5.2. Stress Variation Patterns of Flexible Mattress During Deployment

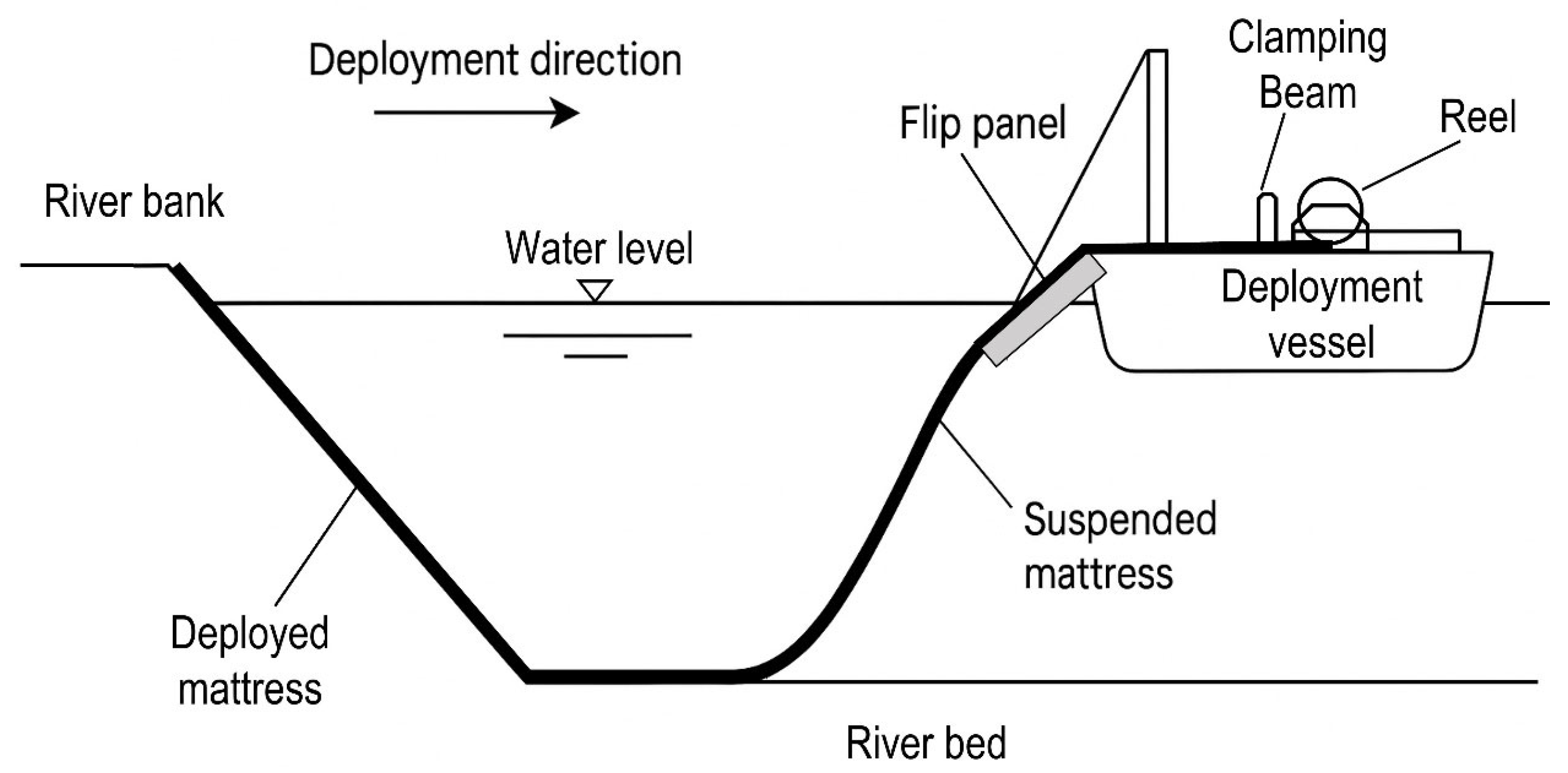

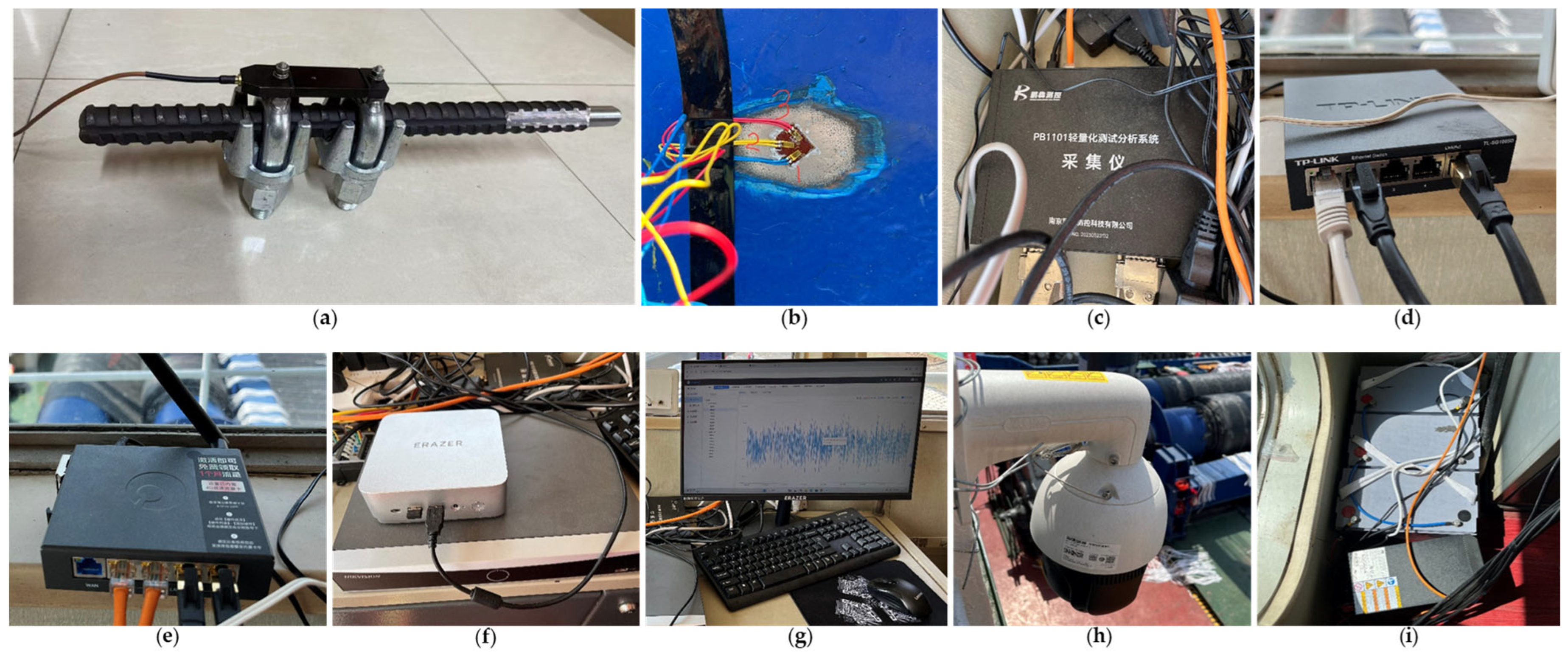

During the construction process, two main types of strain sensors were utilized in the monitoring system: the PB-530 tension sensor, installed on the steel cable of the flip plate; and the BE120-3CA-P300 three-axis strain gauge, installed on the roller base and clamping beam base. A total of 28 mattress units were deployed in this project, and the monitoring devices continuously recorded strain data at each monitoring point throughout the entire deployment process.

