Predicting Sandstone Brittleness under Varying Water Conditions Using Infrared Radiation and Computational Techniques

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

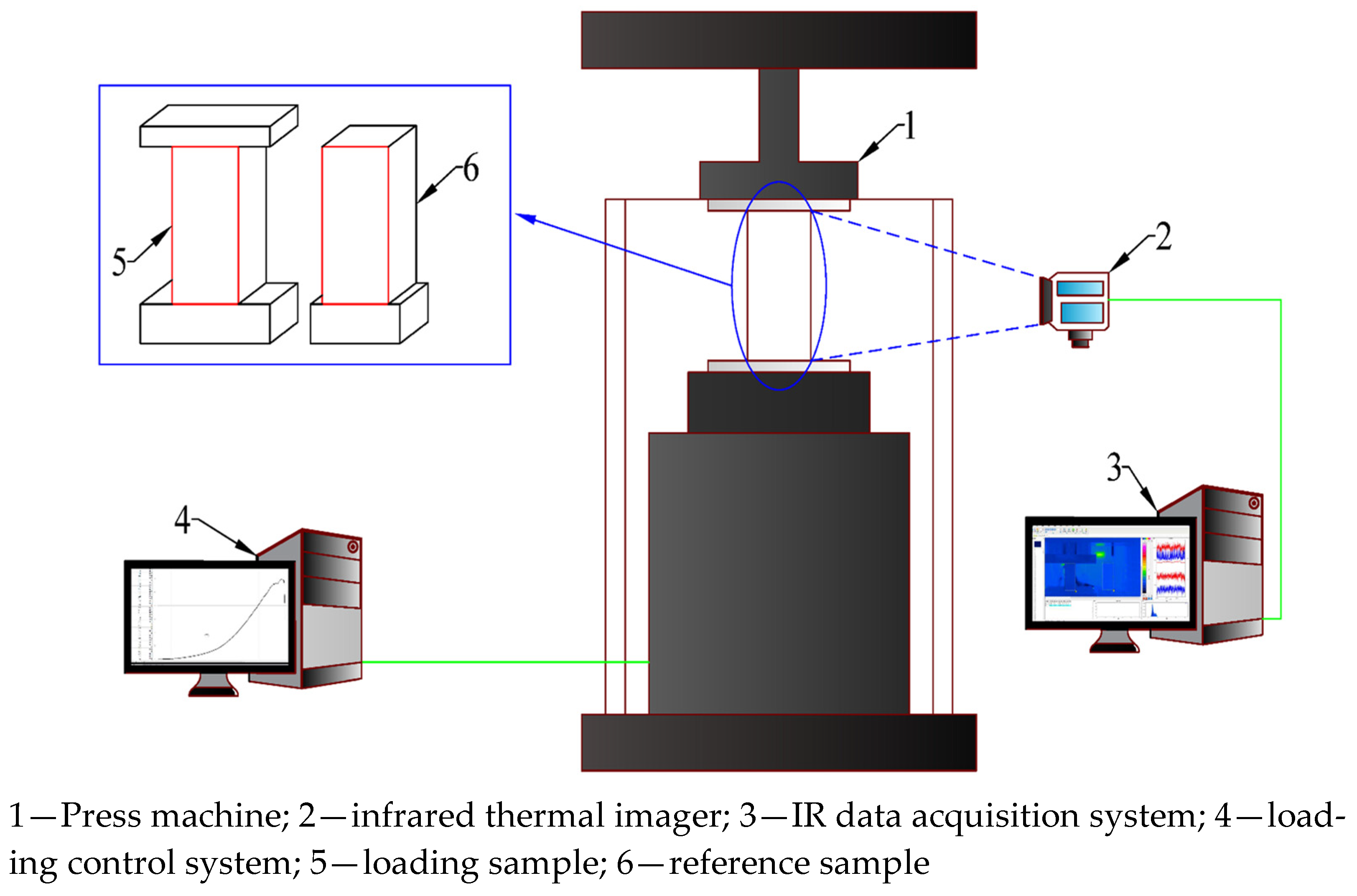

2.2. Experimental Equipment

2.3. Mechanical Parameters

Elasticity Modulus

2.4. Index

2.4.1. Brittleness Index Base on Stress–Strain Curve

2.4.2. Infrared Radiation Variance (IRV)

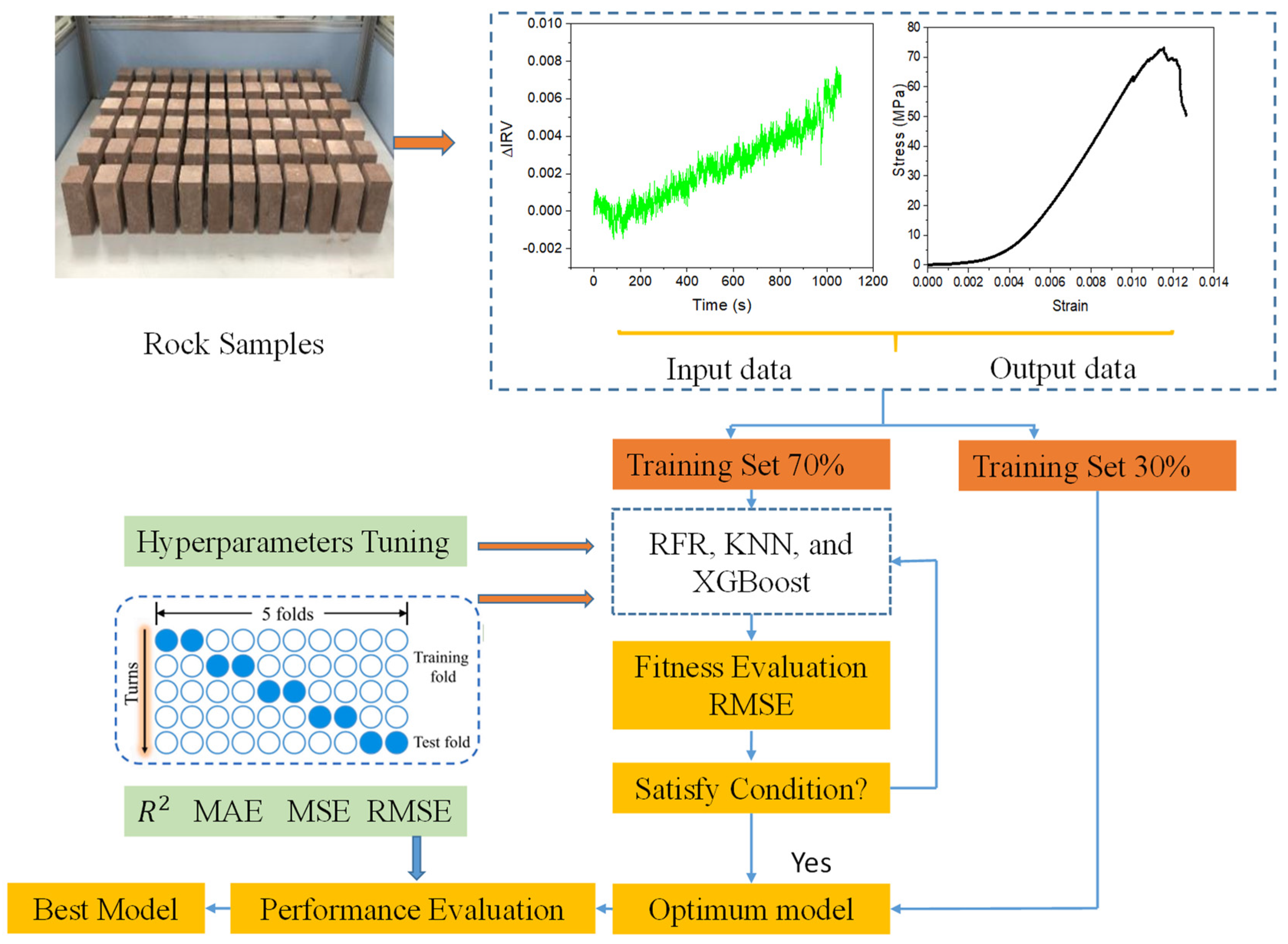

2.5. Artificial Intelligent Techniques

2.5.1. Random Forest Algorithm

2.5.2. KNN

- represents the Euclidean function, which calculates the distance between two points using the Euclidean distance metric.

- represents the Manhattan function, which calculates the distance between two points using the Manhattan distance metric.

- represents the Minkowski function, which calculates the distance between two points using the Minkowski distance metric. The specific value of t indicates the order or power used in the Minkowski distance calculation.

- and li represent the respective coordinates or values of the ith dimension for points k and l.

- represents the order or power used in the Minkowski distance calculation.

