Study on the Characteristics and Evolution Laws of Seepage Damage in Red Mud Tailings Dams

Abstract

1. Introduction

2. Materials and Method

2.1. Materials

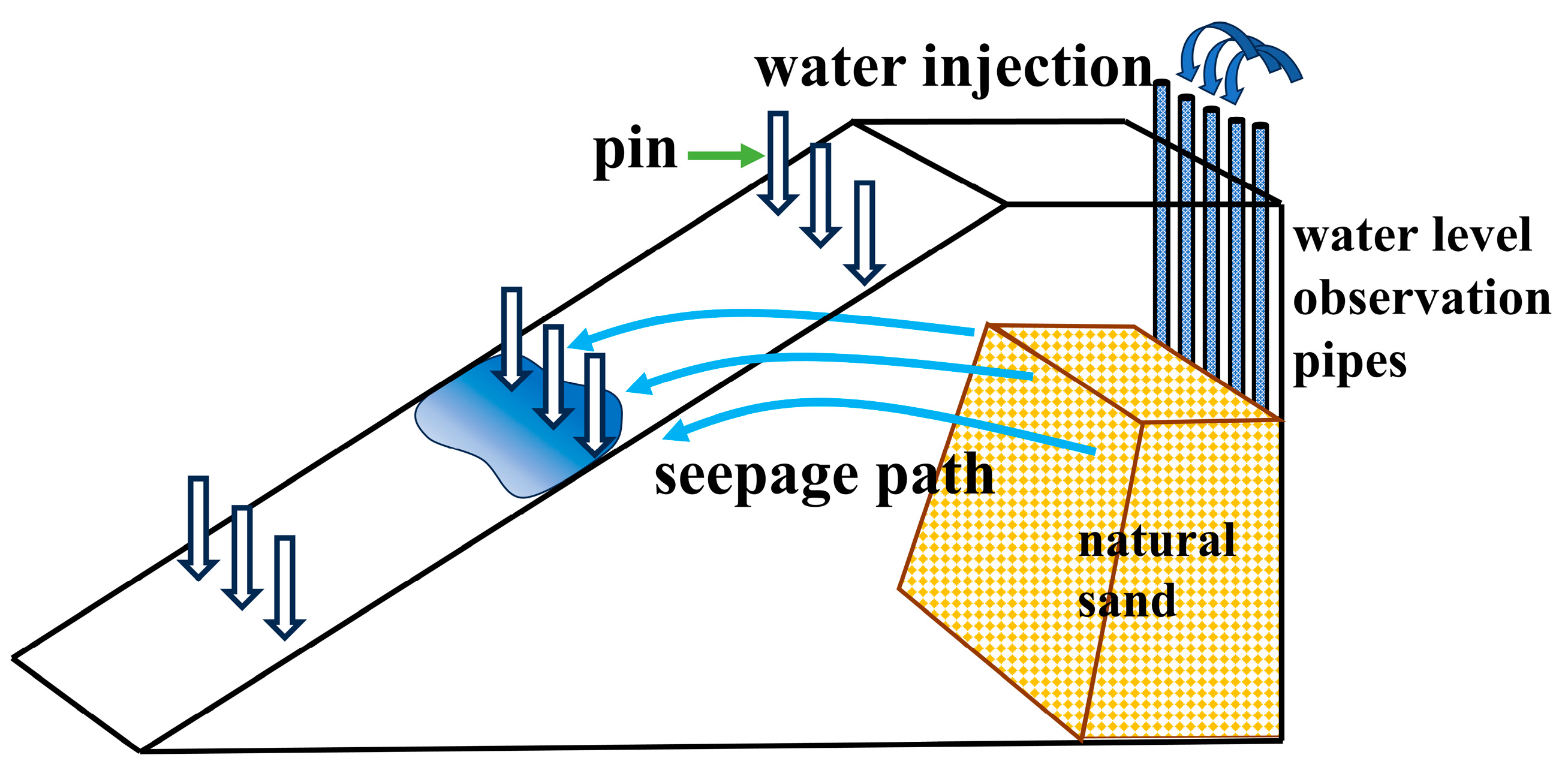

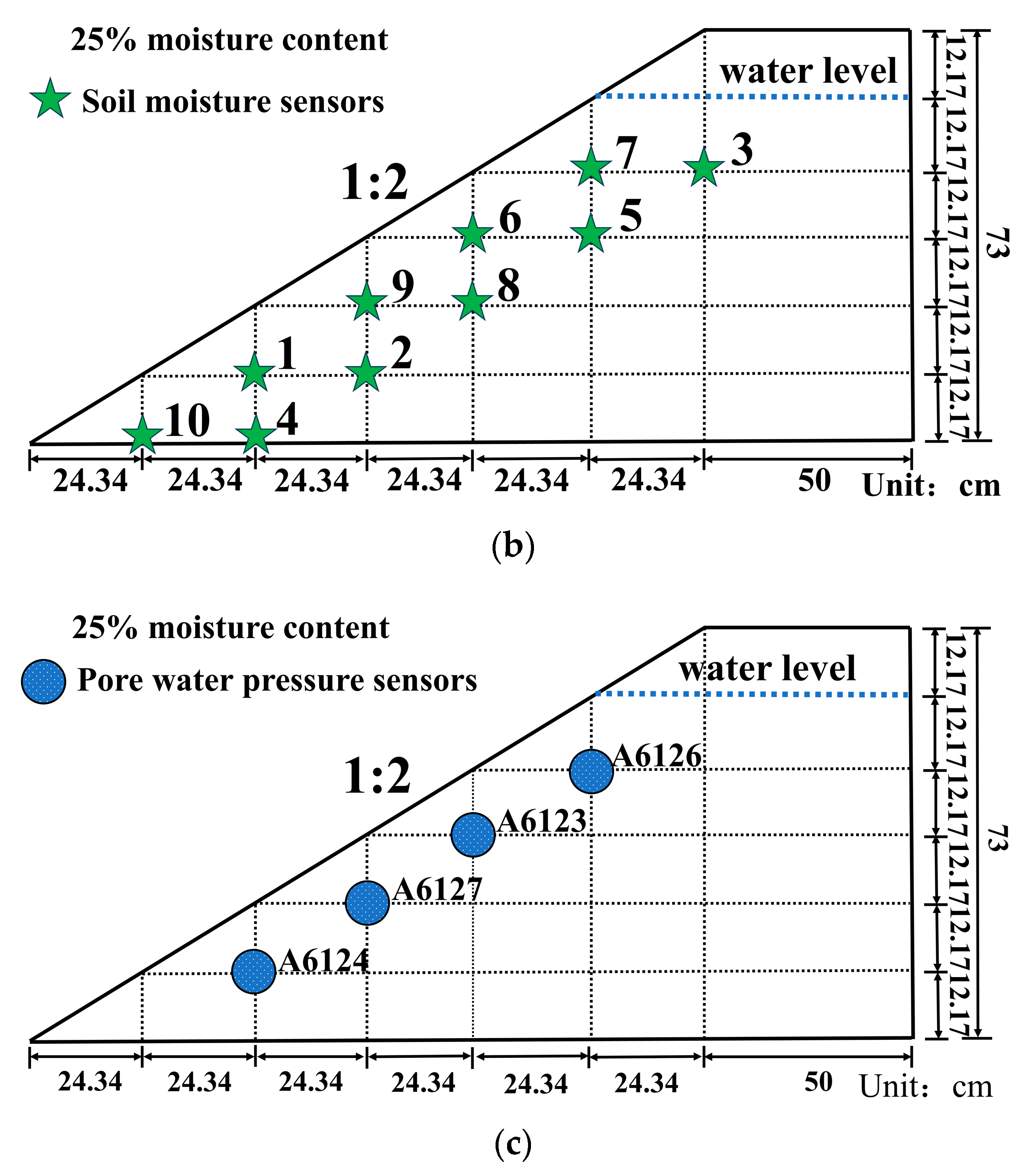

2.2. Laboratory Test Tank

2.3. Water Level Control and Monitoring System

