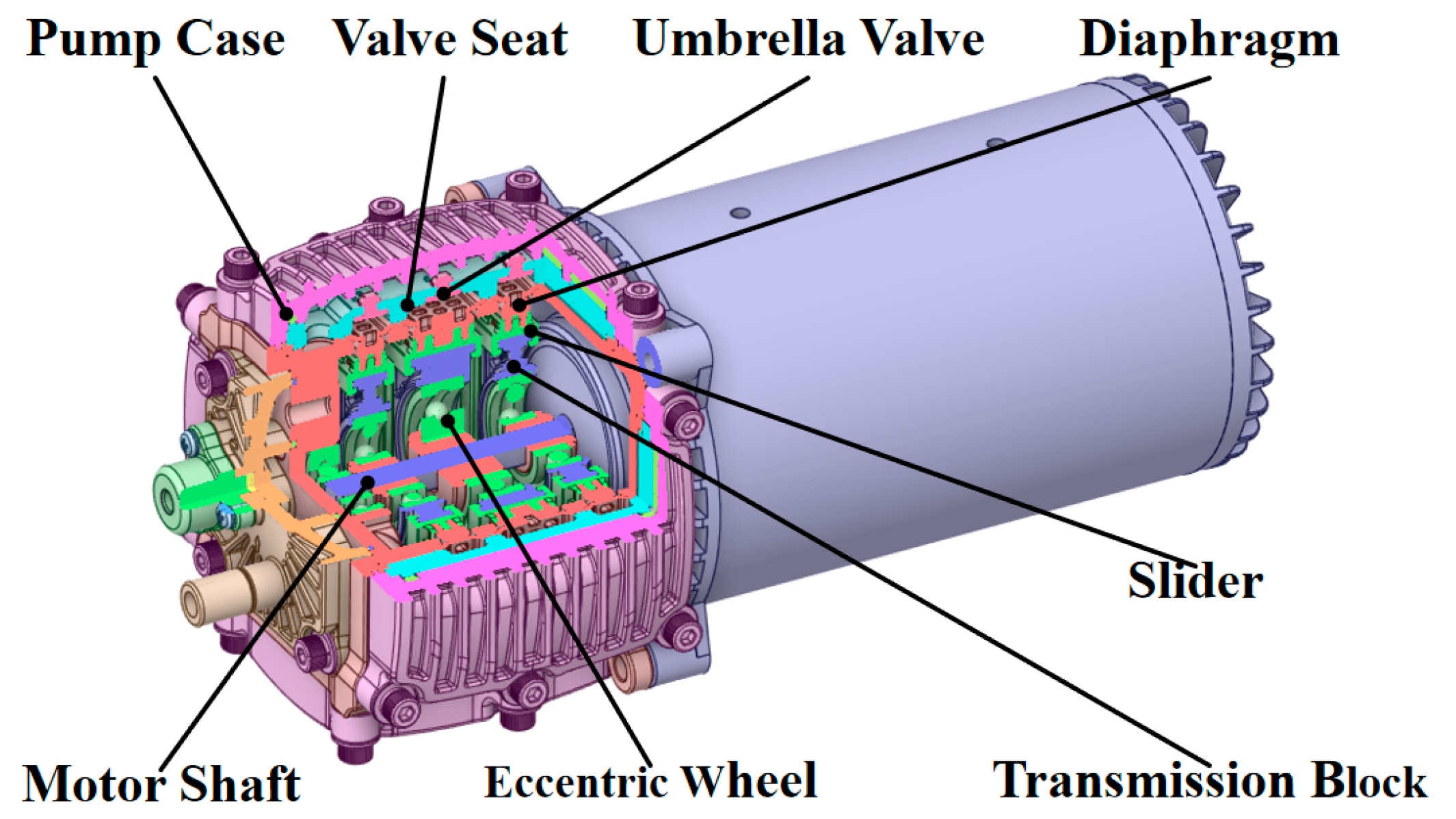

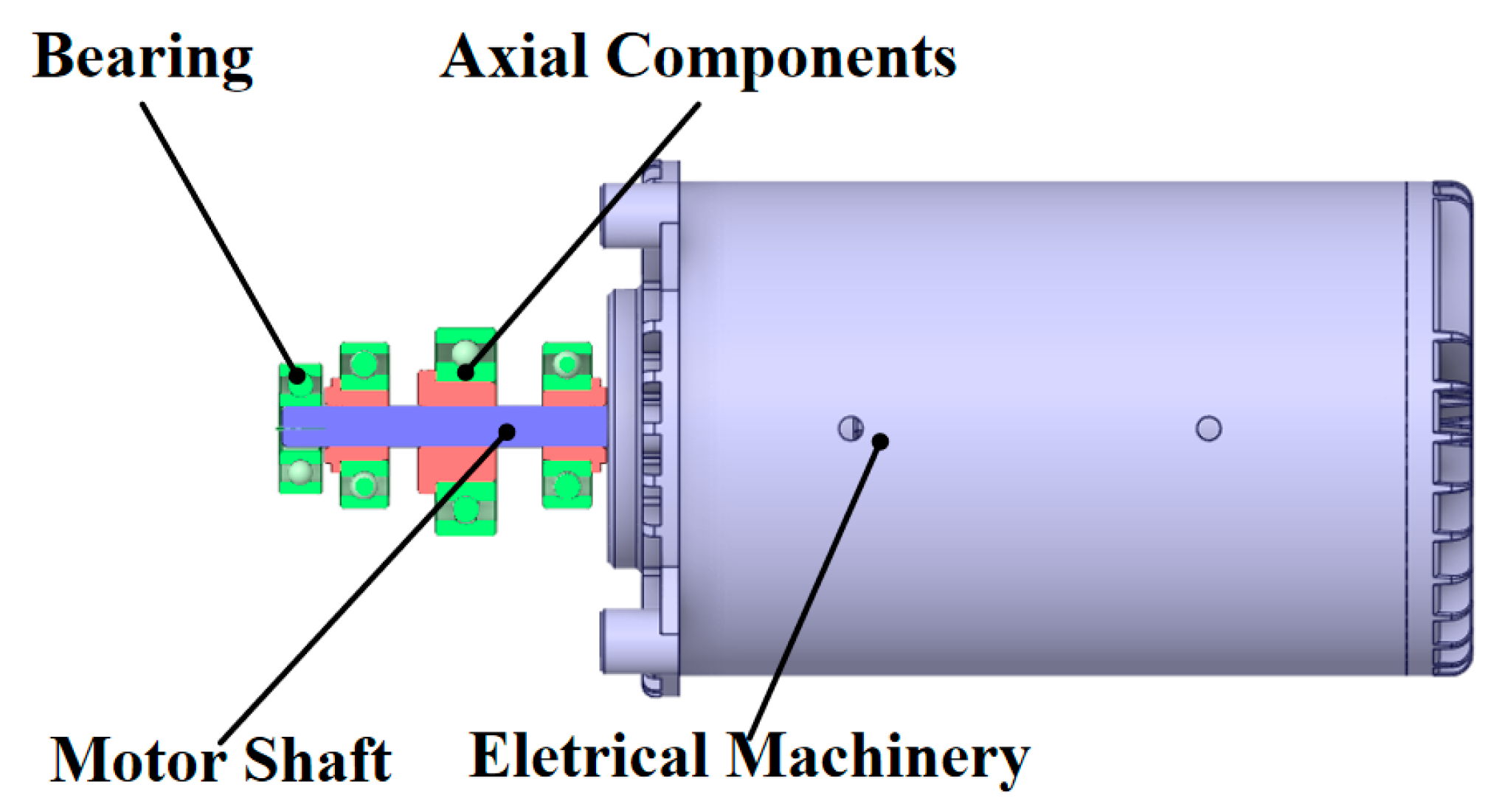

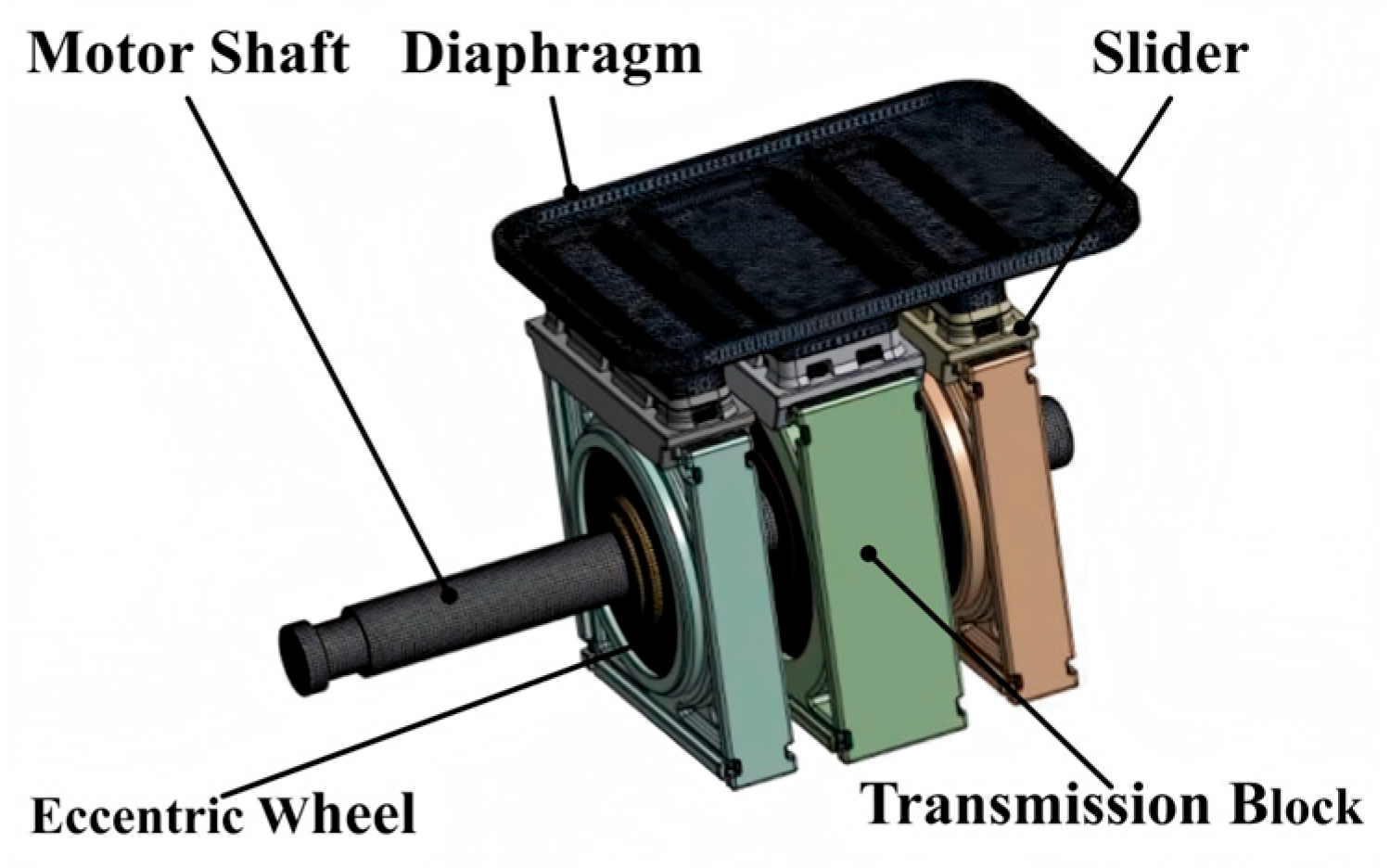

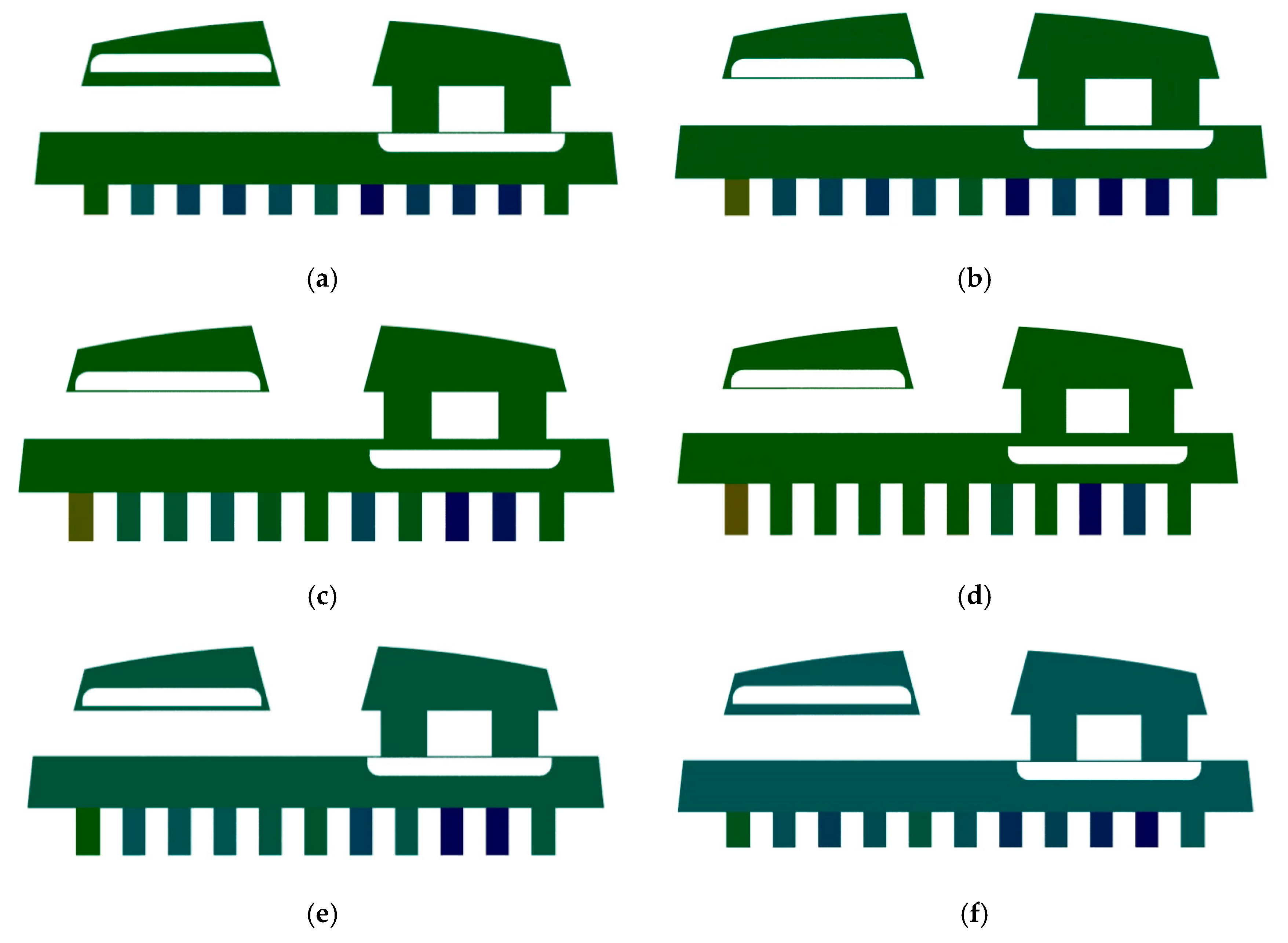

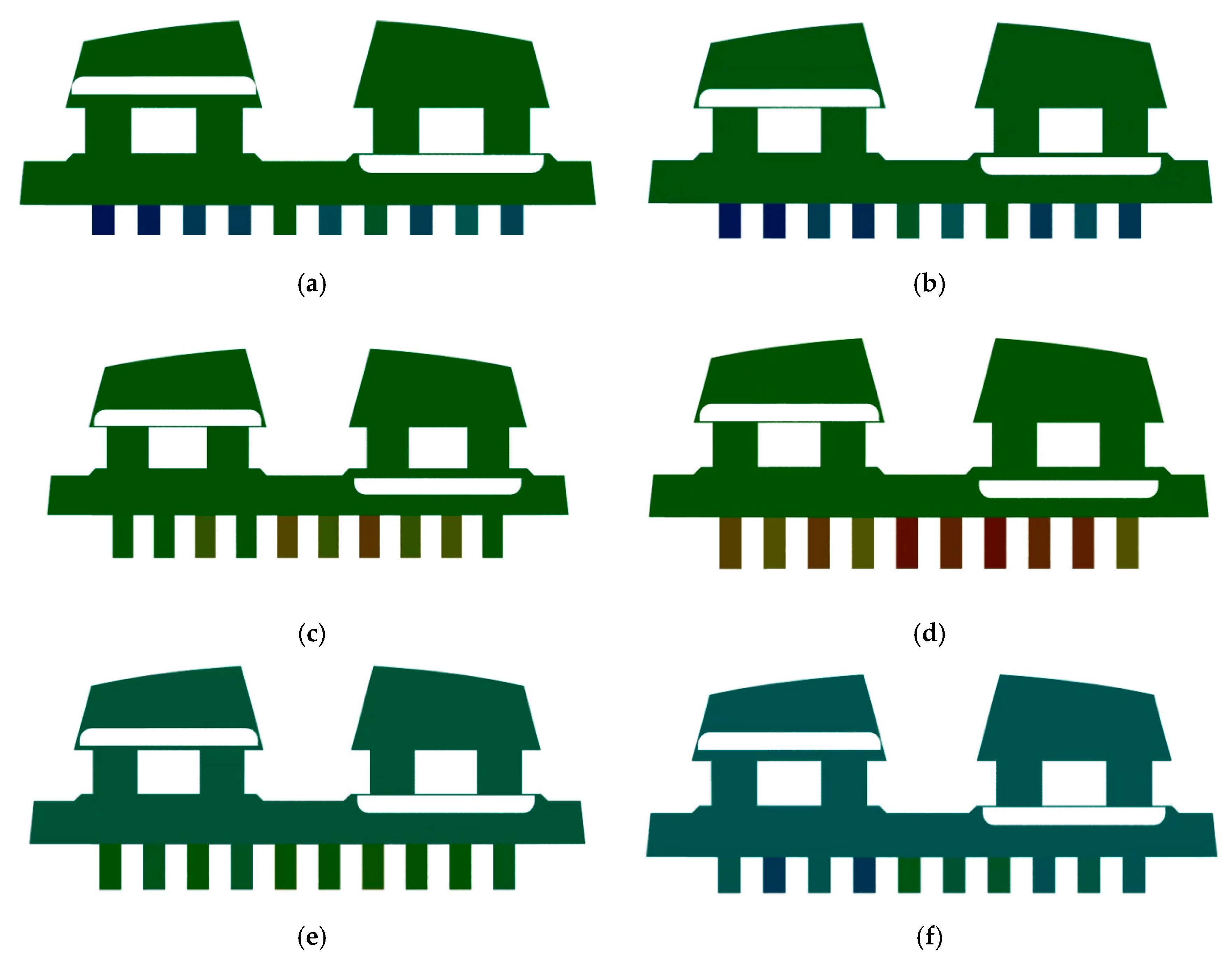

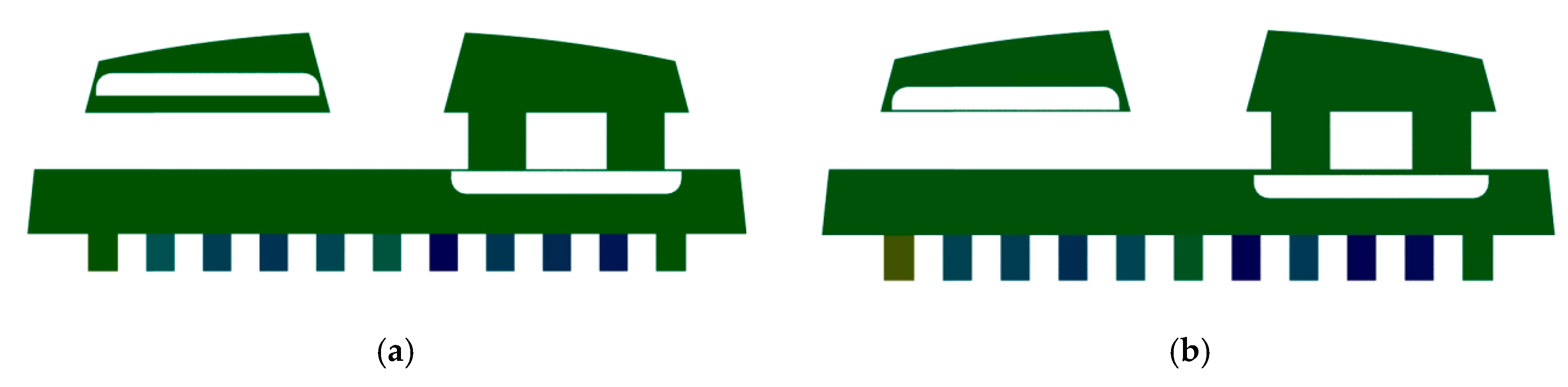

2. Geometry and Working Principles of the Pump

3. Flow Field Simulation and Static Analysis Boundary Conditions

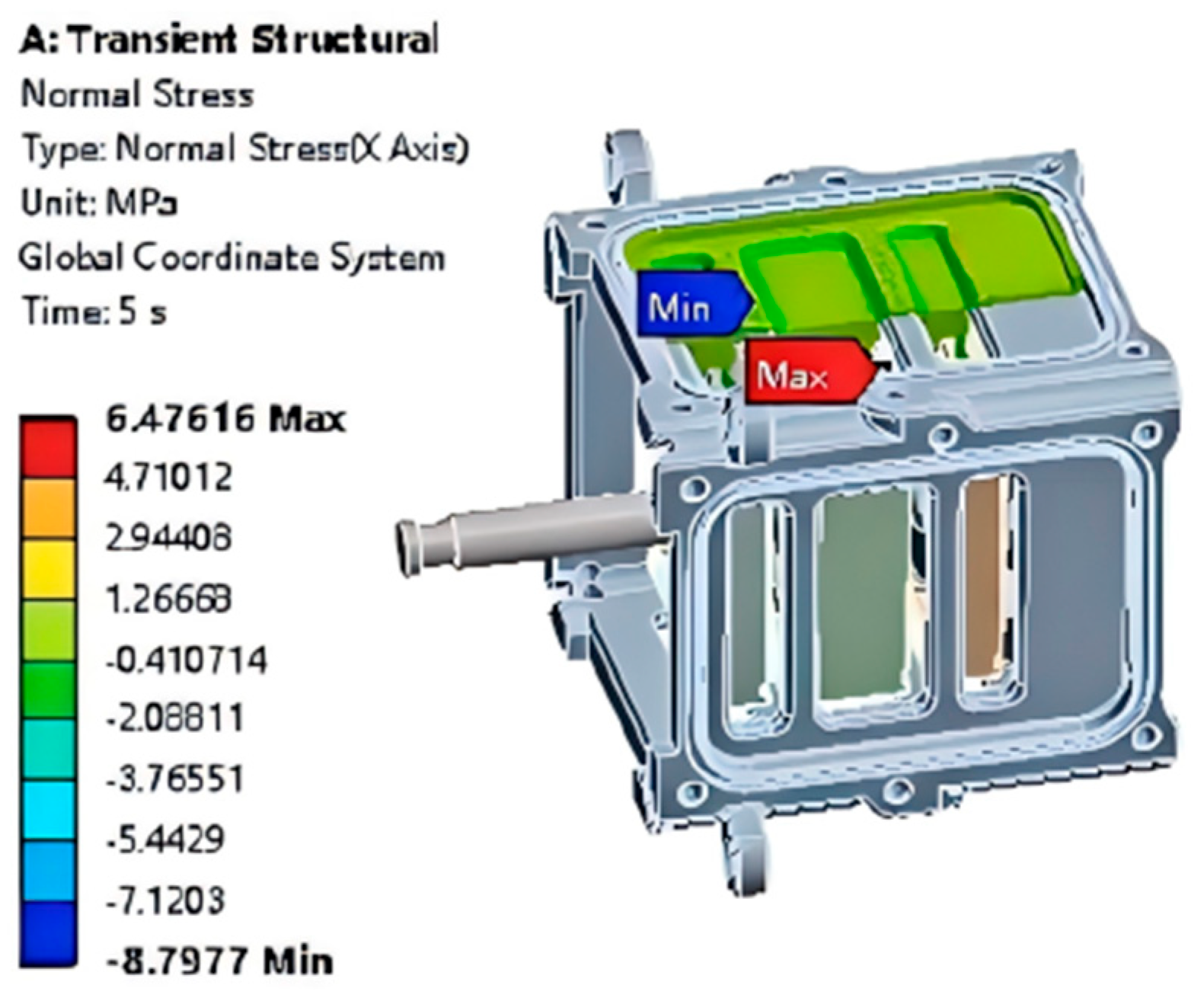

4. Numerical Analysis of Diaphragm Deformation and Stress

4.1. Simulation Model

4.2. Load and Boundary Conditions

4.2.1. Solid Boundary Conditions

4.2.2. Load Conditions

5. Numerical Analysis of Diaphragm Stress and Internal Flow Field Simulation

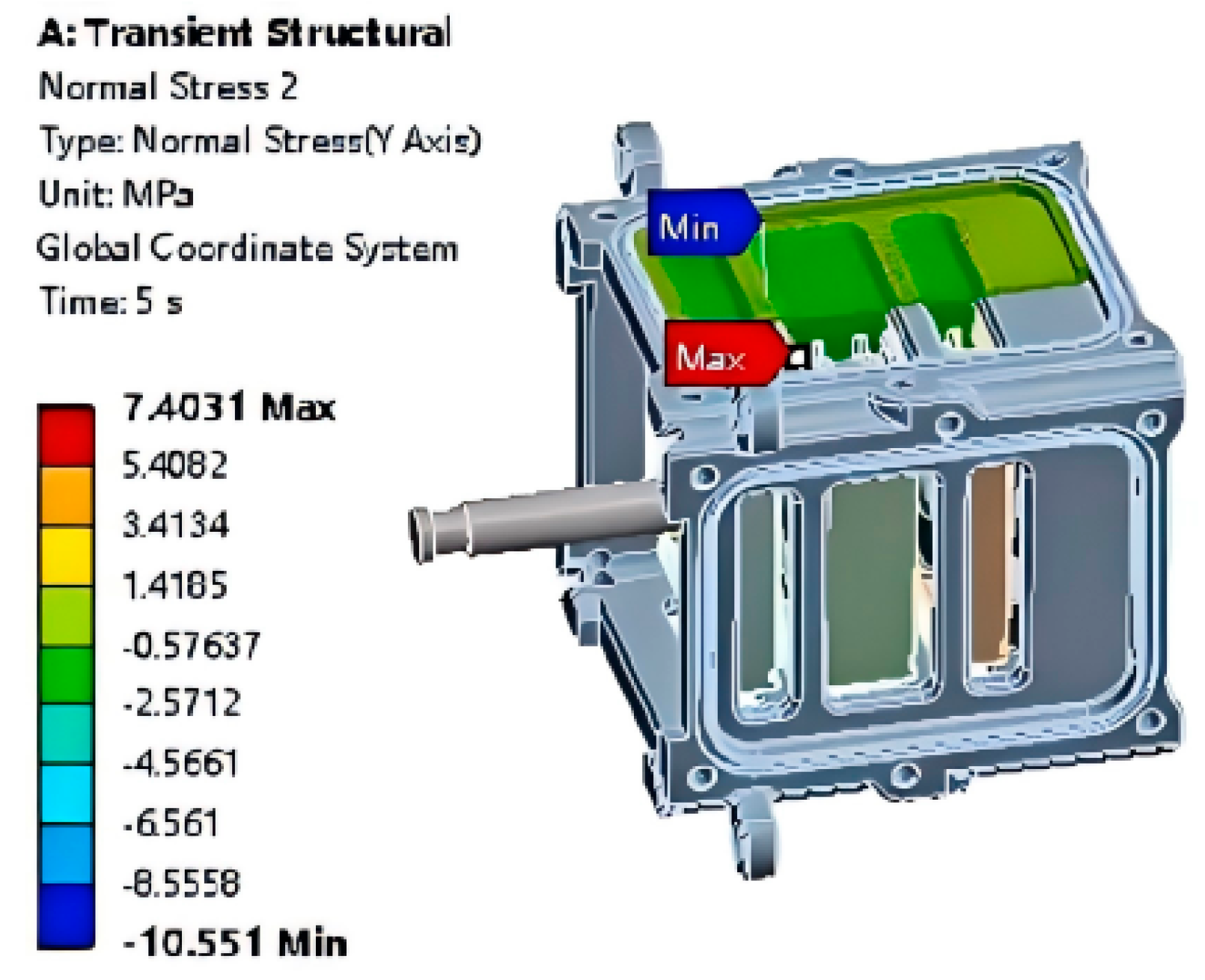

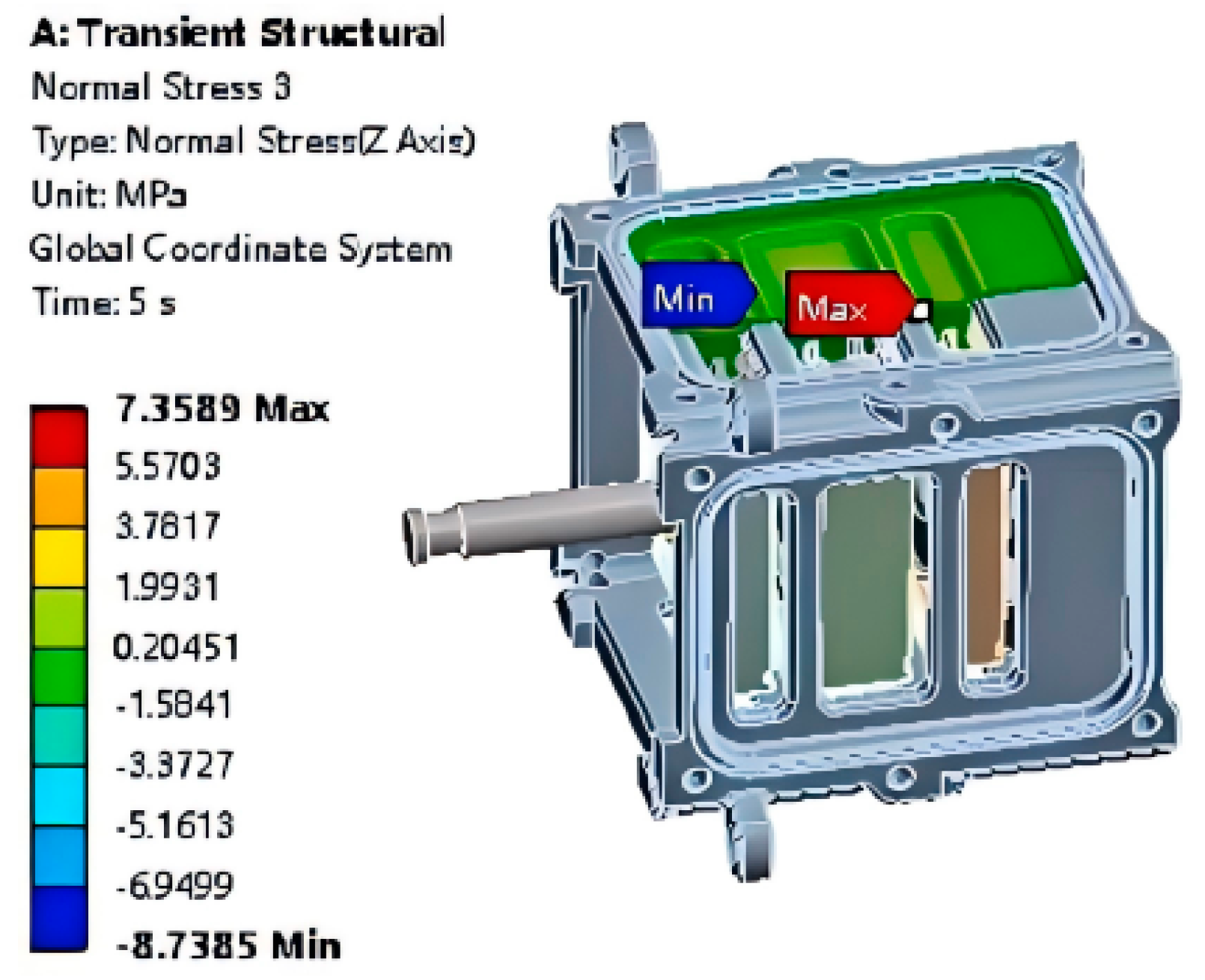

