Scour Effect on the Lateral Bearing Behaviour of Monopiles Considering Different Slenderness Ratios

Abstract

1. Introduction

2. Centrifuge Tests

2.1. Model Pile and Soil Characterisation

2.2. Centrifuge Loading Technique

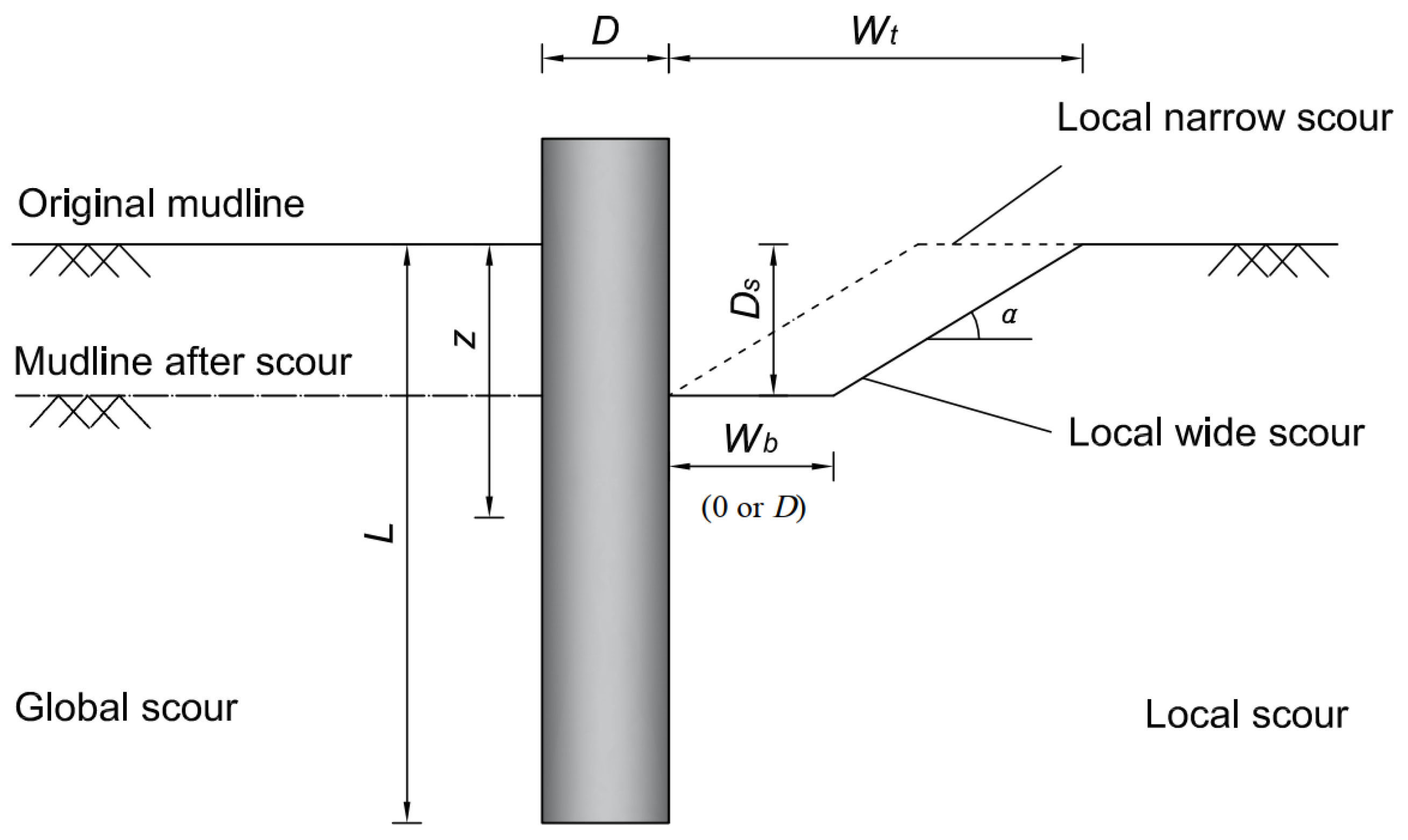

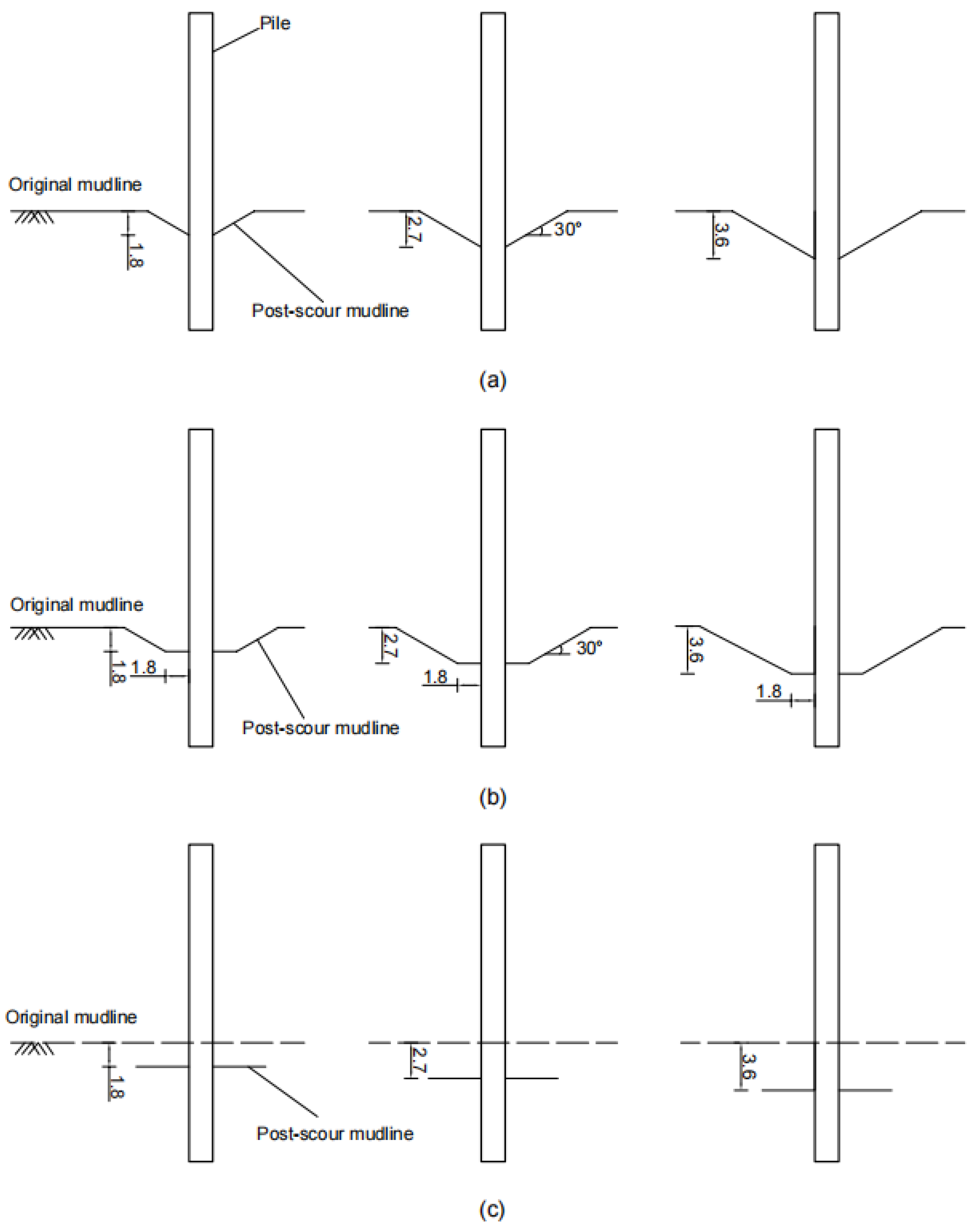

2.3. Scour Hole Formation and Testing Programme

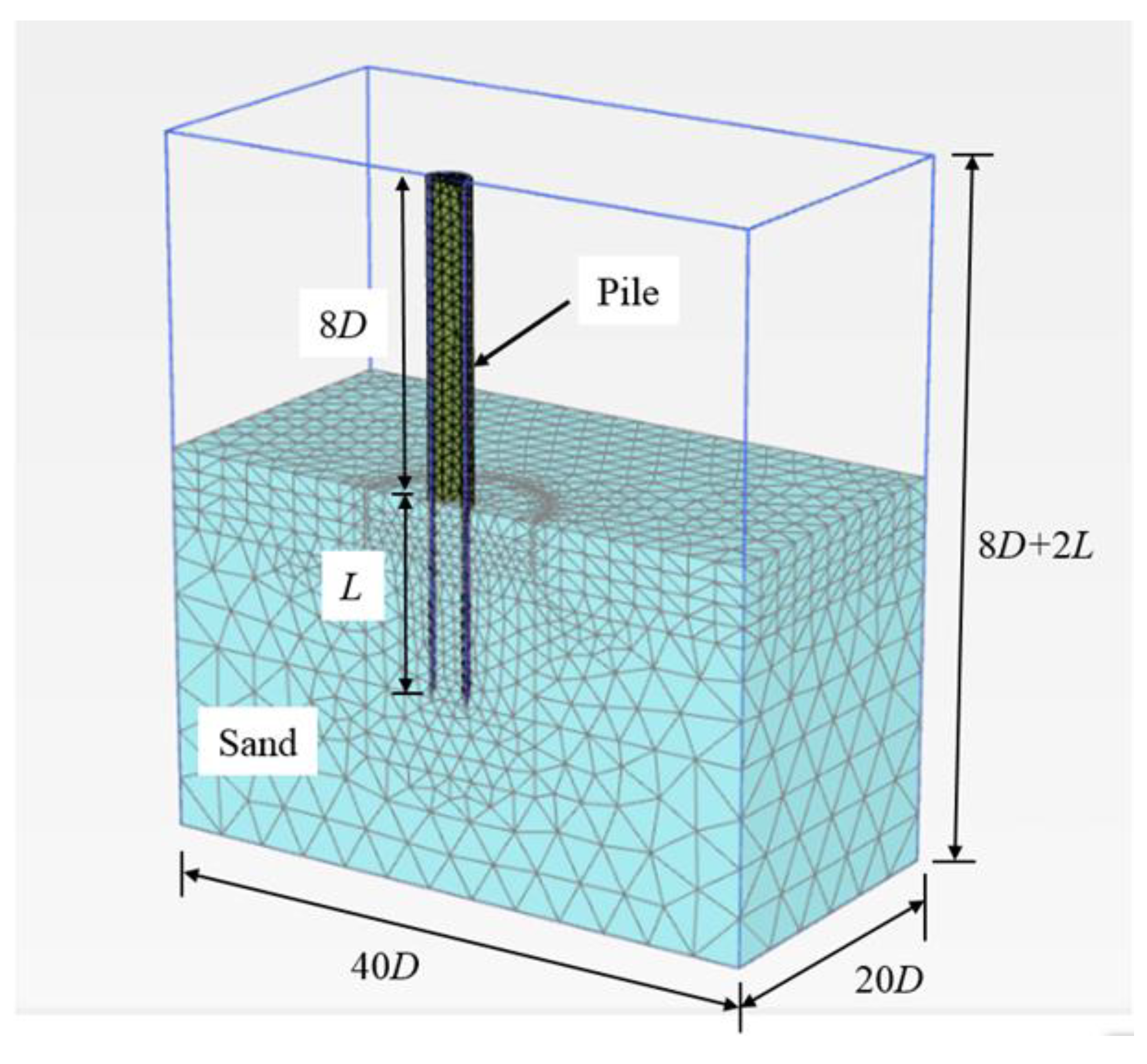

3. Finite Element Analysis

3.1. Mesh Details

3.2. Material Properties

