Evaluation of a Desalination System Combining Photovoltaic and Membrane Technology: A Case Study on the Benefit Analysis of an Apple Orchard

Abstract

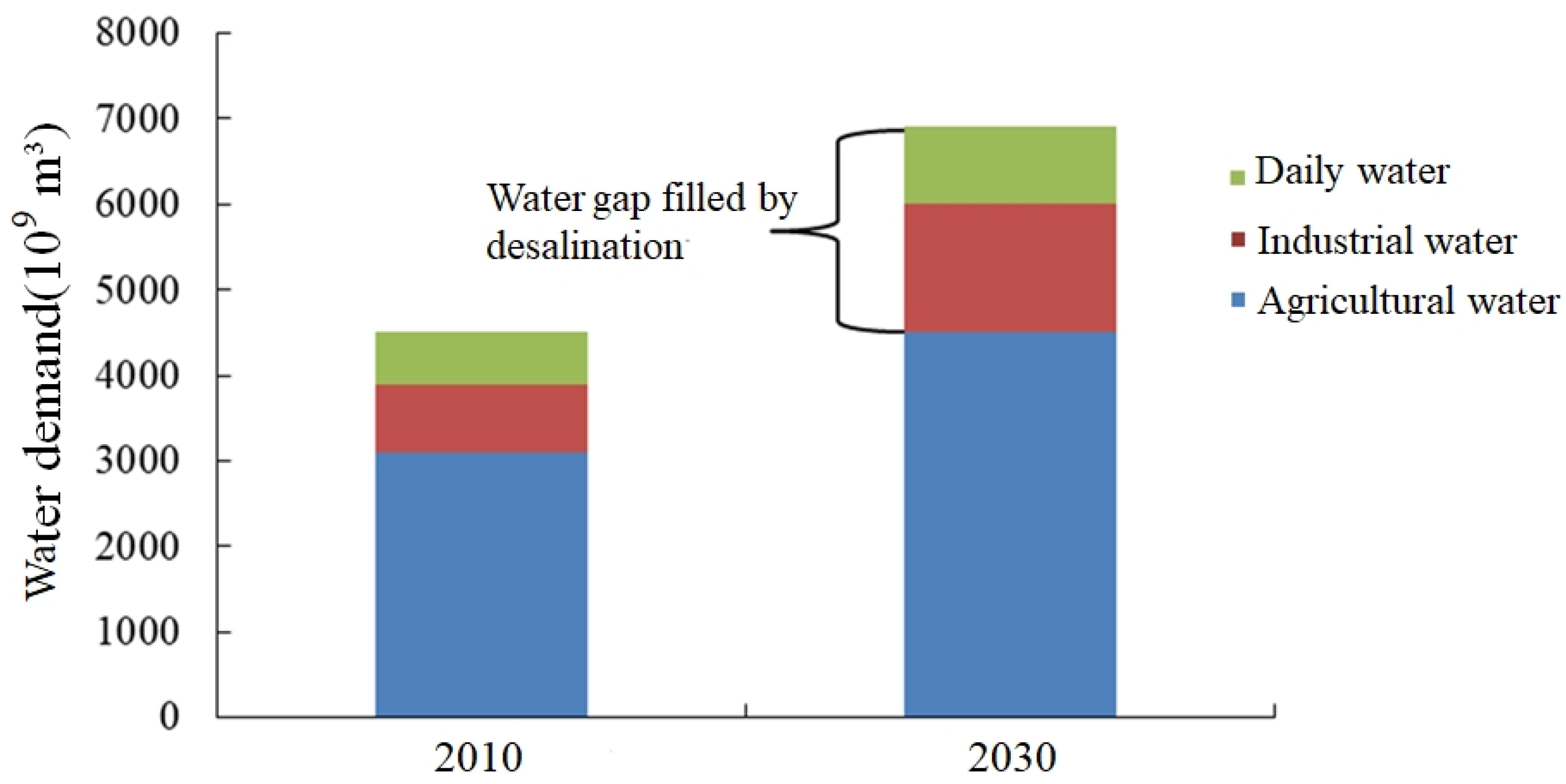

