1. Introduction

As the global human population continues to grow and becomes increasingly more urbanised, groundwater and surface water resources are close to becoming/have become outpaced by demand in many regions [

1,

2,

3]. Presently, over 780 million people globally do not have (easy) access to clean, safe drinking water [

3,

4]. This can have severely negative impacts upon the holistic development of a country/region, in areas such as (but not limited to) economic growth, education, infrastructure, social justice, and responsible resource consumption/utilisation [

2,

5,

6]. The oceans (~97% of the planet’s available water) could be the key towards addressing water scarcity, but only if the high salinity is addressed (i.e., the brine is extracted). Water desalination is a process in which brine is extracted from seawater/brackish water, thereby broadening freshwater availability that can also be utilised for various other purposes, such as agriculture [

2,

3,

7].

Approximately half of all conventional desalination units in the world (totalling at >15,000, with a total daily freshwater production rate of ~70 million m

3) are in the Middle East, largely due to its being one of the most water-scarce regions in the world [

2,

3,

6]. Thermal and electrical separation are the primary industrial methods for water desalination [

7]. In thermal separation, such as multi-stage flash (MSF) and multi-effect distillation (MED), high temperature steam vaporises the water, leaving behind the brine (and waste) [

7,

8]. In contrast, the latter involves utilising high pressure generated via pressurised water sent through series of membranes [

7,

8]. Reverse osmosis (RO), an electrical-based technology, dominates the desalination market, with ≥60% of desalination plants using RO [

2,

7,

8]. Seawater-derived RO is comparatively less energy-intensive than MED at 3–6 kW/m

3 vs. 3–22 kW/m

3, though this is dependent on the thermal separation method, salinity, and total capacity [

8].

Table 1 shows the desalination water costs, which were obtained using a modified version of [

9].

On the other hand, in comparison to groundwater pumping, using RO to derive desalinated water is far more costly at USD 0.49–2.89 per m

3 [

10]. The key issues associated with desalination are energy costs and the disposal of brine waste. According to the IEA, desalination accounted for 5% of the Middle East’s total energy consumption in 2016, while only generating 3% of the region’s water supply [

10].

Figure 1 illustrates that ~41% of total costs can be attributed to the energy demands required to generate the necessary temperatures and pressures for desalination, which can also have severe adverse environmental effects [

11]. A total of 200 kWh/day is consumed globally by desalination plants, with a ratio of 3–10 kWh to 1 m

3 of desalinated water (<1 kWh for conventional drinking water) [

11,

12]. Up to 99% of the total energy demand is derived from fossil fuels [

13].

Desalination plants must therefore transition towards (green) sustainability, which could be achieved with process intensification and modularisation using stranded renewable energy sources, such as wind and solar, especially in water-scarce regions [

3,

6,

14]. Smaller, modularised plants are more cost-effective overall than downsizing existing large-capacity plants, especially in conjunction with process intensification (i.e., improvements in overall efficiency, reduced overall costs, and better water quality). RO systems are optimised towards smaller, modularised plants, as they have an adaptable and easily maintainable modular membrane design, though this requires further design development [

11,

14]. That said, such systems are highly geared towards process intensification for various additional reasons, especially due to developments in recent decades: low energy intensity, high efficiency, low capital costs, and high selectivity/permeability regarding transportation components [

15].

Multi-criteria Decision Making (MCDM) could be the key towards incorporating and/or improving the sustainability of small-scale desalination processes. MCDM enables a novel approach towards the selection of the most optimal small-scale RO desalination pathway(s), based on (green) sustainability-related criteria, which encompasses sustainable water desalination (

Figure 2).

Section 2 details a case study regarding a relatively small-scale (i.e., community-scale) RO desalination and water treatment plant system in Sohar, Oman. The Analytical Hierarchy Process (AHP) was selected as the MCDM methodology because it is highly adaptable, easy to use, and presents a clear hierarchical structure. A Fuzzy Analytical Hierarchy Process (FAHP) framework was developed and implemented to determine the most optimal sustainable desalination configuration pathway(s), based on the quantitative and qualitative data of various capacities and diesel-to-solar energy mixes. The FAHP framework seeks to illustrate that the most sustainable pathway(s) overall can be identified and selected via MCDM, while also meeting population and industry demands (e.g., cost).

2. Materials and Methods

The standard plant configuration is single-pass RO with continuous operation, based in Sohar, Oman. Improved recovery was achieved via small-unit recirculation of reject water, though this was not modelled in the case study. The desalination process design and modelling insights were obtained from [

16]. Whenever and wherever possible, water sample information was acquired from numerous sources for the Gulf of Oman. If this was not possible, the Persian Gulf served as an appropriate substitute, due to its relative proximity.

Appendix A lists the key parameters for designing RO systems, Omani drinking water quality standards, and the recommended limits regarding design for conventional desalination via surface seawater [

17,

18,

19]. The model design accounted for seasonal-based variations, particularly the maximum range values, in water characteristics and their effects on RO systems [

18]. Smaller units can improve recovery via reject water recirculation; however, this was not modelled for this study.

Water flux, the most essential design characteristic, is dependent upon the source(s) and quality of feed water, which in turn affect the risk of membrane fouling [

18,

20,

21,

22]. Therefore, membrane characteristics must be designed to address fouling, for the sake of reliable, long-term (membrane) performance and integrity in sustainable desalination [

21,

22]. Water Application Value Engine (WAVE) and Desalination Economic Evaluation Program (DEEP) software were optimised to assess relatively small-scale desalination plants, with an assumed 24 h/day operation (daily rates) for modelling consistency. Additionally, model plant life was set to 20 years, with an annual availability of 90% based on the literature findings [

16,

18,

21,

22].

