The Influence of Combined Energy Dissipators on Navigable Flow Characteristics at Main Channel—Tributary Confluences in Trans-Basin Canals: A Case Study of the Jiuzhou River Section, Pinglu Canal

Abstract

1. Introduction

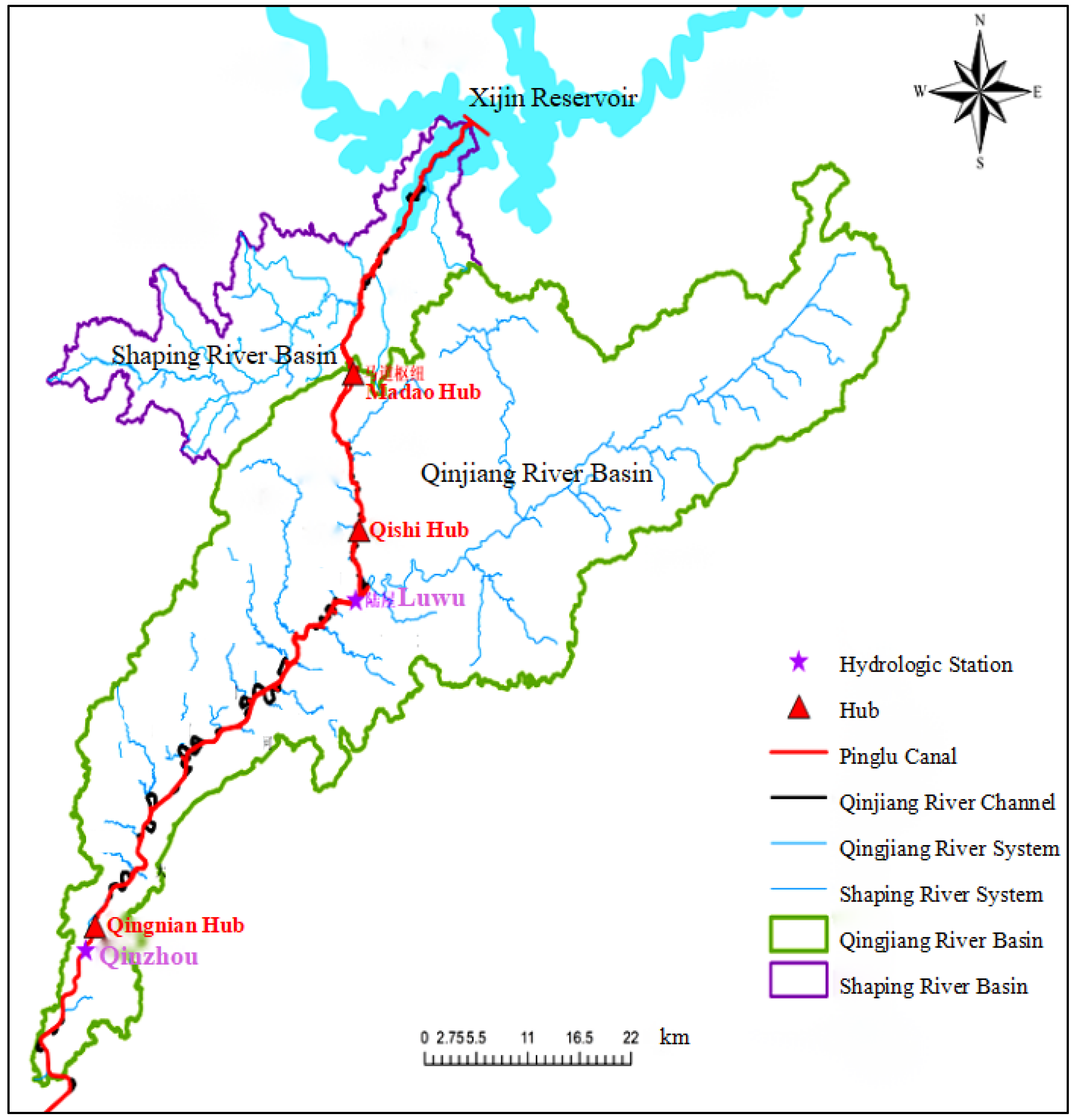

