Management of Thermal Hazards in Deep Mines in China: Applications and Prospects of Mine Cooling Technology

Abstract

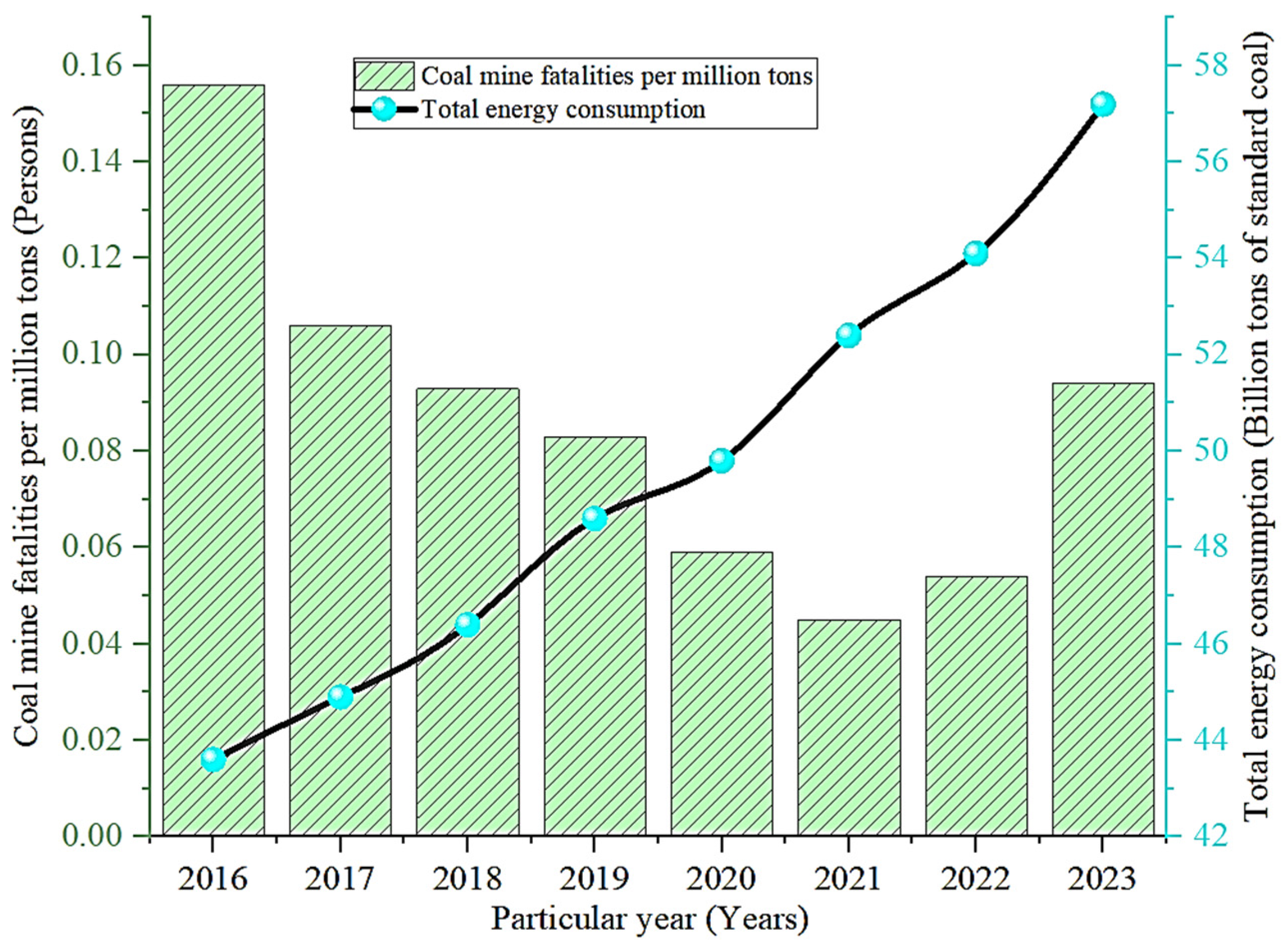

1. Introduction

2. Main Heat Sources and Damage in Mines

2.1. Main Heat Source in Mines

2.2. Influence of Mine Heat Disasters

3. Classification and Application of Mine Cooling Technology

3.1. Mechanical Cooling Technology

3.1.1. Cold Water Cooling System

- (1)

- The mine cooling water cooling system works by using chilled water and airflow from the air cooler. It consists of a refrigeration center, cooling tower, cooling water pump, air cooler, and other components. Depending on the spatial layout positions, the system can be categorized into three types: ground-centralized, underground-centralized, and underground combined. The advantage of this cold water cooling system is its adjustable design for specific mines, allowing for future expansion or transformation. With an advanced control system in place, precise temperature control can be achieved to meet the strict temperature and humidity requirements. In a ground-centralized refrigeration cooling system, the refrigeration unit is set on the ground. Through the high- and low-pressure heat exchange unit, frozen water is transported to cool the mining face via airflow. Because the refrigeration station and cooling water circulation circuit are located on the ground, the ground-centralized refrigeration and cooling system has the advantages of taking up little underground space, conveniently condensing heat emission, requiring no explosion-proof treatment, and having high safety and low investment levels. However, with increased mining depths, the distance to the roadway is extended, and the distance required to lay down the cold water circuit increases, resulting in an increased loss of cold energy. In addition, high- and low-pressure heat exchange units also experience cold energy loss.

- (2)

- The downhole-centralized refrigeration cooling system consists of an underground refrigeration station, a cooling water circulation system, and fan coils. The refrigerator is located underground and has no heat exchanger; it only utilizes a cold water circuit with a short and easy-to-maintain water supply pipeline [54]. The underground centralized refrigeration and cooling system has the advantages of short water pipelines, minimal cold loss, and a small footprint, making it suitable for small mines. As the refrigeration station is located underground, a specialized electromechanical chamber needs to be excavated, and the equipment must be waterproof and explosion-proof. This efficient, energy-saving, safe, and stable system promotes green mining development.

- (3)

- Combined centralized cooling and cooling systems for upper and lower mines: Refrigeration units are set up both on the ground and underground, and the cold water prepared by the ground refrigeration unit is transported underground for heat exchange via a first-stage cold water circulation pipeline. The underground refrigeration unit adopts the fresh air heat removal method, introducing colder air into the air-cooled cooler and exchanging heat to reduce the cooling water temperature. After the two-stage cold water cycle, it enters the refrigeration unit again to cool down [55]. This system can reduce the cooling capacity and cold energy loss of the ground centralized refrigeration station, thus addressing the difficulties the underground refrigerator faces in discharging heat. However, the equipment is scattered and costly, meaning it is only suitable for large mines.