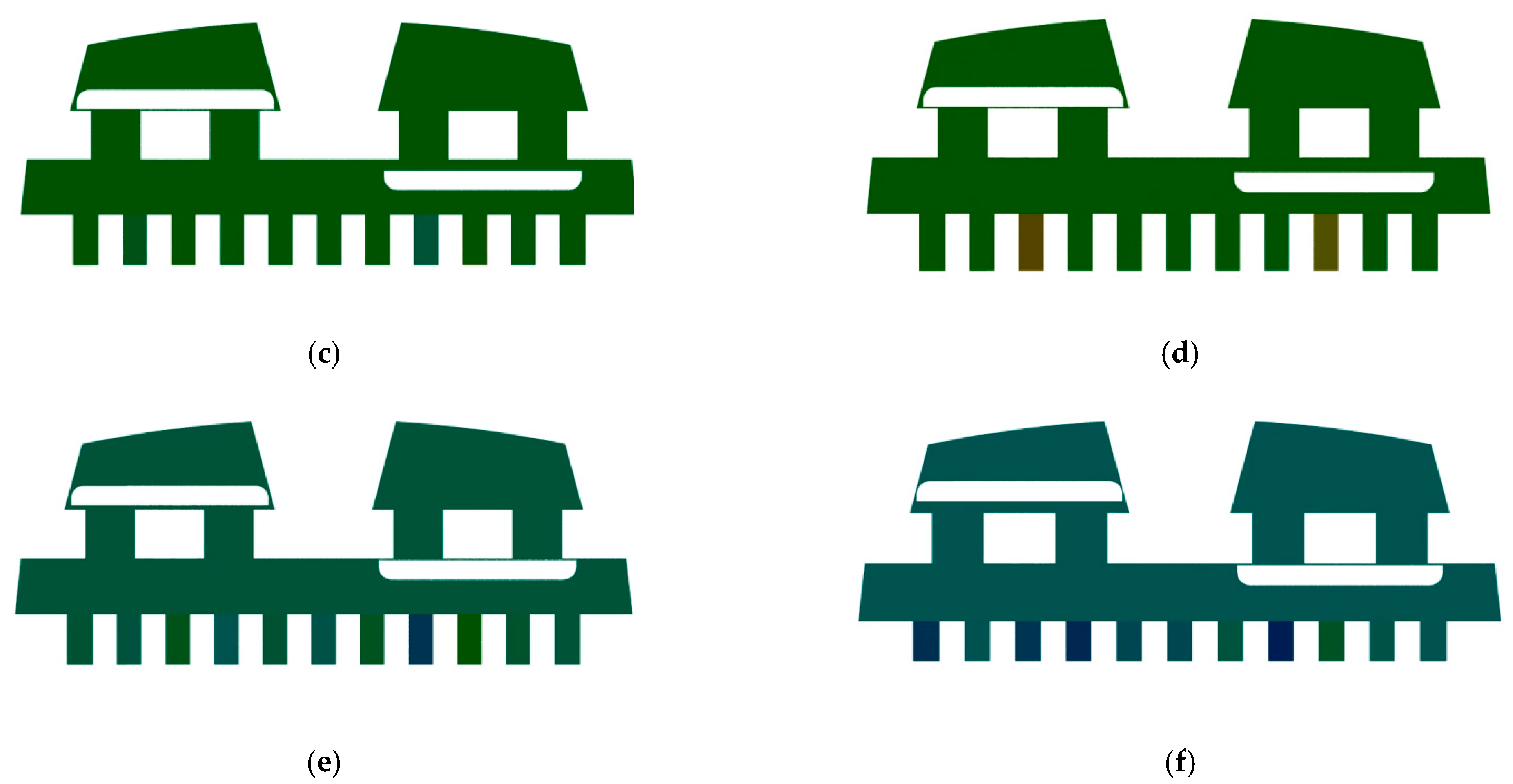

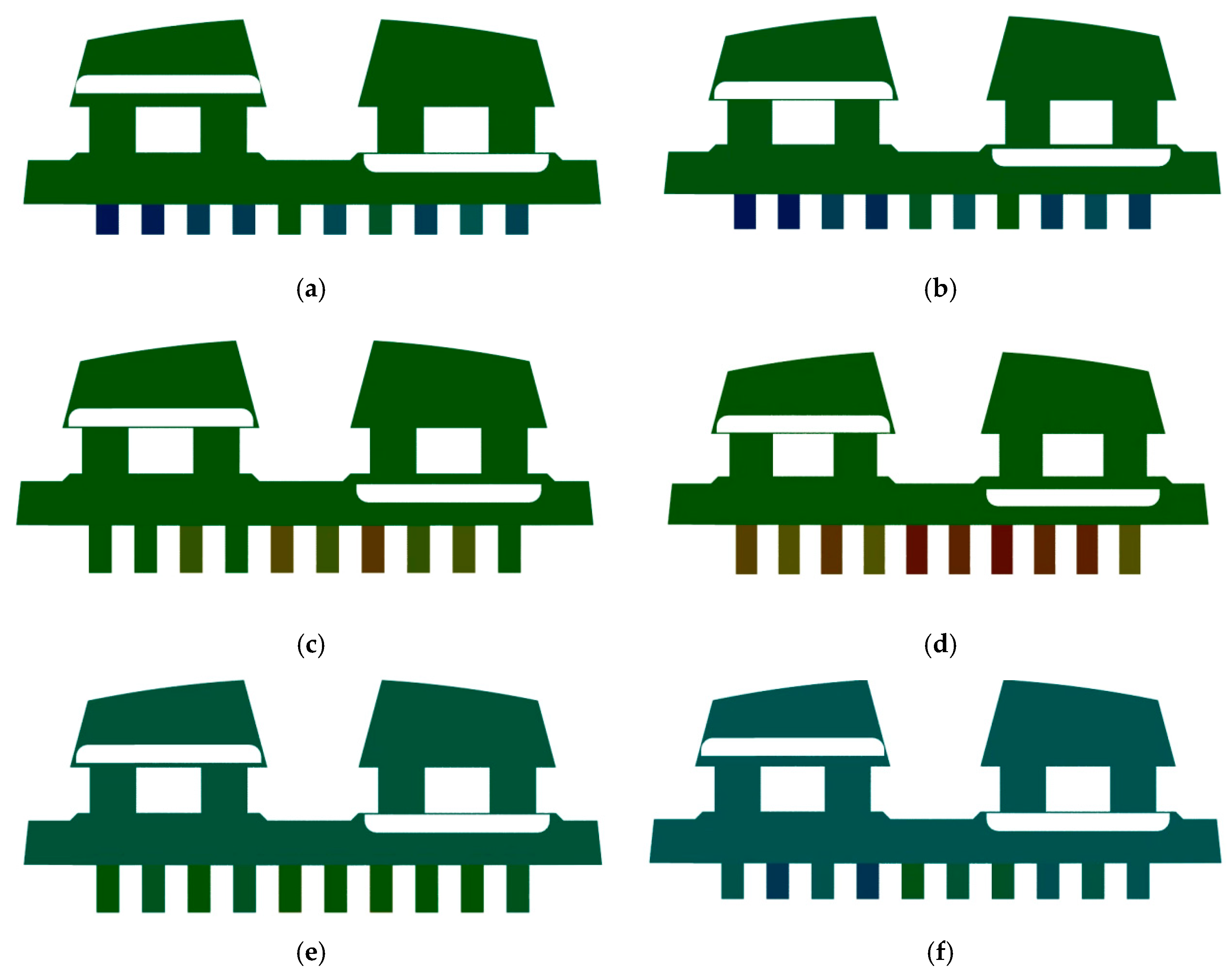

5.1. Numerical Analysis of Diaphragm Stress

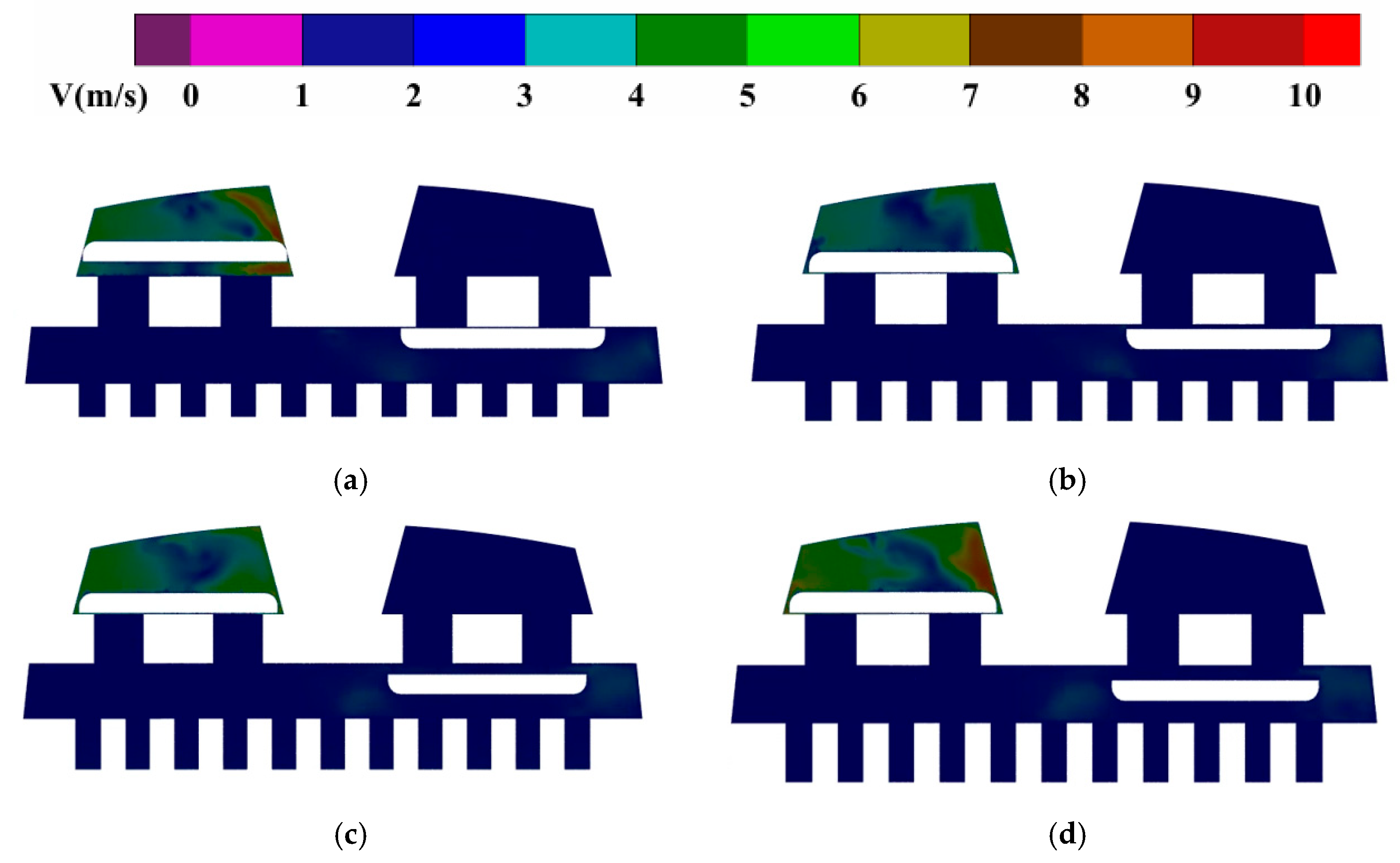

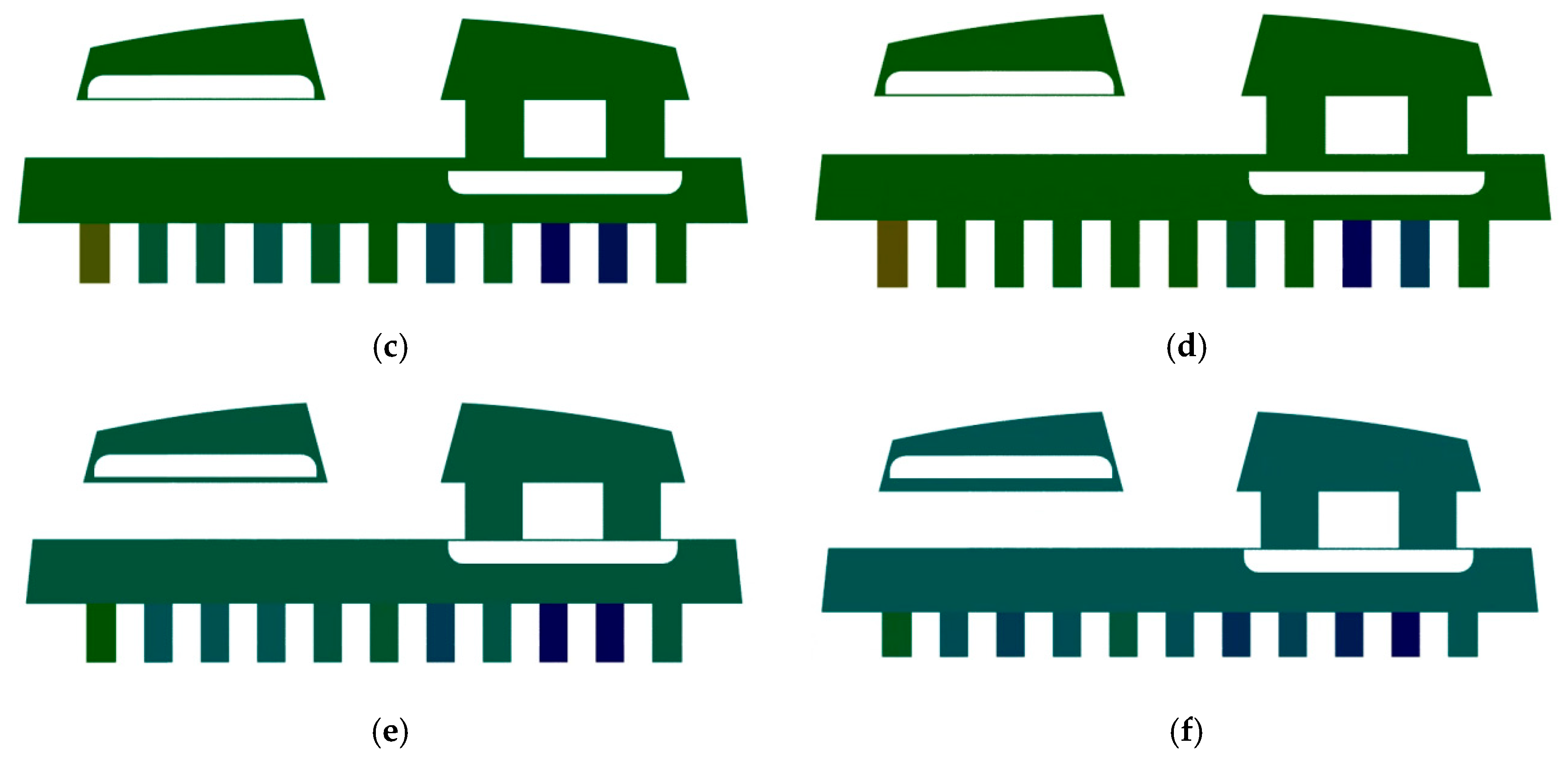

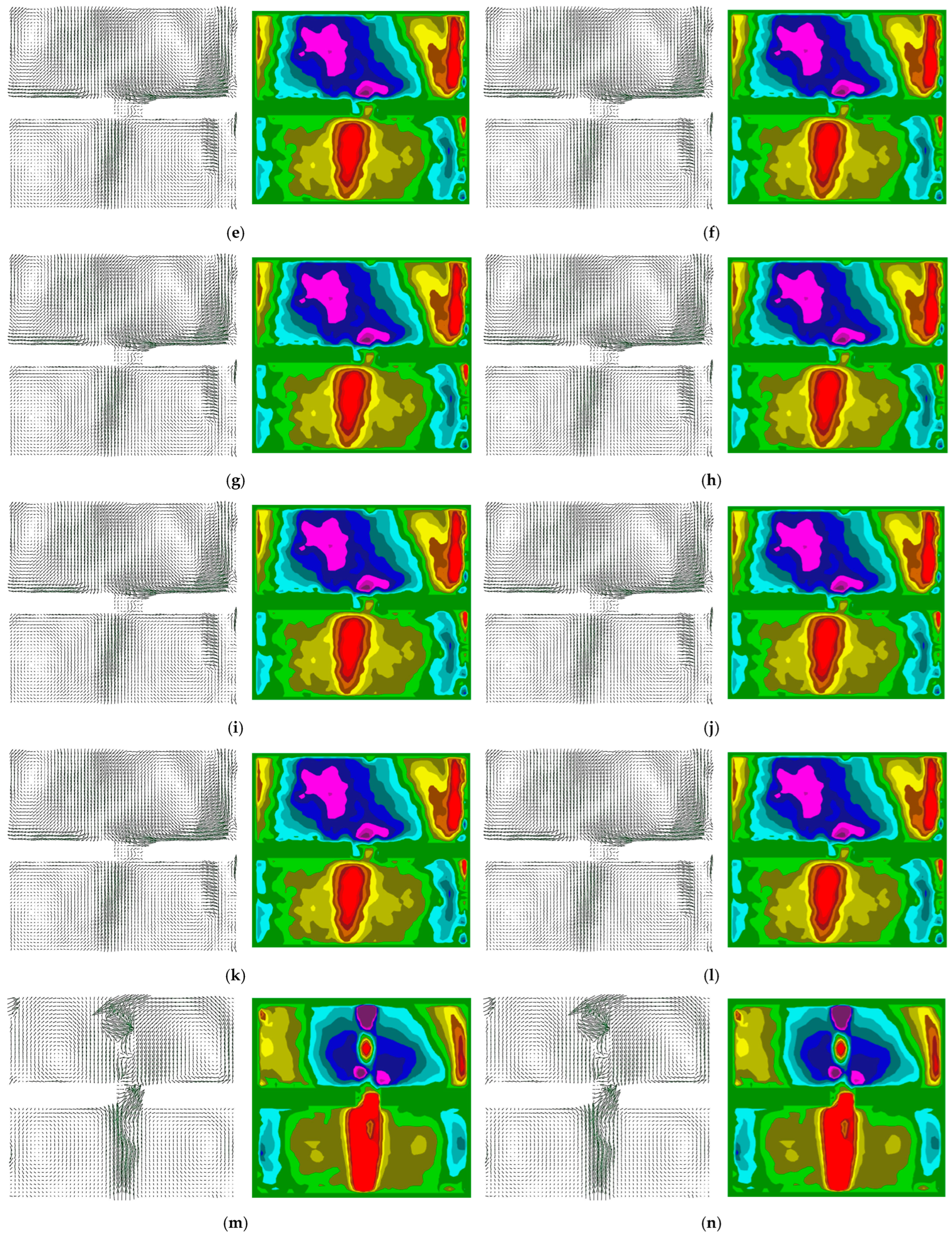

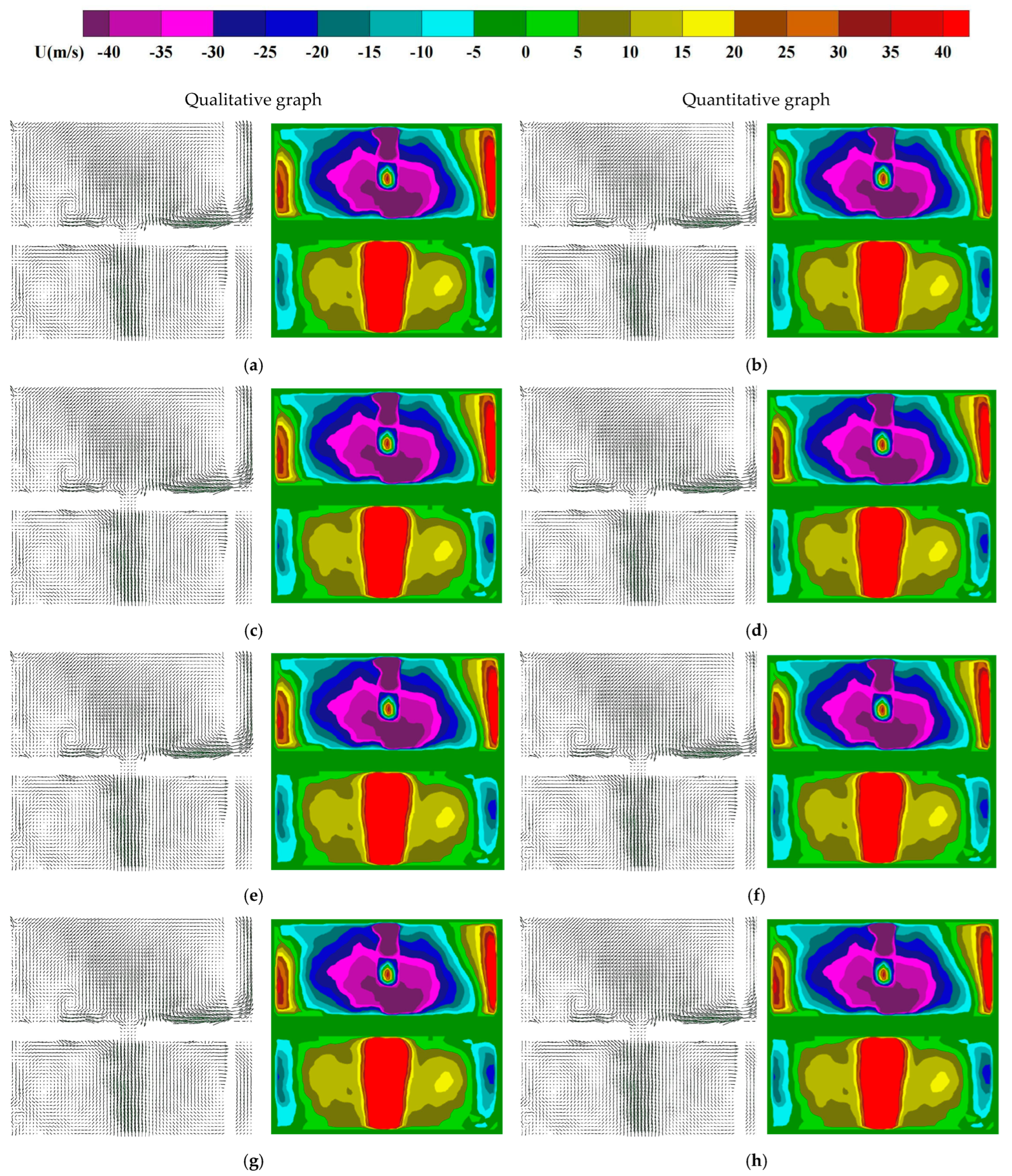

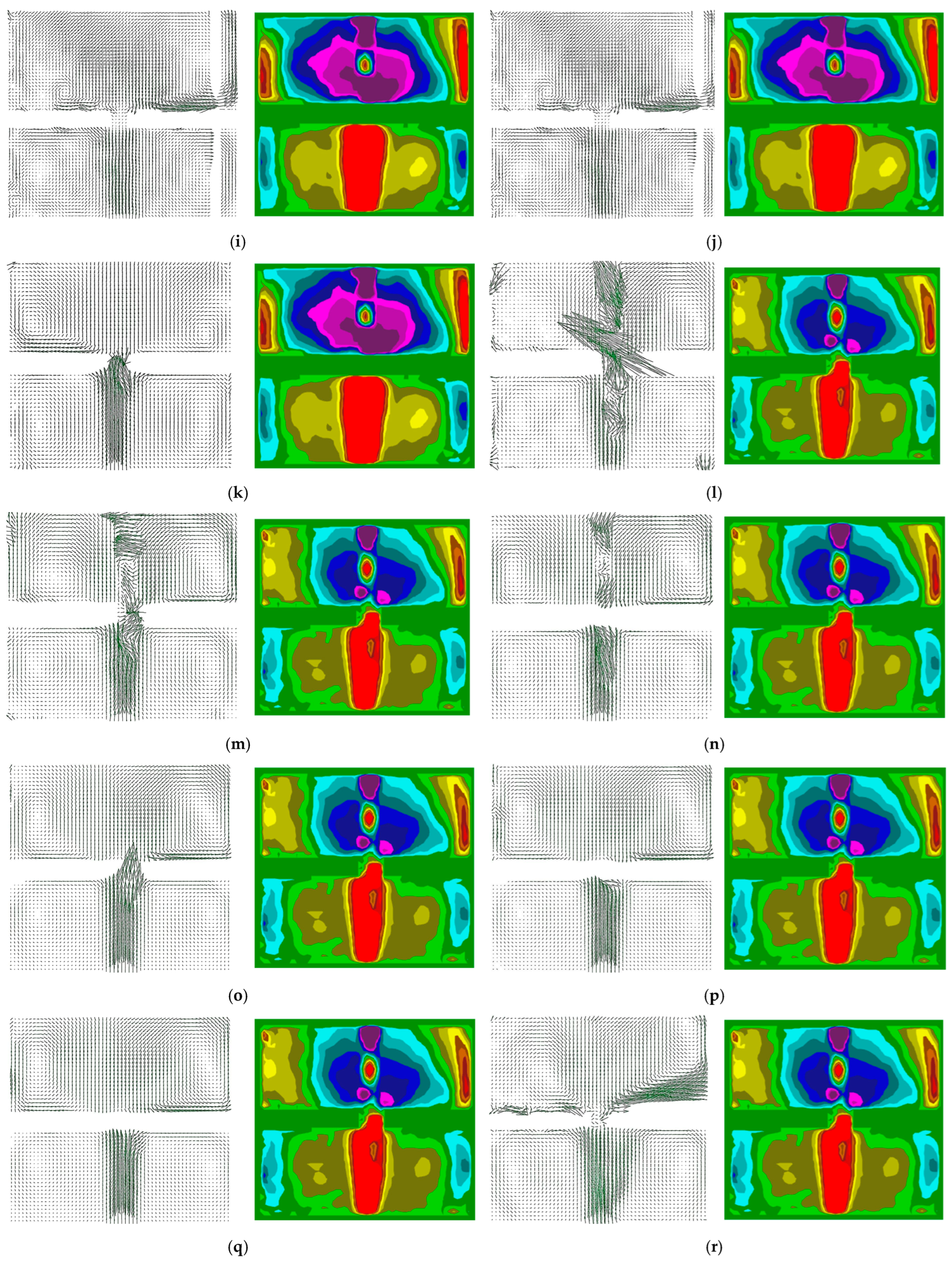

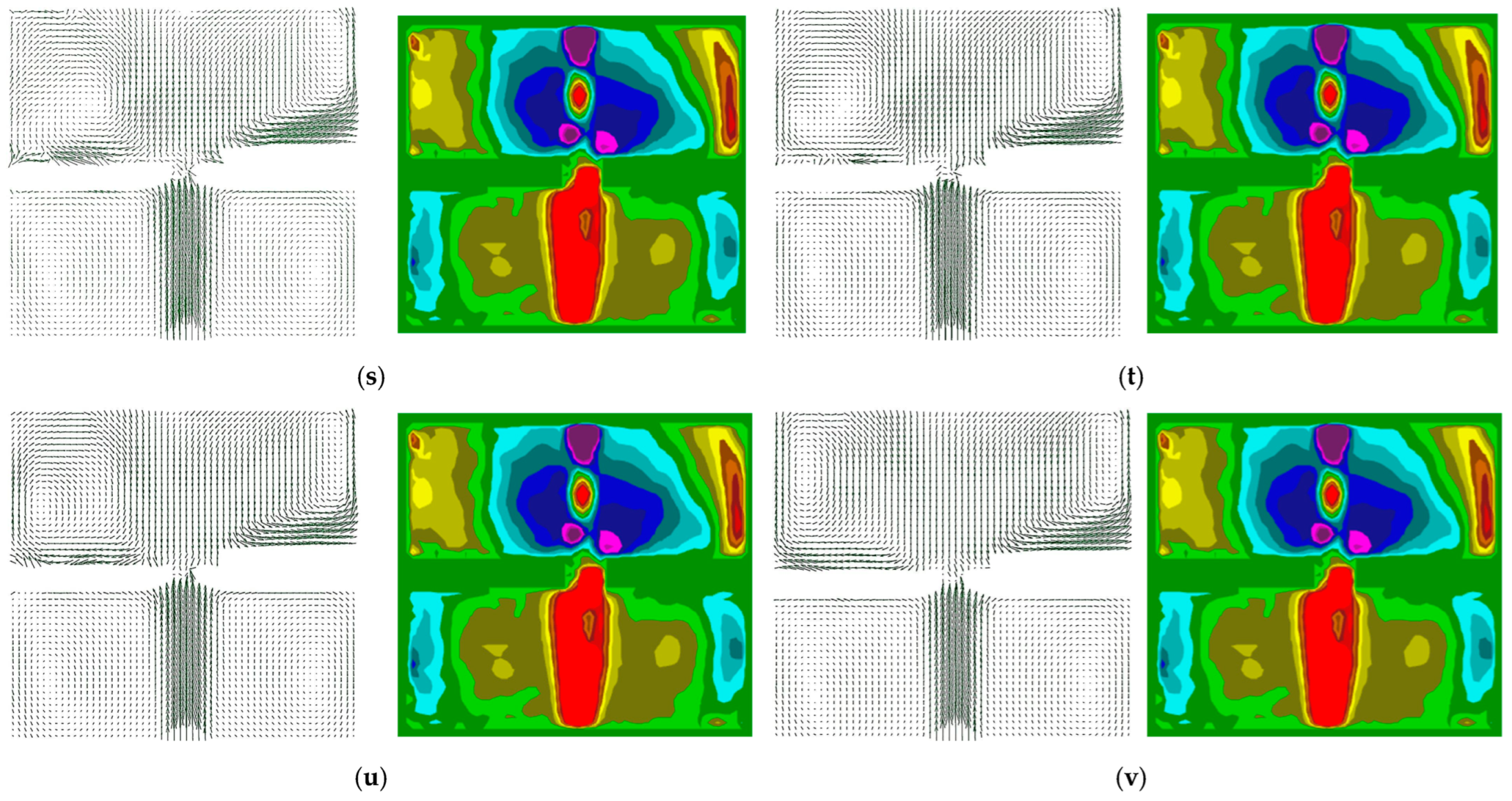

5.2. Internal Flow Field Simulation

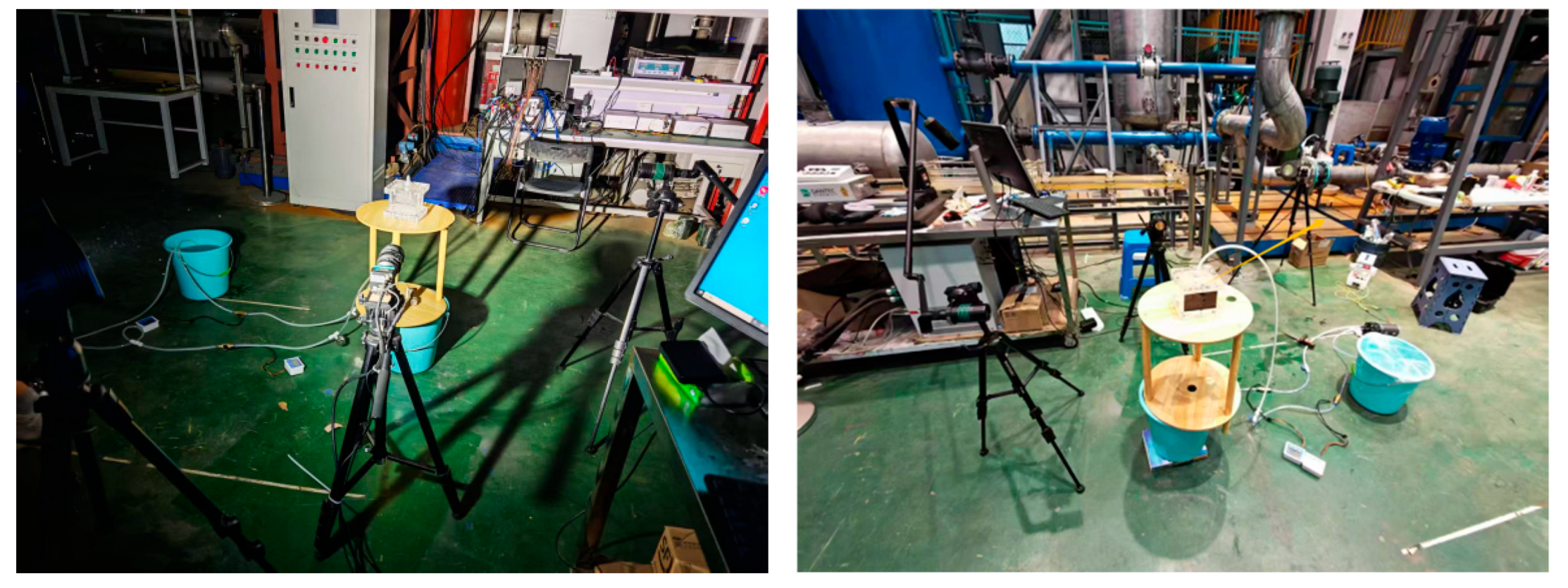

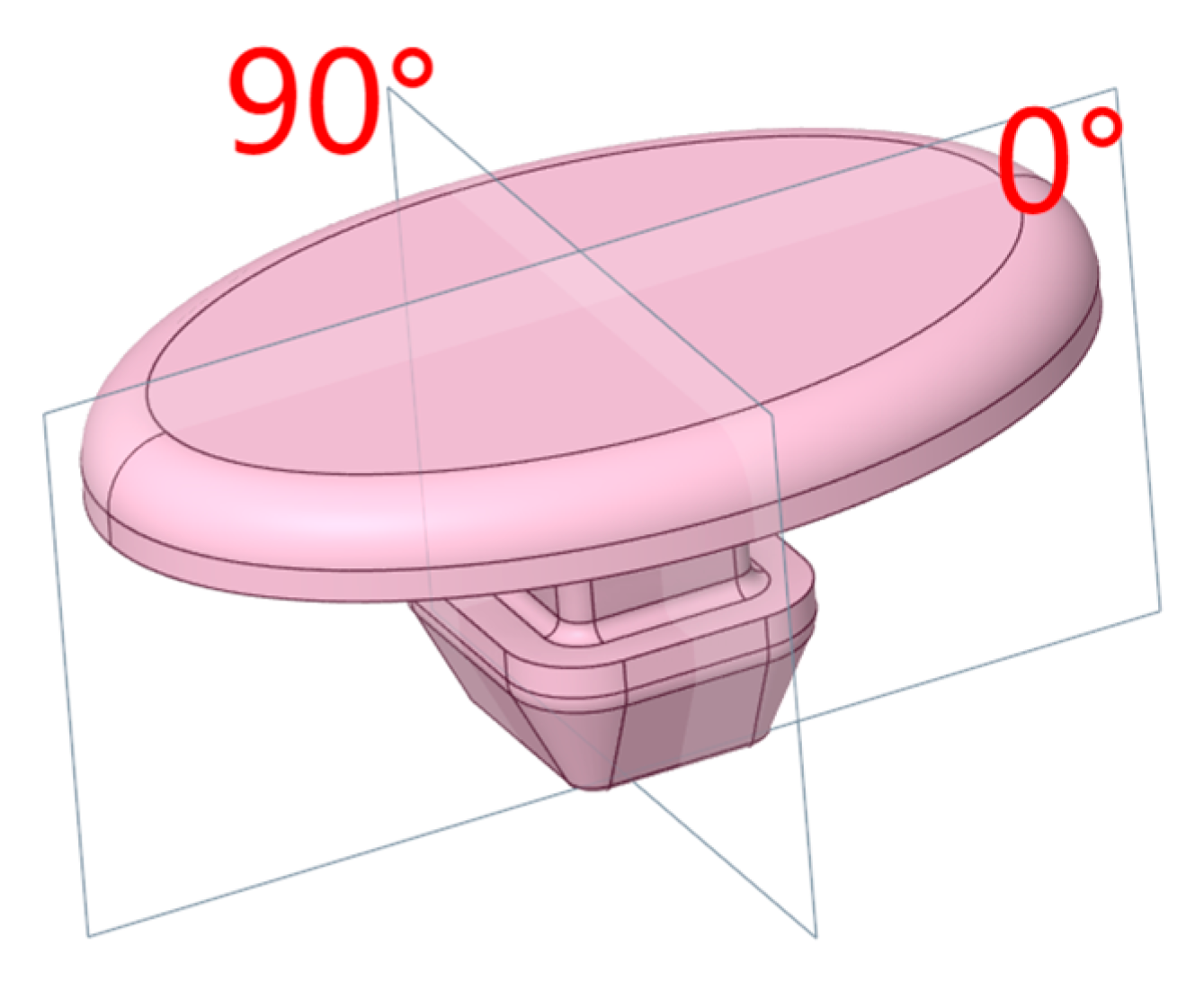

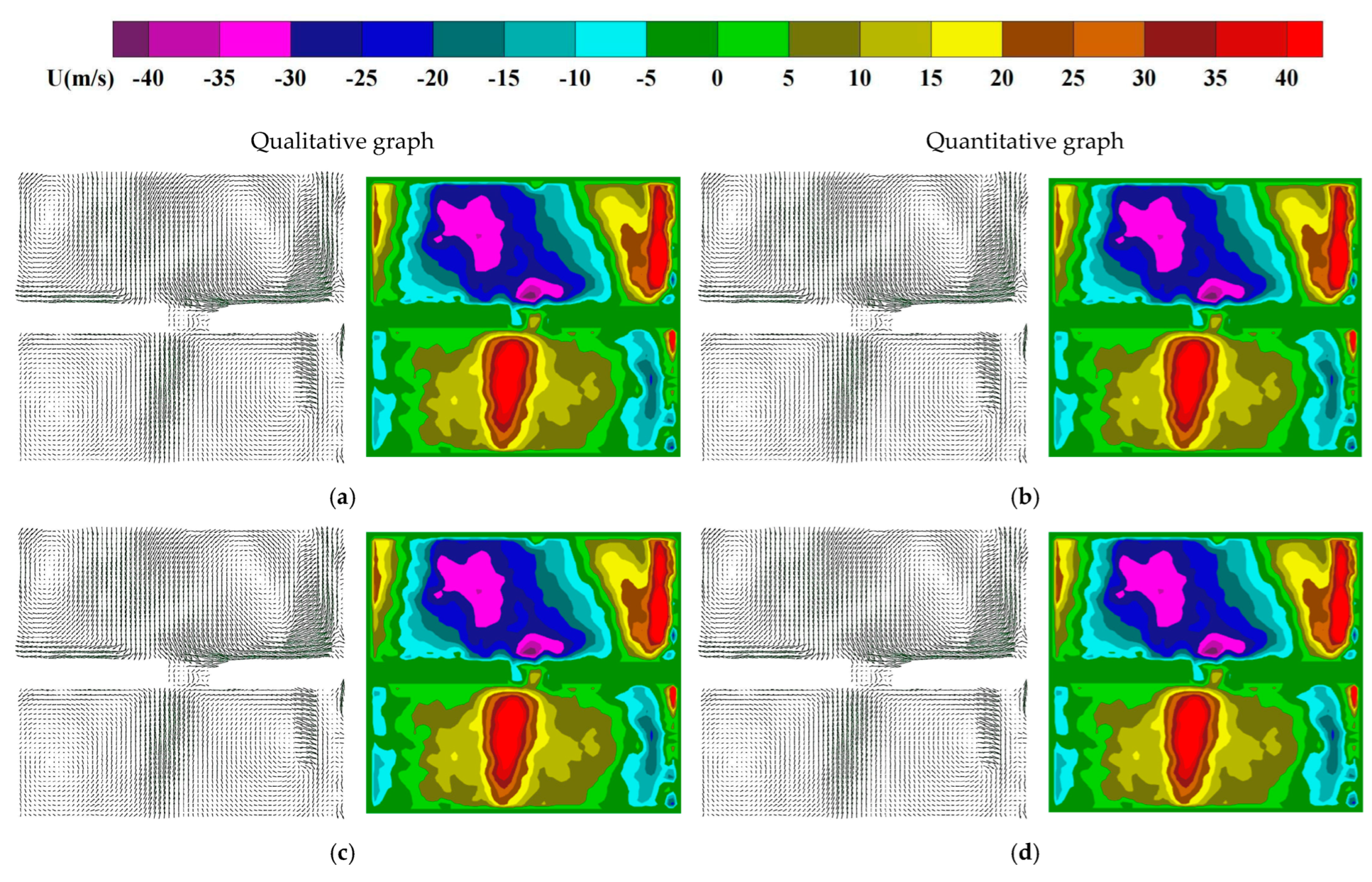

6. PIV Experiment Investigation of Umbrella Valve

7. Conclusions

- 1.