- (1)

Strain Variation on the Roller Base Caused by Flow-Induced Impact on the Mattress

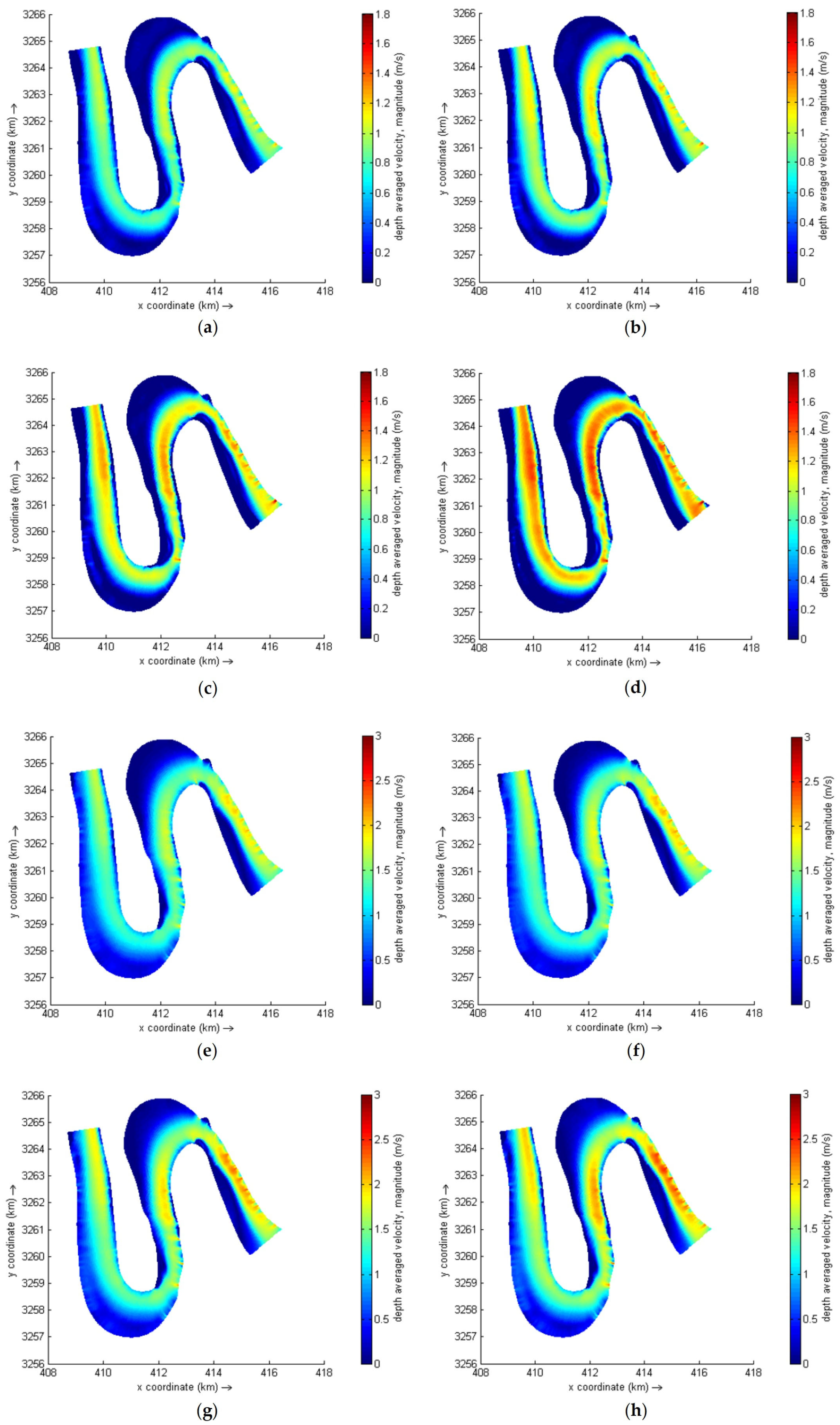

Given the close proximity between the clamping beam base and the roller base, and the similarity in their data variation trends, a triaxial strain gauge (Model: E120-3CA-P300) mounted on the bow-side roller base was selected for analysis, with monitoring data at this location extracted accordingly (

Figure 15a). The strain gauge follows the principle of “positive for tension, negative for compression.” When the tensile force in the mattress increases, the force transmitted to the base also increases, resulting in greater compressive stress at the monitoring point—therefore, the sensor output decreases. Conversely, if the tensile force decreases, the compressive stress on the base is reduced and the sensor output increases.

Monitoring data show that from 08:00 to 08:22, strain gradually decreased from approximately 1.115 µε to 1.110 µε (Δε = −0.005 µε, ≈ −0.45%). Around 08:22, the first short-term fluctuation occurred, with strain rising from the baseline of 1.110 µε to a peak of 1.122 µε (Δε = +0.012 µε, ≈ +1.08%), before returning to baseline. A second brief rise occurred around 08:42, from 1.110 µε to 1.118 µε (Δε = +0.008 µε, ≈ +0.72%), and quickly stabilized.

Both surges in strain correspond with field construction records. At approximately 08:25, a sudden increase in lateral water flow caused partial lifting of the mattress, counteracting part of its own weight and reducing the tensile force. According to the “positive-tension, negative-compression” principle, reduced tension leads to decreased compressive load on the base, resulting in an increased sensor output. The quantitative results match the observed site events closely, verifying the system’s sensitivity and effectiveness under dynamic loading conditions.