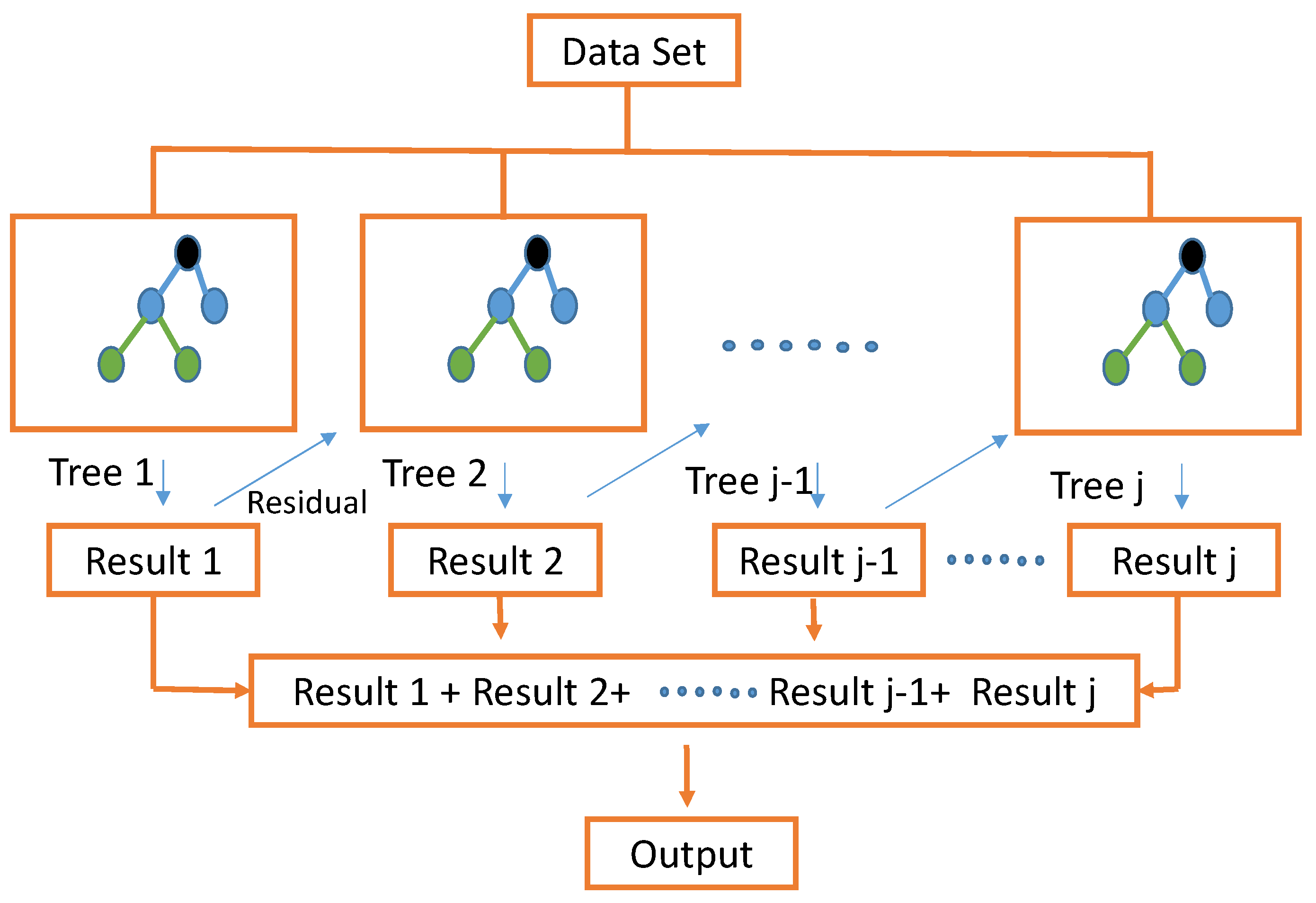

2.5.3. Extreme Gradient Boosting

3. Results and Discussion

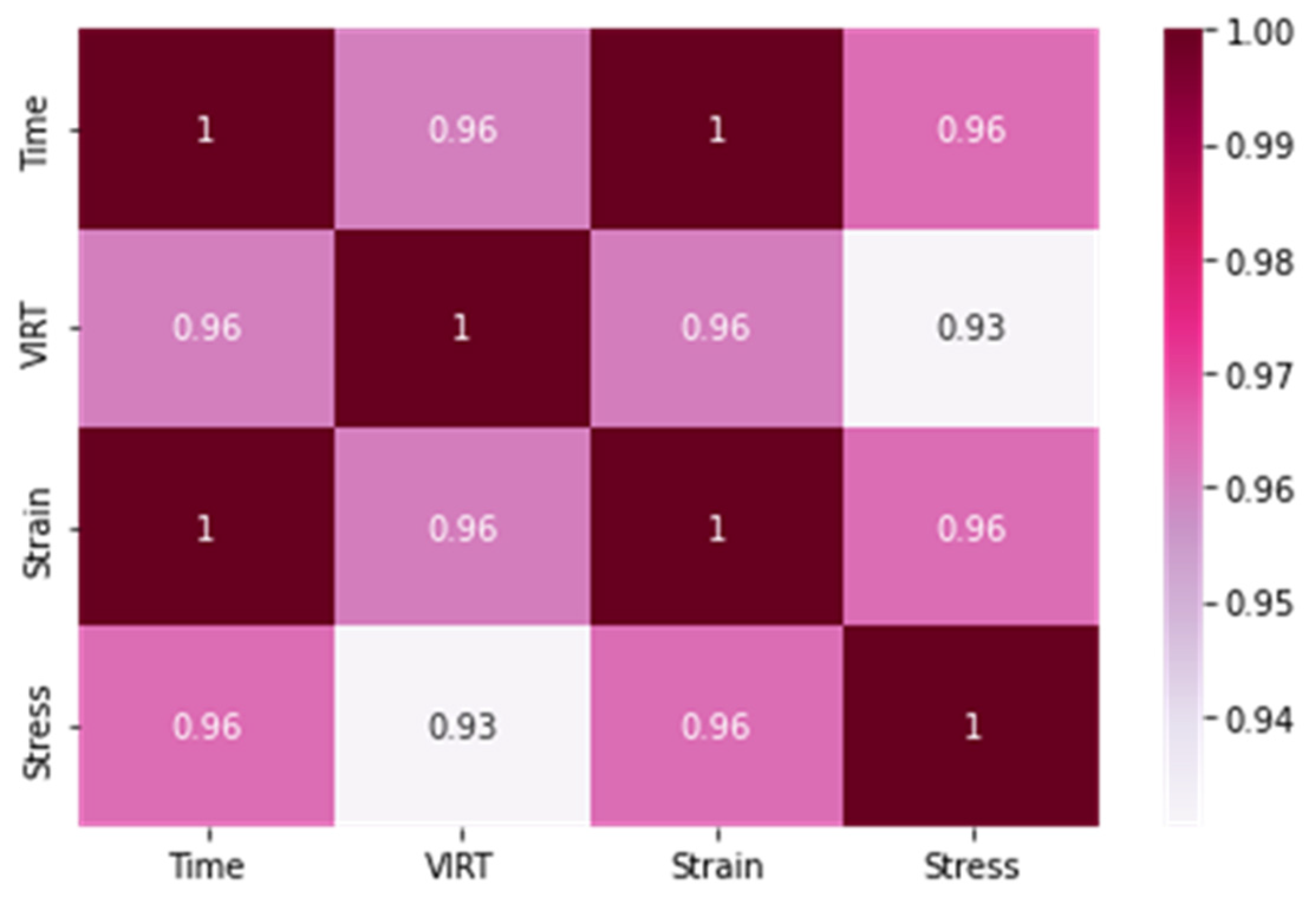

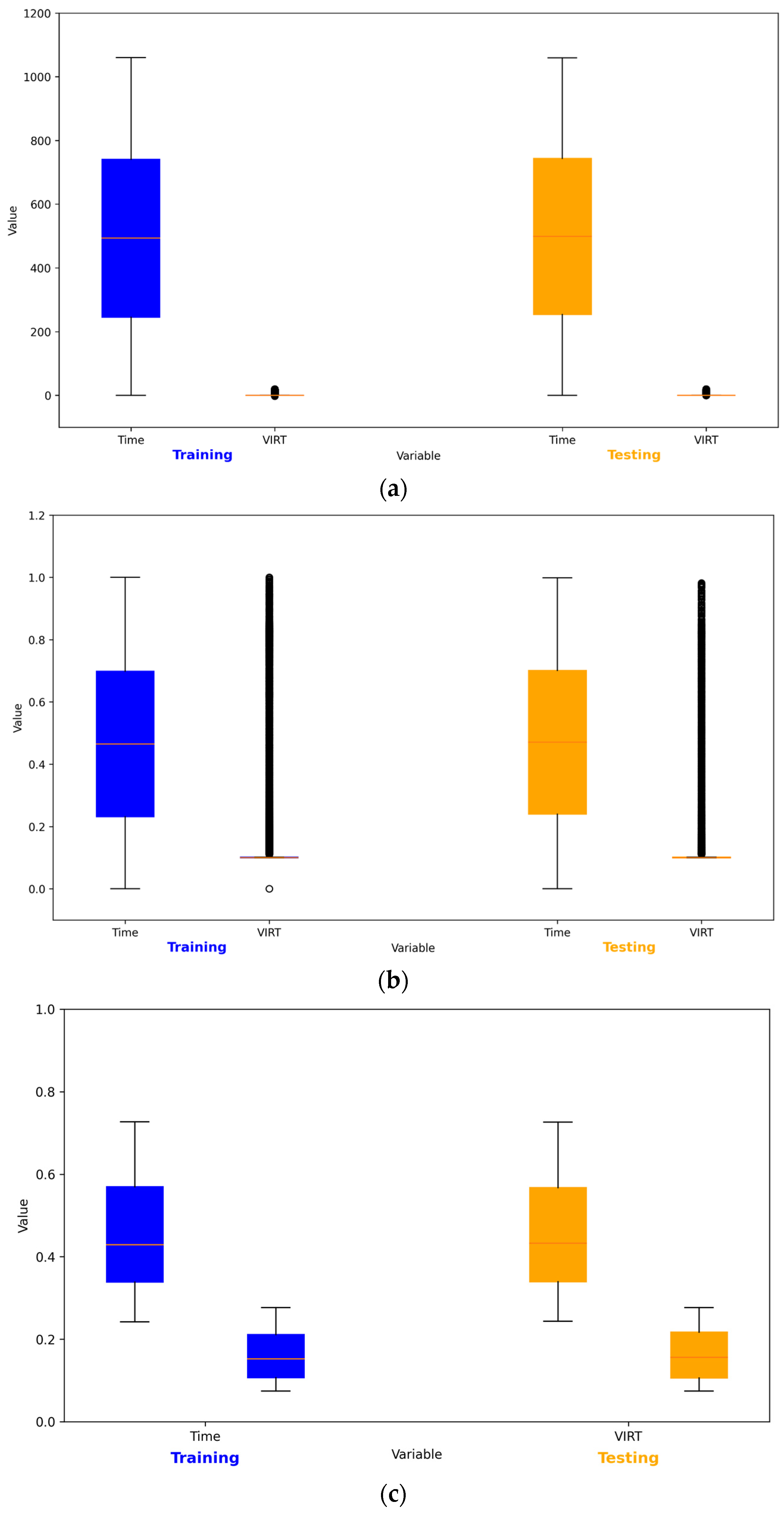

3.1. Data Statistical Analysis

3.2. Effect of Water on Stress–Strain

Initiation of Crack and Crack Damage Stress

3.3. Effect of Water Content on Rock Behaviors

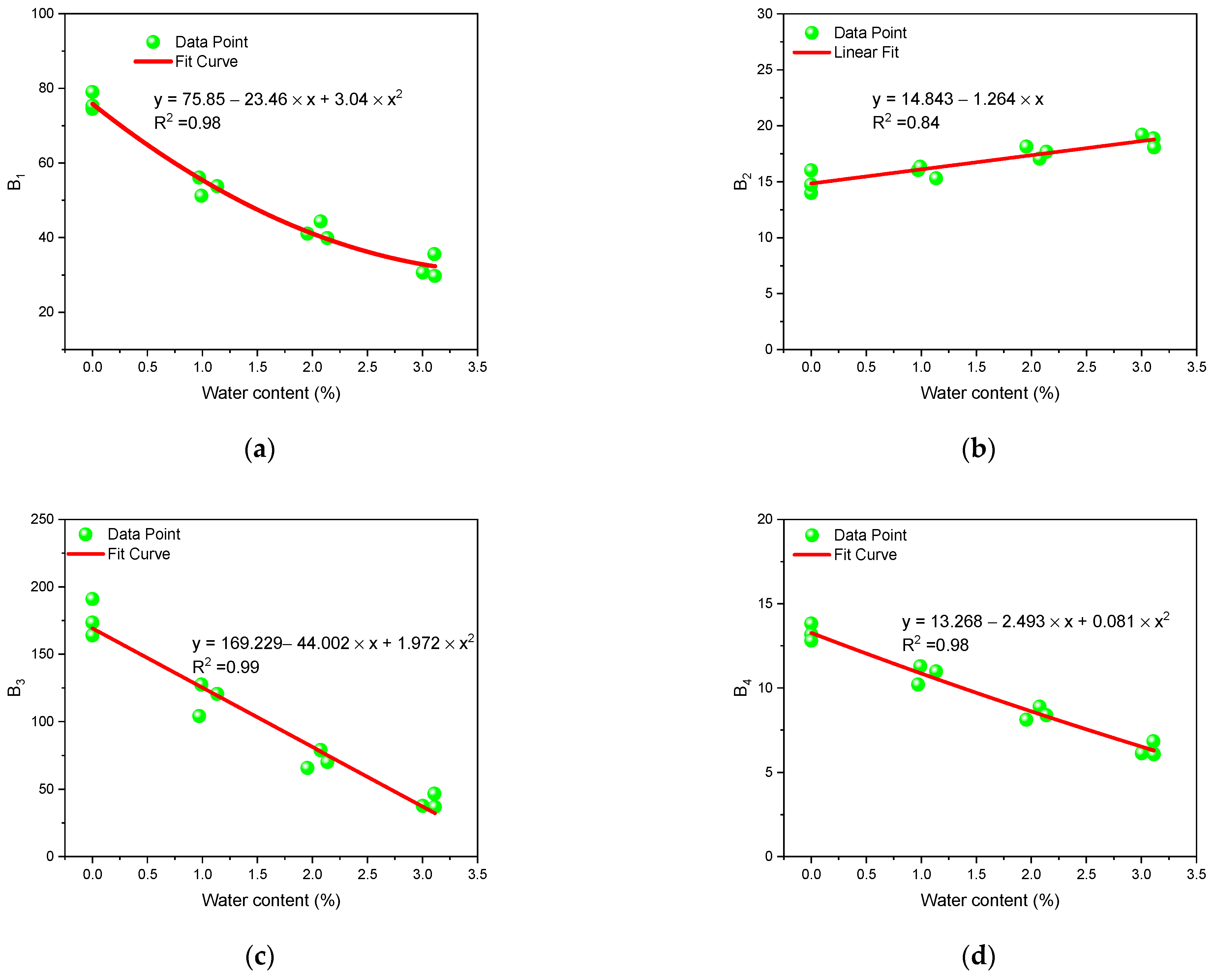

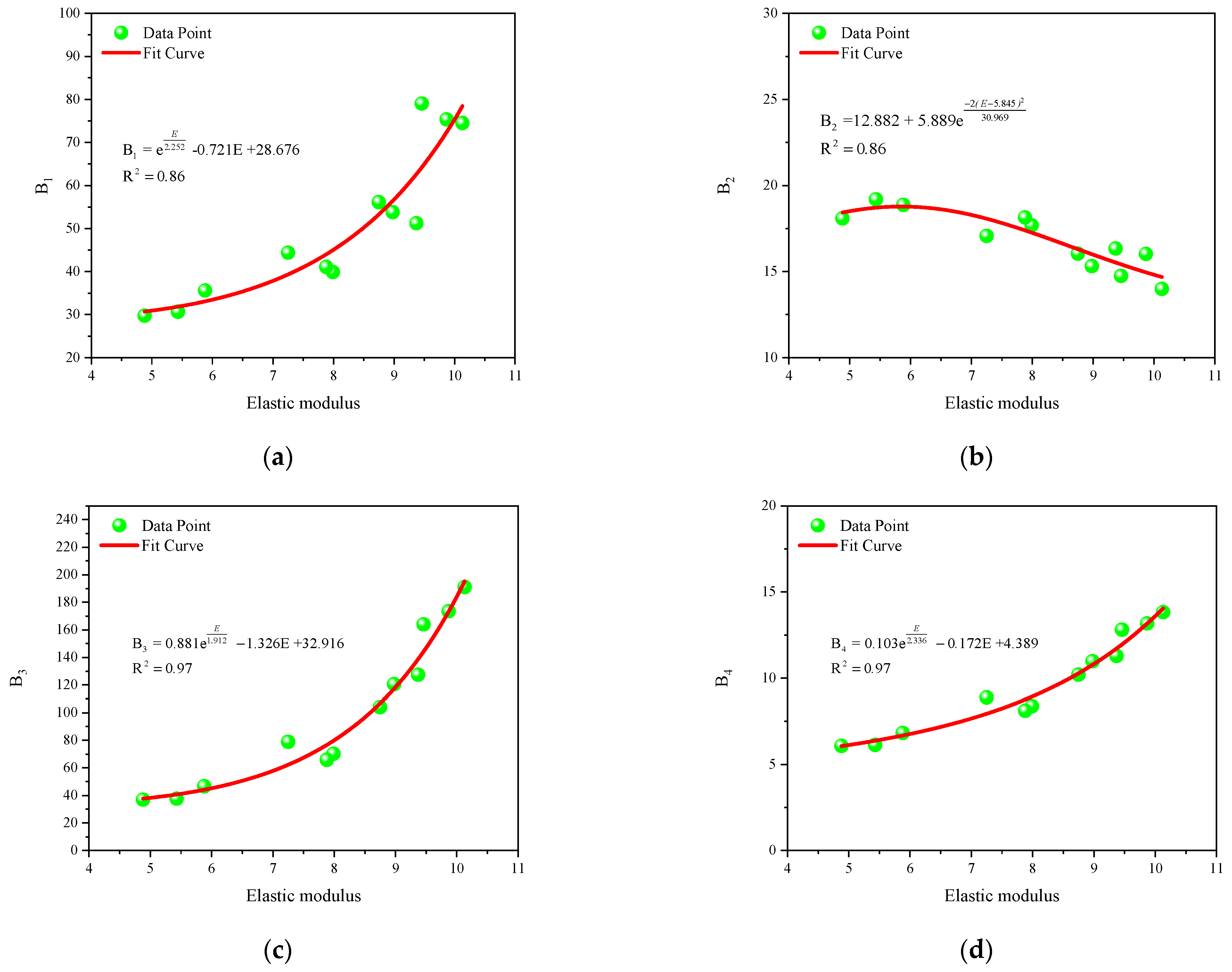

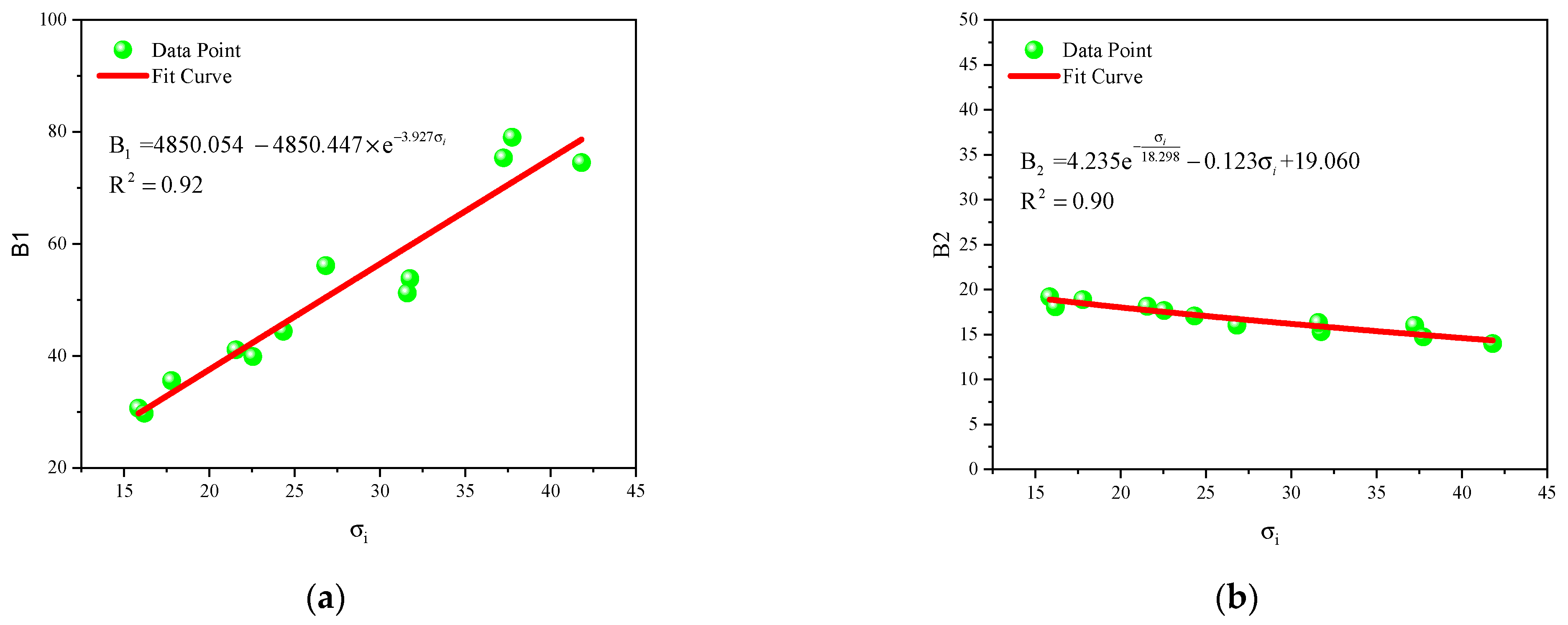

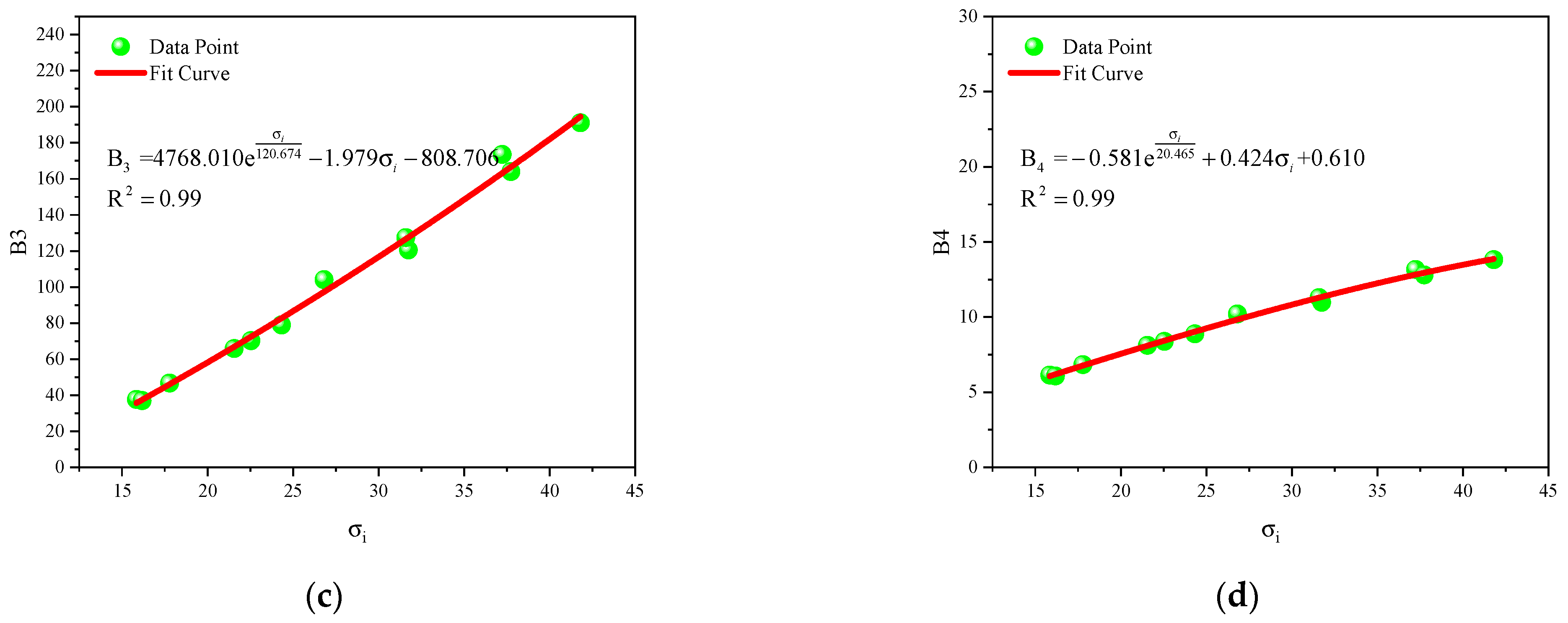

3.4. Proposed Brittleness Index under Stress–Strain Condition

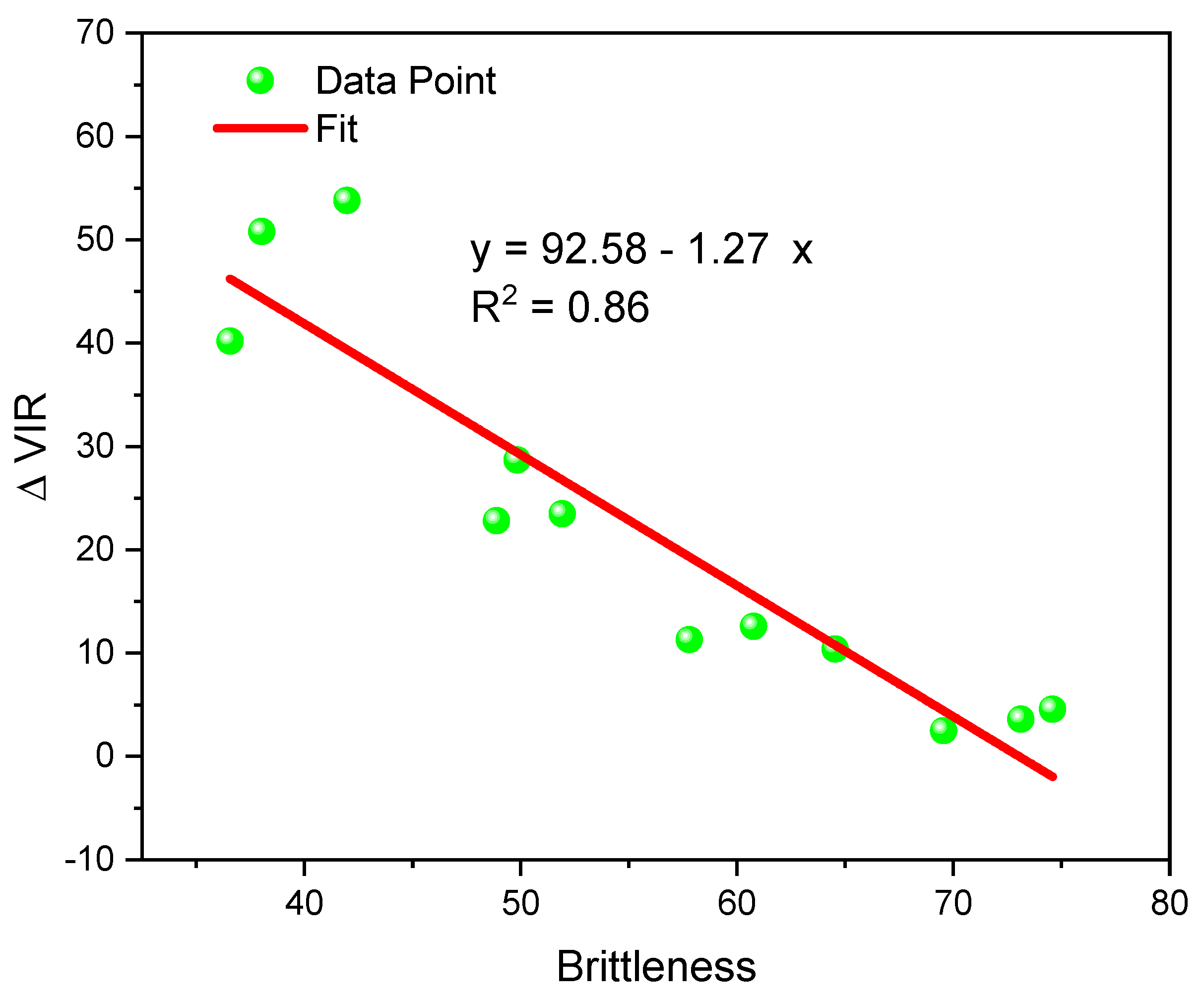

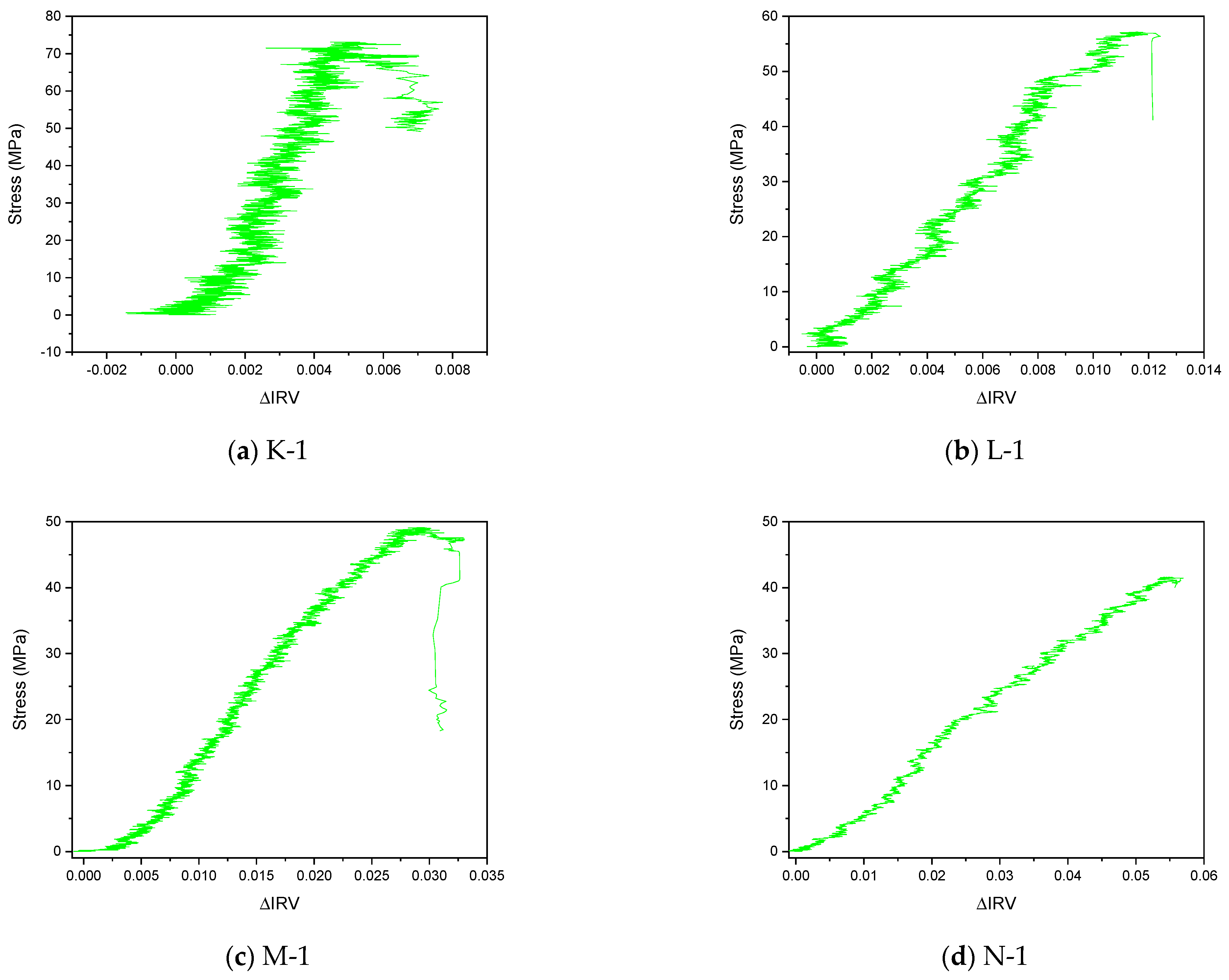

3.5. Brittleness Index Using IRV under Different Water Conditions

3.6. IRV Characteristic under Stress–Strain Curve Stages

3.7. Prediction Models

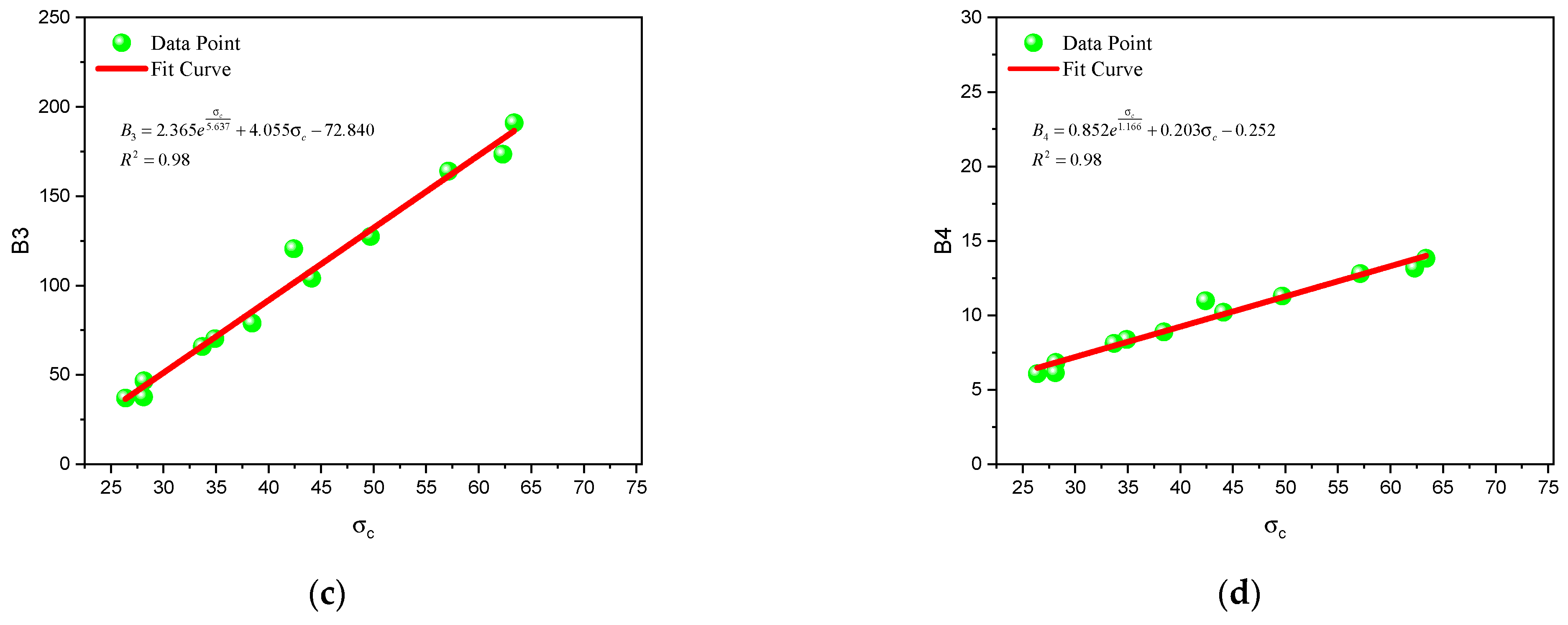

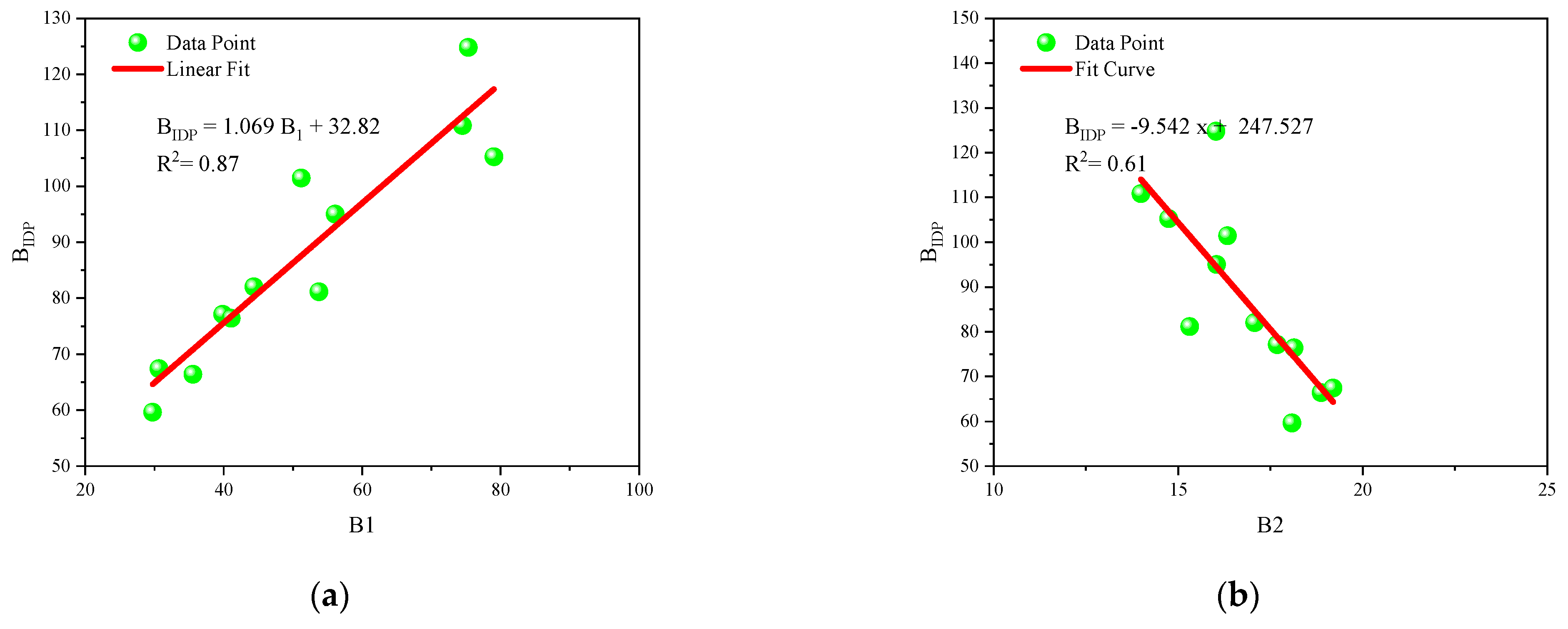

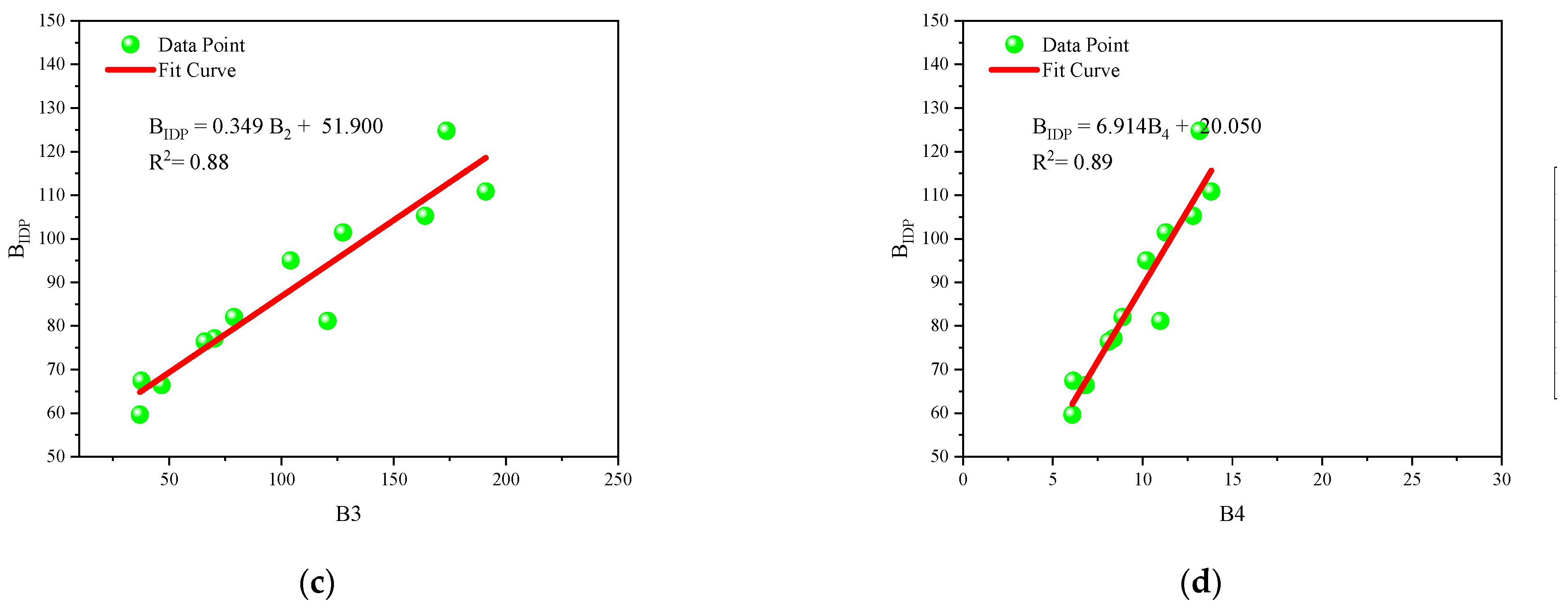

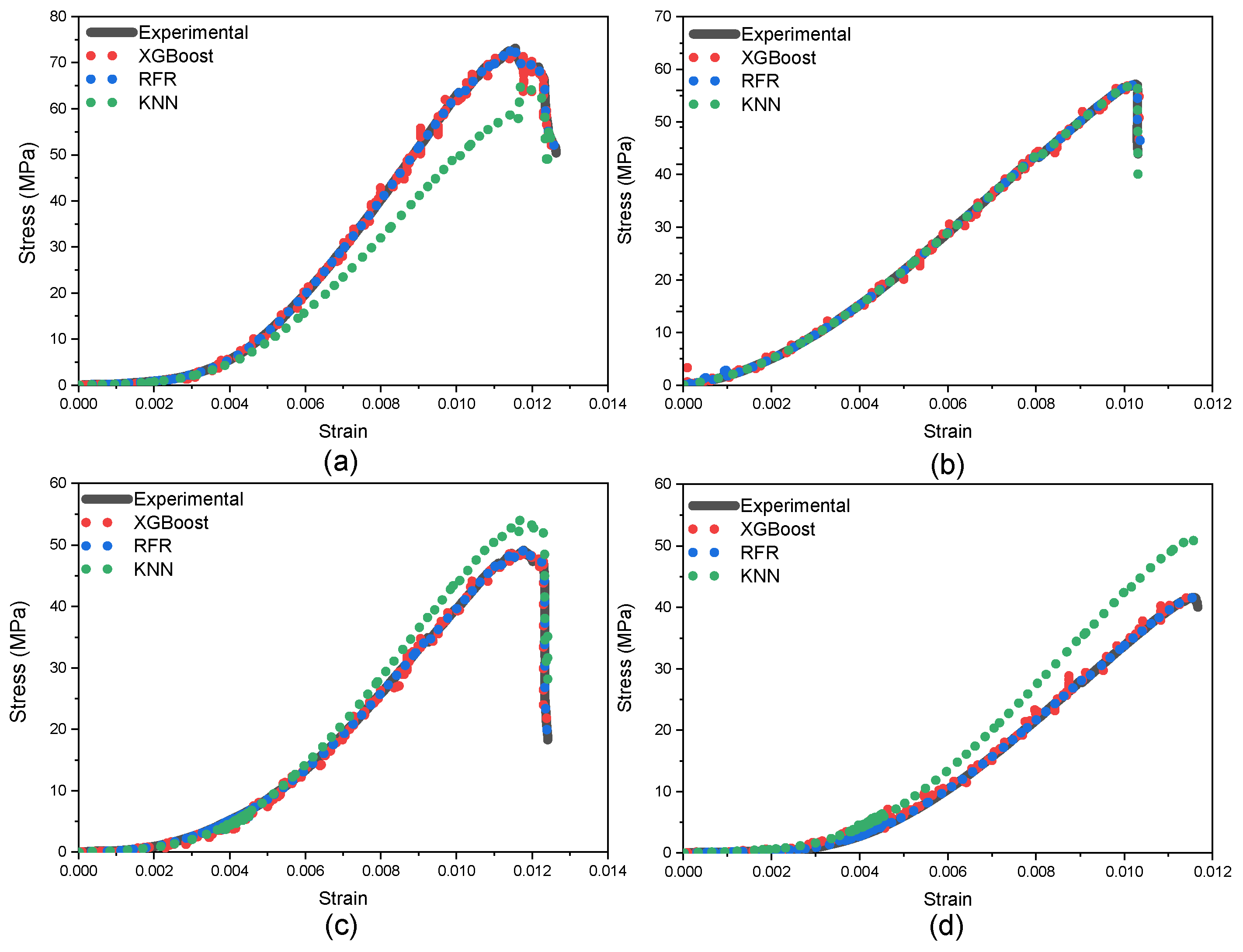

3.7.1. Regression Models

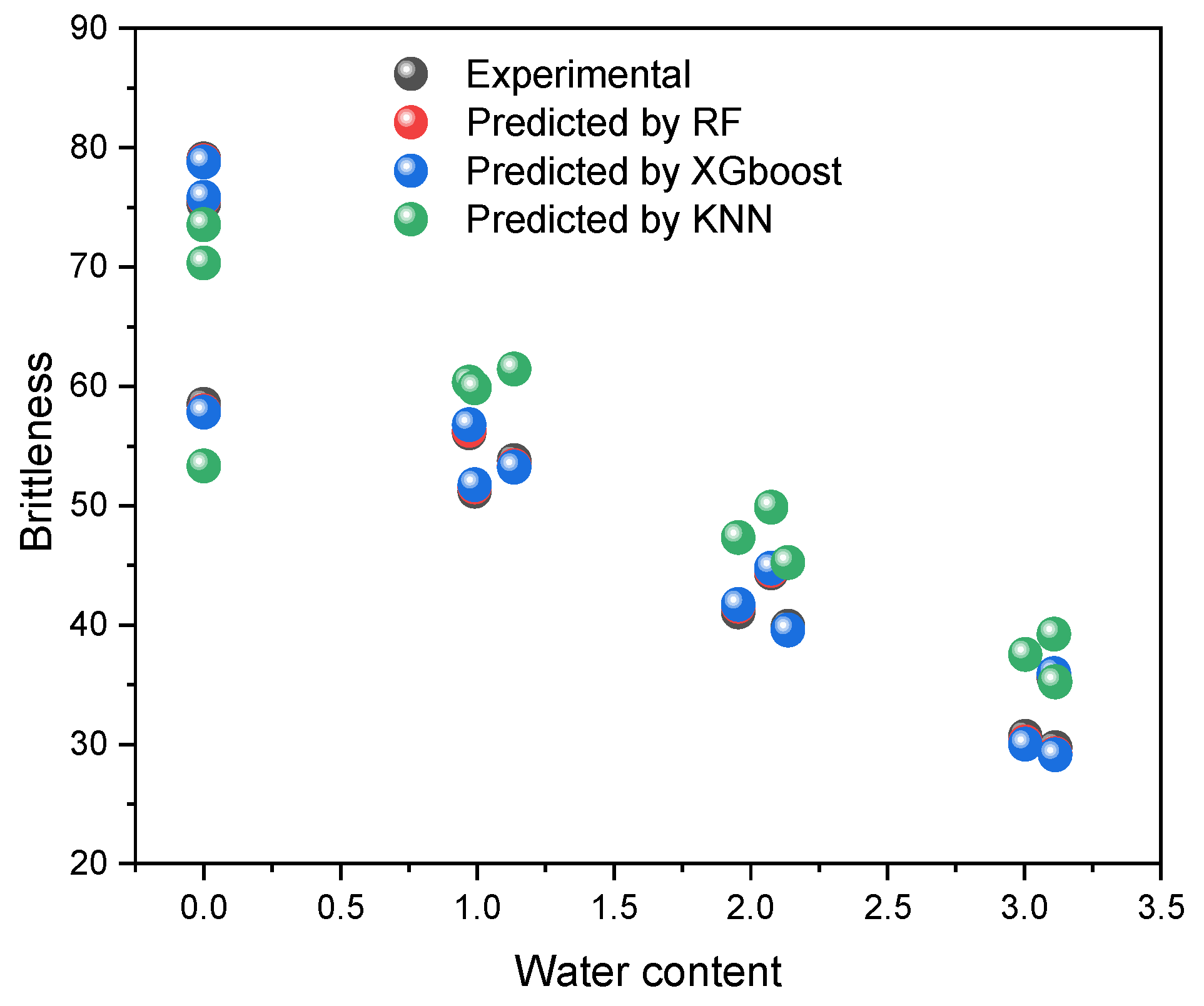

3.7.2. Performance of Models

3.7.3. Models Strength and Limitation

3.8. Significance of the Research Study

4. Conclusions

- Water content significantly influences the mechanical properties and brittleness of rocks. Studies indicate that, upon exposure to water, rocks experience a 41% reduction in brittleness, which lowers the likelihood of rock burst incidents. However, this interaction also compromises rock strength, increasing the risk of rock failure due to decreased overall strength.

- The brittleness indices such as B1, B2, and B4 show a positive linear exponential correlation, whereas B2 shows a poor negative linear exponential correlation with crack initiation, elastic modulus, and crack damage stress. The proposed brittleness index BIDP has a high linear correlation (R2 > 0.88) with B1, B2, and B4 and a poor negative linear correlation (R2 > 0.88) with B2. Therefore, the proposed index has high significance.

