3.1. Mechanical Characterization of Sandstone under the Influence of Submersion Depth

Sandstones often contain a class of minerals that are particularly susceptible to weakening due to water. When subjected to water infiltration, these minerals can alter the internal structure of the rock, impairing the bonding between particles and loosening the overall structure, which ultimately diminishes its mechanical performance. The softening of the rock becomes increasingly pronounced as the depth of water infiltration increases. To investigate the changes in compressive strength and deformation properties during this process—especially in rocks containing circular holes—a series of uniaxial compression experiments were designed and conducted, encompassing various water immersion depths. The primary objective of these experiments is to analyze how the uniaxial compressive strength values, modulus of elasticity, and other key physico-mechanical indices of sandstones with circular holes are affected by variations in water immersion depth. Based on the experimental data, we plotted the complete stress–strain relationship of the saturated rock samples under different immersion durations, as illustrated in

Figure 3, thereby visualizing the dynamic relationship between these parameters [

27,

28,

29,

30].

Figure 3 clearly illustrates that the depth of water immersion significantly influences the mechanical response of sandstones containing circular holes under uniaxial compression. As the duration of submergence increases, the trajectories of the complete stress–strain curves for these rock samples transition markedly from typical elastic deformation to nonlinear deformation characteristics. Specifically, under shallow submergence conditions, the sandstone with circular holes exhibits high uniaxial compressive strength and distinct brittle fracture characteristics during failure. This observation reveals that the internal structure of the rock still maintains a high degree of integrity and thus has the ability to withstand externally applied pressure. When the depth of submergence is increased to a moderate level, the curves display a notable downward section after reaching peak compressive strength, suggesting that the samples retain a certain degree of load-bearing capacity post-peak stress, although they are unable to resist further pressure. As the water immersion depth increases to a more significant level, a pronounced decline occurs after the peak compressive strength is achieved. This indicates that the rock samples have surpassed peak stress; while they still possess some load-bearing capacity, they exhibit more pronounced plastic deformation, with an increase in deformation compared to the case of bottom plate submergence, demonstrating stronger ductile damage characteristics. When the water immersion depth is further increased to the top plate, the slope of the ascending portion of the stress–strain curve decreases further, implying that the samples begin to accumulate greater deformation in the early stages of loading. After reaching peak strength, the curve does not drop sharply but instead undergoes a relatively gentle transition before gradually declining. This behavior indicates that the rock samples retain a considerable degree of residual strength after failure, with significantly enhanced deformation capacity and more pronounced toughness characteristics. This process clearly demonstrates that increased immersion depth facilitates the transformation of sandstone mechanical behavior from brittle to ductile.

The blue, green, and red areas in

Figure 3 represent the compaction stage, elasticity stage, and yielding stage, respectively. The blue line segment indicates the onset of the elasticity stage for the rock samples at three different immersion depths, while the red line segment marks the conclusion of the yielding stage. Observations reveal that as the immersion depth of the rock samples increases, both the onset of the elasticity stage and the conclusion of the yielding stage shift progressively backward. However, the duration of the elasticity stage remains nearly constant across all three samples. This suggests that while increased immersion depth extends the compaction and yielding phases of the rock samples containing round holes, it has minimal impact on the duration of the elasticity phase.

Figure 4 illustrates the uniaxial compressive strength, maximum peak strain, and modulus of elasticity curves for sandstone rock samples containing circular holes at various immersion depths. The analysis reveals that the uniaxial compressive strength of sandstone is 76.29 MPa, with a peak strain of 1.52% under bottom plate immersion. Under middle plate immersion, the uniaxial compressive strength decreases to 71.04 MPa, representing a 6.88% reduction compared to the bottom plate immersion, while the peak strain increases to 1.60%, which is 8% higher than that of the sample under bottom plate immersion. Furthermore, the uniaxial compressive strength of sandstone under top plate immersion is 62.93 MPa, indicating an 11.42% decrease compared to the middle plate immersion, with a peak strain of 1.78%, which is 11.25% higher than that of the samples under middle plate immersion. As the immersion depth increases, both the uniaxial compressive strength and the elastic modulus of the sandstone with circular holes significantly decrease, while the peak strain gradually increases. Notably, the greater the immersion depth of the rock samples, the more rapidly the uniaxial compressive strength declines, and the peak strain correspondingly increases. This trend suggests that as the water immersion depth increases, the structure of the sandstone becomes progressively looser due to higher water saturation, leading to an increase in pore space and fissures. Consequently, the rock experiences greater deformation during compression before reaching the failure point. The increase in peak strain indicates that the rock can endure greater deformation prior to damage, despite a reduction in its load-bearing capacity (compressive strength). The water-saturated portion of the rock contributes to structural damage; as applied pressure increases, the formation of additional cracks and pores allows water to infiltrate, creating a ‘lubrication’ effect that reduces internal friction. This reduction in internal friction diminishes the cohesive properties of the rock, resulting in a decrease in the overall modulus of elasticity as immersion depth increases. This phenomenon is the primary cause of the observed decrease in the modulus of elasticity.