- (2)

Influence of Flip Plate Angle Adjustment on Steel Cable Strain

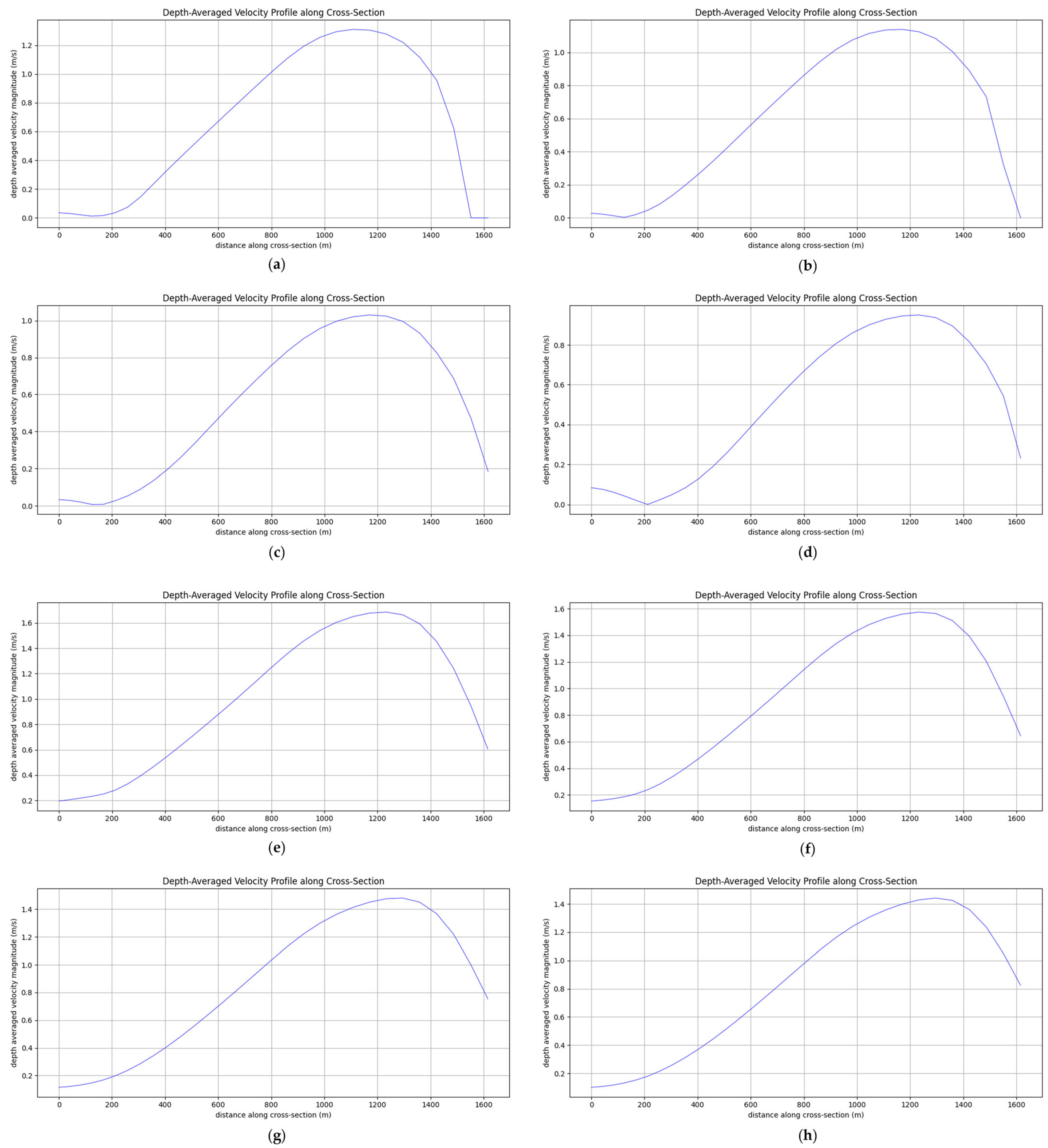

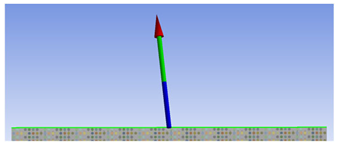

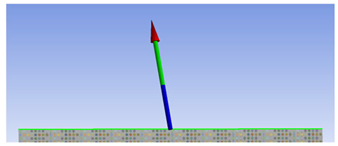

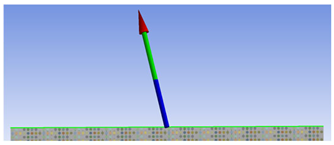

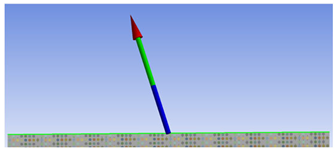

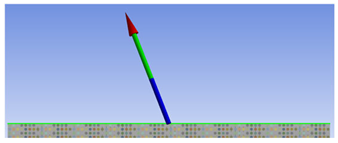

In the strain curve shown in

Figure 14b, the PB-530 tension sensor recorded an average strain of approximately ε

1 ≈ 559.78 με from 08:00 to 08:07, with a standard deviation of only about 0.02 με. Subsequently, as the flip plate angle was adjusted from an initial inclination of θ

1 ≈ 3.5° to θ

2 ≈ 10.6° (see

Figure 16), the average strain during the 08:08–08:20 interval decreased to ε

2 ≈ 559.25 με, resulting in Δε ≈ −0.53 με. Assuming a sensor calibration constant of K = 1 kN/με, the corresponding load reduction is approximately ΔF = K × Δε ≈ 0.53 kN.

This leads to an estimated flip plate strain sensitivity of approximately:

Which provides a quantitative basis for subsequent control of the flip plate angle during construction operations.

- (3)

