1. Introduction

Multistage centrifugal pumps are pivotal components in fluid conveying systems, and their performance directly dictates the performance and operational reliability of the entire system [

1,

2]. They find extensive application in various scenarios, including deep-sea mining, groundwater extraction, and agricultural irrigation and drainage [

3]. However, in practical applications, the continuous impact and cutting action of numerous solid particles within the fluid against flow passage components stand as the primary cause of wear and deformation under long-term operation, severely threatening equipment lifespan and system safety [

4,

5]. Therefore, an in-depth investigation into the wear mechanisms and patterns under varying discharge conditions in the pump system is of great significance for optimizing designs to enhance its wear resistance.

Researchers have conducted extensive studies on the factors influencing the hydraulic function of multistage centrifugal pumps [

6,

7]. Wang et al. [

8] analyzed various energy losses within multistage centrifugal pumps. Liu et al. [

9] established that impeller-diffuser interaction and multiphase flow morphology principally influence flow field fluctuations in multistage centrifugal pumps. Maleki et al. [

10] investigated the influence of liquid viscous properties on the flow domain of multistage centrifugal pumps, discovering that an increase in viscosity leads to a shift in the pump’s best efficiency point. Pugliese et al. [

11] explored how the number of stages affects the hydraulic performance of multistage centrifugal pumps. Zhai et al. [

12] identified backflow, jet-wake flow, and rotor-stator interaction fluid behavior as dominant influences on energy loss and hydraulic performance degradation in pumping systems. Gu et al. [

13] found that the axial oscillation frequency of floating impellers periodically impacts the efficiency and head coefficient of multistage centrifugal pumps. Sampedro et al. [

14] studied the implementation of multistage centrifugal pumping devices integrated with compressed air reservoirs. Xu et al. [

15] analyzed the effects of blade wrap angles on the internal flow field of a multistage centrifugal pump running in reverse as a turbine. Gu et al. [

16] analyzed the impact of floating impellers on the hydraulic performance of multistage centrifugal pumps under conditions of damaged sealing gaskets. To enhance the hydraulic performance of multistage centrifugal pumps, Ping et al. [

17] introduced machine learning and hybrid algorithms to predict and optimize pump efficiency and head under all operating conditions. Wu et al. [

18] developed an integrated design optimization framework incorporating design of experiments algorithms, which effectively improves the efficiency and head of multistage centrifugal pumps. Zhao et al. [

19] innovatively redesigned blades based on neural network models and inverse design methods to maximize the efficiency of multistage centrifugal pumps and reduce hydraulic losses. In summary, substantial progress has been made in existing research on the factors influencing the hydraulic performance of multistage centrifugal pumps, but their analysis objects have primarily been limited to clear water media. This presents challenges for comprehensively understanding and predicting their actual operating characteristics and potential issues in solid-liquid two-phase flow.

Regarding the issues of solid particle motion in pumps and the wear it causes, researchers have conducted extensive studies [

20,

21]. Dong et al. [

22] discovered that the presence of solid particles in centrifugal pumps leads to significant changes in head, efficiency, and shaft power. Shen et al. [

23] assessed the influence of particle diameter, shape, and concentration on pump performance. Peng et al. [

24] employed the Euler–Lagrange method to simulate solid-liquid two-phase flow in pumps under different particle volume concentrations, with results indicating that as particle volumetric fraction rises, both pump head and efficiency decrease. Beyond affecting the hydraulic performance of pumps, the physical properties of solid particles also exert a non-negligible influence on the formation and development of wear mechanisms [

25,

26]. Zhao et al. [

27] investigated the significant impact of particle sharpness on pump wear. Mendi et al. [

28] discovered that as particle volumetric fraction rises, the wear rate of blades gradually increases. Pu et al. [

29] utilized a two-way coupling method to analysis the effect of particle density on the wear characteristics of solid-liquid two-phase flow within pumps, showing that as particle density increases, the wear on centrifugal pump walls correspondingly intensifies. The wear characteristics of pumps are not only dependent on the physical attributes of solid particles but are also significantly influenced by their operating conditions [

30,

31]. Wang et al. [

32] used numerical simulation methods to study the wear characteristics of solid-liquid two-phase flow in pumps under flow separation regimes, with findings revealing that as the degree of stall increases, the wear rate in the impeller gradually decreases. Pan et al. [

33] simulated solid-liquid two-phase flow under various pump and turbine operating conditions, finding that the runner/impeller is the component most susceptible to wear. Although existing research has achieved significant results concerning the impact of particle parameters or different operating conditions on pump wear, a systematic elucidation of the wear characteristics of various key components in multistage centrifugal pumps under different flow rate conditions, and their differential evolution mechanisms, is still lacking.

To investigate the solid-liquid two-phase flow characteristics and the wear patterns of key components in multistage centrifugal pumps under different flow rate conditions, this paper employs the Euler–Lagrange approach and the Tabakoff wear model. Combined with experimental results, the study analyzes the influence mechanisms of varying flow rates on particle trajectories within the pump, the wear distribution on the impeller and peripheral casing, and hydraulic performance.