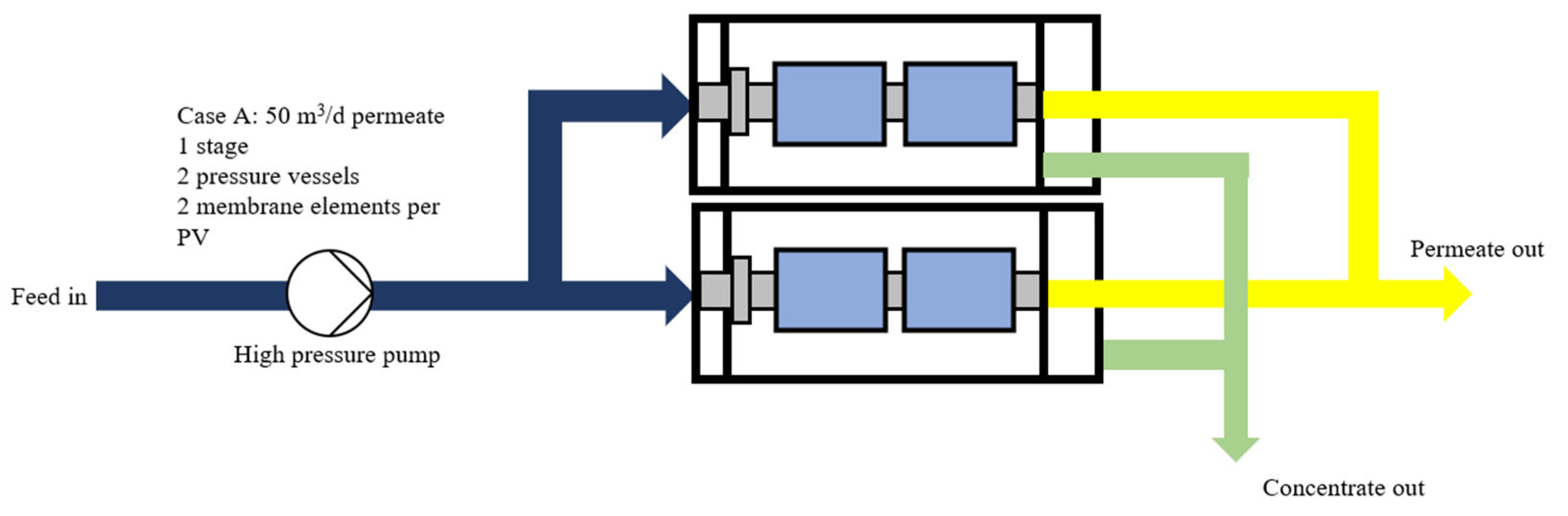

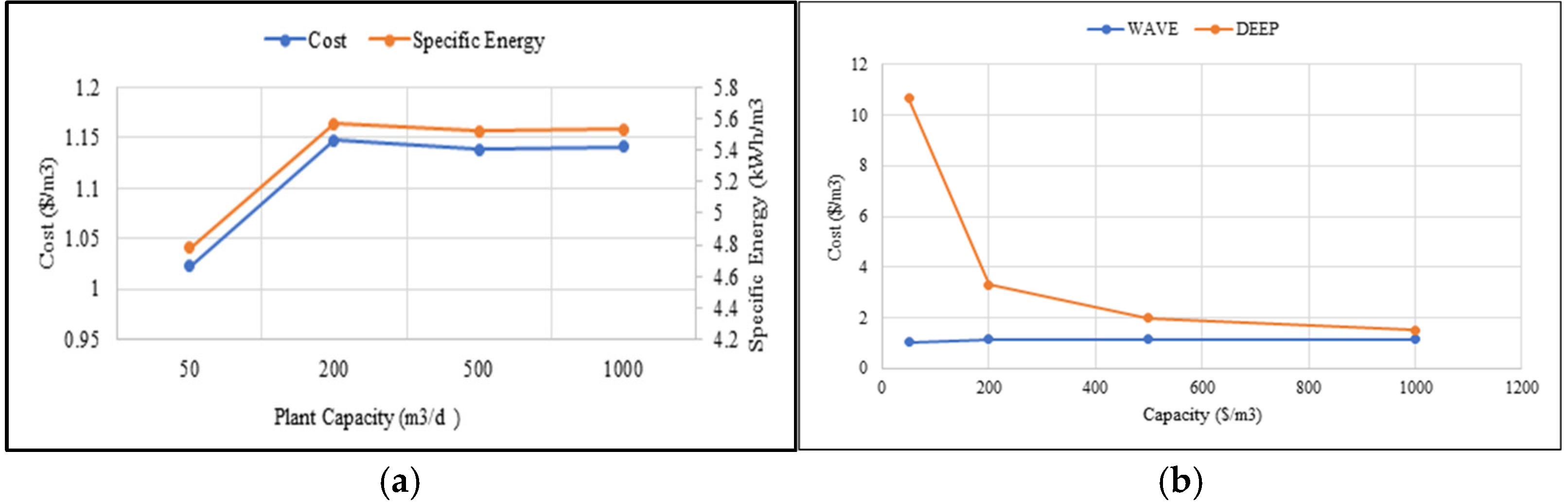

WAVE, developed by Dupont Water Solutions, is a popular software platform for modelling advanced desalination and water treatment technologies [

23,

24,

25,

26]. Four cases were optimised—each at 50, 200, 500, and 1000 m

3/day (

Table 2)—with the full parameter details listed in

Appendix B. A conservative-to-typical flux rate range of 7–8.6 GFD was selected, while total energy use (kWh/m

3 of product water) and USD price were minimised via adjustments to the following characteristics: pressure vessels per stage, membrane type, number of membrane stages, and membrane elements per pressure vessel.

