An Investigation of the Influence on Compacted Snow Hardness by Density, Temperature and Punch Head Velocity

Abstract

1. Introduction

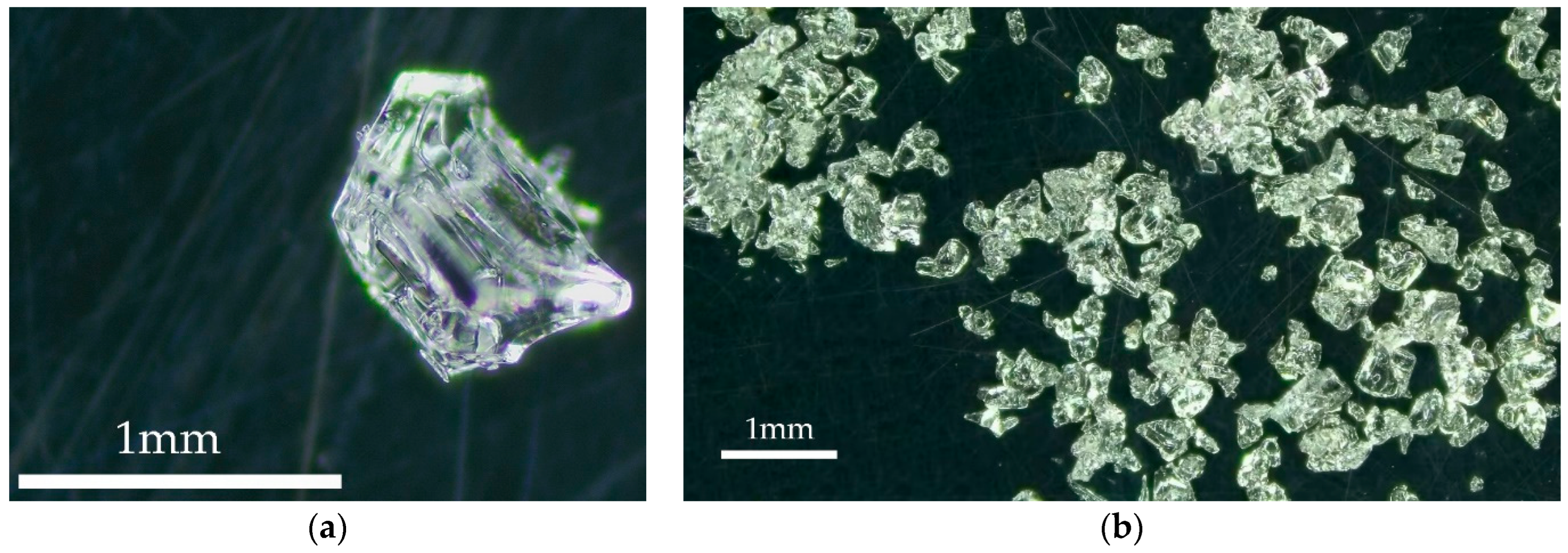

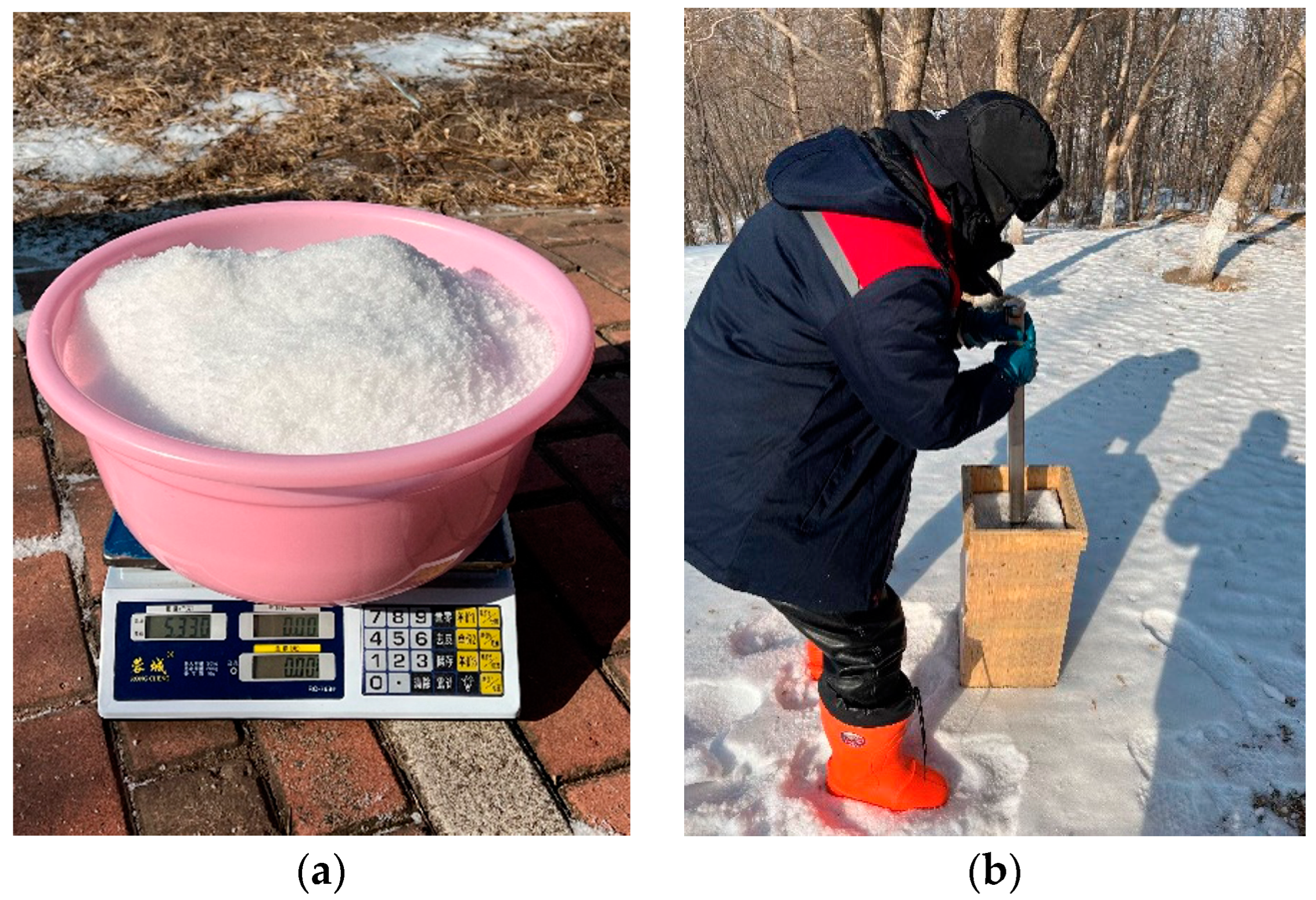

2. Materials and Methods