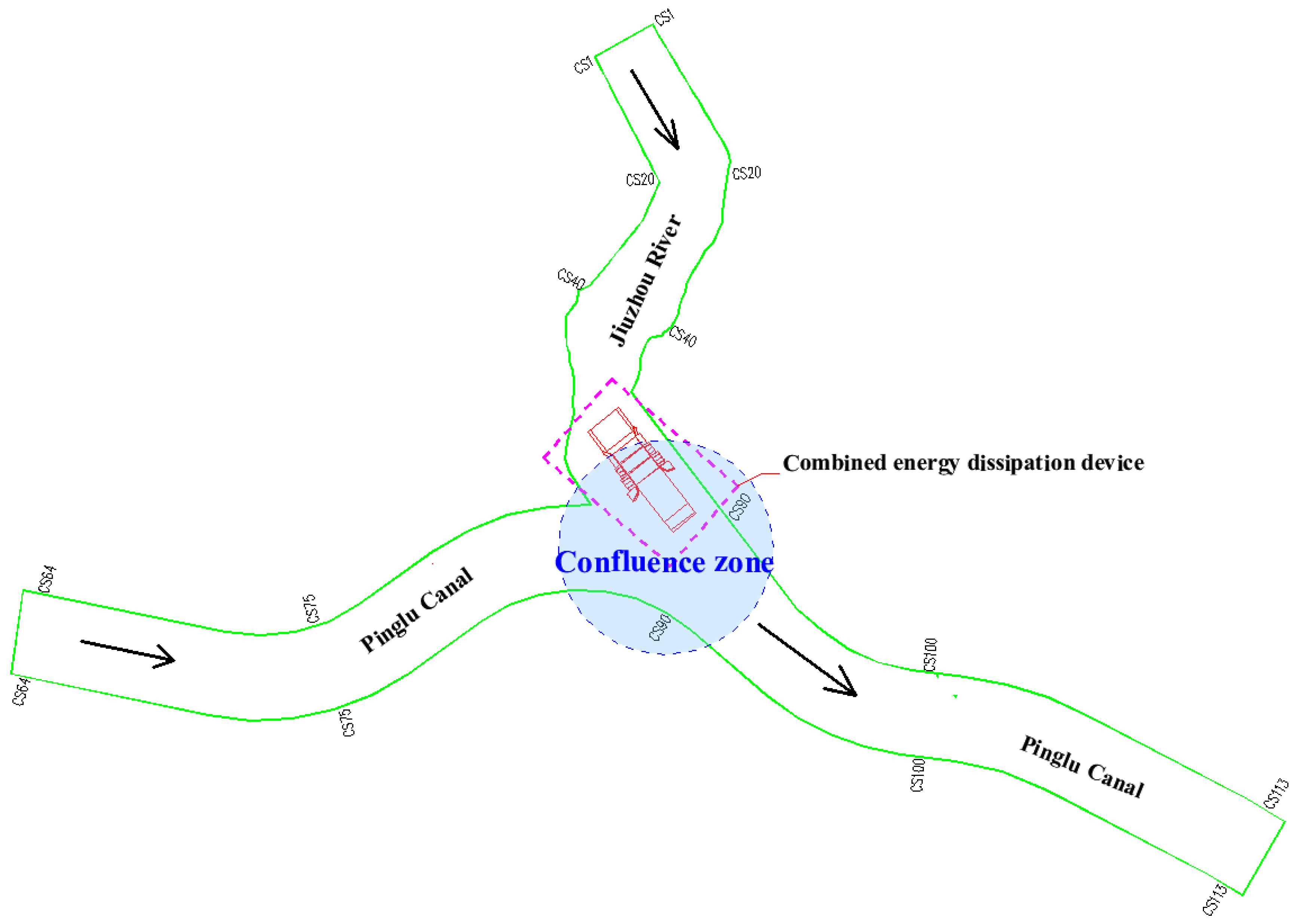

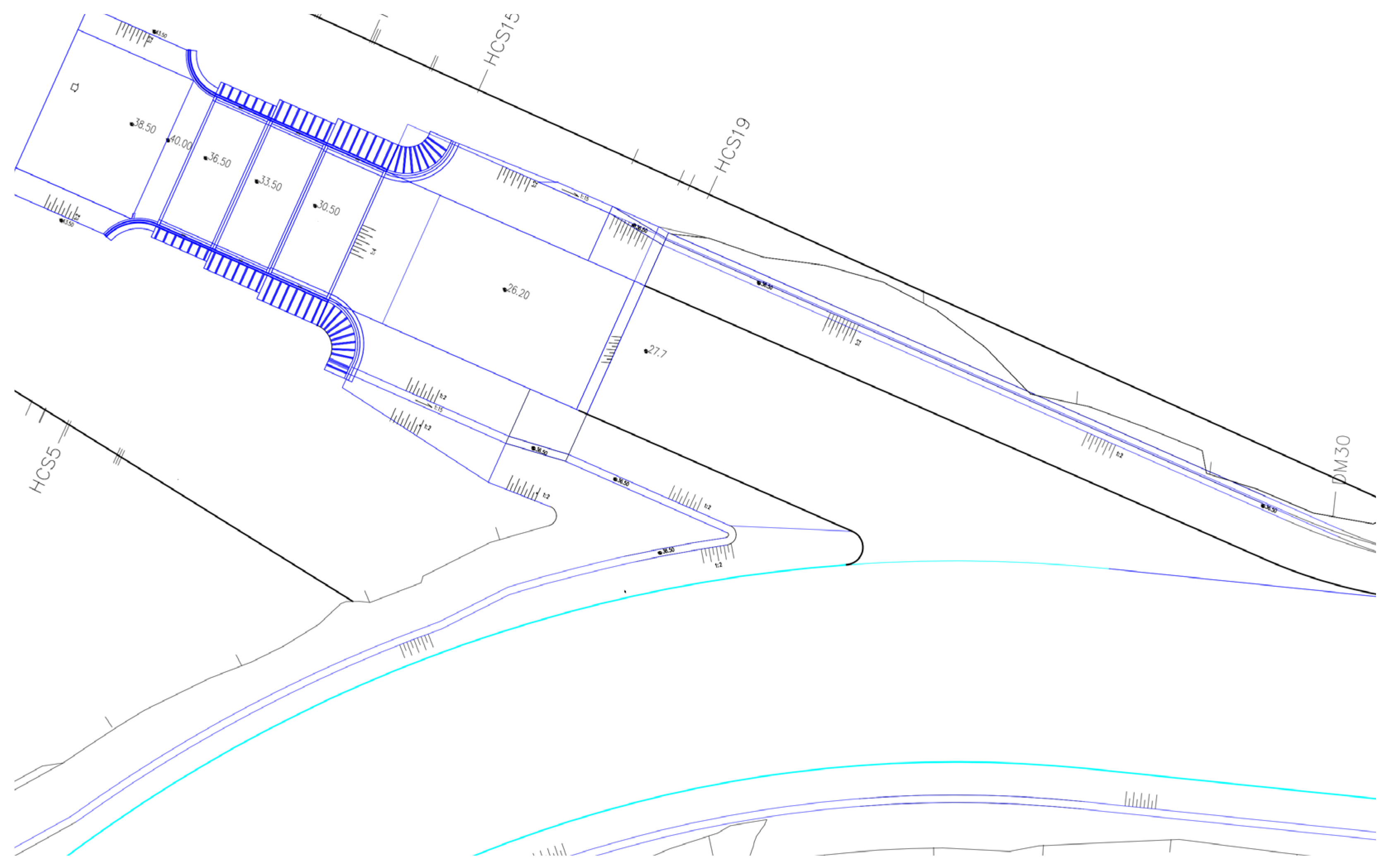

2. Overview of Jiuzhou River

3. Model Design and Verification

Establishment of Physical Mode

4. Physical Model Validation

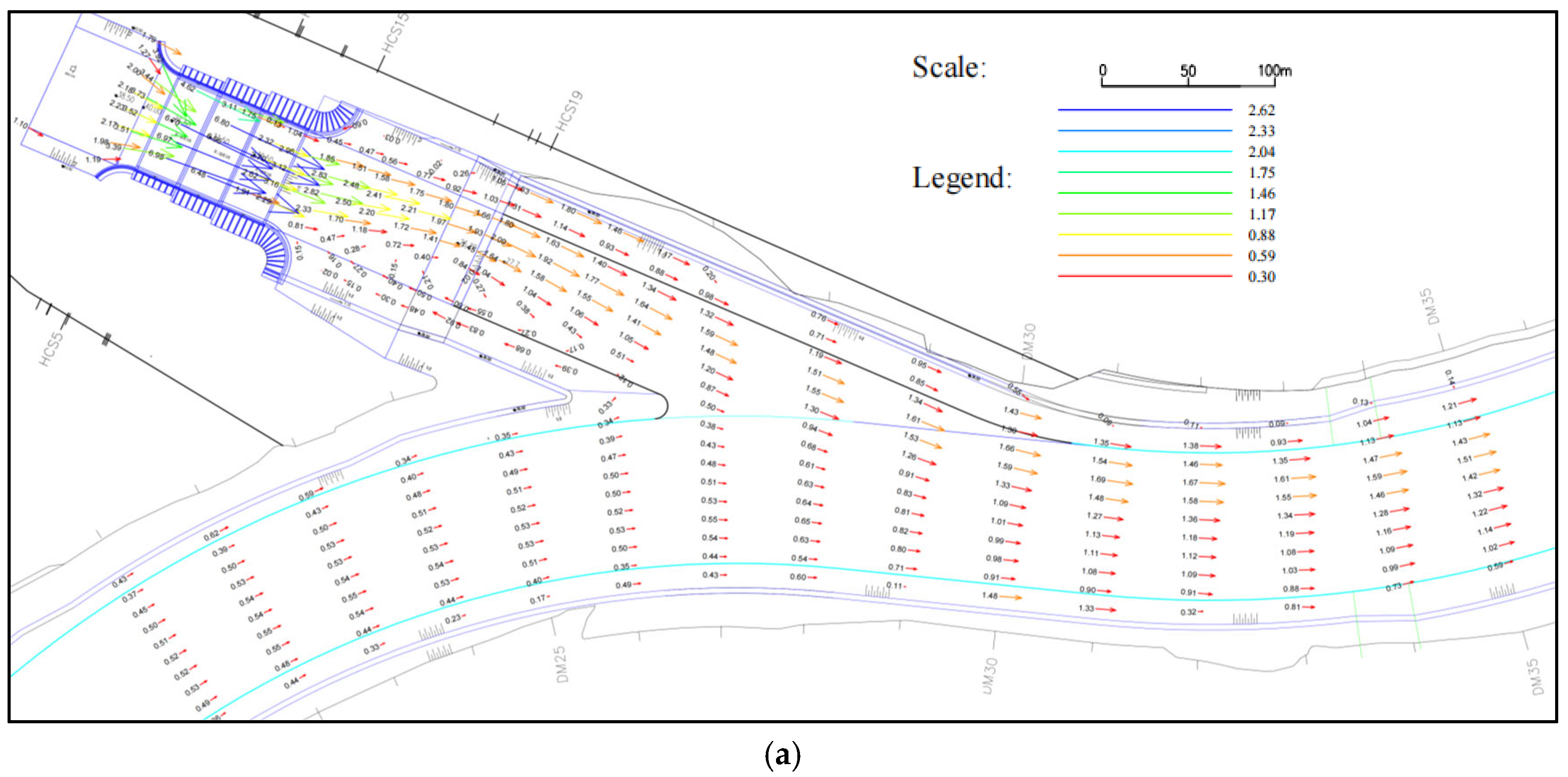