Effect of Flip Plate Loading on Steel Cable Strain

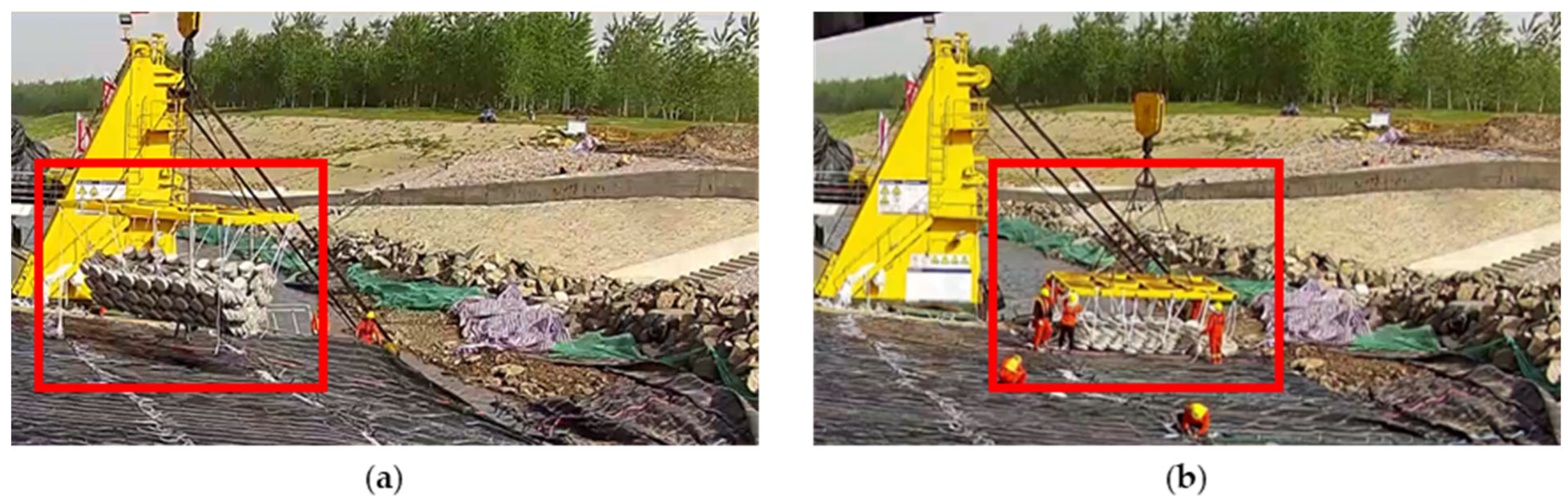

At approximately 08:43, the first placement of concrete interlocking blocks onto the flip plate was observed (

Figure 17). At that moment (

Figure 14b), the strain recorded by the sensor surged from the post-unloading baseline of ε

2 ≈ 559.25 με to a peak of ε

3 ≈ 559.95 με, corresponding to Δε ≈ +0.70 με (approximately 0.70 kN assuming K = 1 kN/με). The time lag between the block placement captured by video monitoring and the strain curve response was less than 10 s, indicating that both the sensor and its mounting base responded quickly and without noticeable delay.

From that point until 09:00, the strain curve exhibited 3–5 slow undulations, with each fluctuation ranging from Δε ≈ 0.15 to 0.25 με, corresponding to ΔF ≈ 0.15–0.25 kN, and occurring in cycles of approximately 120–300 s. Correlation with site records of alternating crane operations revealed that each crane’s unloading of a block caused a temporary reduction in load, producing a strain trough; when the crane lifted another block, the load recovered or slightly exceeded the prior level, resulting in a strain peak. Due to asynchronous crane operation cycles, their combined loading effects overlapped on the flip plate, producing multi-cycle, small-amplitude oscillations in the strain curve.

In summary, the flip plate steel cable strain during this construction process responded linearly and sensitively to both angle adjustments and initial loading events, and also accurately reflected small-scale load variations throughout ongoing operations. By analyzing the relationships between Δε and Δθ (angle change) as well as ΔF (load change), this monitoring provides reliable calibration parameters for optimizing flip plate angle control and crane operation rhythm.

- (4)