- A steady-state structural analysis of the diaphragm pump was conducted using ANSYS, incorporating both large deformation and nonlinear material behavior of the rubber. The simulation results reveal a maximum stress of 8.64 MPa and a displacement of 0.134 mm, which occur at the lower edge of the fluid–solid coupling surface. These findings indicate that the fluid pressures are effectively balanced, providing critical insights for the structural optimization of diaphragm pump designs.

- 2.

- A comparison between experimental results and actual operating conditions reveals that maximum stress occurs at the edge of the fluid–solid interface, aligning with the observed diaphragm failure locations. During the diaphragm’s return stroke, elevated tension in this region causes a sharp increase in local stress. Prolonged operation under these conditions leads to material fatigue and eventual structural failure. The observed damage at the diaphragm edge corroborates the predicted failure sites, thereby validating the accuracy of the stress analysis.

- 3.

- PIV experiments on the umbrella valve demonstrate that, at a constant flow rate, increasing the voltage leads to greater valve opening, higher flow velocity, a wider velocity distribution, and more complex flow field patterns. These changes are accompanied by a loss of symmetry in the flow structure. Quantitative analysis shows a significant increase in both the maximum and minimum velocity values, with more pronounced velocity fluctuations near the valve edges. Abrupt changes are concentrated in the plane perpendicular to both the valve edge and the midline. At an angle of 90°, the edge velocity exhibits more frequent and larger amplitude variations.

- 4.

- At constant pressure, an increase in flow rate leads to an expansion in vortex volume and higher energy consumption due to intensified vortex activity. This results in greater pressure loss and reduced overall efficiency. The elevated flow rate also introduces a left–right pressure differential, altering local velocities and destabilizing the flow distribution, which promotes the formation of additional small-scale vortices. Under varying flow rates, the behavior of the standard diaphragm becomes more complex. Vortices become