2.4. Red Mud Filling Process in the Laboratory

2.5. Test Program

3. Results and Discussion

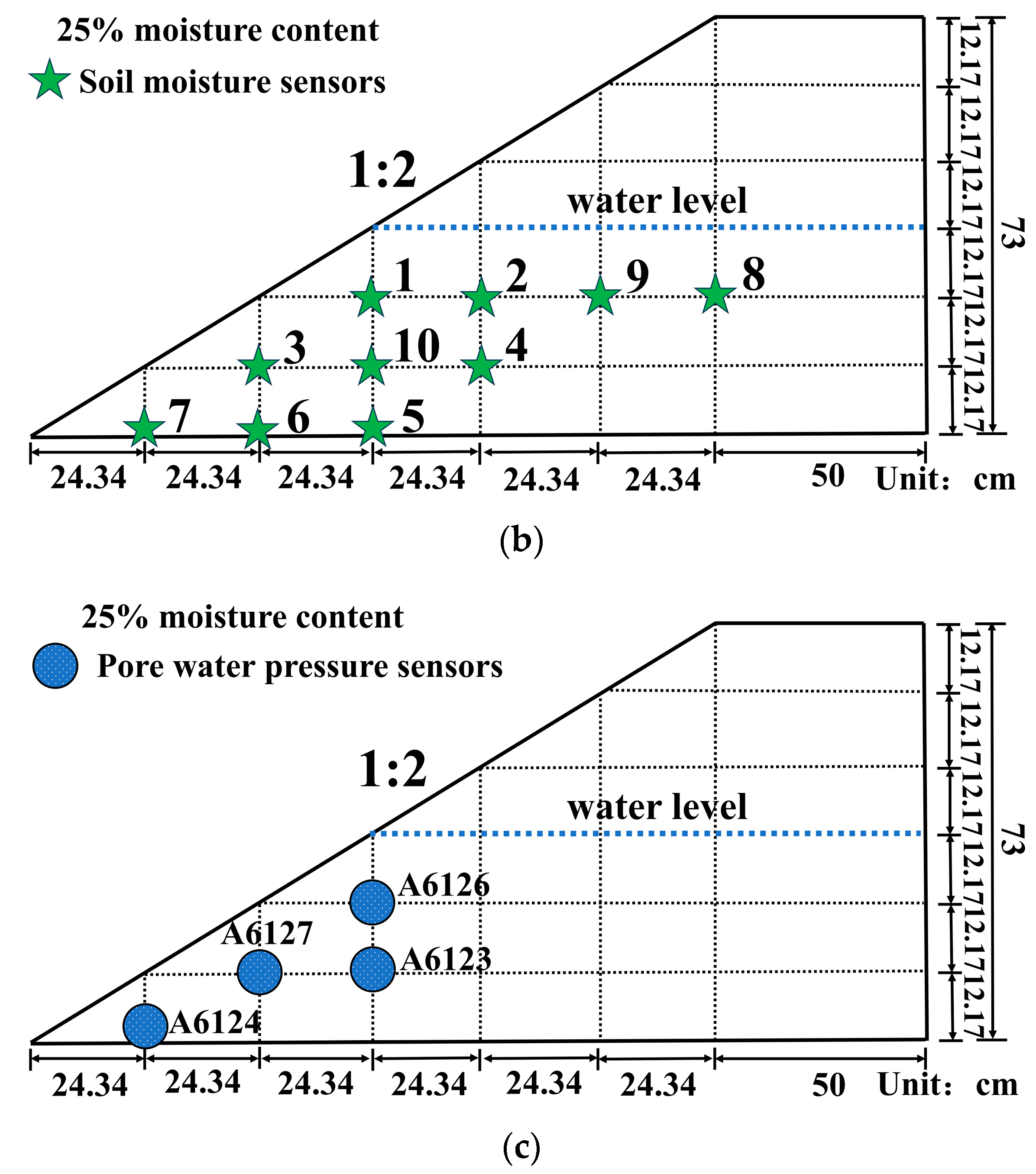

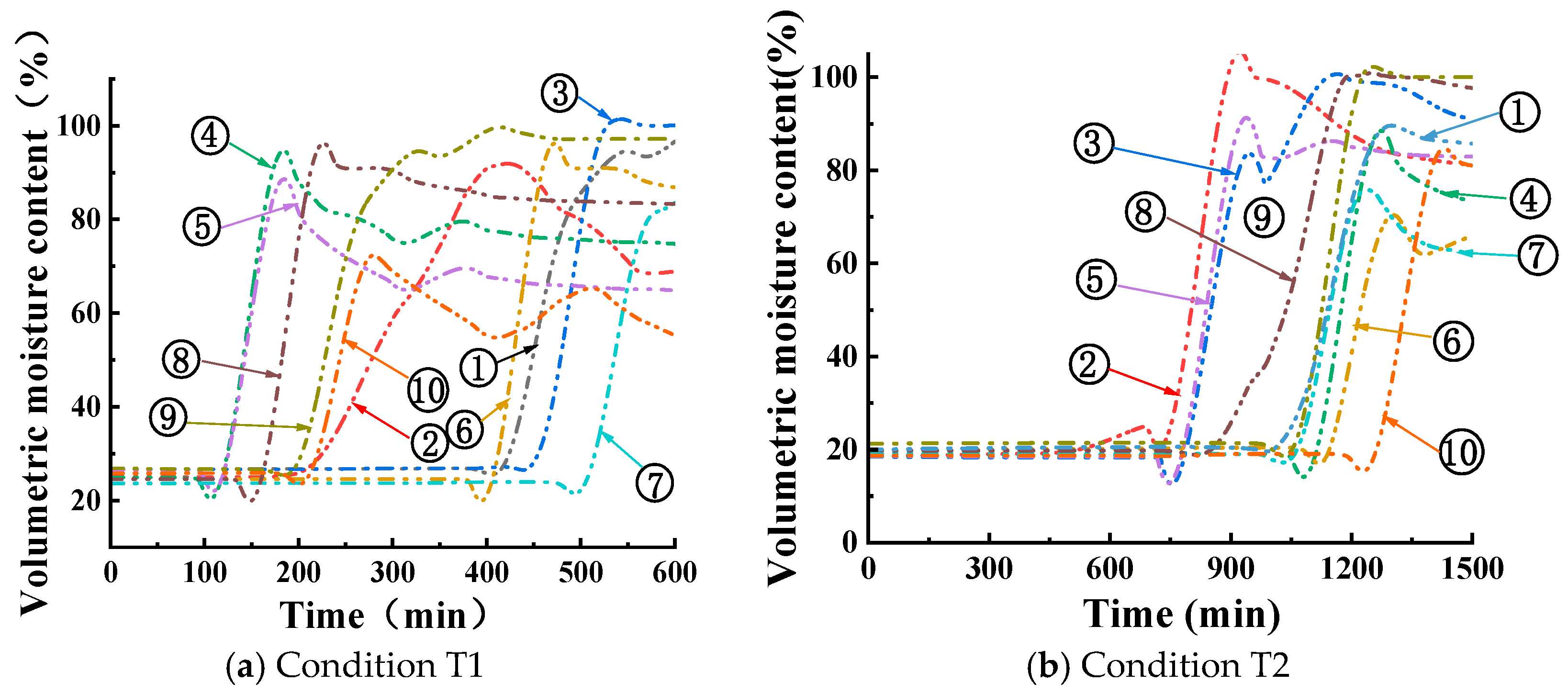

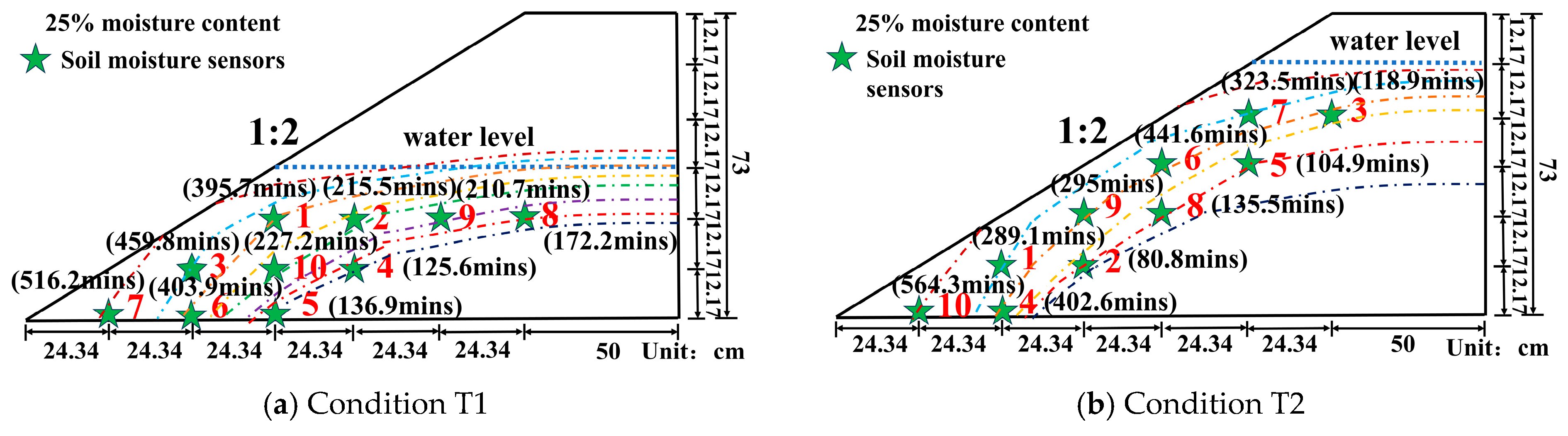

3.1. Evolution Law of Infiltration Line in Red Mud Dams with Seepage Damage at Different Water Levels

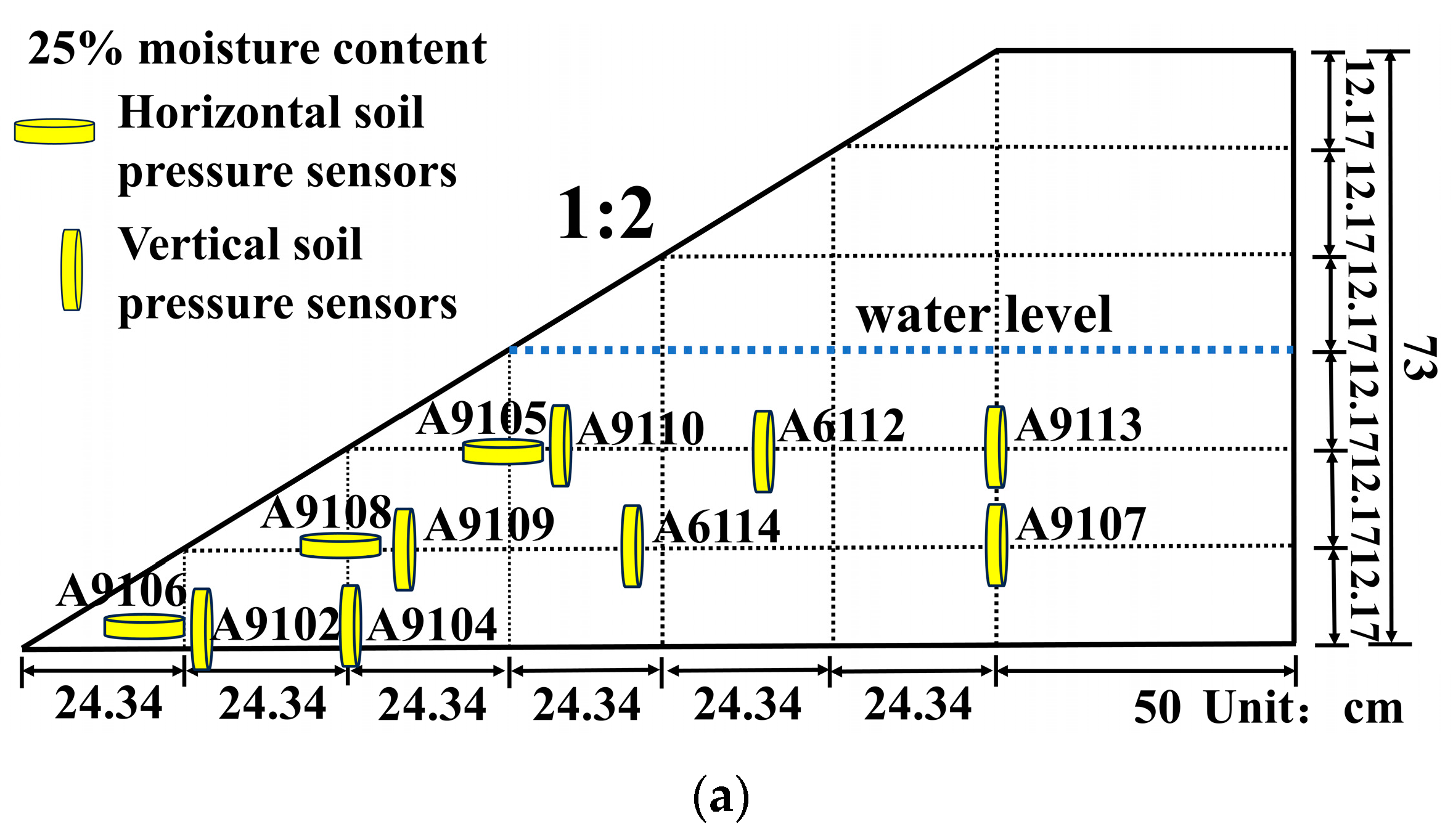

