Utilising Artificial Intelligence to Predict Membrane Behaviour in Water Purification and Desalination

Abstract

1. Introduction

2. Membranes in Water Purification and Desalination

3. Predicting the Membrane Behaviour by AI Models

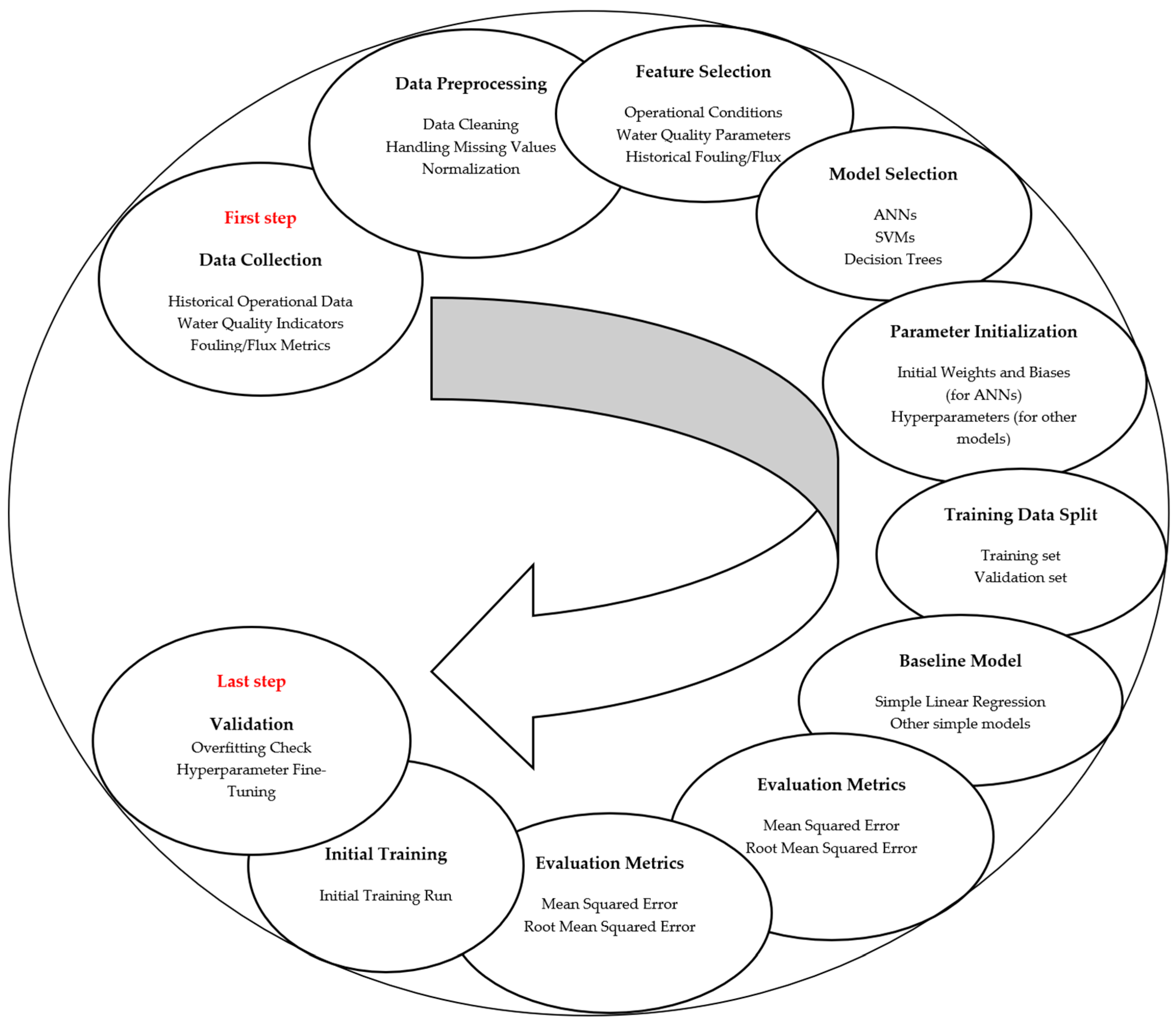

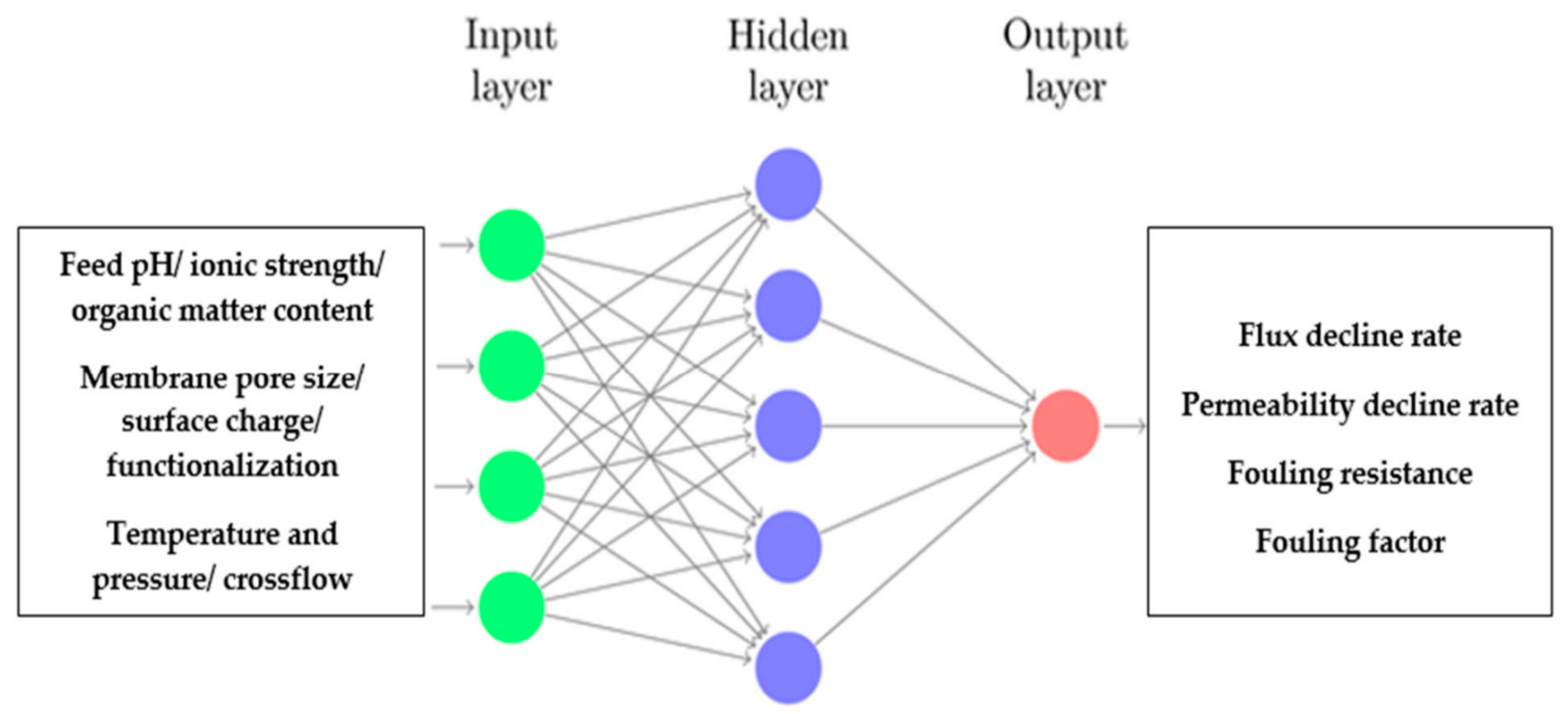

3.1. Fouling Prediction in Membranes by AI-Based Models

3.2. AI-Based Flux Modelling in Membranes

3.3. AI in Micropollutant Prediction in Water Purification and Desalination by Membranes

4. The Limitations and Challenges of AI in Predicting Membrane Behaviour and Future Directions

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ANNs | Artificial neural networks |