3.3. Modelling of Scour and Parametric Case Studies

4. Analysis and Results

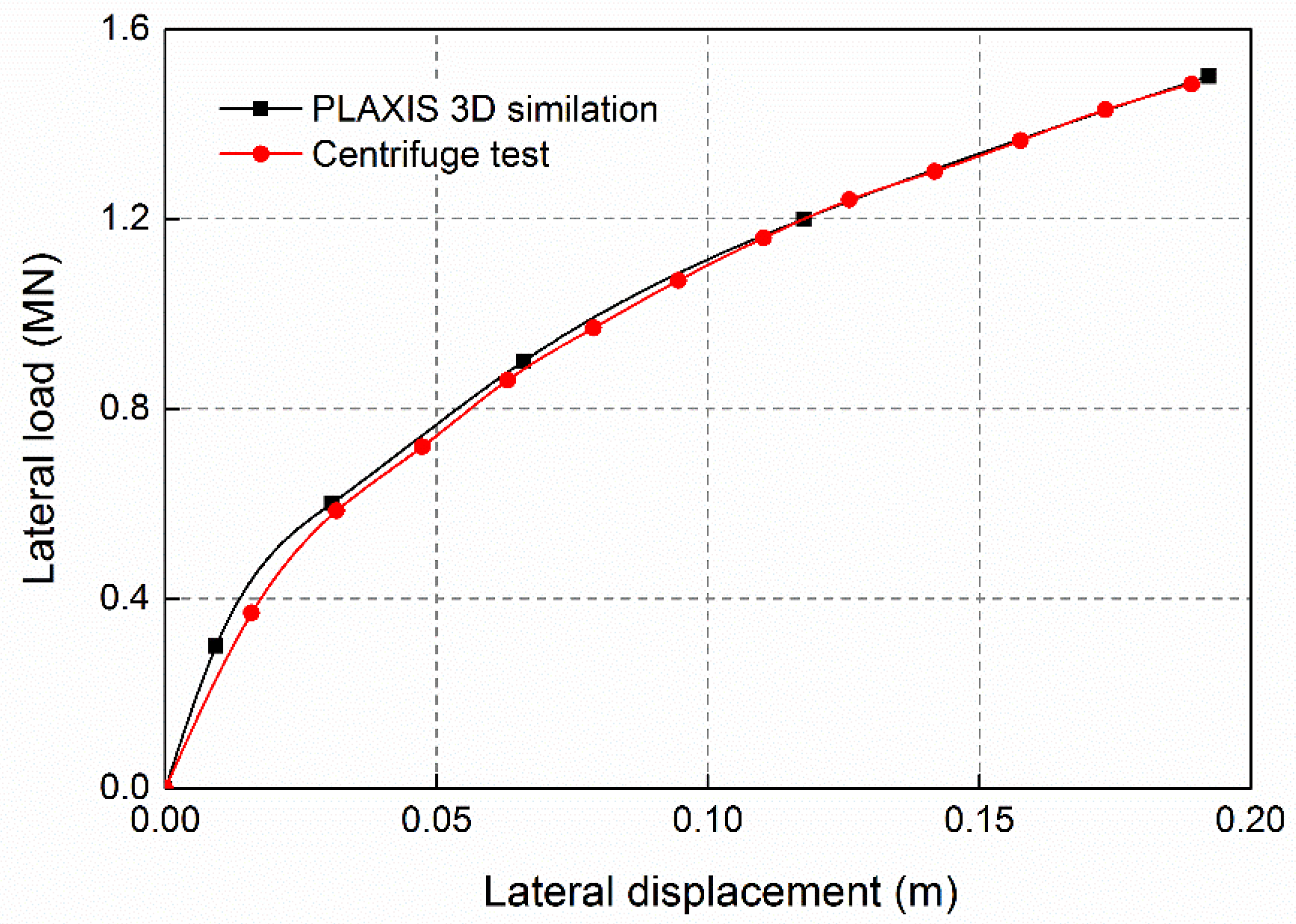

4.1. Model Calibration

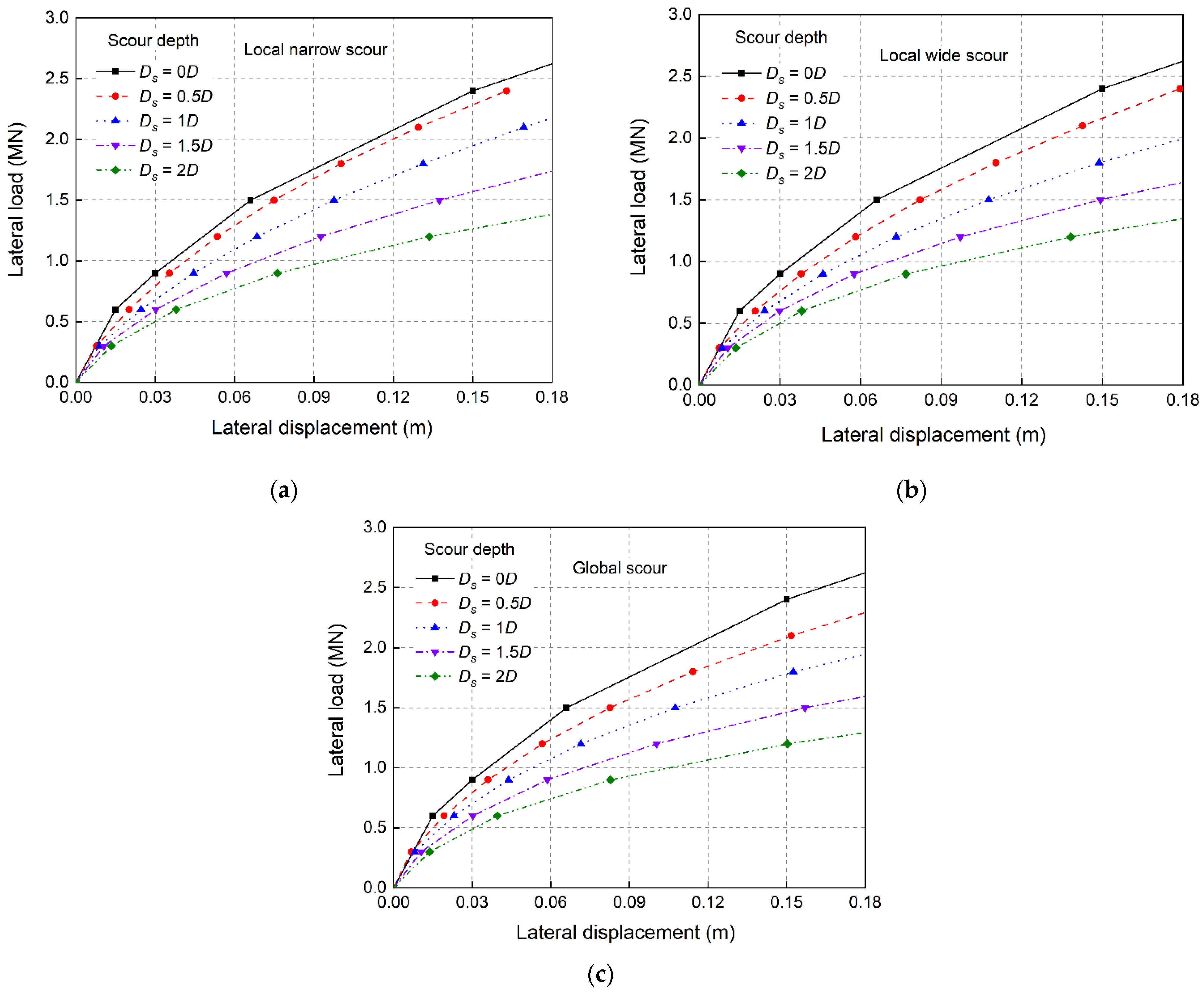

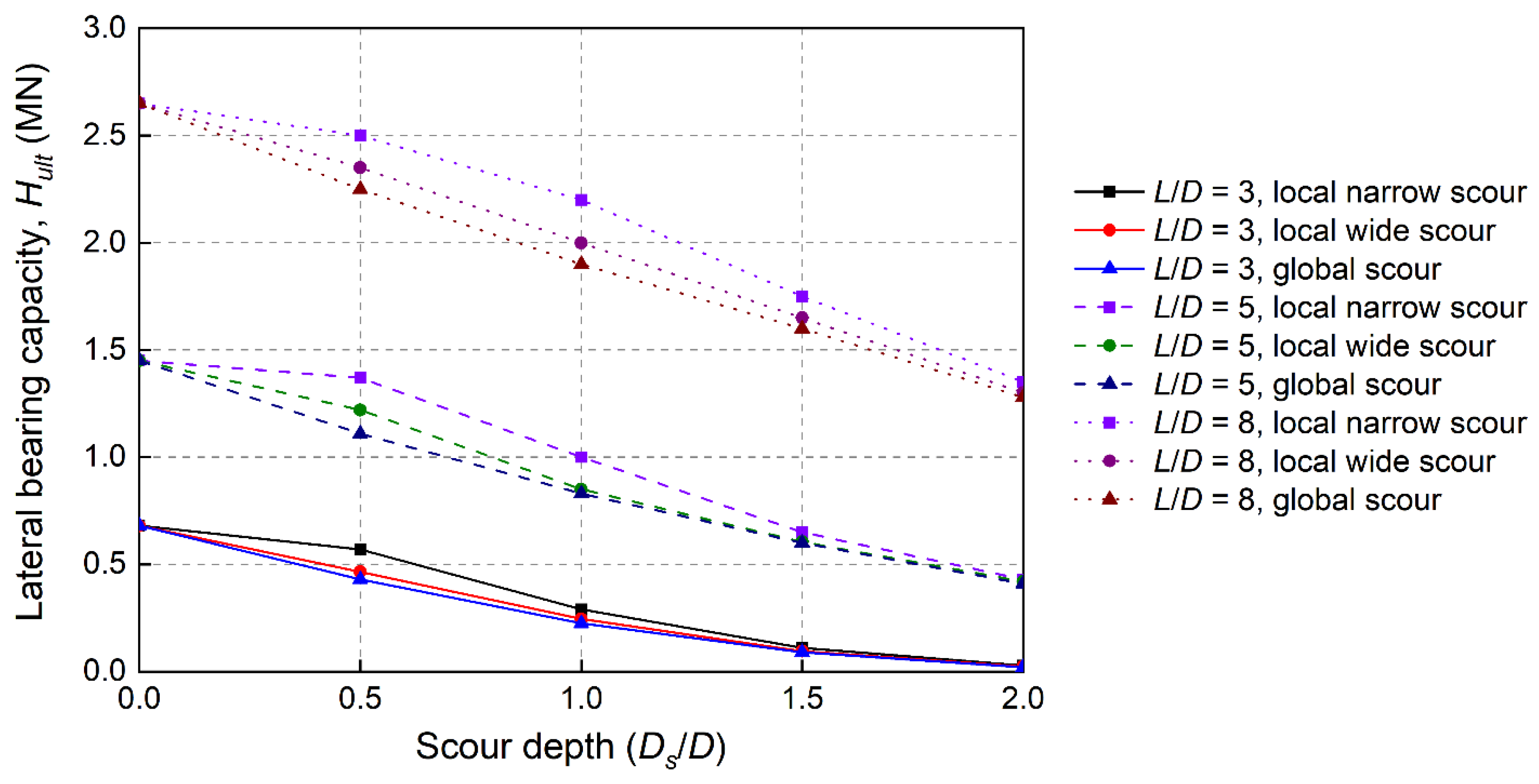

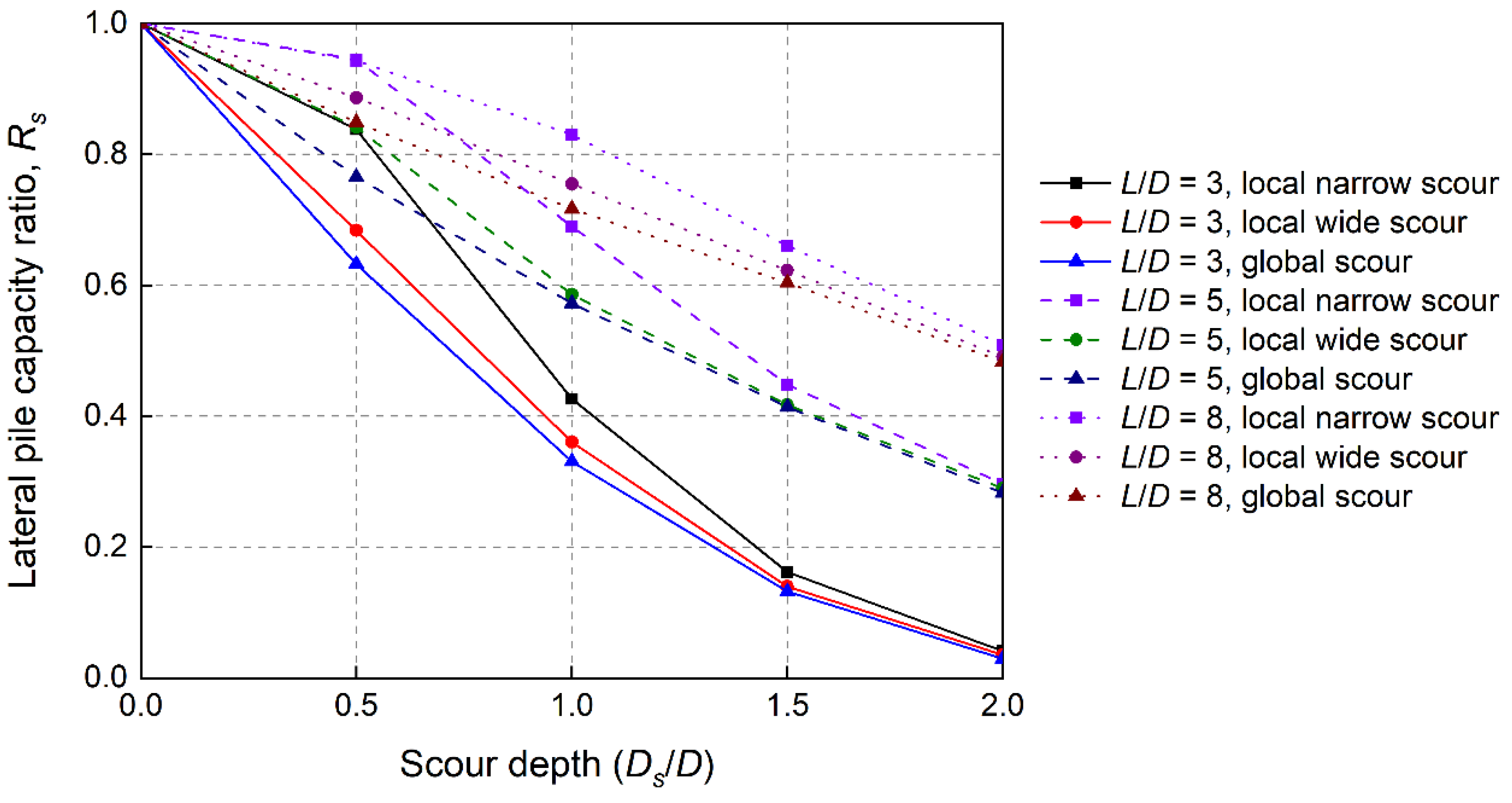

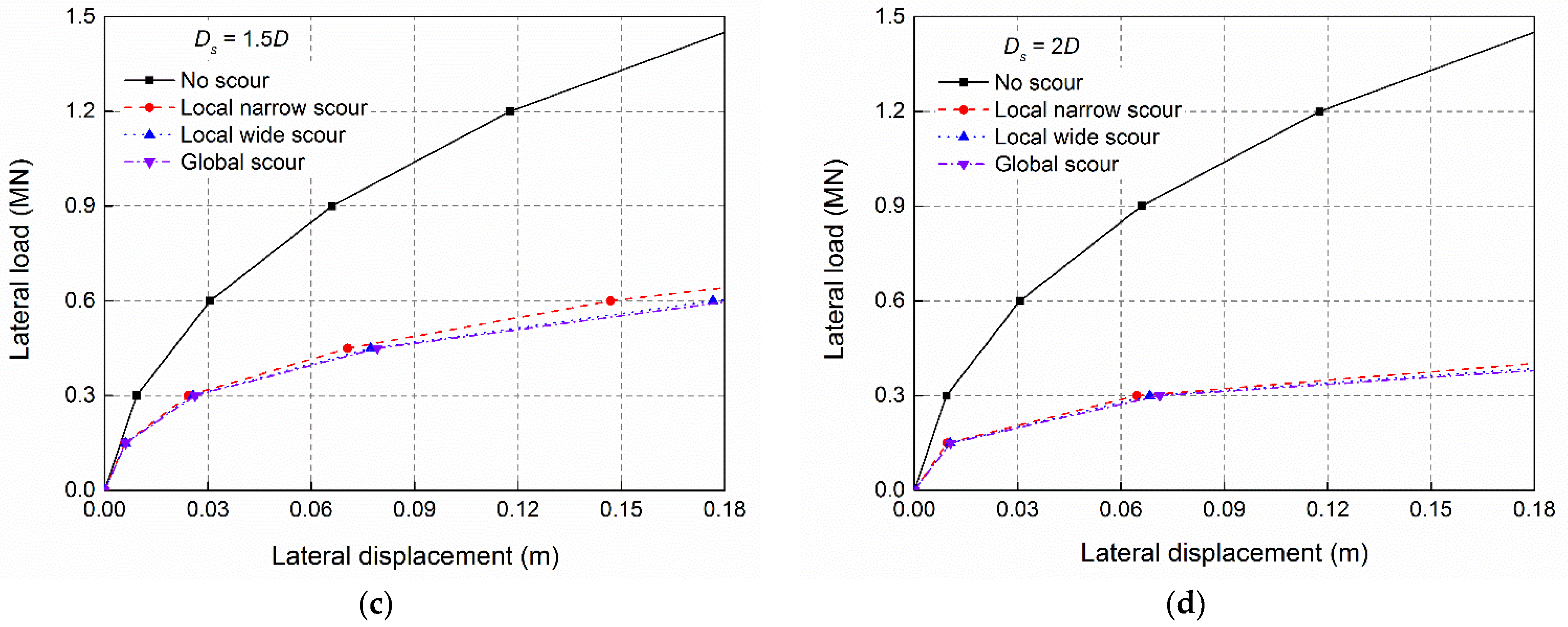

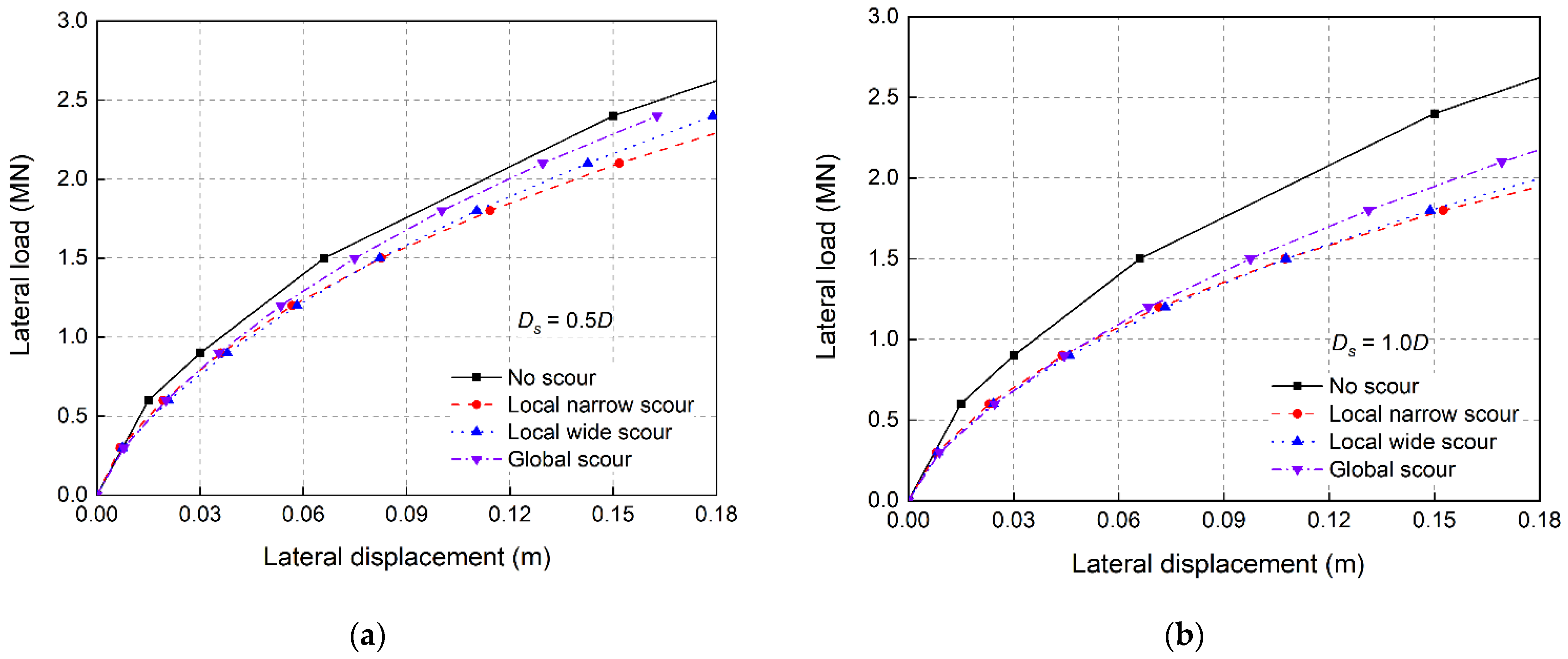

4.2. Effect of Scour Depth

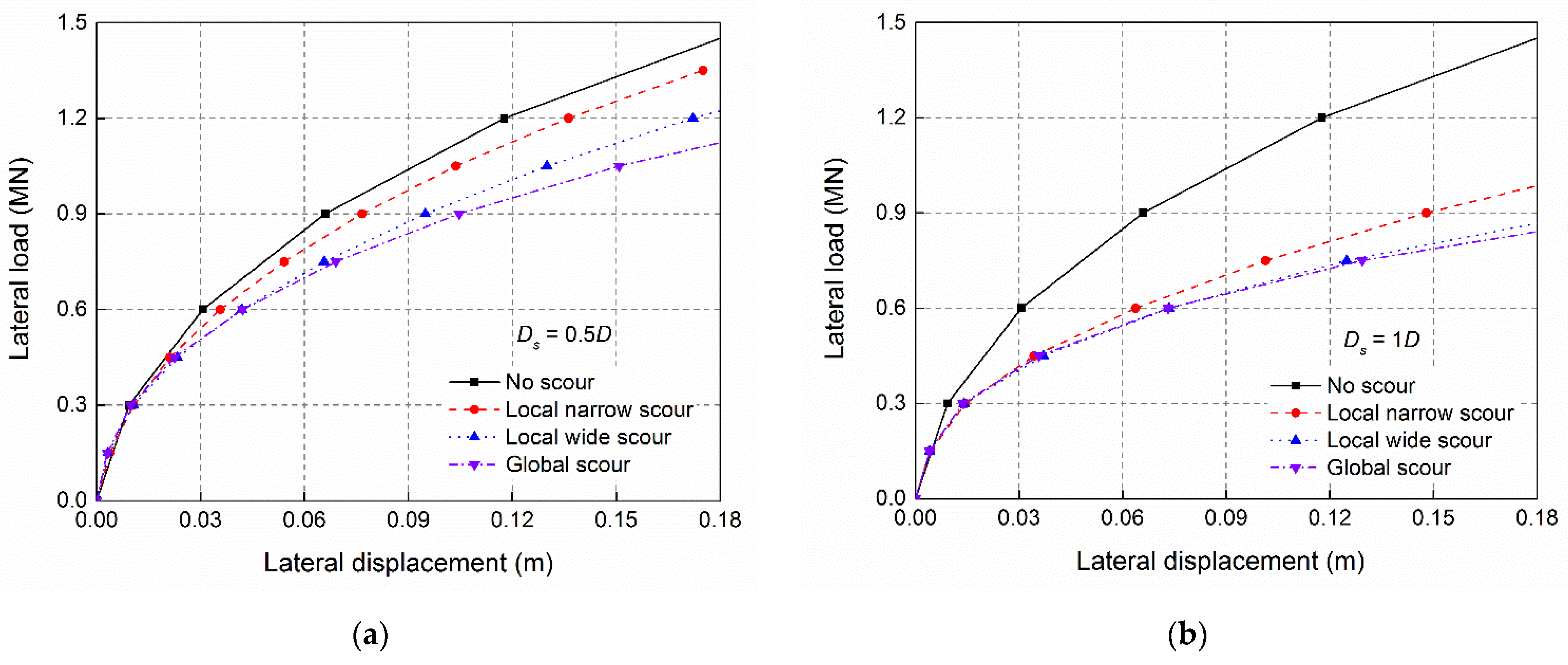

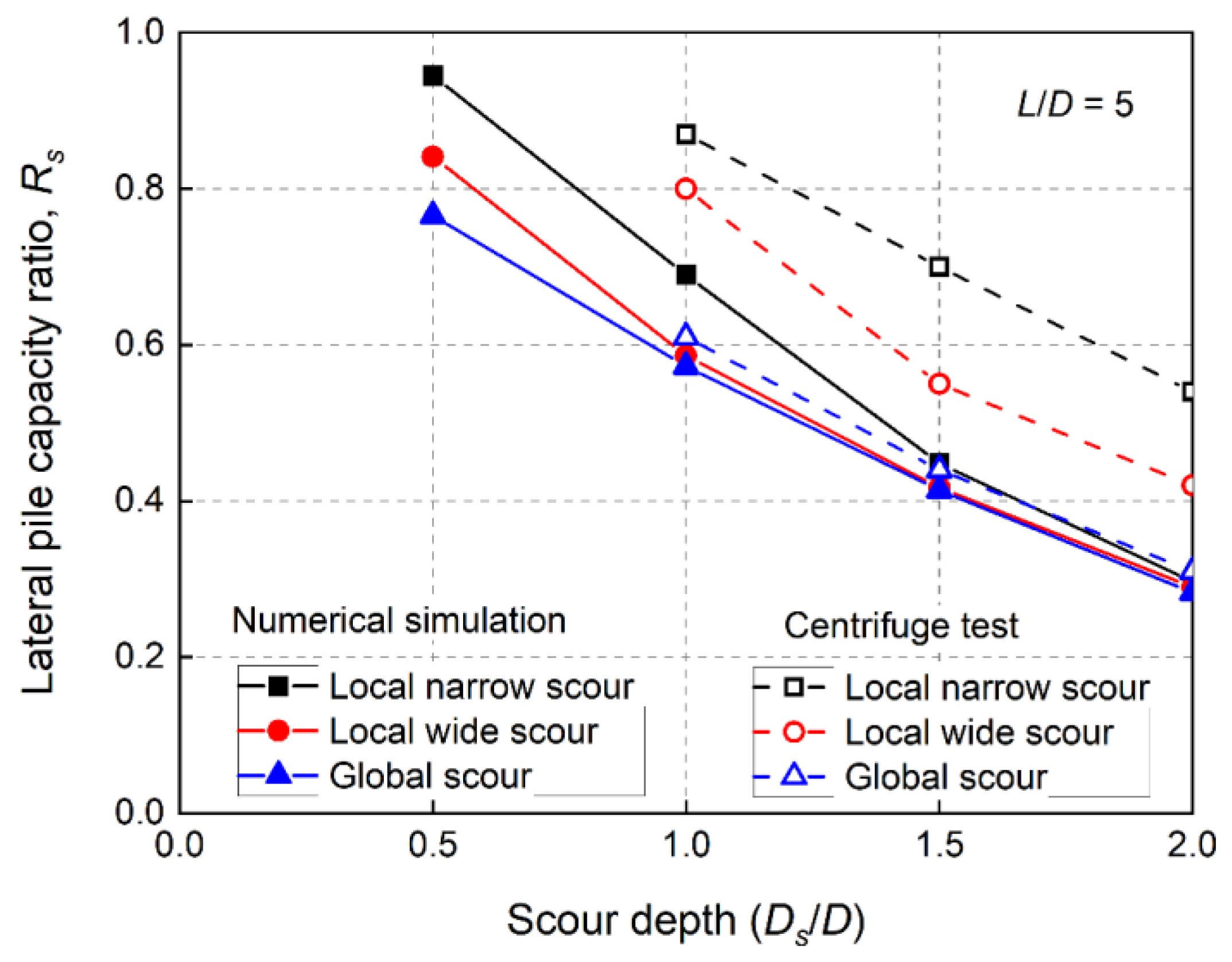

4.3. Effect of Scour Type