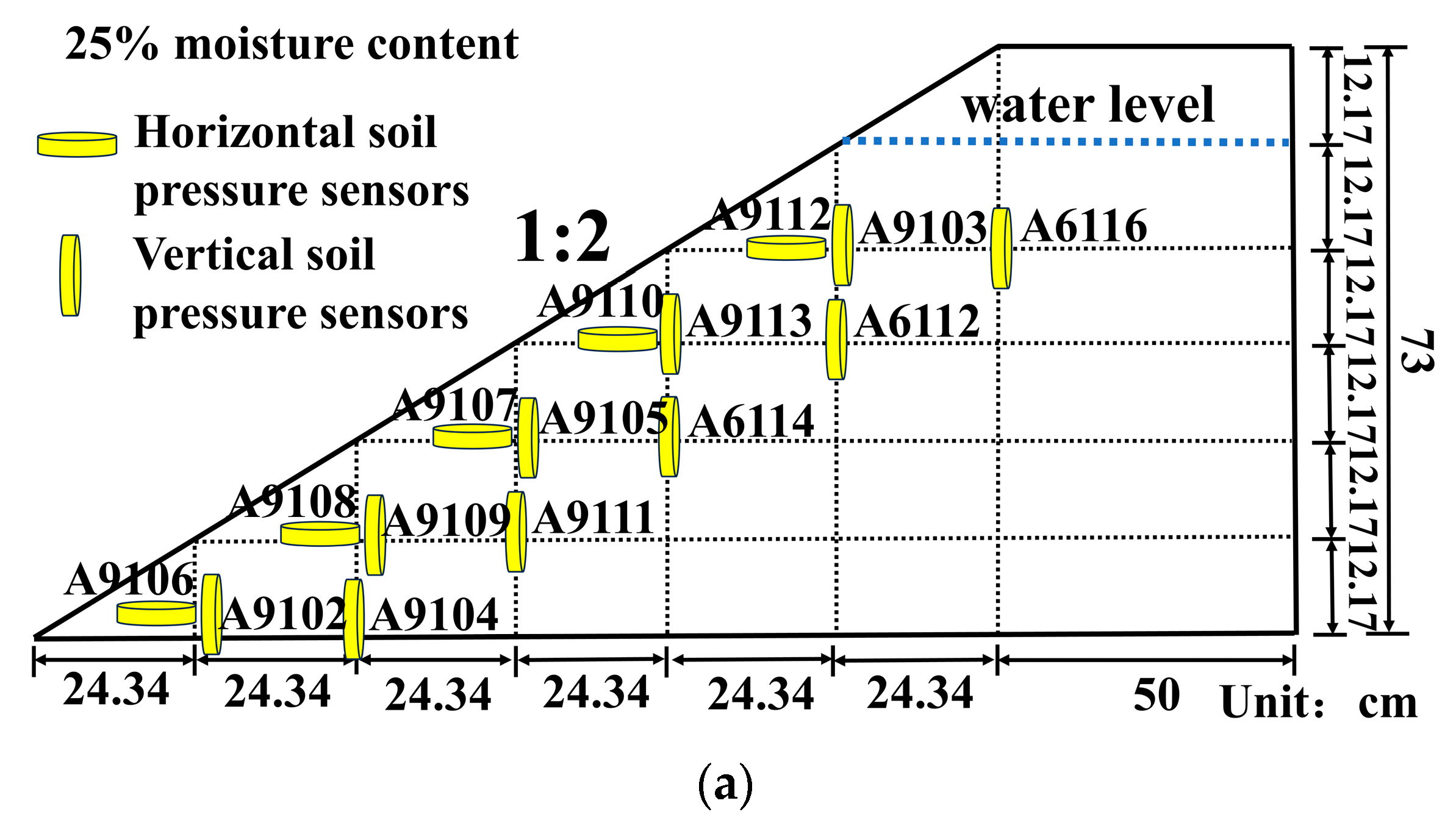

3.2. Distribution Law of Soil Pressure in Red Mud Dams with Seepage Failure at Different Water Levels

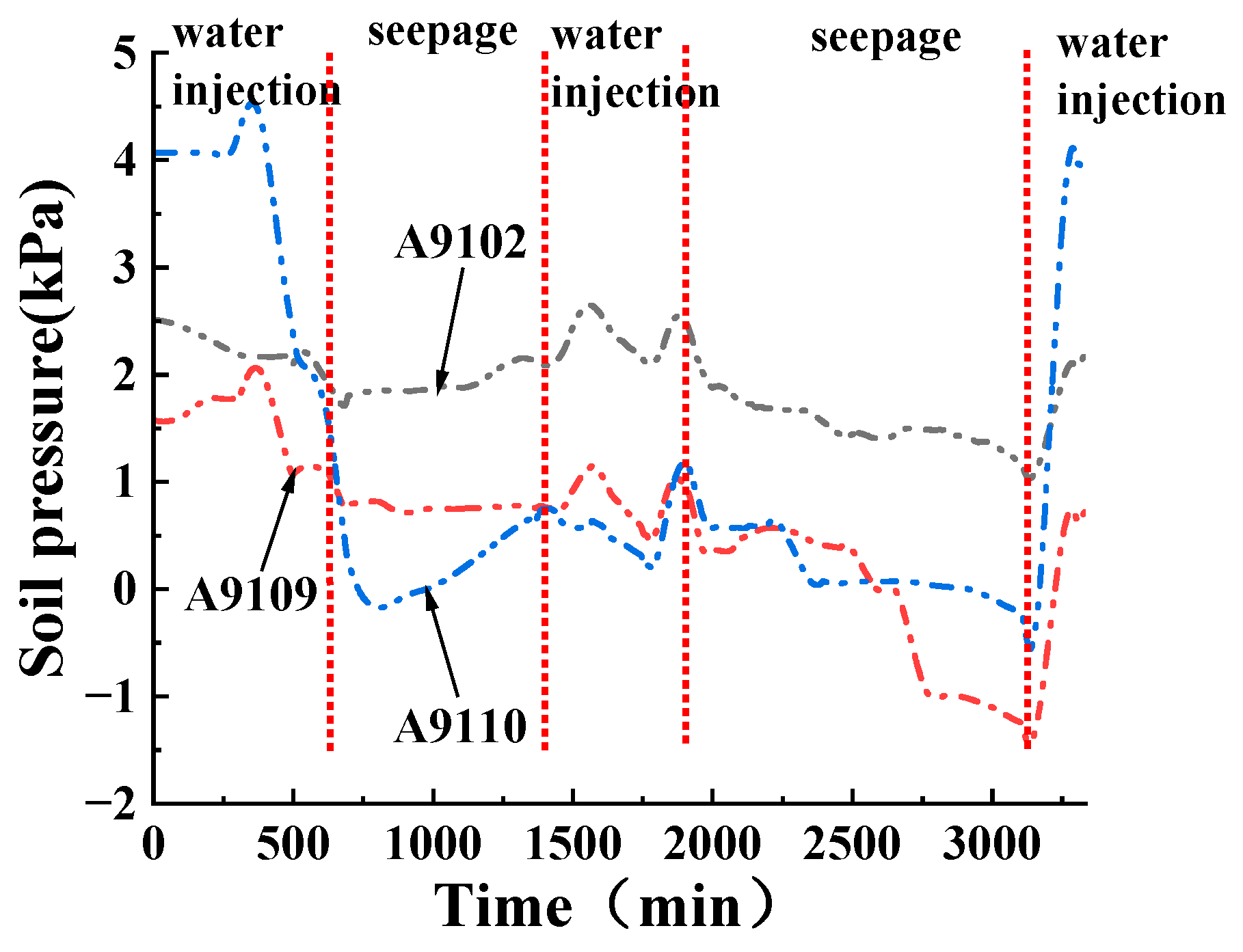

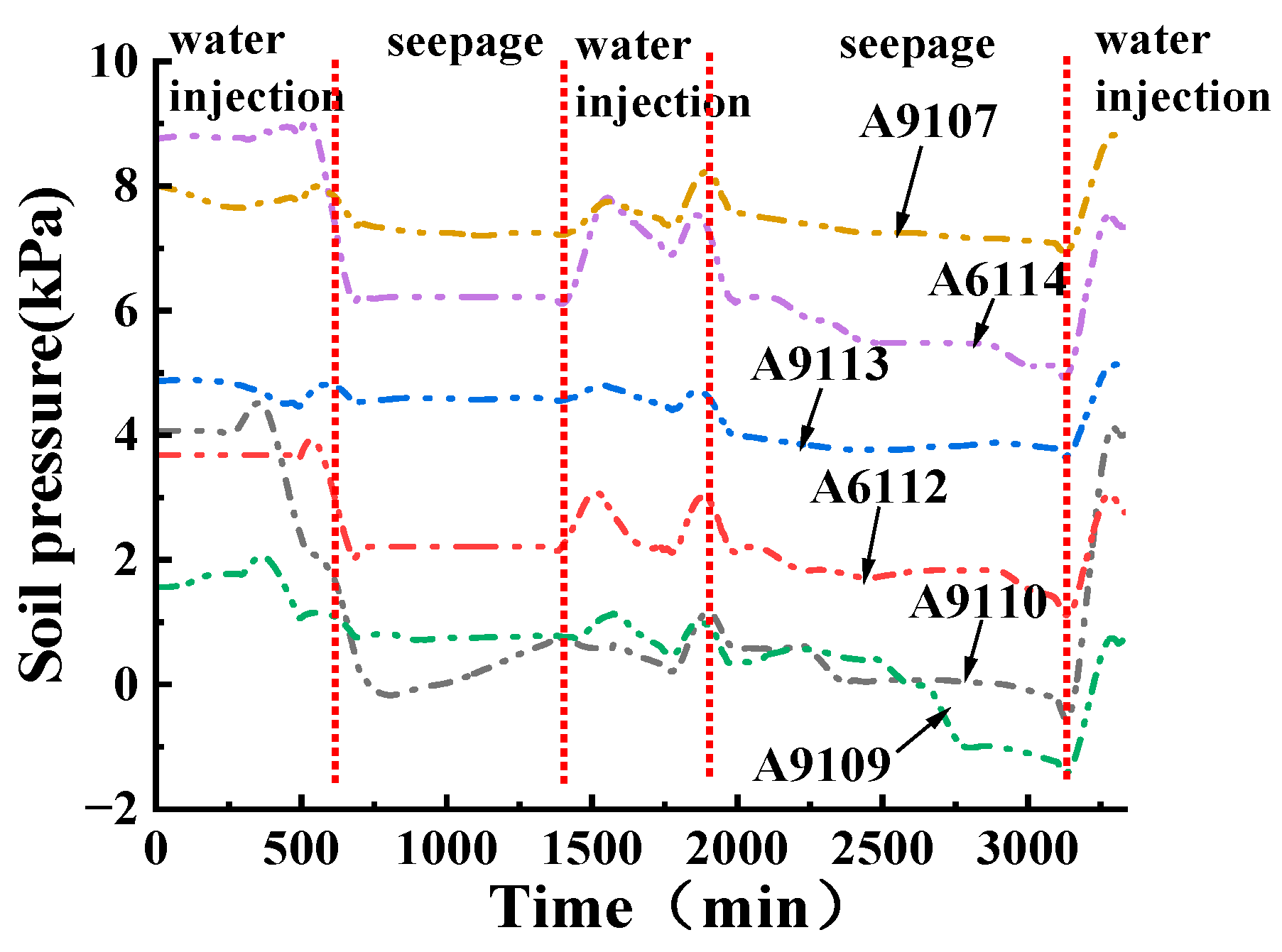

3.2.1. The Variation Law of the Vertical Soil Pressure near the Slope Surface in Condition T1 with Time