1. Introduction

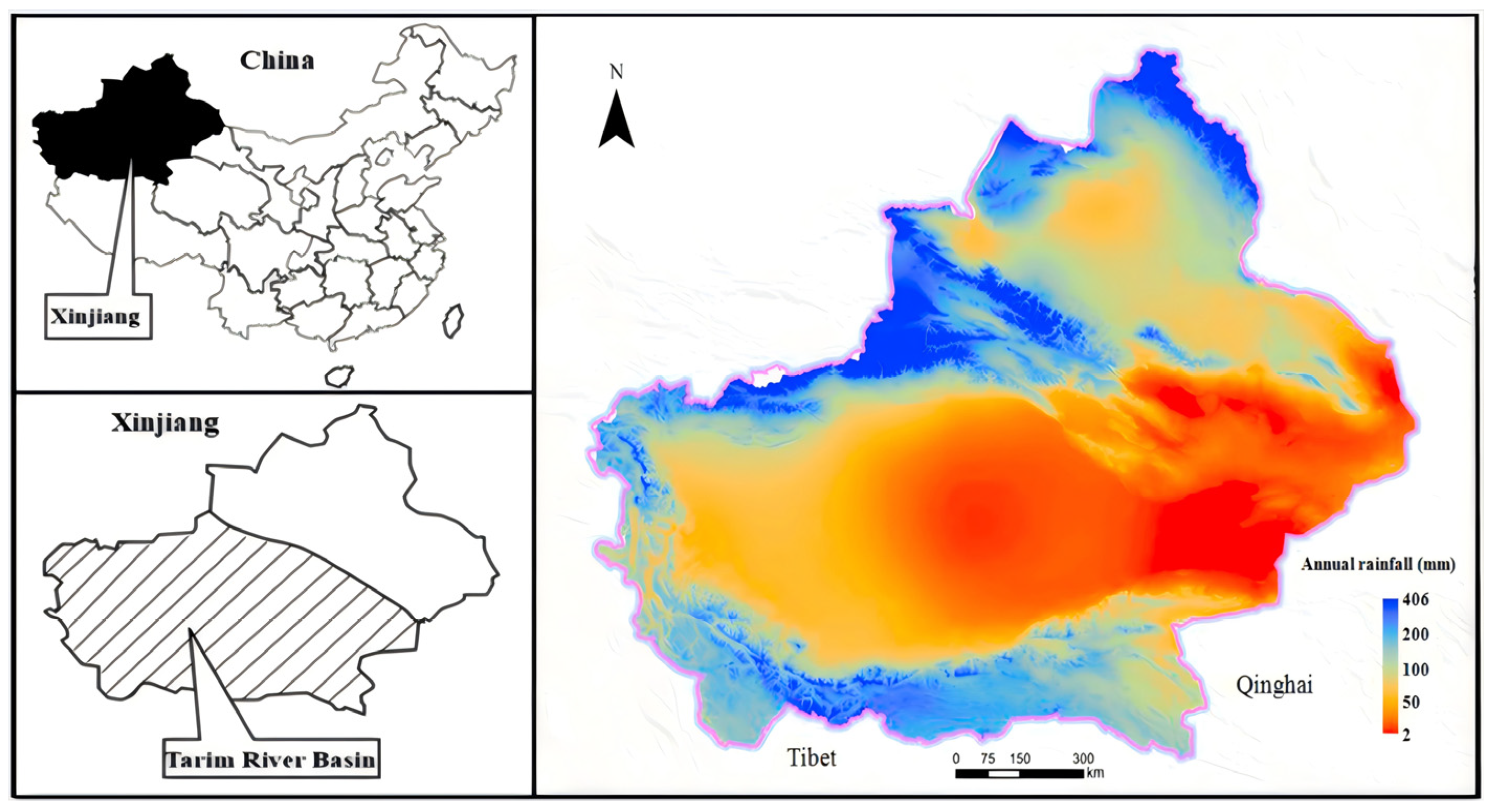

2. Material

3. Technology and Analytical Methods

3.1. Desalination Device

3.2. Photovoltaic Device

3.3. Economic Evaluation