4.4. Comparison between Centrifuge Tests and Finite Element Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| CC | curvature coefficient |

| CU | uniformity coefficient |

| (effective) cohesion | |

| D | pile outer diameter |

| D50 | average grain size |

| Ds | scour depth |

| E | elasticity modulus |

| secant stiffness for CD triaxial test | |

| tangent oedometer stiffness | |

| unloading–reloading stiffness | |

| e | loading eccentricity |

| emax | maximum void ratio of sand |

| emin | minimum void ratio of sand |

| EI | bending stiffness |

| Gs | specific gravity |

| g | gravitational acceleration rate |

| H | lateral load |

| Hn | lateral bearing capacity without the influence of scour |

| Hs | lateral bearing capacity under the influence of scour |

| Hult | lateral bearing capacity |

| I | moment of inertia |

| -value for normal consolidation | |

| L | pile embedded length |

| m | power of stress-level dependency of stiffness |

| p | soil reaction |

| reference stress for stiffness | |

| R0 | distance from the pivot point to the toe of the pile |

| failure ratio | |

| Rs | lateral pile capacity ratio considering the effect of scour |

| RD | relative density |

| t | pile wall thickness |

| Wb | bottom scour width |

| Wt | top scour width |

| y | lateral displacement of the pile |

| z | depth below original mudline |

| α | scour slope angle |

| θ | rotation angle of the pile |

| (effective) angle of internal friction | |

| ψ | angle of dilation |

| γ | unit weight of sand |

| ν | Poisson’s ratio |

| Poisson’s ratio for unloading–reloading | |

| EU | European Union |

| FEA | finite element analysis |

| FLS | fatigue limit state |

| HS | Hardening Soil |

| OWT | offshore wind turbine |

| ULS | ultimate limit state |

References

- Li, Q. Response of Monopiles Subjected to Combined Vertical and Lateral Loads, Lateral Cyclic Load, and Scour Erosion in Sand. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2020. [Google Scholar] [CrossRef]