5. Energy Dissipation Scheme and Effect Analysis

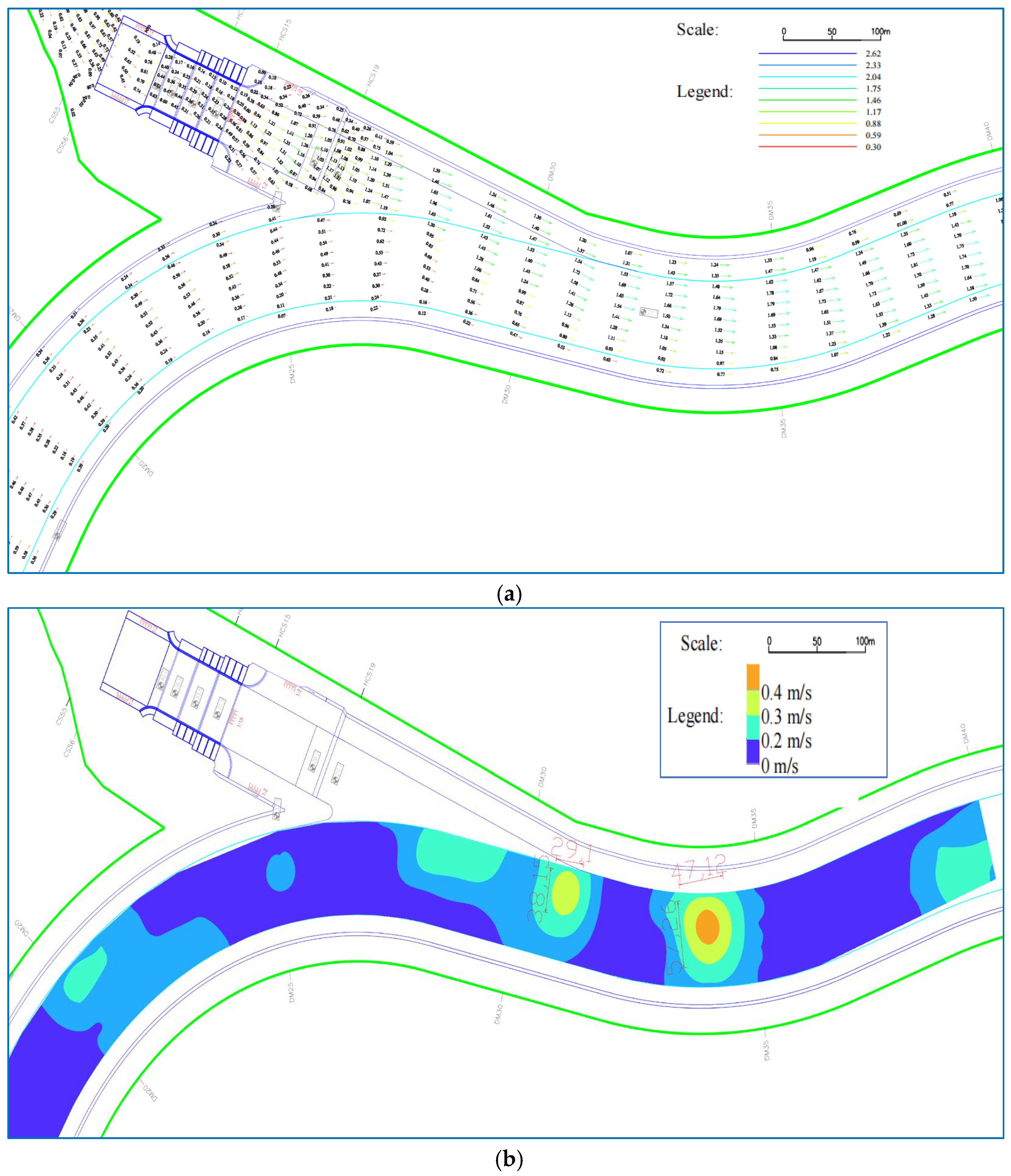

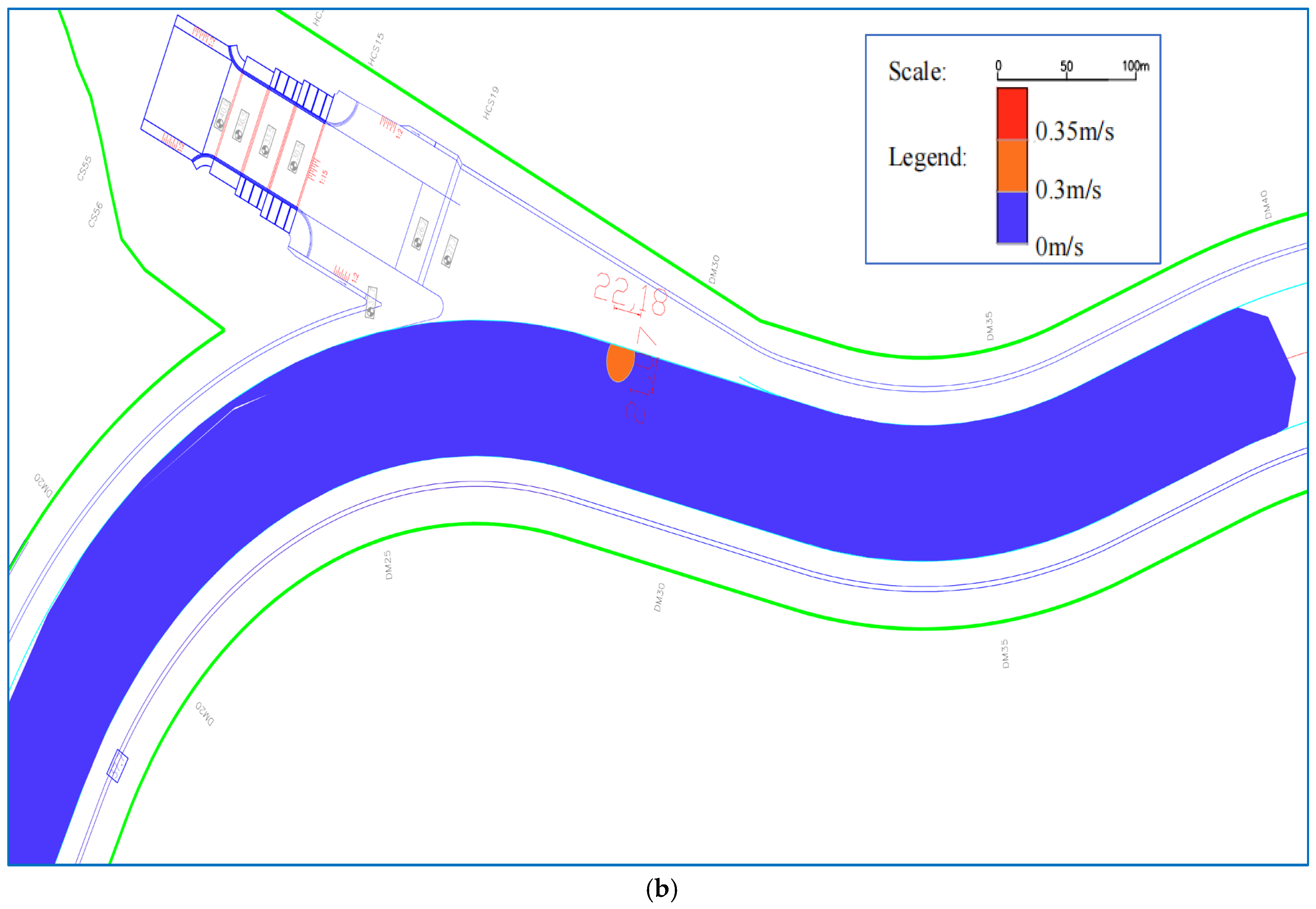

5.1. Measure One: Three-Stage Stilling Basin + 1:15 Slope

5.2. Measure Two: 1:15 Gentle Slope + Three-Stage Stilling Basin

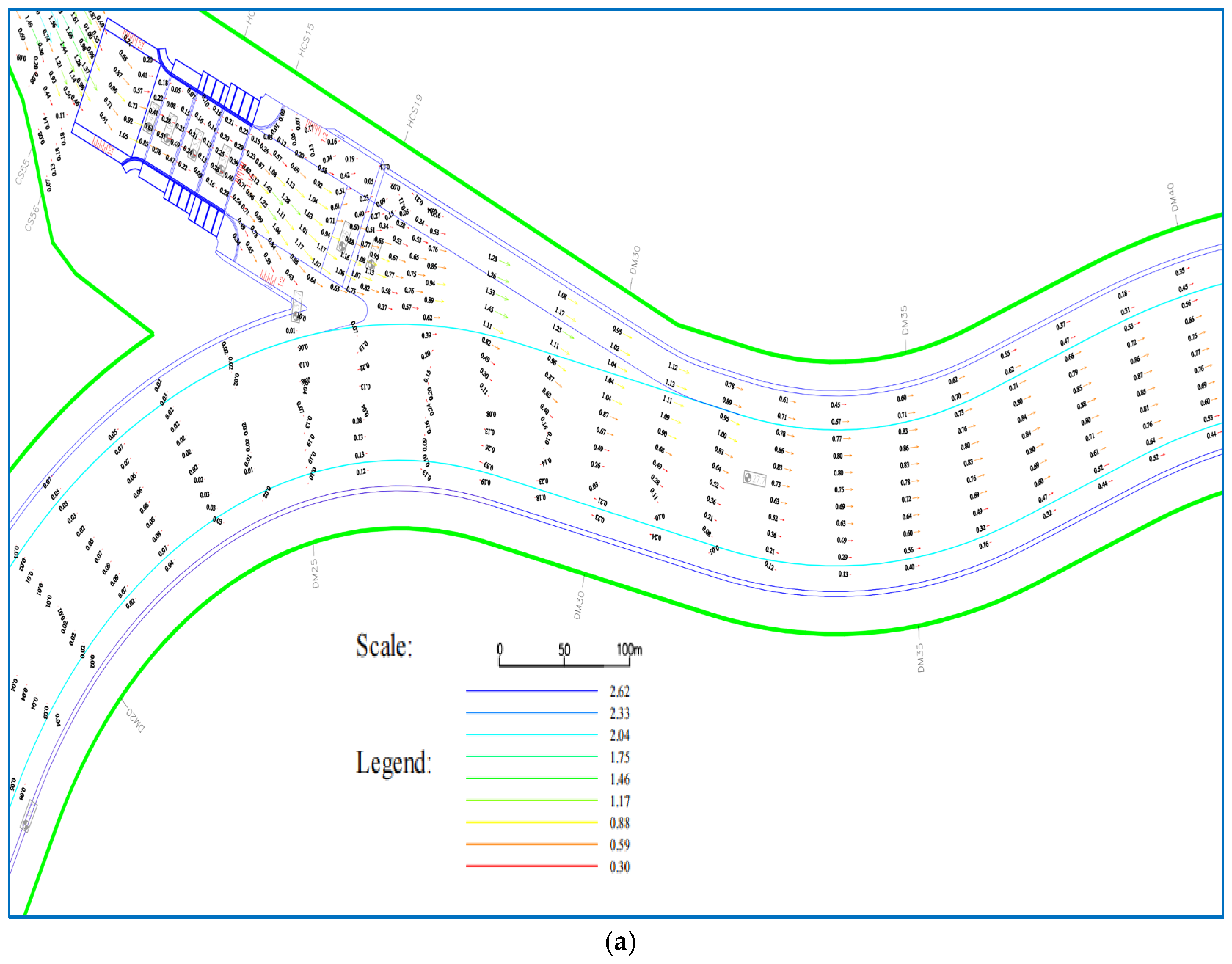