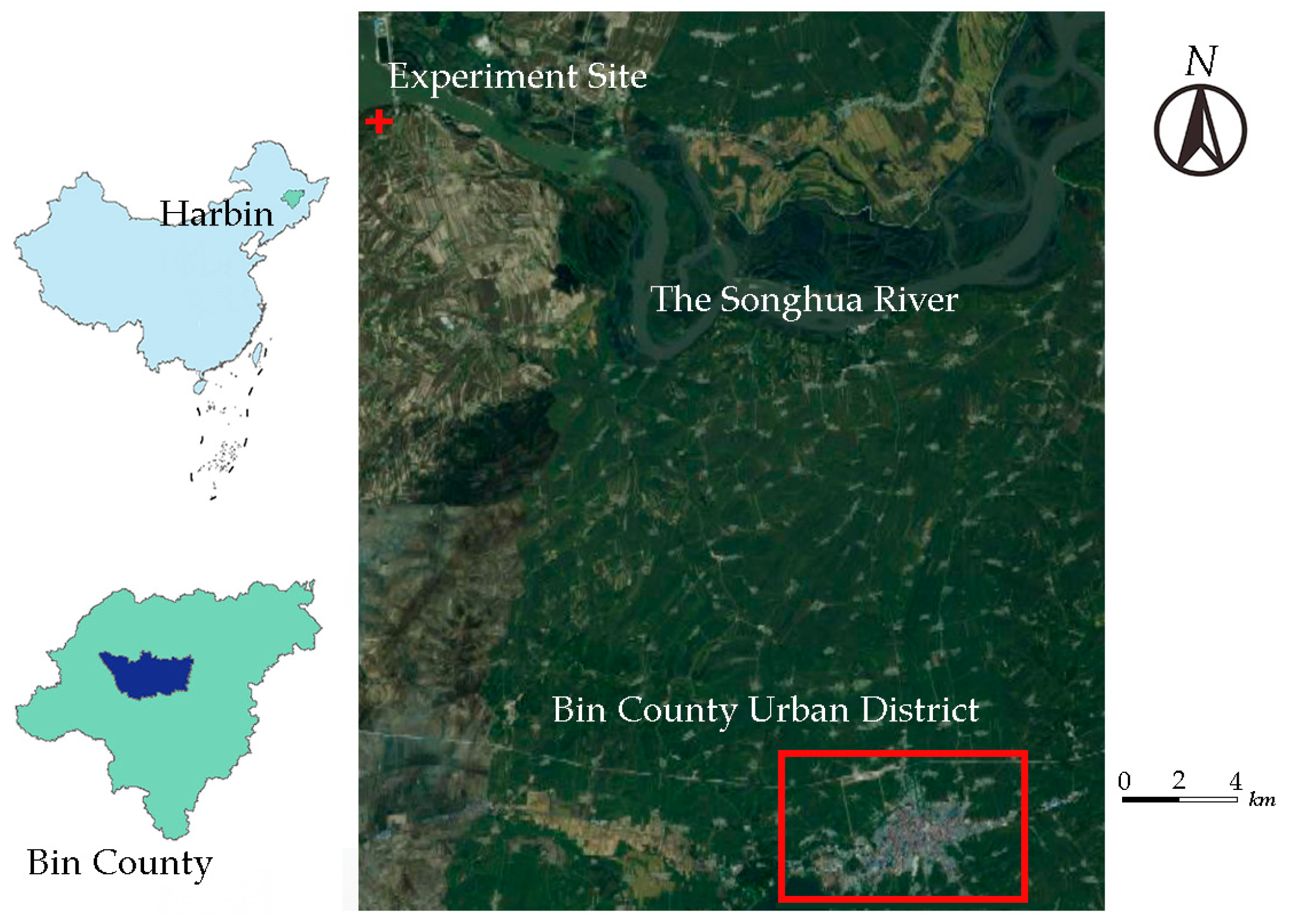

2.1. Overview of the Research Area

2.2. Research Equipment

3. Orthogonal Test Method

3.1. Factors Affecting the Hardness of Compacted Snow

3.2. Arrangement and Results of Orthogonal Experiment

3.3. Range Analysis Results and Discussions