- The proposed brittleness considered elastic modulus, crack initiation, crack damage, and peak stress under different water contents, which truly reflected the brittleness intensity. The intensity decreases linearly exponentially (R2 > 0.90) in the presence of water content.

- During the peak stress phase, the rate of IRV rises in the presence of water but declines when the rock’s brittleness decreases. This implies that water presence impacts the IRV rate, while the rock’s brittleness affects its overall performance.

- To predict the proposed index, three different models, namely XGBoost, RF, and KNN, were utilized. By comparing their performance, it was found that both RF and XGBoost exhibit high prediction accuracy. Specifically, the RF model achieved an impressive R2 value of 0.999, along with low values for RMSE (0.383), MSE (0.007), and MAE (0.002). Therefore, the RF model is recommended to be used effectively in the prediction of rock brittleness.

- These research findings establish a solid theoretical foundation for evaluating rock brittleness and predicting rock burst susceptibility. The incorporation of water conditions and the proposed index offer valuable insights for effectively assessing and mitigating the risks associated with rock burst incidents. These findings open up new avenues for further discussions and exploration in this field, paving the way for innovative approaches to rock burst prevention and management.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meng, F.; Zhou, H.; Zhang, C.; Xu, R.; Lu, J. Evaluation methodology of brittleness of rock based on post-peak stress–strain curves. Rock Mech. Rock Eng. 2015, 48, 1787–1805. [Google Scholar] [CrossRef]

- Zhao, Z.; Ali, E.; Wu, G.; Wang, X. Assessment of strain energy storage and rock brittleness indices of rockburst potential from microfabric characterizations. Am. J. Earth Sci. 2015, 2, 8. [Google Scholar]

- Zhang, C.; Lu, J.; Chen, J.; Zhou, H.; Yang, F. Discussion on rock burst proneness indexes and their relation. Rock Soil Mech. 2017, 38, 1397–1404. [Google Scholar]