5.3. Measure Three: 1:4 Steep Slope + Three-Stage Stilling Pool

5.4. Analysis of Results

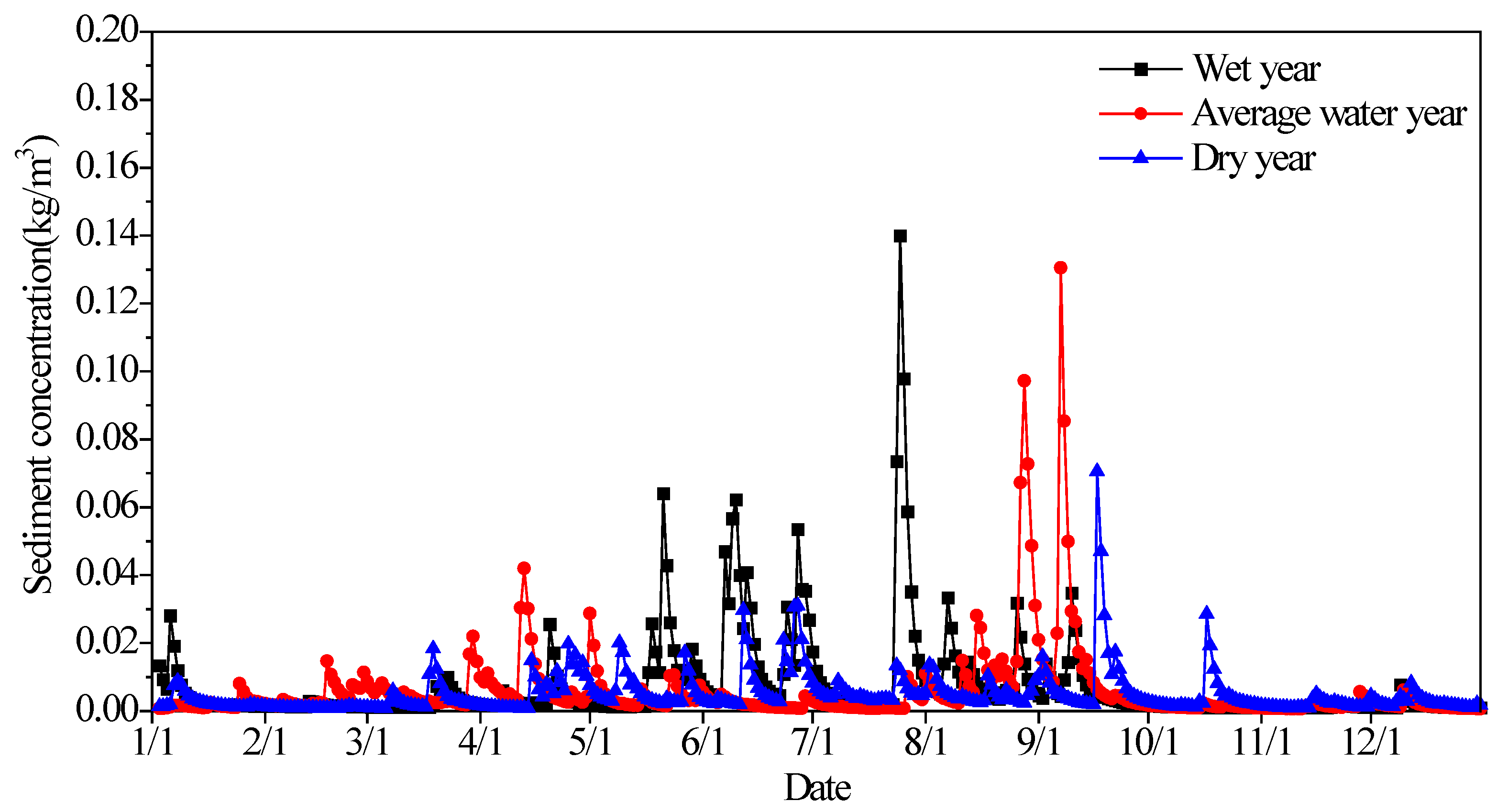

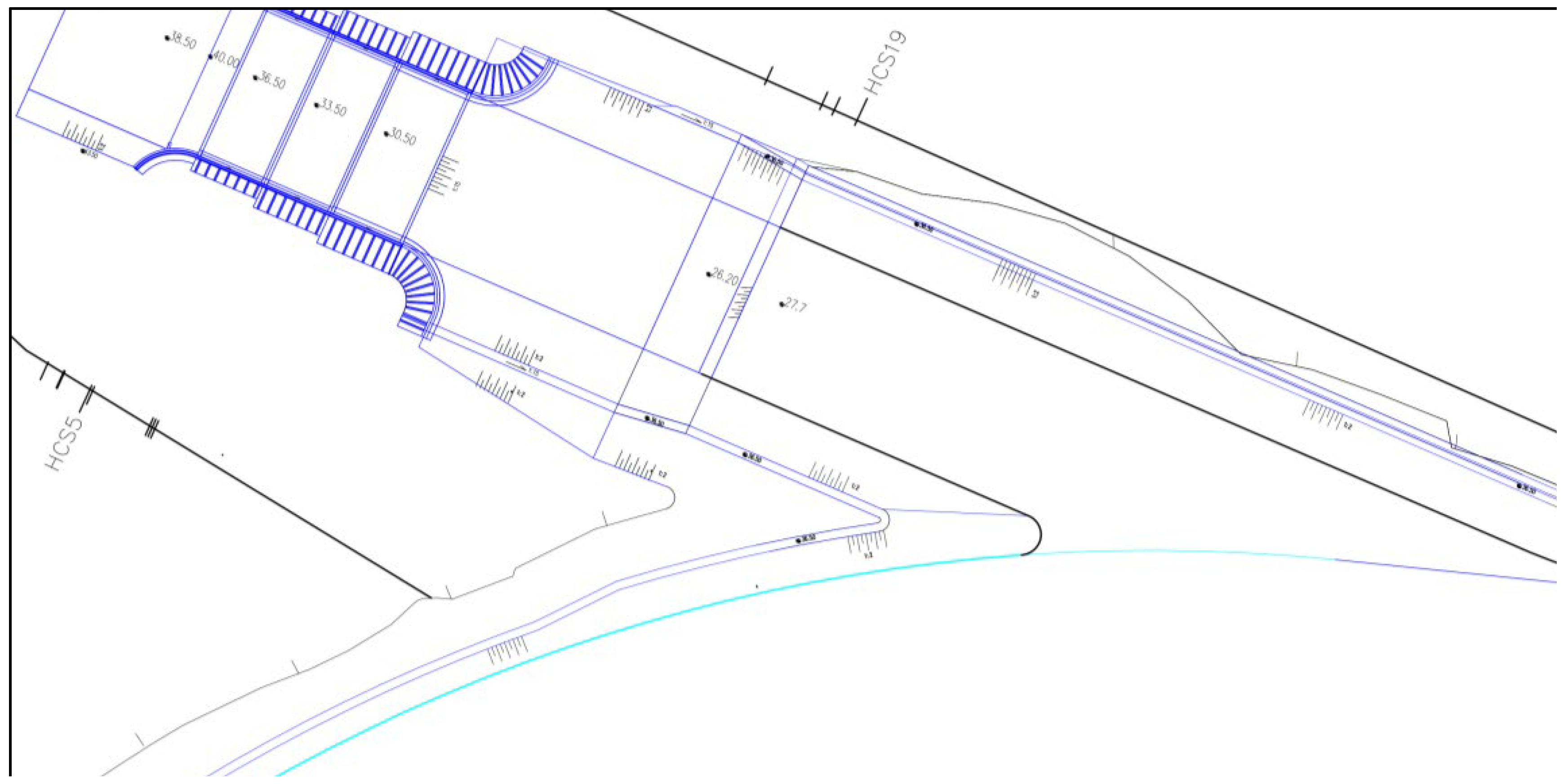

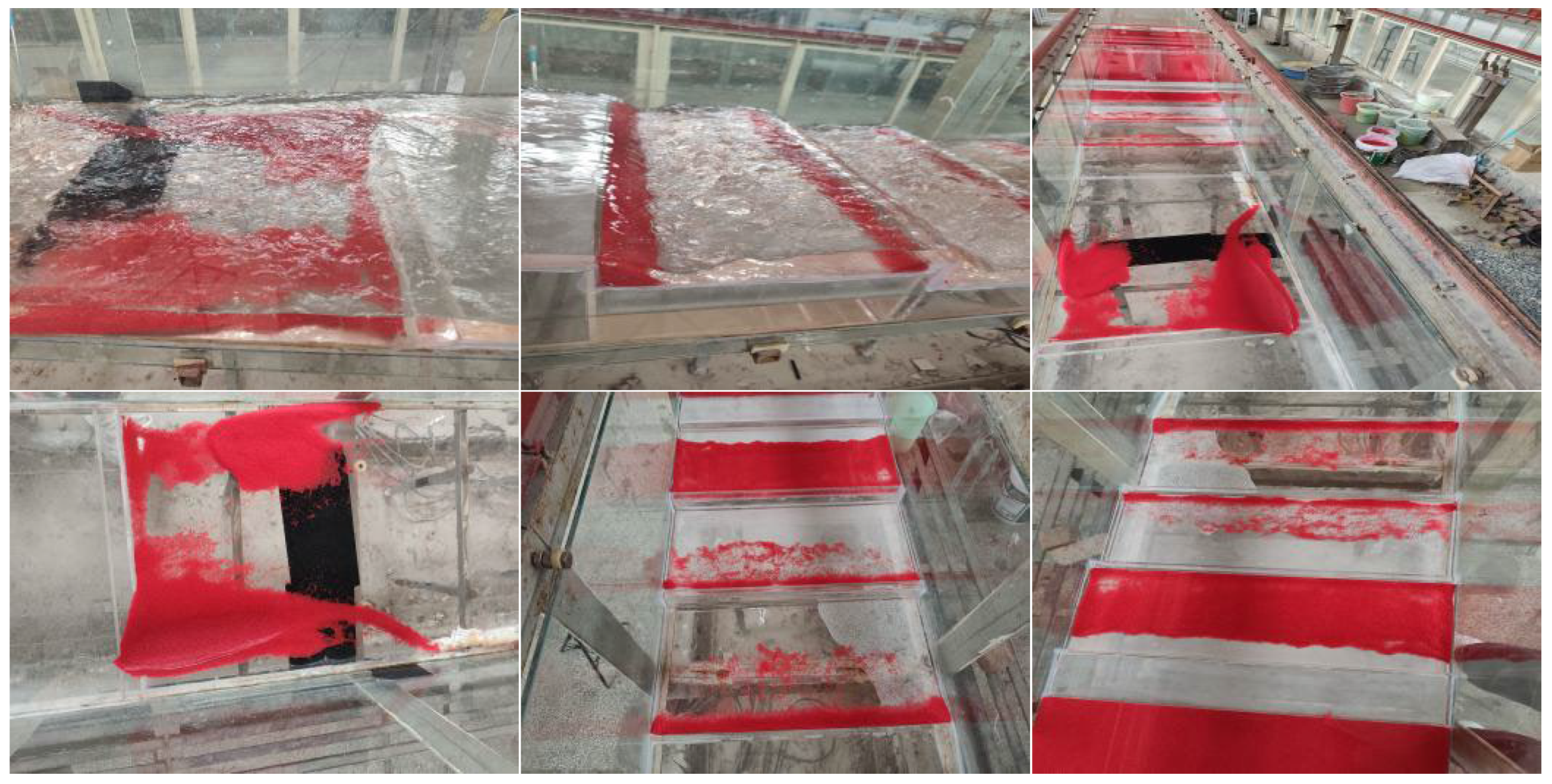

6. Analysis of Sediment Deposition in Tributary Mouth