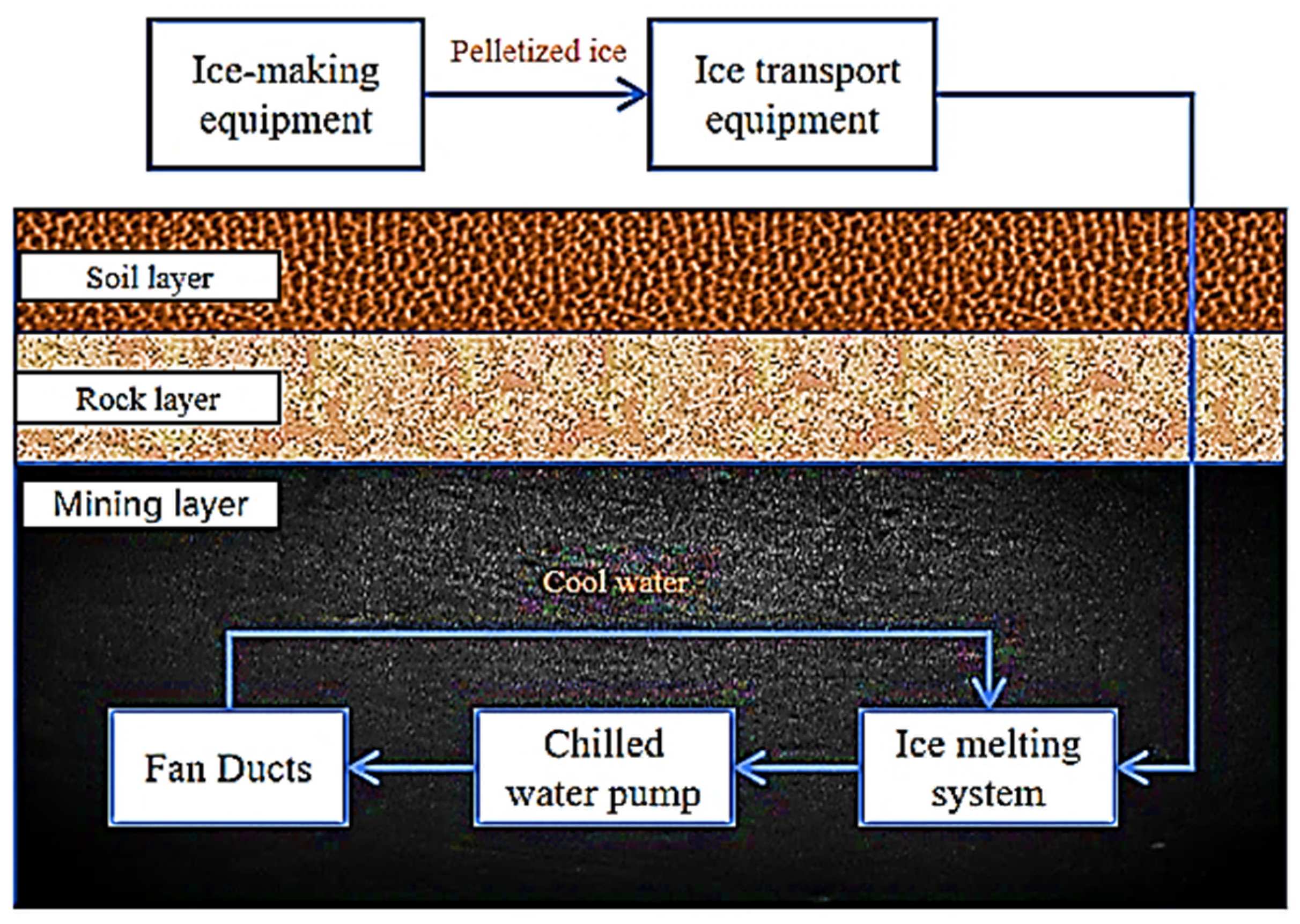

3.1.2. Ice Cooling System

3.1.3. Air Compression Refrigeration Cooling System

3.2. Other Mine-Cooling Technologies

- (1)

- Numerical simulation technology (CFD) has been widely used in recent years to analyze the thermodynamic characteristics of mine airflows and the variation law of surrounding rock temperatures [61]. This technology is used to optimize mine development modes, design better ventilation routes, shorten ventilation distances, and reduce heat release from surrounding rock. Ventilation optimization also includes airflow organization inside the mine to reduce the impact of heat generated by hot magma and equipment on the operating environment.

- (2)

- Improve and optimize the existing ventilation system, increase the ventilation volume, avoid underground high-temperature geothermal areas, and use pre-cooled airflows to control heat damage. This method requires a lot of preparatory work and easily makes the ventilation system more complex.

- (3)

- In order to reduce heat release from surrounding rock, cooling can be achieved via the filling and spraying of thermal insulation materials. However, due to the particularity of the underground environment, this method has higher requirements for the toughness and anti-viral properties of thermal insulation materials.

- (4)

- For some mines with good hydrological conditions, spraying or water injection can be considered for cooling treatments. However, it should be noted that this method may increase downhole humidity and that its cooling effect may be relatively limited.

- (5)

- Heat pipe cooling is another cooling method that transfers downhole heat to the surface through a pipe, achieving downhole cooling and dehumidification. However, the arrangement of underground heat pipes can increase the ventilation resistance, meaning the cooling capacity and conditions for use are limited.

- (6)

- Underground workers wearing cooling clothes can effectively cool their bodies; this can greatly reduce the energy consumption of refrigeration and reduce cooling costs. However, their structure is more complicated, and wearing these clothes increases the burden on the human body, reduces work efficiency, and can easily cause frostbite.

- (7)

- Using the cooling characteristics of groundwater, the heat in the mine is brought out of the ground through the groundwater circulation system, which reduces heat transfer to the roadway and the temperature of the underground environment.

3.2.1. High-Performance Mine Cooling Clothes

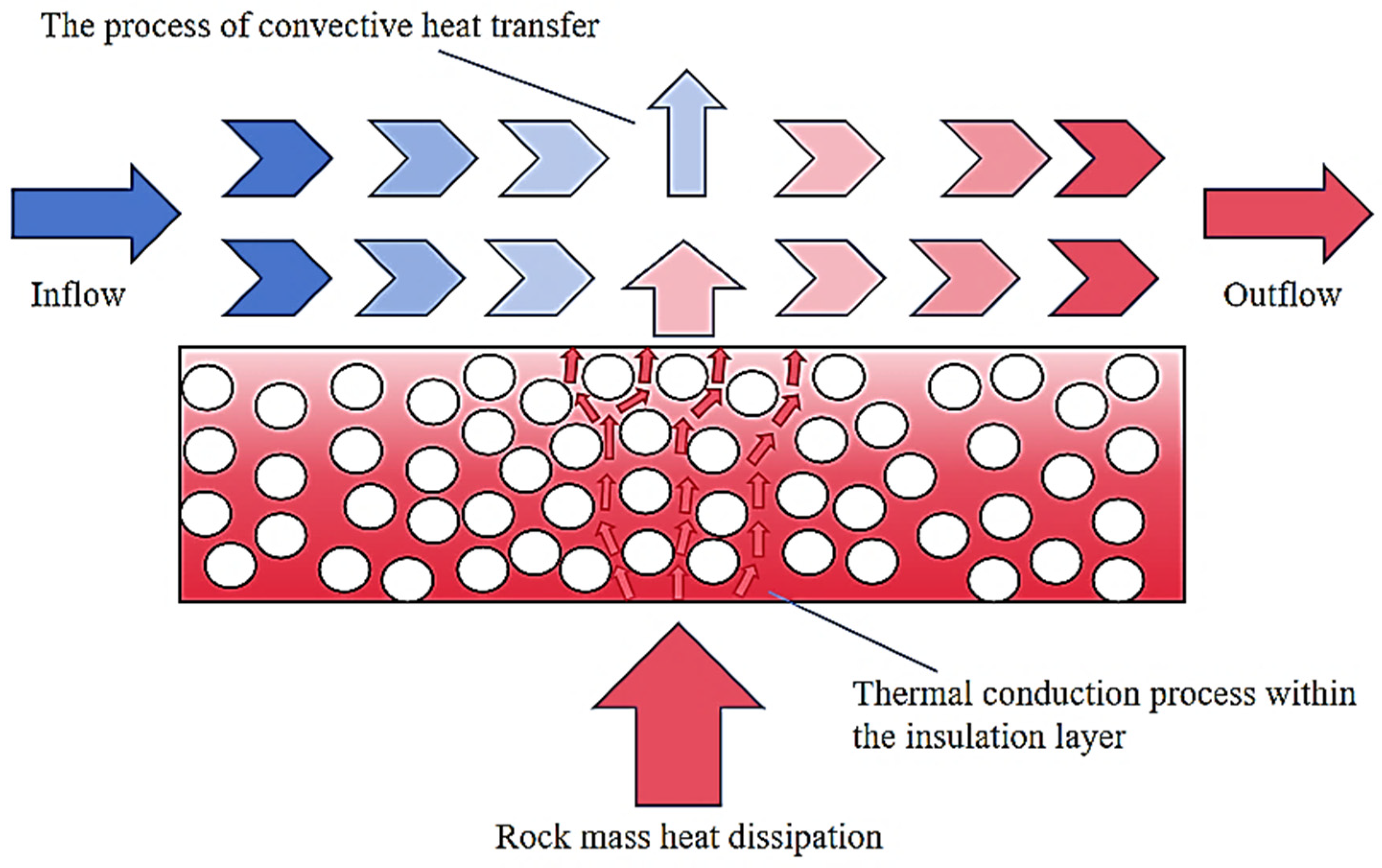

- (1)

- Air-cooled clothes: Air-cooled clothing uses air as the cooling medium in the heat transfer process between the airflow and the skin’s surface; this promotes sweat evaporation and thus achieves cooling. The most common air-cooled clothes are miniature fan-cooled and vortex-cooled. In a micro-fan cooling suit, the fan is woven into the clothing, generating airflow through its rotation to the skin’s surface. An eddy current cooling suit adopts eddy current tube-cooling technology to provide effective cooling protection for underground workers. A cooling suit uses compressed air as the cooling medium, and the cold end is tightly attached to the skin’s surface via a cold and hot separation mechanism [68]. An air-cooled suit is suitable for complex mining environments due to its simple structure, convenient operation, and taking up little space. The application of air-cooled clothing integrates the expertise of heat transfer and fluid mechanics. By regulating the gas flow and heat exchange process in the tiny space between the skin’s surface and clothing, body temperature is regulated, and thermal comfort is improved. A system diagram of the heat transfer and cooling process is shown in Figure 4.