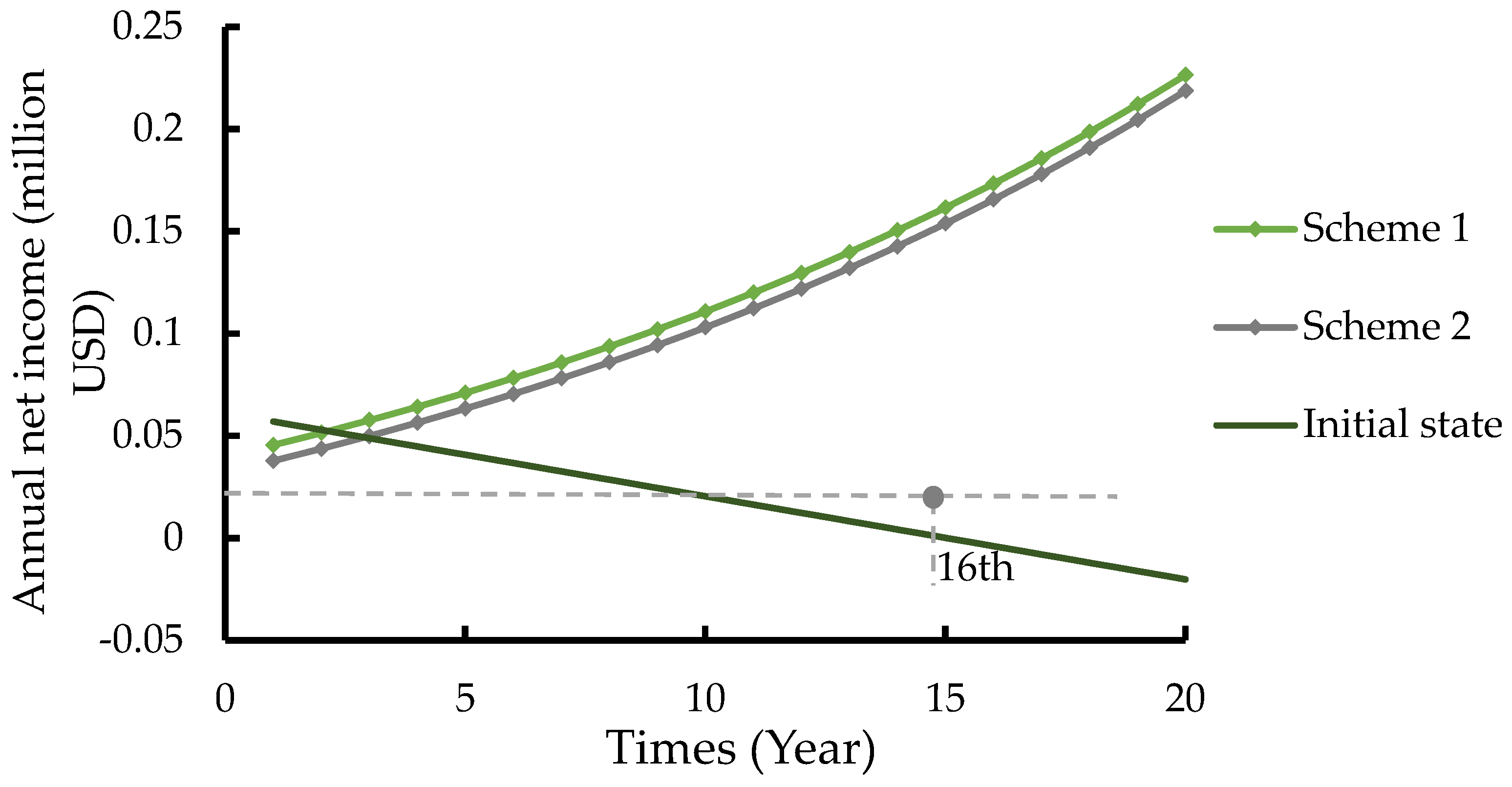

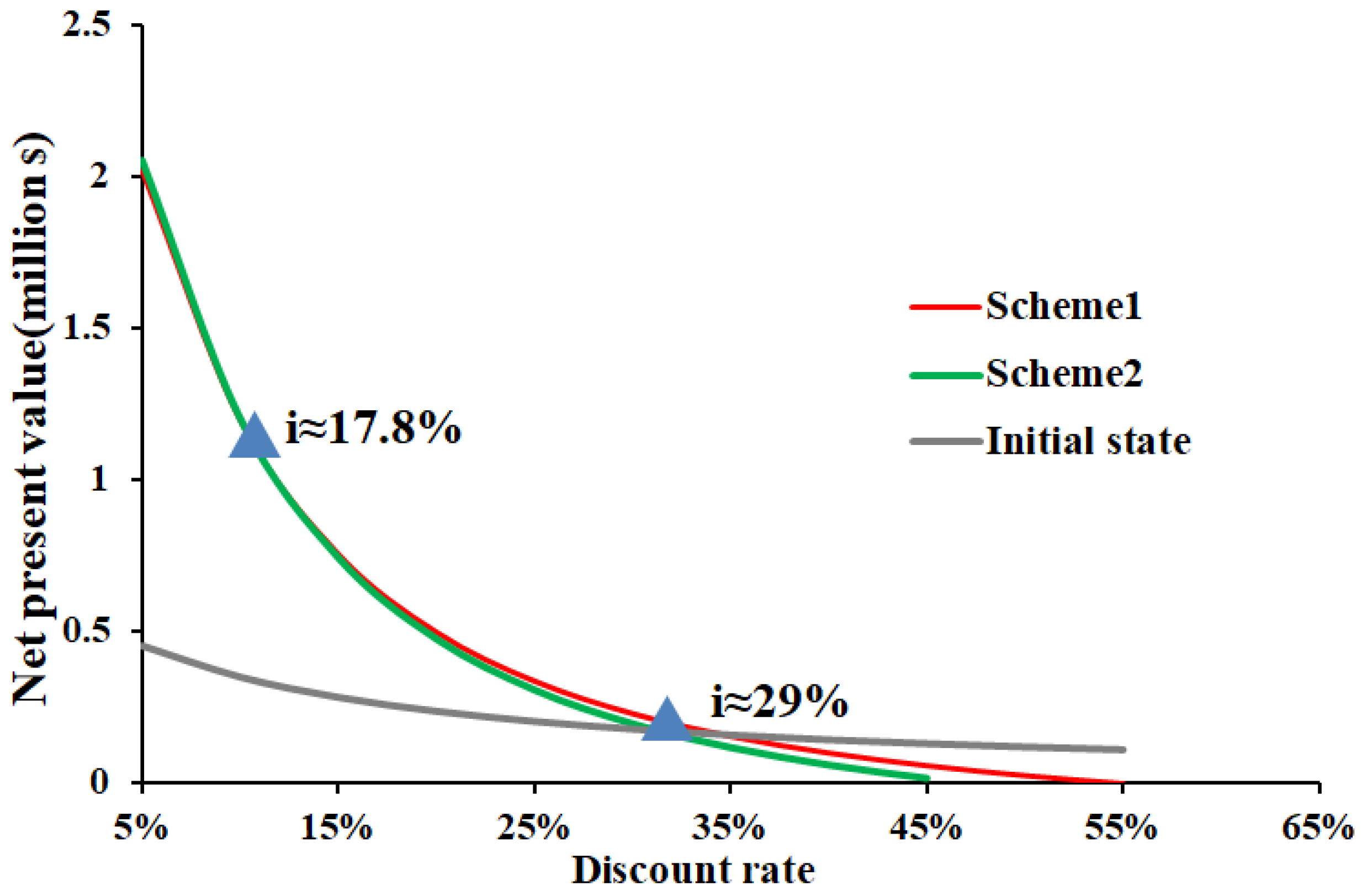

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| TDS | Total dissolved solids (mg/L) |