| FNNs | Feedforward neural networks |

| SGD | Stochastic gradient descent |

| ML | Machine learning |

| AI | Artificial intelligence |

| RO | Reverse osmosis |

| FO | Forward osmosis |

| DL | Deep learning |

| SWAT | Soil water assessment tool |

| LSTM | Long short-term memory |

| ANFIS | Adaptive neuro-fuzzy interference system |

| MOPSO | Multi-objective particle swarm optimisation |

| SVR | Support vector regression |

| RSM | Response surface methodology |

| OCT | Optical coherence tomography |

| RNN | Recurrent neural network |

| MLP | Multilayer perceptron |

| SHAP | Shapley additive explanations |

| GPR | Gaussian process regression |

References

- Abas, P.E.; Mahlia, T. Techno-Economic and Sensitivity Analysis of Rainwater Harvesting System as Alternative Water Source. Sustainability 2019, 11, 2365. [Google Scholar] [CrossRef]

- Filali, H.; Barsan, N.; Souguir, D.; Nedeff, V.; Tomozei, C.; Hachicha, M. Greywater as an Alternative Solution for a Sustainable Management of Water Resources—A Review. Sustainability 2022, 14, 665. [Google Scholar] [CrossRef]

- Fane, S.A.; Liu, A.; Falletta, J. Assessing Minimum Water Efficiency Standards for Plumbing Products in Homes and Business. Water Supply 2024, 24, 1164–1175. [Google Scholar] [CrossRef]

- Nazemi Rafi, Z.; Kazemi, F.; Tehranifar, A. Public Preferences toward Water-Wise Landscape Design in a Summer Season. Urban For. Urban Green. 2020, 48, 126563. [Google Scholar] [CrossRef]

- Eshoul, N.; Almutairi, A.; Lamidi, R.; Alhajeri, H.; Alenezi, A. Energetic, Exergetic, and Economic Analysis of MED-TVC Water Desalination Plant with and without Preheating. Water 2018, 10, 305. [Google Scholar] [CrossRef]

- Shahid, M.K.; Mainali, B.; Rout, P.R.; Lim, J.W.; Aslam, M.; Al-Rawajfeh, A.E.; Choi, Y. A Review of Membrane-Based Desalination Systems Powered by Renewable Energy Sources. Water 2023, 15, 534. [Google Scholar] [CrossRef]

- Dudziak, M. Retention of Mycoestrogens in Nanofiltration. Impact of Feed Water Chemistry, Membrane Properties and Operating Process Conditions. Environ. Prot. Eng. 2012, 38, 5–17. [Google Scholar] [CrossRef]

- Wan, L.; Xiong, L.; Zhang, L.; Lu, W. High Loaded Bioflocculation Membrane Reactor of Novel Structure for Organic Matter Recovery from Sewage: Effect of Temperature on Bioflocculation and Membrane Fouling. Water 2020, 12, 2497. [Google Scholar] [CrossRef]

- Miao, S.; Ma, J.; Zhou, X.; Zhang, Y.; Chu, H. A Review of CFD Simulation in Pressure Driven Membrane with Fouling Model and Anti-Fouling Strategy. Front. Environ. Sci. Eng. 2024, 18, 93. [Google Scholar] [CrossRef]

- Ina, T.; Idomura, Y.; Imamura, T.; Yamashita, S.; Onodera, N. Iterative Methods with Mixed-Precision Preconditioning for Ill-Conditioned Linear Systems in Multiphase CFD Simulations. In Proceedings of the 2021 12th Workshop on Latest Advances in Scalable Algorithms for Large-Scale Systems (ScalA), St. Louis, MN, USA, 19 November 2021; pp. 1–8. [Google Scholar]

- Chakachaka, V.M.; Tshangana, C.S.; Mamba, B.B.; Muleja, A.A. CFD-Assisted Process Optimization of an Integrated Photocatalytic Membrane System for Water Treatment. Membranes 2023, 13, 827. [Google Scholar] [CrossRef]

- Goi, Y.K.; Liang, Y.Y.; Lau, W.J.; Fimbres Weihs, G.A. Analysis of the Effect of Advanced FO Spacer on the Specific Energy Consumption of Hybrid RO Desalination System. J. Memb. Sci. 2023, 668, 121247. [Google Scholar] [CrossRef]

- Yagnambhatt, S.; Khanmohammadi, S.; Maisonneuve, J. Demonstration of a Real-Time Maximum Power Point Tracker for Salt Gradient Osmotic Power Systems. Appl. Energy 2024, 376, 124205. [Google Scholar] [CrossRef]

- Suleman, M.; Asif, M.; Jamal, S.A. Temperature and Concentration Polarization in Membrane Distillation: A Technical Review. Desalination Water Treat. 2021, 229, 52–68. [Google Scholar] [CrossRef]

- Habieeb, A.R.; Kabeel, A.E.; Sultan, G.I.; Abdelsalam, M.M. Advancements in Water Desalination Through Artificial Intelligence: A Comprehensive Review of AI-Based Methods for Reverse Osmosis Membrane Processes. Water Conserv. Sci. Eng. 2023, 8, 53. [Google Scholar] [CrossRef]

- Jittawiriyanukoon, C.; Srisarkun, V. Simulation for Predictive Maintenance Using Weighted Training Algorithms in Machine Learning. Int. J. Electr. Comput. Eng. (IJECE) 2022, 12, 2839. [Google Scholar] [CrossRef]

- Assegie, T.A.; Rangarajan, P.K.; Kumar, N.K.; Vigneswari, D. An Empirical Study on Machine Learning Algorithms for Heart Disease Prediction. IAES Int. J. Artif. Intell. (IJ-AI) 2022, 11, 1066. [Google Scholar] [CrossRef]

- Negri, V.; Mingotti, A.; Tinarelli, R.; Peretto, L. Uncertainty and Lack of Information Affecting the Training of Machine Learning Algorithms for Fault Prediction of Cable-Joints. In Proceedings of the 2023 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Kuala Lumpur, Malaysia, 22–25 May 2023; pp. 1–5. [Google Scholar]

- Lasisi, K.H.; Abass, O.K.; Zhang, K.; Ajibade, T.F.; Ajibade, F.O.; Ojediran, J.O.; Okonofua, E.S.; Adewumi, J.R.; Ibikunle, P.D. Recent Advances on Graphyne and Its Family Members as Membrane Materials for Water Purification and Desalination. Front. Chem. 2023, 11, 1125625. [Google Scholar] [CrossRef]

- AlSawaftah, N.; Abuwatfa, W.; Darwish, N.; Husseini, G. A Comprehensive Review on Membrane Fouling: Mathematical Modelling, Prediction, Diagnosis, and Mitigation. Water 2021, 13, 1327. [Google Scholar] [CrossRef]