- (2)

- Liquid-cooled clothes: These types of clothes rely on micro-pumps to cool the liquid medium. This is then transmitted to various parts of the human body through a network of in-built pipes, removing heat from the skin’s surface by convection and heat conduction. After absorbing heat, the cooling medium returns to the refrigeration device for re-cooling so that the cooling effect can be recirculated. Liquid-cooled clothing is widely used in high-temperature operations such as fire protection, mining, electricity, and transportation due to its strong cooling capacity and reliability. The disadvantage is that the refrigeration source needs to consume electric energy, and the battery needs to be replaced over time, thus proving inconvenient for underground operations [69].

- (3)

- Phase change cooling clothes: When the skin surface temperature exceeds the phase change temperature, the material will absorb heat and achieve cooling. A phase change material cooling suit uses a phase change material to absorb heat when the ambient temperature is higher than the phase change temperature [70]. Phase change cooling clothing is widely used because of its simple structure, strong cooling capacity, and low pollution levels. Although phase change materials have an excellent refrigeration effect, their temperature cannot be controlled, which means that the skin’s surface temperature can easily be supercooled. Phase change materials need to be stored cold repeatedly, and their continuous working time is short.

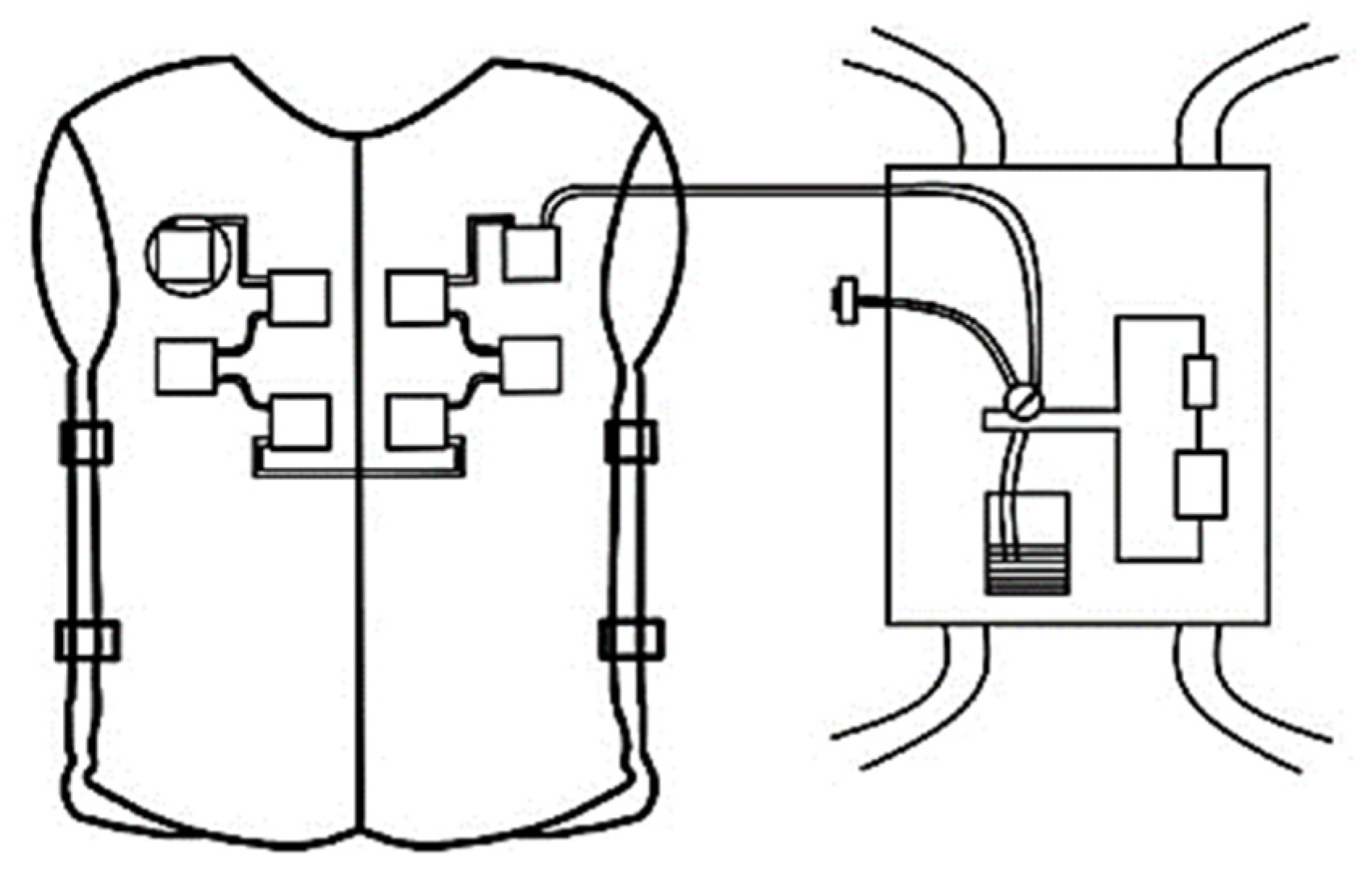

- (4)

- Semiconductor cooling clothes: Semiconductor cooling clothes are based on the principle of thermoelectric refrigeration, whereby semiconductor refrigeration sheets are applied to clothes. Multiple semiconductor refrigeration sheets are connected in a series and then connected in parallel with the water pump; this can effectively realize body cooling. Wen Hu et al. (2017) proposed a new design, skillfully stitching semiconductor materials in parallel onto basic clothing [71]. When the power supply is turned on, the cold end of the material can effectively absorb the heat of the surrounding environment, thereby achieving a cooling effect. An example of semiconductor refrigeration protective clothing is shown in Figure 5.

- (5)

- Chemical ice bag cooling clothes: Chemical ice bag cooling clothes absorb heat through the chemical reactions of an internal coolant to achieve the purpose of refrigeration. The coolant is based on ammonium nitrate, ammonium chloride, urea, and other substances in granular form. The advantage of chemical ice bag cooling clothes is that they can be used on demand without additional refrigeration equipment and are easy to operate. However, their disadvantage is that the reaction process of the chemical ice bag is irreversible, so it can only be used once and cannot be recycled. In addition, its cooling effect cannot be accurately regulated, so it is not suitable for use in extreme environments such as high-temperature mines. There are some problems in the application of existing human cooling clothing in high-temperature mine environments, such as insufficient technical maturity, short cooling efficiency, complex cooling system structures, and poor wearing comfort.