Relationship Between Flip Plate Steel Cable Strain and Water Depth

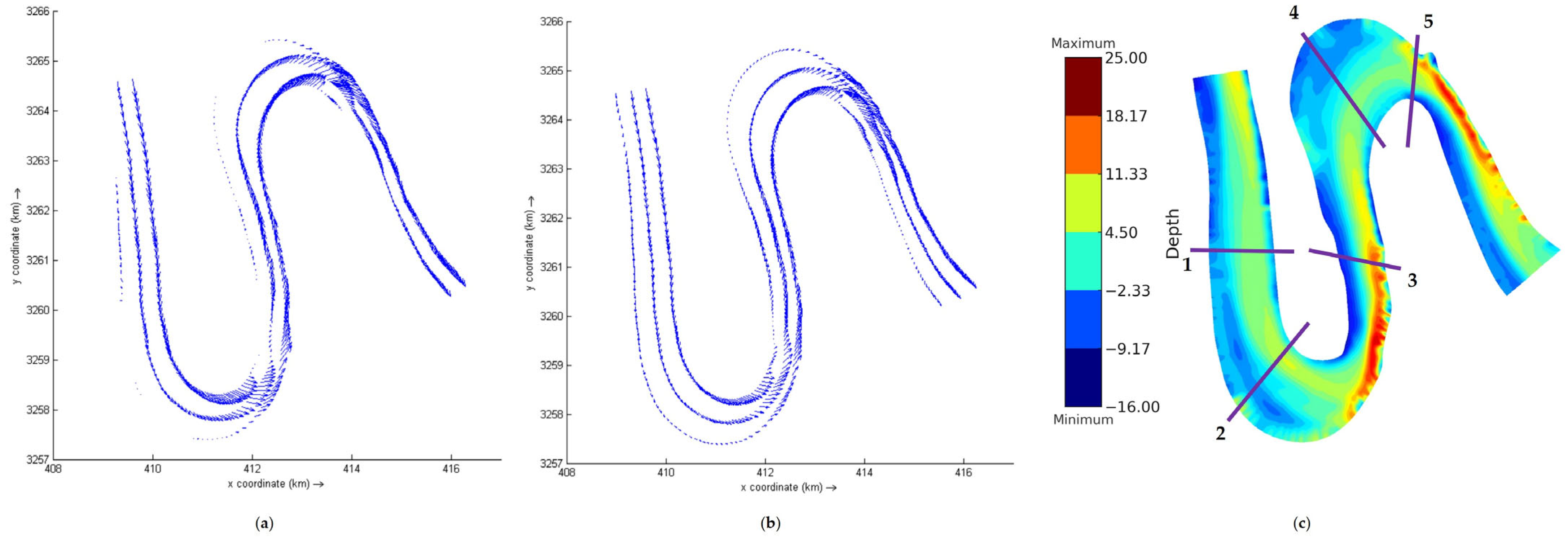

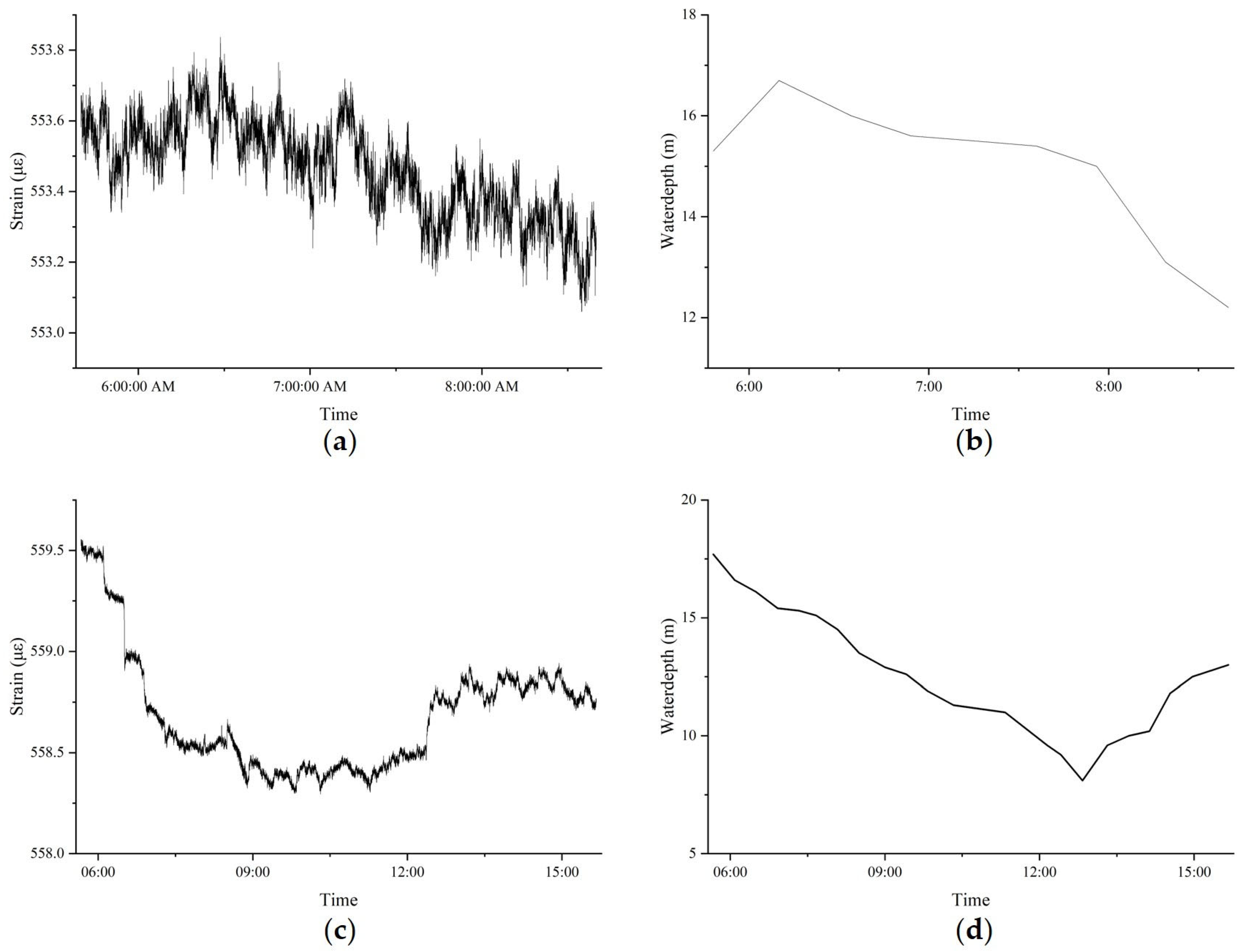

To assess whether changes in the flip plate steel cable loading during mattress deployment are correlated with water depth variations, a synchronous analysis was conducted using data from two deployment days:

Period 1: 5:40–8:40 time window (

Figure 18a,b), and

Period 2: 5:30–15:30 time window (

Figure 18c,d).

Strain data were collected from the upstream flip plate steel cable, where changes in strain reflect load variations on the flip plate of the deployment vessel, which are, in turn, directly influenced by the forces acting on the mattress. The strain readings follow the “positive in tension, negative in compression” principle—i.e., an increase in cable tension results in an increase in strain value.

Table 8 illustrates the correspondence between water depth variations and steel cable strain across different time intervals, revealing a generally linear association between the two. In

Figure 18a,b, strain exhibits a clear response to rising and falling water levels, with an initially high sensitivity (Δε/ΔH ≈ 0.33 με/m) that gradually decreases to 0.13 με/m. The overall regression slope is relatively low (Δε/ΔH ≈ 0.06 με/m), indicating non-uniform force responses. In

Figure 18c,d, a strong linear relationship is observed during the 6:00–9:00 AM period (Δε/ΔH ≈ 0.19 με/m, r ≈ 0.92), while the strain remains nearly constant from 9:00 to 12:00 PM, with a sharp drop in correlation (r ≈ 0.12), suggesting a stabilized stress condition of the mattress structure at specific water depths. The overall regression result (Δε/ΔH ≈ 0.15 με/m, r ≈ 0.91) further confirms an approximately linear strain response to water depth variation within a certain range. However, temporal and segmental discrepancies in strain behavior are evident, likely influenced by flow disturbances and changes in structural pretension.

The above quantitative results are highly consistent with the mechanism of self-weight-induced loading. As water depth increases, the submerged length of the mattress increases, thereby increasing the total self-weight and the pitching moment exerted on the flip plate. This results in increased steel cable tension and correspondingly higher strain values. Conversely, when water depth decreases, the submerged length shortens, self-weight is reduced, and strain values drop accordingly. In particular, during periods of rapid water depth changes (e.g., 6:00–6:30 in

Figure 18a, and 6:00–9:00 in

Figure 18c), the strain sensitivity Δε/ΔH reaches 0.19–0.33 με/m, demonstrating that short-term depth variations have a more significant impact on flip plate loading. By contrast, during periods of slow or stable water depth changes (e.g., 9:00–12:00 in

Figure 18c), the strain response tends to stabilize (Δε/ΔH ≈ 0.01 με/m), with a much lower Pearson correlation coefficient, suggesting the presence of additional influencing factors beyond water depth.

Across both representative cases, the strain sensitivity to water depth changes ranges between 0.06 and 0.33 με/m, with higher sensitivity observed during sharp depth transitions. In all cases, the Pearson correlation coefficient exceeds 0.8, confirming a significant linear correlation between steel cable strain and water depth. This quantitative relationship directly reflects how the self-weight of the mattress regulates the loading on the flip plate under varying water depth conditions. It provides a feasible parameter basis for real-time load monitoring and early warning in mattress deployment, and can further support the development of a water-depth-to-load prediction model to optimize flip plate control strategies.

It should be noted that although the overall trend of flip plate steel cable strain exhibits a strong correlation with water depth variation, the two are not strictly synchronous or perfectly matched. In both sets of construction data, local inconsistencies and fluctuations between strain and water depth were observed. The potential reasons for these discrepancies are analyzed as follows:

On the one hand, factors beyond water depth, such as variations in flow velocity and flow regime, can significantly affect the stress state of the flexible mattress. Given the complex hydrodynamics in the construction area, if upstream velocity increases or changes occur in flow direction or turbulence patterns during the deployment process, the direction and distribution of forces acting on the mattress will shift. This, in turn, alters the loading on the flip plate, causing fluctuations in the tensile force experienced by the steel cable—even in the absence of significant water depth changes. Particularly under conditions of localized velocity surges or instantaneous turbulent impacts, the mattress may undergo abrupt stress changes, independent of water depth.

On the other hand, the tension sensor connected to the flip plate steel cable has high sensitivity, capable of capturing stress variations on the order of microstrain (με). During deployment operations, vibrations of the vessel, equipment movements, or manual interventions may introduce localized disturbances to the sensor, manifesting as short-term strain fluctuations that do not necessarily reflect actual changes in structural loading.