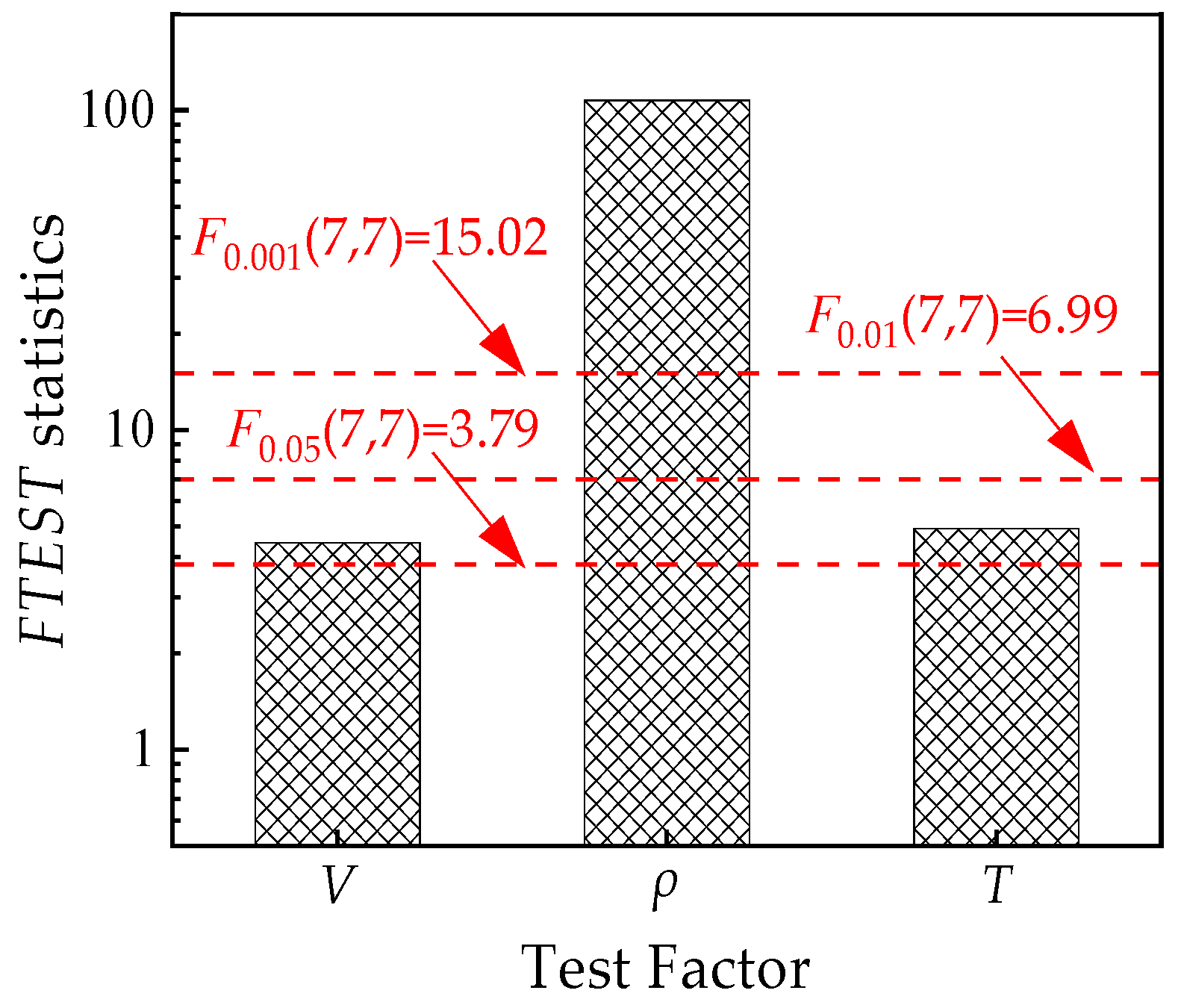

3.4. Variance Analysis

- Sample density has the most significant influence on the hardness of the sample;

- The penetration velocity and sample temperature are significant at an inspection level of 0.05 and cannot be ignored.