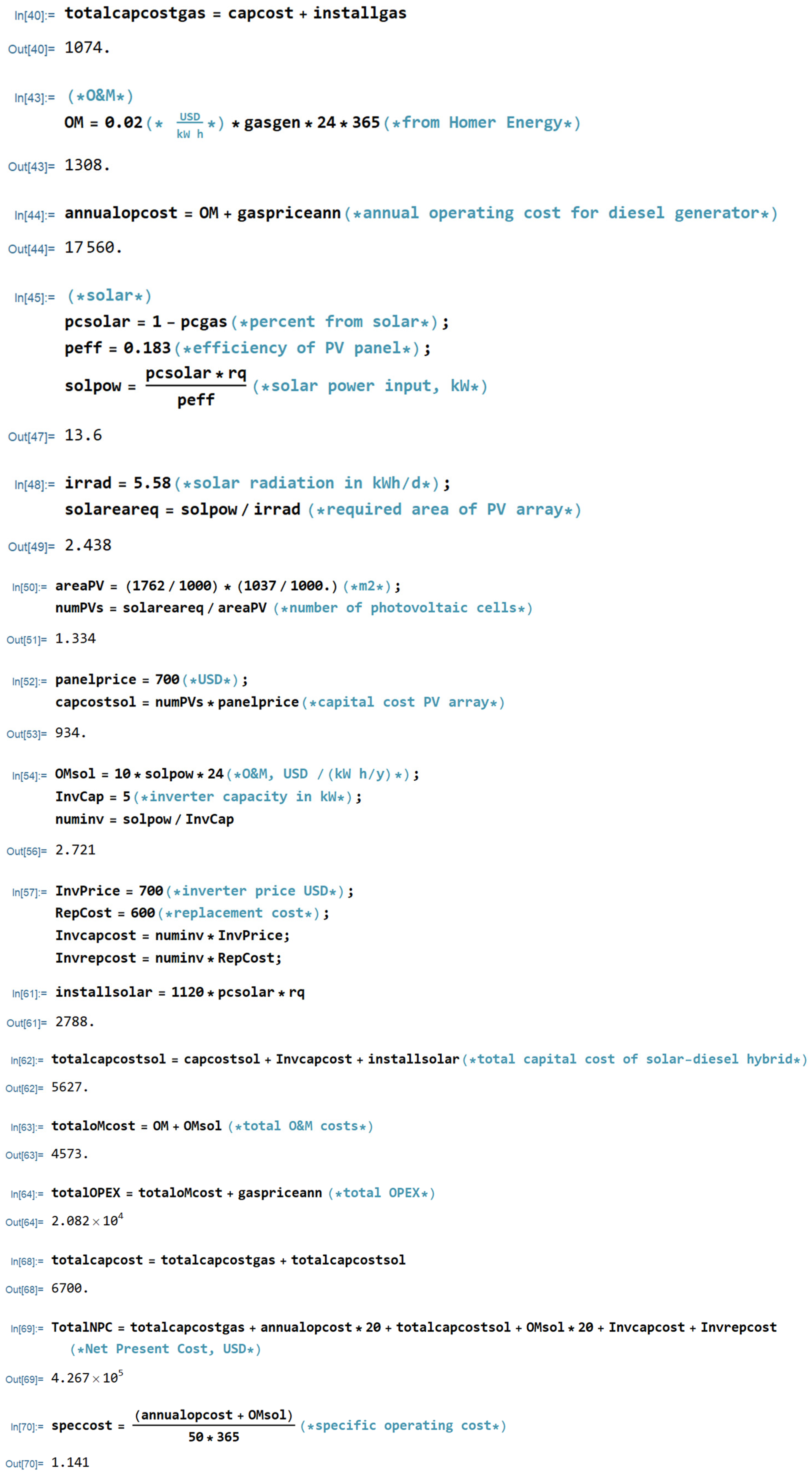

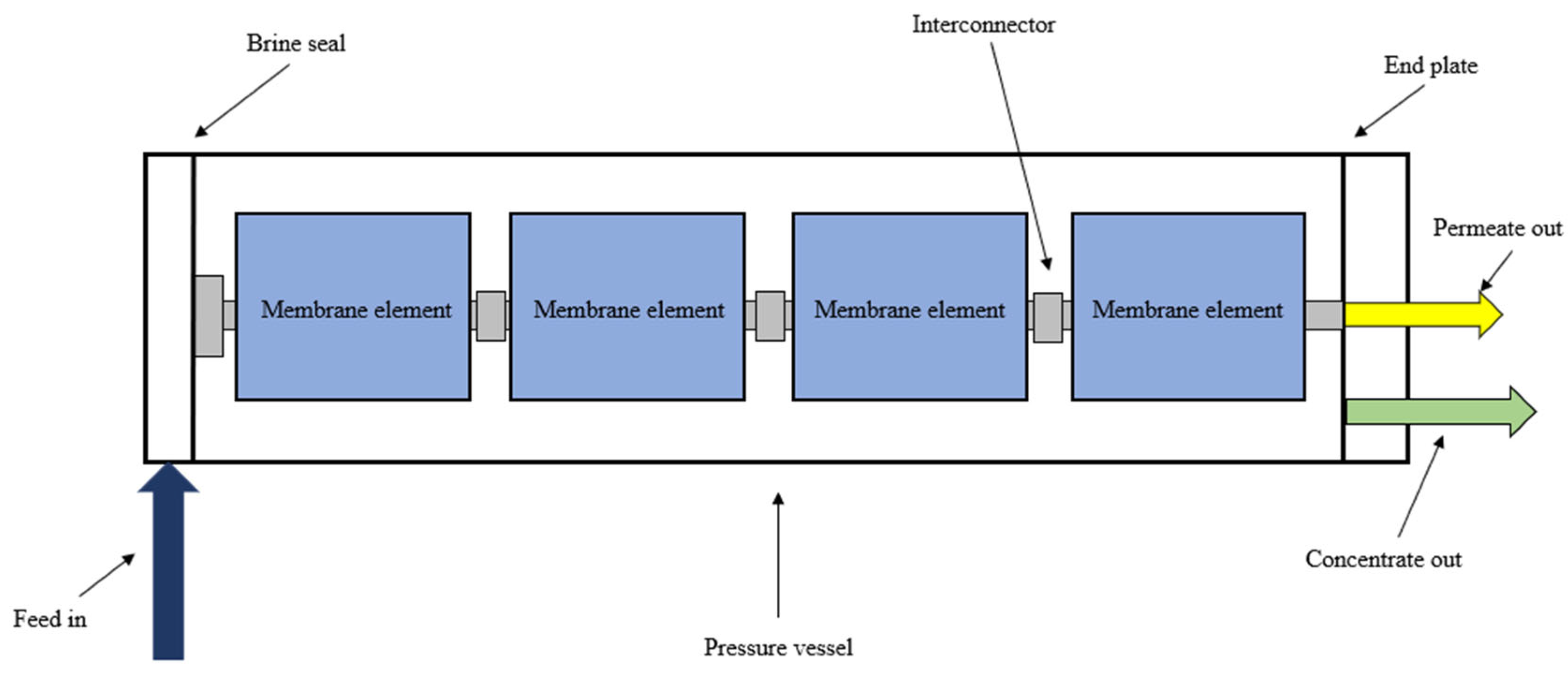

Figure 3 shows the typical detailed design for an RO train [

27], which the study uses as the proposed RO design for the study. The default operating costs were selected (0.14 USD/m

3 and 0.69 USD/m

3), while electricity costs were adjusted to values in Oman, circa September 2022 [