3.2.2. Roadway Insulation Materials

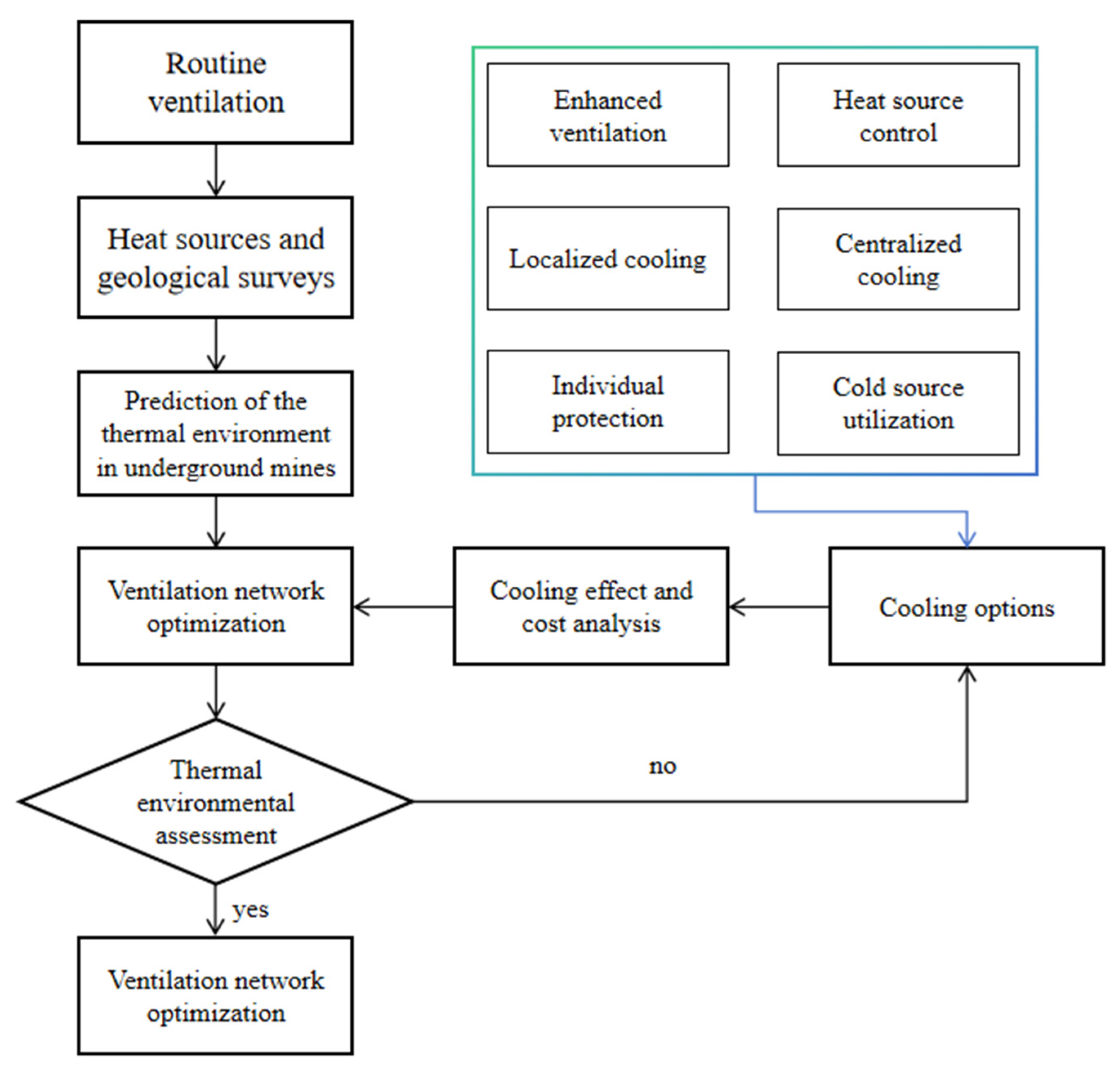

4. Traditional Ideas for Solving the Problem of Mine Thermal Damage and the Shortcomings of Mine Cooling Technologies in Application

4.1. Traditional Ideas for Solving the Problem of Mine Thermal Damage

4.2. The Shortcomings of Mine Cooling Technologies in Application

- (1)

- Large energy consumption does not conform to the concept of green mining. Mechanical cooling technology has gradually become the main energy consumption method for deep mineral resource mining. The refrigeration equipment used in mechanical cooling technology is expensive, and the power consumption for air conditioning is high. Most mechanical cooling technologies are suitable for local cooling areas. With increased mining depths, the transportation route lengthens. Therefore, it is necessary to increase the power of the compression and pressurization components in order to improve the refrigeration capacity and achieve an appropriate working temperature. At this time, the required electric energy also increases, which greatly improves the energy consumption.

- (2)

- High technical and maintenance costs lead to poor operability. In practical applications, some mine cooling technologies encounter problems such as complicated operation, difficult maintenance, and complicated system laying. As such, they require the guidance and operation of professional and technical personnel, which limits the possibility of its wide application.

- (3)

- Only paying attention to mine temperature control leads to ignoring other issues. When only temperature control requirements are considered, high humidity can easily occur in the mine. Various cooling technologies often focus on mine cooling without, or rarely, considering the problems associated with high humidity. In some mechanical refrigeration cooling technologies, temperature control occurs at the expense of humidity control; this is thus contrary to the original intention of improving a mine’s working environment.

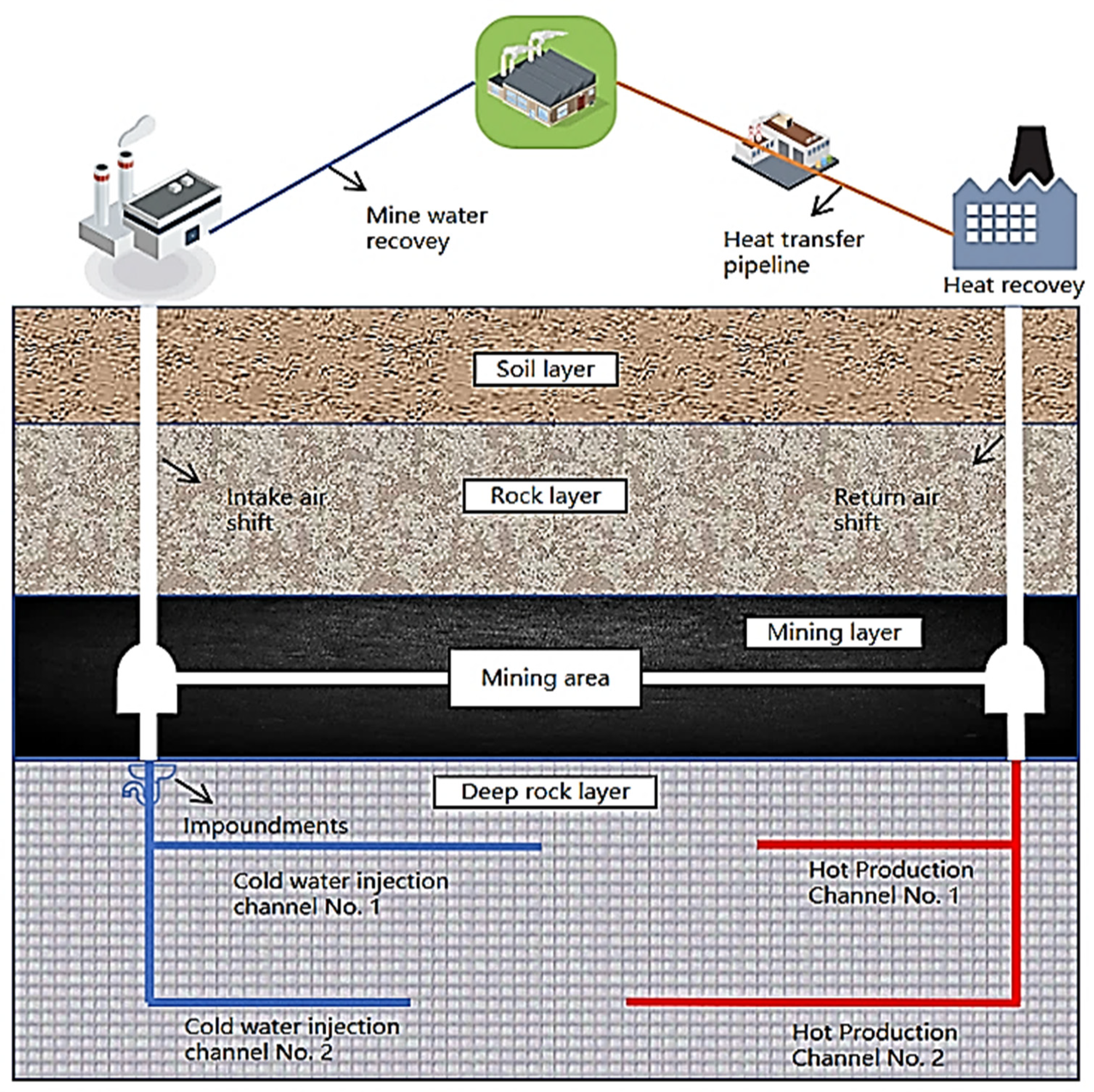

- (4)

- The value of geothermal mines is not fully utilized. Their resources not only provide a heat source for mine cooling but, more importantly, can be used as a renewable energy source for development and utilization. Compared with traditional fossil energy, geothermal energy has the advantages of sustainability, environmental protection, and low carbon emissions. Through reasonable technical means, mine geothermal energy can be converted into electric, heat, and other forms of energy, providing clean energy for industrial production, residential life, and other fields.