5.3. Dynamic Risk Identification and Prediction During Construction

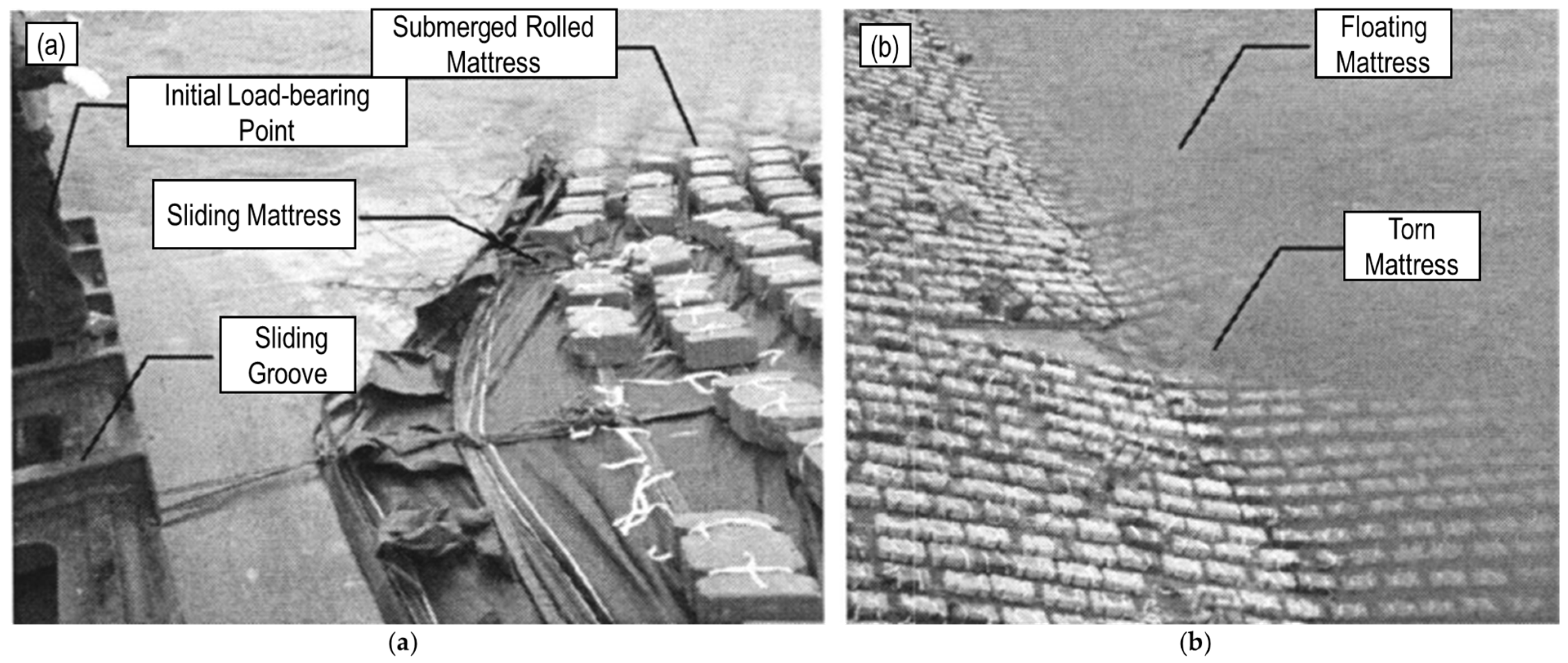

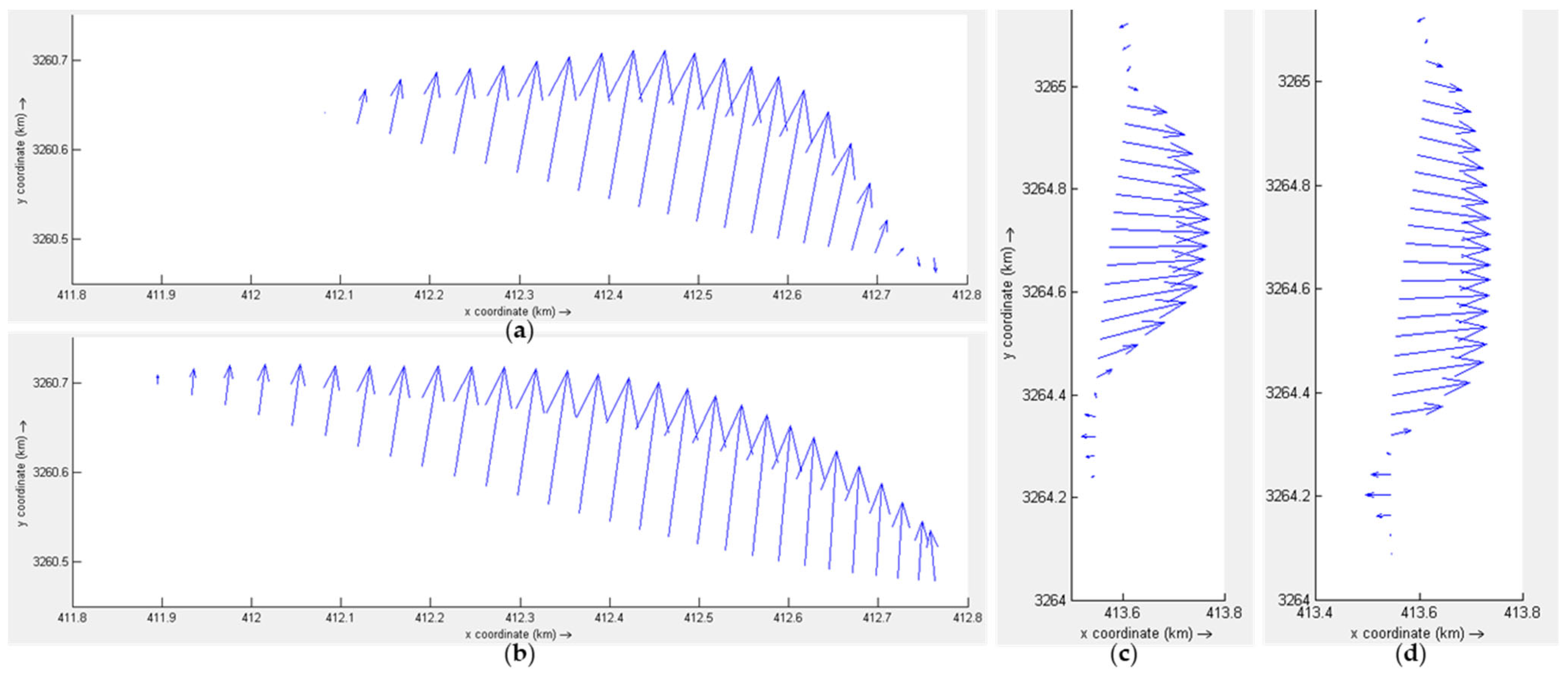

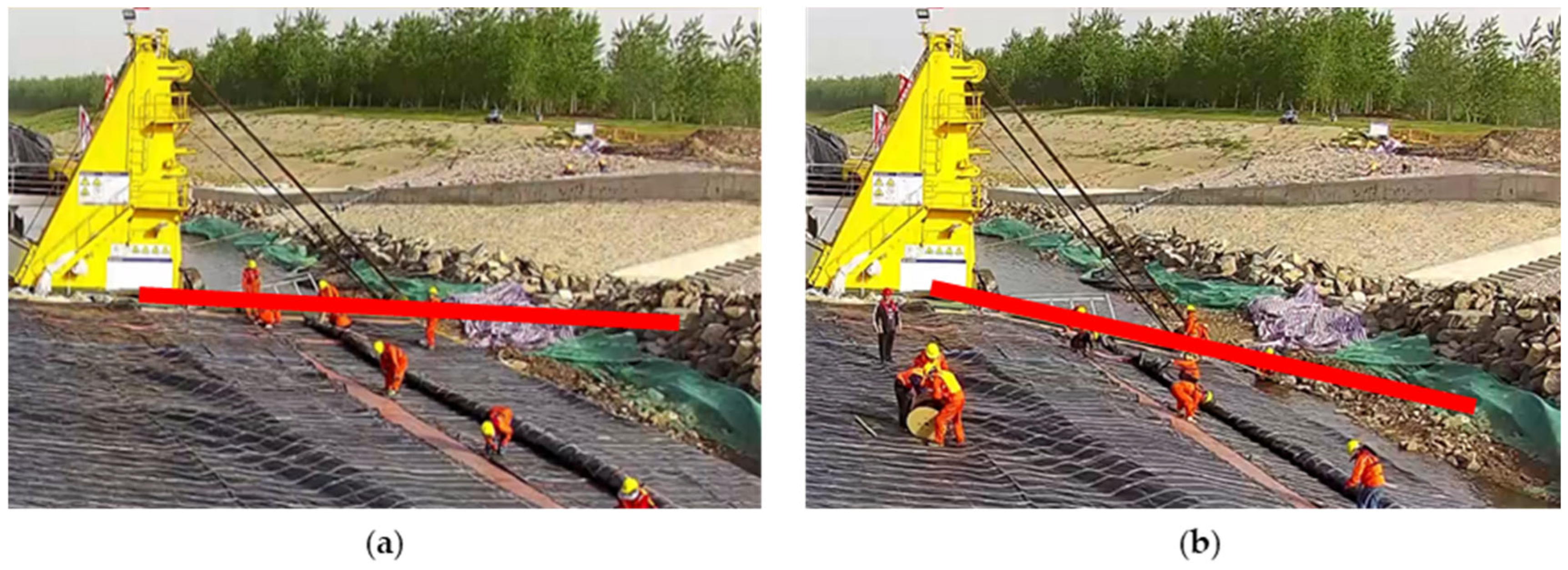