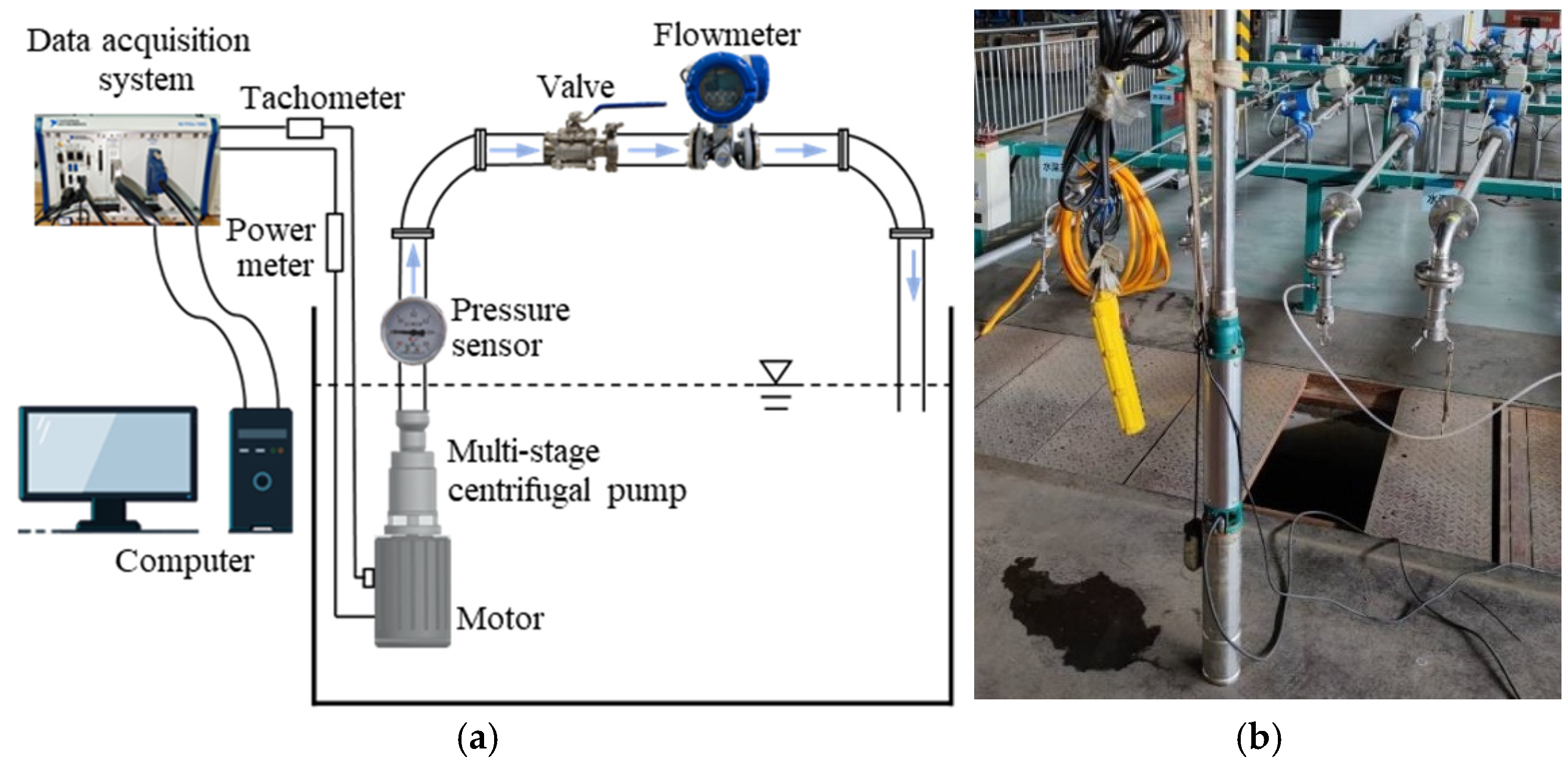

Section 2 presents the pump parameters and experimental setup.