- Jawad, J.; Hawari, A.; Zaidi, S. Modeling and Sensitivity Analysis of the Forward Osmosis Process to Predict Membrane Flux Using a Novel Combination of Neural Network and Response Surface Methodology Techniques. Membranes 2021, 11, 70. [Google Scholar] [CrossRef]

- Almerri, A.H.; Al-Obaidi, M.A.; Alsadaie, S.; Mujtaba, I.M. Modelling and Simulation of Industrial Multistage Flash Desalination Process with Exergetic and Thermodynamic Analysis. A Case Study of Azzour Seawater Desalination Plant. Chem. Product. Process Model. 2023, 18, 73–95. [Google Scholar] [CrossRef]

- Jawad, J.; Hawari, A.H.; Zaidi, S. Modeling of Forward Osmosis Process Using Artificial Neural Networks (ANN) to Predict the Permeate Flux. Desalination 2020, 484, 114427. [Google Scholar] [CrossRef]

- Attarde, D.; Jain, M.; Gupta, S.K. Modeling of a Forward Osmosis and a Pressure-Retarded Osmosis Spiral Wound Module Using the Spiegler-Kedem Model and Experimental Validation. Sep. Purif. Technol. 2016, 164, 182–197. [Google Scholar] [CrossRef]

- Alam, M.d.M.; Tirth, V.; Irshad, K.; Algahtani, A.; Al-Mughanam, T.; Rashid, T.; Azim, R. An Adaptive Power Management Approach for Hybrid PV-Wind Desalination Plant Using Recurrent Neural Networks. Desalination 2024, 569, 117038. [Google Scholar] [CrossRef]

- Shah, Z.; Raja, M.A.Z.; Khan, W.A.; Shoaib, M.; Tirth, V.; Algahtani, A.; Irshad, K.; Al-Mughanam, T. Computational Intelligence Paradigm with Levenberg-Marquardt Networks for Dynamics of Reynolds Nanofluid Model for Casson Fluid Flow. Tribol. Int. 2024, 191, 109180. [Google Scholar] [CrossRef]

- Fetanat, M.; Keshtiara, M.; Low, Z.-X.; Keyikoglu, R.; Khataee, A.; Orooji, Y.; Chen, V.; Leslie, G.; Razmjou, A. Machine Learning for Advanced Design of Nanocomposite Ultrafiltration Membranes. Ind. Eng. Chem. Res. 2021, 60, 5236–5250. [Google Scholar] [CrossRef]

- Rezakazemi, M. CFD Simulation of Seawater Purification Using Direct Contact Membrane Desalination (DCMD) System. Desalination 2018, 443, 323–332. [Google Scholar] [CrossRef]

- Alrefaai, M.M.; Othman, M.H.D.; Rava, M.; Tai, Z.S.; Asnaghi, A.; Puteh, M.H.; Jaafar, J.; Rahman, M.A.; Al-Ogaili, M.F.A. A CFD Analysis of the Desalination Performance of Ceramic-Based Hollow Fiber Membranes in Direct Contact Membrane Distillation. Ceramics 2024, 7, 115–136. [Google Scholar] [CrossRef]

- Abrofarakh, M.; Moghadam, H.; Abdulrahim, H.K. Investigation of Direct Contact Membrane Distillation (DCMD) Performance Using CFD and Machine Learning Approaches. Chemosphere 2024, 357, 141969. [Google Scholar] [CrossRef]

- Bin Abid, M.; Wahab, R.A.; Salam, M.A.; Moujdin, I.A.; Gzara, L. Desalination Technologies, Membrane Distillation, and Electrospinning, an Overview. Heliyon 2023, 9, e12810. [Google Scholar] [CrossRef]

- Toh, K.; Liang, Y.; Lau, W.; Fimbres Weihs, G. A Review of CFD Modelling and Performance Metrics for Osmotic Membrane Processes. Membranes 2020, 10, 285. [Google Scholar] [CrossRef]

- Jahed Mogharrab, A.; Sharifian, S.; Asasian-Kolur, N.; Ghadimi, A.; Haddadi, B.; Harasek, M. Air-to-Air Heat and Moisture Recovery in a Plate-Frame Exchanger Using Composite and Asymmetric Membranes. Membranes 2022, 12, 484. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Guo, F. Finned Tubular Air Gap Membrane Distillation. Membranes 2023, 13, 498. [Google Scholar] [CrossRef] [PubMed]

- Murugesan, V.P.; Ghosh, S.; Tulshyan, A.; Ahmed, A.A.; Sivasamy, B.; Kapoor, A.; Karuppasamy, S. Modeling and Multi-Objective Optimization of Parameters in Fabrication and Performance Analysis of Polyvinylidene Fluoride Spiral-Wound Membrane Modules. Polym. Bull. 2023, 80, 6221–6246. [Google Scholar] [CrossRef]

- Mamtani, V.S.; Ghosh, A.K.; Adak, A.K. A Brief Review on Systematic Approach to Polymer Selection for Development of Capillary/Hollow-Fibre Membrane for Practical Applications. Mater. Technol. Rep. 2023, 1, 103. [Google Scholar] [CrossRef]

- Hossain, M.M.; Rothman, K.; Jiang, W.; Sun, C. Membrane Extraction of a New Antibiotic (Shengjimycin): Equilibrium and Mass Transfer Analysis. J. Chem. Technol. Biotechnol. 2011, 86, 1247–1255. [Google Scholar] [CrossRef]

- Shoshaa, R.; Ashfaq, M.Y.; Al-Ghouti, M.A. Recent Developments in Ultrafiltration Membrane Technology for the Removal of Potentially Toxic Elements, and Enhanced Antifouling Performance: A Review. Environ. Technol. Innov. 2023, 31, 103162. [Google Scholar] [CrossRef]

- Muthukumaran, S.; Jegatheesan, J.V.; Baskaran, K. Comparison of Fouling Mechanisms in Low-Pressure Membrane (MF/UF) Filtration of Secondary Effluent. Desalination Water Treat. 2014, 52, 650–662. [Google Scholar] [CrossRef]

- Zait, M.; Benalla, S.; Bachiri, B.; Tahaikt, M.; Dhiba, D.; Elmidaoui, A.; Taky, M. Performance of Three Ultrafiltration Ceramic Membranes in Reducing Polluting Load of Landfill Leachate. Desalination Water Treat. 2021, 240, 33–42. [Google Scholar] [CrossRef]

- Hamad, J.Z.; Ha, C.; Kennedy, M.D.; Amy, G.L. Application of Ceramic Membranes for Seawater Reverse Osmosis (SWRO) Pre-Treatment. Desalination Water Treat. 2013, 51, 4881–4891. [Google Scholar] [CrossRef]

- Tian, J.; Zhao, X.; Gao, S.; Wang, X.; Zhang, R. Progress in Research and Application of Nanofiltration (NF) Technology for Brackish Water Treatment. Membranes 2021, 11, 662. [Google Scholar] [CrossRef]

- Saxena, K.; Brighu, U.; Jain, S.; Meena, A. Hybrid Configurations for Brackish Water Desalination: A Review of Operational Parameters and Their Impact on Performance. Environ. Technol. Rev. 2023, 12, 1–17. [Google Scholar] [CrossRef]

- Asadi, A.; Gholami, F.; Zinatizadeh, A.A.; Jaberi, H. Application of High Hydrophilic Antifouling Nanofiltration Membranes Embedded with Mesoporous Carbon Based Nanoparticles for Efficient Dye Removal and Salt Rejection. 2021, preprint. [CrossRef]