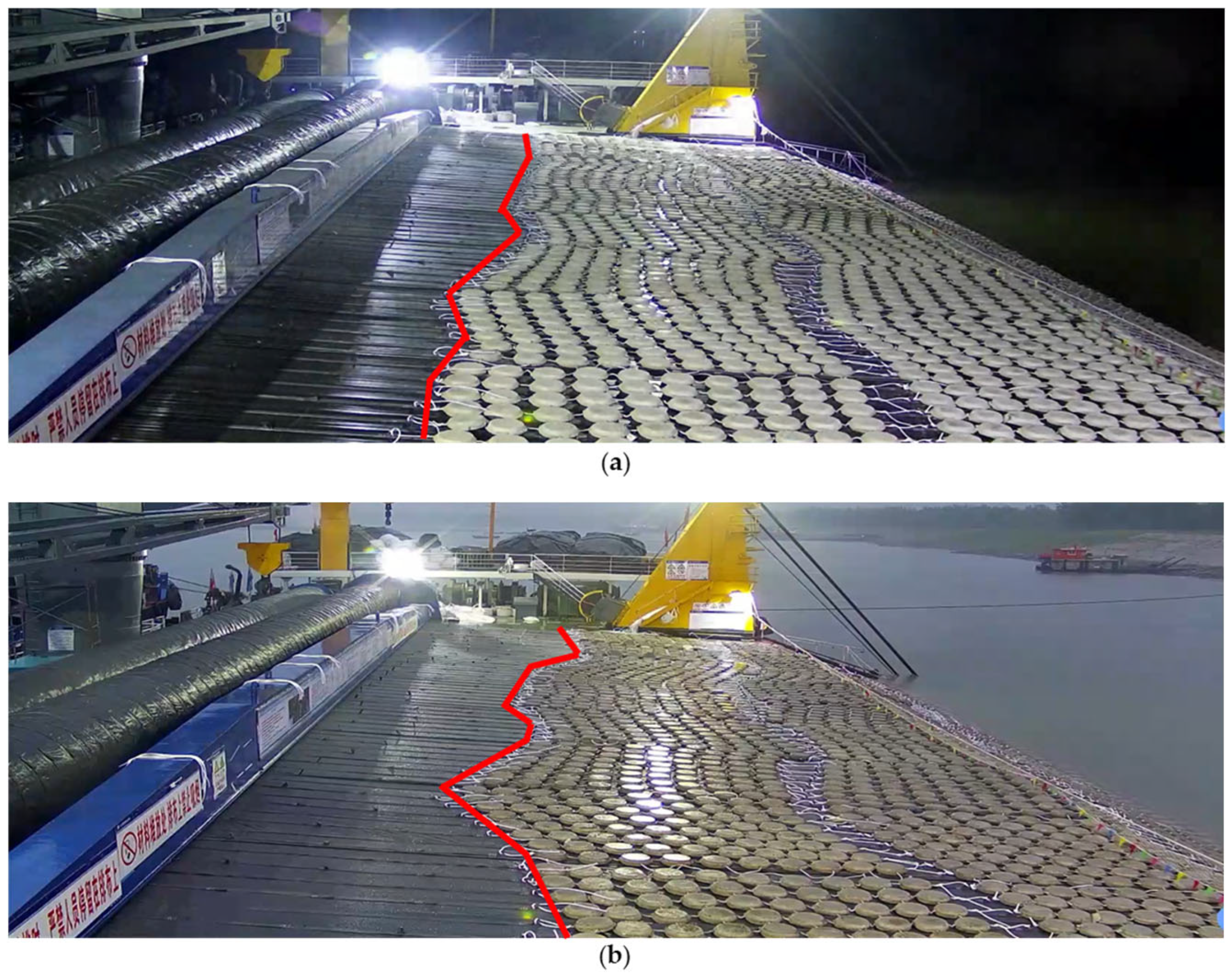

To further analyze the stress variation of the flexible mattress during deployment and its impact on structural bases, on-site surveillance images of the deployment vessel (