| MSF | Multi-stage flash evaporation |

| ED | Electrodialysis |

| MD | Membrane distillation |

| RO | Reverse osmosis |

| PV | Photovoltaic |

| NF | Nano filtration |

| Apple output (kg/ha) | |

| Irrigation water quantity (m3/ha) | |

| ppm | Parts per million |

| NPV | Net present value |

| TC | Total capital cost (USD) |

| UDC | Unit desalination cost (USD/day) |

| CCRF | Capital cost recovery factor (year−1) |

| DP | Daily production (m3/day) |

| Stability factor of operation | |

| Discount rate (%) | |

| Capital cost (USD) | |

| Operating cost (USD) | |

| Specific power consumption (kWh/m3) | |

| Electricity price (USD) | |

| ES | Electricity subsidy (USD) |

Subscripts

| Other instruments | |

| Electrical | |

| Cleaning and replacement | |

| Operation and maintenance | |

| Inverter | |

| Labour | |

| Year | |

| Photovoltaic | |

| Reverse osmosis |

Appendix A

| Parameters | Value |

|---|---|

| Chloride (mg/L) | 2999 |

| Sulfate (mg/L) | 1076 |

| Calcium (mg/L) | 448.9 |

| Magnesium (mg/L) | 97.24 |

| Ferric (mg/L) | 0 |

| COD (mg/L) | 55.68 |

| Hardness | 1520 |

| Alkalinity (mg/L) | 171.4 |

| Turbidity | 0.15 |

| Conductivity (us/cm) | 9800 |

| pH | 6.54 |

| Test Sample | Cl− | SO42− | Ca2+ | COD | Turbidity | Conductivity | pH | Alkalinity |

|---|---|---|---|---|---|---|---|---|

| Unit | mg/L | mg/L | mg/L | mg/L | NTU | ms/cm | mg/L | |

| Drainage channel | 2750 | 392.98 | 412.824 | 46.65 | 14.06 | 10.57 | 5.4 | 92.5925 |

| Sand filtration inlet | 3450 | 88.47 | 200.400 | 106.80 | 0.28 | 10.19 | 7.91 | 102.6625 |

| Sand filtration outlet | Untested | Untested | Untested | Untested | 0.25 | 10.18 | 7.81 | Untested |

| Pump outlet | Untested | Untested | Untested | Untested | Untested | 10.03 | 7.85 | Untested |

| NF inlet | 3475 | Untested | 208.416 | 130.9 | 0.62 | 9.97 | 7.79 | 107.0750 |

| NF outlet | 2625 | Untested | 42.145 | 37.62 | 1.10 | 7.10 | 6.95 | 42.5425 |

| NF concentrated | 4250 | 384.75 | 310.620 | 219.7 | 0.25 | 11.72 | 7.88 | 160.1630 |

| RO inlet | 3380 | Untested | Untested | Untested | 0.09 | 7.32 | 7.94 | Untested |

| RO outlet | 60 | Untested | Untested | Untested | Untested | 0.17 | 6.22 | Untested |

| RO concentrated | 5450 | Untested | Untested | Untested | Untested | 14.06 | 7.66 | Untested |

| Canal | 6650 | 129.7 | 356.71 | 39.13 | 0.13 | 13.78 | 8.36 | 77.5775 |

Appendix B

| Parameters | Active Area ft2 (m2) | Outer Casing | Maximum Operating Pressure | Feed Spacer Mil | pH Range |

| FilmTec™ NF245-390-FF | 390 (36.2) | Mesh wrap | 54.8 bar | 27 | 3–10 |

| FilmTec™ RO-390-FF | 390 (36.2) | Mesh wrap | 54.8 bar | 27 | 2–10 |

References

- World Bank Group. Water in Agriculture. 2020. Available online: https://www.worldbank.org/en/topic/water-in-agriculture (accessed on 12 August 2020).

- Menkouchi Sahli, M.A.; Annouar, S.; Tahaikt, M.; Mountadar, T.; Soufiane, A. Fluoride removal for underground brackish water by adsorption on the natural chitosan and by electro dialysis. Desalination 2007, 212, 37–45. [Google Scholar] [CrossRef]

- Ali, M.B.S.; Mnif, A.; Hamrouni, B.; Dhahbi, M. Electrodialytic desalination of brackish water: Effect of process parameters and water characteristics. Ionics 2010, 16, 621–629. [Google Scholar]

- Mogheir, Y.; Foul, A.A.; Abuhabib, A.A.; Mohammad, M.A. Assessment of large scale brackish water desalination plants in the Gaza Strip. Desalination 2013, 314, 96–100. [Google Scholar] [CrossRef]

- Zhao, S.; Zou, L.; Mulcahy, D. Brackish water desalination by a hybrid forward osmosis–Nano filtration system using divalent draw solute. Desalination 2012, 284, 175–181. [Google Scholar] [CrossRef]

- Lopez, A.M.; Williams, M.; Paiva, M.; Demydov, D.; Fairey, J.L. Potential of electrodialytic techniques in brackish desalination and recovery of industrial process water for reuse. Desalination 2017, 409, 108–114. [Google Scholar] [CrossRef]

- Rafique, H.M.; Abbas, I.; Sohl, M.A.; Shehzadi, R. Appraisal of drinking water quality of tehsil Jampur, Pakistan. Desalination Water Treat. 2013, 52, 4618–4641. [Google Scholar] [CrossRef]

- Xu, X.; He, Q.; Ma, G.; Wang, H.; Nirmalakhandan, N. Selective separation of mono- and di-valent cations in electrodialysis during brackish water desalination: Bench and pilot-scale studies. Desalination 2018, 428, 146–160. [Google Scholar] [CrossRef]

- Oren, S.; Birnhack, L.; Lehmann, O.; Lahav, O. A different approach for brackish water desalination, comprising acidification of the feed-water and CO2(aq) reuse for alkalinity, Ca2+ and Mg2+ supply in the post treatment stage. Sep. Purif. Technol. 2012, 89, 252–260. [Google Scholar] [CrossRef]

- Sarai Atab, M.; Smallbone, A.J.; Roskilly, A.P. An operational and economic study of a reverse osmosis desalination system for potable water and land irrigation. Desalination 2016, 397, 174–184. [Google Scholar] [CrossRef]

