Evaluation of Selected Operating Process Variables for a Bioflocculant Supported Column Flotation System

Abstract

1. Introduction

2. Materials and Methods

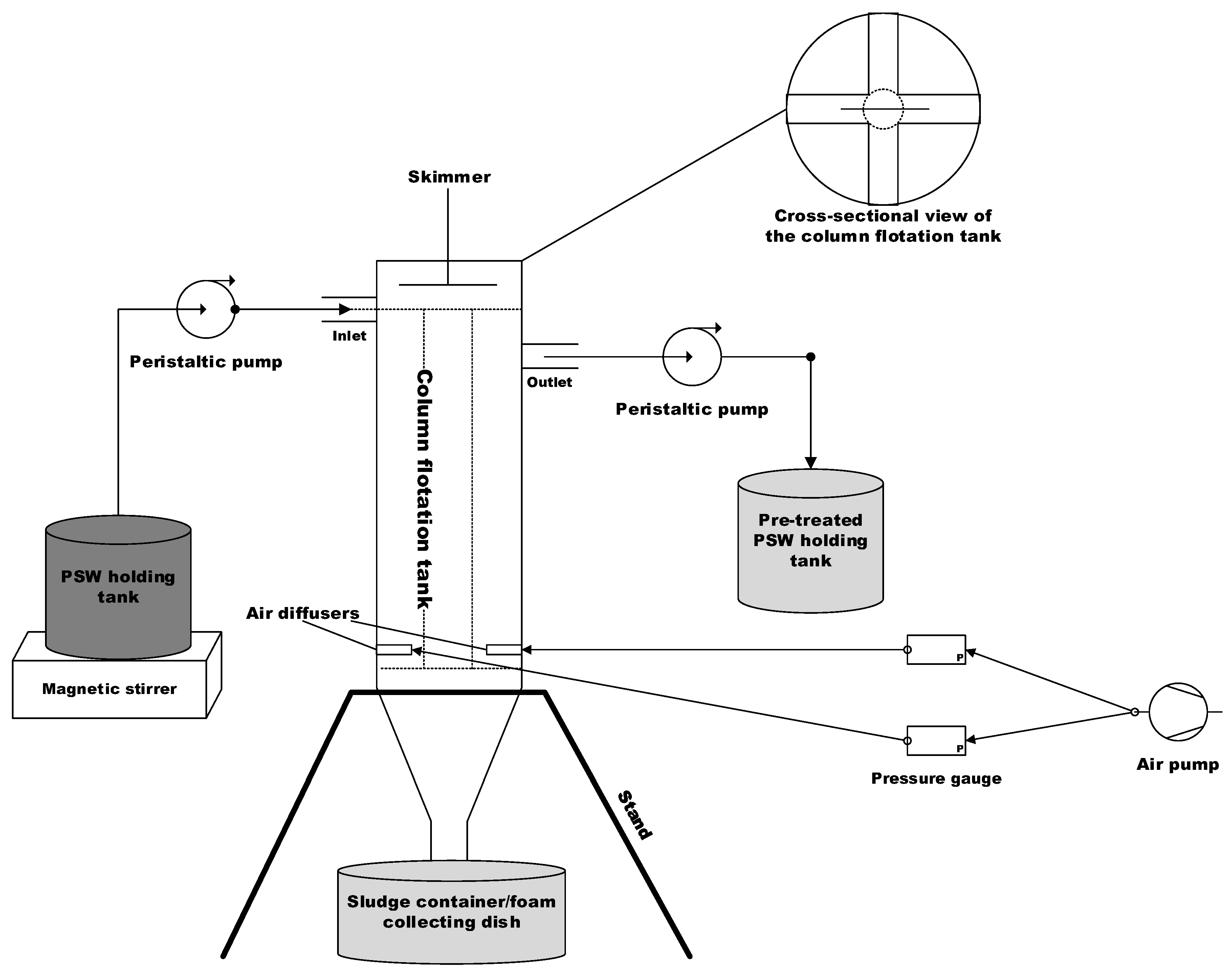

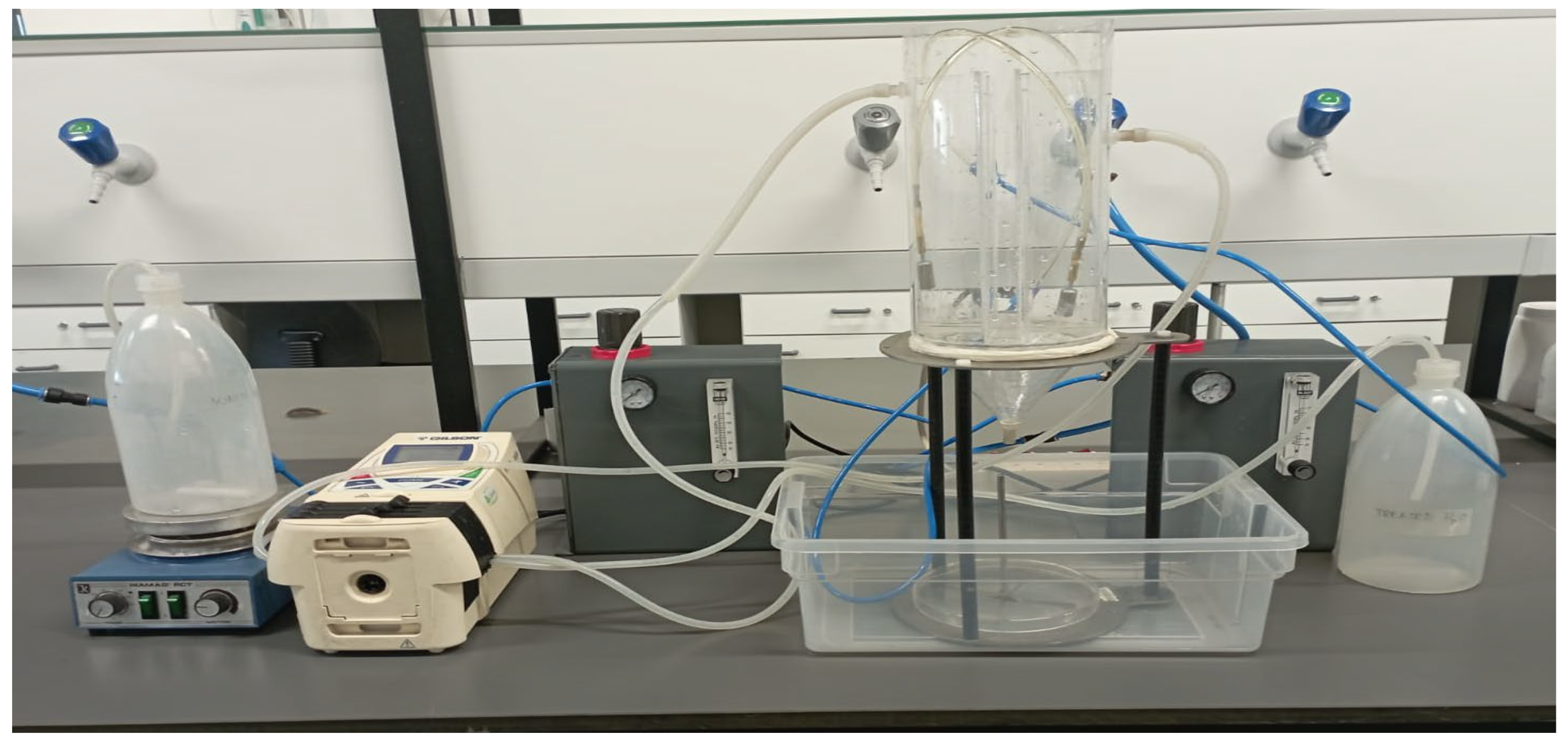

2.1. Column Air Flotation Bench Scale Setup

2.2. Wastewater Source

2.3. Bioflocculant Production and Flocculation Activity Confirmation

- A = absorbance of control, and

- B = absorbance of sample.