4. Support Vector Regression (SVR) Algorithm for Model Development

4.1. The Selection of Kernel Function

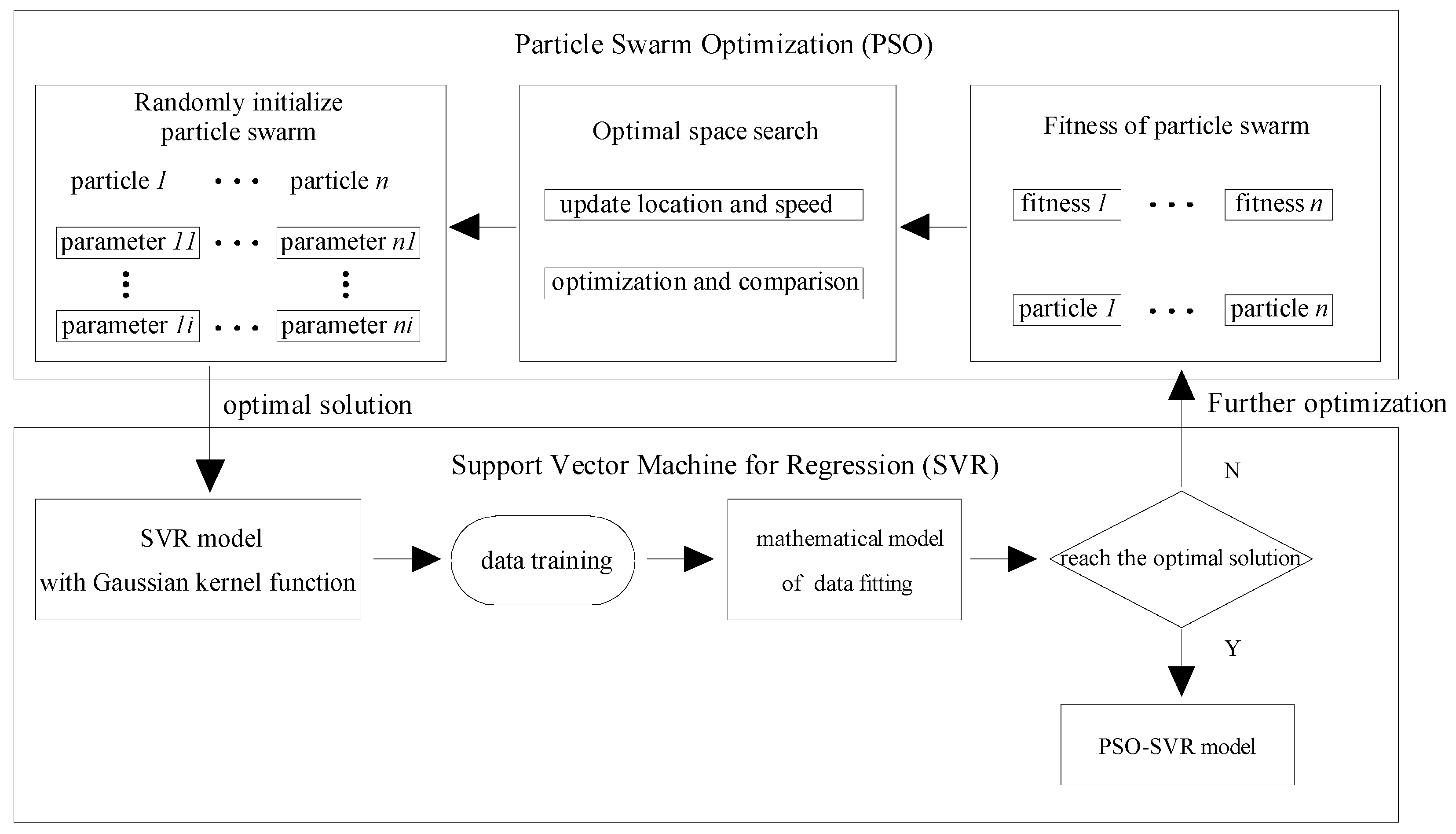

4.2. The Particle Swarm Optimization-Support Vector Regression (PSO-SVR) Parameter Optimization Architecture and Proceeding

- Initialize all particle positions and speeds at random;

- Based on the fitness function of the snow hardness estimate issue, the fitness value of each particle is determined;

- The fitness value of each particle is compared with both Pbest (i.e., the best position visited by this particle so far) and Gbest (i.e., the best position found by all the particles so far). In the event that the fitness value surpasses the current value of Pbest, it is necessary to update Pbest with the new fitness value. In the event that the fitness value surpasses the current value of Gbest, the Gbest should be updated with the new fitness value;

- In order to expand the space for particles and prevent convergence to local optima, it is necessary to reset the penalty factor c of the SVR on each update;

- Update the position and speed of every individual particle until the predetermined maximum number of iterations has been attained. Subsequently, output the optimal parameters. Alternatively, go back to Step 2.

4.3. The Result of PSO-SVR Algorithm

5. Conclusions

- This study uses the orthogonal experiment method, and orthogonal experiments are conducted on 64 different samples of compacted snow. The results of the range analysis indicate that the density of compacted snow samples has the most sensitive impact on hardness. Temperature and penetration velocity have far less sensitive effect on hardness than density.

- According to the variance analysis of the orthogonal experiment, the effect of density on hardness within the range of this experiment is the most significant. Comparatively, the effects of temperature and penetration velocity are limited to the inspection level of 0.05, which cannot be ignored completely. The significance of density is clearly supported by the current findings.