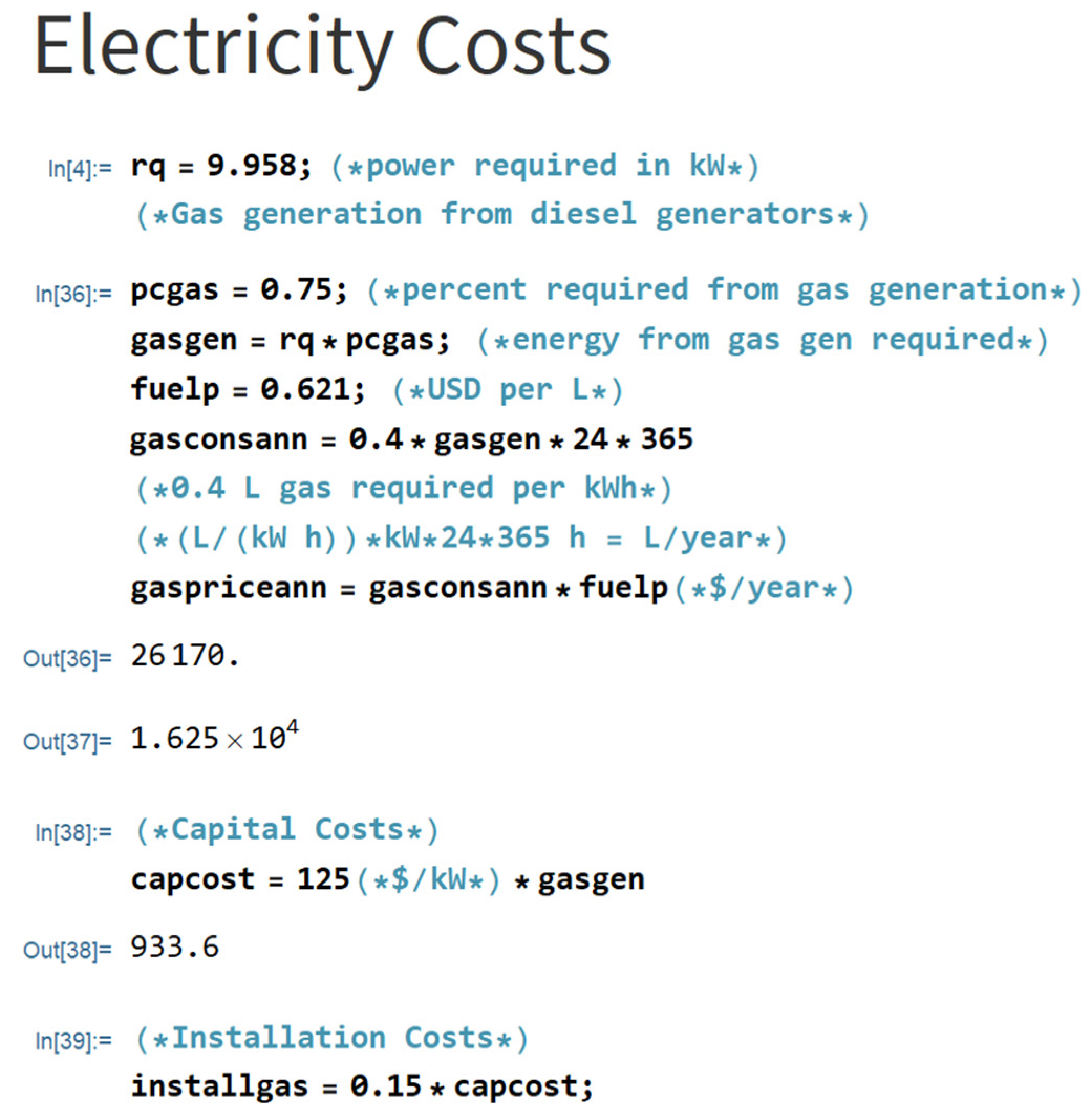

28]. Each case has an assumed recovery of 75.4% that was used to calculate the input flow rates.