2.4. Using Design Expert Software for Performance Analysis of the Bioflocculant Column Flotation System

- % is the yield (COD or tSS or turbidity) percentage removal,

- is the response variable initial value, and

- is the response variable final value.

2.5. Analytical Methods

2.6. Statistical Analysis

3. Results

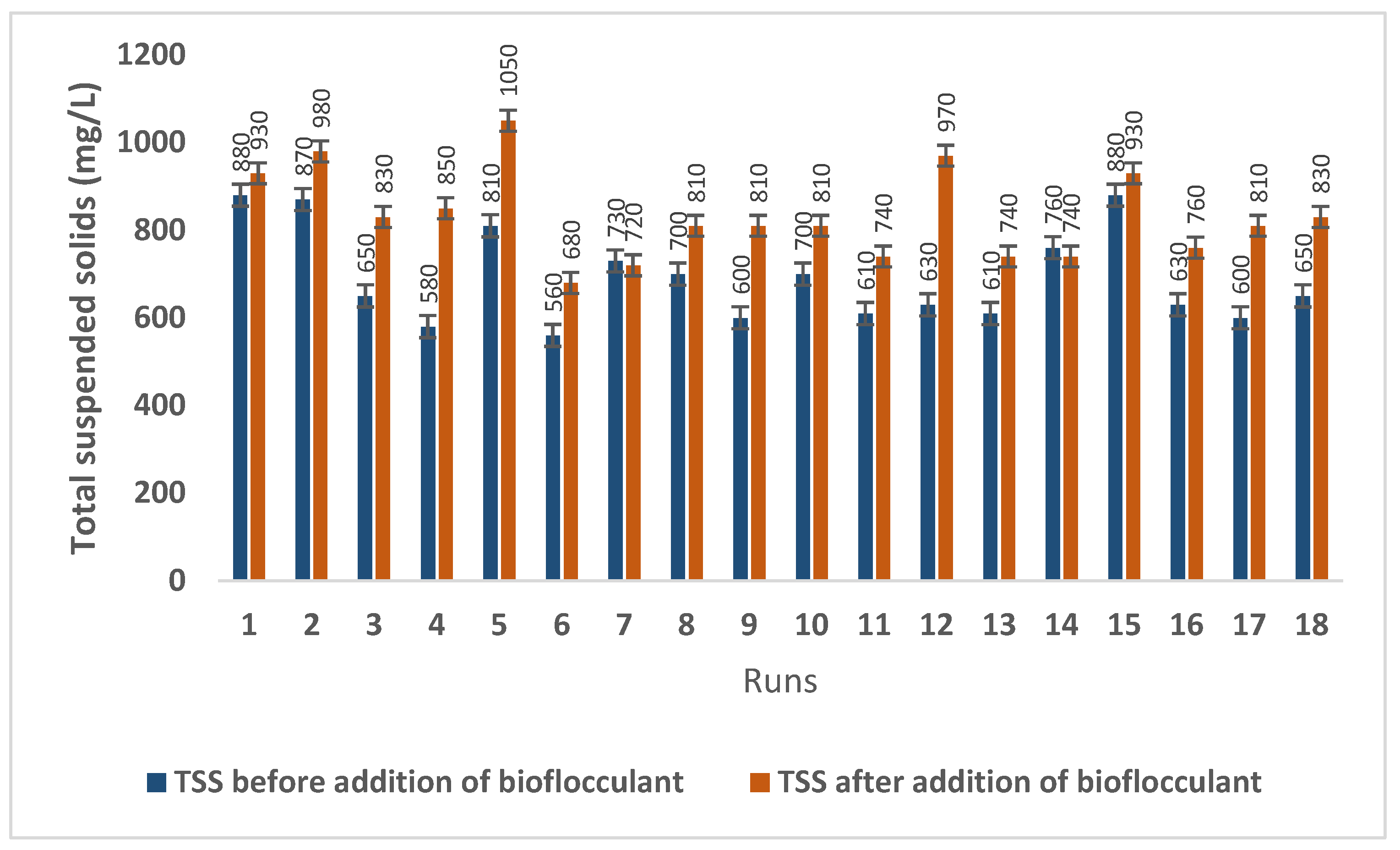

3.1. Influence of Bioflocculants on Poultry Slaughterhouse Wastewater Pretreatment

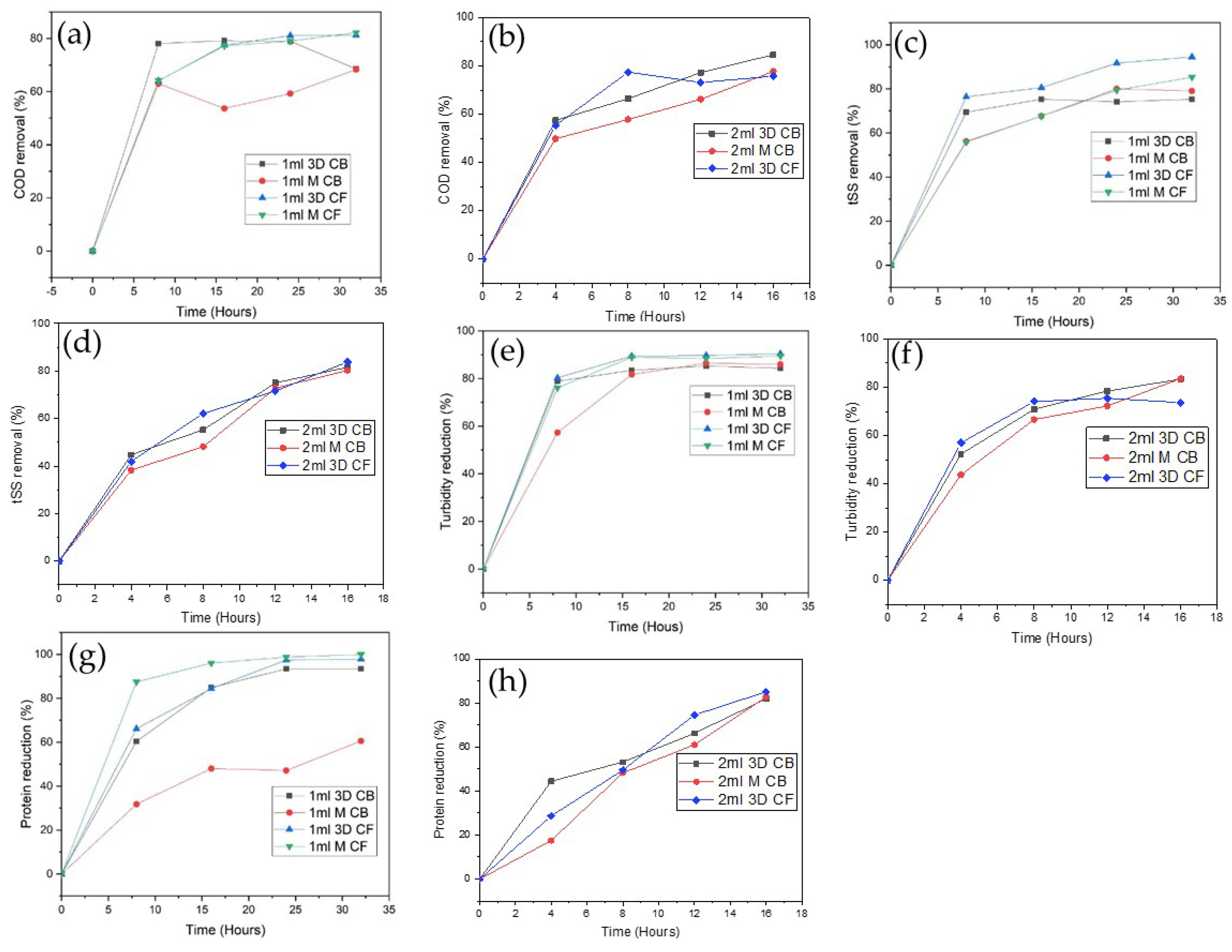

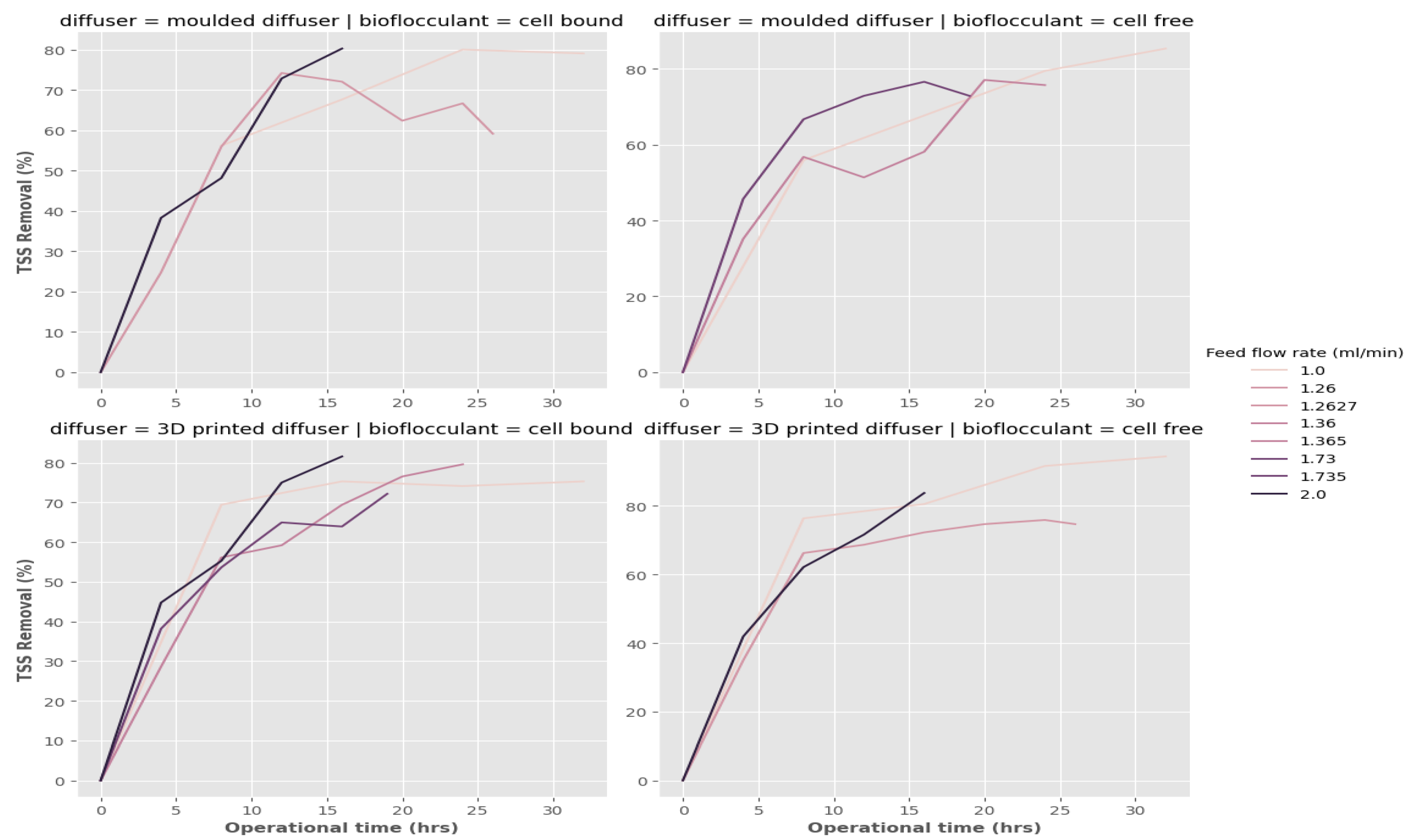

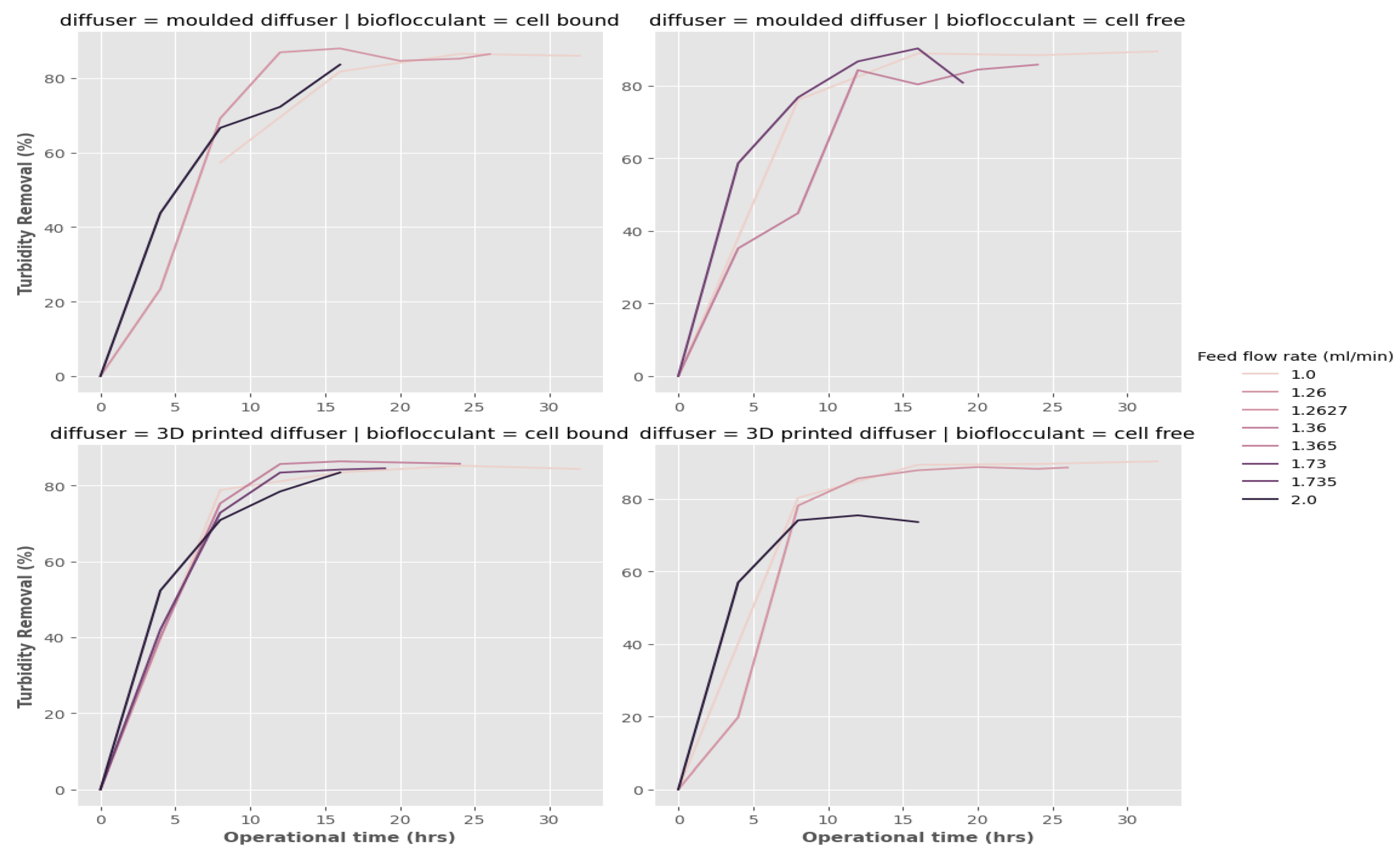

