Simulation Feedback of Temperature Field of Super-High Arch Dam during Operation and Its Difference with Design Temperature

Abstract

:1. Introduction

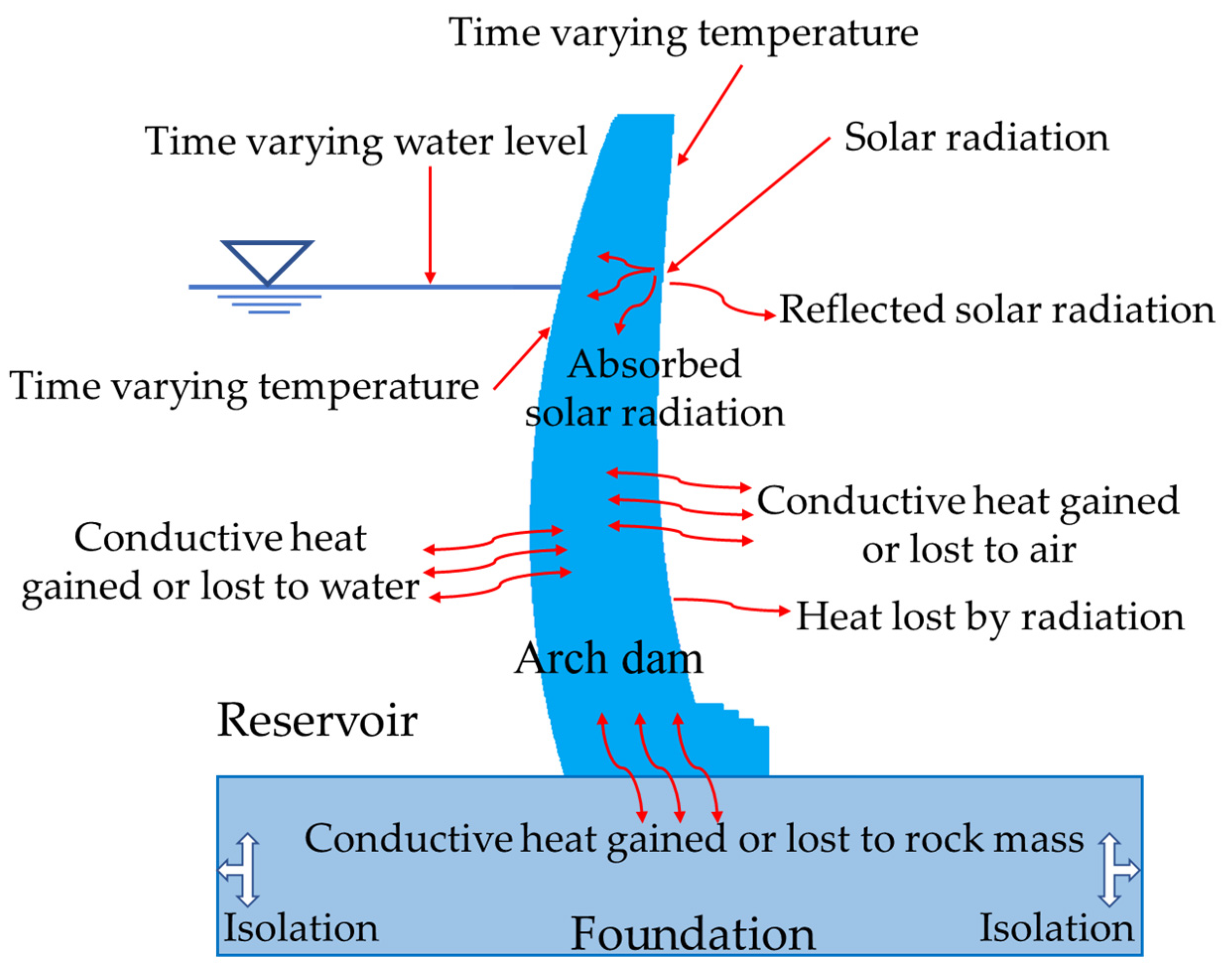

2. Calculation Principles and Methods