- Wang, K.; Abdalla, A.A.; Hilal, H. Mechanical properties of water desalination and wastewater treatment membranes. Desalination 2017, 401, 190–205. [Google Scholar]

- Das, R.; Ali, M.E.; Hamid, S.B.A.; Ramakrishna, S.; Chowdhury, Z.Z. Carbon nanotube membranes for water purification: A bright future in water desalination. Desalination 2014, 336, 97–109. [Google Scholar] [CrossRef]

- Birnhack, L.; Shlesinger, N.; Lahav, O. A cost effective method for improving the quality of inland desalinated brackish water destined for agricultural irrigation. Desalination 2010, 262, 152–160. [Google Scholar] [CrossRef]

- Fritzmann, C.; Löwenberg, J.; Wintgens, T.; Melin, T. State-of-the-art of reverse osmosis desalination. Desalination 2007, 216, 1–76. [Google Scholar] [CrossRef]

- Gökçek, M.; Gökçek, Ö.B. Technical and economic evaluation of freshwater production from a wind-powered small-scale seawater reverse osmosis system (WP-SWRO). Desalination 2016, 381, 47–57. [Google Scholar] [CrossRef]

- Ahmad, G.E.; Schmid, J. Feasibility study of brackish water desalination in the Egyptian deserts and rural regions using PV systems. Energy Convers. Manag. 2002, 43, 2641–2649. [Google Scholar] [CrossRef]

- Ghaffour, N.; Bundschuh, J.; Mahmoudi, H.; Goosen, M.F. Renewable energy-driven desalination technologies: A comprehensive review on challenges and potential applications of integrated systems. Desalination 2015, 356, 94–114. [Google Scholar] [CrossRef]

- Richards, B.S.; Schafer, A.I. Design considerations for a solar-powered desalination system for remote communities in Australia. Desalination 2002, 144, 193–199. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.; El Haj Assad, M.; Sayed, E.T.; Soudan, B. Recent progress in the use of renewable energy sources to power water desalination plants. Desalination 2018, 435, 97–113. [Google Scholar] [CrossRef]

- Parsa, S.M.; Norouzpour, F.; Shoeibi, S.; Shahsavar, A.; Aberoumand, S.; Said, Z.; Karimi, N. A comprehensive study to find the optimal fraction of nanoparticle coated at the interface of solar desalination absorbers: 5E and GHGs analysis in different seasons. Sol. Energy Mater. Sol. Cells 2023, 256, 112308. [Google Scholar] [CrossRef]

- Masoud, S.P. Mega-scale desalination efficacy (Reverse Osmosis, Electrodialysis, Membrane Distillation, MED, MSF) during COVID-19: Evidence from salinity, pretreatment methods, temperature of operation. J. Hazard. Mater. Adv. 2023, 9, 100217. [Google Scholar]

- Li, X.; Jin, M.; Yuan, J. Salt evaluation of drip irrigation in cotton field under brackish water film. J. Hydraul. Eng. 2014, 9, 1091–1098. [Google Scholar]

- Zhao, M.; Li, Y.H.; Li, F.D. Analysis of the spatial variability of soil moisture and salinity in Ebinur Lake wetlands, Xinjiang. J. Lake Sci. 2016, 28, 1328–1337. [Google Scholar]

- Ma, Z.M.; Luan, F.J.; Jia, R.L.; Zhou, J.L. Remote sensing interpretation and analysis of land desertification and salinization in Xinjiang Beitun area. Ground Water 2017, 3, 140–141. [Google Scholar]

- Hu, H.; Tian, F.; Zhang, Z. The leaching and multi-year dynamics of soil salinity in farmland under mulch drip irrigation in arid areas during non-growth period. J. Hydraul. Eng. 2015, 46, 1037–1046. [Google Scholar]

- Zhou, H.; Wang, S.; Yao, X. Study on the characteristics of directional migration and distribution of soil water and salt and the salt discharge effect of drip irrigation under mulch. J. Hydraul. Eng. 2013, 44, 1380–1388. [Google Scholar]

- Chen, L.J.; Feng, Q.; Li, F.R.; Li, C.S. Simulation of soil water and salt transfer under mulched furrow irrigation with saline water. Geoderma 2015, 241–242, 87–96. [Google Scholar] [CrossRef]

- Wang, Z.; Jin, M.; Simunek, J.; van Genuchten, M.T. Evaluation of mulched drip irrigation for cotton in arid Northwest China. Irrig. Sci. 2014, 32, 15–27. [Google Scholar] [CrossRef]

- Wang, Z.M.; Su, J.; Zhu, G.Y.; Han, J.F.; Wang, Y. Characteristics and accumulation mechanism of quasi-layered Ordovocian carbonate reservoirs in the Tazhong area, Tarim Basin. Energy Explor. Exploit. 2013, 31, 545–567. [Google Scholar] [CrossRef]

- Zhang, S.C.; Huang, H.P.; Su, J.; Zhu, G.Y.; Wang, X.M. Geochemistry of Paleozoic marine oils from the Tarim Basin, NW China. Part 4: Paleobiodegradation and oil charge mixing. Org. Geochem. 2014, 67, 41–57. [Google Scholar] [CrossRef]

- Zhao, W.Z.; Shen, A.J.; Pan, W.Q. A research on carbonate karst reservoirs classification and its implication on hydrocarbon exploration: Cases studies from Tarim Basin. Acta Petrol. Sin. 2013, 29, 3213–3222. [Google Scholar]

- Fang, S.B.; Tu, W.R. Saline alkali water desalination project in Southern Xinjiang of China: A review of desalination planning, desalination schemes and economic analysis. Renew. Sustain. Energy Rev. 2019, 113, 109268. [Google Scholar] [CrossRef]