3.2. Characteristics of Sandstone Deformation under the Influence of Submergence Depth

Under submerged water conditions, the deformation characteristics of sandstone rock samples containing round holes will vary significantly when subjected to the same force. This difference is attributed to the varying water depths in the roadway caused by different water levels. Underwater immersion, the initial fine cracks in the rock samples will change. As the immersion time increases, the microstructure of the rock samples will become looser, leading to damage in the bonding of the rock sample particles. Consequently, the mechanical properties will weaken, and the rock samples will gradually soften. By analyzing the change in rule between the radial and axial directions of the circular roadway in the bottom plate, top plate, and overall immersion at different water depths, a time–strain curve is plotted, as depicted in

Figure 5 [

31].

Circular channel morphology sandstone is under pressure in the depth of water to the bottom plate. According to

Figure 5a, the maximum axial strain is 6%

−3, and the minimum is about 5%

−3. The far-field strain detection point, far from the center of the channel, detected a larger strain than the near-field detection point. The submerged part of the strain, both in the far-field and near-field, is greater than the non-immersed part of the strain. According to

Figure 5b, it can be seen that among the radial strains under the subgrade immersion, the radial strain in the non-immersed part of the far-field is the largest at about 4.5%

−3, while the radial strain in the immersed part of the near-field is the smallest at about 1.5%

−3. Additionally, during the compression process, the strain of the non-immersed part increases more rapidly, resulting in a larger strain.

The sandstone exhibiting circular pore morphology is subjected to pressure at water depths up to the midpoint, as illustrated in

Figure 5c. In this figure, the near-field non-immersed region experiences the highest strain, with a maximum axial strain of approximately 8%

−3 to 3%

−3. Conversely, the near-field immersed region shows the lowest strain, with an axial strain of about 1.5%

−3 to 3%

−3. The two far-field strain detection points, located farther from the circular channel, exhibit more similar strain values, both around 4%

−3 to 3%

−3. According to

Figure 5d, the near-field immersed region has the largest radial strain, measuring approximately 3.5%

−3 to 3%

−3. The far-field non-immersed region displays the smallest axial strain, with a radial strain of about 1.2%

−3 to 3%

−3. Additionally, the far-field immersed region shows a radial strain similar to that of the far-field non-immersed region, indicating that the radial strains of both areas are quite comparable.

As shown in

Figure 5e, the circular channelized morphology of the sandstone experienced complete submergence pressurization. The radial strain in the upper part of the near field is the largest, measuring approximately 7.5%

−3, whereas the axial strain in the lower part of the far field is the smallest, at around 1%

−3. According to

Figure 5f, the radial strain in the upper part of the near field is the largest, with an axial strain of about 4%

−3, while the radial strain in the upper part of the far field is the smallest, with an axial strain of about 1%

−3.

Through the comprehensive analysis of the time–strain curves at various immersion depths, it is observed that the strain of the sandstone specimens with rounded channel morphology deviates locally during bottom immersion and full immersion. This deviation may be attributed to the pressurization of the specimen under water, causing slight displacement of the monitoring point initially. The strain curves of the rock samples under three different water depth immersions are consistent with the fissure evolution pattern of the rock samples. The uniaxial compressive tests conducted on the rock samples under water immersion conditions revealed that the axial strain was consistently greater than the radial strain, regardless of the level of water immersion. The deformation curves of the rock samples were smoother during the compression-tightening stage. Upon entering the elastic stage, the friction between the cracks of the rock samples decreased as a result of the significant immersion in water. The strains were influenced by the water, causing irregular fluctuations in the axial and radial strain curves. Water alters the pore structure and permeability of the rock, resulting in modifications to the rock’s deformation properties [

32]. Increasing the depth of immersion will make the deformation of the rock samples more significant.