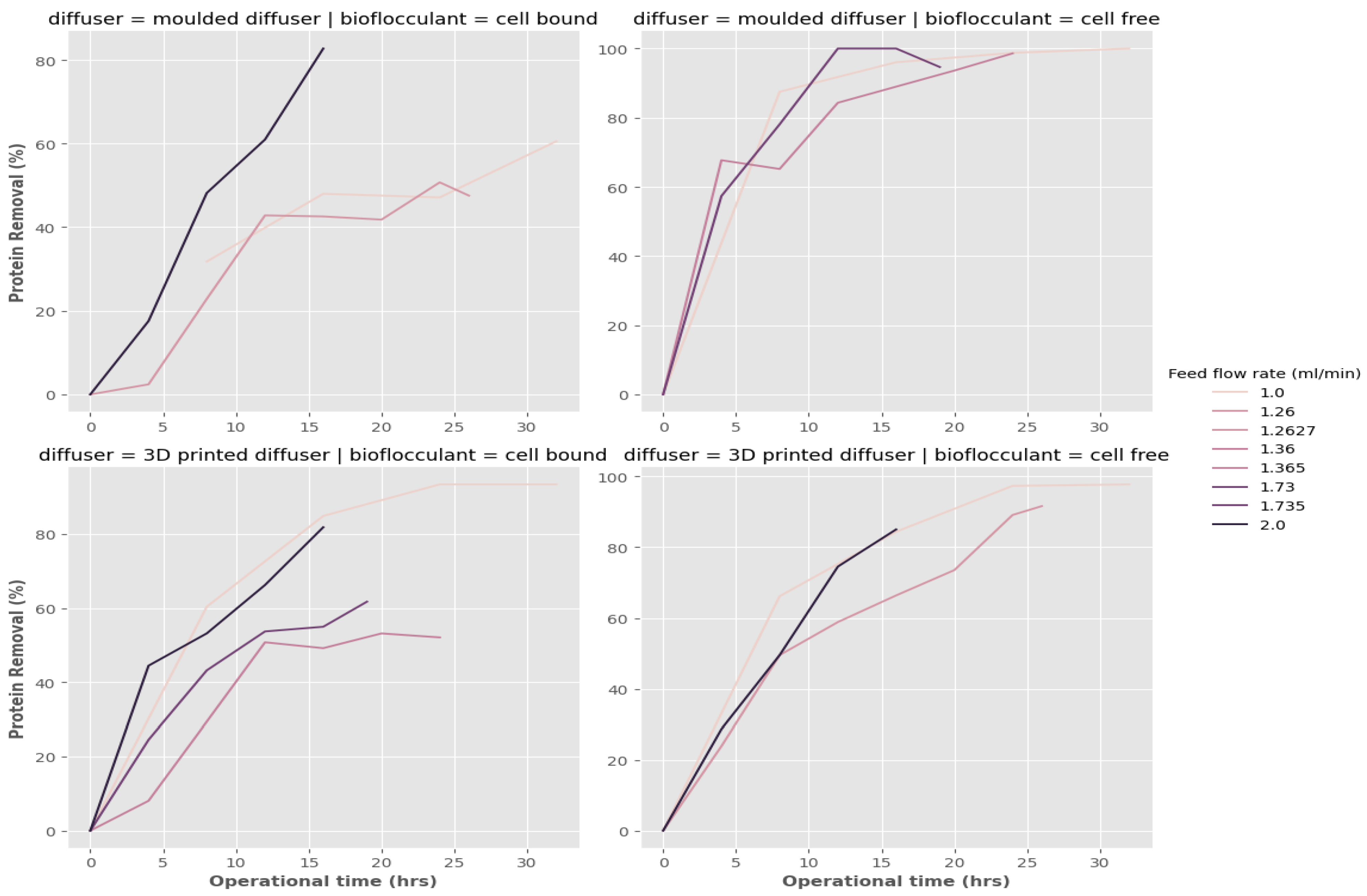

3.2. Comparative Analysis of Comparable Variables

3.2.1. Comparison of Bioflocculant Forms

3.2.2. Comparison of Diffuser Types

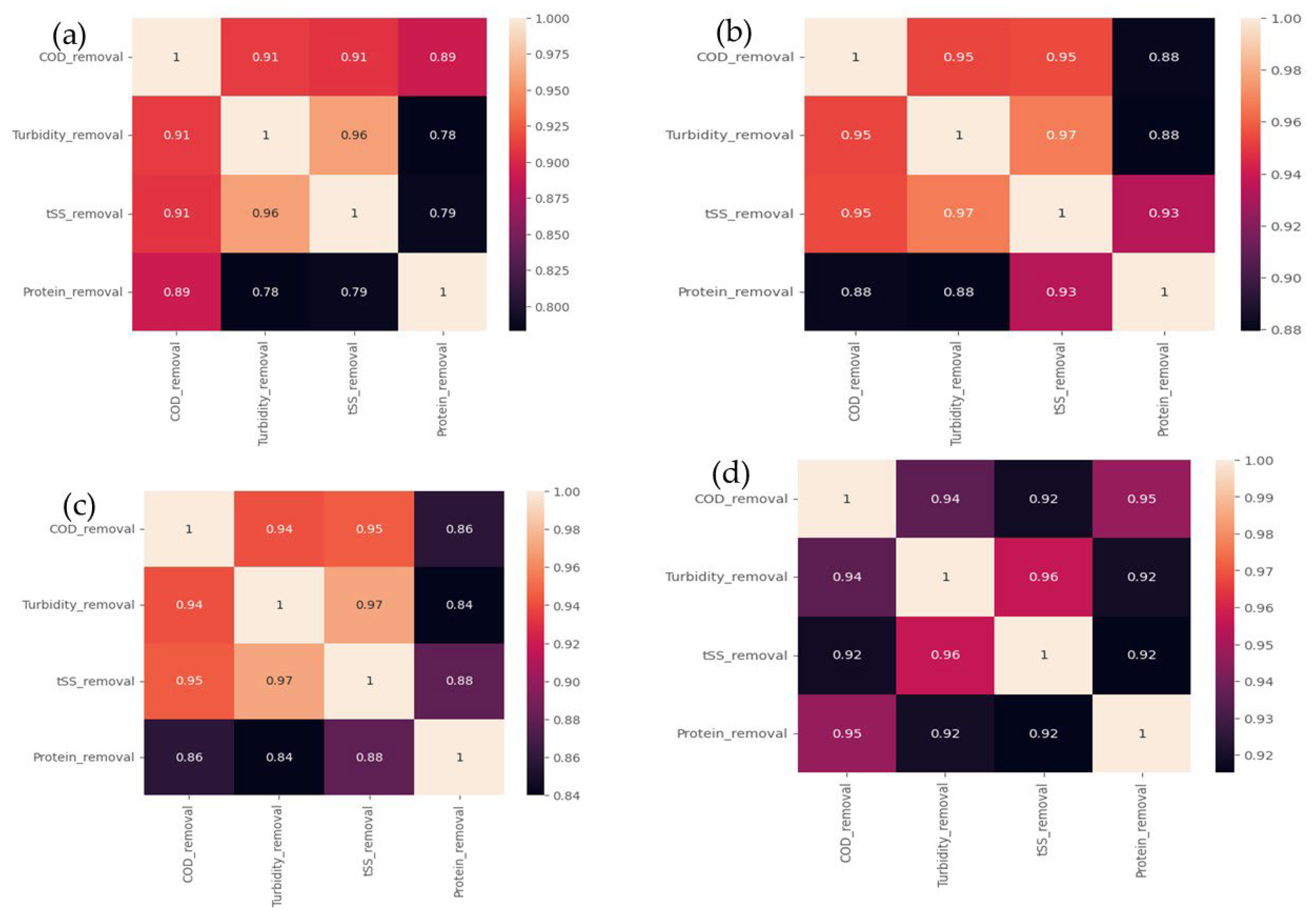

3.3. Correlation of the Variables

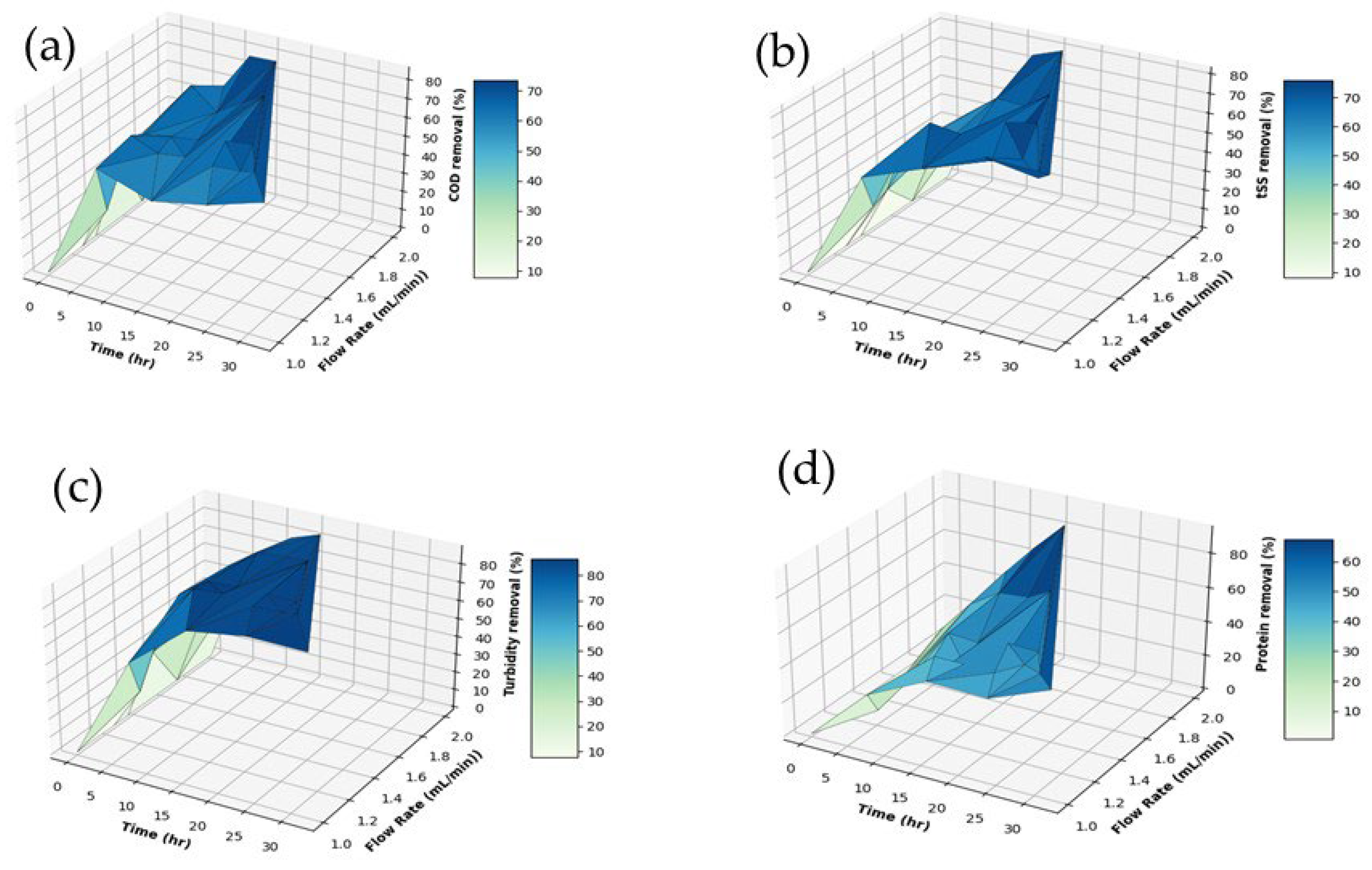