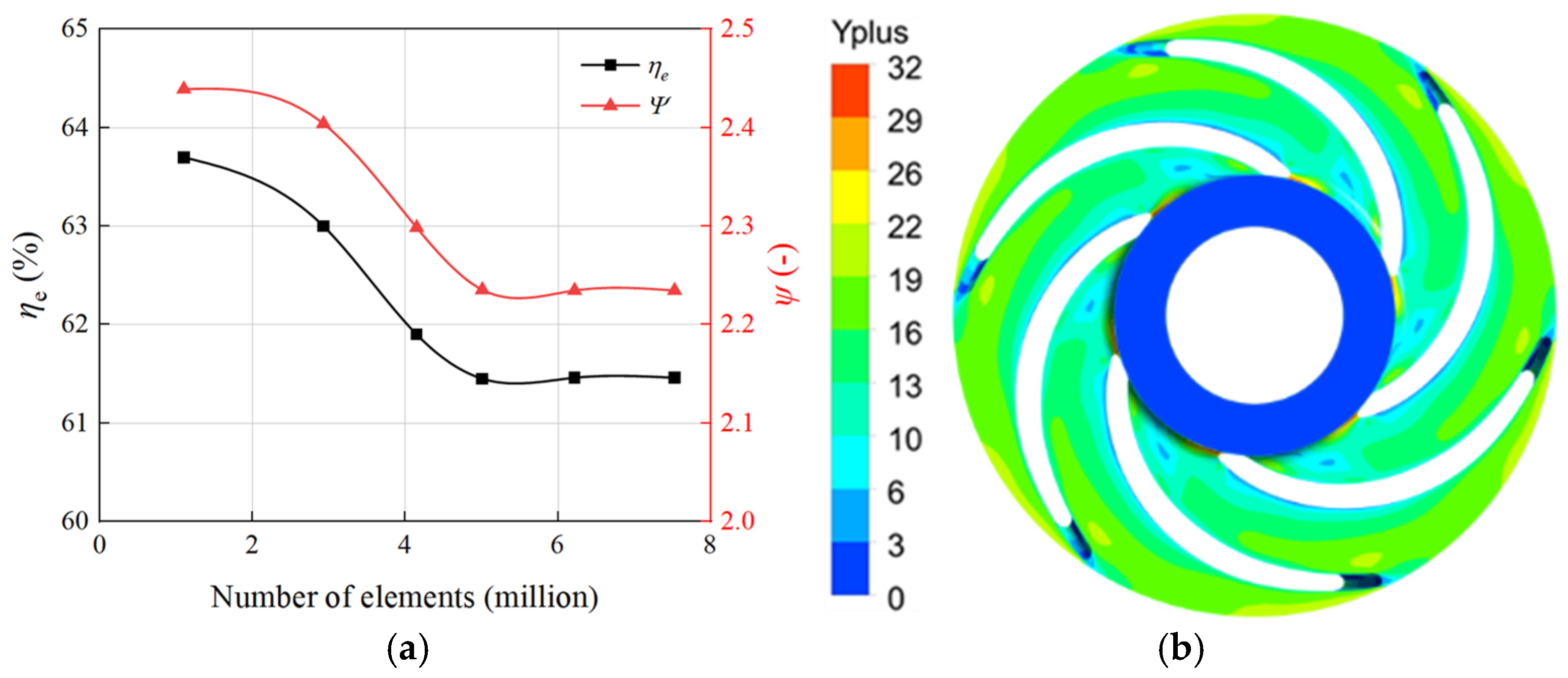

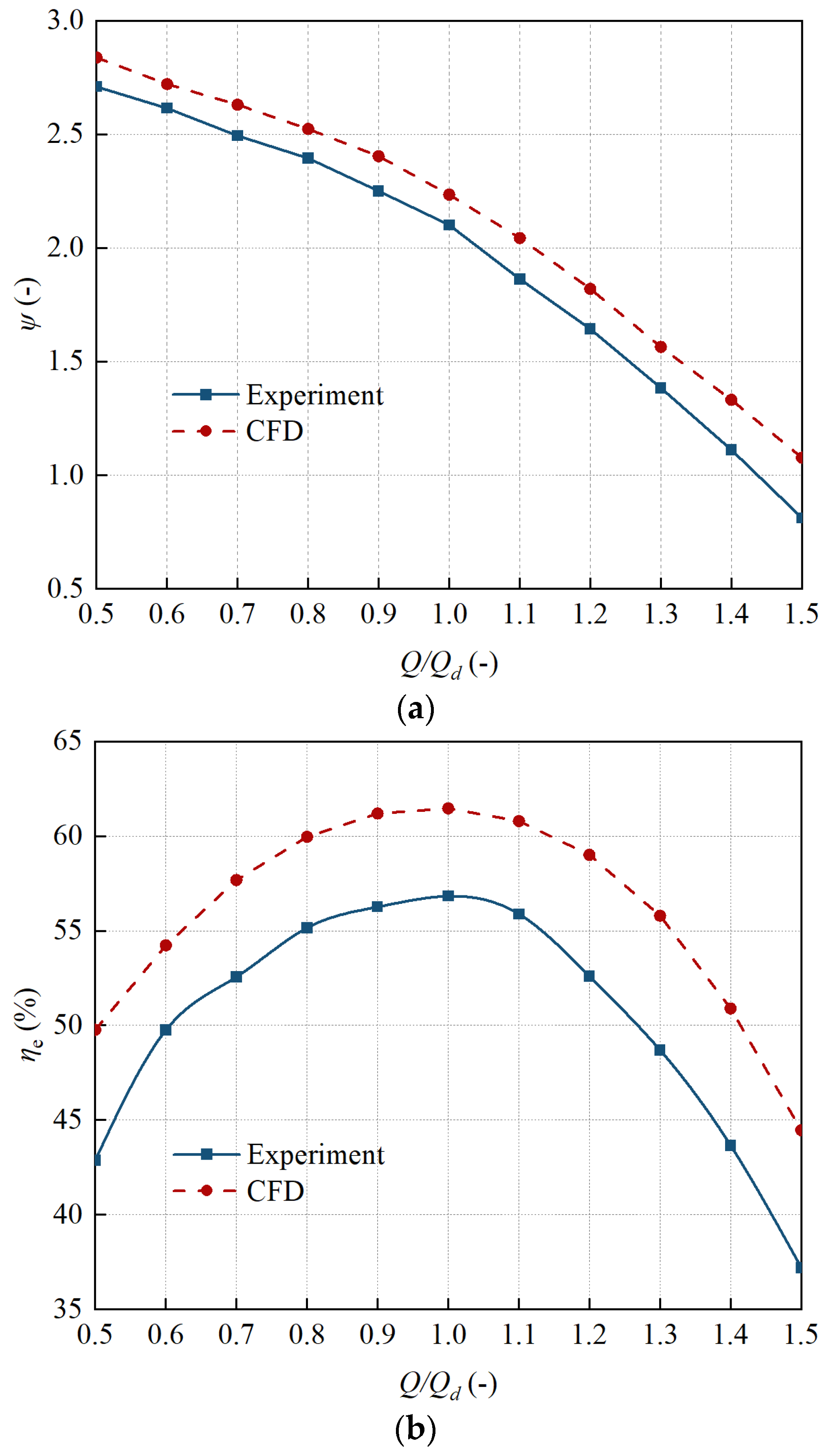

Section 3 details the configuration of the numerical simulation and validates the simulation results with experimental data.

Section 4 analyzes the influence of flow rate on wear in the impeller and peripheral casing, as well as on hydraulic performance. This study holds significant importance for improving the unit performance, safe operation, and service life of multistage centrifugal pumps handling solid-liquid two-phase flow.

5. Conclusions

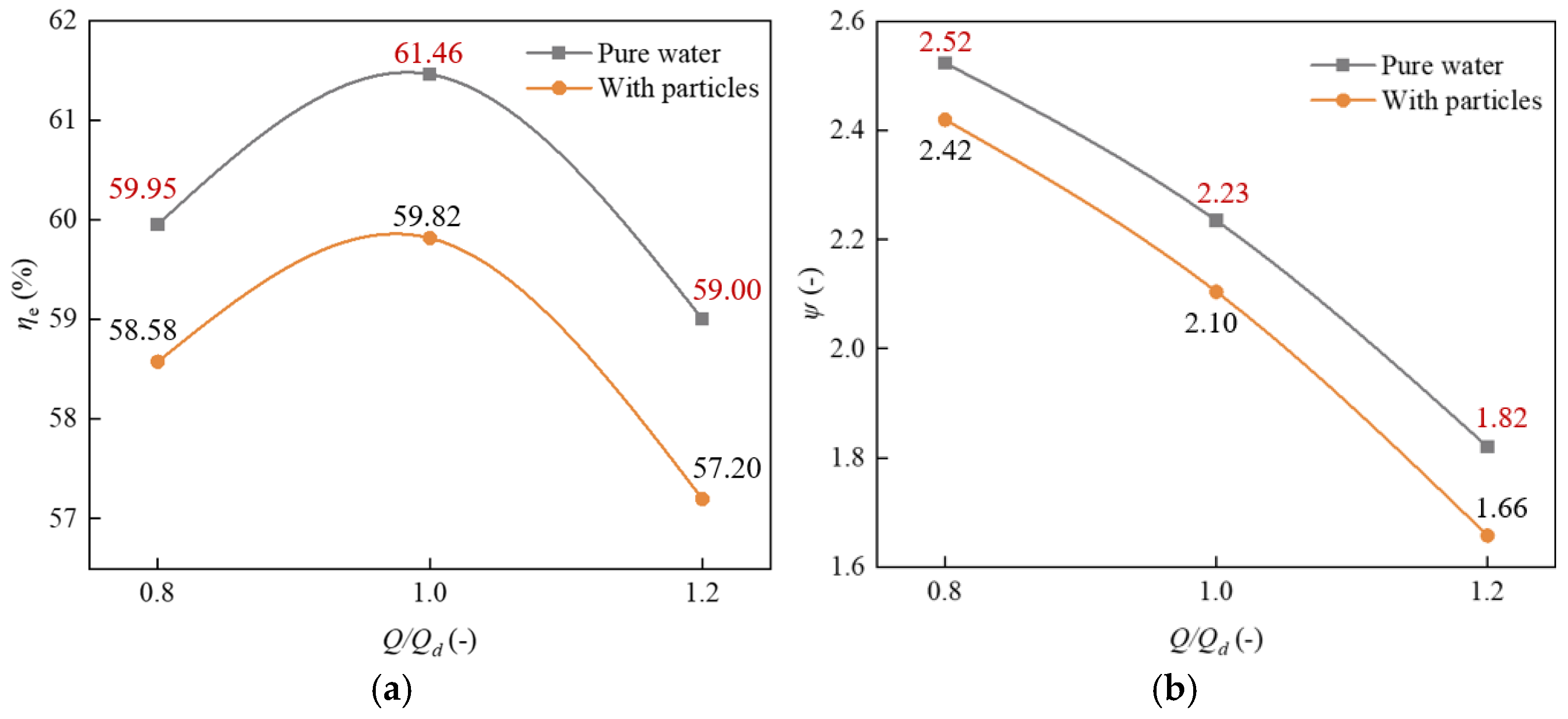

To investigate the solid-liquid two-phase flow characteristics and wear patterns of impellers and peripheral casings in multistage centrifugal pumps under different flow conditions, numerical simulations were conducted based on the Euler–Lagrange approach and Tabakoff wear model. Hydraulic performance experiments verified the accuracy of the numerical simulations, enabling analysis of flow rate variations on particle trajectories, wear distributions of impellers and peripheral casings, and hydraulic performance. The following conclusions were drawn.

- (1)

As the flow rate increases, both efficiency and head of the centrifugal pump under solid-liquid two-phase conditions gradually decrease compared to clean water conditions. This occurs because higher flow rates enhance particle momentum, intensifying energy dissipation through inertial collisions. Simultaneously, the impeller requires additional work to maintain particle transport. These combined effects lead to increased shaft power, ultimately resulting in degraded pump performance characteristics.

- (2)