- Employing PSO-SVR analysis, we obtain the continuous function relationship between the IMSP Value and the three factors (i.e., density, temperature, penetration velocity), within the experimental range. This study not only confirms the positive correlation between density and hardness [32], but also discovers the relationship between temperature and hardness. By carefully examining the model, it is found that if the density of compacted snow is low, the hardness of the snow also tends to remain low. In this case, there is no significant positive relationship between snow density and hardness at specific temperatures and punch head speeds. Therefore, when constructing compacted snow roads, it is necessary to avoid the occurrence of weak areas of low-density snow. One of the more significant findings to emerge from this study is that when the temperature approaches the melting point of snow, even with high density, the hardness remains low, which is especially apparent at high penetration velocities. This indicates that the hardness of snow suffers a fundamental decrease at high temperatures. In actual compacted snow road projects, when the temperature approaches 0 °C, even if the density of the compacted snow road is high, maintenance of the piste is still required. In this case, skiing is never permitted because of this sharp decrease in hardness, which could cause serious safety issues.

- The IMSP employs an electric motor to precisely control the penetration speed, and utilizes the sensors to precisely measure the end snow resistance. This device can be used as a penetrating instrument on pistes and lays the groundwork for future research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Number | Coefficient Term | Super Vector | Number | Coefficient Term | Super Vector | ||||

|---|---|---|---|---|---|---|---|---|---|

| V | ρ | T | V | ρ | T | ||||

| 1 | −2.773 | −1.000 | 0.714 | 1.000 | 30 | −8.594 | −0.141 | 0.429 | −0.143 |

| 2 | 0.615 | −1.000 | 1.000 | 0.714 | 31 | 8.594 | 0.141 | 0.714 | −0.143 |

| 3 | −3.694 | −1.000 | −1.000 | 0.429 | 32 | −5.231 | 0.141 | 1.000 | −0.429 |

| 4 | 8.594 | −1.000 | −0.714 | 0.143 | 33 | 0.681 | 0.141 | −1.000 | −0.714 |

| 5 | −0.921 | −1.000 | −0.429 | −0.143 | 34 | 8.594 | 0.141 | −0.714 | −1.000 |

| 6 | −4.251 | −1.000 | −0.143 | −0.429 | 35 | −8.594 | 0.141 | −0.429 | 1.000 |

| 7 | −8.594 | −1.000 | 0.143 | −0.714 | 36 | −0.577 | 0.141 | −0.143 | 0.714 |

| 8 | 0.134 | −1.000 | 0.429 | −1.000 | 37 | −8.594 | 0.141 | 0.143 | 0.429 |

| 9 | −8.594 | −0.714 | 0.714 | 0.714 | 38 | −8.594 | 0.141 | 0.429 | 0.143 |

| 10 | 5.390 | −0.714 | 1.000 | 1.000 | 39 | 8.594 | 0.428 | 0.714 | −0.429 |

| 11 | −8.594 | −0.714 | −0.714 | 0.429 | 40 | −8.165 | 0.428 | 1.000 | −0.143 |

| 12 | −7.315 | −0.714 | −0.429 | −0.429 | 41 | −8.147 | 0.428 | −1.000 | −1.000 |

| 13 | 8.594 | −0.714 | −0.143 | −0.143 | 42 | 8.594 | 0.428 | −0.714 | −0.714 |

| 14 | 8.594 | −0.714 | 0.143 | −1.000 | 43 | −8.594 | 0.428 | −0.429 | 0.714 |

| 15 | 8.594 | −0.714 | 0.429 | −0.714 | 44 | 8.594 | 0.428 | −0.143 | 1.000 |

| 16 | 8.594 | −0.428 | 0.714 | 0.429 | 45 | 8.594 | 0.428 | 0.143 | 0.143 |

| 17 | 4.388 | −0.428 | 1.000 | 0.143 | 46 | 8.594 | 0.428 | 0.429 | 0.429 |

| 18 | −4.978 | −0.428 | −1.000 | 1.000 | 47 | −5.572 | 0.763 | 0.714 | −0.714 |

| 19 | 8.594 | −0.428 | −0.714 | 0.714 | 48 | 6.969 | 0.763 | 1.000 | −1.000 |

| 20 | 8.594 | −0.428 | −0.429 | −0.714 | 49 | −3.816 | 0.763 | −1.000 | −0.143 |

| 21 | −2.825 | −0.428 | −0.143 | −1.000 | 50 | −4.590 | 0.763 | −0.714 | −0.429 |

| 22 | 8.594 | −0.428 | 0.143 | −0.143 | 51 | 8.594 | 0.763 | −0.429 | 0.429 |

| 23 | −8.594 | −0.428 | 0.429 | −0.429 | 52 | 1.699 | 0.763 | −0.143 | 0.143 |

| 24 | −8.594 | −0.141 | 0.714 | 0.143 | 53 | −1.500 | 0.763 | 0.143 | 1.000 |

| 25 | 3.708 | −0.141 | 1.000 | 0.429 | 54 | −5.748 | 0.763 | 0.429 | 0.714 |

| 26 | 8.594 | −0.141 | −0.714 | 1.000 | 55 | −6.869 | 1.000 | 0.714 | −1.000 |

| 27 | −8.594 | −0.141 | −0.429 | −1.000 | 56 | 6.076 | 1.000 | 1.000 | −0.714 |

| 28 | −8.594 | −0.141 | −0.143 | −0.714 | 57 | 8.594 | 1.000 | −1.000 | −0.429 |