3.2.2. The Variation Law of the Horizontal Soil Pressure near the Slope Surface in Condition T1 with Time

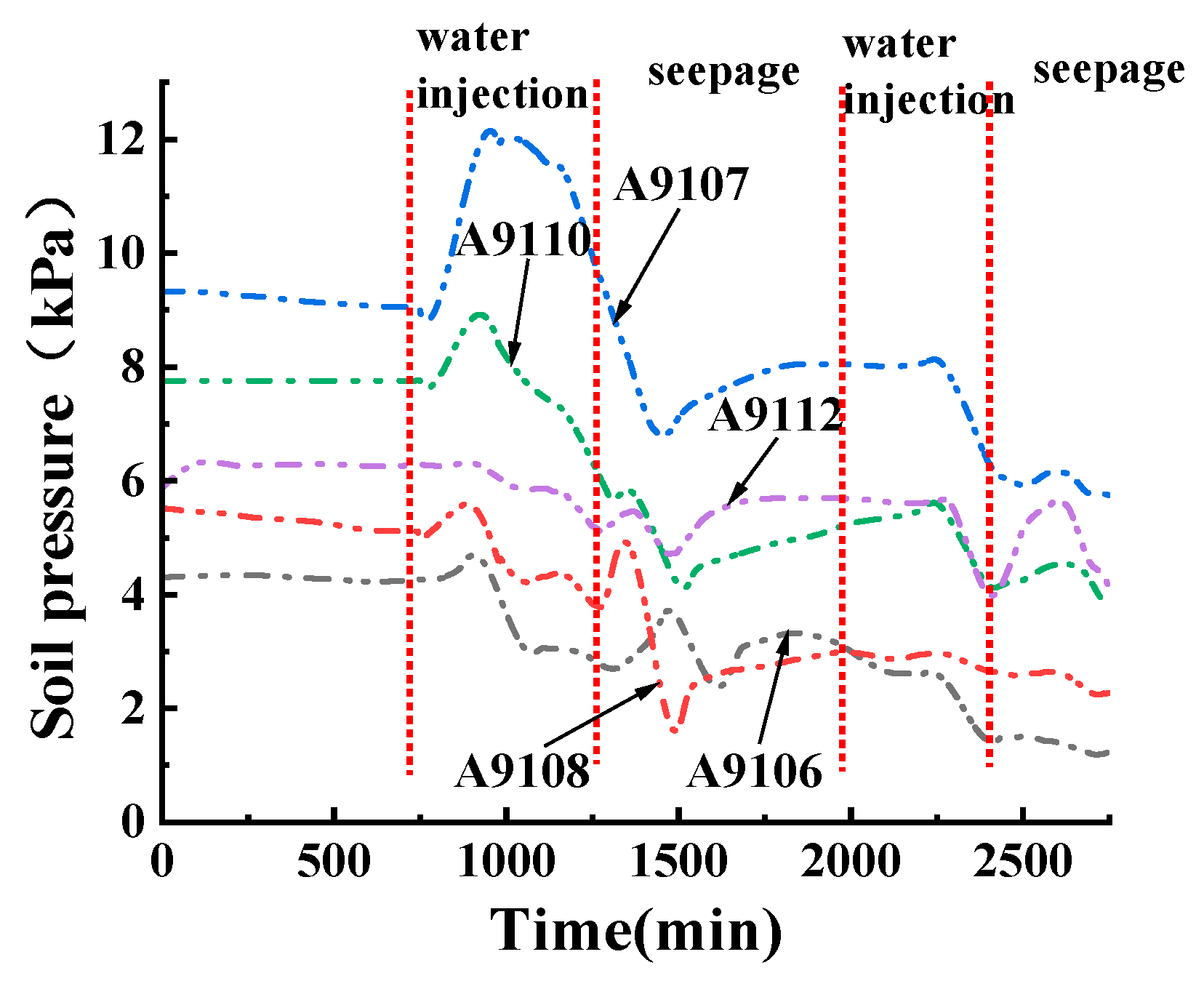

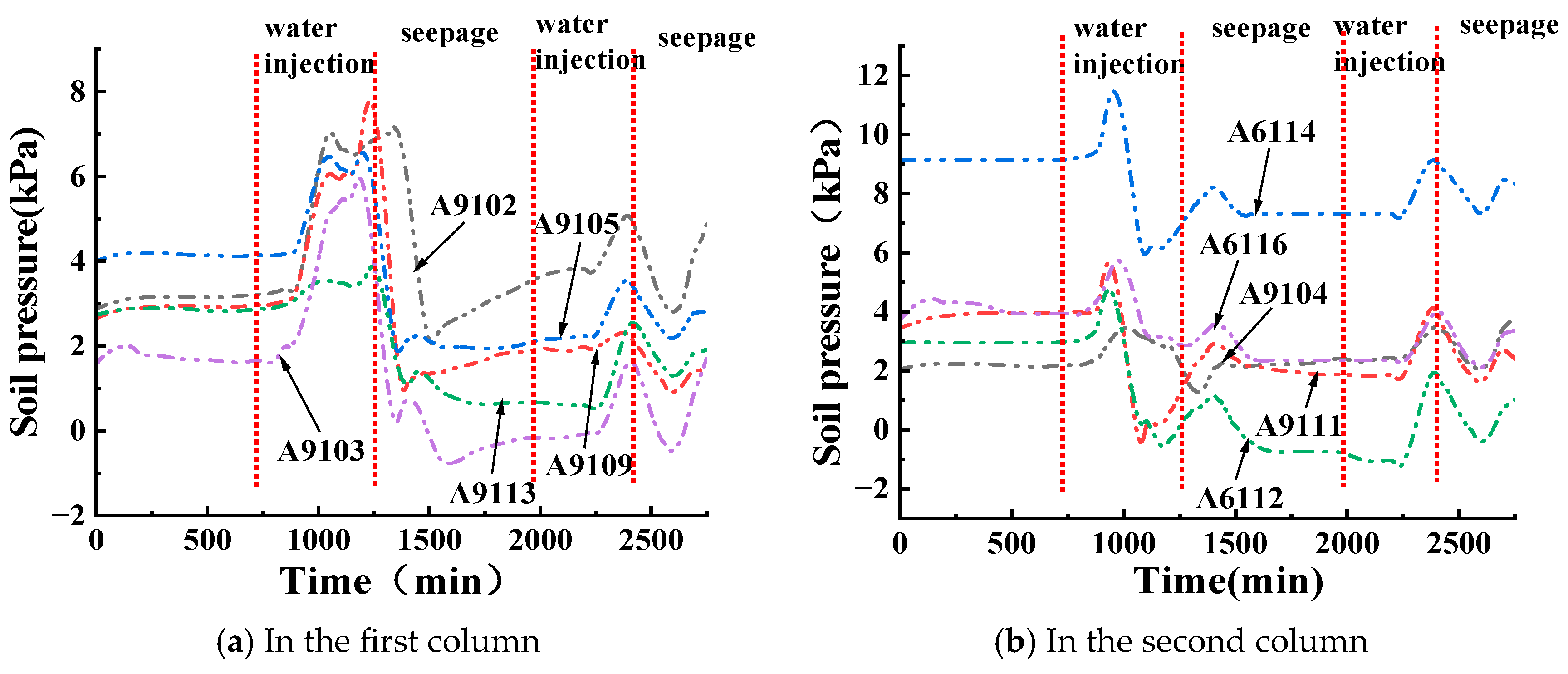

3.2.3. The Variation Law of the Vertical Soil Pressure near the Slope Surface in Condition T2 with Time