- Fang, C.Y.; Wang, L.; Zhang, Y.; Wang, A.T. Two new species of brackish water Macrostomum (Platyhelminthes, Macrostomida) from southern China. Zootaxa 2016, 4170, 298–310. [Google Scholar] [CrossRef]

- Ruiz, G.A.; Ruiz, S.E. 80,000 h operational experience and performance analysis of a brackish water reverse osmosis desalination plant, Assessment of membrane replacement cost. Desalination 2015, 375, 81–88. [Google Scholar] [CrossRef]

- Zarzo, D.; Campos, E.; Terrero, P. Spanish experience in desalination for agriculture. Desalination Water Treat. 2013, 51, 53–66. [Google Scholar] [CrossRef]

- Bennett, A. Developments in desalination and water reuse. Filtr. Sep. 2015, 52, 28–33. [Google Scholar] [CrossRef]

- Al-Amshawee, S. Electrodialysis desalination for water and wastewater: A review. Chem. Eng. J. 2020, 380, 122231. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, H.F.; Zhao, Y.S. Solar-driven natural vacuum desalination system with inner condenser. Appl. Therm. Eng. 2021, 196, 117320. [Google Scholar] [CrossRef]

- Namboodiri, V.; Rajagopalan, N. Comprehensive Water Quality and Purification; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Pendergast, M.M.; Hoek, E.M.V. A review of water treatment membrane nanotechnologies. Energy Env. Sci. 2011, 4, 1946–1971. [Google Scholar] [CrossRef]

- International Desalination Association. IDA Desalination Yearbook, 2010–2019. Available online: https://idadesal.org/ (accessed on 1 July 2024).

- Shahzad, M.W.; Burhan, M.; Ang, L.; Ng, K.C. Energy-water-environment nexus underpinning future desalination sustainability. Desalination 2017, 413, 52–64. [Google Scholar] [CrossRef]

- Shatat, M.; Worall, M.; Riffat, S. Opportunities for solar water desalination worldwide: Review. Sustain. Cities Soc. 2013, 9, 67–80. [Google Scholar] [CrossRef]

- Cao, H. The Effect of Irrigation System on the Growth, Yield and Quality of Drip Irrigation Apples with Short Stocks in Southern Xinjiang. Master’s Thesis, Tarim University, Alar, China, 2021. [Google Scholar]

| Country | Site | TDS (mg/L) | Type of Water |

|---|---|---|---|

| Africa | Morocco | 2208 | Ground |

| Africa | Tunisia | 5424 | Surface |

| Australia | Mawson Lake | 3970 | Surface |

| China | Kashgar River | 5817 | Surface |

| China | Longdong | 2506 | Ground |

| Egypt | Sinai | 2000 | Ground |

| Arabian Peninsula | Gaza Strip | 2359 | Surface |

| Pakistan | Champu | 4213 | Surface |

| Israel | Carmel Coast | 3890 | Surface |

| Iran | Iraq | 5471 | Surface |

| United States | Perris | 2780 | Well |

| United States | El Paso | 2736 | Ground |

| Parameters | Value |

|---|---|

| Inlet flow of total system (m3/day) | 440 |

| Inlet flow of NF device (m3/day) | 420 |

| Permeation flow of NF device (m3/day) | 335 |

| Concentration flow of NF device (m3/day) | 85 |

| Permeation flow of RO device (m3/day) | 289 |

| Concentration flow of RO device (m3/day) | 46 |

| Total irrigation flow (m3/day) | 37 |

| Recovery rate of NF device (%) | 79% |

| Recovery rate of RO device (%) | 86% |

| Total recovery (%) | 85% |

| Influent salinity (ppm) | 6500 |

| Influent temperature (°C) | 25 |

| Membrane element type | Stage 1: FilmTec™ NF245-390-FF Stage 2: FilmTec™ RO-390-FF |