- Komusanac, I.; Brindley, G.; Fraile, D.; Ramirez, L. Wind Energy in Europe. 2021 Statistics and the Outlook for 2022–2026. Technical Report. 2022. Available online: https://www.anev.org/wp-content/uploads/2022/02/220222-Stats-Outlook.pdf (accessed on 3 December 2023).

- Prendergast, L.J.; Reale, C.; Gavin, K. Probabilistic examination of the change in eigenfrequencies of an offshore wind turbine under progressive scour incorporating soil spatial variability. Mar. Struct. 2018, 57, 87–104. [Google Scholar] [CrossRef]

- Prendergast, L.J.; Gavin, K.; Doherty, P. An investigation into the effect of scour on the natural frequency of an offshore wind turbine. Ocean Eng. 2015, 101, 1–11. [Google Scholar] [CrossRef]

- Sørensen, S.P.H.; Ibsen, L.B. Assessment of foundation design for offshore monopiles unprotected against scour. Ocean Eng. 2013, 63, 17–25. [Google Scholar] [CrossRef]

- Tang, D.; Zhao, M. Scour Effect on Dynamic Characteristics and Responses of Offshore Wind Turbines. Comput. Model. Eng. Sci. 2020, 124, 433–457. [Google Scholar] [CrossRef]

- Zhang, F.; Dai, G.; Gong, W. Analysis solution of the lateral load response of offshore monopile foundations under asymmetric scour. Ocean Eng. 2021, 239, 109826. [Google Scholar] [CrossRef]

- Harris, J.; Whitehouse, R.; Tavouktsoglou, N.; Godinho, P. Foundation scour as a geohazard. J. Waterw. Port Coast. Ocean Eng. 2019, 6, 145. [Google Scholar] [CrossRef]

- Hucker, N.; Ward, I.; Manceau, S. Measured changes in the natural frequency of offshore wind turbines with monopile foundations. In Proceedings of the SECED: Conference in Earthquake Risk and Engineering towards a Resilient World 2019, London, UK, 9–10 September 2019. [Google Scholar]

- Mayall, R.O.; McAdam, R.A.; Whitehouse, R.J.S.; Burd, H.J.; Byrne, B.W.; Heald, S.G.; Sheil, B.B.; Slater, P.L. Flume tank testing of offshore wind turbine dynamics with foundation scour and scour protection. J. Waterw. Port Coast. Ocean Eng. 2020, 146, 04020033. [Google Scholar] [CrossRef]

- Dai, S.; Han, B.; Wang, B.; Luo, J.; He, B. Influence of soil scour on lateral behavior of large-diameter offshore wind-turbine monopile and corresponding scour monitoring method. Ocean Eng. 2021, 239, 109809. [Google Scholar] [CrossRef]

- Jiang, W.; Lin, C.; Sun, M. Seismic responses of monopile-supported offshore wind turbines in soft clays under scoured conditions. Soil Dyn. Earthq. Eng. 2021, 142, 106549. [Google Scholar] [CrossRef]

- Jiang, W.; Lin, C. Lateral responses of monopile-supported offshore wind turbines in sands under combined effects of scour and earthquakes. Soil Dyn. Earthq. Eng. 2022, 155, 107193. [Google Scholar] [CrossRef]

- Lin, Y.; Lin, C. Scour effects on lateral behavior of pile groups in sands. Ocean Eng. 2020, 208, 107420. [Google Scholar] [CrossRef]

- Chen, S.; Gong, E.; Zhao, X.; Arikawa, T.; Chen, X. Large-scale experimental study on scour around offshore wind monopiles under irregular waves. Water Sci. Eng. 2022, 15, 40–46. [Google Scholar] [CrossRef]

- Carlos, M.V.; Susana, L.Q.; Bhattacharya, S.; Simons, R. Numerical study on the effects of scour on monopile foundations for Offshore Wind Turbines: The case of Robin Rigg wind farm. Soil Dyn. Earthq. Eng. 2023, 167, 107803. [Google Scholar] [CrossRef]

- Sumer, B.M.; Fredsøe, J.; Christiansen, N. Scour around vertical pile in waves. J. Waterw. Port Coast. Ocean Eng. 1992, 118, 15–31. [Google Scholar] [CrossRef]

- Offshore Standard DNV-OS-J101 6; Design of Offshore Wind Turbine Structures. Det Norske Veritas: Bærum, Norway, 2004.

- Zaaijer, M.B.; Tempel, J. Scour protection, a necessity or a waste of money. In Proceedings of the 43 IEA Topixal Expert Meeting, Skaerbaek, Denmark, 9–10 March 2004; pp. 43–51. [Google Scholar]

- Arany, L.; Bhattacharya, S.; Macdonald, J.; Hogan, S. Design of monopiles for offshore wind turbines in 10 steps. Soil Dyn. Earthq. Eng. 2017, 92, 126–152. [Google Scholar] [CrossRef]

- Tempel, J.; Zaaijer, M.B.; Subroto, H. The effects of scour on the design of offshore wind turbines. In Proceedings of the 3rd International Conference on Marine Renewable Energy, London, UK, 7–9 July 2004; pp. 27–35. [Google Scholar]

- Li, Q.; Askarinejad, A.; Gavin, K. The impact of scour on the lateral resistance of wind turbine monopiles: An experimental study. Can. Geotech. J. 2020, 58, 1770–1782. [Google Scholar] [CrossRef]

- Li, Y.; Chen, X.; Fan, S.; Briaud, J.L.; Chen, H.C. Is scour important for pile foundation design in deepwater? In Proceedings of the 2009 Offshore Technology Conference, Houston, TX, USA, 4–7 May 2009; pp. 1–12. [Google Scholar]

- Lin, C.; Bennett, C.; Han, J.; Parsons, R.L. Scour effects on the response of laterally loaded piles considering stress history of sand. Comput. Geotech. 2010, 37, 1008–1014. [Google Scholar] [CrossRef]

- Achmus, M.; Kuo, Y.S.; Abdel-Rahman, K. Numerical investigation of scour effect on lateral resistance of windfarm monopiles. In Proceedings of the 20th International Offshore and Polar Engineering Conference, Beijing, China, 20–25 June 2010; pp. 619–623. [Google Scholar]