3.3. Characteristics of Sandstone Damage under Different Immersion Depths

In order to analyze the influence mechanism of crack propagation in sandstone containing circular holes under submerged water conditions during the rock damage process, the crack extension paths and mechanisms of rock samples were examined by extracting images of crack propagation at various submerged water depths.

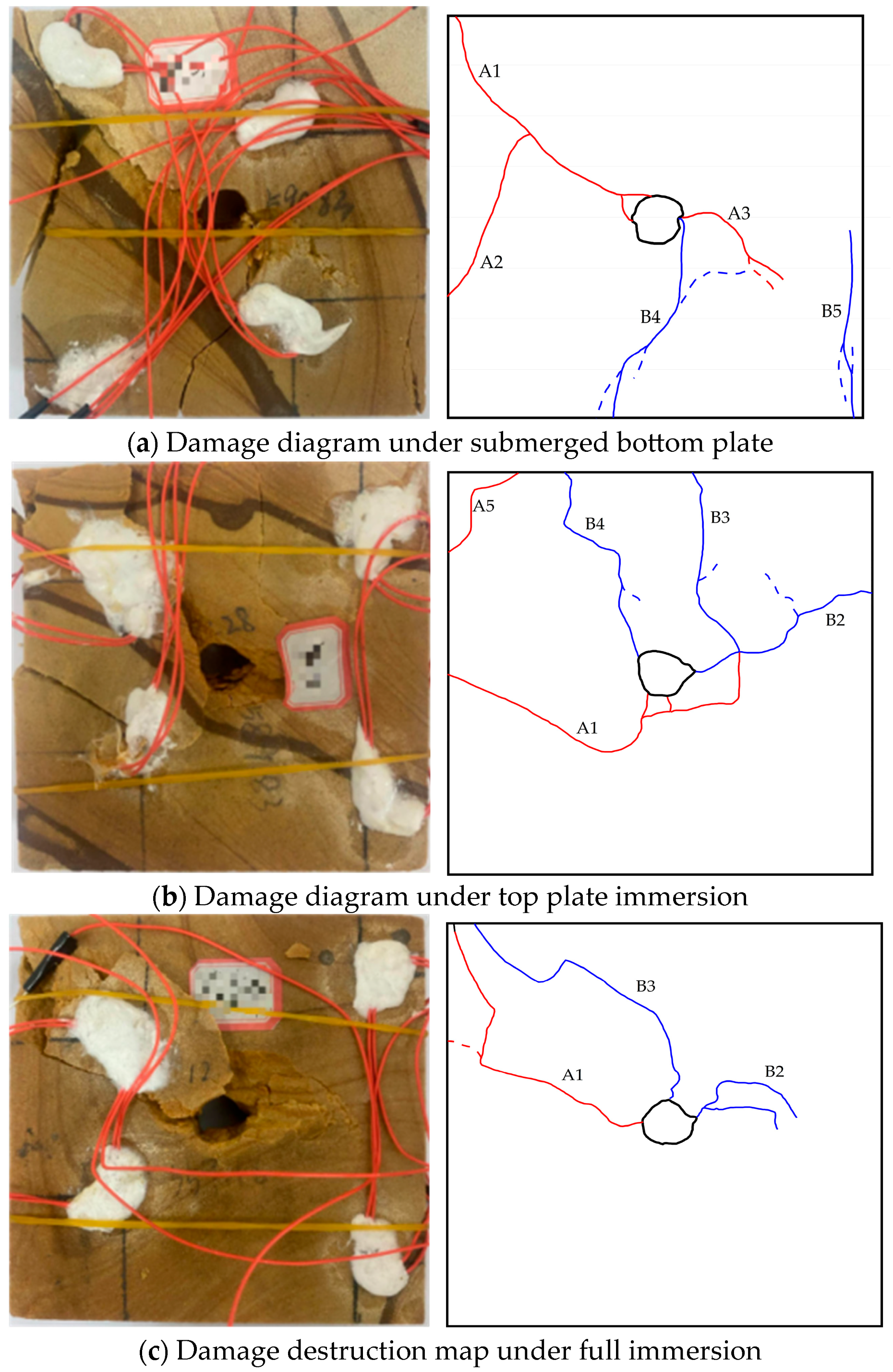

To better analyze the effects of submerged water conditions on the damage to sandstone with circular holes, the diagrams are sequentially marked to indicate the order of crack generation and the type of crack (tensile or shear) for quantitative analysis and assessment. The letters in