5. Development Directions for Thermal Environment Improvement in Deep Mines

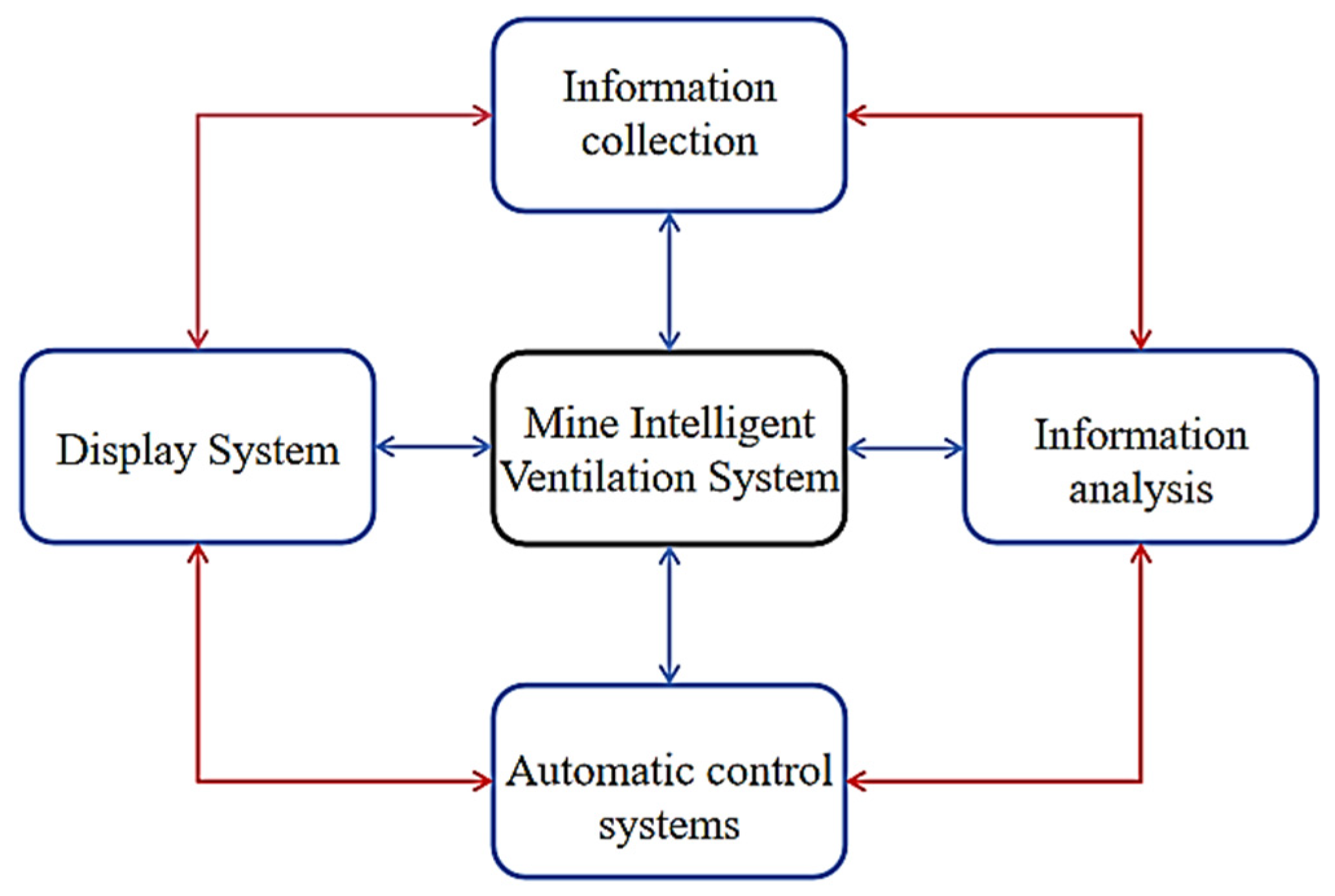

5.1. Intelligent Ventilation Systems Regulate Thermal Environments

5.2. Multiple Cooling Methods: Combined Cooling

5.3. Geothermal Utilization and Mine Thermal Environment Improvement

6. Conclusions

- (1)

- Mine ventilation and air conditioning are increasingly becoming the dominant means of energy consumption in the mining of deep mineral resources. Therefore, the advancement and economic efficiency of mine thermal environment control technology have a direct, decisive role in the maximum mining depth of the mine. In the future, the mine’s intelligent ventilation system will become a new trend.

- (2)

- Mine cooling can be carried out by improving mine ventilation conditions, increasing the air volume, protecting personnel, reducing heat transfer, reducing heat sources, etc. The methods presented in this study belong to other mine cooling techniques. Other mine cooling techniques are generally economical and applicable, but their cooling effects are limited. The most direct and effective method is mechanical cooling technology.

- (3)

- In the future, the trend for cooling deep mine thermal environments will be a combined cooling mode using multiple cooling methods. The combined cooling method starts from the overall system of the mine and integrates and optimizes various cooling measures to achieve more efficient cooling effects.

- (4)

- The synergistic mining of deep mineral resources and geothermal energy in rock strata is essentially a combination of mining and stratum heat extraction. This method not only allows us to obtain renewable, clean energy from geothermal energy, providing power for economic development but also reduces environmental pressure through conserving energy and reducing emissions. In addition, it can also play a role in controlling mine heat damage, improving the working environment of miners, and ensuring their health and safety.

Author Contributions

Funding

Conflicts of Interest

References

- Liu, X.; Yang, X.; Guo, R. Regional Differences in Fossil Energy-Related Carbon Emissions in China’s Eight Economic Regions: Based on the Theil Index and PLS-VIP Method. Sustainability 2020, 12, 2576. [Google Scholar] [CrossRef]

- Xie, Q.; Ren, B.; Hursthouse, A.; Shi, X. Effects of Mining Activities on the Distribution, Controlling Factors, and Sources of Metals in Soils from the Xikuangshan South Mine, Hunan Province. Integr. Environ. Assess. Manag. 2022, 18, 748–756. [Google Scholar] [CrossRef]

- Lu, L.; Fan, H.; Liu, J.; Liu, J.; Yin, J. Time Series Mining Subsidence Monitoring with Temporarily Coherent Points Interferometry Synthetic Aperture Radar: A Case Study in Peixian, China. Environ. Earth Sci. 2019, 78, 461. [Google Scholar] [CrossRef]

- Deng, M.; Zhong, S.; Xiang, G. Carbon Emission Reduction Effect of China’s Final Demand Structure Change from 2013 to 2020: A Scenario-Based Analysis. Carbon Manag. 2019, 10, 387–404. [Google Scholar] [CrossRef]

- Luo, W.; Tian, Z.; Zhong, S.; Lyu, Q.; Deng, M. Global Evolution of Research on Sustainable Finance from 2000 to 2021: A Bibliometric Analysis on WoS Database. Sustainability 2022, 14, 9435. [Google Scholar] [CrossRef]

- Tang, J.; Fang, Y.; Tian, Z.; Gong, Y.; Yuan, L. Ecosystem Services Research in Green Sustainable Science and Technology Field: Trends, Issues, and Future Directions. Sustainability 2022, 15, 658. [Google Scholar] [CrossRef]

- Ren, B.; Zhou, Y.; Ma, H.; Deng, R.; Zhang, P.; Hou, B. Sb Release Characteristics of the Solid Waste Produced in Antimony Mining Smelting Process. J. Mater. Cycles Waste Manag. 2018, 20, 193–200. [Google Scholar] [CrossRef]

- Xu, J.; Wang, Q.; Zhang, Y.; Li, W.; Li, X. Evaluation of Coal-Seam Roof-Water Richness Based on Improved Weight Method: A Case Study in the Dananhu No.7 Coal Mine, China. Water 2024, 16, 1847. [Google Scholar] [CrossRef]

- National Bureau of Statistics. Statistical Bulletin of the People’s Republic of China on National Economic and Social Development in 2023. People’s Daily. 1 March 2023. Available online: https://kns.cnki.net/kcms2/article/abstract?v=01ddXewXOSBlD5Qb_-M5OfXOFRPbNqVnEpMWRYmTI_4c_57Ho2vSY5WAfPkTKRNrTqbC57-DAWso9iV4AIbVTvSZZ7pn_YbPQ_QMZxxvsy3C5gDiSqAbAcrBrQL0ecA77nl3wIQU7ZSSHQWk_-UUToO0lZ35yH3F9IFpZhYouJO3KIxB9s6RDcKbNNnj-Cxq0uFiq7iE2fk=&uniplatform=NZKPT&language=CHS (accessed on 12 August 2024).

- Chen, C.; Peng, Z.; Gu, J.; Peng, Y.; Huang, X.; Wu, L. Exploring Environmentally Friendly Biopolymer Material Effect on Soil Tensile and Compressive Behavior. Int. J. Environ. Res. Public Health 2020, 17, 9032. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Ren, B.; Hursthouse, A.S.; Zhou, S. Antimony Ore Tailings: Heavy Metals, Chemical Speciation, and Leaching Characteristics. Pol. J. Environ. Stud. 2019, 28, 485–495. [Google Scholar] [CrossRef]

- Hao, X.; Guo, C.; Lin, Y.; Wang, H.; Liu, H. Analysis of Heat Stress and the Indoor Climate Control Requirements for Movable Refuge Chambers. Int. J. Environ. Res. Public Health 2016, 13, 518. [Google Scholar] [CrossRef]

- Hu, K.; Zheng, J.; Wu, H.; Jia, Q. Temperature Distribution and Equipment Layout in a Deep Chamber: A Case Study of a Coal Mine Substation. Sustainability 2022, 14, 3852. [Google Scholar] [CrossRef]

- Han, Q.; Lin, D.; Yang, X.; Li, K.; Yin, W. Thermal Environment Control at Deep Intelligent Coal Mines in China Based on Human Factors. Sustainability 2023, 15, 3193. [Google Scholar] [CrossRef]

- Jia, Z.; Tao, F.; Ye, Q. Experimental Research on Coal-Gas Outburst Prevention by Injection Liquid Freezing during Uncovering Coal Seam in Rock Crosscut. Sustainability 2023, 15, 1788. [Google Scholar] [CrossRef]