- Zhang, L.; Cong, Y.; Meng, F.; Wang, Z.; Zhang, P.; Gao, S. Energy evolution analysis and failure criteria for rock under different stress paths. Acta Geotech. 2021, 16, 569–580. [Google Scholar] [CrossRef]

- Gong, F.; Yan, J.; Li, X.; Luo, S. A peak-strength strain energy storage index for rock burst proneness of rock materials. Int. J. Rock Mech. Sci. 2019, 117, 76–89. [Google Scholar] [CrossRef]

- Song, S.; Ren, T.; Dou, L.; Sun, J.; Yang, X.; Tan, L. Fracture features of brittle coal under uniaxial and cyclic compression loads. Int. J. Coal Sci. Technol. 2023, 10, 9. [Google Scholar] [CrossRef]

- Ali, Z.; Karakus, M.; Nguyen, G.D.; Amrouch, K. Effect of loading rate and time delay on the tangent modulus method (TMM) in coal and coal measured rocks. Int. J. Coal Sci. Technol. 2022, 9, 81. [Google Scholar] [CrossRef]

- Bai, Q.; Zhang, C.; Paul Young, R. Using true-triaxial stress path to simulate excavation-induced rock damage: A case study. Int. J. Coal Sci. Technol. 2022, 9, 49. [Google Scholar] [CrossRef]

- Chen, Y.; Zuo, J.; Liu, D.; Li, Y.; Wang, Z. Experimental and numerical study of coal-rock bimaterial composite bodies under triaxial compression. Int. J. Coal Sci. Technol. 2021, 8, 908–924. [Google Scholar] [CrossRef]

- Chi, X.; Yang, K.; Wei, Z. Breaking and mining-induced stress evolution of overlying strata in the working face of a steeply dipping coal seam. Int. J. Coal Sci. Technol. 2021, 8, 614–625. [Google Scholar] [CrossRef]

- Feng, F.; Chen, S.; Zhao, X.; Li, D.; Wang, X.; Cui, J. Effects of external dynamic disturbances and structural plane on rock fracturing around deep underground cavern. Int. J. Coal Sci. Technol. 2022, 9, 15. [Google Scholar] [CrossRef]

- He, S.; Qin, M.; Qiu, L.; Song, D.; Zhang, X. Early warning of coal dynamic disaster by precursor of AE and EMR “quiet period”. Int. J. Coal Sci. Technol. 2022, 9, 46. [Google Scholar] [CrossRef]

- Huang, F.; Xiong, H.; Chen, S.; Lv, Z.; Huang, J.; Chang, Z.; Catani, F. Slope stability prediction based on a long short-term memory neural network: Comparisons with convolutional neural networks, support vector machines and random forest models. Int. J. Coal Sci. Technol. 2023, 10, 18. [Google Scholar] [CrossRef]