| 29 | 4.343 | −0.141 | 0.143 | −0.429 | 58 | −8.594 | 1.000 | −0.714 | −0.143 |

References

- Mössner, M.; Heinrich, D.; Schindelwig, K.; Schretter, H.; Nachbauer, W. Modeling the ski–snow contact in skiing turns using a hypoplastic vs an elastic force–penetration relation. Scand. J. Med. Sci. Spor. 2014, 24, 577–585. [Google Scholar] [CrossRef] [PubMed]

- Hasler, M.; Schindelwig, K.; Mayr, B.; Knoflach, C.; Rohm, S.; van Putten, J.; Nachbauer, W. A novel ski–snow tribometer and its precision. Tribol. Lett. 2016, 63, 33. [Google Scholar] [CrossRef]

- Mössner, M.; Schindelwig, K.; Heinrich, D.; Hasler, M.; Nachbauer, W. Effect of load, ski and snow properties on apparent contact area and pressure distribution in straight gliding. Cold Reg. Sci. Tech. 2023, 208, 103799. [Google Scholar] [CrossRef]

- Gold, L.W. The strength of snow in compression. J. Glaciol. 1956, 2, 719–725. [Google Scholar] [CrossRef]

- Hirashima, H.; Abe, O.; Sato, A.; Lehning, M. An adjustment for kinetic growth metamorphism to improve shear strength parameterization in the SNOWPACK model. Cold Reg. Sci. Tech. 2009, 59, 169–177. [Google Scholar] [CrossRef]

- Landauer, J.K. Stress-Strain Relations in Snow under Uniaxial Compression. J. Appl. Phys. 1955, 26, 1493–1497. [Google Scholar] [CrossRef]

- Lintzén, N.; Edeskär, T. Uniaxial strength and deformation properties of machine-made snow. J. Cold Reg. Eng. 2015, 29, 04014020. [Google Scholar] [CrossRef]

- Wang, E.; Fu, X.; Han, H.; Liu, X.; Xiao, Y.; Leng, Y. Study on the mechanical properties of compacted snow under uniaxial compression and analysis of influencing factors. Cold Reg. Sci. Tech. 2021, 182, 103215. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.; Dhawan, K. An L9 orthogonal design methodology to study the impact of operating parameters on particulate emission and related characteristics during pulse-jet filtration process. Powder Technol. 2009, 195, 128–134. [Google Scholar] [CrossRef]

- Li, X.; Hao, J. Orthogonal test design for optimization of synthesis of super early strength anchoring material. Constr. Build. Mater. 2018, 181, 42–48. [Google Scholar] [CrossRef]

- Ben-Hur, A.; Ong, C.S.; Sonnenburg, S.; Schölkopf, B.; Rätsch, G. Support vector machines and kernels for computational biology. PLoS Comput. Biol. 2008, 4, e1000173. [Google Scholar] [CrossRef]

- Orrù, G.; Pettersson-Yeo, W.; Marquand, A.F.; Sartori, G.; Mecheli, A. Using support vector machine to identify imaging biomarkers of neurological and psychiatric disease: A critical review. Neurosci. Biobehav. Rev. 2012, 36, 1140–1152. [Google Scholar] [CrossRef]

- Glaser, J.I.; Benjamin, A.S.; Farhoodi, R.; Kording, K.P. The roles of supervised machine learning in systems neuroscience. Prog. Neurobiol. 2019, 175, 126–137. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, Y.; Infield, D.; Zhao, Y.; Han, S.; Yan, J. A hybrid forecasting method for wind power ramp based on orthogonal test and support vector machine (OT-SVM). IEEE Trans. Sustain. Energy 2016, 8, 451–457. [Google Scholar] [CrossRef]

- Zhang, N. Experimental Research on the Relationship between Hardness and Density of Different Snow Shapes. Master’s Thesis, Dalian University of Technology, Dalian, China, 2022. (In Chinese). [Google Scholar] [CrossRef]

- Zhuang, F. Experimental Study on Snow Hardness and Its Testing Technology. Master’s Thesis, Dalian University of Technology, Dalian, China, 2019. (In Chinese). [Google Scholar] [CrossRef]

- Fu, X. Study on the Thermal Characteristics and Mechanical Properties of Seasonal Snow in Northeast China. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2020. (In Chinese). [Google Scholar]

- Li, Y.; She, L.; Wen, L.; Zhang, Q. Sensitivity analysis of drilling parameters in rock rotary drilling process based on orthogonal test method. Eng. Geol. 2020, 270, 105576. [Google Scholar] [CrossRef]