3.2.4. The Variation Law of the Horizontal Soil Pressure near the Slope Surface in Condition T2 with Time

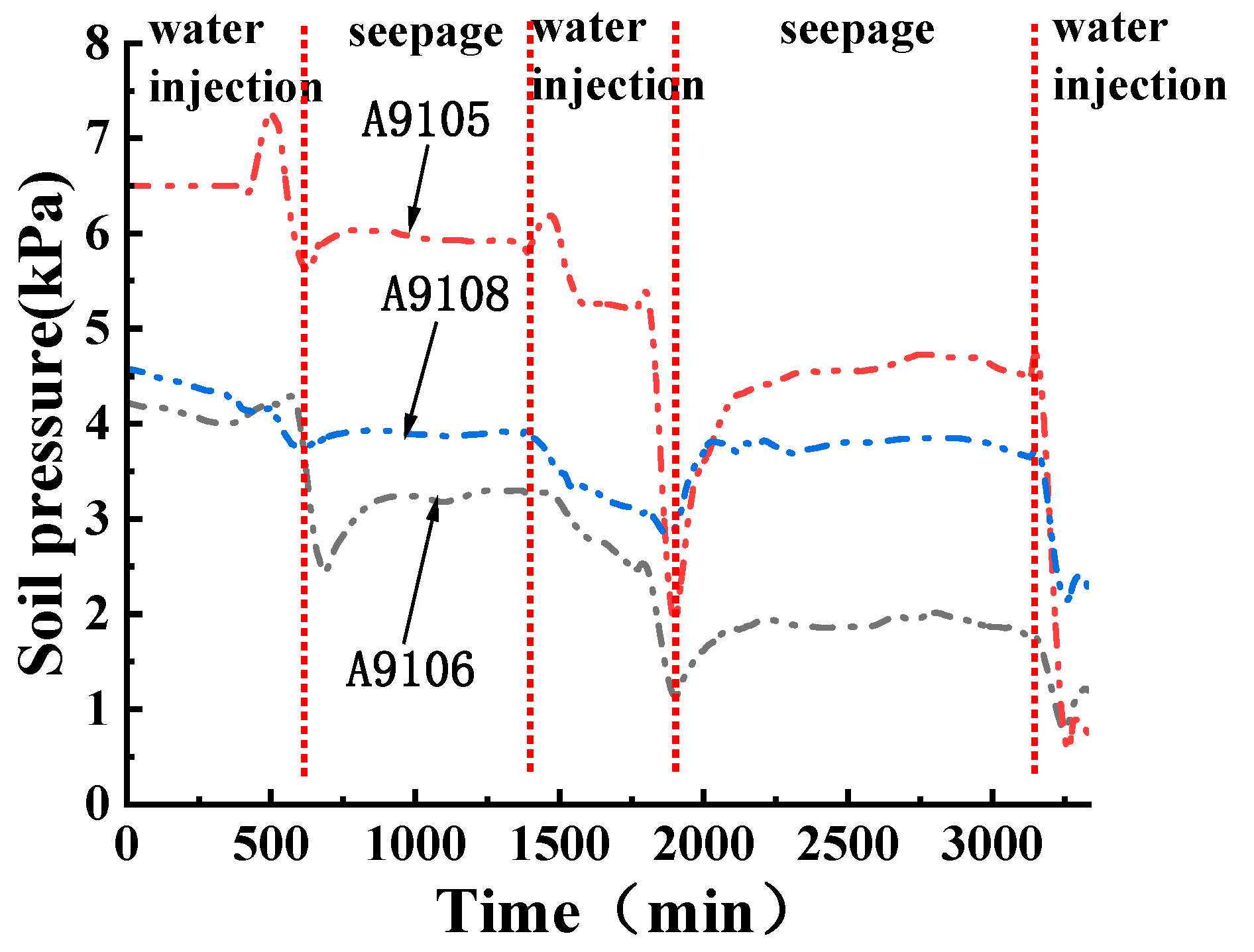

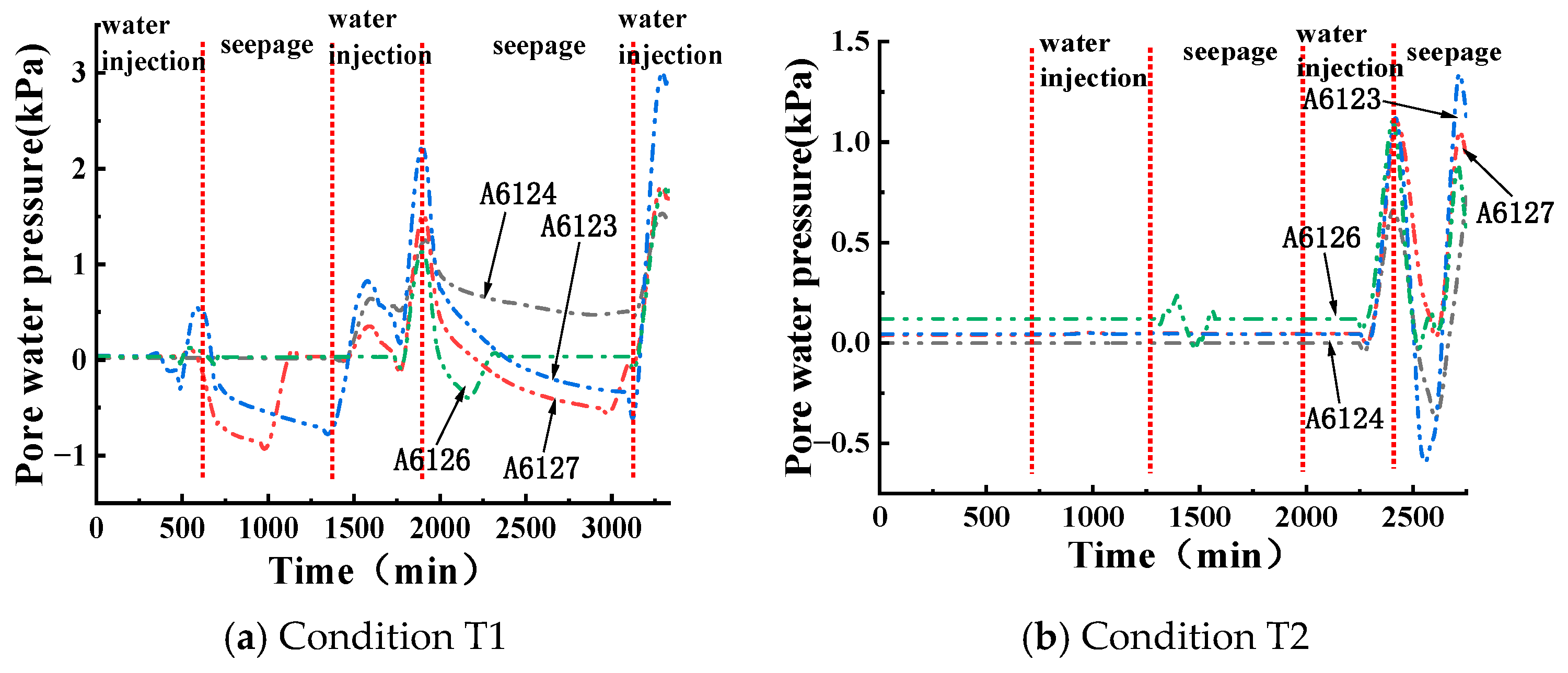

3.3. Pore Water Pressure Change Rule under Water Level Change

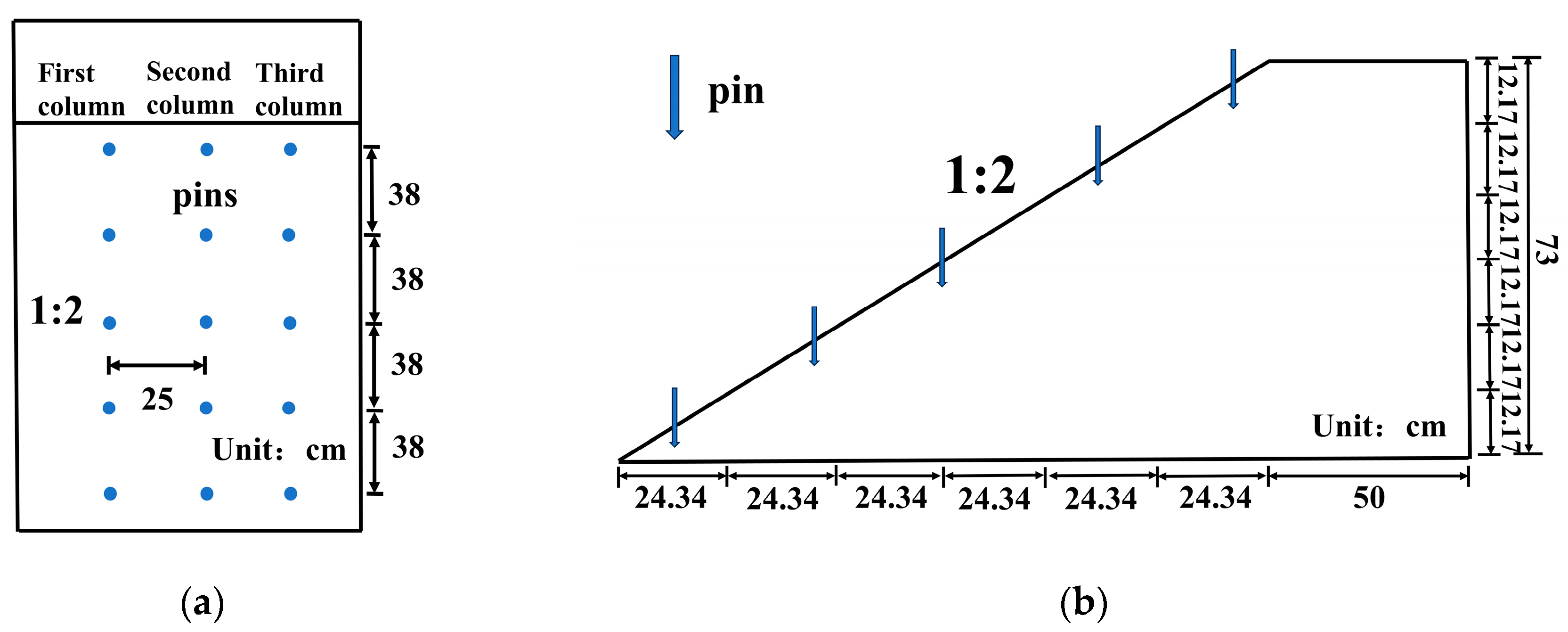

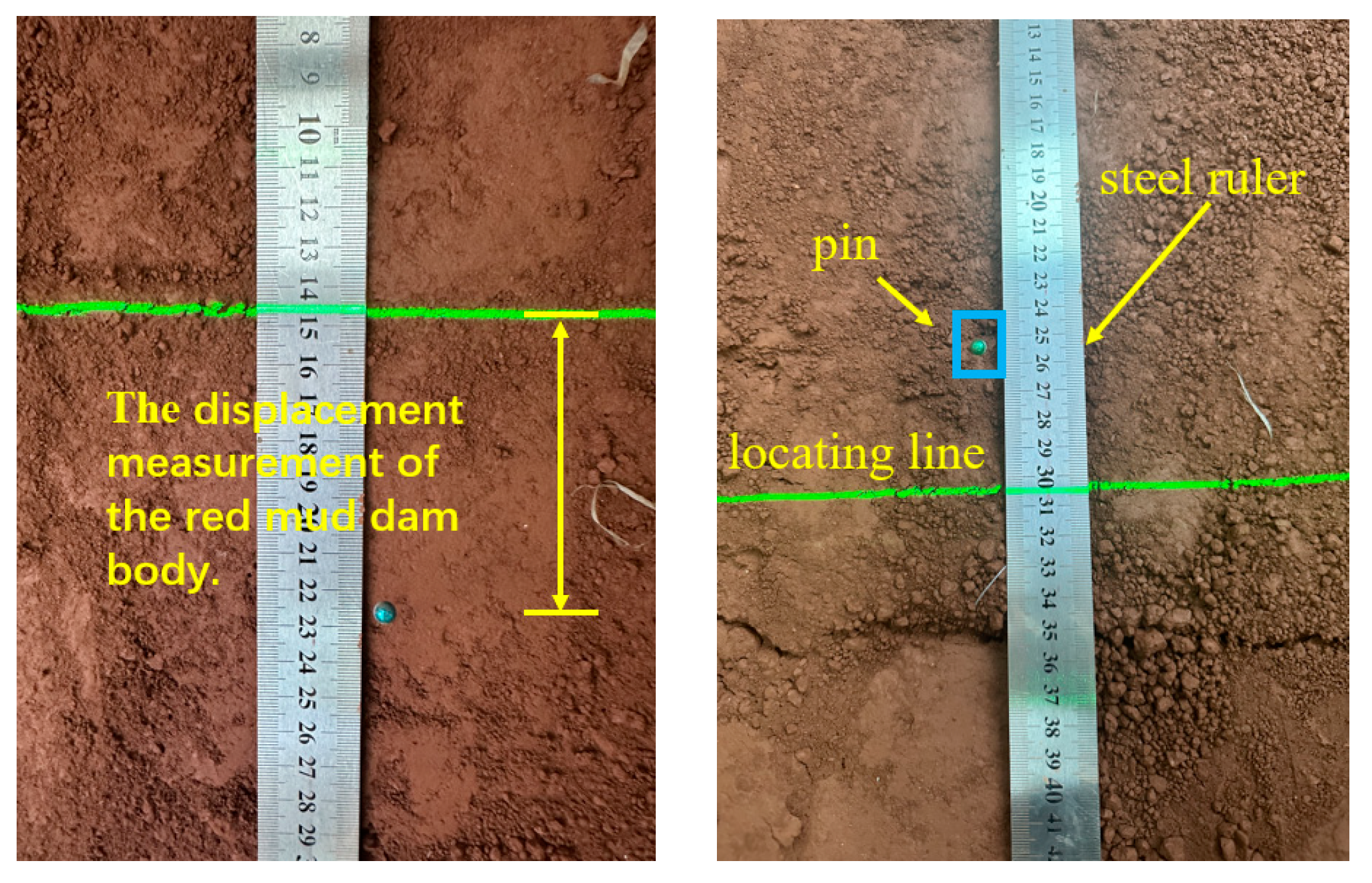

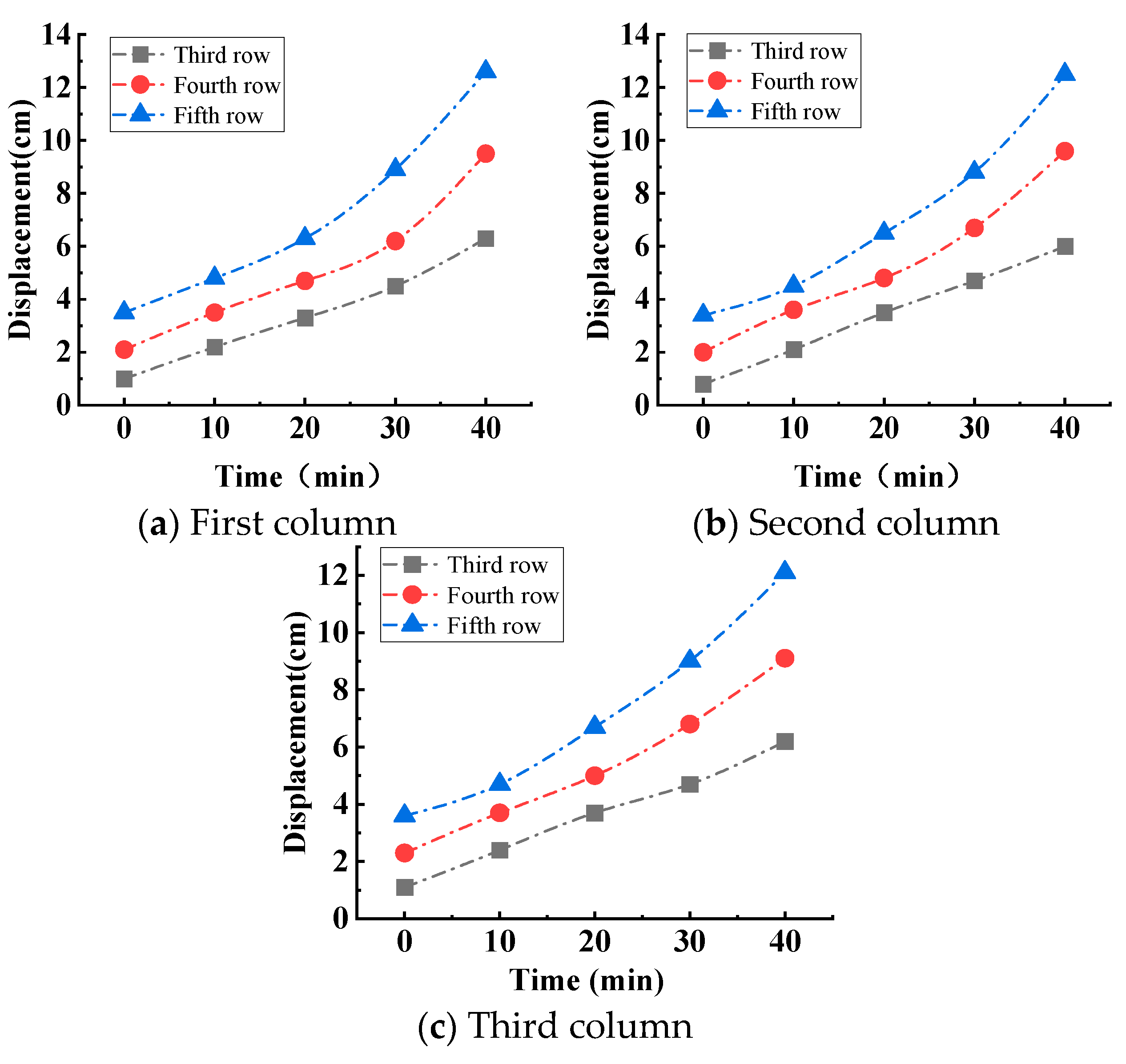