- Mostafa, Y.E. Effect of local and global scour on lateral response of single piles in different soil conditions. Engineering 2012, 4, 297–306. [Google Scholar] [CrossRef]

- Li, F.; Han, J.; Lin, C. Effect of scour on the behavior of laterally loaded single piles in marine clay. Mar. Georesour. Geotechnol. 2013, 31, 271–289. [Google Scholar] [CrossRef]

- Brinkgreve, R.; Kumarswam, S.; Swolfs, W. Plaxis 3D Anniversary Edition Manual; Plaxis bv.: Delft, The Netherlands, 2015. [Google Scholar]

- Maghsoudloo, A.; Askarinejad, A.; Jager, R.R.D.; Molenkamp, F.; Hicks, M. Experimental investigation of pore pressure and acceleration development in static liquefaction induced failures in submerged slopes. In Proceedings of the 9th International Conference of Physical Modelling in Geotechnics, London, UK, 17–20 July 2018. [Google Scholar]

- Roulund, A.; Sumer, B.M.; Fredsøe, J.; Michelsen, J. Numerical and experimental investigation of flow and scour around a circular pile. J. Fluid Mech. 2005, 534, 351–401. [Google Scholar] [CrossRef]

- Hoffmans, G.J.; Verheij, H.J. Scour Manual; CRC Press: Boca Raton, FL, USA, 1997. [Google Scholar]

- Schanz, T. Zur Modellierung des Mechanischen Verhaltens von Reibungsmaterialen. Ph.D. Thesis, Stuttgart University, Stuttgart, Germany, 1998. (In German). [Google Scholar]

- Kondner, R.L. Hyperbolic stress-strain response: Cohesive soils. ASCE J. Soil Mech. Found. 1963, 89, 115–143. [Google Scholar] [CrossRef]

- Duncan, J.M.; Chang, C.Y. Nonlinear analysis of stress and strain insoils. ASCE J. Soil Mech. Found. 1970, 96, 1629–1653. [Google Scholar] [CrossRef]

- Brinkgreve, R.; Engin, E.; Engin, H.K. Validation of empirical formulas to derive model parameters for sands. In Proceedings of the 7th NUMGE 2010, Trodheim, Norway, 2–4 June 2010. [Google Scholar]

- JGS 0162-2009; Tests for Physical Properties: Test Methods for Minimum and Maximum Densities of Sands. The Japanese Geotechnical Society: Tokyo, Japan, 2010; pp. 162–170.

- Kishore, Y.N.; Rao, S.N.; Mani, J. Influence of the scour on laterally loaded piles. In Proceedings of the 12th International Conference of International Association for Computer Methods and Advances in Geomechanics, Goa, India, 1–6 October 2008; pp. 3283–3288. [Google Scholar]

| Property | Model Pile | Prototype Pile |

|---|---|---|

| Length (embedded + load eccentricity) | 90 + 144 mm | 9 + 14.4 m |

| Diameter, outer | 18 mm | 1.8 m |

| Wall thickness | 1 mm | 30 mm |

| Elasticity modulus (E) | 70 GPa | 210 GPa |

| Moment of inertia (I) | 1936 mm4 | 0.065 m4 |

| Bending stiffness (EI) | 0.137 kPa·m4 | 13.7 GPa·m4 |

| Material | aluminium | steel (assumed) |

| emin | emax | Gs | D50 (mm) | CU | CC |

|---|---|---|---|---|---|

| 0.64 | 1.07 | 2.67 | 0.11 | 1.55 | 1.24 |

| No. | Materials - | Outer Diameter/D m | Length/L m | L/D Ratio - | Wall Thickness/t mm |

|---|---|---|---|---|---|

| 1 | Steel | 1.8 | 5.4 | 3 | 30 |

| 2 | Steel | 1.8 | 9 | 5 | 30 |

| 3 | Steel | 1.8 | 14.4 | 8 | 30 |

| Parameter | Name | Brinkgreve et al. [35] | After Calibration | Unit |

|---|---|---|---|---|

| Unit weight | γ | 18.2 | 15.57 (real value) | [kN/m3] |

| (Effective) cohesion | 0 (pre-defined) | 0 (pre-defined) | [kN/m2] | |

| (Effective) angle of internal friction | 38 | 34 (real value) | [°] | |

| Angle of dilation | ψ | 8 | 4 (real value) | [°] |

| Secant stiffness for CD triaxial test | 4.8 × 104 | 4.1 × 104 | [kN/m2] | |

| Tangent oedometer stiffness | 4.8 × 104 | 2.1 × 104 | [kN/m2] | |

| Unloading reloading stiffness | 1.44 × 105 | 1.23 × 105 | [kN/m2] | |

| Power of stress-level dependency of stiffness | m | 0.45 | 0.5 | [-] |

| Poisson’s ratio for unloading–reloading | 0.2 | 0.2 | [-] | |

| Reference stress for stiffnesses | 100 | 100 | [kN/m2] | |

| Failure ratio | 0.9 | 0.9 | [-] | |

| K0-value for normal consolidation | 0.4408 | 0.4408 | [-] |

| Ds | L/D = 3 | L/D = 5 | L/D = 8 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Local Narrow | Local Wide | Global | Local Narrow | Local Wide | Global | Local Narrow | Local Wide | Global | |

| 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 0.5D | 0.838 | 0.684 | 0.632 | 0.945 | 0.841 | 0.766 | 0.943 | 0.887 | 0.849 |

| 1D | 0.426 | 0.360 | 0.331 | 0.690 | 0.586 | 0.572 | 0.830 | 0.755 | 0.717 |

| 1.5D | 0.162 | 0.140 | 0.132 | 0.448 | 0.417 | 0.414 | 0.660 | 0.623 | 0.604 |

| 2D | 0.041 | 0.035 | 0.029 | 0.297 | 0.290 | 0.283 | 0.509 | 0.491 | 0.483 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Wang, X.; Gavin, K.; Jiang, S.; Diao, H.; Wang, M.; Wang, K. Scour Effect on the Lateral Bearing Behaviour of Monopiles Considering Different Slenderness Ratios. Water 2024, 16, 226. https://doi.org/10.3390/w16020226

Li Q, Wang X, Gavin K, Jiang S, Diao H, Wang M, Wang K. Scour Effect on the Lateral Bearing Behaviour of Monopiles Considering Different Slenderness Ratios. Water. 2024; 16(2):226. https://doi.org/10.3390/w16020226

Chicago/Turabian StyleLi, Qiang, Xinquan Wang, Kenneth Gavin, Shengxiang Jiang, Hongguo Diao, Mingyuan Wang, and Kangyu Wang. 2024. "Scour Effect on the Lateral Bearing Behaviour of Monopiles Considering Different Slenderness Ratios" Water 16, no. 2: 226. https://doi.org/10.3390/w16020226

APA StyleLi, Q., Wang, X., Gavin, K., Jiang, S., Diao, H., Wang, M., & Wang, K. (2024). Scour Effect on the Lateral Bearing Behaviour of Monopiles Considering Different Slenderness Ratios. Water, 16(2), 226. https://doi.org/10.3390/w16020226