- Li, X.Y.; Zhang, L.W.; Wang, C.W. Review of Disposal of Concentrate Streams from Nanofiltration (NF) or Reverse Osmosis (RO) Membrane Process. Adv. Mat. Res. 2012, 518–523, 3470–3475. [Google Scholar] [CrossRef]

- Ali, K.; Zeidan, Hani; Ben Amar, R. Evaluation of the Use of Agricultural Waste Materials as Low-Cost and Eco-Friendly Sorbents to Remove Dyes from Water: A Review. Desalination Water Treat. 2023, 302, 231–252. [Google Scholar] [CrossRef]

- Zare, J.; Abbasi, M.; Hashemifard, S.A.; Dizge, N.; Dibaj, M.; Akrami, M. Eco-Friendly Superhydrophobic Modification of Low-Cost Multi-Layer Composite Mullite Base Tubular Ceramic Membrane for Water Desalination. Water 2024, 16, 1593. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J.; Hoek, E.M.V.; Municchi, F.; Tilton, N.; Cath, T.Y.; Turchi, C.S.; Heeley, M.B.; Jassby, D. Multistage Surface-Heated Vacuum Membrane Distillation Process Enables High Water Recovery and Excellent Heat Utilization: A Modeling Study. Environ. Sci. Technol. 2023, 57, 643–654. [Google Scholar] [CrossRef]

- Rahmadhanty, S.F.; Subrahmanya, T.M.; Hung, W.-S.; Lin, P.T. Optimization of Self-Heated Vacuum Membrane Distillation Using Response Surface Methodology. In Proceedings of the Volume 3B: 48th Design Automation Conference (DAC), St. Louis, MI, USA, 14–17 August 2022. [Google Scholar]

- Said, I.A.; Fuentes, N.; He, Z.; Xin, R.; Zuo, K.; Li, Q. Low-Cost Desalination of Seawater and Hypersaline Brine Using Nanophotonics Enhanced Solar Energy Membrane Distillation. Environ. Sci. 2020, 6, 2180–2196. [Google Scholar] [CrossRef]

- Said, I.A.; Wang, S.; Li, Q. Field Demonstration of a Nanophotonics-Enabled Solar Membrane Distillation Reactor for Desalination. Ind. Eng. Chem. Res. 2019, 58, 18829–18835. [Google Scholar] [CrossRef]

- Liu, J.; Lin, W.; Hai, F.I.; Ma, Z. A Hybrid Solar-Driven Membrane Distillation-Assisted Liquid Desiccant Air Conditioning System: Mathematical Modeling and Feasibility Analysis. Energy Convers. Manag. 2024, 314, 118686. [Google Scholar] [CrossRef]

- Shafieian, A.; Roostaee, A.; Behnam, P.; Khiadani, M. Performance Analysis of a Solar-Driven Integrated Direct-Contact Membrane Distillation and Humidification–Dehumidification System. Energy Convers. Manag. 2022, 274, 116479. [Google Scholar] [CrossRef]

- Garg, K.; Rathore, A.; Yadav, R.; Das, S.K.; Tyagi, H. Thermodynamic Analysis of the Volumetric Absorption Solar Collector-Driven Direct Contact Membrane Distillation System. J. Therm. Sci. Eng. Appl. 2022, 14, 091010. [Google Scholar] [CrossRef]

- Shahouni, R.; Abbasi, M.; Kord, M.; Akrami, M. Modelling and Optimising of MED-TVC Seawater Desalination Plants Assisted with Electric Heaters. Water Resour. Ind. 2024, 32, 100262. [Google Scholar] [CrossRef]

- Wei-Song, H.; TM, S.; Widakdo, J.; Austria, H.F.M.; Kurkuri, M.; Wang, C.-F.; Hu, C.-C.; Kueir-Rarn, L.; Lai, J.-Y. Flow-Through In-Situ Evaporation Membrane Enabled Self-Heated Membrane Distillation for Efficient Desalination of Hypersaline Water. SSRN Electron. J. 2022, 452, 139170. [Google Scholar] [CrossRef]

- Li, C.; Liu, W.; Mao, J.; Hu, L.; Yun, Y.; Li, B. Superhydrophobic PVDF Membrane Modified by Dopamine Self-Polymerized Nanoparticles for Vacuum Membrane Distillation. Sep. Purif. Technol. 2023, 304, 122182. [Google Scholar] [CrossRef]

- Bin Abid, M.; Abdul Wahab, R.; Gzara, L. Membrane Distillation for Desalination and Current Advances in MD Membranes. J. Appl. Membr. Sci. Technol. 2023, 27, 39–88. [Google Scholar] [CrossRef]

- Alanezi, A.A.; Hakobyan, A.; Hakobyan, A.; Bassyouni, M. A Novel Hybrid Compact System of Photovoltaic Solar Still Air Gap Membrane Distillation for the Simultaneous Production of Water and Energy. Desalination Water Treat. 2023, 292, 1–9. [Google Scholar] [CrossRef]

- ElKasaby, M.M.; Hassan, M.A.; Khalil, A. Energy and Economic Performance Assessment of a Solar-Assisted Regenerative Vacuum Membrane Desalination System. Appl. Therm. Eng. 2023, 225, 120181. [Google Scholar] [CrossRef]

- Mohammed, R.H.; Qasem, N.A.A.; Farid, A.M.; Zubair, S.M.; Alsaman, A.S.; Askalany, A.A.; Ali, E.S. A Novel Solar-Powered Thermal Desalination Unit Coupled with a Reverse Osmosis Plant to Increase Overall Water Recovery. Appl. Therm. Eng. 2023, 234, 121306. [Google Scholar] [CrossRef]

- Giagnorio, M.; Morciano, M.; Zhang, W.; Hélix-Nielsen, C.; Fasano, M.; Tiraferri, A. Coupling of Forward Osmosis with Desalination Technologies: System-Scale Analysis at the Water-Energy Nexus. Desalination 2022, 543, 116083. [Google Scholar] [CrossRef]

- AL Mashrafi, S.; Diaz-Elsayed, N.; Benjamin, J.; Arias, M.E.; Zhang, Q. An Environmental and Economic Sustainability Assessment of a Pressure Retarded Osmosis System. Desalination 2022, 537, 115869. [Google Scholar] [CrossRef]

- Lowe, M.; Qin, R.; Mao, X. A Review on Machine Learning, Artificial Intelligence, and Smart Technology in Water Treatment and Monitoring. Water 2022, 14, 1384. [Google Scholar] [CrossRef]

- Douterelo, I.; Dutilh, B.E.; Arkhipova, K.; Calero, C.; Husband, S. Microbial Diversity, Ecological Networks and Functional Traits Associated to Materials Used in Drinking Water Distribution Systems. Water Res. 2020, 173, 115586. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Li, C. Prediction and Analysis of MBR Membrane Flux Based on Wavelet Neural Network Optimized by Shuffled Frog-Leaping Algorithm. In Proceedings of the 2022 International Conference on Computer Technologies (ICCTech), Melaka, Malaysia, 24–26 February 2022; pp. 96–100. [Google Scholar]

- Ling, G.; Wang, Z.; Shi, Y.; Wang, J.; Lu, Y.; Li, L. Membrane Fouling Prediction Based on Tent-SSA-BP. Membranes 2022, 12, 691. [Google Scholar] [CrossRef] [PubMed]