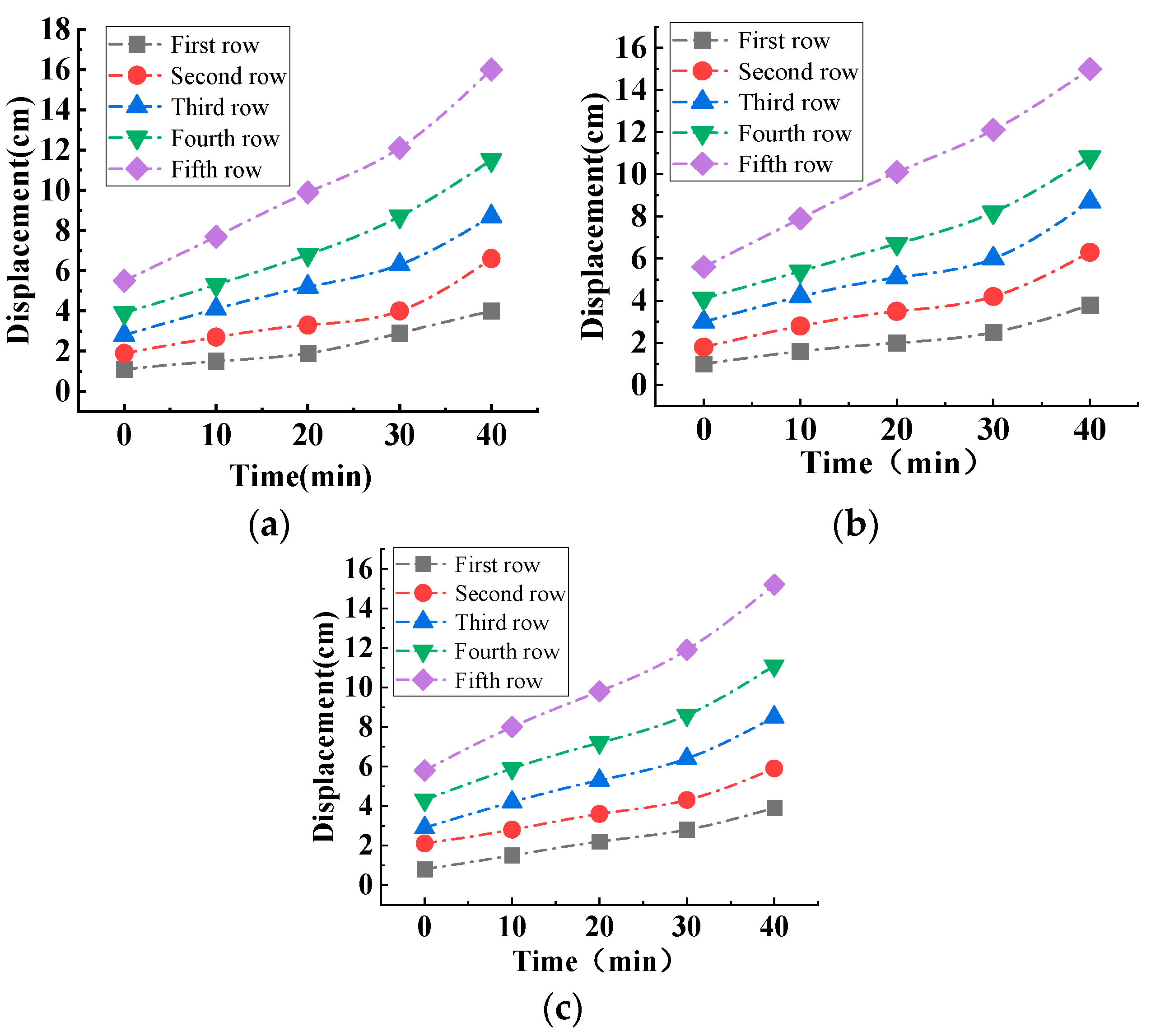

3.4. Displacement Evolution Law of Red Mud Dams with Seepage Failure at Different Water Levels

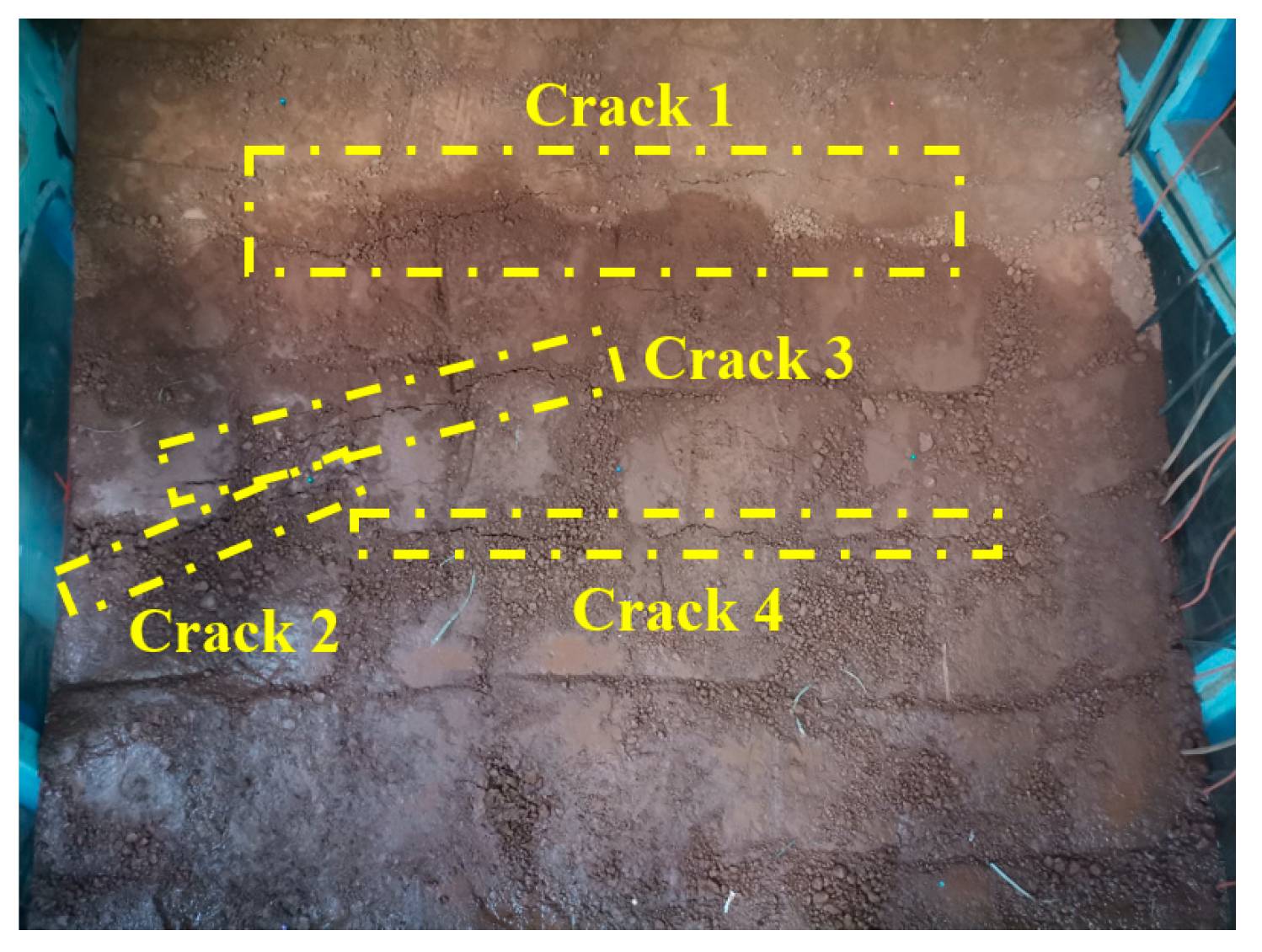

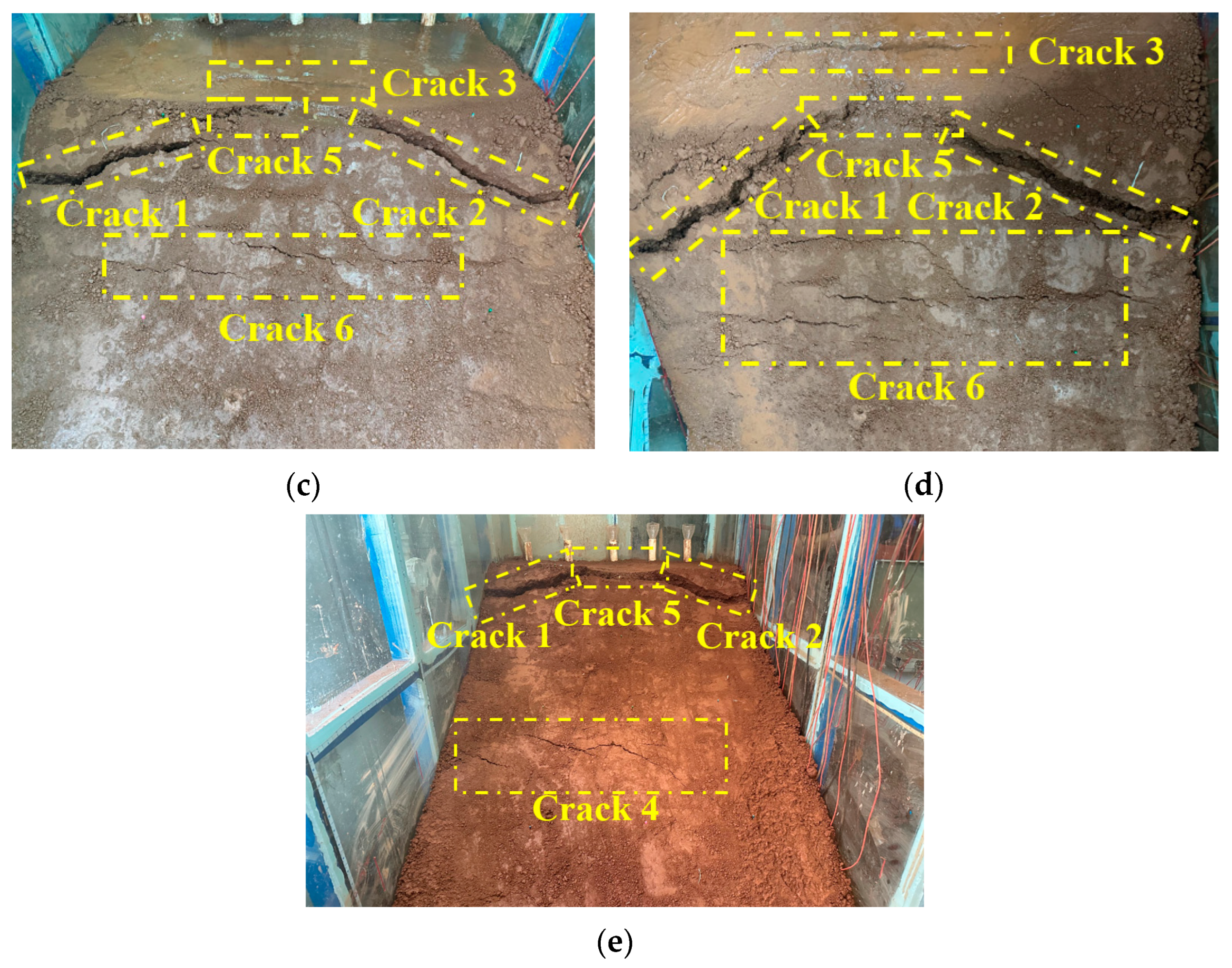

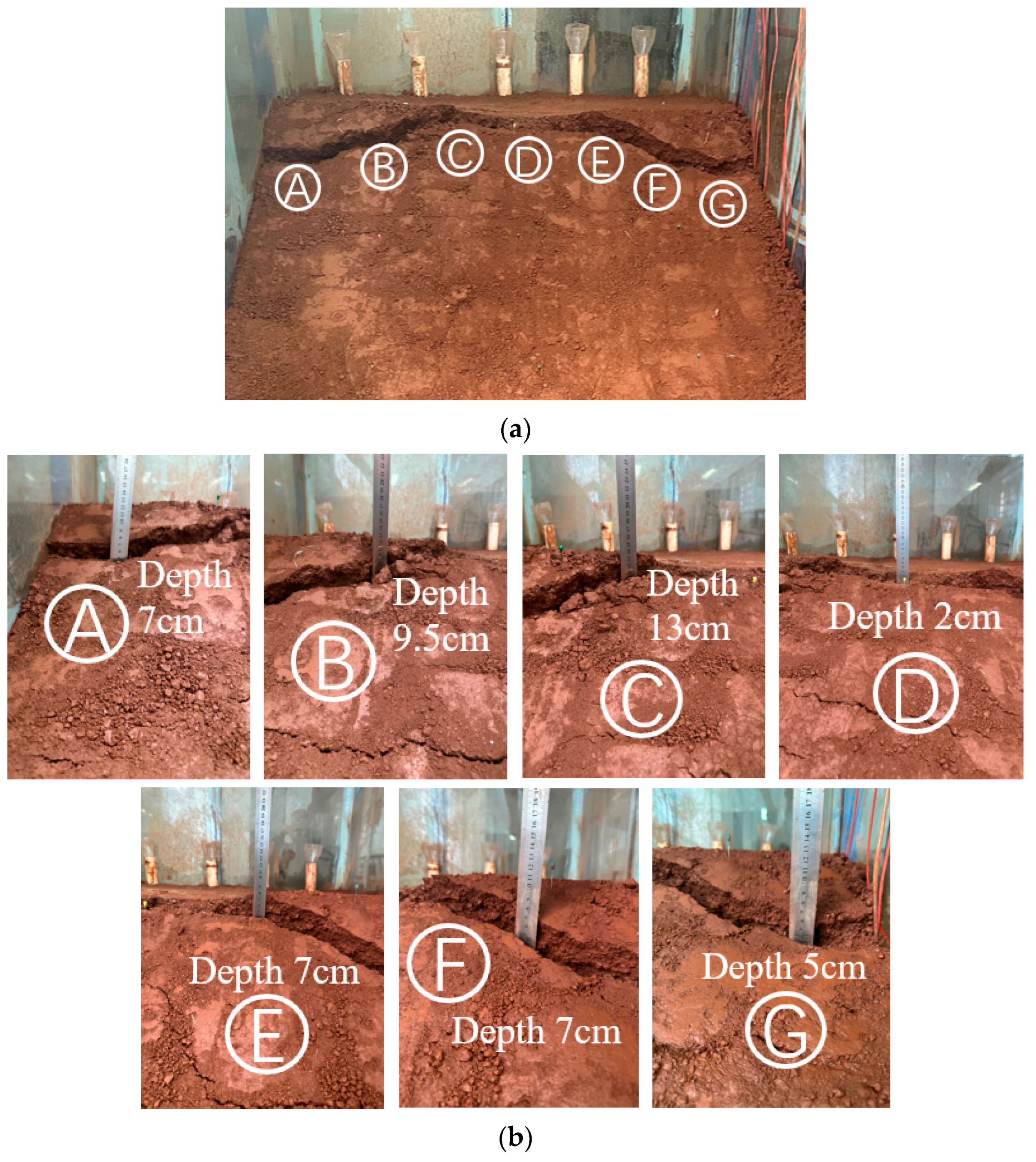

3.5. Evolution Law of Cracks in Red Mud Dams with Seepage Failure at Different Water Levels