Figure 6 denote the types of cracks: A represents a shear crack, which typically extends from the edges of the holes in the rock samples and propagates toward the edges of the samples, with the direction of propagation being diagonal, either upward or downward. B denotes a tensile crack, which occurs when the rock samples experience tensile stresses in both upward and downward directions, usually extending along the axial direction. This tensile crack may deviate to some extent when subjected to various external conditions [

33,

34,

35,

36]. The angular numbers indicate the chronological order of crack generation. The red line segments represent shear cracks, the blue line segments represent tensile cracks, and the dashed lines indicate secondary cracks formed during crack propagation.

Under submerged water conditions at the base plate, the damage diagram of the rock sample is illustrated in

Figure 6a. During the process of applying axial gradual pressure, a shear crack A1 emerged from the left side of the hole, extending toward the upper left. As the crack propagated, a second shear crack A2 developed, extending toward the lower left, followed by another shear crack A3 that formed on the right side of the hole, extending toward the lower right. With the instability of the upper part of the sample, new cracks formed in the area below the hole, including two tension cracks B4 and B5 that extended from the top to the bottom, along with several secondary cracks. The damage schematic diagram of the rock sample, which features a circular hole morphology in sandstone under central submerged water conditions, is presented in

Figure 6b. Initially, a shear crack A1 formed in the region below the hole. As the loading pressure gradually increased, a tensile crack B2 appeared, extending to the upper right from the right side of the hole. Subsequently, a second tensile crack B3 developed, extending upward during the propagation process. Additionally, new cracks B4 and B5 extended to the upper left from the right side of the hole, accompanied by several secondary cracks originating from the upper side of the hole. A tensile crack B4 also extended to the upper left, and the final shear crack A5 was generated in the last stage of the sample rupture. The damage schematic of the rock sample, featuring a circular hole morphology in sandstone under top plate flooding conditions, is depicted in

Figure 6c. A total of three main cracks were generated, all extending from the holes to various regions of the rock sample. The first crack, a shear crack A1, extended from the left to the upper left. This was followed by two tensile cracks: B2, extending to the upper right, and B3, extending to the upper left in the upper part of the hole. All three cracks were relatively concentrated in the upper part of the rock sample, which remained unsaturated.

The analysis was conducted at three different submergence depths, with pressure applied at the water depth submerged to the bottom plate. Water infiltrated the rock body, resulting in water-induced splitting and fracturing below. The rock samples surrounding the holes experienced local softening, which adversely affected their overall compressive strength. When pressurized at the water depth submerged to the middle, water penetrated the rock body to a greater extent. The portion of the rock that remained above the water was significantly more brittle than the submerged section, resulting in the formation of smaller cracks. However, the primary cracks leading to overall structural imbalance were still located in the submerged area, indicating that the water-saturated portion is more susceptible to damage than the dry part. In the case of complete submergence, the rock was entirely saturated with water. This water absorption led to an increase in the volume of the rock samples, which in turn raised the internal stress and made the formation of tensile cracks within the rock samples more likely. It is evident that as the submergence depth increases, the rock samples become increasingly prone to tensile cracks, while the number of secondary cracks that develop during the crack propagation process gradually decreases.

To thoroughly investigate the extension characteristics of cracks at various developmental stages, we utilized the RA (rise time/amplitude) and AF (average frequency) values from the acoustic emission technique as analytical tools to systematically quantify and analyze the damage patterns of cracks. We selected several sandstone samples exhibiting circular pore characteristics for the immersion test and processed the acoustic emission data points collected during the experiment. Subsequently, we plotted these data points on RA-AF diagrams for visual representation [

37,

38]. Based on the distribution characteristics of the acoustic emission signals under two distinct rupture mechanisms—tension and shear—we clearly delineated a dividing line on the RA-AF diagrams to differentiate between these two damage modes. Furthermore, we calculated the slope of this demarcation line to be 5.48, a result clearly illustrated in

Figure 7. Through this analysis, we gained a more precise understanding of the crack extension mechanism and its characteristics at different stages.