- Suárez, F.; del Río, M.B.; Aravena, J.E. Water Flux Prediction in Direct Contact Membrane Distillation Subject to Inorganic Fouling. Membranes 2022, 12, 157. [Google Scholar] [CrossRef]

- Abuwatfa, W.H.; AlSawaftah, N.; Darwish, N.; Pitt, W.G.; Husseini, G.A. A Review on Membrane Fouling Prediction Using Artificial Neural Networks (ANNs). Membranes 2023, 13, 685. [Google Scholar] [CrossRef]

- Yusuf, Z.; Abdul Wahab, N.; Sudin, S. Soft Computing Techniques in Modelling of Membrane Filtration System: A Review. Desalination Water Treat. 2019, 161, 144–155. [Google Scholar] [CrossRef]

- Cejnar, P.; Kuckova, S.; Prochazka, A.; Karamonova, L.; Svobodova, B. Principal Component Analysis of Normalized Full Spectrum Mass Spectrometry Data in MultiMS-toolbox: An Effective Tool to Identify Important Factors for Classification of Different Metabolic Patterns and Bacterial Strains. Rapid Commun. Mass Spectrom. 2018, 32, 871–881. [Google Scholar] [CrossRef]

- Kazemi, Z.; Jonidi Jafari, A.; Farzadkia, M.; Kazemnezhad Leyli, E.; Shahsavani, A.; Kermani, M. Assessment of the Risk of Exposure to Air Pollutants and Identifying the Affecting Factors on Making Pollution by PCA, CFA. Int. J. Environ. Anal. Chem. 2024, 104, 2128–2147. [Google Scholar] [CrossRef]

- Mahapatra, P. Determination of Key Success Factors for Winning Achievement of Indian Insurers: A PCA Approach. Int. J. Financ. Entrep. Sustain. 2021, 1. [Google Scholar] [CrossRef]

- Koziel, S.; Pietrenko-Dabrowska, A. Low-cost Data-driven Modelling of Microwave Components Using Domain Confinement and PCA-based Dimensionality Reduction. IET Microw. Antennas Propag. 2020, 14, 1643–1650. [Google Scholar] [CrossRef]

- Naessens, W.; Maere, T.; Gilabert-Oriol, G.; Garcia-Molina, V.; Nopens, I. PCA as Tool for Intelligent Ultrafiltration for Reverse Osmosis Seawater Desalination Pretreatment. Desalination 2017, 419, 188–196. [Google Scholar] [CrossRef]

- Rezaei, M.; Asadizadeh, M. Predicting Unconfined Compressive Strength of Intact Rock Using New Hybrid Intelligent Models. J. Min. Environ. 2020, 11, 231–246. [Google Scholar] [CrossRef]

- Yadav, A.; Chithaluru, P.; Singh, A.; Albahar, M.A.; Jurcut, A.; Álvarez, R.M.; Mojjada, R.K.; Joshi, D. Suspended Sediment Yield Forecasting with Single and Multi-Objective Optimization Using Hybrid Artificial Intelligence Models. Mathematics 2022, 10, 4263. [Google Scholar] [CrossRef]

- Torkan, M.; Dehkordi, M.N. Development of Anfis-Pso, Svr-Pso, and Ann-Pso Hybrid Intelligent Models For Predicting the Compressive Strength of Concrete. Iran Univ. Sci. Technol. 2019, 8, 547–563. [Google Scholar]

- Roehl, E.A.; Ladner, D.A.; Daamen, R.C.; Cook, J.B.; Safarik, J.; Phipps, D.W.; Xie, P. Modeling Fouling in a Large RO System with Artificial Neural Networks. J. Memb. Sci. 2018, 552, 95–106. [Google Scholar] [CrossRef]

- Shetty, G.R.; Chellam, S. Predicting Membrane Fouling during Municipal Drinking Water Nanofiltration Using Artificial Neural Networks. J. Memb. Sci. 2003, 217, 69–86. [Google Scholar] [CrossRef]

- CHELLAM, S. Artificial Neural Network Model for Transient Crossflow Microfiltration of Polydispersed Suspensions. J. Memb. Sci. 2005, 258, 35–42. [Google Scholar] [CrossRef]

- Shim, J.; Park, S.; Cho, K.H. Deep Learning Model for Simulating Influence of Natural Organic Matter in Nanofiltration. Water Res. 2021, 197, 117070. [Google Scholar] [CrossRef]

- Im, S.J.; Viet, N.D.; Jang, A. Real-Time Monitoring of Forward Osmosis Membrane Fouling in Wastewater Reuse Process Performed with a Deep Learning Model. Chemosphere 2021, 275, 130047. [Google Scholar] [CrossRef]

- Park, S.; Baek, S.-S.; Pyo, J.; Pachepsky, Y.; Park, J.; Cho, K.H. Deep Neural Networks for Modeling Fouling Growth and Flux Decline during NF/RO Membrane Filtration. J. Memb. Sci. 2019, 587, 117164. [Google Scholar] [CrossRef]

- Bagheri, M.; Akbari, A.; Mirbagheri, S.A. Advanced Control of Membrane Fouling in Filtration Systems Using Artificial Intelligence and Machine Learning Techniques: A Critical Review. Process Saf. Environ. Prot. 2019, 123, 229–252. [Google Scholar] [CrossRef]

- Viet, N.D.; Im, S.-J.; Kim, C.-M.; Jang, A. An Osmotic Membrane Bioreactor–Clarifier System with a Deep Learning Model for Simultaneous Reduction of Salt Accumulation and Membrane Fouling. Chemosphere 2021, 272, 129872. [Google Scholar] [CrossRef] [PubMed]

- Rezakazemi, M.; Dashti, A.; Asghari, M.; Shirazian, S. H2-Selective Mixed Matrix Membranes Modeling Using ANFIS, PSO-ANFIS, GA-ANFIS. Int. J. Hydrogen Energy 2017, 42, 15211–15225. [Google Scholar] [CrossRef]

- Zhang, J. Toward Modeling of Performance of Hydrogen Selective Mixed Matrix Membrane Using Artificial Neural Network. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 3036–3043. [Google Scholar] [CrossRef]

- Jawad, J.; Hawari, A.H.; Javaid Zaidi, S. Artificial Neural Network Modeling of Wastewater Treatment and Desalination Using Membrane Processes: A Review. Chem. Eng. J. 2021, 419, 129540. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, Z.; Du, X.; Gong, B.; Lu, Y.; Li, L. Membrane Fouling Diagnosis of Membrane Components Based on Multi-Feature Information Fusion. J. Memb. Sci. 2022, 657, 120670. [Google Scholar] [CrossRef]

- Yusof, Z.; Abdul Wahab, N.; Ibrahim, S.; Sahlan, S.; Che Razali, M. Modeling of Submerged Membrane Filtration Processes Using Recurrent Artificial Neural Networks. IAES Int. J. Artif. Intell. (IJ-AI) 2020, 9, 155. [Google Scholar] [CrossRef]

- Fitriana, D.N.; Sibaroni, Y. Sentiment Analysis on KAI Twitter Post Using Multiclass Support Vector Machine (SVM). J. RESTI (Rekayasa Sist. Dan Teknol. Inf.) 2020, 4, 846–853. [Google Scholar] [CrossRef]

- Hu, R.; Zhang, L.; Wei, J. Adaptive Laplacian Support Vector Machine for Semi-Supervised Learning. Comput. J. 2021, 64, 1005–1015. [Google Scholar] [CrossRef]