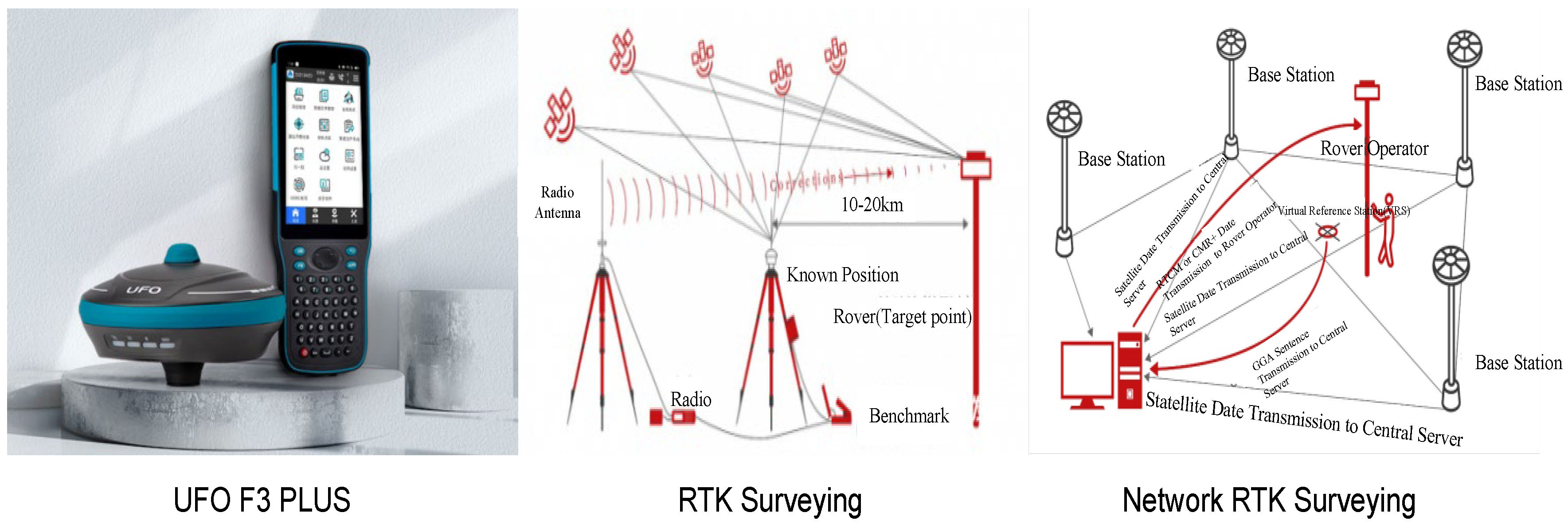

6.1. High-Precision Adjustable-Slope Flume Test System

6.2. Sediment Deposition Conditions

7. Conclusions

- (1)

- Effective Solution for Complex Confluences: The integrated structure featuring a 1:4 steep slope connected to a three-stage stilling basin proved to be the optimal solution for mitigating adverse navigational flow conditions under such challenging confluence geometry. This combined dissipator effectively addressed the high-energy inflow and large elevation drop.