- Anderson, R. Heat Stress Management in Underground Mines. Int. J. Min. Sci. Technol. 2017, 27, 651–655. [Google Scholar] [CrossRef]

- Xu, Z.; Li, J.; Hao, S.; Wen, L.; Ma, Q.; Liu, C.; Shen, W. Temporal and Spatial Analysis of Water Resources under the Influence of Coal Mining: A Case Study of Yangquan Basin, China. Water 2023, 15, 3058. [Google Scholar] [CrossRef]

- Xue, T.; Xue, X.; Long, S.; Chen, Q.; Lu, S.; Zeng, C. Effect of Pre-Existing Underground Structures on Groundwater Flow and Strata Movement Induced by Dewatering and Excavation. Water 2023, 15, 814. [Google Scholar] [CrossRef]

- Pan, Y.-H.; Qi, J.-R.; Zhang, J.-F.; Peng, Y.-X.; Chen, C.; Ma, H.-N.; Ye, C. A Comparative Study on Steady-State Water Inflow into a Circular Underwater Tunnel with an Excavation Damage Zone. Water 2022, 14, 3154. [Google Scholar] [CrossRef]

- Xie, W.; Ren, B.; Hursthouse, A.S.; Wang, Z.; Luo, X. Simulation of Manganese Transport in Groundwater Using Visual MODFLOW: A Case Study from Xiangtan Manganese Ore Area in Central China. Pol. J. Environ. Stud. 2020, 30, 1409–1420. [Google Scholar] [CrossRef]

- Zhao, Y.; Tang, J.; Chen, Y.; Zhang, L.; Wang, W.; Wan, W.; Liao, J. Hydromechanical Coupling Tests for Mechanical and Permeability Characteristics of Fractured Limestone in Complete Stress–Strain Process. Environ. Earth Sci. 2017, 76, 24. [Google Scholar] [CrossRef]

- Yu, W.; Li, K.; Liu, Z.; An, B.; Wang, P.; Wu, H. Mechanical Characteristics and Deformation Control of Surrounding Rock in Weakly Cemented Siltstone. Environ. Earth Sci. 2021, 80, 337. [Google Scholar] [CrossRef]

- Wu, H.; Jia, Q.; Wang, W.; Zhang, N.; Zhao, Y. Experimental Test on Nonuniform Deformation in the Tilted Strata of a Deep Coal Mine. Sustainability 2021, 13, 13280. [Google Scholar] [CrossRef]

- Lan, H.; Chen, D.; Mao, D. Analysis of current situation and disaster prevention of deep mining in coal mines in China. Coal Sci. Technol. 2016, 44, 39–46. [Google Scholar]

- Qin, B.; Li, L.; Ma, D.; Lu, Y.; Zhong, X.; Jia, Y. Control Technology for the Avoidance of the Simultaneous Occurrence of a Methane Explosion and Spontaneous Coal Combustion in a Coal Mine: A Case Study. Process Saf. Environ. Prot. 2016, PA, 203–211. [Google Scholar] [CrossRef]

- Li, M.; Lv, H.; Lu, Y.; Wang, D.; Shi, S.; Li, R. Instantaneous Discharge Characteristics and Its Methane Ignition Mechanism of Coal Mine Rock Damage. Environ. Sci. Pollut. Res. Int. 2022, 29, 62495–62506. [Google Scholar] [CrossRef] [PubMed]

- Jia, X.; Wu, J.; Lian, C.; Wang, J.; Rao, J.; Feng, R.; Chen, Y. Investigating the Effect of Coal Particle Size on Spontaneous Combustion and Oxidation Characteristics of Coal. Environ. Sci. Pollut. Res. 2022, 29, 16113–16122. [Google Scholar] [CrossRef]

- Zuo, J.; Lv, P.; Cheng, G. High temperature mine heat source analysis and refrigeration cooling technology application. Coal Mine Saf. 2008, 46–49. Available online: https://kns.cnki.net/kcms2/article/abstract?v=01ddXewXOSAXDpIoX5e35mWymJ7FCWgodkP8M5IkNCkB9u_lpgerDBQquay314zJpmx7fLdtzEXWRh9XORey9AC410XeiX4i0xp8GYRV54JK609u3w-rkT2YeGa5yW8Dju2UVaMRlhEsw19hJMv-g6UqDDboe45vYB1yD-E-2l3zsh_e1RNiReaDCbwLV09M&uniplatform=NZKPT&language=CHS (accessed on 12 August 2024).

- Lu, R.-Y.; Chen, R.-D. A Review of Recent Studies on Extreme Heat in China. Atmos. Ocean. Sci. Lett. 2016, 9, 114–121. [Google Scholar]

- Gao, N.; Wang, X.; Liang, H.J.; Du, L.; Mao, X.; Luo, L. Genetic model and development potential of geothermal system in the large-ranking depression of Linqing depression at the junction of Hebei, Shandong and Henan provinces. Geol. China 2023, 50, 1149–1162. [Google Scholar]

- Liu, C.-H.; Wang, J.-X.; Wang, J.-G.; Bao, L.-L. Research and development of mine heat source analysis and cooling technology. Met. Mines 2014, 151–154. Available online: https://kns.cnki.net/kcms2/article/abstract?v=01ddXewXOSArDju1MhuGfTGlNUf5_eaomfA37MEW901bG4Hlb7XafR91RKXLP33K3bxLRtE3pxJvO6NKVxRxLi32a8yJr8Y3TGyOviaQxJjTG5oGXTFSdV3ZpbOoJxOBnbUtrZPzvWMOPqvEIDfK6b-cGRw9sa_BjHFJNjh_kRmwXUVDSqAhdftCYA0NOnwa&uniplatform=NZKPT&language=CHS (accessed on 12 August 2024).

- Huang, Z.; Zhang, L.; Yang, Z.; Zhang, J.; Gao, Y.; Zhang, Y. Preparation and Properties of a Rock Dust Suppressant for a Copper Mine. Atmos. Pollut. Res. 2019, 10, 2010–2017. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, Y.; Shi, S.; Wang, G.G.X.; Li, H.; Wang, T. Micro-Particles Stabilized Aqueous Foam for Coal Spontaneous Combustion Control and Its Flow Characteristics. Process Saf. Environ. Prot. 2020, 139, 262–272. [Google Scholar] [CrossRef]

- Li, X.; Meng, D.; Li, J.; Yin, H.; Liu, H.; Liu, X.; Cheng, C.; Xiao, Y.; Liu, Z.; Yan, M. Response of Soil Microbial Communities and Microbial Interactions to Long-Term Heavy Metal Contamination. Environ. Pollut. (Barking Essex 1987) 2017, 231, 908–917. [Google Scholar] [CrossRef]

- Azam, M.; Liu, L.; Ahmad, N. Impact of Institutional Quality on Environment and Energy Consumption: Evidence from Developing World. Environ. Dev. Sustain. 2021, 23, 1646–1667. [Google Scholar] [CrossRef]

- Liu, D.; Hao, S.; Liu, X.; Li, B.; He, S.; Warrington, D.N. Effects of Land Use Classification on Landscape Metrics Based on Remote Sensing and GIS. Environ. Earth Sci. 2013, 68, 2229–2237. [Google Scholar] [CrossRef]

- You, B.; Wu, C.; Li, J.; Liao, H. Physiological Responses of People in Working Faces of Deep Underground Mines. Int. J. Min. Sci. Technol. 2014, 5, 683–688. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, H.; Zhang, F.; Qian, J.; Han, S.; Dai, F. Groundwater Hydrogeochemical Processes and Potential Threats to Human Health in Fengfeng Coal Mining Area, China. Water 2023, 15, 4024. [Google Scholar] [CrossRef]

- You, B.; Wu, C.; Wang, M. Study on simulation test of high temperature environmental impact in confined space of deep well. Sci. Technol. Saf. Prod. China 2013, 9, 30–36. [Google Scholar]

- Wright, I.A.; Christie, A.; Gilpin, A.-M. Water Quality of Roof-Harvested Drinking Water Tanks in a Rural Area near a Gold and Copper Mine: Potential Health Risk from a Layer of Metal-Enriched Water and Sediment. Water 2024, 16, 773. [Google Scholar] [CrossRef]

- Arenas-Collao, K.; Valdés-González, H.; Reyes-Bozo, L.; Salazar, J.L. The Water Management Impacts of Large-Scale Mining Operations: A Social and Environmental Perspective. Water 2024, 16, 1745. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Z.; Ma, H.; Hursthouse, A.S. Removal of Manganese(II) from Acid Mine Wastewater: A Review of the Challenges and Opportunities with Special Emphasis on Mn-Oxidizing Bacteria and Microalgae. Water 2019, 11, 2493. [Google Scholar] [CrossRef]