- Wang, X.; He, Q.; Huang, Y.; Song, Q.; Zhang, X.; Xing, F. Mechanical characteristics of fiber-reinforced microcapsule self-healing cementitious composites by orthogonal tests. Constr. Build. Mater. 2023, 383, 131377. [Google Scholar] [CrossRef]

- Ståhle, L.; Wold, S. Analysis of variance (ANOVA). Chemometr. Intell. Lab. 1989, 6, 259–272. [Google Scholar] [CrossRef]

- Wu, X.; Leung, D.Y.C. Optimization of biodiesel production from camelina oil using orthogonal experiment. Appl. Energy 2011, 88, 3615–3624. [Google Scholar] [CrossRef]

- Wang, B.; Lin, R.; Liu, D.; Xu, J.; Feng, B. Investigation of the effect of humidity at both electrode on the performance of PEMFC using orthogonal test method. Int. J. Hydrog. 2019, 44, 13737–13743. [Google Scholar] [CrossRef]

- Liu, S.; Liu, W. Experimental development process of a new fluid–solid coupling similar-material based on the orthogonal test. Processes 2018, 6, 211. [Google Scholar] [CrossRef]

- Zheng, K.; Du, C.; Yang, D. Orthogonal test and support vector machine applied to influence factors of coal and gangue separation. Int. J. Coal Prep. Util. 2014, 34, 75–84. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, H. Inflatable wing design parameter optimization using orthogonal testing and support vector machines. Chin. J. Aeronaut. 2012, 25, 887–895. [Google Scholar] [CrossRef]

- Smola, A.J.; Schölkopf, B. A tutorial on support vector regression. Stat. Comput. 2004, 14, 199–222. [Google Scholar] [CrossRef]

- Sánchez, A.V.D. Advanced support vector machines and kernel methods. Neurocomputing 2003, 55, 5–20. [Google Scholar] [CrossRef]

- Kumar, K. Comprehensive Composition to Spot Intrusions by Optimized Gaussian Kernel SVM. Int. J. Knowl. Based Organ. 2022, 12, 1–27. [Google Scholar] [CrossRef]

- Adaryani, F.R.; Mousavi, S.J.; Jafari, F. Short-term rainfall forecasting using machine learning-based approaches of PSO-SVR, LSTM and CNN. J. Hydrol. 2022, 614, 128463. [Google Scholar] [CrossRef]

- Duan, P.; Xie, K.; Guo, T.; Huang, X. Short-term load forecasting for electric power systems using the PSO-SVR and FCM clustering techniques. Energies 2011, 4, 173–184. [Google Scholar] [CrossRef]

- Luo, H.; Zhou, P.; Shu, L.; Mou, J.; Zheng, H.; Jiang, C.; Wang, Y. Energy performance curves prediction of centrifugal pumps based on constrained PSO-SVR model. Energies 2022, 15, 3309. [Google Scholar] [CrossRef]

- Kachniarz, K.; Grabiec, M.; Ignatiuk, D.; Laska, M.; Luks, B. Changes in the structure of the snow cover of Hansbreen (S Spitsbergen) derived from repeated high-frequency radio-echo sounding. Remote Sens. 2022, 15, 189. [Google Scholar] [CrossRef]

| Level Number | Factors | ||

|---|---|---|---|

| V (mm/s) | ρ (kg/m3) | T (°C) | |

| 1 | 15.03 | 426 | −3 |

| 2 | 15.90 | 438 | −8 |

| 3 | 16.77 | 354 | −13 |

| 4 | 17.64 | 366 | −18 |

| 5 | 18.50 | 378 | −23 |

| 6 | 19.37 | 390 | −28 |

| 7 | 20.39 | 402 | −33 |

| 8 | 21.11 | 414 | −38 |

| Test Number | Factor Level | Empty Column | IMSP Value (kPa) | Test Number | Factor Level | Empty Column | IMSP Value (kPa) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| V | ρ | T | e | V | ρ | T | e | ||||