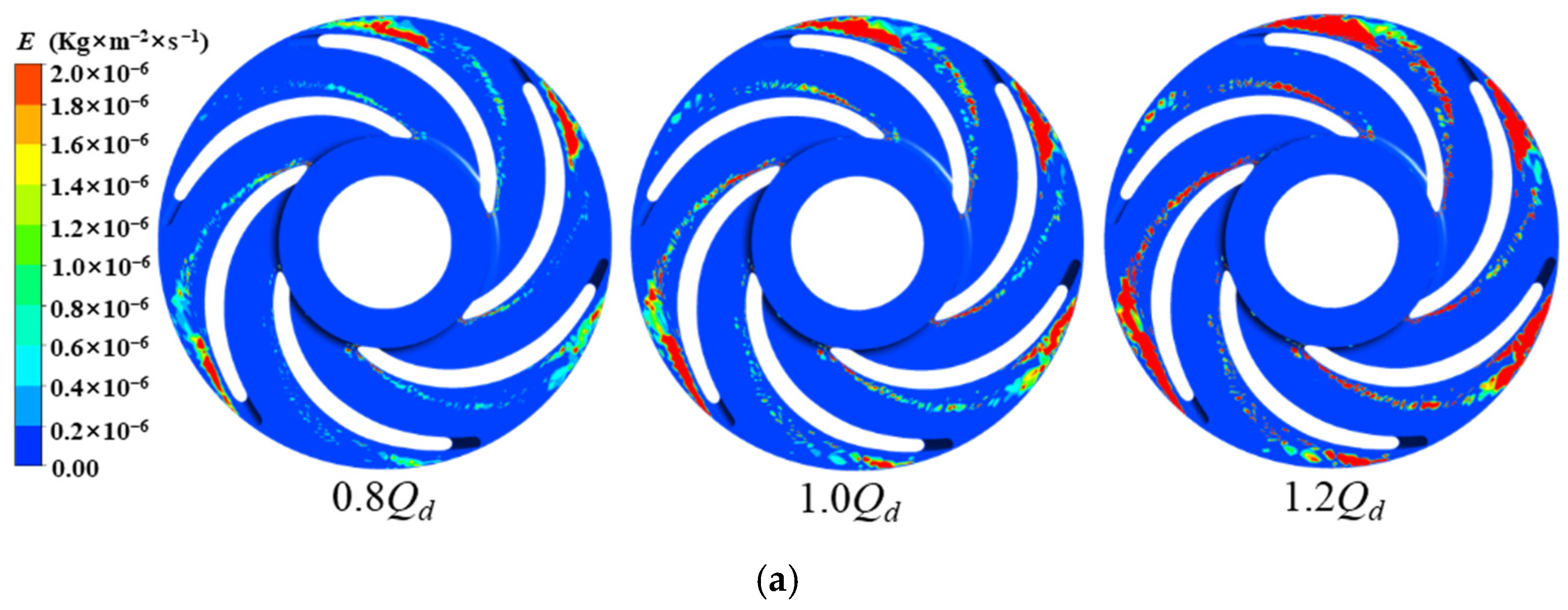

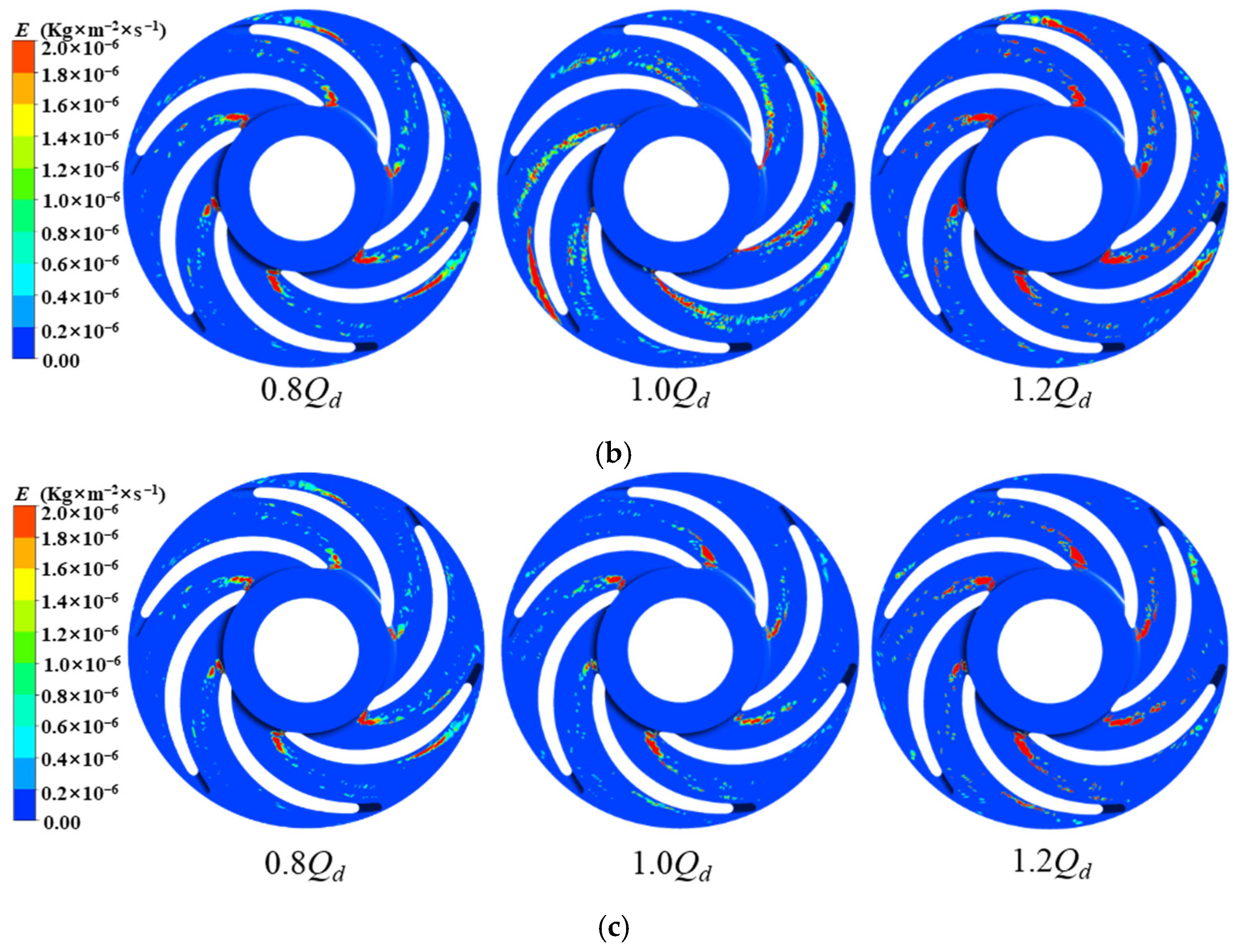

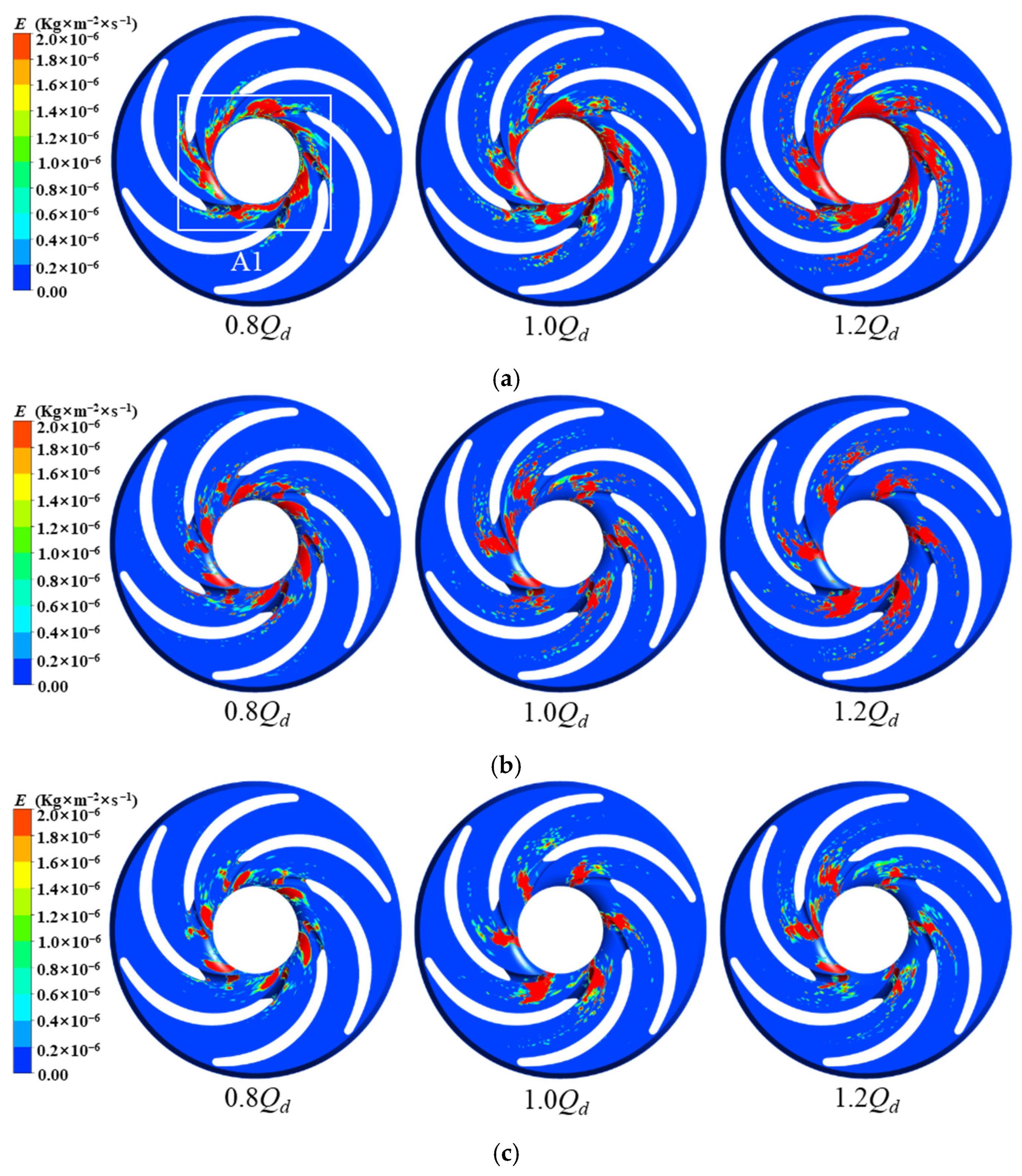

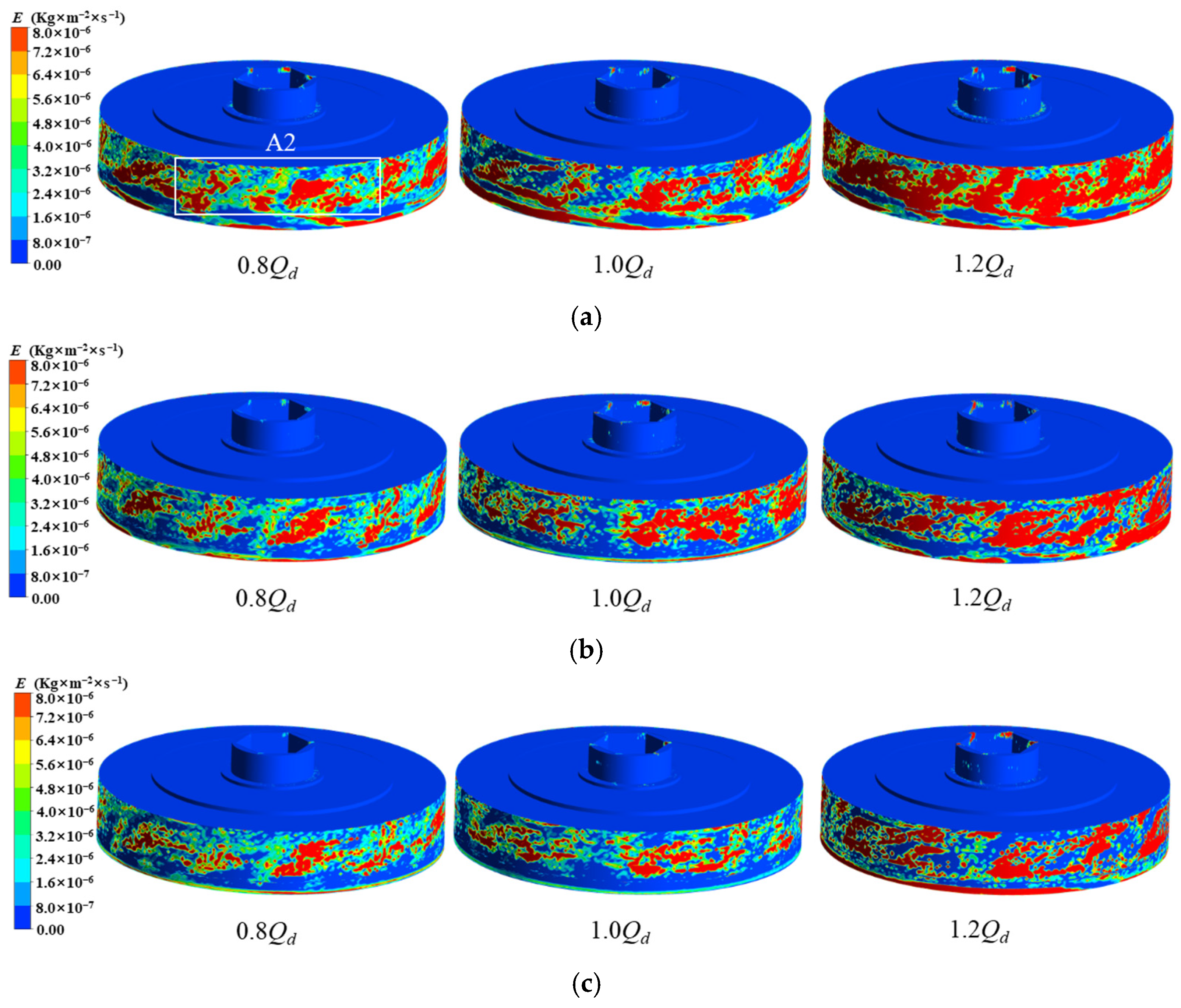

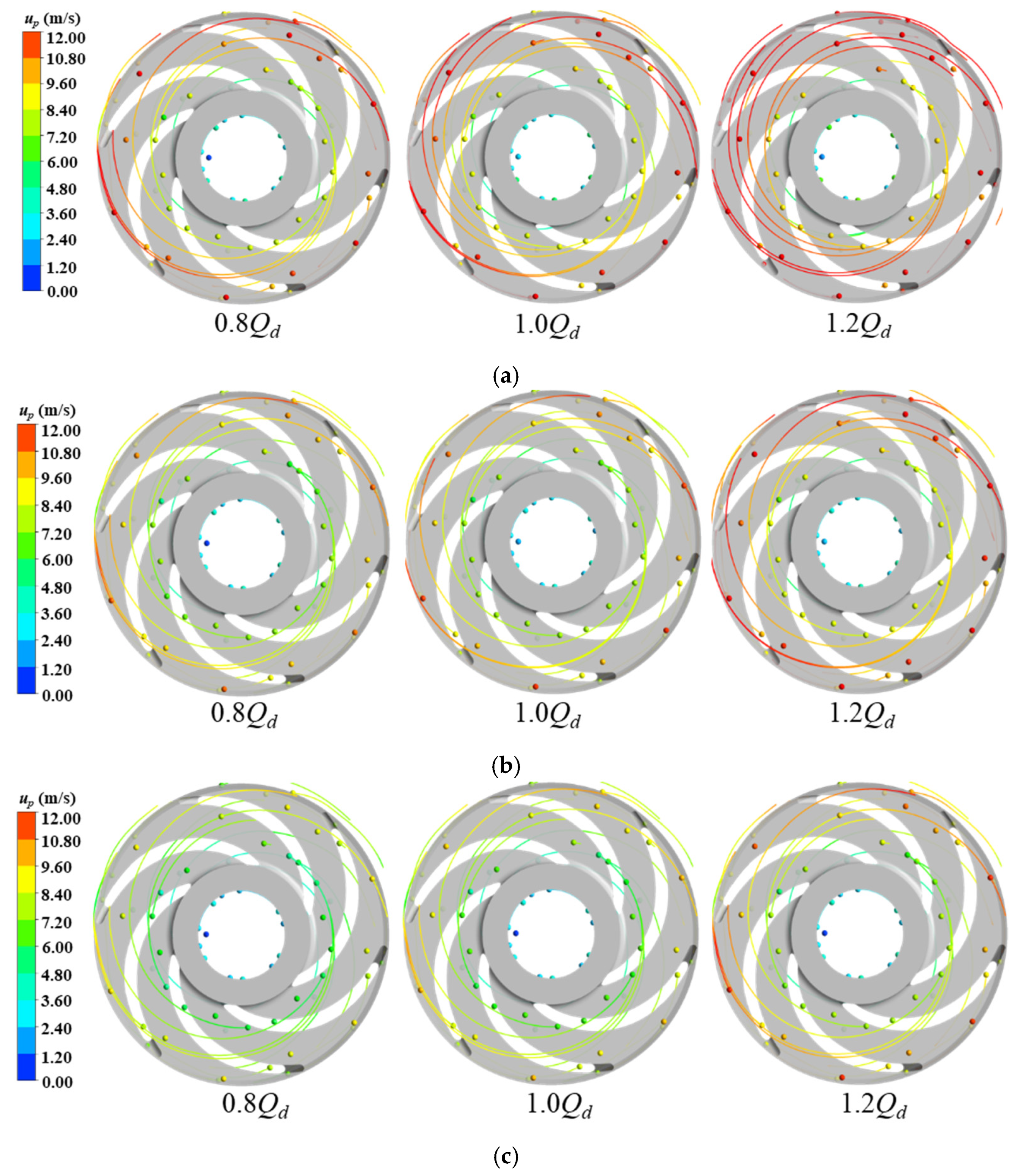

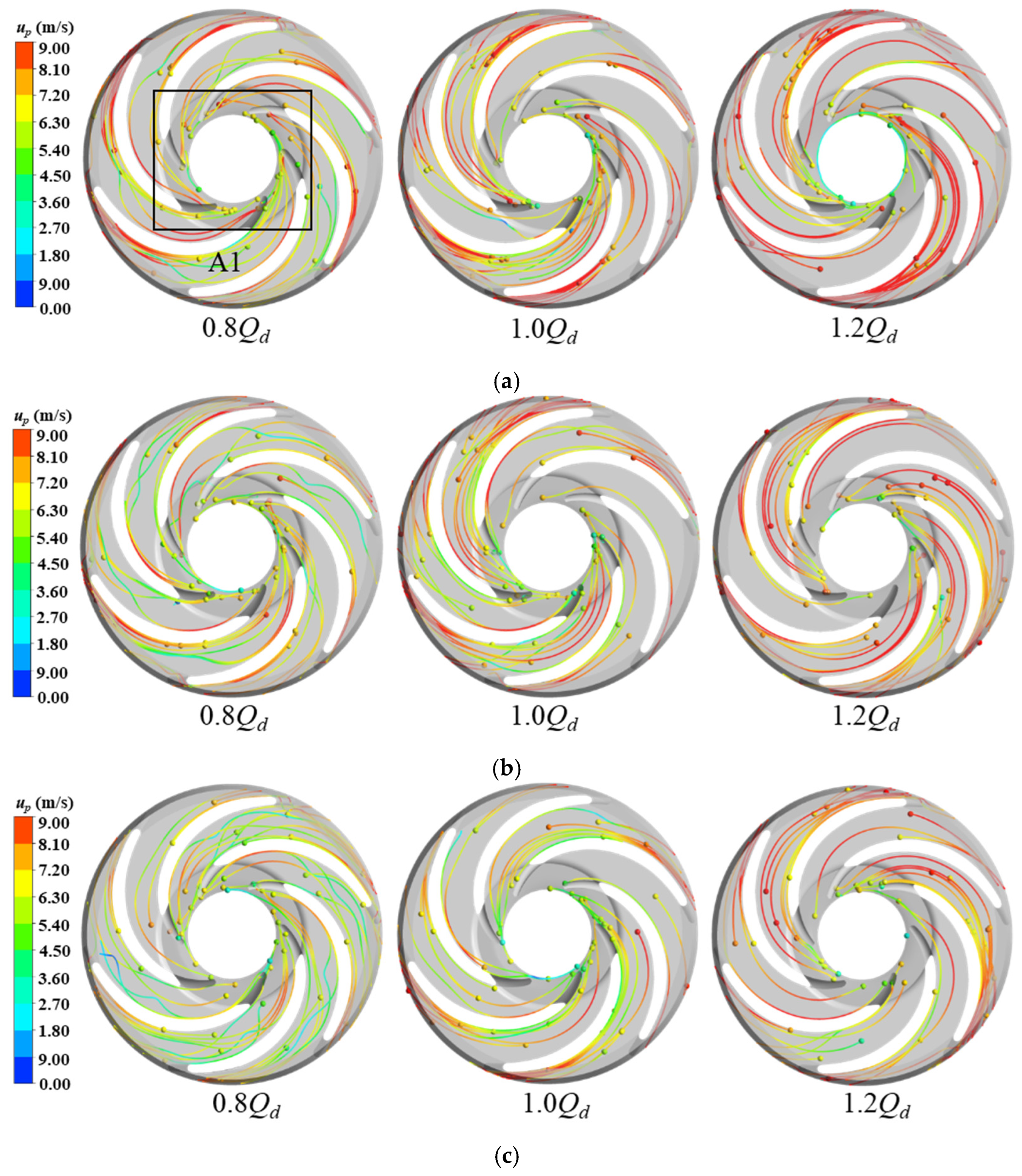

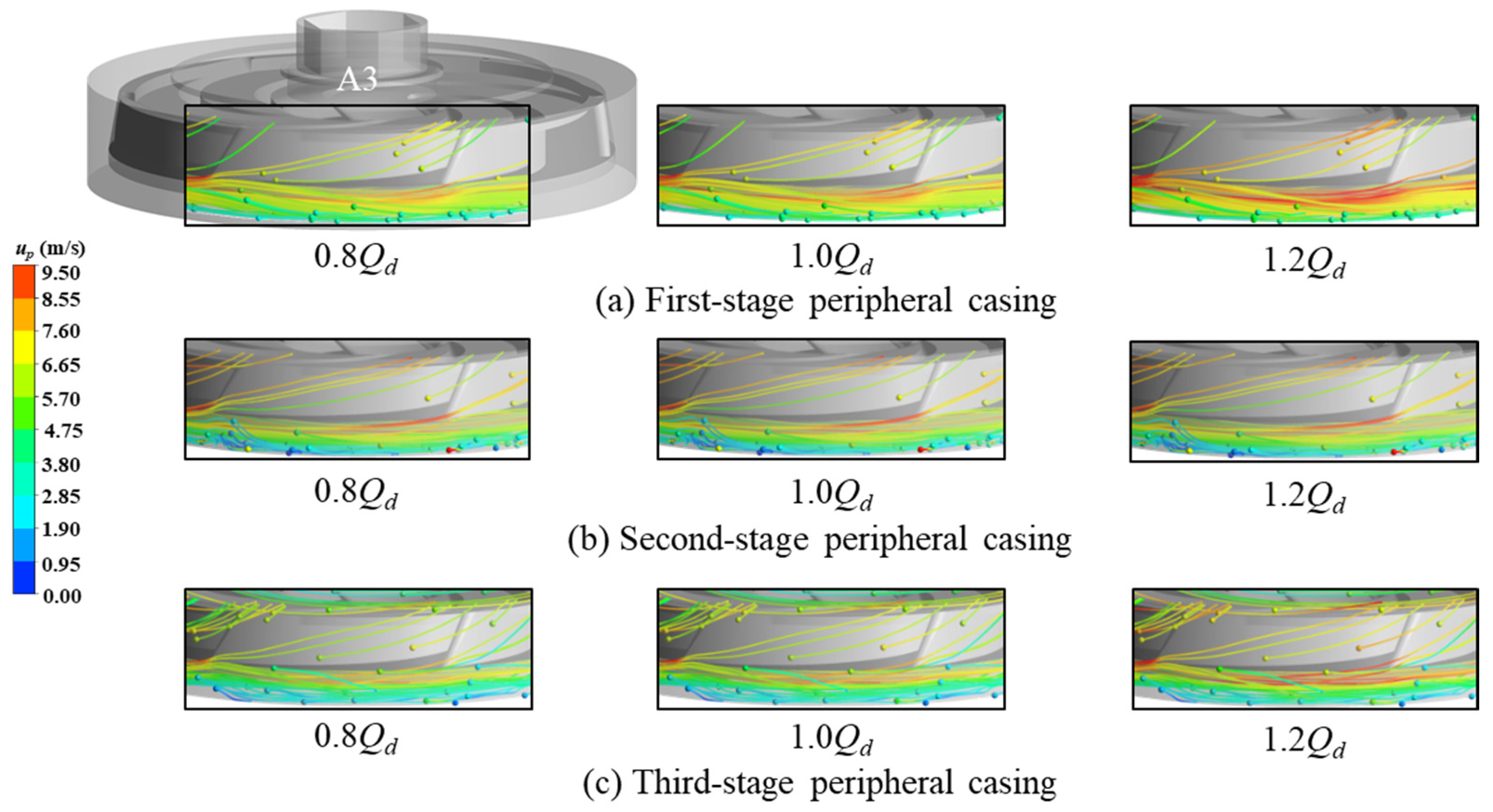

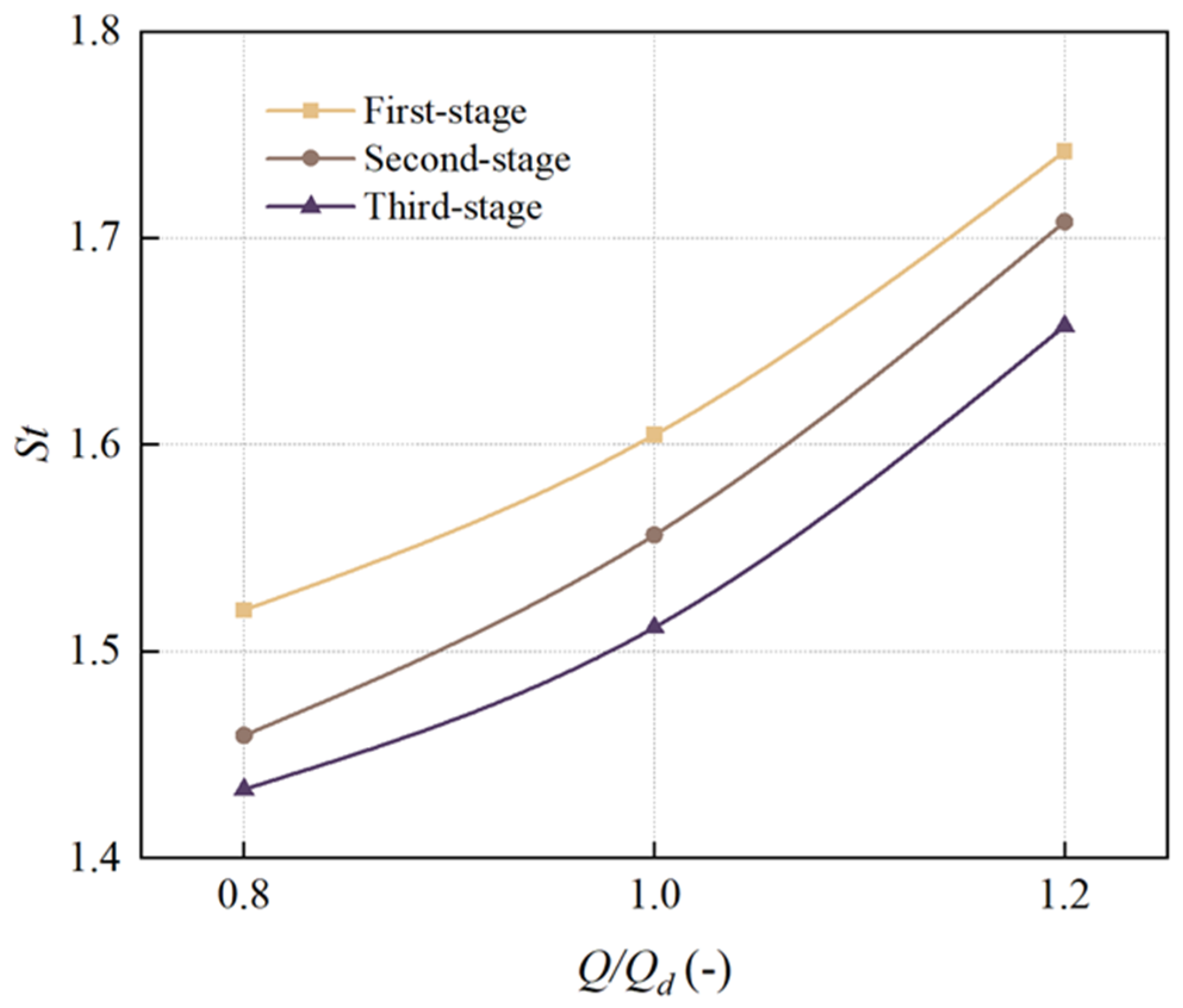

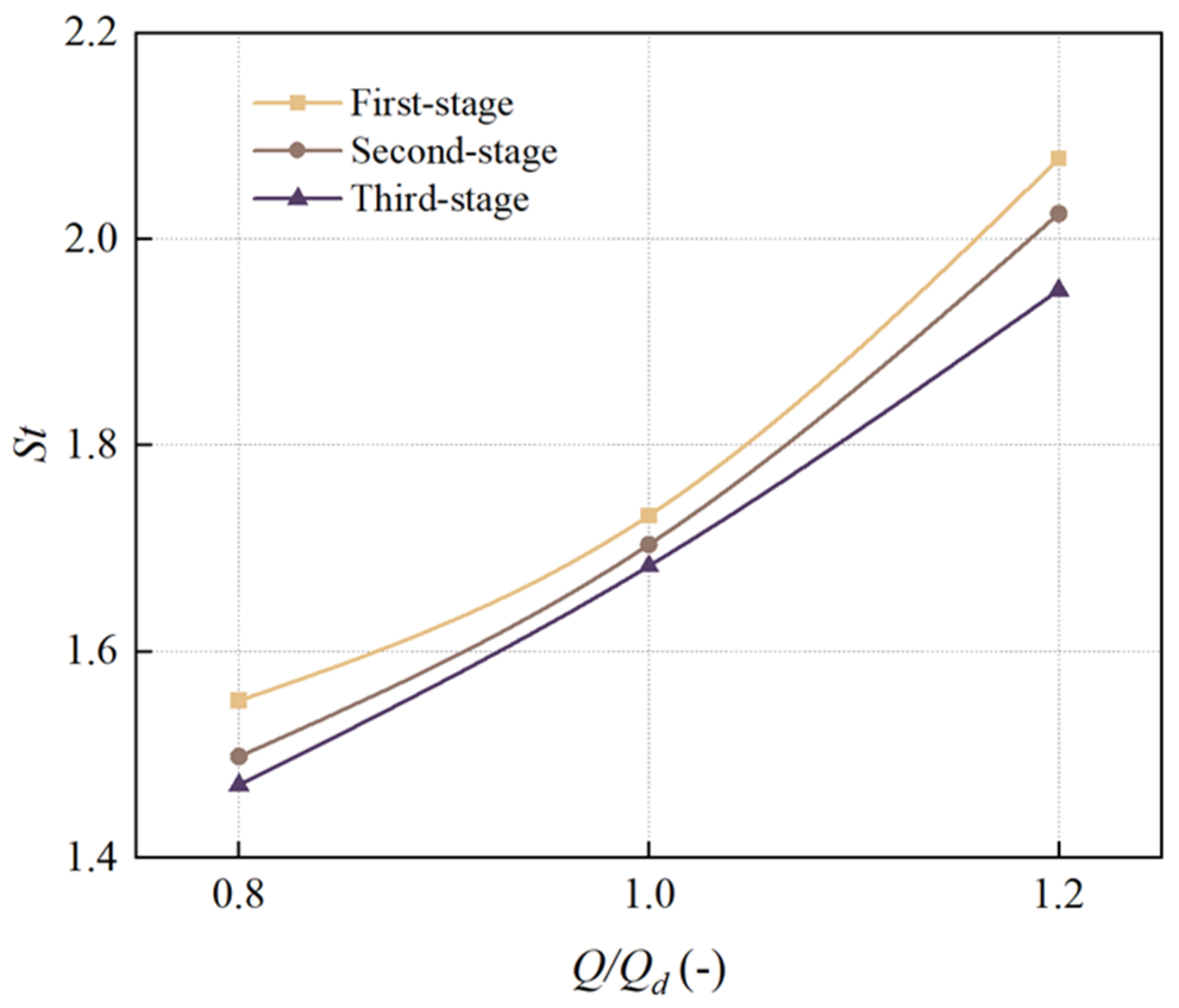

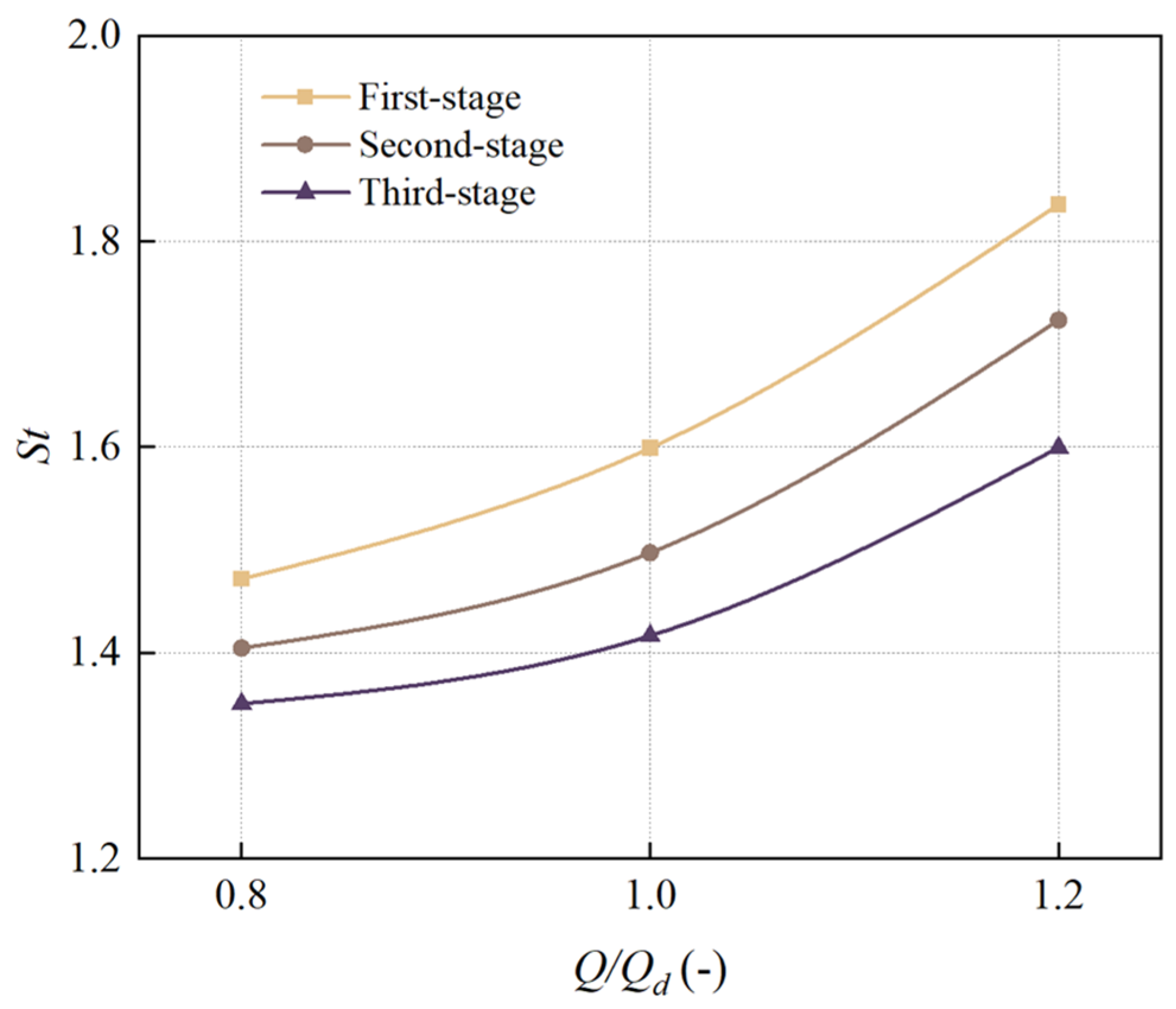