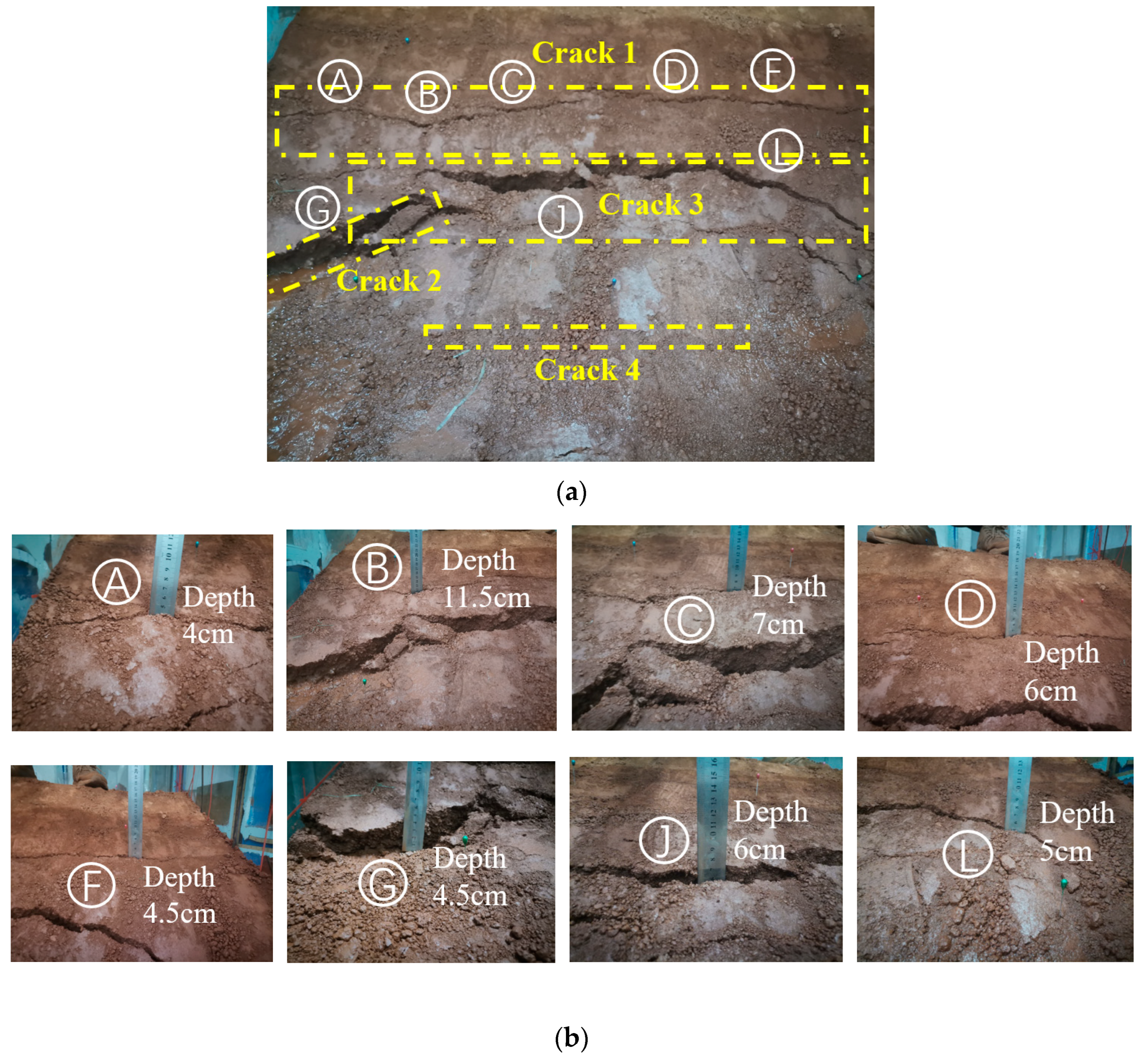

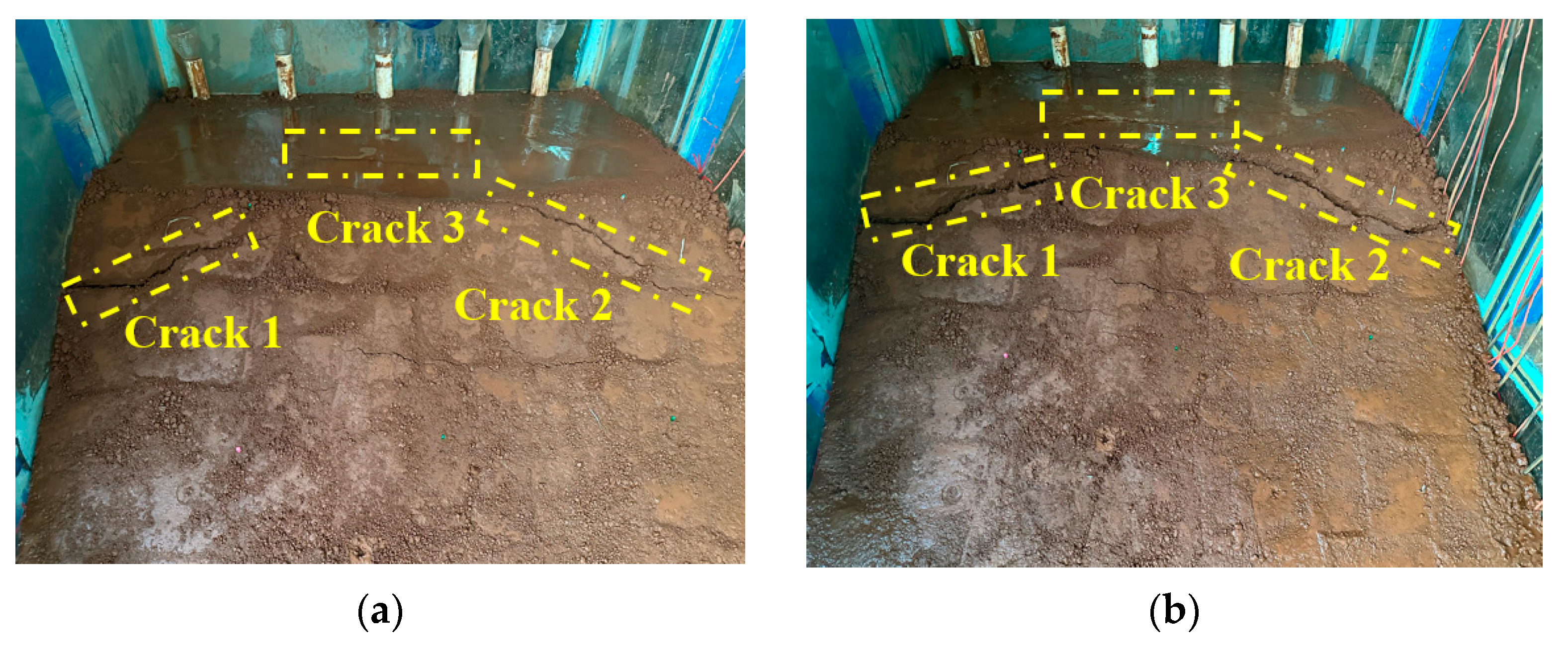

3.5.1. Evolution Law of Cracks in Red Mud Dams with Seepage Failure in Condition T1

3.5.2. Evolution Law of Cracks in Red Mud Dams with Seepage Failure in Condition T2

3.6. Discussion

4. Conclusions

- (1)