| 1 | 1 | 1 | 1 | 1 | 717.88 | 33 | 5 | 1 | 5 | 2 | 869.88 |

| 2 | 1 | 2 | 2 | 2 | 1030.80 | 34 | 5 | 2 | 6 | 1 | 888.56 |

| 3 | 1 | 3 | 3 | 3 | 187.04 | 35 | 5 | 3 | 7 | 4 | 457.92 |

| 4 | 1 | 4 | 4 | 4 | 309.32 | 36 | 5 | 4 | 8 | 3 | 630.40 |

| 5 | 1 | 5 | 5 | 5 | 325.68 | 37 | 5 | 5 | 1 | 6 | 255.24 |

| 6 | 1 | 6 | 6 | 6 | 371.40 | 38 | 5 | 6 | 2 | 5 | 441.52 |

| 7 | 1 | 7 | 7 | 7 | 436.44 | 39 | 5 | 7 | 3 | 8 | 469.88 |

| 8 | 1 | 8 | 8 | 8 | 791.60 | 40 | 5 | 8 | 4 | 7 | 519.20 |

| 9 | 2 | 1 | 2 | 3 | 696.52 | 41 | 6 | 1 | 6 | 4 | 820.04 |

| 10 | 2 | 2 | 1 | 4 | 1075.16 | 42 | 6 | 2 | 5 | 3 | 799.80 |

| 11 | 2 | 3 | 4 | 1 | 326.76 | 43 | 6 | 3 | 8 | 2 | 363.64 |

| 12 | 2 | 4 | 3 | 2 | 295.84 | 44 | 6 | 4 | 7 | 1 | 468.60 |

| 13 | 2 | 5 | 6 | 7 | 405.80 | 45 | 6 | 5 | 2 | 8 | 415.92 |

| 14 | 2 | 6 | 5 | 8 | 574.20 | 46 | 6 | 6 | 1 | 7 | 525.88 |

| 15 | 2 | 7 | 8 | 5 | 651.32 | 47 | 6 | 7 | 4 | 6 | 619.52 |

| 16 | 2 | 8 | 7 | 6 | 799.40 | 48 | 6 | 8 | 3 | 5 | 562.60 |

| 17 | 3 | 1 | 3 | 6 | 938.96 | 49 | 7 | 1 | 7 | 5 | 891.88 |

| 18 | 3 | 2 | 4 | 5 | 1000.28 | 50 | 7 | 2 | 8 | 6 | 1150.84 |

| 19 | 3 | 3 | 1 | 8 | 231.96 | 51 | 7 | 3 | 5 | 7 | 365.88 |

| 20 | 3 | 4 | 2 | 7 | 376.12 | 52 | 7 | 4 | 6 | 8 | 420.48 |

| 21 | 3 | 5 | 7 | 2 | 463.60 | 53 | 7 | 5 | 3 | 1 | 634.56 |

| 22 | 3 | 6 | 8 | 1 | 466.40 | 54 | 7 | 6 | 4 | 2 | 567.28 |

| 23 | 3 | 7 | 5 | 4 | 588.44 | 55 | 7 | 7 | 1 | 3 | 402.20 |

| 24 | 3 | 8 | 6 | 3 | 667.64 | 56 | 7 | 8 | 2 | 4 | 466.52 |

| 25 | 4 | 1 | 4 | 8 | 426.20 | 57 | 8 | 1 | 8 | 7 | 909.32 |

| 26 | 4 | 2 | 3 | 7 | 925.00 | 58 | 8 | 2 | 7 | 8 | 1116.48 |

| 27 | 4 | 3 | 2 | 6 | 311.40 | 59 | 8 | 3 | 6 | 5 | 390.84 |

| 28 | 4 | 4 | 1 | 5 | 388.48 | 60 | 8 | 4 | 5 | 6 | 384.04 |

| 29 | 4 | 5 | 8 | 4 | 379.04 | 61 | 8 | 5 | 4 | 3 | 646.20 |

| 30 | 4 | 6 | 7 | 3 | 344.92 | 62 | 8 | 6 | 3 | 4 | 397.24 |

| 31 | 4 | 7 | 6 | 2 | 592.48 | 63 | 8 | 7 | 2 | 1 | 572.80 |

| 32 | 4 | 8 | 5 | 1 | 613.24 | 64 | 8 | 8 | 1 | 2 | 612.36 |

| Factors | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| V | 521.27 | 603.13 | 591.68 | 497.60 | 566.57 | 572.01 | 612.46 | 628.66 | 131.07 |

| ρ | 783.84 | 998.36 | 329.43 | 409.16 | 440.75 | 461.11 | 541.64 | 629.07 | 668.94 |

| T | 526.14 | 538.95 | 551.39 | 551.85 | 565.14 | 569.66 | 622.41 | 667.83 | 141.69 |

| Sources | SSi | dfi | Vi | FTESTi |

|---|---|---|---|---|

| V | 114,441.90 | 7 | 16,348.84 | 4.44 |

| ρ | 2,765,486.06 | 7 | 395,069.44 | 107.35 |

| T | 126,117.76 | 7 | 18,016.82 | 4.90 |

| e | 25,760.88 | 7 | 3680.13 | —— |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Q.; Li, Z.; Lu, P.; Wang, Q.; Wei, J.; Hu, S.; Yang, H. An Investigation of the Influence on Compacted Snow Hardness by Density, Temperature and Punch Head Velocity. Water 2023, 15, 2897. https://doi.org/10.3390/w15162897

Zhao Q, Li Z, Lu P, Wang Q, Wei J, Hu S, Yang H. An Investigation of the Influence on Compacted Snow Hardness by Density, Temperature and Punch Head Velocity. Water. 2023; 15(16):2897. https://doi.org/10.3390/w15162897

Chicago/Turabian StyleZhao, Qiuming, Zhijun Li, Peng Lu, Qingkai Wang, Jie Wei, Shengbo Hu, and Haorong Yang. 2023. "An Investigation of the Influence on Compacted Snow Hardness by Density, Temperature and Punch Head Velocity" Water 15, no. 16: 2897. https://doi.org/10.3390/w15162897

APA StyleZhao, Q., Li, Z., Lu, P., Wang, Q., Wei, J., Hu, S., & Yang, H. (2023). An Investigation of the Influence on Compacted Snow Hardness by Density, Temperature and Punch Head Velocity. Water, 15(16), 2897. https://doi.org/10.3390/w15162897