With increasing flow rate, the average wear rate and wear area of the impeller’s front shroud, rear shroud, pressure side, and casing all gradually increase. The highest wear rate among all components occurs at the first-stage rear casing under 1.2Qd operating conditions, with an average wear rate of 8.35 × 10−6 kg/m2/s. This phenomenon occurs because higher flow rates enhance particle momentum and Stokes number, strengthening inertial effects while weakening particle-fluid coupling. Consequently, the intensified impact forces on flow passage components lead to progressive enlargement of wear areas.

- (3)

Under identical flow conditions, the wear areas and intensity on the front shroud, rear shroud, pressure side, and peripheral casing of the upstream impeller stage consistently exceed those of the downstream stage. This occurs because when particles transition from the upstream to downstream casing chambers, the flow becomes more uniform with reduced turbulence intensity after passing through the return guide vanes. Additionally, the particle Stokes numbers in the downstream region are lower than those upstream, resulting in weakened inertial effects and enhanced particle-fluid coupling. These factors collectively reduce impact forces on flow passage components, thereby mitigating wear severity in the downstream stage.

In future studies, we will conduct erosion experiments on multistage centrifugal pumps to validate numerical simulation results. Subsequently, we will systematically compare three widely recognized erosion models—the Finnie model, Tabakoff model, and E/CRC model—under identical operating conditions to evaluate their predictive accuracy for wear rate and spatial distribution characteristics, thereby establishing model selection criteria. Finally, based on these findings, we will focus on optimizing the pump’s geometric configuration to simultaneously reduce wear and enhance hydraulic efficiency.