- Li, Y.; Mitri, H.S. Determination of mining-induced stresses using diametral rock core deformations. Int. J. Coal Sci. Technol. 2022, 9, 80. [Google Scholar] [CrossRef]

- Zhao, Y.; He, X.; Jiang, L.; Wang, Z.; Ning, J.; Sainoki, A. Influence analysis of complex crack geometric parameters on mechanical properties of soft rock. Int. J. Coal Sci. Technol. 2023, 10, 78. [Google Scholar] [CrossRef]

- Xu, L.; Fan, C.; Luo, M.; Li, S.; Han, J.; Fu, X.; Xiao, B. Elimination mechanism of coal and gas outburst based on geo-dynamic system with stress–damage–seepage interactions. Int. J. Coal Sci. Technol. 2023, 10, 74. [Google Scholar] [CrossRef]

- Soleimani, F.; Si, G.; Roshan, H.; Zhang, J. Numerical modelling of gas outburst from coal: A review from control parameters to the initiation process. Int. J. Coal Sci. Technol. 2023, 10, 81. [Google Scholar] [CrossRef]

- Munoz, H.; Taheri, A.; Chanda, E. Rock drilling performance evaluation by an energy dissipation based rock brittleness index. Rock Mech. Rock Eng. 2016, 49, 3343–3355. [Google Scholar] [CrossRef]

- Meng, F.; Wong, L.N.Y.; Zhou, H. Rock brittleness indices and their applications to different fields of rock engineering: A review. J. Rock Mech. Geotech. Eng. 2021, 13, 221–247. [Google Scholar] [CrossRef]

- Liang, L.; Liu, X.; Xiong, J.; Wu, T.; Ding, Y. New model to evaluate the Brittleness in shale formation. In International Geophysical Conference, Qingdao, China, 17–20 April 2017; SEG Global Meeting Abstracts; Society of Exploration Geophysicists and Chinese Petroleum Society: Houston, TX, USA, 2017; pp. 1248–1251. [Google Scholar]

- Gong, X.; Sun, C.C. A new tablet brittleness index. Eur. J. Pharm. Biopharm. 2015, 93, 260–266. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Wu, Y.; Ben, Y.; Li, S.; He, J.; Zhang, B. Research on relationship between crack initiation stress level and brittleness indices for brittle rocks. Chin. J. Rock Mech. Eng. 2014, 33, 264–275. [Google Scholar]