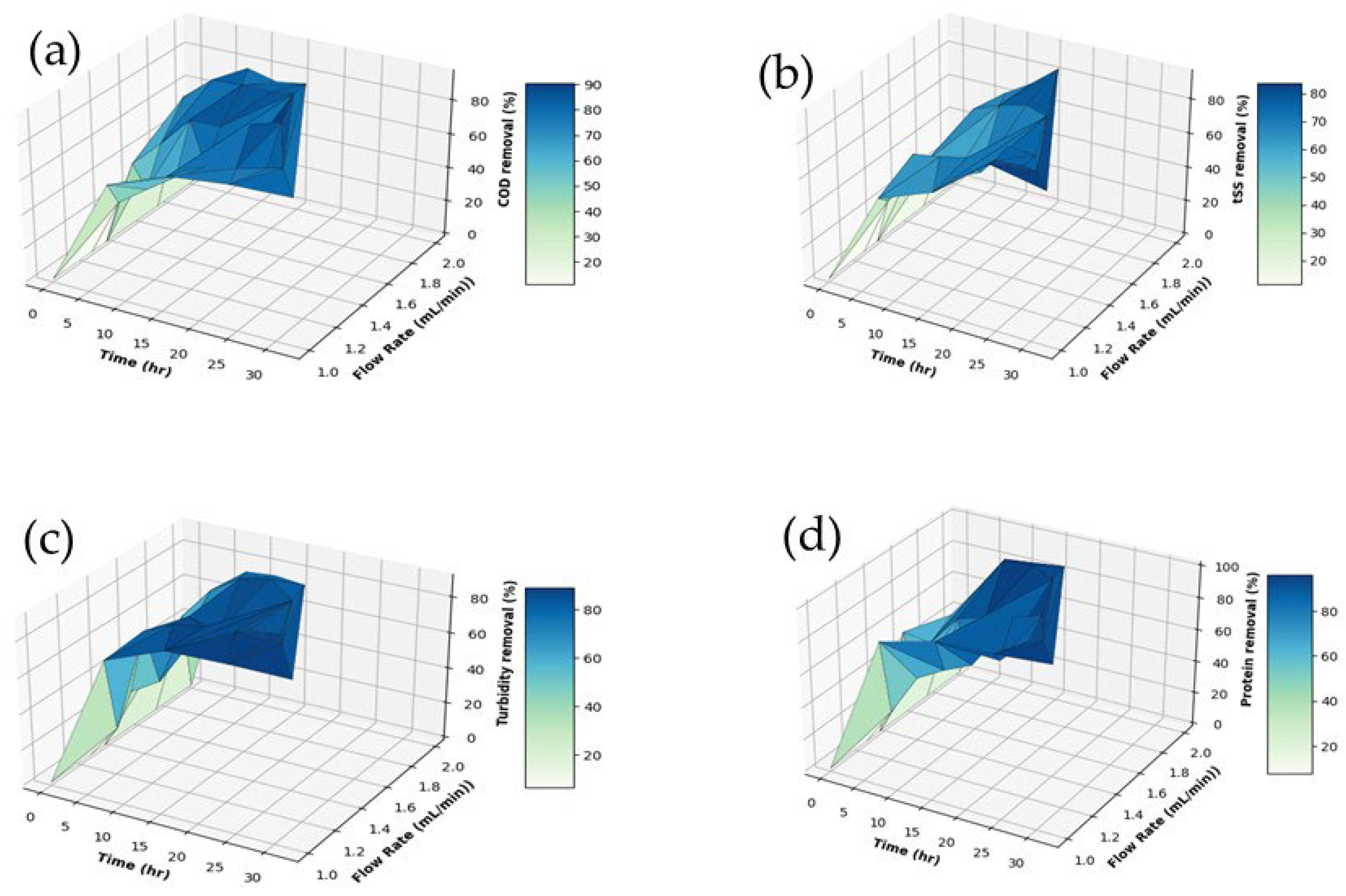

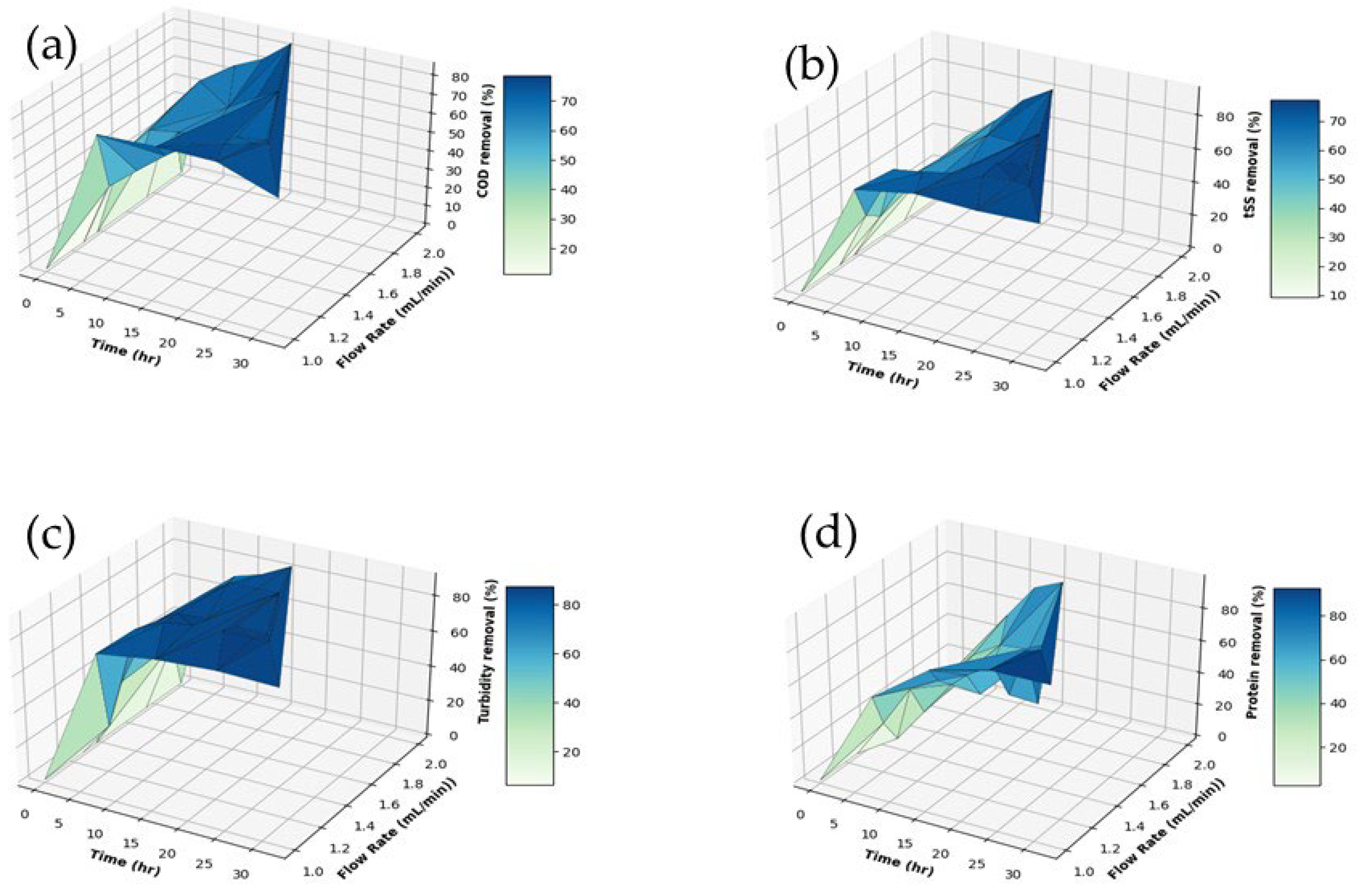

3.4. Surface Plots of the Comparable Variables Based on Pollutant Removal

3.5. Overall Bioflocculant Column Flotation (BioCF) System Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Meiramkulova, K.; Zorpas, A.A.; Orynbekov, D.; Zhumagulov, M.; Saspugayeva, G.; Kydyrbekova, A.; Mkilima, T.; Inglezakis, V.J. The effect of scale on the performance of an integrated poultry slaughterhouse wastewater treatment process. Sustainability 2020, 12, 4679. [Google Scholar] [CrossRef]