- Mekni, N.; Coronnello, C.; Langer, T.; De Rosa, M.; Perricone, U. Support Vector Machine as a Supervised Learning for the Prioritization of Novel Potential SARS-CoV-2 Main Protease Inhibitors. Int. J. Mol. Sci. 2021, 22, 7714. [Google Scholar] [CrossRef]

- Waqas, S.; Harun, N.Y.; Sambudi, N.S.; Arshad, U.; Nordin, N.A.H.M.; Bilad, M.R.; Saeed, A.A.H.; Malik, A.A. SVM and ANN Modelling Approach for the Optimization of Membrane Permeability of a Membrane Rotating Biological Contactor for Wastewater Treatment. Membranes 2022, 12, 821. [Google Scholar] [CrossRef]

- Taherian, M.; Mousavi, S.M.; Chamani, H. An Agent-Based Simulation with NetLogo Platform to Evaluate Forward Osmosis Process (PRO Mode). Chin. J. Chem. Eng. 2018, 26, 2487–2494. [Google Scholar] [CrossRef]

- Pardeshi, P.M.; Mungray, A.A.; Mungray, A.K. Determination of Optimum Conditions in Forward Osmosis Using a Combined Taguchi–Neural Approach. Chem. Eng. Res. Des. 2016, 109, 215–225. [Google Scholar] [CrossRef]

- Han, H.-G.; Zhang, L.; Liu, H.-X.; Qiao, J.-F. Multiobjective Design of Fuzzy Neural Network Controller for Wastewater Treatment Process. Appl. Soft Comput. 2018, 67, 467–478. [Google Scholar] [CrossRef]

- Lee, Y.G.; Lee, Y.S.; Jeon, J.J.; Lee, S.; Yang, D.R.; Kim, I.S.; Kim, J.H. Artificial Neural Network Model for Optimizing Operation of a Seawater Reverse Osmosis Desalination Plant. Desalination 2009, 247, 180–189. [Google Scholar] [CrossRef]

- Ma, S.; Wu, X.; Fan, L.; Xie, Z. Predicting Water Flux and Reverse Solute Flux in Forward Osmosis Processes Using Artificial Neural Networks (ANN) Modelling with Structural Parameters. Sep. Purif. Technol. 2024, 351, 128092. [Google Scholar] [CrossRef]

- Libotean, D.; Giralt, J.; Giralt, F.; Rallo, R.; Wolfe, T.; Cohen, Y. Neural Network Approach for Modeling the Performance of Reverse Osmosis Membrane Desalting. J. Memb. Sci. 2009, 326, 408–419. [Google Scholar] [CrossRef]

- Hekmatmehr, H.; Esmaeili, A.; Atashrouz, S.; Hadavimoghaddam, F.; Abedi, A.; Hemmati-Sarapardeh, A.; Mohaddespour, A. On the Evaluating Membrane Flux of Forward Osmosis Systems: Data Assessment and Advanced Intelligent Modeling. Water Environ. Res. 2024, 96, e10960. [Google Scholar] [CrossRef]

- K, A.; Mungray, A.; Agarwal, S.; Ali, J.; Chandra Garg, M. Performance Optimisation of Forward-Osmosis Membrane System Using Machine Learning for the Treatment of Textile Industry Wastewater. J. Clean. Prod. 2021, 289, 125690. [Google Scholar] [CrossRef]

- Hosseinzadeh, A.; Zhou, J.L.; Altaee, A.; Baziar, M.; Li, X. Modeling Water Flux in Osmotic Membrane Bioreactor by Adaptive Network-Based Fuzzy Inference System and Artificial Neural Network. Bioresour. Technol. 2020, 310, 123391. [Google Scholar] [CrossRef]

- Kim, J.; Jeon, J.; Kim, N.; Kim, S. Predicting Flux of Forward Osmosis Membrane Module Using Deep Learning. J. Korean Soc. Water Wastewater 2021, 35, 93–100. [Google Scholar] [CrossRef]

- Yuan, Z.; Nag, R.; Cummins, E. Human Health Concerns Regarding Microplastics in the Aquatic Environment–From Marine to Food Systems. Sci. Total Environ. 2022, 823, 153730. [Google Scholar] [CrossRef] [PubMed]

- Ebrahimi, P.; Abbasi, S.; Pashaei, R.; Bogusz, A.; Oleszczuk, P. Investigating Impact of Physicochemical Properties of Microplastics on Human Health: A Short Bibliometric Analysis and Review. Chemosphere 2022, 289, 133146. [Google Scholar] [CrossRef] [PubMed]

- Viet, N.D.; Jang, A. Machine Learning-Based Real-Time Prediction of Micropollutant Behaviour in Forward Osmosis Membrane (Waste) Water Treatment. J. Clean. Prod. 2023, 389, 136023. [Google Scholar] [CrossRef]

- Zhu, T.; Zhang, Y.; Li, Y.; Tao, C.; Cao, Z.; Cheng, H. Assessment of Organic Micropollutants Rejection by Forward Osmosis System Using Interpretable Machine Learning-Assisted Approach: A New Perspective on Optimization of Multifactorial Forward Osmosis Process. J. Environ. Chem. Eng. 2023, 11, 110847. [Google Scholar] [CrossRef]

- Yogarathinam, L.T.; Abba, S.I.; Usman, J.; Lawal, D.U.; Aljundi, I.H. Predicting Micropollutant Removal through Nanopore-Sized Membranes Using Several Machine-Learning Approaches Based on Feature Engineering. RSC Adv. 2024, 14, 19331–19348. [Google Scholar] [CrossRef]

- Yun, D.; Abbas, A.; Jeon, J.; Ligaray, M.; Baek, S.-S.; Cho, K.H. Developing a Deep Learning Model for the Simulation of Micro-Pollutants in a Watershed. J. Clean. Prod. 2021, 300, 126858. [Google Scholar] [CrossRef]

- Kumar, R. Double Internal Loop Higher-Order Recurrent Neural Network-Based Adaptive Control of the Nonlinear Dynamical System. Soft Comput. 2023, 27, 17313–17331. [Google Scholar] [CrossRef]

- Xu, J.; Suzuki, K. Massive-training Support Vector Regression and Gaussian Process for False-positive Reduction in Computer-aided Detection of Polyps in CT Colonography. Med. Phys. 2011, 38, 1888–1902. [Google Scholar] [CrossRef]

- Samuel, B.; Hota, M.K. A Nonlinear Functional Link Multilayer Perceptron Using Volterra Series as an Adaptive Noise Canceler for the Extraction of Fetal Electrocardiogram. Ann. Biomed. Eng. 2024, 52, 627–637. [Google Scholar] [CrossRef]

- Vora, M.J. Optimization of ANN Architecture and Training Parameters Using Taguchi Method. ECS Trans. 2022, 107, 2351–2362. [Google Scholar] [CrossRef]

- Freeborough, W.; van Zyl, T. Investigating Explainability Methods in Recurrent Neural Network Architectures for Financial Time Series Data. Appl. Sci. 2022, 12, 1427. [Google Scholar] [CrossRef]

- Goh, G.B.; Siegel, C.; Vishnu, A.; Hodas, N.O.; Baker, N. Chemception: A Deep Neural Network with Minimal Chemistry Knowledge Matches the Performance of Expert-Developed QSAR/QSPR Models. arXiv 2017, arXiv:1706.06689. [Google Scholar]