| Number of pressure vessels in Stage 1 | 3 |

| Number of elements per each pressure vessels in Stage 1 | 4 |

| Number of pressure vessels in Stage 2 | 4 |

| Number of elements per each pressure vessels in Stage 2 | 4 |

| Total number of elements | 28 |

| Total active area (m2) | 1014 |

| Total average flux (L/m2·h) | 13.7 |

| NF membrane flux (L/m2·h) | 23 |

| Permeate flow salinity of NF device (ppm) | 3909 |

| Concentrate flow salinity of NF device (ppm) | 7618 |

| RO membrane flux (L/m2·h) | 17 |

| Permeate flow salinity of RO device (ppm) | 85 |

| Concentrate flow salinity of RO device (ppm) | 7030 |

| Booster pump efficiency (%) | 80 |

| Feed pressure (bar) | 22.6 |

| Outlet pressure (bar) | 20.6 |

| System power (kW) | 30.8 |

| Specific energy consumption (kWh/m3) | 2 |

| Parameters | Value |

|---|---|

| Photovoltaic panel model | Eagle 72P 320–340 W |

| Number of panels | 128 |

| Module area (m2) | 210 |

| Module size (mm) | 1956 × 992 × 40 |

| Maximum power (wp) | 340 |

| PV module efficiency (%) | 17% |

| PV module lifecycle (years) | 25 |

| Nominal battery operating temperature (NOCT) (°C) | 45 ± 2 |

| PV module output power deviation | 0~3% |

| Total installed capacity (kWac) | 80 |

| Inverter model | SDP-40 |

| Inverter power (kWac) | 40 |

| Inverter efficiency (%) | 96 |

| Number of inverters | 2 |

| Inverter lifecycle (years) | 10 |

| Energy loss of PV and inverter (%) | 12 |

| Annual output of PV modules (kWh) | 122,700 |

| Parameters | Value |

|---|---|

| Desalination device availability (%) | 95 |

| Plant lifecycle (years) | 20 |

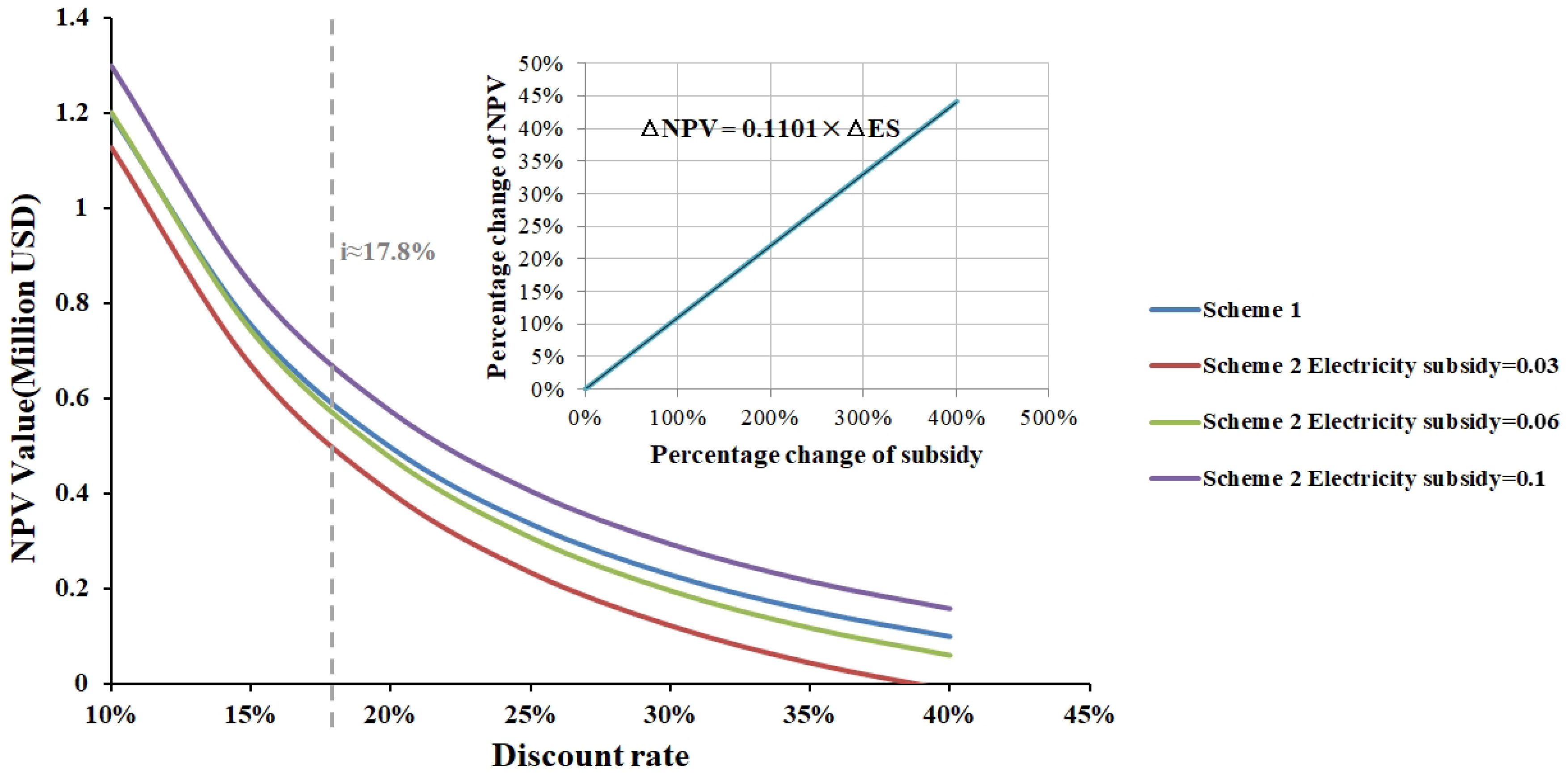

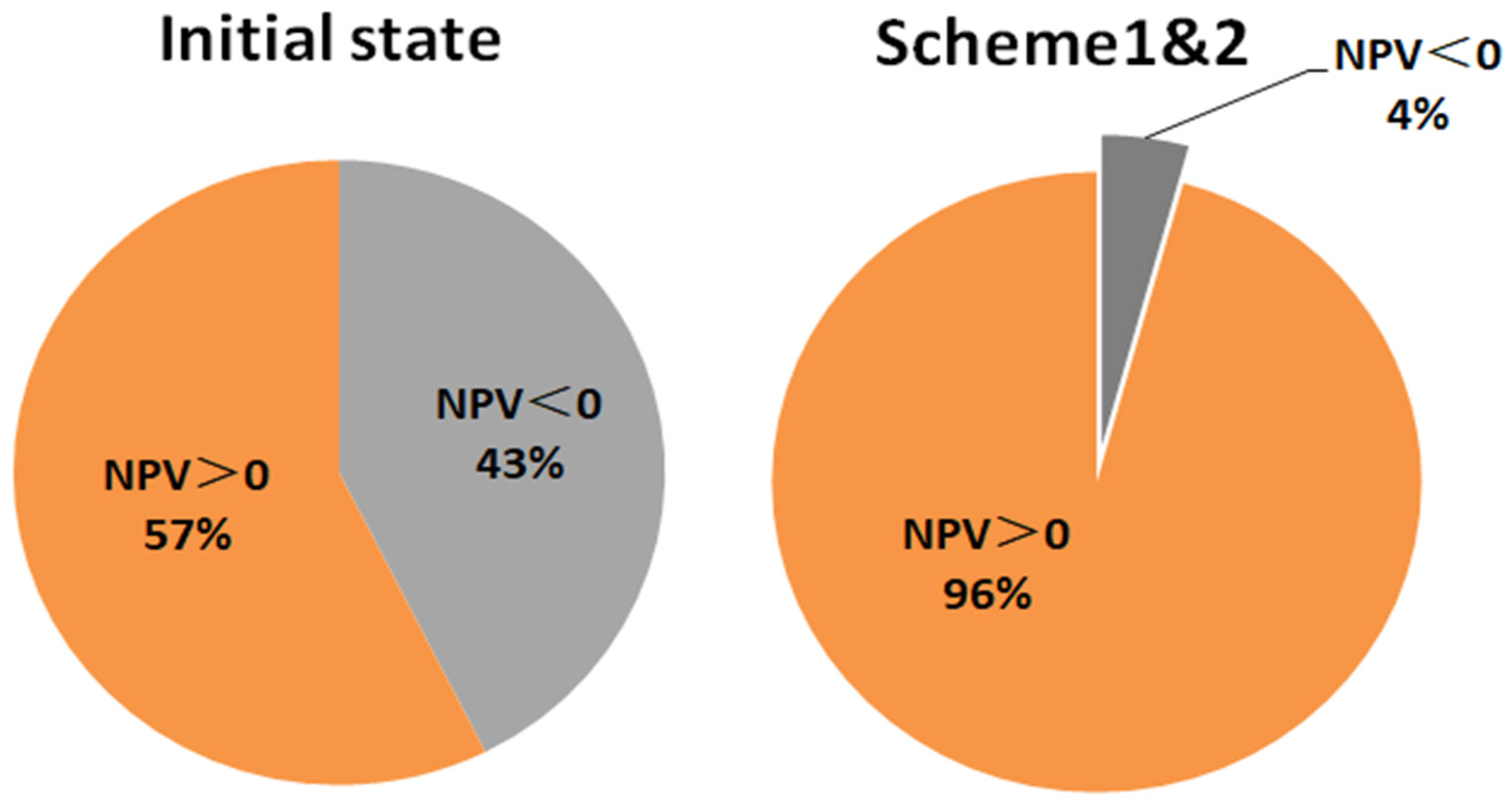

| Discount rate (%) | 17.8 |

| Apple selling price (USD/kg) | 3.5 |

| Orchard specific operating cost (USD/year/ha) | 1000 |

| Annual escalation rate for incomes (%) | 5 |

| Capital cost recovery factor (year−1) | 0.18 |

| Specific total capital cost of the solar panels (USD/kWp) | 219 |

| Exchange rate (USD/RMB) | 6.4 |

| Electricity price (USD/kWh) | 0.04 |

| Electricity subsidy (USD/kWh) | 0.06 |

| Scheme 1 | Scheme 2 | |