- Kanafin, Y.N.; Makhatova, A.; Meiramkulova, K.; Poulopoulos, S.G. Treatment of a poultry slaughterhouse wastewater using advanced oxidation processes. J. Water Process Eng. 2022, 47, 102694. [Google Scholar] [CrossRef]

- Aziz, H.A.; Puat, N.N.A.; Alazaiza, M.Y.; Hung, Y.T. Poultry slaughterhouse wastewater treatment using submerged fibers in an attached growth sequential batch reactor. Int. J. Environ. Res. Public Health 2018, 15, 1734. [Google Scholar] [CrossRef] [PubMed]

- Meiramkulova, K.; Temirbekova, A.; Saspugayeva, G.; Kydyrbekova, A.; Devrishov, D.; Tulegenova, Z.; Aubakirova, K.; Kovalchuk, N.; Meirbekov, A.; Mkilima, T. Performance of a combined treatment approach on the elimination of microbes from poultry slaughterhouse Wastewater. Sustainability 2021, 13, 3467. [Google Scholar] [CrossRef]

- Bingo, M.N.; Njoya, M.; Basitere, M.; Ntwampe, S.K.O.; Kaskote, E. Performance evaluation of an integrated multi-stage poultry slaughterhouse wastewater treatment system. J. Water Process Eng. 2021, 43, 102309. [Google Scholar] [CrossRef]

- Uribe, I.O.; Mosquera-Corral, A.; Rodicio, J.L.; Esplugas, S. Advanced technologies for water treatment and reuse. AIChE J. 2015, 61, 3146–3158. [Google Scholar] [CrossRef]

- Peleka, E.N.; Gallios, G.P.; Matis, K.A. A perspective on flotation: A review. J. Chem. Technol. Biotechnol. 2018, 93, 615–623. [Google Scholar] [CrossRef]

- Bürger, R.; Diehl, S.; Martí, M.C.; Vásquez, Y. Simulation and control of dissolved air flotation and column froth flotation with simultaneous sedimentation. Water Sci. Technol. 2020, 81, 1723–1732. [Google Scholar] [CrossRef]

- Grzegorzek, M.; Wartalska, K.; Kaźmierczak, B. Review of water treatment methods with a focus on energy consumption. Int. Commun. Heat Mass Transf. 2023, 143, 106674. [Google Scholar] [CrossRef]

- Lu, Y.; Zhang, F.; Zhang, Y.; Hu, K.; Wang, S. Research of oily wastewater treatment by micro-bubble flotation experimental device. In Proceedings of the 2016 International Field Exploration and Development Conference (IFEDC), Beijing, China, 11–12 August 2016. [Google Scholar] [CrossRef]

- Wang, J.; Park, H.; Ng, C.Y.; Wang, L. Use of oscillatory air supply for improving the throughput and carrying capacity of column flotation. Powder Technol. 2019, 353, 41–47. [Google Scholar] [CrossRef]

- Coterio, R.V.A. Optimization of Air-injection Spargers for Column Flotation Applications. Master’s Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2016. [Google Scholar]

- Harbort, G.; Clarke, D. Fluctuations in the popularity and usage of flotation columns—An overview. Miner. Eng. 2017, 100, 17–30. [Google Scholar] [CrossRef]

- Li, M.; Hu, K.; Wang, J. Study on optimal conditions of flocculation in deinking wastewater treatment. J. Eng. Appl. Sci. 2021, 68, 35. [Google Scholar] [CrossRef]

- Santos, M.A.; Capponi, F.; Ataíde, C.H.; Barrozo, M.A. Wastewater treatment using DAF for process water reuse in apatite flotation. J. Clean. Prod. 2021, 308, 127285. [Google Scholar] [CrossRef]

- Bakar, S.N.H.A.; Hasan, H.A.; Abdullah, S.R.S.; Kasan, N.A.; Muhamad, M.H.; Kurniawan, S.B. A review of the production process of bacteria-based polymeric flocculants. J. Water Process Eng. 2021, 40, 101915. [Google Scholar] [CrossRef]

- Li, H.; Wu, S.; Du, C.; Zhong, Y.; Yang, C. Preparation, performances, and mechanisms of microbial flocculants for wastewater treatment. Int. J. Environ. Res. Public Health 2020, 17, 1360. [Google Scholar] [CrossRef]

- Chen, X.; Kong, F.; Fu, Y.; Si, C.; Fatehi, P. Improvements on activated sludge settling and flocculation using biomass-based fly ash as activator. Sci. Rep. 2019, 9, 14590. [Google Scholar] [CrossRef]

- Bezawada, J.; Hoang, N.V.; More, T.T.; Yan, S.; Tyagi, N.; Tyagi, R.D.; Surampalli, R.Y. Production of extracellular polymeric substances (EPS) by Serratia sp. 1 using wastewater sludge as raw material and flocculation activity of the EPS produced. J. Environ. Manag. 2013, 128, 83–91. [Google Scholar] [CrossRef]

- Basuvaraj, M.; Fein, J.; Liss, S.N. Protein and polysaccharide content of tightly and loosely bound extracellular polymeric substances and the development of a granular activated sludge floc. Water Res. 2015, 82, 104–117. [Google Scholar] [CrossRef]

- Vasseghian, Y.; Ahmadi, M.; Joshaghani, M. Ultrasound assisted ash and sulphur removal from bitumen using column flotation technique: Experimental, RSM and ANN methods in modelling and optimization of process. Iran. J. Sci. Technol. Trans. A Sci. 2017, 41, 1149–1163. [Google Scholar] [CrossRef]

- Bedekovic, G. A study of the effect of operating parameters in column flotation using experimental design. Physicochem. Probl. Miner. 2016, 52, 523–535. [Google Scholar]

- Sakr, M.; Mohamed, M.M.; Maraqa, M.A.; Hamouda, M.A.; Hassan, A.A.; Ali, J.; Jung, J. A critical review of the recent developments in micro–nano bubbles applications for domestic and industrial wastewater treatment. Alex. Eng. J. 2022, 61, 6591–6612. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R.J.P.M. An overview on 3D printing technology: Technological, materials, and applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Ramya, A.; Vanapalli, S.L. 3D printing technologies in various applications. Int. J. Mech. Eng. Technol. 2016, 7, 396–409. [Google Scholar]

- Kamran, M.; Saxena, A. A comprehensive study on 3D printing technology. MIT Int. J. Mech. Eng. 2016, 6, 63–69. [Google Scholar]

- Sahana, V.W.; Thampi, G.T. 3D printing technology in industry. In Proceedings of the 2018 2nd International Conference on Inventive Systems and Control (ICISC), Coimbatore, India, 19–20 January 2018. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. On the environmental impacts of 3D printing technology. Appl. Mater. Today 2020, 20, 100689. [Google Scholar] [CrossRef]