- Izonin, I.; Tkachenko, R.; Berezsky, O.; Krak, I.; Kováč, M.; Fedorchuk, M. Improvement of the ANN-Based Prediction Technology for Extremely Small Biomedical Data Analysis. Technologies 2024, 12, 112. [Google Scholar] [CrossRef]

- Bose, S.; Banerjee, S.; Kumar, S.; Saha, A.; Nandy, D.; Hazra, S. Review of Applications of Artificial Intelligence (AI) Methods in Crop Research. J. Appl. Genet. 2024, 65, 225–240. [Google Scholar] [CrossRef] [PubMed]

- Gao, G.; Wang, Y.; Vink, J.C.; Wells, T.J.; Saaf, F.J.F.E. Distributed Quasi-Newton Derivative-Free Optimization Method for Optimization Problems with Multiple Local Optima. Comput. Geosci. 2022, 26, 847–863. [Google Scholar] [CrossRef]

- Zhang, C.; Fu, S.; Ou, B.; Liu, Z.; Hu, M. Prediction of Dam Deformation Using SSA-LSTM Model Based on Empirical Mode Decomposition Method and Wavelet Threshold Noise Reduction. Water 2022, 14, 3380. [Google Scholar] [CrossRef]

- Shen, Y.; Mercatoris, B.; Cao, Z.; Kwan, P.; Guo, L.; Yao, H.; Cheng, Q. Improving Wheat Yield Prediction Accuracy Using LSTM-RF Framework Based on UAV Thermal Infrared and Multispectral Imagery. Agriculture 2022, 12, 892. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, J.; Li, H.; Dong, A.; Kang, Y.; Zhu, J.; Wang, Y.; Yang, Y. Deep Learning CNN-GRU Method for GNSS Deformation Monitoring Prediction. Appl. Sci. 2024, 14, 4004. [Google Scholar] [CrossRef]

- Rengasamy, D.; Juwono, F.H.; Nandong, J.; Brennan, A.J.; Gopal, L. Optimizing NARX-RNN Performance to Predict Precious Metal Futures Market. In Proceedings of the 2022 International Conference on Green Energy, Computing and Sustainable Technology (GECOST), Miri Sarawak, Malaysia, 26–28 October 2022; pp. 387–393. [Google Scholar]

- Moness, M.; Diaa-Eldeen, T. Experimental Nonlinear Identification of a Lab-Scale Helicopter System Using MLP Neural Network. In Proceedings of the 2017 13th International Computer Engineering Conference (ICENCO), Cairo, Egypt, 27–28 December 2017; pp. 166–171. [Google Scholar]

- Zhaka, L.; Xhina, E. Canada’s Provinces Geospatial Data Visualization Using NetLogo and GIS. Int. J. Sci. Technol. Res. 2021, 7. [Google Scholar] [CrossRef]

- Harwick, C. Helipad: A Framework for Agent-Based Modeling in Python. SSRN Electron. J. 2021. [Google Scholar] [CrossRef]

- Nehri, Y.E.; Oral, A.; Toktaş, A. Optimisation of Machining Parameters of AISI 304L Stainless Steel with the Least Error Method Using Taguchi, RSM, and ANN. Aust. J. Mech. Eng. 2024, 1–11. [Google Scholar] [CrossRef]

- Nasr, M.; Rabiee, A.; Kamwa, I. MPC and Robustness Optimisation-based EMS for Microgrids with High Penetration of Intermittent Renewable Energy. IET Gener. Transm. Distrib. 2020, 14, 5239–5248. [Google Scholar] [CrossRef]

- Mathur, P.; Sangaraju, S.H.V.; Jindal, S.K. Quantitative Nuclei Analysis for Accurate Detection of Breast Abnormalities through Machine Learning. In Proceedings of the 2023 Global Conference on Information Technologies and Communications (GCITC), Bangalore, India, 1–3 December 2023; pp. 1–8. [Google Scholar]

- Gajjar, A.; Kashyap, P.; Aysu, A.; Franzon, P.; Dey, S.; Cheng, C. FAXID: FPGA-Accelerated XGBoost Inference for Data Centers Using HLS. In Proceedings of the 2022 IEEE 30th Annual International Symposium on Field-Programmable Custom Computing Machines (FCCM), New York City, NY, USA, 15–18 May 2022; pp. 1–9. [Google Scholar]

- Singh, A.; Giannakoudakis, D.; Arkas, M.; Triantafyllidis, K.; Nair, V. Composites of Lignin-Based Biochar with BiOCl for Photocatalytic Water Treatment: RSM Studies for Process Optimization. Nanomaterials 2023, 13, 735. [Google Scholar] [CrossRef] [PubMed]

- Alahmadi, R.A.; Raza, J.; Mushtaq, T.; Abdelmohsen, S.A.M.; Gorji, M.R.; Hassan, A.M. Optimization of MHD Flow of Radiative Micropolar Nanofluid in a Channel by RSM: Sensitivity Analysis. Mathematics 2023, 11, 939. [Google Scholar] [CrossRef]

- Panja, B.; Ogunyanwo, O.; Meharia, P. Training of Intelligent Intrusion Detection System Using Neuro Fuzzy. In Proceedings of the 15th IEEE/ACIS International Conference on Software Engineering, Artificial Intelligence, Networking and Parallel/Distributed Computing (SNPD), Las Vegas, NV, USA, 30 June–2 July 2014; pp. 1–6. [Google Scholar]

- Siddique, M.M.; Zheng, Y.; Yang, X.; Beddoe, G. Reduction of False Positives by Extracting Fuzzy Rules from Data for Polyp Detection in CTC Scans. In Medical Imaging 2008: Computer-Aided Diagnosis; Giger, M.L., Karssemeijer, N., Eds.; SPIE: Bellingham, WA, USA, 2008; p. 69150S. [Google Scholar]

- Khan, M.; Raza, M.A.; Jumani, T.A.; Mirsaeidi, S.; Ali, A.; Abbas, G.; Touti, E.; Alshahir, A. Modeling of Intelligent Controllers for Solar Photovoltaic System under Varying Irradiation Conditions. Front. Energy Res. 2023, 11, 1288486. [Google Scholar] [CrossRef]

- Lee, N.; Moore, P.W.; Brattain, L.J. Scalable Deep Learning for Pilot Performance Analysis Using Multimodal Physiological Time Series. In Proceedings of the 2023 IEEE High Performance Extreme Computing Conference (HPEC), Boston, MA, USA, 25–29 September 2023; pp. 1–6. [Google Scholar]

| Model Type | Method | Performance Metrics | Results |

|---|---|---|---|

| Empirical [15] | RO | Water flux, fouling rate | Moderate accuracy, high energy consumption |

| Mechanistic [20] | Multi-Stage Flash Distillation | Energy efficiency, salt rejection | High energy consumption, reliable performance |

| Transport Phenomena [20] | Electrodialysis | Ion removal efficiency | Effective for specific ions, moderate energy use |

| AI/ML (ANN) [21] | FO | Water flux, fouling prediction | High accuracy, low energy consumption (R2ANN = 0.98036, R2RSM = 0.9408) |

| AI/ML [22] | FO | Permeate quality, fouling prediction | High performance of 0.997, mean square error of 0.04 |

| Methods | Features |

|---|---|

| Self-heated vacuum membrane distillation (MD) | - Eliminating the preheating of feed solution and temperature polarisation [48,56]; - Enhancing permeate flux and reducing energy requirements [48]; - Impressive performance [57]; - The lowest specific heating energy consumption [48,56]; - The highest gain output ratio [55]; - Suitable for high-purity water production [56,57]. |