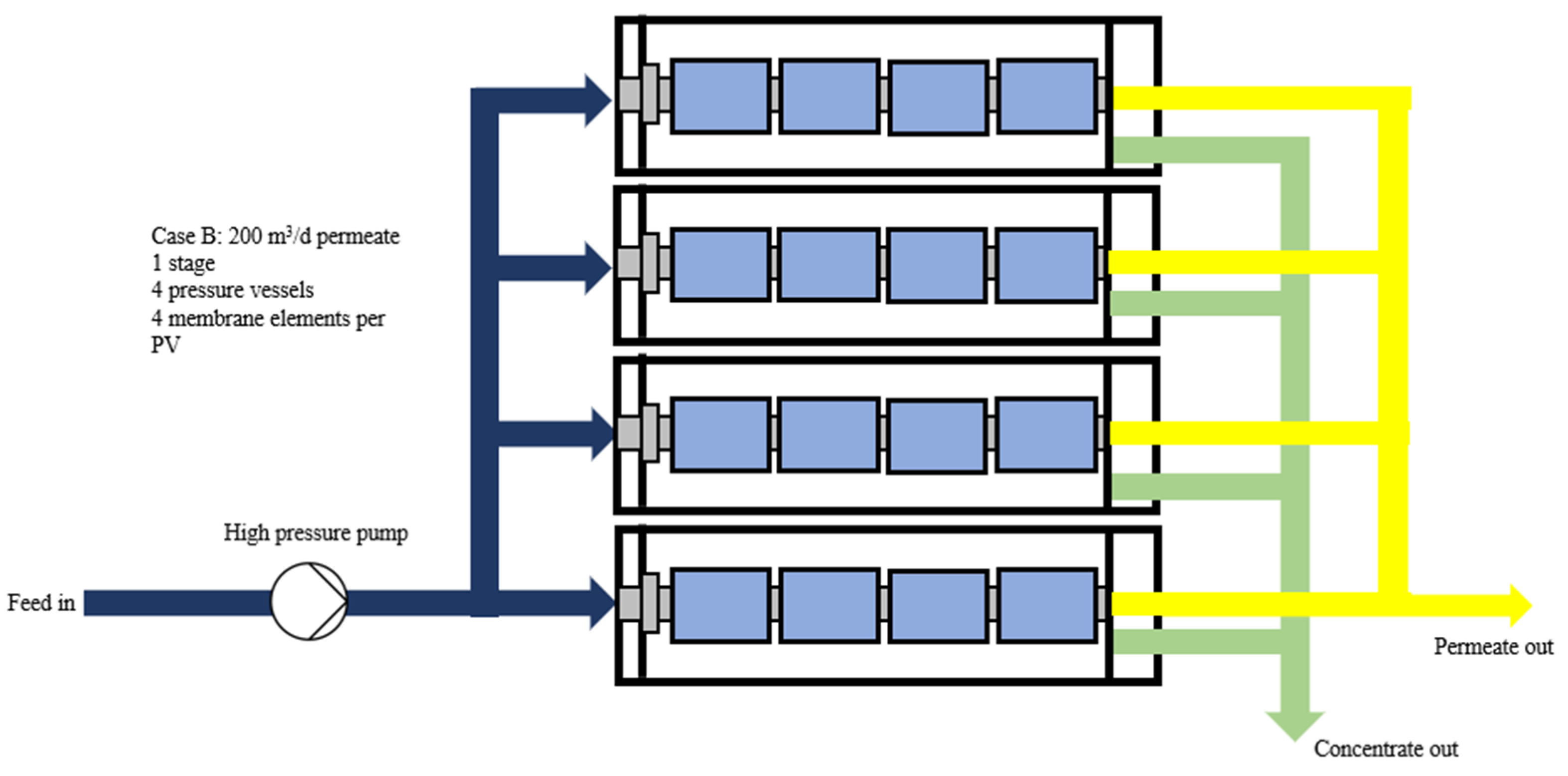

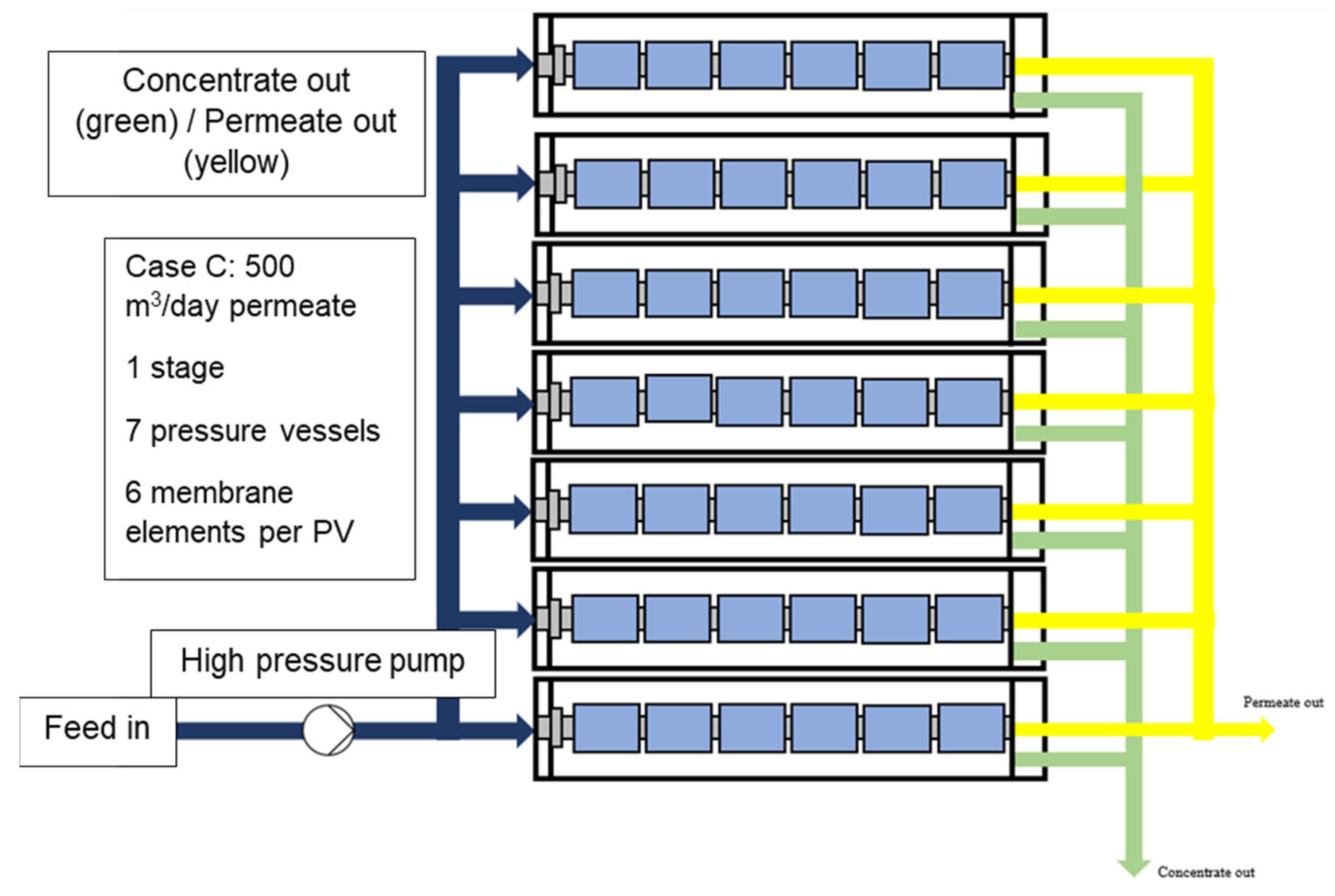

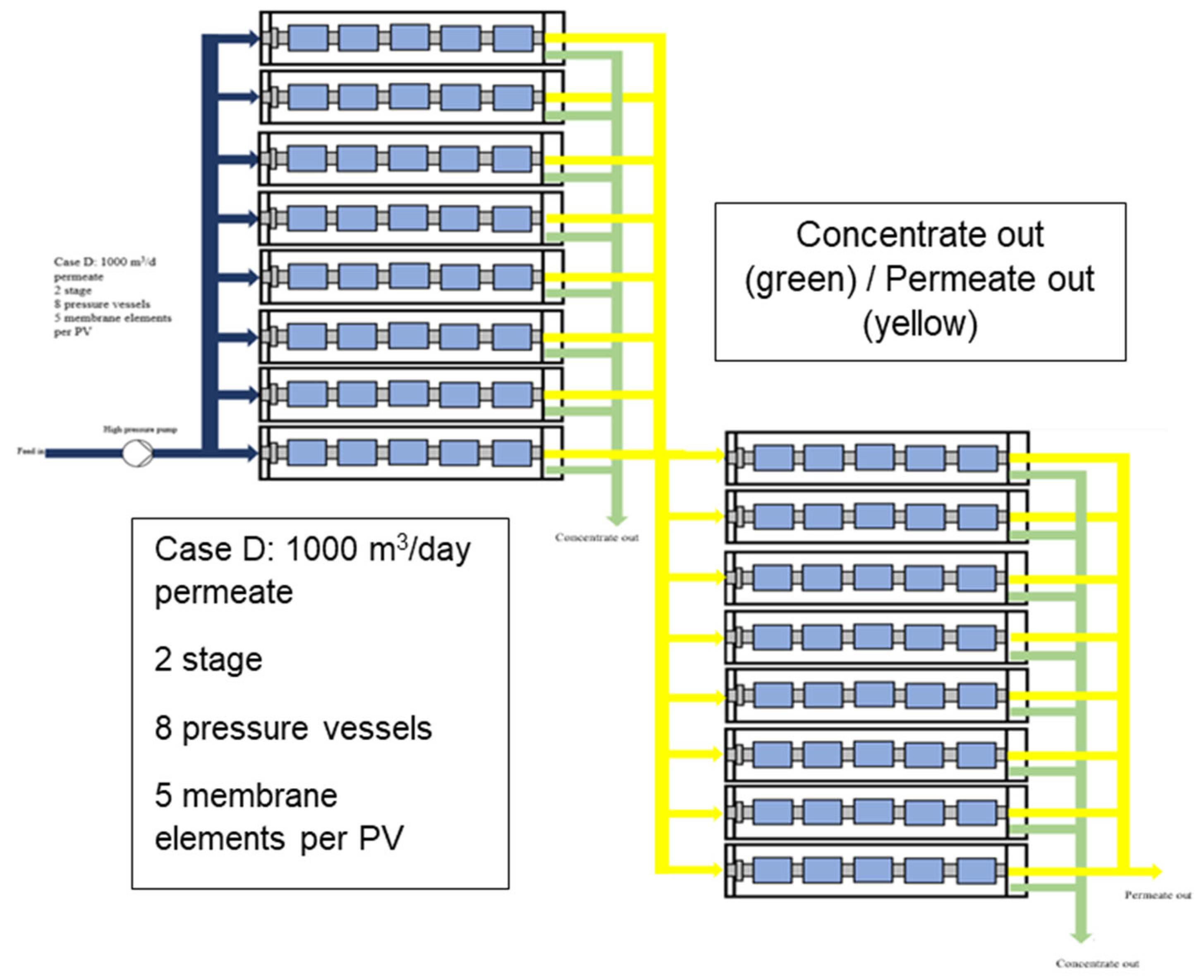

Figure 4 shows the configuration for Case A, with B–D in

Appendix C.

In contrast to WAVE, DEEP is a relatively more complex desalination modelling software platform that utilises Excel, developed by the International Atomic Energy Agency (IAEA) to highlight the potential of nuclear-powered desalination. DEEP was capable of modelling various electrical- and thermal-based desalination designs that run on alternative energy sources, including but not limited to renewables and/or nuclear power. DEEP could also generate high(er)-level economic information (and sensitivity analysis) via changes in input data, salinity, energy type(s), and plant capacity. Annual specific water cost (SWC), one of the key parameters, combined the operation and maintenance (O&M) costs with annual capital costs. DEEP has energy options for grid-connected renewables, though they were not intuitive to the model, even when using the v5.1 manual. Instead, the power type was simply set to combined cycle gas, without the utilisation of financial data (e.g., operating costs) via the outputs.