- Bishop, A. Progressive failure-with special reference to the mechanism causing it. In Proceedings of the Geotechnical Conference Oslo 1967 on Shear Strength Properties of Natural Soils and Rocks; Norwegian Geotechnical Institute: Oslo, Norway, 1967; pp. 142–150. [Google Scholar]

- Baud, P.; Zhu, W.; Wong, T.F. Failure mode and weakening effect of water on sandstone. J. Geophys. Res. Solid Earth 2000, 105, 16371–16389. [Google Scholar] [CrossRef]

- Liu, X.; Yang, C.; Yu, J. The influence of moisture content on the time-dependent characteristics of rock material and its application to the construction of a tunnel portal. Adv. Mater. Sci. Eng. 2015, 2015, 725162. [Google Scholar] [CrossRef]

- Nicolas, A.; Fortin, J.; Regnet, J.; Dimanov, A.; Guéguen, Y. Brittle and semi-brittle behaviours of a carbonate rock: Influence of water and temperature. Geophys. J. Int. 2016, 206, 438–456. [Google Scholar] [CrossRef]

- Li, Y.; Yang, R.; Fang, S.; Lin, H.; Lu, S.; Zhu, Y.; Wang, M. Failure analysis and control measures of deep roadway with composite roof: A case study. Int. J. Coal Sci. Technol. 2022, 9, 2. [Google Scholar] [CrossRef]

- Liu, B.; Zhao, Y.; Zhang, C.; Zhou, J.; Li, Y.; Sun, Z. Characteristic strength and acoustic emission properties of weakly cemented sandstone at different depths under uniaxial compression. Int. J. Coal Sci. Technol. 2021, 8, 1288–1301. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.; Fu, X.; Liu, A. Mechanical criterion for coal and gas outburst: A perspective from multiphysics coupling. Int. J. Coal Sci. Technol. 2021, 8, 1423–1435. [Google Scholar] [CrossRef]

- Małkowski, P.; Niedbalski, Z.; Balarabe, T. A statistical analysis of geomechanical data and its effect on rock mass numerical modeling: A case study. Int. J. Coal Sci. Technol. 2021, 8, 312–323. [Google Scholar] [CrossRef]

- Pang, Y.; Wang, H.; Lou, J.; Chai, H. Longwall face roof disaster prediction algorithm based on data model driving. Int. J. Coal Sci. Technol. 2022, 9, 11. [Google Scholar] [CrossRef]