increasingly unstable and prone to breakdown under different pressure conditions, ultimately reducing the system’s dynamic response speed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| A2 cross-section diaphragm travel trajectory control code: #include “udf.h” #include <math.h> /* Define constants */ #define A 0.042/* Amplitude of motion in y-direction 6mm */ #define PI M_PI/* Value of pi */ DEFINE_CG_MOTION(translate_invalva, dt, vel, omega, time, dtime) { real t, T, v_y; T = 60.0/1350.0; /* Calculate the current time */ t = time/T - floor(time/T); /* Define the y-velocity as a function of time */ if (t < 0.1) { v_y = 5*A*sin(PI*t/0.1); } else if (t < 0.5) { v_y = 0.0; } else { v_y = -A*sin(PI*(t-0.5)/0.5); } /* Set the velocity vector */ vel[1] = v_y; } |

| A1, A3 cross-section diaphragm travel trajectory control code: #include “udf.h” #include <math.h> /* Define constants */ #define A 0.042 /* Amplitude of motion in y-direction */ #define PI M_PI/* Value of pi */ DEFINE_CG_MOTION(translate_outvalve, dt, vel, omega, time, dtime) { real t, T, v_y; T = 60.0/1350.0; /* Calculate the current time */ t = time/T - floor(time/T); /* Define the y-velocity as a function of time */ if (t < 0.5) { /* Before half of the period */ v_y = A*sin(PI*t/0.5); } else if (t < 0.6) { /* Transition period */ v_y = -5*A*sin(PI*(t-0.5)/0.1); } else { /* After the transition period */ v_y = 0.0; } /* Set the velocity vector */ vel[1] = v_y; } |