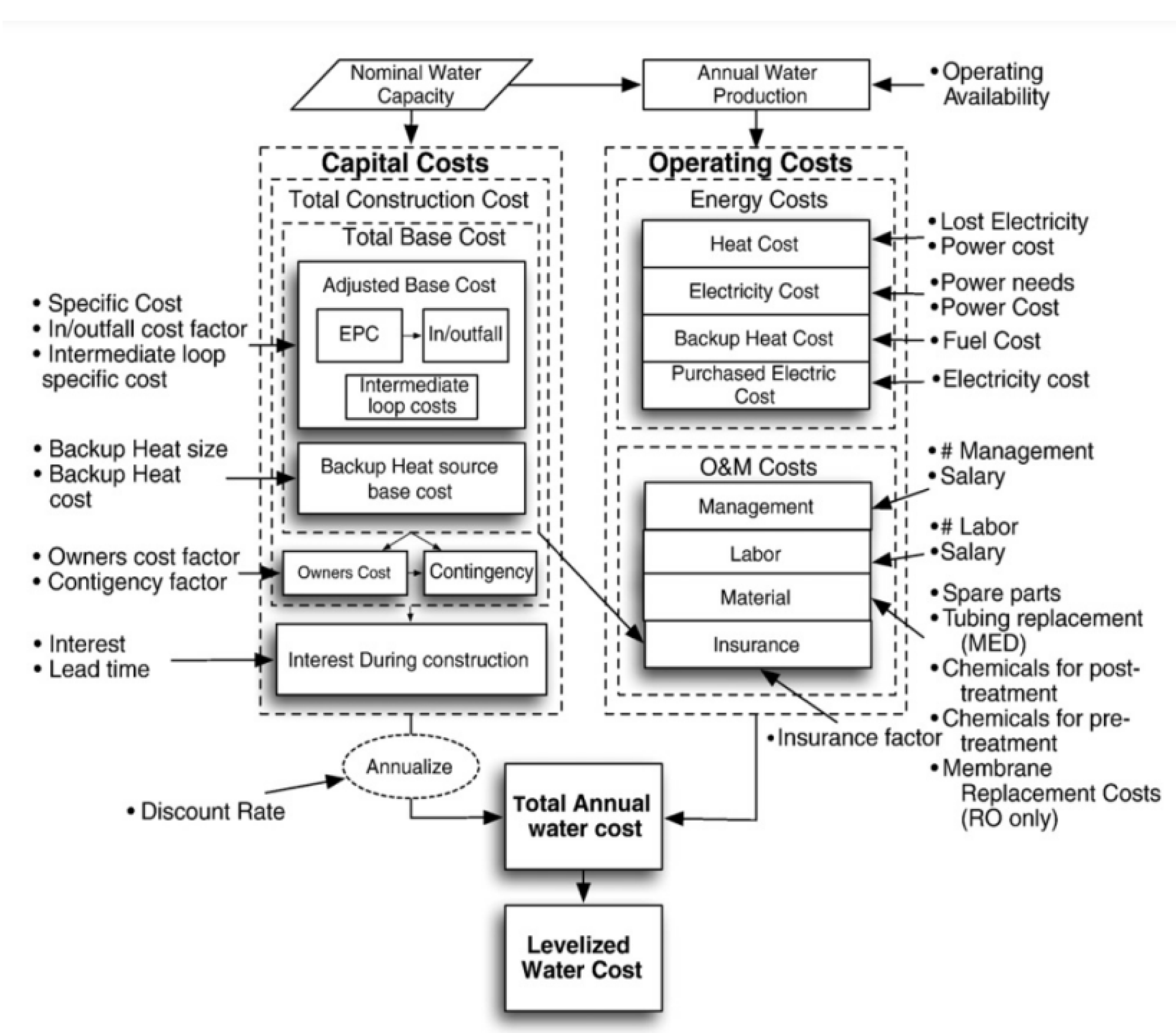

Figure 5 summarises the economic evaluation capabilities and methodology of DEEP [

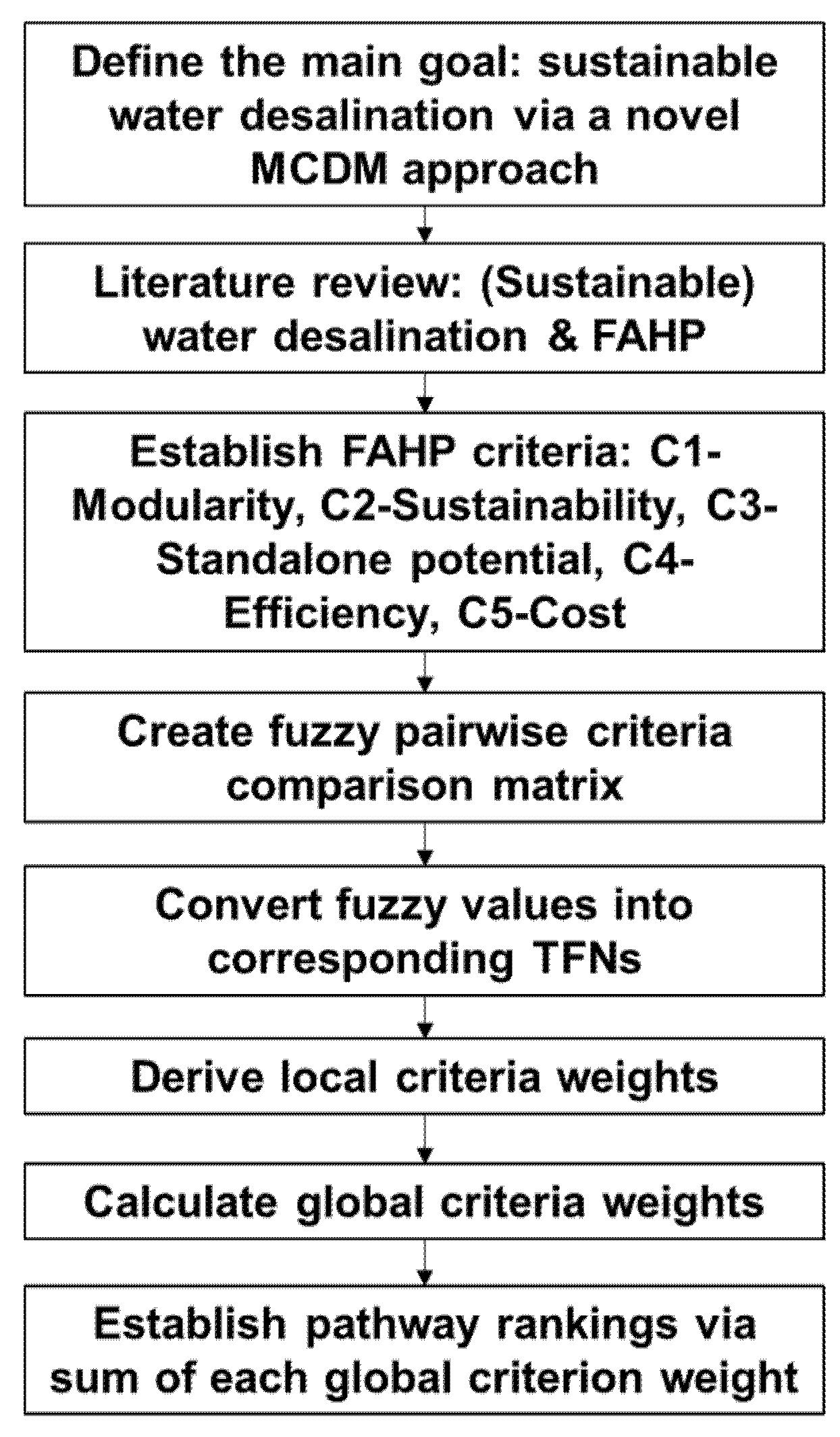

29]. For the MCDM framework, the FAHP was utilised via Excel and MATLAB v24.1 to establish criteria weightings and subsequently rank twelve potential pathways for relatively small-scale, modular sustainable water desalination (

Table 3).