- Wang, G.; Ren, H.; Zhao, G.; Zhang, D.; Wen, Z.; Meng, L.; Gong, S. Research and practice of intelligent coal mine technology systems in China. Int. J. Coal Sci. Technol. 2022, 9, 24. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, C.; Canbulat, I.; Song, Z.; Dai, L. A review of investigations on ground support requirements in coal burst-prone mines. Int. J. Coal Sci. Technol. 2022, 9, 13. [Google Scholar] [CrossRef]

- Khan, N.M.; Ma, L.; Cao, K.; Hussain, S.; Liu, W.; Xu, Y.; Yuan, Q.; Gu, J. Prediction of an early failure point using infrared radiation characteristics and energy evolution for sandstone with different water contents. Bull. Eng. Geol. Environ. 2021, 80, 6913–6936. [Google Scholar] [CrossRef]

- Song, Z.; Zhang, J.; Wu, S. Energy Dissipation and Fracture Mechanism of Layered Sandstones under Coupled Hydro-Mechanical Unloading. Processes 2023, 11, 2041. [Google Scholar] [CrossRef]

- Wasantha, P.L.P.; Ranjith, P.G. Water-weakening behavior of Hawkesbury sandstone in brittle regime. Eng. Geol. 2014, 178, 91–101. [Google Scholar] [CrossRef]

- Ortlepp, W.D. Rock Fracture and Rockbursts: An Illustrative Study; South African Institute of Mining and Metallurgy: Johannesburg, South Africa, 1997; Volume 9. [Google Scholar]

- Fowkes, N. Rockbursts mud and plastic. In Proceedings of the 19th International Congress on Modelling and Simulation, Modelling and Simulation Society of Australia and New Zealand, Perth, Australia, 12–16 December 2011; pp. 12–16. [Google Scholar]

- Gong, Q.M.; Yin, L.J.; Wu, S.Y.; Zhao, J.; Ting, Y. Rock burst and slabbing failure and its influence on TBM excavation at headrace tunnels in Jinping II hydropower station. Eng. Geol. 2012, 124, 98–108. [Google Scholar] [CrossRef]

- Wu, H.; Chen, Y.; Lv, H.; Xie, Q.; Chen, Y.; Gu, J. Stability analysis of rib pillars in highwall mining under dynamic and static loads in open-pit coal mine. Int. J. Coal Sci. Technol. 2022, 9, 38. [Google Scholar] [CrossRef]

- Wu, H.; Ju, Y.; Han, X.; Ren, Z.; Sun, Y.; Zhang, Y.; Han, T. Size effects in the uniaxial compressive properties of 3D printed models of rocks: An experimental investigation. Int. J. Coal Sci. Technol. 2022, 9, 83. [Google Scholar] [CrossRef]

- Wu, R.; Zhang, P.; Kulatilake, P.H.S.W.; Luo, H.; He, Q. Stress and deformation analysis of gob-side pre-backfill driving procedure of longwall mining: A case study. Int. J. Coal Sci. Technol. 2021, 8, 1351–1370. [Google Scholar] [CrossRef]

- Xie, J.; Ge, F.; Cui, T.; Wang, X. A virtual test and evaluation method for fully mechanized mining production system with different smart levels. Int. J. Coal Sci. Technol. 2022, 9, 41. [Google Scholar] [CrossRef]

- Xue, D.; Lu, L.; Zhou, J.; Lu, L.; Liu, Y. Cluster modeling of the short-range correlation of acoustically emitted scattering signals. Int. J. Coal Sci. Technol. 2021, 8, 575–589. [Google Scholar] [CrossRef]

- Yang, D.; Ning, Z.; Li, Y.; Lv, Z.; Qiao, Y. In situ stress measurement and analysis of the stress accumulation levels in coal mines in the northern Ordos Basin, China. Int. J. Coal Sci. Technol. 2021, 8, 1316–1335. [Google Scholar] [CrossRef]

- Yuan, Y.; Wang, S.; Wang, W.; Zhu, C. Numerical simulation of coal wall cutting and lump coal formation in a fully mechanized mining face. Int. J. Coal Sci. Technol. 2021, 8, 1371–1383. [Google Scholar] [CrossRef]

- Zhang, S.; Lu, L.; Wang, Z.; Wang, S. A physical model study of surrounding rock failure near a fault under the influence of footwall coal mining. Int. J. Coal Sci. Technol. 2021, 8, 626–640. [Google Scholar] [CrossRef]

- Zhou, J.; Lin, H.; Jin, H.; Li, S.; Yan, Z.; Huang, S. Cooperative prediction method of gas emission from mining face based on feature selection and machine learning. Int. J. Coal Sci. Technol. 2022, 9, 51. [Google Scholar] [CrossRef]

- Pappalardo, G.; Mineo, S.; Zampelli, S.P.; Cubito, A.; Calcaterra, D. InfraRed Thermography proposed for the estimation of the Cooling Rate Index in the remote survey of rock masses. Int. J. Rock Mech. Min. Sci. 2016, 83, 182–196. [Google Scholar] [CrossRef]

- Cao, K.; Ma, L.; Wu, Y.; Khan, N.; Yang, J. Using the characteristics of infrared radiation during the process of strain energy evolution in saturated rock as a precursor for violent failure. Infrared Phys. Technol. 2020, 109, 103406. [Google Scholar] [CrossRef]

- Sun, X.; Xu, H.; He, M.; Zhang, F. Experimental investigation of the occurrence of rockburst in a rock specimen through infrared thermography and acoustic emission. Int. J. Rock Mech. Min. Sci. 2017, 93, 9. [Google Scholar] [CrossRef]

- Ma, L.; Sun, H.; Zhang, Y.; Zhou, T.; Li, K.; Guo, J. Characteristics of infrared radiation of coal specimens under uniaxial loading. Rock Mech. Rock Eng. 2016, 49, 1567–1572. [Google Scholar] [CrossRef]

- Hou, L.; Ma, L.; Cao, K.; Muhammad Khan, N.; Feng, X.; Zhang, Z.; Cao, A.; Wang, D.; Wang, X. Analysis of fracture characteristics of saturated sandstone based on infrared radiation variance. Phys. Chem. Earth Parts A/B/C 2024, 133, 103517. [Google Scholar] [CrossRef]

- Cao, K.; Dong, F.; Liu, W.; Khan, N.M.; Cui, R.; Li, X.; Hussain, S.; Alarifi, S.S.; Niu, D.J.I.P. Infrared radiation denoising model of “sub-region-Gaussian kernel function” in the process of sandstone loading and fracture. Infrared Phys. Technol. 2023, 129, 104583. [Google Scholar] [CrossRef]

- Hou, L.; Cao, K.; Muhammad Khan, N.; Jahed Armaghani, D.; SAlarifi, S.; Hussain, S.; Ali, M. Precursory Analysis of Water-Bearing Rock Fracture Based on The Proportion of Dissipated Energy. Sustainability 2023, 15, 1769. [Google Scholar] [CrossRef]

- Muhammad Khan, N.; Ma, L.; Feroze, T.; Wang, D.; Cao, K.; Gao, Q.; Wang, H.; Hussain, S.; Zhang, Z.; Alarifi, S.S. Investigating average infrared radiation temperature characteristics during shear and tensile cracks in sandstone under different water contents. Infrared Phys. Technol. 2023, 135, 104968. [Google Scholar] [CrossRef]

- Cao, K.; Dong, F.; Ma, L.; Khan, N.M.; Alarifi, S.S.; Hussain, S.; Armaghani, D.J. Infrared radiation constitutive model of sandstone during loading fracture. Infrared Phys. Technol. 2023, 133, 104755. [Google Scholar] [CrossRef]

- Cao, K.; Dong, F.; Yu, Y.; Khan, N.M.; Hussain, S.; Alarifi, S.S. Infrared radiation response mechanism of sandstone during loading and fracture process. Theor. Appl. Fract. Mech. 2023, 126, 103974. [Google Scholar] [CrossRef]

- Wu, L.; Liu, S.; Wu, Y.; Wang, C. Precursors for rock fracturing and failure—Part II: IRR T-Curve abnormalities. Int. J. Rock Mech. Min. Sci. 2006, 43, 483–493. [Google Scholar] [CrossRef]

- Liu, S.; Wu, L.; Wu, Y. Infrared radiation of rock at failure. Int. J. Rock Mech. Min. Sci. 2006, 43, 972–979. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, Y. An Experimental Study on Infrared Radiation Characteristics of Sandstone Samples Under Uniaxial Loading. Rock Mech. Rock Eng. 2019, 52, 3493–3500. [Google Scholar] [CrossRef]

- Ma, L.; Khan, N.M.; Cao, K.; Rehman, H.; Salman, S.; Rehman, F.U. Prediction of Sandstone Dilatancy Point in Different Water Contents Using Infrared Radiation Characteristic: Experimental and Machine Learning Approaches. Lithosphere 2022, 2021, 3243070. [Google Scholar] [CrossRef]

- Wei, Y.; Li, Z.; Kong, X.; Zhang, Z.; Cheng, F.; Zheng, X.; Wang, C. The precursory information of acoustic emission during sandstone loading based on critical slowing down theory. J. Geophys. Eng. 2018, 15, 2150–2158. [Google Scholar] [CrossRef]

- Sharma, L.K.; Singh, T.N. Regression-based models for the prediction of unconfined compressive strength of artificially structured soil. Eng. Comput. 2018, 34, 175–186. [Google Scholar] [CrossRef]

- Huang, B.; Liu, J. The effect of loading rate on the behavior of samples composed of coal and rock. Int. J. Rock Mech. Min. Sci. 2013, 61, 23–30. [Google Scholar] [CrossRef]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Ogunkunle, T.F.; Okoro, E.E.; Rotimi, O.J.; Igbinedion, P.; Olatunji, D.I. Artificial intelligence model for predicting geomechanical characteristics using easy-to-acquire offset logs without deploying logging tools. Petroleum 2022, 8, 192–203. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A.; Du, X.; Tang, X. Prediction of open stope hangingwall stability using random forests. Nat. Hazards 2018, 92, 1179–1197. [Google Scholar] [CrossRef]

- Zhou, J.; Li, X.; Mitri, H.S. Comparative performance of six supervised learning methods for the development of models of hard rock pillar stability prediction. Nat. Hazards 2015, 79, 291–316. [Google Scholar] [CrossRef]

- Qi, Q.; Yue, X.; Duo, X.; Xu, Z.; Li, Z. Spatial prediction of soil organic carbon in coal mining subsidence areas based on RBF neural network. Int. J. Coal Sci. Technol. 2023, 10, 30. [Google Scholar] [CrossRef]

- Khan, N.M.; Cao, K.; Yuan, Q.; Bin Mohd Hashim, M.H.; Rehman, H.; Hussain, S.; Emad, M.Z.; Ullah, B.; Shah, K.S.; Khan, S. Application of machine learning and multivariate statistics to predict uniaxial compressive strength and static Young’s modulus using physical properties under different thermal conditions. Sustainability 2022, 14, 9901. [Google Scholar] [CrossRef]

- Yang, Z.; Wu, Y.; Zhou, Y.; Tang, H.; Fu, S. Assessment of Machine Learning Models for the Prediction of Rate-Dependent Compressive Strength of Rocks. Minerals 2022, 12, 731. [Google Scholar] [CrossRef]

- Wu, X.; Kumar, V.; Ross Quinlan, J.; Ghosh, J.; Yang, Q.; Motoda, H.; McLachlan, G.J.; Ng, A.; Liu, B.; Yu, P.S.; et al. Top 10 algorithms in data mining. Knowl. Inf. Syst. 2008, 14, 1–37. [Google Scholar] [CrossRef]