- Jiménez, M.; Romero, L.; Domínguez, I.A.; Espinosa, M.D.M.; Domínguez, M. Additive manufacturing technologies: An overview about 3D printing methods and future prospects. Complexity 2019, 2019, 9656938. [Google Scholar] [CrossRef]

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Dlangamandla, C. Bioflocculant Dissolved Air Flotation System for the Reduction of suspended Solids-Lipids-Proteinaceous matter from Poultry Slaughterhouse Wastewater. Master’s Thesis, Cape Peninsula University of Technology, Cape Town, South Africa, 2016. [Google Scholar]

- Del Nery, V.; De Nardi, I.R.; Damianovic, M.H.R.Z.; Pozzi, E.; Amorim, A.K.B.; Zaiat, M. Long-term operating performance of a poultry slaughterhouse wastewater treatment plant. Resour. Conserv. Recycl. 2007, 50, 102–114. [Google Scholar] [CrossRef]

- Mukandi, M. Modelling of a Bioflocculant Supported Dissolved Air Flotation System for Fats Oil and Grease Laden Wastewater Pretreatment. Master’s Thesis, Cape Peninsula University of Technology, Cape Town, South Africa, 2017. [Google Scholar]

- Tetteh, E.K.; Rathilal, S. Evaluation of the coagulation floatation process for industrial mineral oil wastewater treatment using response surface methodology (RSM). Int. J. Environ. Impacts 2018, 1, 491–502. [Google Scholar] [CrossRef][Green Version]

- Hamza, M.; Abbas, N.; Asghar, A.; Iqbal, J. Evaluation and Optimization of Synthesized Poly (acrylamide-co-acrylic acid) for Tannery Wastewater Treatment via RSM. Arab. J. Sci. Eng. 2023, 49, 231–259. [Google Scholar] [CrossRef]

- Gupta, A.; Kumar, M.; Sharma, R.; Tripathi, R.; Kumar, V.; Thakur, I.S. Screening and characterization of bioflocculant isolated from thermotolerant Bacillus sp. ISTVK1 and its application in wastewater treatment. Environ. Technol. Innov. 2023, 30, 103135. [Google Scholar] [CrossRef]

- Agunbiade, M.; Oladipo, B.; Ademakinwa, A.N.; Awolusi, O.; Adesiyan, I.M.; Oyekola, O.; Ololade, O.; Ojo, A. Bioflocculant produced by Bacillus velezensis and its potential application in brewery wastewater treatment. Sci. Rep. 2022, 12, 10945. [Google Scholar] [CrossRef] [PubMed]

- de Sena, R.F.; Moreira, R.F.; José, H.J. Comparison of coagulants and coagulation aids for treatment of meat processing wastewater by column flotation. Bioresour. Technol. 2008, 99, 8221–8225. [Google Scholar] [CrossRef] [PubMed]

- Sheng, G.P.; Yu, H.Q.; Li, X.Y. Extracellular polymeric substances (EPS) of microbial aggregates in biological wastewater treatment systems: A review. Biotechnol. Adv. 2010, 28, 882–894. [Google Scholar] [CrossRef] [PubMed]

- Badireddy, A.R.; Chellam, S.; Gassman, P.L.; Engelhard, M.H.; Lea, A.S.; Rosso, K.M. Role of extracellular polymeric substances in bioflocculation of activated sludge microorganisms under glucose-controlled conditions. Water Res. 2010, 44, 4505–4516. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Klai, N.; Nguyen, T.D.; Tyagi, R.D. Impact of extraction methods on bio-flocculants recovered from backwashed sludge of bio-filtration unit. J. Environ. Manag. 2016, 180, 344–350. [Google Scholar] [CrossRef] [PubMed]

- Bolto, B.; Xie, Z. The use of polymers in the flotation treatment of wastewater. Processes 2019, 7, 374. [Google Scholar] [CrossRef]

- Ansari, S.; Alavi, J.; Yaseen, Z.M. Performance of full-scale coagulation-flocculation/DAF as a pre-treatment technology for biodegradability enhancement of high strength wastepaper-recycling wastewater. Environ. Sci. Pollut. Res. 2018, 25, 33978–33991. [Google Scholar] [CrossRef]

- Mulu, A.; Ayenew, T. Characterization of abattoir wastewater and evaluation of the effectiveness of the wastewater treatment systems in Luna and Kera Abattoirs in Central Ethiopia. Int. J. Sci. Eng. Res. 2015, 6, 1026–1040. [Google Scholar]

| Parameter | Average |

|---|---|

| pH | 6.64 |

| COD | 2017.62 mg/L |

| Turbidity | 449.87 NTU |

| Suspended solids | 836.15 mg/L |

| Protein | 370.68 µg/mL |

| Factor 1 | Factor 2 | Factor 3 | |

|---|---|---|---|

| Run | A: Feed Flow Rate (mL/min) | B: Diffuser (Type) | C: Bioflocculants (Appendage Type) |

| 1 | 1.26 | Moulded | Cell bound |

| 2 | 1.37 | 3D printed | Cell bound |

| 3 | 1.26 | 3D printed | Cell free |

| 4 | 1.00 | 3D printed | Cell bound |

| 5 | 1.00 | Moulded | Cell bound |

| 6 | 1.00 | Moulded | Cell free |

| 7 | 1.00 | 3D printed | Cell free |

| 8 | 1.74 | Moulded | Cell free |

| 9 | 2.00 | Moulded | Cell bound |

| 10 | 1.74 | Moulded | Cell free |

| 11 | 2.00 | 3D printed | Cell free |

| 12 | 1.73 | 3D printed | Cell bound |

| 13 | 2.00 | 3D printed | Cell free |

| 14 | 1.37 | Moulded | Cell free |

| 15 | 1.26 | Moulded | Cell bound |

| 16 | 2.00 | 3D printed | Cell bound |

| 17 | 2.00 | Moulded | Cell bound |

| 18 | 1.26 | 3D printed | Cell free |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mukandi, M.R.; Basitere, M.; Ntwampe, S.K.O.; Njoya, M.; Chidi, B.S.; Dlangamandla, C.; Mpongwana, N. Evaluation of Selected Operating Process Variables for a Bioflocculant Supported Column Flotation System. Water 2024, 16, 329. https://doi.org/10.3390/w16020329

Mukandi MR, Basitere M, Ntwampe SKO, Njoya M, Chidi BS, Dlangamandla C, Mpongwana N. Evaluation of Selected Operating Process Variables for a Bioflocculant Supported Column Flotation System. Water. 2024; 16(2):329. https://doi.org/10.3390/w16020329

Chicago/Turabian StyleMukandi, Melody R., Moses Basitere, Seteno K. O. Ntwampe, Mahomet Njoya, Boredi S. Chidi, Cynthia Dlangamandla, and Ncumisa Mpongwana. 2024. "Evaluation of Selected Operating Process Variables for a Bioflocculant Supported Column Flotation System" Water 16, no. 2: 329. https://doi.org/10.3390/w16020329

APA StyleMukandi, M. R., Basitere, M., Ntwampe, S. K. O., Njoya, M., Chidi, B. S., Dlangamandla, C., & Mpongwana, N. (2024). Evaluation of Selected Operating Process Variables for a Bioflocculant Supported Column Flotation System. Water, 16(2), 329. https://doi.org/10.3390/w16020329