- Jiang, F.; Ren, B.; Hursthouse, A.; Deng, R.; Wang, Z. Distribution, Source Identification, and Ecological-Health Risks of Potentially Toxic Elements (PTEs) in Soil of Thallium Mine Area (Southwestern Guizhou, China). Environ. Sci. Pollut. Res. 2019, 26, 16556–16567. [Google Scholar] [CrossRef]

- Wang, Z.; Liao, L.; Hursthouse, A.; Song, N.; Ren, B. Sepiolite-Based Adsorbents for the Removal of Potentially Toxic Elements from Water: A Strategic Review for the Case of Environmental Contamination in Hunan, China. Int. J. Environ. Res. Public Health 2018, 15, 1653. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Deng, R.-J.; Zhang, J.; Ren, B.-Z.; Hursthouse, A. Regional Distribution Characteristics and Ecological Risk Assessment of Heavy Metal Pollution of Different Land Use in an Antimony Mining Area—Xikuangshan, China. Hum. Ecol. Risk Assess. 2019, 26, 1779–1794. [Google Scholar] [CrossRef]

- Li, Y.; Hu, X.; Ren, B. Treatment of Antimony Mine Drainage: Challenges and Opportunities with Special Emphasis on Mineral Adsorption and Sulfate Reducing Bacteria. Water Sci. Technol. A J. Int. Assoc. Water Pollut. Res. 2016, 73, 2039–2051. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A.A.; Chrysanidis, T.; Anagnostopoulou, M. Experimental data of cement grouting in coarse soils with different superplasticisers. Data Brief 2020, 30, 105612. [Google Scholar] [CrossRef]

- Zhao, Y.; Luo, S.; Wang, Y.; Wang, W.; Zhang, L.; Wan, W. Numerical Analysis of Karst Water Inrush and a Criterion for Establishing the Width of Water-Resistant Rock Pillars. Mine Water Environ. 2017, 36, 508–519. [Google Scholar] [CrossRef]

- Lu, Y.; Li, H.; Lu, J.; Shi, S.; Wang, G.G.X.; Ye, Q.; Li, R.; Zhu, X. Clean up Water Blocking Damage in Coalbed Methane Reservoirs by Microwave Heating: Laboratory Studies. Process Saf. Environ. Prot. 2020, 138, 292–299. [Google Scholar] [CrossRef]

- Zheng, C.; Jiang, B.; Xue, S.; Chen, Z.; Li, H. Coalbed Methane Emissions and Drainage Methods in Underground Mining for Mining Safety and Environmental Benefits: A Review. Process Saf. Environ. Prot. 2019, 127, 103–124. [Google Scholar] [CrossRef]

- He, S.; Lu, Y.; Li, M. Probabilistic Risk Analysis for Coal Mine Gas Overrun Based on FAHP and BN: A Case Study. Environ. Sci. Pollut. Res. 2022, 29, 28458–28468. [Google Scholar] [CrossRef]

- Zhang, Q.; Zheng, J.; Zhang, B.; Linga, P. Coal Mine Gas Separation of Methane via Clathrate Hydrate Process Aided by Tetrahydrofuran and Amino Acids. Appl. Energy 2021, 287, 116576. [Google Scholar] [CrossRef]

- Gao, C.; Wang, D.; Ma, J.; Liu, K.; Fang, Y. Local Water Inrush Risk Assessment Method Based on Moving Window and Its Application in the Liangshuijing Mining Area. Water 2024, 16, 1083. [Google Scholar] [CrossRef]

- Zhao, C.; Zhao, J.; Wang, M. Performance Analysis and Optimization of Solar-Coupled Mine Water-Source Heat Pump Combined Heating and Cooling System. Sustainability 2024, 16, 4752. [Google Scholar] [CrossRef]

- Yu, H.; Gui, H.; Zhao, H.; Wang, M.; Li, J.; Fang, H.; Jiang, Y.; Zhang, Y. Hydrochemical Characteristics and Water Quality Evaluation of Shallow Groundwater in Suxian Mining Area, Huaibei Coalfield, China. Int. J. Coal Sci. Technol. 2020, 7, 825–835. [Google Scholar] [CrossRef]

- Sun, Z.; Li, Y.; Lin, R.; Zhang, Z. Application of Mechanical Refrigeration Cooling System in Coal Mine (China). Coal Mine Saf. 2009, 40, 26–29. [Google Scholar]

- Du, W.; Zheng, G. Application of ice slurry refrigeration and cooling system in Pingdingshan No.6 Coal Mine (China). Coal Eng. 2009, 63–65. Available online: https://kns.cnki.net/kcms2/article/abstract?v=01ddXewXOSDlej_GAndqbmTGTEesnXsE4DaOz-hamorAAjZcaH6LkqXYLheYBJxnhjr5ypgNeZYXxuQR_aWiBgCQ0nRuc09-8giRdTM2608A6ZjgTX3ENE8UYs0uOQiwj9zrS8wdBUr12kfEei7lwS7Qw3_MJzem&uniplatform=NZKPT (accessed on 12 August 2024).

- Xiong, Y.; Qian, X.; Cheng, L.; Feng, Z.; Xu, P.; Wang, G. Application and analysis of high temperature mine refrigeration and cooling technology. Gas Heat 2021, 41, 13–19. [Google Scholar]

- Application of Compressed Air Refrigeration Technology in Barapukuria Coal Mine, Bangladesh (China). Coal Eng. 2005. Available online: https://kns.cnki.net/kcms2/article/abstract?v=01ddXewXOSDid3CTvuiYg90NJmj4oOvQMQGG693F0oq3tpDvfXGL1isJqJTqlxDCyEA0hdaDua94suYXm9YUWOdtqUgvAtU67Ut9Awrozqe3DpvjbL2qXiBZqvKHunCYH-p8GtQhABGV_BJVCVgO48lkr1GbdH44&uniplatform=NZKPT (accessed on 12 August 2024).

- Xie, Z. Application of non-mechanical cooling technology in the treatment of high temperature heat harm mine (China). Coal Min. 2009, 14, 88–89. [Google Scholar]

- Zhang, Z.-Y.; Yin, W.; Wang, T.-W.; O’Donovan, A. Effect of Cross-Ventilation Channel in Classrooms with Interior Corridor Estimated by Computational Fluid Dynamics. Indoor Built Environ. 2022, 31, 1047–1065. [Google Scholar]

- Zhao, Y.; Liu, Q.; Lin, H.; Wang, Y.; Tang, W.; Liao, J.; Li, Y.; Wang, X. A Review of Hydromechanical Coupling Tests, Theoretical and Numerical Analyses in Rock Materials. Water 2023, 15, 2309. [Google Scholar] [CrossRef]

- You, B.; Yang, J.; Liu, J.; Liu, H.; Lu, Y.; Han, Q.; Zhang, Y. Study of the Influence of Different Clothing Materials for Mine Ventilation Clothing on Human Body and Microclimate under Clothing. Sustainability 2022, 14, 13460. [Google Scholar] [CrossRef]

- Liu, H.; Gao, L.; You, B. Experiments on factors affecting thermal comfort of gas cooling garments. J. Xi’an Univ. Sci. Technol. 2018, 38, 910–918. [Google Scholar]

- Jiang, R.; Wang, Y. Research progress on heat transfer performance of air layer under clothing (China). Silk 2018, 55, 41–48. [Google Scholar]

- Li, W.; Zhao, M. Study on the relationship between underwear space and clothing comfort. Knitt. Ind. 2023, 74–78. Available online: https://kns.cnki.net/kcms2/article/abstract?v=01ddXewXOSAJ8acr6ddZtBNiEMFPGLHPShPmY_2lqubQs8lY8y0hBd4SC9gWeSfibilgS8dkmvM5w6LL5iuAx5nX5erj2wdYee2kKljqsDIOfSfkzAbF64EzJe40A5ToVyvfMnDzYz_6lpHfjIPzl6WfK8r5TDdkiuYIe8KcChDvUSdowrzRSbOgzE4jPP2vb8kBCSw967M=&uniplatform=NZKPT&language=CHS (accessed on 12 August 2024).

- Ke, Y.; Zhang, H. Research status and development trend of cooling clothing (China). J. Cloth. 2020, 5, 40–46. [Google Scholar]

- Wang, J. Basic research on the application of vortex cooling suit in mine (China). Xi’an Univ. Sci. Technol. 2017. Available online: https://kns.cnki.net/kcms2/article/abstract?v=01ddXewXOSCbdMXQDvdoyF4PrWjQwl6X_KHqxkO6kNEuV1SHsYNDhgg4g7shaChaoFy2vO6ldOz5hzSlu7GQ3qjfNZbFvUNN2qGwAmQCyPIsPwbBLaHV8i4Q6VxpGwaL190luDGrdb_LGeTIAqivx5q7PdTfRm0kKMICrb9wun3SStsWA6i_deZgv6HgJ5_Ed9ykU7p5GqI=&uniplatform=NZKPT&language=CHS (accessed on 12 August 2024).