- (2)

- Significant Flow Improvement: The implementation of this steep slope + three-stage basin scheme drastically improved the flow field within the navigation channel. Under high-flow conditions (tributary Q = 532 m3/s, main channel Q = 340 m3/s), the maximum longitudinal velocity was reduced to 1.58 m/s and the maximum transverse velocity was reduced to 0.29 m/s. These values are well within the Class I waterway navigation safety standards (longitudinal ≤ 2.5 m/s, transverse ≤ 0.3 m/s).

- (3)

- Elimination of Flow Hazards: The optimized scheme completely eliminated the large areas of excessive transverse velocity and complex, disturbed flow patterns (such as oversized recirculation zones) observed in the initial design and other tested schemes (e.g., single three-stage basin, gentle slope + basin). Flow stability was achieved, particularly in the critical confluence reach (sections DM27-DM35), maintaining favorable flow patterns even amidst significant water-level fluctuations.

- (4)

- Superiority over Alternatives: Comparative analysis demonstrated the clear advantage of the 1:4 steep slope + three-stage basin (Measure 3) over the single three-stage basin (Measure 1) and the 1:15 gentle slope + basin (Measure 2). Measure 1 suffered from widespread transverse velocity exceedance and complex flows. Measure 2 met velocity standards but still exhibited potentially disruptive flow patterns due to unfavorable flow angles in the bend confluence area. Measure 3 not only met all velocity standards but also achieved stable flow alignment and efficiently dissipated energy before significant interaction with the main channel flow. The steep slope structure also aided in deflecting the tributary inflow toward the right bank, optimizing the confluence angle.

- (5)

- Effective Sediment Management: Physical sediment modeling confirmed the high sediment retention efficiency of the recommended combined dissipator. Under high-flow conditions (Condition 1), retention rates exceeded 94%, primarily depositing sediment in the first-stage basin and downstream settling basin. Under moderate flow (Condition 2), retention reached near 100%. This significantly minimizes sediment intrusion into the high-velocity sections of the dissipators and the main navigation channel, reducing long-term maintenance requirements.

- (6)

- Current research on diverse combinations of complex conditions within river basins remains limited. Establishing effective navigation management strategies for waterway systems integrating such multifaceted scenarios would significantly advance future waterway regulation efforts.

- (7)

- Compared to previous studies, while a single stepped stilling basin demonstrates excellent energy dissipation efficacy under conventional conditions, it proves inadequate for achieving effective energy reduction in trans-basin river systems under complex scenarios. In this study, the combined energy dissipation system has demonstrated remarkable performance in effectively resolving the challenges posed by high-energy inflows and significant elevation drops. Consequently, the combined deployment of multiple energy dissipators becomes imperative.

- (8)

- Practical Significance: Considering the demonstrated improvements in navigational flow safety, effective sediment control, structural feasibility, and cost-effectiveness, the 1:4 steep slope combined with the three-stage stilling basin is strongly recommended as the optimal remediation measure for the Jiuzhou River confluence into the Pinglu Canal.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, Y.; Wu, J.; Ma, F.; Hu, J. Uniform flow and energy dissipation of hydraulic-jump-stepped spillways. Water Sci. Technol. Water Supply 2020, 20, 1546–1553. [Google Scholar] [CrossRef]

- Tian, Y.; Li, Y.; Sun, X. Study on the Hydraulic Characteristics of the Trapezoidal Energy Dissipation Baffle Block-Step Combination Energy Dissipator. Water 2022, 14, 2239. [Google Scholar] [CrossRef]

- Salmasi, F.; Abraham, J. Effect of slope on energy dissipation for flow over a stepped spillway. Water Sci. Technol. Water Supply 2022, 22, 5056–5069. [Google Scholar] [CrossRef]

- Zhang, T.; Wu, C.; Lu, H.; Zheng, Z. 3-D numerical simulation of flow on stepped spill way combined with X-shape flaring gate piers. J. Hydraul. Eng. 2004, 8, 15–20. (In Chinese) [Google Scholar]

- Stojnic, I.; Pfister, M.; Matos, J.; Schleiss, A.J. Airwater flow in a plain stilling basin below smooth and stepped chutes. J. Hydraul. Res. 2023, 61, 51–66. [Google Scholar] [CrossRef]

- Hashjani, T.S. Hydraulic Study of Secondary Stilling Basins; University of Windsor: Windsor, Canada, 1997. [Google Scholar]

- Feng, Z.; Li, Y.; Tian, Y.; Li, Q. Effects of Energy Dissipation Pier Arrangements on the Hydraulic Characteristics of Segmented Pier-Type Step Energy Dissipator Structures. Water 2022, 14, 3590. [Google Scholar] [CrossRef]

- Chavhan, V.; Hinge, G. Trajectory features and energy dissipation of conventional and modified (Deflector) Ski-Jump bucket. Mater. Today Proc. 2021, 49, 1973. [Google Scholar] [CrossRef]

- Nikseresht, A.H.; Talebbeydokhti, N.; Rezaei, M.J. Numerical simulation of two-phase flow on step-pool spillways. Sci. Iran. 2013, 2, 222–230. [Google Scholar]

- Ghaderi, A.; Abbasi, S.; Francesco, S.D. Numerical Study on the Hydraulic Properties of Flow over Different Pooled Stepped Spillways. Water 2021, 13, 710. [Google Scholar] [CrossRef]

- Guenther, P.; Felder, S.; Chanson, H. Flow aeration, cavity processes and energy dissipation on flat and pooled stepped spillways for embankments. Environ. Fluid Mech. 2013, 13, 50. [Google Scholar] [CrossRef]

- Ghobadian, R.; Tabar, Z.S.; Koochak, P. Numerical study of junction-angle effects on flow pattern in a river confluence located in a river bend. Water SA 2016, 42, 43–51. [Google Scholar] [CrossRef]

- Pourvahedi, M.; Hosseini, K.; Mousavi, S.F.; Geranmayeh, K. Effect of geometry and hydraulic parameters on the bed morphology in a confluence using numerical approach. Appl. Water Sci. 2023, 13, 180. [Google Scholar] [CrossRef]

- Guillén Ludeña, S.; Cheng, Z.; Constantinescu, G.; Franca, M.J. Hydrodynamics of mountain-river confluences and its relationship to sediment transport. J. Geophys. Res. Earth Surf. 2017, 122, 901–924. [Google Scholar] [CrossRef]

- Liu, X.; Li, L.; Hua, Z.; Tu, Q.; Yang, T.; Zhang, Y. Flow Dynamics and Contaminant Transport in Y-Shaped River Channel Confluences. Int. J. Environ. Res. Public Health 2019, 16, 572. [Google Scholar] [CrossRef] [PubMed]