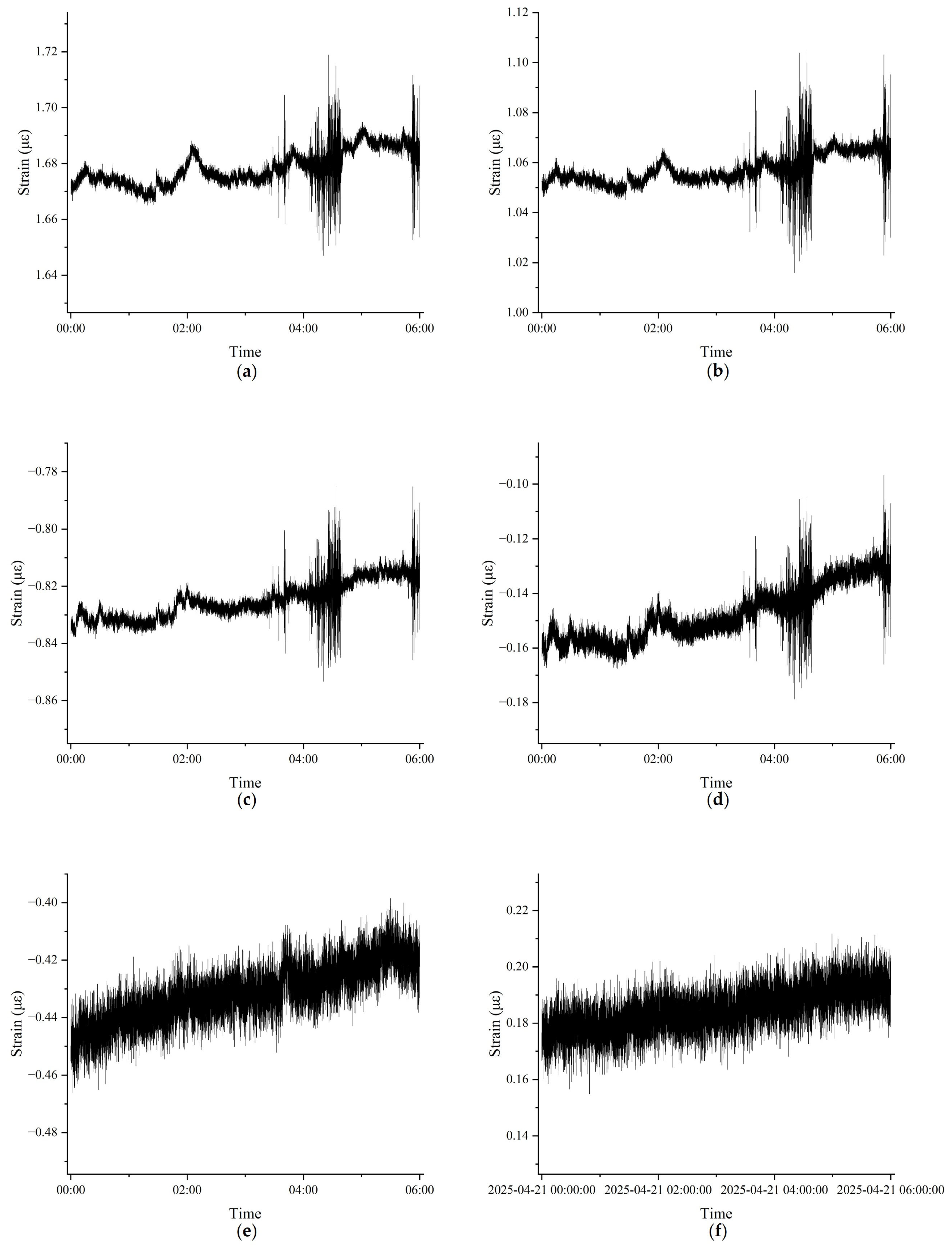

Figure 19), strain data from the roller base and the clamping beam base were selected for the 00:00–06:00 time period of a construction day (

Figure 20) for comprehensive analysis. On that day, the deployment vessel had paused operations with the mattress suspended, and the water depth at the site was approximately 15 m. Comparison between

Figure 19a,b clearly shows a significant rightward displacement of the mattress, attributed to excessive loading. According to field construction records, during this incident the mattress experienced excessive tensile stress, resulting in partial structural damage. Deployment could only continue after adjustments were made to the mattress.

For monitoring points on the bow side (

Figure 20a–d), during the pre-event phase (00:00–04:00), both the peak-to-valley strain difference (Δε) and standard deviation (σ) remained stable at Δε ≈ 0.02 με and σ ≈ (1.5–1.9) × 10

−3 με (see

Table 9), indicating stable structural loading with minimal fluctuation. However, starting from approximately 04:00, both Δε and σ increased sharply—by 175–300% and 331–433%, respectively—accompanied by pronounced high-frequency oscillations. This reflects a global shift of the mattress structure under combined gravitational and hydrodynamic forces, with the resultant load being transmitted longitudinally to the roller and clamping beam bases, inducing strong compressive stress responses.

In contrast, monitoring points on the stern side (

Figure 20e–f) exhibited consistently smaller baseline fluctuations (Δε ≈ 0.03 με, σ ≈ 2 × 10

−3 με, see

Table 9), and post-event increases were limited to 17–30%, with only mild high-frequency oscillations—significantly lower than those observed at the bow. This discrepancy can be attributed to the bow side, facing upstream, bearing the brunt of initial hydrodynamic impact. Additionally, localized deformation likely caused the flexible mattress to deviate from the vessel’s longitudinal axis, further amplifying the tensile stress on the upstream side, while reducing the stress experienced downstream.

According to the JTS/T 148-2020 Technical Specification for the Application of Geosynthetics in Port and Waterway Engineering [

32], the tensile safety factor for flexible mattresses during construction should be between two and three. Based on the monitoring data, we propose the following early-warning criterion:

When either the peak-to-valley strain difference or the standard deviation at any upstream monitoring point increases by more than 200% compared to its baseline, the condition is classified as high-risk, indicating potential mattress overloading or displacement instability, requiring immediate suspension of operations and on-site inspection. Experimental results confirm that, following the event, all bow-side monitoring points exhibited 200–300% increases, exceeding the high-risk threshold. This validates the high sensitivity and reliability of base strain monitoring in capturing stress variations and provides a critical basis for safety monitoring and early warning in subsequent mattress deployment operations.