- Akbulut, Y.; Sengur, A.; Guo, Y.; Smarandache, F. NS-k-NN: Neutrosophic Set-Based k-Nearest Neighbors Classifier. Symmetry 2017, 9, 179. [Google Scholar] [CrossRef]

- Qian, Y.; Zhou, W.; Yan, J.; Li, W.; Han, L. Comparing Machine Learning Classifiers for Object-Based Land Cover Classification Using Very High Resolution Imagery. Remote Sens. 2015, 7, 153–168. [Google Scholar] [CrossRef]

- Chen, T.; Guestrin, C. Xgboost: A scalable tree boosting system. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; pp. 785–794. [Google Scholar]

- Zhu, X.; Chu, J.; Wang, K.; Wu, S.; Yan, W.; Chiam, K. Prediction of rockhead using a hybrid N-XGBoost machine learning framework. J. Rock Mech. Geotech. Eng. 2021, 13, 1231–1245. [Google Scholar] [CrossRef]

- Liu, X.; Chen, H.; Liu, B.; Wang, S.; Liu, Q.; Luo, Y.; Luo, J. Experimental and numerical investigation on failure characteristics and mechanism of coal with different water contents. Int. J. Coal Sci. Technol. 2023, 10, 49. [Google Scholar] [CrossRef]

- Ma, L.; Muhammad Khan, N.; Feroze, T.; Sazid, M.; Cao, K.; Hussain, S.; Gao, Q.; Alarifi, S.S.; Wang, H. Prediction of rock loading stages using average infrared radiation temperature under shear and uniaxial loading. Infrared Phys. Technol. 2024, 136, 105084. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, L.; Wang, W.; Tang, J.; Lin, H.; Wan, W. Transient pulse test and morphological analysis of single rock fractures. Int. J. Rock Mech. Min. Sci. 2017, 91, 139–154. [Google Scholar] [CrossRef]

- Liu, X.; Fu, Y.; Zheng, Y.; Liang, N. A review on deterioration of rock caused by water-rock interaction. Chin. J. Undergr. Space Eng. 2012, 8, 77–82. [Google Scholar]

- Cao, K.; Ma, L.; Zhang, D.; Lai, X.; Zhang, Z.; Khan, N.M. An experimental study of infrared radiation characteristics of sandstone in dilatancy process. Int. J. Rock Mech. Min. Sci. 2020, 136, 104503. [Google Scholar] [CrossRef]

- Liashchynskyi, P.; Liashchynskyi, P. Grid search, random search, genetic algorithm: A big comparison for NAS. arXiv 2019, arXiv:1912.06059. [Google Scholar]

- Yang, H.Q.; Zeng, Y.Y.; Lan, Y.F.; Zhou, X.P. Analysis of the excavation damaged zone around a tunnel accounting for geostress and unloading. Int. J. Rock Mech. Min. Sci. 2014, 69, 59–66. [Google Scholar] [CrossRef]

- Chai, C.; Ling, S.; Wu, X.; Hu, T.; Sun, D. Characteristics of the In Situ Stress Field and Engineering Effect along the Lijiang to Shangri-La Railway on the Southeastern Tibetan Plateau, China. Adv. Civ. Eng. 2021, 2021, 6652790. [Google Scholar] [CrossRef]

- Deng, D.; Wang, H.; Xie, L.; Wang, Z.; Song, J. Experimental study on the interrelation of multiple mechanical parameters in overburden rock caving process during coal mining in longwall panel. Int. J. Coal Sci. Technol. 2023, 10, 47. [Google Scholar] [CrossRef]

- Tan, Y.; Ma, Q.; Liu, X.; Liu, X.; Elsworth, D.; Qian, R.; Shang, J. Study on the disaster caused by the linkage failure of the residual coal pillar and rock stratum during multiple coal seam mining: Mechanism of progressive and dynamic failure. Int. J. Coal Sci. Technol. 2023, 10, 45. [Google Scholar] [CrossRef]

- Leśniak, G.; Brunner, D.J.; Topór, T.; Słota-Valim, M.; Cicha-Szot, R.; Jura, B.; Skiba, J.; Przystolik, A.; Lyddall, B.; Plonka, G. Correction to: Application of long-reach directional drilling boreholes for gas drainage of adjacent seams in coal mines with severe geological conditions. Int. J. Coal Sci. Technol. 2023, 10, 39. [Google Scholar] [CrossRef]

- Luo, J.; Li, Y.; Meng, X.; Guo, Q.; Zhao, G. Influence of coupling mechanism of loose layer and fault on multi-physical fields in mining areas. Int. J. Coal Sci. Technol. 2023, 10, 86. [Google Scholar] [CrossRef]

| Parameters | Mean | Standard Deviation | Minimum | Median | Maximum |

|---|---|---|---|---|---|

| Time | 473.200 | 273.130 | 0.200 | 473.200 | 946.200 |

| IR | 0.010 | 0.008 | 0.000 | 0.008 | 0.028 |

| Strain | 0.010 | 0.000 | 0.000 | 0.010 | 0.010 |

| Stress | 20.430 | 18.163 | 0.005 | 15.518 | 55.053 |

| Samples No. | Water Content (%) | E (GPa) | σp (MPa) | ϵp 10−2 | σi (MPa) | σd (MPa) |

|---|---|---|---|---|---|---|

| K-1 | 0.0000 | 10.1310 | 73.1210 | 1.2510 | 41.8100 | 63.3810 |

| K-2 | 0.0000 | 9.8710 | 74.5810 | 0.9940 | 37.2300 | 62.2900 |

| K-2 | 0.0000 | 9.4620 | 69.5520 | 0.8820 | 37.7410 | 57.1330 |

| L-1 | 0.9710 | 8.7510 | 57.7910 | 1.0330 | 26.8200 | 44.1020 |

| L-2 | 1.1350 | 8.9800 | 60.7720 | 1.1300 | 31.7500 | 42.4010 |

| L-3 | 0.9910 | 9.3700 | 64.5310 | 1.2600 | 31.6000 | 49.6900 |

| M-1 | 2.0750 | 7.2500 | 51.9230 | 1.1740 | 24.3320 | 38.4420 |

| M-2 | 2.1360 | 7.9910 | 49.8420 | 1.2520 | 22.5500 | 34.9020 |

| M-3 | 1.9540 | 7.8820 | 48.8930 | 1.1930 | 21.5600 | 33.7000 |

| N-1 | 3.1090 | 5.8810 | 41.9710 | 1.1810 | 17.7910 | 28.1510 |

| N-2 | 3.0040 | 5.4320 | 38.0320 | 1.2420 | 15.8500 | 28.1020 |

| N-3 | 3.1130 | 4.8830 | 36.5710 | 1.2310 | 16.1800 | 26.3900 |

| Indices | Intensity of Brittleness | ||||

|---|---|---|---|---|---|

| Extreme | High | Intermediate High | Middle | Low | |

| BIDP | >100 | 90–100 | 80–90 | 70–80 | <70 |

| Samples | Water Content | Previous Brittleness Indices | Proposed Brittleness Indices | ||||||

|---|---|---|---|---|---|---|---|---|---|

| No. | B1 | Grade | B2 | B3 | B4 | Grade | BIDP | Grade | |

| K-1 | 0.0000 | 58.4960 | Extremely | 13.9911 | 191.0743 | 13.8230 | Moderate | 110.8463 | Extremely |

| K-2 | 0.0000 | 75.3330 | Extremely | 16.0260 | 173.5407 | 13.1735 | Moderate | 124.7824 | Extremely |

| K-2 | 0.0000 | 79.0340 | Extremely | 14.7430 | 164.0601 | 12.8086 | Moderate | 105.2891 | Extremely |

| L-1 | 0.9710 | 56.1070 | Extremely | 16.0419 | 104.0960 | 10.2027 | Moderate | 88.4351 | Moderate |

| L-2 | 1.1350 | 53.7790 | Extremely | 15.3126 | 120.5944 | 10.9815 | Moderate | 81.1589 | Moderate |

| L-3 | 0.9910 | 51.2140 | Extremely | 16.3370 | 127.4487 | 11.2893 | Moderate | 99.4308 | High |

| M-1 | 2.0750 | 44.3760 | Extremely | 17.0715 | 78.9619 | 8.8861 | Brittle | 82.0329 | Moderate |

| M-2 | 2.1360 | 39.8720 | High | 17.6823 | 70.2461 | 8.3813 | Brittle | 77.1435 | Low |

| M-3 | 1.9540 | 41.0840 | Extremely | 18.1421 | 65.8833 | 8.1169 | Brittle | 76.4237 | Low |

| N-1 | 3.1090 | 35.5680 | Extremely | 18.8729 | 46.6691 | 6.8315 | Brittle | 66.4114 | Low |

| N-2 | 3.0040 | 30.6690 | Extrmely | 19.1960 | 37.6755 | 6.1380 | Brittle | 67.4306 | Low |

| N-3 | 3.1130 | 29.7310 | Brittle | 18.0821 | 36.9824 | 6.0813 | Brittle | 59.6483 | Low |

| Output | Model | Parameters |

|---|---|---|

| Stress, Strain | RF | n_estimator = 30, max_depth = 13, random state = 42 |

| KNN | n_neighbors = 3, metric = Minkowski | |

| XG Boost | n_estimator = 100, reg_ lambda = 1, max_depth = 3, random state = 10 |

| S.no | Models | Accuracy (Training) | Accuracy (Testing) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| R2 | MAE | MSE | RMSE | R2 | MAE | MSE | RMSE | ||

| 1 | XGBoost Regressor | 0.998 | 0.193 | 0.146 | 0.382 | 0.999 | 0.193 | 0.147 | 0.383 |

| 2 | RF | 0.999 | 0.142 | 0.078 | 0.279 | 0.999 | 0.164 | 0.069 | 0.262 |

| 3 | KNN | 0.853 | 6.195 | 60.961 | 7.807 | 0.853 | 6.201 | 61.017 | 7.811 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, N.M.; Ma, L.; Emad, M.Z.; Feroze, T.; Gao, Q.; Alarifi, S.S.; Sun, L.; Hussain, S.; Wang, H. Predicting Sandstone Brittleness under Varying Water Conditions Using Infrared Radiation and Computational Techniques. Water 2024, 16, 143. https://doi.org/10.3390/w16010143

Khan NM, Ma L, Emad MZ, Feroze T, Gao Q, Alarifi SS, Sun L, Hussain S, Wang H. Predicting Sandstone Brittleness under Varying Water Conditions Using Infrared Radiation and Computational Techniques. Water. 2024; 16(1):143. https://doi.org/10.3390/w16010143

Chicago/Turabian StyleKhan, Naseer Muhammad, Liqiang Ma, Muhammad Zaka Emad, Tariq Feroze, Qiangqiang Gao, Saad S. Alarifi, Li Sun, Sajjad Hussain, and Hui Wang. 2024. "Predicting Sandstone Brittleness under Varying Water Conditions Using Infrared Radiation and Computational Techniques" Water 16, no. 1: 143. https://doi.org/10.3390/w16010143

APA StyleKhan, N. M., Ma, L., Emad, M. Z., Feroze, T., Gao, Q., Alarifi, S. S., Sun, L., Hussain, S., & Wang, H. (2024). Predicting Sandstone Brittleness under Varying Water Conditions Using Infrared Radiation and Computational Techniques. Water, 16(1), 143. https://doi.org/10.3390/w16010143