- Penna, N.; De Marchis, M.; Canelas, O.B.; Napoli, E.; Cardoso, A.H.; Gaudio, R. Effect of the Junction Angle on Turbulent Flow at a Hydraulic Confluence. Water 2018, 10, 469. [Google Scholar] [CrossRef]

- Mosley, M.P. An experimental study of channel confluences. J. Geol. 1976, 84, 538–562. [Google Scholar] [CrossRef]

- Bradbrook, K.F.; Lane, S.N.; Richards, K.S. Role of Bed Discordance at Asymmetrical River Confluences. J. Hydraul. Eng. 2001, 127, 351–368. [Google Scholar] [CrossRef]

- Canelas, O.B.; Ferreira, R.M.L.; Guillén-Ludea, S.; Alegria, F.C.; Cardoso, A.H. Three-dimensional flow structure at fixed 70° open-channel confluence with bed discordance. J. Hydraul. Res. 2019, 58, 434–446. [Google Scholar] [CrossRef]

- Zhao, D.Z.; Li, Y. Effect of surface tension on hydraulic model test. J. Hydraul. Eng. 2004, 4, 38–41. (In Chinese) [Google Scholar] [CrossRef]

| Tributary Name | Tributary 20-Year Flood Discharge (m3/s) | Maximum Longitudinal Velocity (m/s) | Maximum Transverse Velocity (m/s) | Present Bed Elevation of Tributary (m) | Designed Channel Bed Elevation (m) | Bed Elevation Difference (m) | Angle Between Tributary and Channel (°) |

|---|---|---|---|---|---|---|---|

| Lion River | 277 | 0.57 | 0.28 | 60 | 52.3 | 7.7 | 90 |

| Shaping River | 1260 | 2.13 | 0.82 | 58 | 52.3 | 5.7 | 40 |

| Jiuzhou River | 489 | 1.3 | 0.76 | 37 | 27.3 | 9.7 | 90 |

| Xinping River | 704 | 1.02 | 0.82 | 14.3 | 1.3 | 13 | 45 |

| Wangwu River | 88.6 | 1.25 | 0.32 | 36 | 27.3 | 8.7 | 45 |

| Datang River | 210 | 0.95 | 0.35 | 32 | 27.3 | 4.7 | 45 |

| Jiawu River | 181 | 1.07 | 0.28 | 17 | 1.3 | 15.7 | 50 |

| Yawan River | 49.8 | 1.16 | 0.08 | 17 | 1.3 | 15.7 | 90 |

| Dingwu River | 419 | 1.56 | 0.34 | 15.5 | 1.3 | 14.2 | 30 |

| Jiucun River | 129 | 1.28 | 0.25 | 13.7 | 1.3 | 12.4 | 60 |

| Qingtang River | 567 | 1.81 | 0.87 | 13.5 | 1.3 | 12.2 | 70 |

| Shabu River | 471 | 1.22 | 0.55 | 12 | 1.3 | 10.7 | 45 |

| Chenwu River | 72.9 | 1.4 | 0.12 | 11 | 1.3 | 9.7 | 100 |

| Yangwu River | 42.6 | 1.51 | 0.20 | 11 | 1.3 | 9.7 | 55 |

| Guangping River | 257 | 1.9 | 0.42 | 11.7 | 1.3 | 10.4 | 90 |

| Yangmei River | 59.9 | 1.56 | 0.25 | 9 | 1.3 | 7.7 | 110 |

| Panbiao River | 53.9 | 1.3 | 0.42 | 8.3 | 1.3 | 7 | 35 |

| Santa River | 622 | 1.78 | 0.60 | 5.7 | 1.3 | 4.4 | 30 |

| Xinwu River | 115 | 1.78 | 0.60 | 5.7 | 1.3 | 4.4 | 30 |

| Xiadi River | 264 | 1.82 | 0.59 | 3.4 | 1.3 | 2.1 | 60 |

| Niujiang River | 155 | 1.82 | 0.59 | 3.4 | 1.3 | 2.1 | 60 |

| Laocun River | 354 | 1.95 | 0.45 | 3 | 1.3 | 1.7 | 45 |

| Dawu River | 75.1 | 1.98 | 0.50 | 5 | 1.3 | 3.7 | 45 |

| Maoping River | 230 | 2.42 | 0.45 | 5 | 1.3 | 3.7 | 45 |

| Water Ruler No. | Results | |||

|---|---|---|---|---|

| Model Water Depth (m) | Model Corresponding to Prototype Water Depth (m) | Prototype Water Depth (m) | Relative Error (‰) | |

| Z1 | 0.8102 | 40.51 | 40.53 | 0.49 |

| Z2 | 0.8004 | 40.02 | 39.99 | 0.75 |

| Z3 | 0.793 | 39.65 | 39.60 | 1.26 |

| Z4 | 0.7892 | 39.46 | 39.45 | 0.25 |

| Control Measures | Working Condition | Maximum Longitudinal Velocity m/s | Maximum Transverse Velocity m/s | Angle Between Central Line of Channel and Main Stream | Maximum Water-Level Fluctuation Difference (cm) |

|---|---|---|---|---|---|

| Three-stage stilling basin | 1 | 1.79 | 0.49 | mi | 33 |

| 2 | 1.11 | 0.28 | mi | 33.54 | |

| 1: 15 gentle slope + three-stage stilling pool | 1 | 1.69 | 0.3 | the larger | -- |

| 1: 4 steep slope + three-stage stilling basin | 1 | 1.58 | 0.29 | mi | 44.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, L.; Deng, K.; Yu, T.; He, J. The Influence of Combined Energy Dissipators on Navigable Flow Characteristics at Main Channel—Tributary Confluences in Trans-Basin Canals: A Case Study of the Jiuzhou River Section, Pinglu Canal. Water 2025, 17, 2214. https://doi.org/10.3390/w17152214

Han L, Deng K, Yu T, He J. The Influence of Combined Energy Dissipators on Navigable Flow Characteristics at Main Channel—Tributary Confluences in Trans-Basin Canals: A Case Study of the Jiuzhou River Section, Pinglu Canal. Water. 2025; 17(15):2214. https://doi.org/10.3390/w17152214

Chicago/Turabian StyleHan, Linfeng, Kaixian Deng, Tao Yu, and Junhui He. 2025. "The Influence of Combined Energy Dissipators on Navigable Flow Characteristics at Main Channel—Tributary Confluences in Trans-Basin Canals: A Case Study of the Jiuzhou River Section, Pinglu Canal" Water 17, no. 15: 2214. https://doi.org/10.3390/w17152214

APA StyleHan, L., Deng, K., Yu, T., & He, J. (2025). The Influence of Combined Energy Dissipators on Navigable Flow Characteristics at Main Channel—Tributary Confluences in Trans-Basin Canals: A Case Study of the Jiuzhou River Section, Pinglu Canal. Water, 17(15), 2214. https://doi.org/10.3390/w17152214