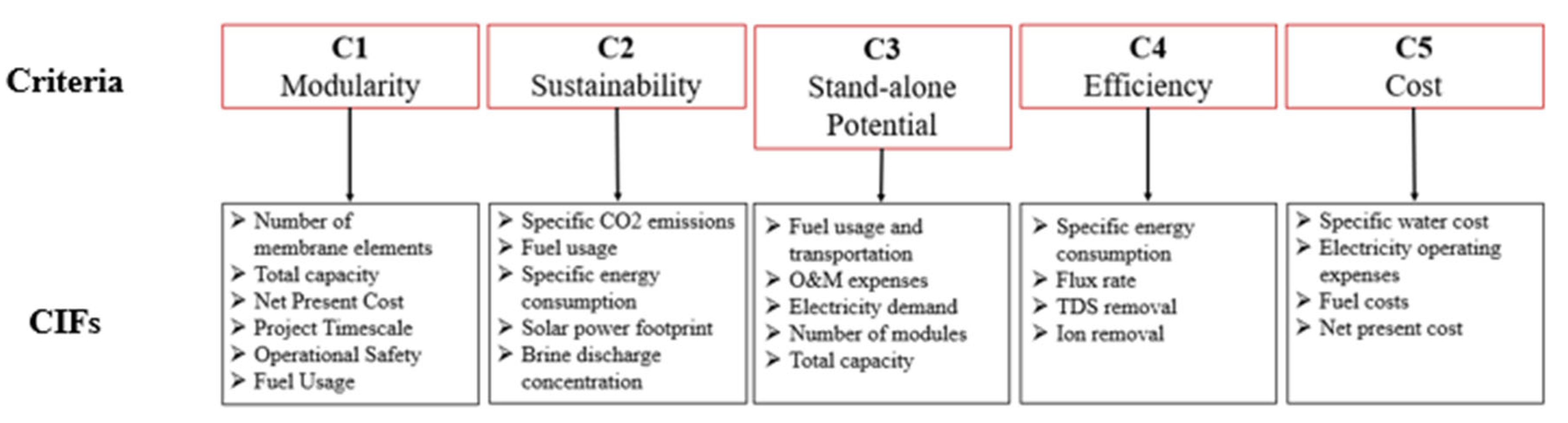

A linguistic-based fuzzy pairwise comparison matrix was created to derive quantitative and qualitative criteria weightings in MATLAB v24.1, from the following criteria that encompass sustainability: C1—modularity, C2—sustainability, C3—standalone potential, C4—efficiency, and C5—cost (

Figure 6). The FAHP framework was modified from Clara Bartram’s AHP analysis of sustainable water desalination in Oman. The FAHP included the capability of using linguistic “fuzzy” variables for non-numerical (i.e., qualitative) data in MCDM, as opposed to the standard AHP, so long as they were converted into their corresponding TFNs via Equation (1) (

Table 4) [

30]. The consistency ratio (CR) was calculated to be acceptable at 0.039 < 0.1 [

31,

32,

33]. Local weights for each pathway were derived via a fuzzy pairwise comparison matrix as per the criterion in Excel. Local criteria weights (

Table 5) were multiplied by the local matrix weights to generate the global weights (

Table 6). The sum of the global weights for each pathway determined its ranking, with a greater sum value denoting a higher ranking.

4. Discussion

Sustainable water desalination should primarily aim towards reducing energy use and CO

2 emissions, in comparison to conventional desalination. WAVE and DEEP software platforms were utilised to analyse and assess RO diesel–solar energy configurations in Oman, from economic and environmental dimensions (

Figure 6). It was determined that smaller-scale, modular, intensified RO system designs could be the key towards (green and) sustainable water desalination, particularly with more balanced diesel–solar (i.e., 60–40% > 75–25%) energy configurations that utilise available stranded renewable energy sources (e.g., solar/wind) from within a/across region(s) [

3,

6,

13,

28,

38]. Moreover, it was determined that the proposed sustainable water desalination can be cost-effective, with costs that are similar to their conventional counterparts (USD 0.49–2.89 per m

3) [

8]. In terms of specific energy costs (

Figure 6), any significant differences between WAVE and DEEP may be (more) attributable to the calculation methods, as opposed to factors like plant capacity. On the other hand, while