- The maximum pore water pressure is located at the highest infiltration line of the slope surface. Horizontal soil pressure gradually increases under the action of pore water pressure; as the pore water pressure increases, the effective stress decreases, the shear strength decreases, and the likelihood of damage increases. It can also be seen from the test results that the high water level seepage damage is faster and occurs at a higher damage location than low level seepage;

- (2)

- For the displacement of the dam body caused by seepage damage, the infiltration line does not cover the whole slope under the influence of low water levels, the displacement of the dam body mainly appears in the dam body below the infiltration line, and the dam body above the infiltration line does not have any displacement during the process of water level change. The infiltration line covers the whole slope surface under the influence of high water levels, and displacement occurs on the whole dam slope surface. The displacement of the dam body is mainly due to the continuous expansion of the main crack produced by seepage damage, and the higher the water level is, the greater the displacement of the dam body is;

- (3)

- The crack evolution law of seepage-induced damage in the red mud dam reveals that the cracks primarily occur below the infiltration line. As seepage continues, the seepage force mobilizes red mud particles, creating water pathways within the dam body and resulting in surface cracks. The main crack, expanding most rapidly, is a longitudinal crack aligned with the dam axis. The higher the water level, the higher the position at which the primary crack emerges. The main crack continues to expand until it penetrates the entire width direction of the dam body. With continuous water injection, both the width and depth of the main crack increase.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wei, D.; Jun-Hui, X.; Yang, P. Iron Extraction from Red Mud using Roasting with Sodium Salt. Miner. Process. Extr. Metall. Rev. 2019, 42, 153–161. [Google Scholar] [CrossRef]

- Reddy, P.S.; Narala, G.R.; Serjun, V.Z.; Mohanty, B.; Rao, B.H. Properties and assessment of applications of red mud (bauxite residue): Current status and research needs. Waste Biomass Valorization 2021, 33, 1185–1217. [Google Scholar] [CrossRef]

- Fang, H.; Guo, N.X. The Current Situation of Recovery and Utilization of Red Mud from Alumina Solid Waste. China Resour. Compr. Util. 2011, 29, 21–24. (In Chinese) [Google Scholar]

- Nan, X.L.; Zhang, T.A.; Liu, Y. Comprehensive utilization and analysis of Chinese red mud. Process Eng. 2010, 10, 264–270. [Google Scholar]

- Bian, J.; Li, S.; Zhang, Q. Experimental Investigation on Red Mud from the Bayer Process for Cemented Paste Backfill. Int. J. Environ. Res. Public Health 2022, 19, 11926. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Jin, H.; Deng, Y. Comprehensive utilization status of red mud in China: A critical review. J. Clean. Prod. 2021, 289, 125136. [Google Scholar] [CrossRef]

- Lima, M.S.S.; Thives, L.P. Evaluation of red mud as filler in Brazilian dense graded asphalt mixtures. Constr. Build. Mater. 2020, 260, 119894. [Google Scholar] [CrossRef]

- Hui, S.; Charlebois, L.E.W.; Sun, C. Real-time monitoring for structural health, public safety, and risk management of mine tailings dams. Can. J. Earth Sci. 2017, 55, 221–229. [Google Scholar] [CrossRef]

- Song, C.W.; Yu, G.M.; Xue, B.F. A huge source of pollution hazard -Disaster and cure of tailings pond. In Proceedings of the IEEE International Conference on Electronics, Communications and Control (ICECC), Ningbo, China, 9–11 September 2011. [Google Scholar]

- Lin, S.Q.; Wang, G.J.; Liu, W.L.; Zhao, B.; Shen, Y.M.; Wang, M.L.; Li, X.S. Regional Distribution and Causes of Global Mine Tailings Dam Failures. Metals 2022, 12, 905. [Google Scholar] [CrossRef]

- Clarkson, L.; Williams, D. An Overview of Conventional Tailings Dam Geotechnical Failure Mechanisms. Min. Metall. Explor. 2021, 38, 1305–1328. [Google Scholar] [CrossRef]

- Lyu, Z.J.; Chai, J.; Qin, Y.; Cao, J. A Comprehensive Review on Reasons for Tailings Dam Failures Based on Case History. Adv. Civ. Eng. 2019, 2019, 4159306. [Google Scholar] [CrossRef]

- Wang, G.J.; Tian, S.; Xu, Z.; Kong, X. Evolution Pattern of Tailings Flow from Dam Failure and the Buffering Effect of Debris Blocking Dams. Water 2019, 11, 2388. [Google Scholar] [CrossRef]

- Wang, G.J.; Tian, S.; Hu, B.; Kong, X.Y.; Chen, J. An experimental study on tailings deposition characteristics and variation of tailings dam saturation line. Geomech. Eng. 2020, 23, 85–92. [Google Scholar]

- Yin, G.; Li, G.; Wei, Z.; Wan, L.; Shui, G.; Jing, X. Stability analysis of a copper tailings dam via laboratory model tests: A Chinese case study. Miner. Eng. 2011, 24, 122–130. [Google Scholar] [CrossRef]

- Du, C.; Jiang, X.; Wang, L.; Yi, F.; Niu, B. Experimental study on dynamic characteristics of tailings under different consolidation conditions. Sci. Rep. 2024, 14, 735. [Google Scholar] [CrossRef] [PubMed]

- Luo, C.; Li, D.; Xu, B. Study on the Evolution of Tailings Dam Break Disaster under Complex Environment. Sustainability 2023, 15, 14728. [Google Scholar] [CrossRef]

- Özgenç Aksoy, A.; Doğan, M.; Oğuzhan Güven, S.; Tanır, G.; Güney, M.Ş. Experimental and Numerical Investigation of the Flood Waves Due to Partial Dam Break. Iran. J. Sci. Technol. Trans. Civ. Eng. 2022, 46, 4689–4704. [Google Scholar] [CrossRef]

- Schaefer, M.; Bugnion, L. Velocity Profile Variations in Granular Flows with Changing Boundary Conditions: Insights from Experiments. Phys. Fluids 2013, 25, 063303. [Google Scholar] [CrossRef]

- Wang, S.R.; Zhang, H.Q.; Zou, Z.S.; Liu, X.L. Liquid-solid coupling analysis of tailings dam under complex engineering conditions. In Proceedings of the 3rd International Symposium on Mine Safety Science and Engineering (ISMS), Montreal, QC, Canada, 13–19 August 2016. [Google Scholar]

- Li, Q.; Zhang, L.T.; Qi, Q.L. Instability characteristics and stability analysis of a tailings dam based on fluid-solid coupling theory. Rock Soil Mech. 2012, 33, 243–250. [Google Scholar]

- Liu, H.X.; Li, N.; Liao, X. Unsteady seepage analysis of tailings dams considering coupling of stress and seepage fields. J. Rock Mech. Eng. 2004, 23, 2870. [Google Scholar]

- Lu, M.L.; Cui, L. Three-dimensional seepage analysis for complex topographical tailings dam. Rock Soil Mech. 2006, 27, 1176–1180. [Google Scholar]

- Singh, S.; Kumar, A.; Sitharam, T.G. Investigating the strength and durability properties of alkali activated red mud for tailings pond embankment material. Geomech. Energy Environ. 2023, 36, 100500. [Google Scholar] [CrossRef]

- Wang, C.; Harbottle, D.; Liu, Q.X.; Xu, Z.H. Current state of fine mineral tailings treatment: A critical review on theory and practice. Miner. Eng. 2014, 58, 113–131. [Google Scholar] [CrossRef]

- Li, Q.; Wu, B.Z.; Li, X.; Jia, S.; Zhen, F.H.; Gao, S. The Relatively Stable Seepage Field: A New Concept to Determine Seepage Field in the Design of a Dry-Stack Tailings Pond. Appl. Sci. 2022, 12, 12123. [Google Scholar] [CrossRef]

- Cui, W.W.; Dong, X.Q.; Duan, W.; Liu, J.J.; Zhao, R.Y.; He, G.L. Design of all solid waste red mud-based cementitious materials based on the simplex centroid method. Constr. Build. Mater. 2024, 418, 135439. [Google Scholar] [CrossRef]

- Tian, H.; Williams, D.J.; Mandisodza, K.; Zhang, C.M.; Olaya, S.Q.; Zhang, W.Q.; Tang, C.Y. Engineering properties of fine-grained red mud, International Journal of Mining. Reclam. Environ. 2023, 37, 399–418. [Google Scholar] [CrossRef]

- Liu, D.Y.; Wu, C.S. Stockpiling and Comprehensive Utilization of Red Mud Research Progress. Materials 2012, 5, 1232–1246. [Google Scholar] [CrossRef]

| Chemical Composition | CaO | Fe2O3 | Al2O3 | SiO2 | TiO2 | Na2O | SO3 | Others |

|---|---|---|---|---|---|---|---|---|

| Percentage content (%) | 26.39 | 25.71 | 17.77 | 15.06 | 6.83 | 5.91 | 0.81 | 1.52 |

| Relative Density | Maximum Dry Density | Optimum Moisture | Permeability Coefficient | Liquid Limit | Plastic Limit | Plasticity Index | Void Ratio | PH |

|---|---|---|---|---|---|---|---|---|

| 2.71 | 1.33 g/cm3 | 33% | 2.58 × 10−6 cm/s | 42.7 | 29.8 | 12.9 | 1.02 | 11 |

| Physical Quantity | Similarity Ratio | Physical Quantity | Similarity Ratio | Physical Quantity | Similarity Ratio |

|---|---|---|---|---|---|

| Length | 1:200 | Permeability Coefficient | 1:1 | Volume | 1:2003 |

| Cohesiveness | 1:1 | Density | 1:1 | Internal Friction Angle | 1:1 |

| Acceleration | 200:1 | Moisture Content | 1:1 | Stress | 1:1 |

| Strain | 1:1 | Slope | 1:1 | Displacement | 1:200 |

| Sequence Number | Initial Dry Density | Initial Water Content | Slope Ratio | Water Levels |

|---|---|---|---|---|

| T1 | 1.279 g/cm3 | 25% | 1:2 | 36.51 cm |

| T2 | 1.283 g/cm3 | 25% | 1:2 | 60.85 cm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, S.; Dong, X.; Liu, X.; Xu, X.; Zhang, H.; Huang, Y. Study on the Characteristics and Evolution Laws of Seepage Damage in Red Mud Tailings Dams. Water 2024, 16, 1487. https://doi.org/10.3390/w16111487

Chang S, Dong X, Liu X, Xu X, Zhang H, Huang Y. Study on the Characteristics and Evolution Laws of Seepage Damage in Red Mud Tailings Dams. Water. 2024; 16(11):1487. https://doi.org/10.3390/w16111487

Chicago/Turabian StyleChang, Shiqi, Xiaoqiang Dong, Xiaofeng Liu, Xin Xu, Haoru Zhang, and Yinhao Huang. 2024. "Study on the Characteristics and Evolution Laws of Seepage Damage in Red Mud Tailings Dams" Water 16, no. 11: 1487. https://doi.org/10.3390/w16111487

APA StyleChang, S., Dong, X., Liu, X., Xu, X., Zhang, H., & Huang, Y. (2024). Study on the Characteristics and Evolution Laws of Seepage Damage in Red Mud Tailings Dams. Water, 16(11), 1487. https://doi.org/10.3390/w16111487