From the analysis of the percentages of crack types, it is evident that under bottom plate immersion, the percentage of tensile damage points is 31.4%, which is significantly lower than the percentage of shear damage points. Under middle plate immersion, the percentage of tensile damage points rises to 47.1%, approaching the percentage of shear damage points. In contrast, under top plate immersion, the percentage of tensile damage points increases to 51.6%, surpassing the percentage of shear damage points. By comparing the damage patterns of rock samples at different immersion depths, as illustrated in

Figure 7, shear and tensile cracks can be clearly distinguished. Observations of each type of damage point indicate that as immersion depth increases, the tensile damage in sandstone rock samples containing round holes progressively intensifies.

Some scholars have reached a consensus that the proportion of tensile cracks in rocks tends to increase as the height of water ingress rises. However, through careful observation and analysis presented in this paper, we have identified a more complex phenomenon: while the number of tensile cracks does increase with greater immersion depth, the growth rate does not continuously accelerate. Instead, it exhibits a trend of gradual decline as immersion depth increases. This finding indicates that the relationship between immersion depth and the expansion rate of tensile cracks is not a simple linear correlation. Rather, it suggests the involvement of more intricate physical and chemical mechanisms, which may include the gradual adaptation of the rock’s internal structure, the osmotic pressure effects of water, and the mechanical properties of the rock material itself. Therefore, future studies should further investigate these mechanisms to achieve a more comprehensive understanding of how immersion depth influences the behavior of tensile crack propagation in rocks.

3.4. Acoustic Emission Characteristics of Sandstone under Different Immersion Depths

During the fracture process, rock accumulates internal strain energy, which is manifested through complex transformations and intermittent releases. The acoustic emission monitoring system can detect the acoustic emission signals generated during the rock damage process. This signal information accurately reflects the expansion of cracks and the extent of damage within the rock. The acoustic emission characteristics of sandstone containing circular holes also exhibit variations at different immersion depths. Acoustic emission ringing counts and cumulative energy are selected as parameters to analyze the intrinsic relationship between the acoustic emission characteristics of sandstone with circular holes and rock damage under varying immersion depths [

39,

40,

41,

42]. To ensure that the overall characteristics are accurately represented, the most representative test results under different immersion depth conditions are selected for analysis. Based on the test data, time–stress–acoustic emission ringing counts–cumulative energy curves are plotted, as shown in

Figure 8. To better illustrate the relationship between immersion depth and acoustic emission phenomena, the curves are divided into four phases: the compression-tightening phase, the elasticity phase, the yielding phase, and the post-peak stage, allowing for a detailed analysis of their main features.

It can be observed from

Figure 8 that all water-immersed rock samples exhibit acoustic emission phenomena to varying degrees throughout all stages of the pressurized damage process. The maximum acoustic emission ringing counts for all samples occur near the peak stress; however, notable differences are evident among the samples at varying depths of immersion across the different stages.

In the OA stage (the compaction stage), purple part, a small amount of acoustic emission phenomena occurs in both bottom-immersed and middle-immersed circular pore-bearing sandstones, while acoustic emission signals from top-immersed circular pore-bearing sandstones are almost nonexistent. The acoustic emission ringing frequency of sandstones under bottom-flooded conditions is approximately one to three times greater than that of sandstones flooded in the center and six to nine times greater than that of sandstones flooded at the top. As the duration of submergence increases, the acoustic emission phenomena of sandstones under the three different submergence depth conditions decrease to varying degrees. This reduction can be primarily attributed to the relatively low stress levels in the rock samples during the compression and densification stage. When pressure is applied, the original small cracks within the rock samples begin to close. During this closure process, damage occurs between the rock cracks, and some friction between rough particles generates a small amount of acoustic emission. Additionally, the presence of water leads to the immersion of cracks, resulting in the softening of the rock. Water also reduces sound propagation, which contributes to the lower acoustic emission ringing counts. As immersion time increases, the softening effect of water on the rock intensifies, further decreasing the acoustic emission phenomena.