- Tokizawa, K.; Son, S.-Y.; Oka, T.; Yasuda, A. Effectiveness of a Field-Type Liquid Cooling Vest for Reducing Heat Strain While Wearing Protective Clothing. Ind. Health 2020, 58, 63–71. [Google Scholar] [CrossRef]

- Deng, J.; He, Q.; Liu, C.; Xiao, Y.; Zhao, J. Development Trend of Phase Change Cooling Clothing (China). Sci. Technol. Guide 2017, 35, 107–114. [Google Scholar]

- Wen, H.; Ding, X.; Liu, C. Experimental study on the cross-over effect of semiconductor cooling clothing (China). J. Refrig. 2017, 38, 40–44. [Google Scholar]

- Huang, Z.; Sun, C.; Gao, Y.; Ji, Y.; Wang, H.; Zhang, Y.; Yang, R. R&D of Colloid Components of Composite Material for Fire Prevention and Extinguishing and an Investigation of Its Performance. Process Saf. Environ. Prot. 2018, 113, 357–368. [Google Scholar] [CrossRef]

- Li, Y.; Zeng, X.; Lin, Z.; Su, J.; Gao, T.; Deng, R.; Liu, X. Experimental Study on Phosphate Rock Modified Soil-Bentonite as a Cut-off Wall Material. Water Supply 2022, 22, 1676–1690. [Google Scholar] [CrossRef]

- Zou, S.; Li, H.; Liu, L.; Wang, S.; Zhang, X.; Zhang, G. Research on Improving Comprehensive Properties of a New Sawdust Composite Insulation Material by Torrefaction. Process Saf. Environ. Prot. 2021, 152, 361–374. [Google Scholar] [CrossRef]

- Yuan, Z.; Yang, H.; Xu, P.; Li, C.; Jian, J.; Zeng, J.; Zeng, L.; Sui, Y.; Zhou, H. Facile in Situ Synthesis of Silver Nanocomposites Based on Cellulosic Paper for Photocatalytic Applications. Environ. Sci. Pollut. Res. Int. 2021, 28, 6411–6421. [Google Scholar] [CrossRef]

- Chen, W.; Wan, W.; Zhao, Y.; Peng, W. Experimental Study of the Crack Predominance of Rock-Like Material Containing Parallel Double Fissures under Uniaxial Compression. Sustainability 2020, 12, 5188. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhao, J.; Li, S.; Jiang, Z.; Huang, F. A Unified Solution for Surrounding Rock of Roadway Considering Seepage, Dilatancy, Strain-Softening and Intermediate Principal Stress. Sustainability 2022, 14, 8099. [Google Scholar] [CrossRef]

- Tian, Z.; Zhang, Z.; Deng, M.; Yan, S.; Bai, J. Gob-Side Entry Retained with Soft Roof, Floor, and Seam in Thin Coal Seams: A Case Study. Sustainability 2020, 12, 1197. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, X.; Huang, C. Numerical simulation analysis of the cooling effect of spraying thermal insulation materials in the west section of Dahongshan Copper Mine. Min. Res. Dev. 2022, 42, 158–162. [Google Scholar]

- Wang, F.; Du, C.; Pang, J. Study on the performance of thermal insulation materials for underground high temperature roadway. Coal Technol. 2017, 36, 187–189. [Google Scholar]

- Gao, J.; Fu, Y.; Meng, X. Intelligent Upgrade and Application Effect Analysis of Ventilation System in Yannan Coal Mine. Int. J. Front. Eng. Technol. 2023, 5, 18–21. [Google Scholar] [CrossRef]

- Li, Y.; Wang, P.; Liu, R.; Gao, R. Optimization of Structural Parameters and Installation Position of the Wall-Mounted Air Cylinder in the Fully Mechanized Excavation Face Based on CFD and Orthogonal Design. Process Saf. Environ. Prot. 2019, 130, 344–358. [Google Scholar] [CrossRef]

- Wang, P.; Gao, R.; Liu, R.; Yang, F. CFD-Based Optimization of the Installation Location of the Wall-Mounted Air Duct in a Fully Mechanized Excavation Face. Process Saf. Environ. Prot. 2020, 141, 234–245. [Google Scholar] [CrossRef]

- Zou, S.; Li, K.; Han, Q.; Yu, C.W. Numerical Simulation of the Dynamic Formation Process of Fog-Haze and Smog in Transport Tunnels of a Hot Mine. Indoor Built Environ. 2017, 26, 1062–1069. [Google Scholar] [CrossRef]

- Wang, P.; Tan, X.; Zhang, L.; Li, Y.; Liu, R. Influence of Particle Diameter on the Wettability of Coal Dust and the Dust Suppression Efficiency via Spraying. Process Saf. Environ. Prot. 2019, 132, 189–199. [Google Scholar] [CrossRef]

- Wang, P.; Shi, Y.; Zhang, L.; Li, Y. Effect of Structural Parameters on Atomization Characteristics and Dust Reduction Performance of Internal-Mixing Air-Assisted Atomizer Nozzle. Process Saf. Environ. Prot. 2019, 128, 316–328. [Google Scholar] [CrossRef]

- Wang, D.; Liu, J.; Deng, L.; Wang, H. Intelligent Diagnosis of Resistance Variant Multiple Fault Locations of Mine Ventilation System Based on ML-KNN. PLoS ONE 2022, 17, e0275437. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Jia, M. Concept and method analysis of deep mine heat hazard control and geothermal energy mining. Chin. J. Nonferrous Met. 2022, 32, 1515–1527. [Google Scholar]

- Zhang, B.; Xue, P.; Liu, L.; Xun, C.; Wang, M.; Zhao, Y.J.; Qin, X.B.; Yang, Q.X. Exploration of deposit-geothermal synergistic mining method in deep filling mines. J. China Coal Soc. 2021, 46, 2824–2837. [Google Scholar]

- Li, Z.; Xu, Y.; Jia, M. Numerical simulation of geothermal energy collaborative mining in deep mine strata to control heat damage. Cent. South Univ. 2021, 52, 671–680. [Google Scholar]

| Serial Number | Mines in China | Elevation and Temperature of Mining Area | Cooling Method | Implementation Effect |

|---|---|---|---|---|

| 1# | Pingdingshan coal Mine | −430 m; 33.2 °C~36.6 °C | Cold water cooling system | The temperature of the mining working face is reduced by about 5 °C |

| 2# | Jinqu gold mine | 280 m; 32 °C~33 °C | Underground centralized cold water cooling system with low-temperature mine water as the cold source | The temperature of the mining face is reduced to 27 °C |

| 3# | Linglong gold mine | −710 m; 34 °C~36 °C | Ice-cooling system | The airflow temperature is reduced to 27.1 °C |

| 4# | Shaxi copper mine | −770 m; 35.5 °C | Mine water local cooling system | The temperature of the mining face is reduced to 29.5 °C |

| 5# | Xincheng gold mine | −1030 m; 33 °C~37 °C | Combined ice-cooling and air-conditioning cooling system | The airflow temperature is reduced by about 4 °C |

| 6# | Sanshandao gold mine | −1140 m; 35°C~41°C | Cold watercooling combined with air-conditioning cooling system: air conditioning unit (840 kW) | The airflow temperature is reduced to 30 °C |

| 7# | Xiadian gold mine | −662 m~−700 m; 37 °C~40 °C | Cold water cooling combined with air-conditioning cooling system: air conditioning unit | The mine was locally cooled to 26 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, B.; Chen, Y.; Yang, M.; Gao, K.; Cui, D.; Lu, M. Management of Thermal Hazards in Deep Mines in China: Applications and Prospects of Mine Cooling Technology. Water 2024, 16, 2347. https://doi.org/10.3390/w16162347

You B, Chen Y, Yang M, Gao K, Cui D, Lu M. Management of Thermal Hazards in Deep Mines in China: Applications and Prospects of Mine Cooling Technology. Water. 2024; 16(16):2347. https://doi.org/10.3390/w16162347

Chicago/Turabian StyleYou, Bo, Yuansen Chen, Ming Yang, Ke Gao, Daxiong Cui, and Man Lu. 2024. "Management of Thermal Hazards in Deep Mines in China: Applications and Prospects of Mine Cooling Technology" Water 16, no. 16: 2347. https://doi.org/10.3390/w16162347

APA StyleYou, B., Chen, Y., Yang, M., Gao, K., Cui, D., & Lu, M. (2024). Management of Thermal Hazards in Deep Mines in China: Applications and Prospects of Mine Cooling Technology. Water, 16(16), 2347. https://doi.org/10.3390/w16162347