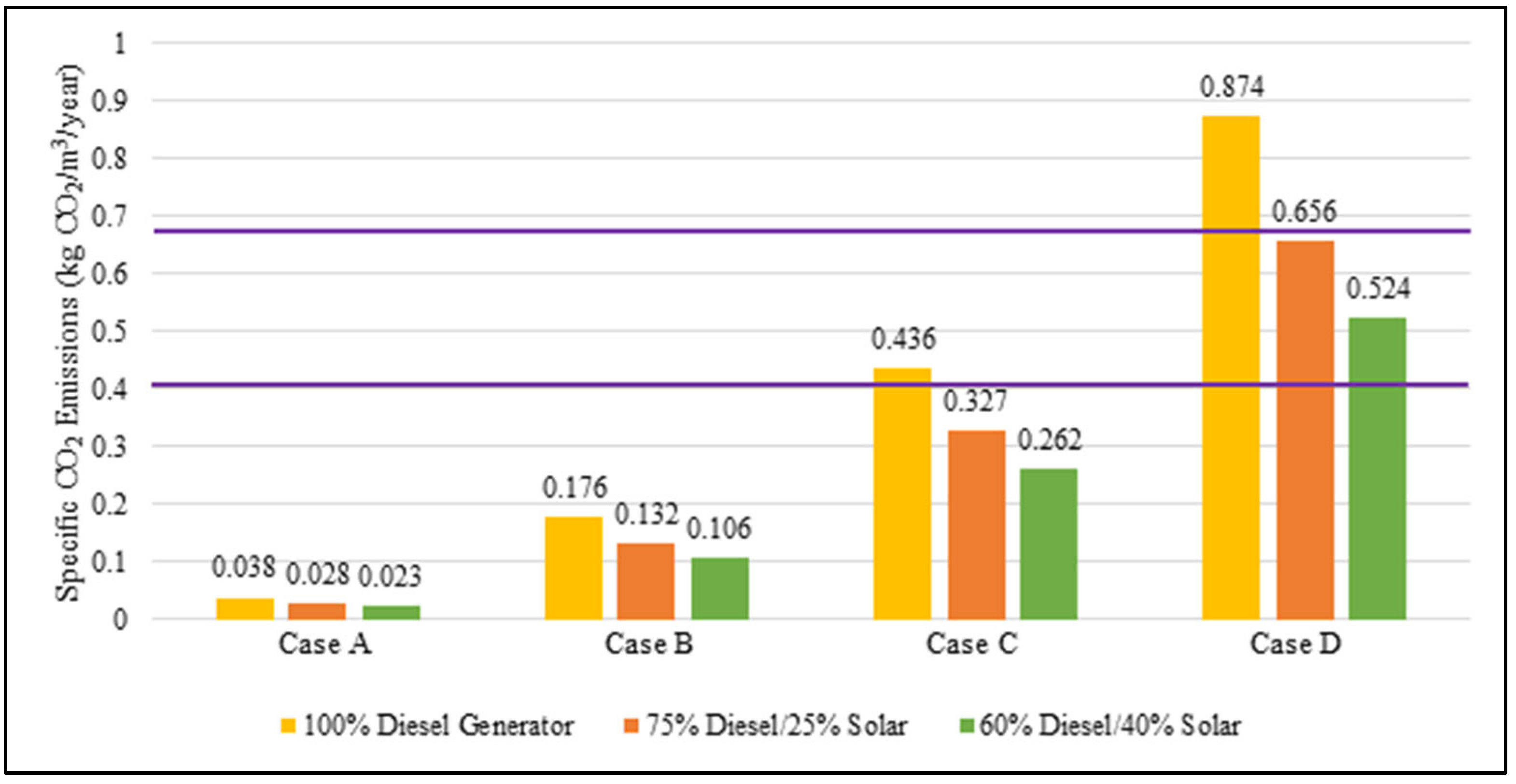

Figure 7 illustrates that the specific CO

2 emissions per m

3 of water per year were reasonable and in accordance with smaller-scale operations, the calculated reductions may have been overstated; diesel generators would not be responsible for all emissions, especially with factors associated with fuel transportation and PV maintenance/installation. Furthermore, from an economic perspective, DEEP (or similar software) may potentially overstate labour and management (L&M) costs, which can heavily skew the economic analysis of smaller-scale plant designs. Therefore, it is essential that the desalination software is optimised towards specific scale(s) of operations on a case-to-case basis, particularly if (significant) upwards scalability is planned in future endeavours [

10,

34]

Solar-leaning configuration pathways are ranked higher than their diesel(-leaning) pathways. Specifically, 60–40% pathways were ranked the highest, followed by 75–25% and 100% diesel. Reduced energy and fuel consumption appear to make a significantly positive contribution towards criteria weightings. Moreover, the hybridisation of diesel with renewable energy, such as solar, has been known to improve the sustainability, overall efficiency, and standalone potential [

12,

37,

38]. That said, dimensions can also be over-represented and/or overweighted by decision makers. This is often due to potential biases and/or simply decision-based fatigue, particularly with regard to more subjective qualitative data and the economic dimension [

29,

31,

32,

35]. However, while possible [

37], this would be more explicitly evident on a real-world, case-to-case basis. Furthermore, only the smallest-scale plant capacity (50 m

3/day; A3 > A2 > A1) appears to be the most optimal, in terms of achieving overall sustainable water desalination, with the assignment of overall lower ranking to the larger plant capacities. Such an assignment of lower rankings appears to more disparate with increasing plant capacity. Thus, scalability would involve the hypothetical upscaling of relatively small-scale ~50 m

3/day capacity configurations, with a key focus on (further) process modularisation and intensification [

14]. This could potentially require modifications to the (overall) methodology framework, which is dependent on site-specific spatial and temporal variables, such as available sunlight hours (solar) [

18,

28,

34,

40] and/or brackish content [

2,

3,

6,

7], which may be beyond the current scope of the study. Weighting issues could be one of the potential limitations of the AHP/FAHP and upscaled methodology frameworks, which could be mitigated/removed by MCDM integration. Each MCDM method has its strengths, weaknesses, and limitations [

40,

41,

42,

43,

44,

45].

Therefore, further works should seek to develop and implement an integrated MCDM framework with more clearly defined criteria and sub-criteria (social, economic, environmental, and technical): FAHP with TOPSIS and/or VIKOR with PROMETHEE-II. Ideally, this would provide more balanced, holistically green, and sustainable perspectives for water desalination. The FAHP is incredibly adaptable, easy to use, and presents a clear hierarchical structure [

29,

30,

31,

32]. The integration of VIKOR would provide a more accurate representation of DM viewpoints via compromise solutions, while removing criterion units in a way that does not distort criteria data [

30,

40,

41]. PROMETHEE-II is a relatively stable and straightforward MCDM method, which is commonly applied in sustainability-related fields, with the ability to provide relatively reliable and nuanced complete pathway rankings [

42,

43,

44,

45]. Its lack of versatility [

41] could be mitigated by the high adaptability and flexibility of the FAHP, while the compromise solutions from VIKOR would maximise the conclusiveness and reliability of the results [

42,

43,

44,

45]. Additionally, further works should consider emission contributors, such as fuel transportation and PV maintenance/installation, in the criteria weightings and subsequent pathway rankings. Such pathways should also consider greater solar percentages, to analyse and evaluate key sustainability-related criteria from balanced perspectives (if possible). And for a truly holistic perspective on sustainable water desalination, the social dimension of sustainable water desalination should be addressed with greater depth. This could be achieved on a case-to-case basis via an eclectic range and quantity of open and closed socio-political surveys [

46], and a systematic integration of established stakeholder engagement(s) with more personalised, general populace perspectives, i.e., how people (actual stakeholders, hypothetical or otherwise) respond and may/can influence case-specific policy, and vice versa. Further works would aim to avoid and/or minimise uncertainties within and among case-to-case criteria and sub-criteria, especially over time.

5. Conclusions

Ocean water desalination could be a crucial pathway towards addressing global water scarcity, in response to the growing demands of a progressively more urbanised global population. However, water desalination strives towards (green) sustainability, in order to address the weaknesses/limitations of conventional desalination: high energy intensity, limited scalability, and significant negative environmental impacts (primarily via emissions and brine disposal) [

11]. Smaller-scale RO desalination plant configurations were assessed via an MCDM framework, known as the Fuzzy Analytical Hierarchy Process (FAHP), based on five key sustainability-related criteria: modularity, standalone potential, efficiency, cost, and sustainability (

Figure 1).

A total of twelve plant configurations were assessed: four plant capacities (50, 100, 150, and 200 m

3/day) per three diesel-to-solar PV energy configurations (100–0%, 75–25%, and 60–40%). It was determined that solar-leaning configurations were ranked higher than their diesel counterparts (i.e., 60–40 > 75–25 > 100–0), largely due to reductions in energy and fuel consumption. The hybridisation of diesel configurations with solar has demonstrated notable improvements in sustainability, overall efficiency, and standalone potential [

36,

37]. Such results also imply that smaller plant capacities (i.e., 50 m

3/day) are the most optimal configurations, with regard to achieving overall sustainability. Thus, potential applications of scalability would ideally focus on modularised smaller plant capacities. That said, the exact extent is not completely clear; emission reductions may have been overstated without considering emission contributors, such as transportation and PV installation/maintenance. Moreover, the criteria can be over-represented and/or overweighted by decision makers with the FAHP, due to potential biases and/or simply decision-based fatigue.

Future research should seek to implement an integrated MCDM framework with more clearly defined sub-criteria per criteria (social, economic, environmental, and technical), while also addressing the individual limitations of the FAHP. This would involve the integration of other MCDM methods (TOPSIS, VIKOR, and PROMETHEE-II). Such methods would serve to promote greater reliability, stability, and accuracy in the results while avoiding/minimising uncertainties. Moreover, for truly holistically green and sustainable perspectives, the social dimension of water desalination could be explored, with consideration of an in-depth, systematic integration between established stakeholders and the general populace.