| Nanophotonic-enhanced solar membrane distillation (NESMD) | - A standalone small-scale system [54]; - A promising approach for decentralised water desalination [50]; - Has the ability to turn almost any source of water into clean water [51]. |

| Membrane distillation coupled with solar energy | - A non-isothermal process with simultaneous mass and heat transfer [58]; - Fully implementable on small- and medium-scales [59]; - An energy-efficient method [55]; - A low-cost method [60]. |

| RO [61] | - High rejection rates for a wide range of contaminants; - Energy efficient with advanced energy recovery systems; - Suitable for large-scale desalination plants; - Requires pre-treatment to prevent membrane fouling. |

| FO [62] | - Lower energy consumption compared to RO; - Utilises natural osmotic pressure differences; - Effective for treating high-salinity and wastewater streams; - Challenges with draw solution recovery and membrane fouling. |

| Pressure Retarded Osmosis (PRO) [63] | - Generates energy from salinity gradients; - Potential for integration with existing desalination and wastewater treatment systems; - High energy efficiency and low environmental impact; - Technical challenges in membrane development and optimisation. |

| Method | Inputs | Outputs | Description |

|---|---|---|---|

| - GA + PSO [87] | - Feed temperature, pressure, pH | - Optimisation/fouling prediction | Integrates genetic algorithm (GA) and particle swarm optimisation (PSO) to enhance the predictive accuracy of fouling behaviour by optimising operational parameters. |

| - MLP + ANN [88] | - Hydraulic and water quality parameters | - Fouling prediction | Utilises multilayer perceptron (MLP) and artificial neural networks (ANN) to model and predict membrane fouling based on complex hydraulic and water quality data. |

| - ANNs [89] | - Polydisperse feed suspensions | - Fouling behaviour | Employs artificial neural networks (ANNs) to simulate the fouling dynamics in systems with polydisperse feed suspensions, capturing the heterogeneity of particle sizes. |

| - LSTM [82] | - Pressure, temperature, pH | - Fouling growth | Leverages long short-term memory (LSTM) networks to forecast the temporal evolution of fouling layers, accounting for sequential dependencies in the data. |

| - CNNs [90] | - Transmembrane pressure, crossflow velocity, temperature, pH | - Fouling prediction | Applies convolutional neural networks (CNNs) to analyse spatial and temporal variations in membrane parameters, providing robust predictions of fouling events. |

| - RNN [91] | - Operating parameters | - Conductivity, fouling and flux prediction | Utilises recurrent neural networks (RNNs) to predict conductivity, fouling and flux variations by modelling the sequential nature of operating conditions. |

| Method | Inputs | Outputs |

|---|---|---|

| - NetLogo [96] | - Operational parameters | - Water flux |

| - Taguchi ANN [97] | - Feed velocity and temperature, draw velocity and temperature | - Solute flux selectivity |

| - MOPSO + FNNC [98] | - Dissolved oxygen and nitrate in the treatment process | - Flux modelling |

| - ANNs [99] | - Feed temperature, flow rate and TDS, transmembrane pressure (TMP), time | - TDS and flow rate |

| - ANNs + SVR [101] | - Past data of permeate flux and salt passage serves | - Permeate flux and salt passage prediction |

| - XGBoost [102] | - Feed solution and draw solution concentrations | - Flux modelling |

| - RSM + ANNs + ANFIS [103] | - Initial draw and feed concentration, time, pH and temperature on water flux and reverse salt flux | - Water flux |

| - ANFIS + ANNs [104] | - Suspended solids, electrical conductivity and dissolved oxygen | - Flux modelling |

| - DL [105] | - Feed flow rate, pressure, ion concentration of DS and FS | - Flux modelling |

| Method | Inputs | Outputs |

|---|---|---|

| - XGBoost-18 + SHAP | - Volume/molecular weight/zeta potential/membrane surface/osmotic pressure | - OMP rejection |

| - NF-GP | - Maximum projection diameter/minimum projection diameter/molecular weight/compound size | - OMP rejection |

| - ANFIS | - Feed temperature/flow rate/TDS/TMP | - OMP rejection |

| - ET | - Feed temperature/flow rate/TDS/TMP | - OMP rejection |

| - LSTM | - Inlet flow/inlet pressure/inlet temperature/surface of membrane | - Predicting MPs |

| - GPR | - Feed temperature/flow rate/TDS/TMP | - OMP rejection |

| - ANFIS + SC | - Operational parameters | - OMP rejection |

| Methods | Positives | Negatives |

|---|---|---|

| LSTM [121,122] | Data-based modelling/High accuracy/cost reduction | Large datasets/overfitting/interpretability |

| CNNs [123] | Feature extraction/translation invariance/transfer learning/segmentation | Large datasets/computational demands/overfitting |

| RNN [116,124] | Time-series data/flexibility/accuracy | Large dataset/complexity/interpretability |

| MLP [125] | Nonlinear relationships/universal approximators/feature extraction/flexibility | Large datasets requirement/overfitting/complexity of tuning |

| NetLogo [126,127] | Visualisation/Agent-Based Modelling/user friendly | The simplicity of modelling/Limited precision/not common platform |

| Taguchi ANN [115,128] | Accurate optimisation/applying setting parameters/numerical modelling | Simplicity of modelling/Data requirement/time-consuming/interpretability |

| MOPSO [129] | Robustness/optimisation/high-speed | Tuning complexity/large data requirement/local optima |

| ANNs [112,114] | Nonlinear mapping/Noise handling/multitasking | Data requirement/interpretability/complexity of tuning |

| SVR [113] | Effective real-value estimation/spares solution/Kernel function | Large datasets/lack of transparency/high-dimensionality difficulties |

| XGBoost [130,131] | High accuracy/handling missing values/regularisation/scalability/ | Complex tuning/spares data/expensive |

| RSM [132,133] | Systematic experiment design/optimisation/interpretable/ | Large datasets requirement/assumption/limited to polynomial models/local optima |

| ANFIS [134,135,136] | Hybrid approach/efficient resource/data-driven learning/ | Resource intensive/large dataset/overfitting |

| DL [137] | Scalable/feature extraction/high performance | Computationally expensive/large dataset/interpretability/overfitting |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahouni, R.; Abbasi, M.; Dibaj, M.; Akrami, M. Utilising Artificial Intelligence to Predict Membrane Behaviour in Water Purification and Desalination. Water 2024, 16, 2940. https://doi.org/10.3390/w16202940

Shahouni R, Abbasi M, Dibaj M, Akrami M. Utilising Artificial Intelligence to Predict Membrane Behaviour in Water Purification and Desalination. Water. 2024; 16(20):2940. https://doi.org/10.3390/w16202940

Chicago/Turabian StyleShahouni, Reza, Mohsen Abbasi, Mahdieh Dibaj, and Mohammad Akrami. 2024. "Utilising Artificial Intelligence to Predict Membrane Behaviour in Water Purification and Desalination" Water 16, no. 20: 2940. https://doi.org/10.3390/w16202940

APA StyleShahouni, R., Abbasi, M., Dibaj, M., & Akrami, M. (2024). Utilising Artificial Intelligence to Predict Membrane Behaviour in Water Purification and Desalination. Water, 16(20), 2940. https://doi.org/10.3390/w16202940