References

- Khattak, M.M.; Dolph, A.W.; Headings, L.M.; Dapino, M.J. Magnetostrictive materials for tunable fluid pumps. In Behavior and Mechanics of Multifunctional Materials XVIII; SPIE: Bellingham, WA, USA, 2024; Volume 12947, pp. 97–107. [Google Scholar]

- Anis, Y.; Meldrum, D. Static and transient response analysis of a piezoelectric actuator driven diaphragm pico-liter pump. In Proceedings of the 2012 4th IEEE RAS & EMBS International Conference on Biomedical Robotics and Biomechatronics, Rome, Italy, 24–27 June 2012; pp. 652–656. [Google Scholar]

- Taylor, A.P.; Velásquez-García, L.F. Miniaturized diaphragm vacuum pump by multi-material additive manufacturing. J. Microelectromech. Syst. 2017, 26, 1316–1326. [Google Scholar] [CrossRef]

- Amiri, A.; Shabani, R.; Rezazadeh, G. Coupled vibrations of a magneto-electro-elastic micro-diaphragm in micro-pumps. Microfluid. Nanofluidics 2016, 20, 18. [Google Scholar] [CrossRef]

- Van Rijswick, R.; Talmon, A.; Van Rhee, C. Fluid structure interaction (FSI) in piston diaphragm pumps. Can. J. Chem. Eng. 2016, 94, 1116–1126. [Google Scholar] [CrossRef]

- Skupień, S.; Kowol, P.; Capizzi, G.; Sciuto, G.L. Control system hardware design, analysis and characterization of electromagnetic diaphragm pump. Appl. Sci. 2024, 14, 8043. [Google Scholar] [CrossRef]

- Ma, H.K.; Chen, R.H.; Yu, N.S.; Hsu, Y.H. A miniature circular pump with a piezoelectric bimorph and a disposable chamber for biomedical applications. Sens. Actuators A Phys. 2016, 251, 108–118. [Google Scholar] [CrossRef]

- Taylor, A.P.; Velásquez-García, L.F. 3-D printed miniaturized diaphragm vacuum pump. In Proceedings of the 2017 IEEE 30th International Conference on Micro Electro Mechanical Systems (MEMS), Las Vegas, NV, USA, 22–26 January 2017; pp. 1292–1295. [Google Scholar]

- Taylor, A.P.; Reyes, J.I.; Velásquez-García, L.F. Compact, magnetically actuated, additively manufactured pumps for liquids and gases. J. Phys. D Appl. Phys. 2020, 53, 355002. [Google Scholar] [CrossRef]

- Jiang, S.; Tang, C.; Dong, X.; Liu, X.J.; Zhao, H. Soft Pocket Pump for Multi-Medium Transportation via an Active Tubular Diaphragm. Adv. Funct. Mater. 2023, 33, 2305289. [Google Scholar] [CrossRef]

- Yang, S.D.; Shi, Y.C.; Pan, X.W.; Liu, Y.S. Theoretical and experimental study on flow characteristics of a diaphragm pump for urea-SCR systems. Int. J. Automot. Technol. 2019, 20, 835–844. [Google Scholar] [CrossRef]

- Thomas, D.J.; Tehrani, Z.; Redfearn, B. 3-D printed composite microfluidic pump for wearable biomedical applications. Addit. Manuf. 2016, 9, 30–38. [Google Scholar] [CrossRef]

- Jairazbhoy, V.; Stevenson, R.C. Mathematical modeling of molten metal dispensing: A study of a pneumatically actuated diaphragm-driven pump. Appl. Math. Model. 2008, 32, 141–169. [Google Scholar] [CrossRef]

- Yang, M.; Kabasawa, Y.; Ito, K. Fabrication of micro metallic valve and pump. In Fourth International Conference on Experimental Mechanics; SPIE: Bellingham, WA, USA, 2010; Volume 7522, pp. 509–514. [Google Scholar]

- Masse, P.A. Computer Modeling and Simulation of Pneumatically Driven Double-Diaphragm Pumps; University of Louisville: Louisville, KY, USA, 1995. [Google Scholar]

- Sakamoto, R.; Dao, D.V.; Tanaka, K.; Sugiyama, S. Design and fabrication process of a micropump using bulk Pb(Zr,Ti)O3 for microfluidic devices. In Device and Process Technologies for Microelectronics, MEMS, Photonics, and Nanotechnology IV; SPIE: Bellingham, WA, USA, 2008; Volume 6800, pp. 439–446. [Google Scholar]

- Lee, S.; Kim, K.J. Design of IPMC actuator-driven valve-less micropump and its flow rate estimation at lowReynolds numbers. Smart Mater. Struct. 2006, 15, 1103. [Google Scholar] [CrossRef]

- Lee, H.J.; Shin, D.J.; Park, K. Ultrasonic thermoforming of a large thermoplastic polyurethane film with the aid of infrared heating. J. Mech. Sci. Technol. 2017, 31, 5687–5693. [Google Scholar] [CrossRef]

- Cao, C.; Gao, X.; Conn, A.T. A magnetically coupled dielectric elastomer pump for soft robotics. Adv. Mater. Technol. 2019, 4, 1900128. [Google Scholar] [CrossRef]

- Ping, X.; Yao, B.; Niu, K.; Yuan, M. A machine learning framework with an intelligent algorithm for predicting the isentropic efficiency of a hydraulic diaphragm metering pump in the organic rankine cycle system. Front. Energy Res. 2022, 10, 851513. [Google Scholar] [CrossRef]

- Abe, T.; Oh-Hara, S.; Ukita, Y. Adoption of reinforcement learning for the intelligent control of a microfluidic peristaltic pump. Biomicrofluidics 2021, 15, 034101. [Google Scholar] [CrossRef]

- Truong, B.N.M.; Ahn, K.K. Modeling, control and experimental investigation of time-average flow rate of a DEAP actuator based diaphragm pump. Int. J. Precis. Eng. Manuf. 2017, 18, 1119–1129. [Google Scholar] [CrossRef]

- Sato, K.; Orihashi, K.; Kurosaki, T.; Tokumine, A.; Fukunaga, S.; Ninomiya, S.; Sueda, T. Analysis of flow patterns in a ventricular assist device: A comparative study of particle image velocimetry and computational fluid dynamics. Artif. Organs 2009, 33, 352–359. [Google Scholar] [CrossRef]

- Van der Burgt, R.C.; Anderson, P.D.; den Toonder, J.M.; van de Vosse, F.N. A microscale pulsatile flow device for dynamic cross-slot rheometry. Sens. Actuators A Phys. 2014, 220, 221–229. [Google Scholar] [CrossRef]

- Zhao, H.; Zhu, B.; Wang, C.; Han, Y. A prospective assessment of vortex evolution mechanisms and pressure fluctuation coupling in novel low-head pumped hydro energy storage units. Energy Convers. Manag. 2025, 342, 120136. [Google Scholar] [CrossRef]

- Zhao, H.; Zhu, B.; Xu, R.; Tan, L.; Zhang, H.; Chen, L.; Liu, Z.; Yang, J.; Deng, F. Evaluating the predictive potential of modeling frameworks for Pelton turbine energy performance and guiding engineering modeling in hydroelectric applications. Energy 2025, 330, 136861. [Google Scholar] [CrossRef]

- Tang, S.; Yan, Z.; Xue, Y.; Lim, K.M.; Zhu, Y. Deep transferable model with multi-head attention for small sample fault diagnosis of hydraulic pumps. Eng. Appl. Artif. Intell. 2025, 160, 111808. [Google Scholar] [CrossRef]

- Zhou, P.; Li, J.; Wu, Y.; Wang, Y.; Zhou, X.; Wen, Z.; Zhao, H. Study of cavitation-induced flow characteristics of a vortex pump based on coherence analysis. Phys. Fluids 2025, 37, 033318. [Google Scholar] [CrossRef]

- Chang, H.; Wang, Z.; Peng, G.; Shi, W.; Lin, R.; Zhou, L. Role of wall roughness on energy dissipation and vortex dynamics in self-priming centrifugal pump: A study via entropy generation and Liutex vortex identification. Energy 2025, 337, 138733. [Google Scholar] [CrossRef]

- Chang, H.; Yang, J.; Wang, Z.; Peng, G.; Lin, R.; Lou, Y.; Zhou, L. Efficiency optimization of energy storage centrifugal pump by using energy balance equation and non-dominated sorting genetic algorithms-II. J. Energy Storage 2025, 114, 115817. [Google Scholar] [CrossRef]

| PARAMETERS | CALIBRATION |

|---|---|

| D1 | 5.5 |

| D2 | 5.5 |

| D3 | 0.55 |

| PIN | 30 |

| POUT | 100 |

| N | 1350 |

| Q | 4000 |

| Parameters | Material | Average Diameter (mm) |

|---|---|---|

| Solid | Polystyrene | 10–100 |

| Aluminum powder | 2–7 | |

| Glass beads | 10–100 | |

| Synthetic cotton particles | 10–500 | |

| Liquid | Various oils | 50–500 |

| Gas | Oxygen bubbles | 50–1000 |

| Parameters | Model | Performance Parameters |

|---|---|---|

| Diaphragm pump | QW | Rated inlet pressure: 207 kPa Rated outlet pressure: 690 kPa Rated flow rate: 4 L/min |

| Terbing flow meter | LWGY-SUP-DN4-JS-BDCC | Flow range: 60 L/h–360 L/h Accuracy: 0.5% |

| Flow control valve | WL94H-320P | Accuracy: ±0.005 mm |

| Pressure gauge | SUP-PX400-JS-BDCC | Pressure range: 0–1.6 MPa Accuracy: 0.25% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, G.; Chai, H.; Liu, C.; Zhao, K.; Zhang, J.; Chang, H. Numerical and Experimental Analysis of Internal Flow Characteristics of Four-Way Opposing Diaphragm Pump. Water 2025, 17, 3094. https://doi.org/10.3390/w17213094

Peng G, Chai H, Liu C, Zhao K, Zhang J, Chang H. Numerical and Experimental Analysis of Internal Flow Characteristics of Four-Way Opposing Diaphragm Pump. Water. 2025; 17(21):3094. https://doi.org/10.3390/w17213094

Chicago/Turabian StylePeng, Guangjie, Han Chai, Chengqiang Liu, Kai Zhao, Jianfang Zhang, and Hao Chang. 2025. "Numerical and Experimental Analysis of Internal Flow Characteristics of Four-Way Opposing Diaphragm Pump" Water 17, no. 21: 3094. https://doi.org/10.3390/w17213094

APA StylePeng, G., Chai, H., Liu, C., Zhao, K., Zhang, J., & Chang, H. (2025). Numerical and Experimental Analysis of Internal Flow Characteristics of Four-Way Opposing Diaphragm Pump. Water, 17(21), 3094. https://doi.org/10.3390/w17213094