The AB stage, green part, also known as the elasticity stage, is characterized by minimal acoustic emission phenomena in the rock samples situated between the middle and top plates during water immersion. This stability arises because, at this stage, the rock primarily undergoes elastic deformation, with minimal plastic deformation occurring. As a result, the generation of acoustic emission signals is limited. While the rock samples at the bottom plate also tend to stabilize during water immersion, slight fluctuations may occur in the middle section. These fluctuations could be attributed to minor detachment of the surface rock layer in the circular hole sandstone, which may generate some acoustic signals.

In the BC stage (yielding stage), yellowish part, damage accumulation contains precursor information indicative of instability. It is observed that during the yielding stage, the acoustic emission counts of the rock samples decreased significantly with increasing immersion depth. Slight fluctuations in the acoustic emission ringing counts of the middle submerged rock samples suggest that crack initiation and expansion during this phase contributed to the accumulation of acoustic emission ringing counts. Additionally, the acoustic emission signals decreased with prolonged submergence time, indicating that the softening effect of water on the rock samples suppressed the generation of these signals. At both the bottom and top slab immersion depths, the acoustic emission signals of the rock samples did not fluctuate significantly. This is likely because this stage represents the initial phase of energy accumulation, where the stress and energy within the rock are insufficient to reach the critical threshold for rupture or significant deformation, resulting in minimal acoustic emission activity. Furthermore, under submerged conditions, water infiltrates the pores and fissures of the sandstone, providing a buffering effect that slows the concentration of stress. Consequently, this reduces stress concentration and crack propagation during the compaction stage, leading to a decrease in the generation of acoustic emission signals.

The post-peak stage, which follows point C, lilac part, exhibits more pronounced acoustic emission signals in sandstones with circular pore morphology at varying submergence depths. Following the destabilization and damage of the rock, a significant amount of energy accumulated during the previous stage is released instantaneously. This release, along with localized damage and particle spalling within the rock, generates additional acoustic emission signals. Under submerged conditions, water acts as a lubricant for crack propagation, facilitating the extension of cracks and resulting in more frequent localized damage. Stress redistribution occurs within the rock, as stresses that were initially concentrated in specific areas are released and transferred to other regions, leading to the initiation of new crack extensions and further damage. This dynamic alteration in stress levels produces a substantial increase in acoustic emission signals, which are significantly higher than those observed during the pressure-tight, elastic, and yield stages.

The cumulative acoustic emission energy of sandstone containing circular roadway holes at various immersion depths is illustrated in

Figure 8. It is evident that the total cumulative acoustic emission energy of the rock samples decreases as the immersion depth increases. Notably, the total energy of the rock samples subjected to deep immersion in the bottom plate water is the highest, measuring 742,547, while the total energy of the rock samples under full immersion is the lowest, at 113,172.

Taking the above analyses into account, we can conclude that the change in the acoustic emission ringing counts demonstrates a high degree of consistency with the damage evolution law within the rock samples. Under submerged conditions, the inherent damage of the rock samples significantly influences the fluctuations in the acoustic emission signal as pressurization time progresses. Additionally, the softening and suppressive effects of water also play a crucial role in these fluctuations. Although the depth of immersion has a complex impact on the acoustic emission signals of sandstone specimens with circular pore morphology, a general trend emerges: the cumulative energy of acoustic emission decreases as the depth of immersion increases.

The study conducted by Zihui Zhu [

43] and other researchers found that in a dry state, the acoustic emission energy curve typically progresses through three phases: smooth, slow rise, and sudden rise. However, as water content increases, the distribution characteristics of these three stages change significantly. Notably, in a water-saturated state, the acoustic emission energy curve is nearly simplified to just two phases: a smooth increase and a sudden increase. By examining the acoustic emission curves under submerged conditions, we also observe that variations in immersion depth influence the pattern of acoustic emission activity. Specifically, during the ‘smooth’ phase, the number of acoustic emission events decreases as immersion depth increases, resulting in smoother behavior during this phase. These findings provide a crucial experimental foundation for a deeper understanding of the mechanical behavior and damage evolution of rocks under submerged conditions, revealing the mechanisms by which submergence depth and water content affect the acoustic emission activity of rocks.