|---|---|---|

| Capital cost (USD) | ||

| Capital cost of the RO system | 234,375 | 234,375 |

| Capital cost of the PV system | N/A | 46,875 |

| Land cost | 4688 | 15,625 |

| Total capital cost | 239,063 | 296,875 |

| Operating cost (USD) | ||

| Electricity cost | 10,512 | 10,512 |

| Membrane cleaning and replacement cost | 11,200 | 11,200 |

| Operation and maintenance cost of the PV system | N/A | 469 |

| Operation and maintenance cost of the RO system | 3516 | 3516 |

| Labour cost | 4700 | 9400 |

| Total operating cost | 29,928 | 34,628 |

| Total annual cost | 72,959 | 88,065 |

| Unit desalination cost (USD/m3) | 0.6 | 0.75 |

| Income from selling apples in 1st year (USD) | 118,494 | 118,494 |

| PV subsidy income (USD) | N/A | 7362 |

| Total income in 1st year (USD) | 118,494 | 125,856 |

| Parameter | Max/Min | Current Amount | Distribution |

|---|---|---|---|

| Inflation rate | 15%/5% | 6.7% | Uniform |

| Apple selling price | +50%/−50% | 3.5 $/kg | Uniform |

| Discount rate | 29%/5% | 17.8% | Triangular |

| Electricity subsidies | +50%/−50% | 0.06 $/kWh | Triangular |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Sun, Z.; Zhai, C. Evaluation of a Desalination System Combining Photovoltaic and Membrane Technology: A Case Study on the Benefit Analysis of an Apple Orchard. Water 2024, 16, 2306. https://doi.org/10.3390/w16162306

Yang Y, Sun Z, Zhai C. Evaluation of a Desalination System Combining Photovoltaic and Membrane Technology: A Case Study on the Benefit Analysis of an Apple Orchard. Water. 2024; 16(16):2306. https://doi.org/10.3390/w16162306

Chicago/Turabian StyleYang, Yang, Zhilin Sun, and Chaoqun Zhai. 2024. "Evaluation of a Desalination System Combining Photovoltaic and Membrane Technology: A Case Study on the Benefit Analysis of an Apple Orchard" Water 16, no. 16: 2306. https://doi.org/10.3390/w16162306

APA StyleYang, Y., Sun, Z., & Zhai, C. (2024). Evaluation of a Desalination System Combining Photovoltaic and Membrane Technology: A Case Study on the Benefit Analysis of an Apple Orchard. Water, 16(16), 2306. https://doi.org/10.3390/w16162306