2.1. Calculation Principle of Unsteady Temperature Field

2.2. Back Analysis of the Adiabatic Temperature Rise of Concrete

3. Analysis of the Temporal-Spatial Evolution Law of Measured Temperature of Arch Dam during the Operation Period

3.1. Outline of the XLD Super-High Arch Dam in China

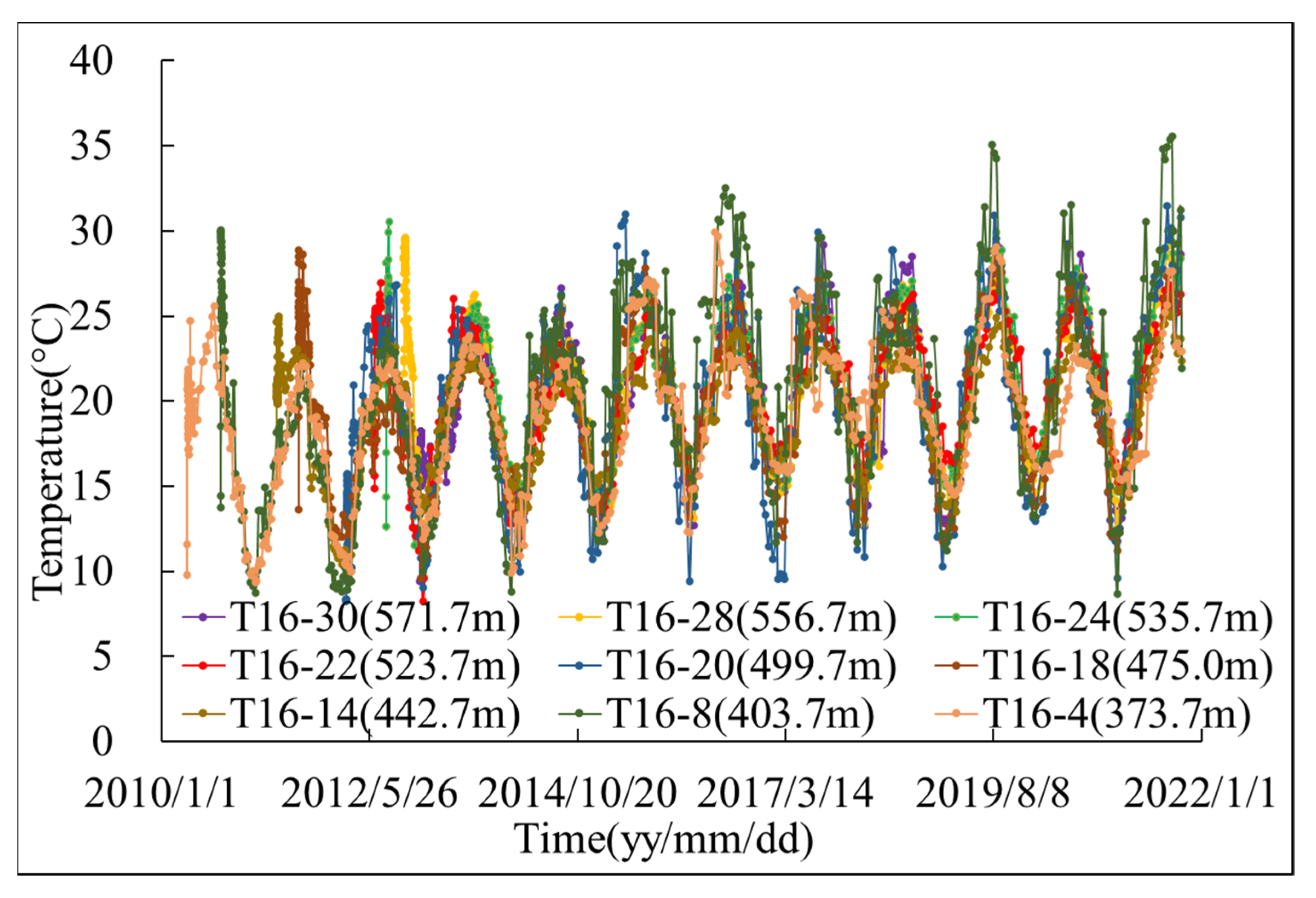

3.2. Analysis of Surface Temperature

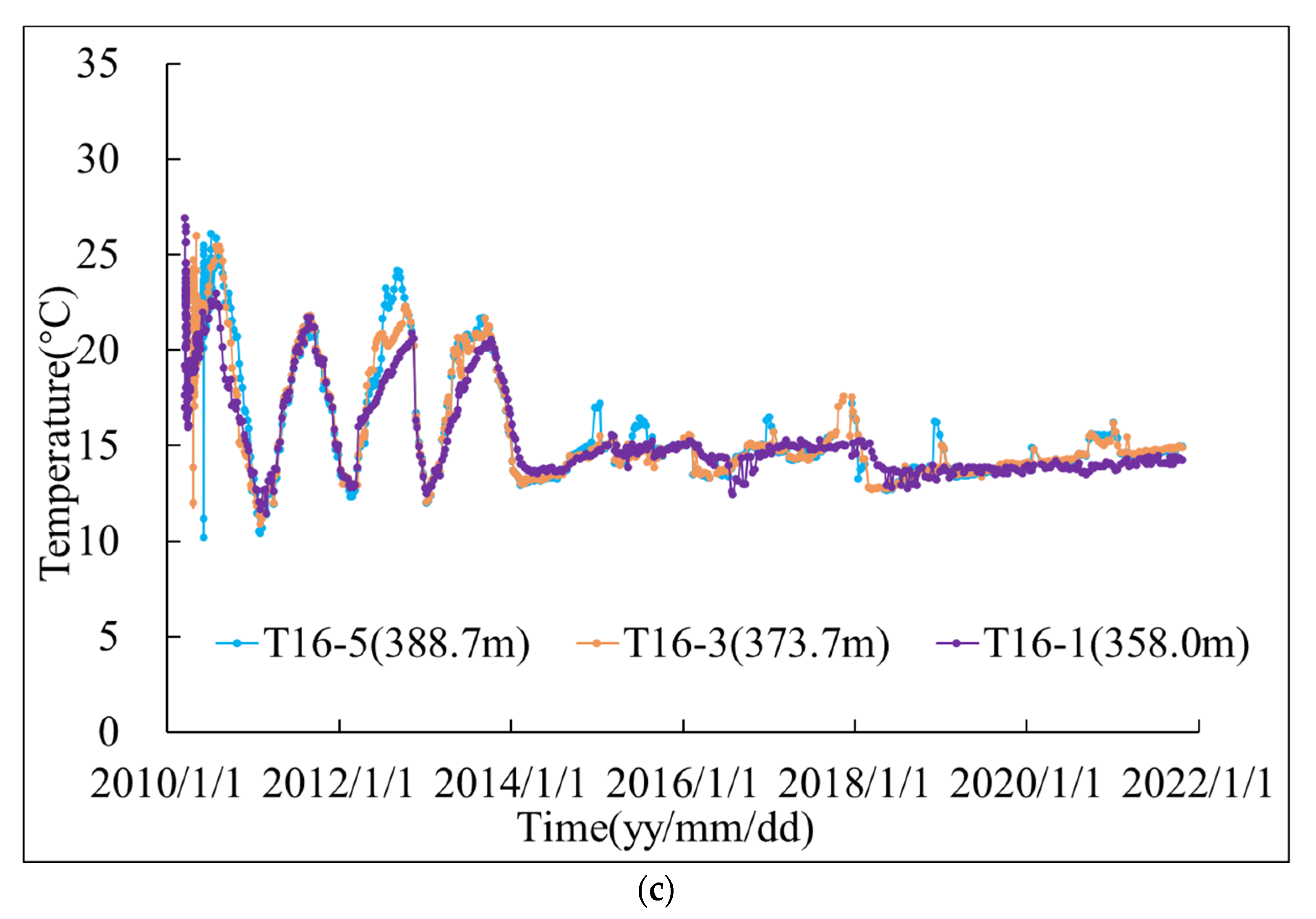

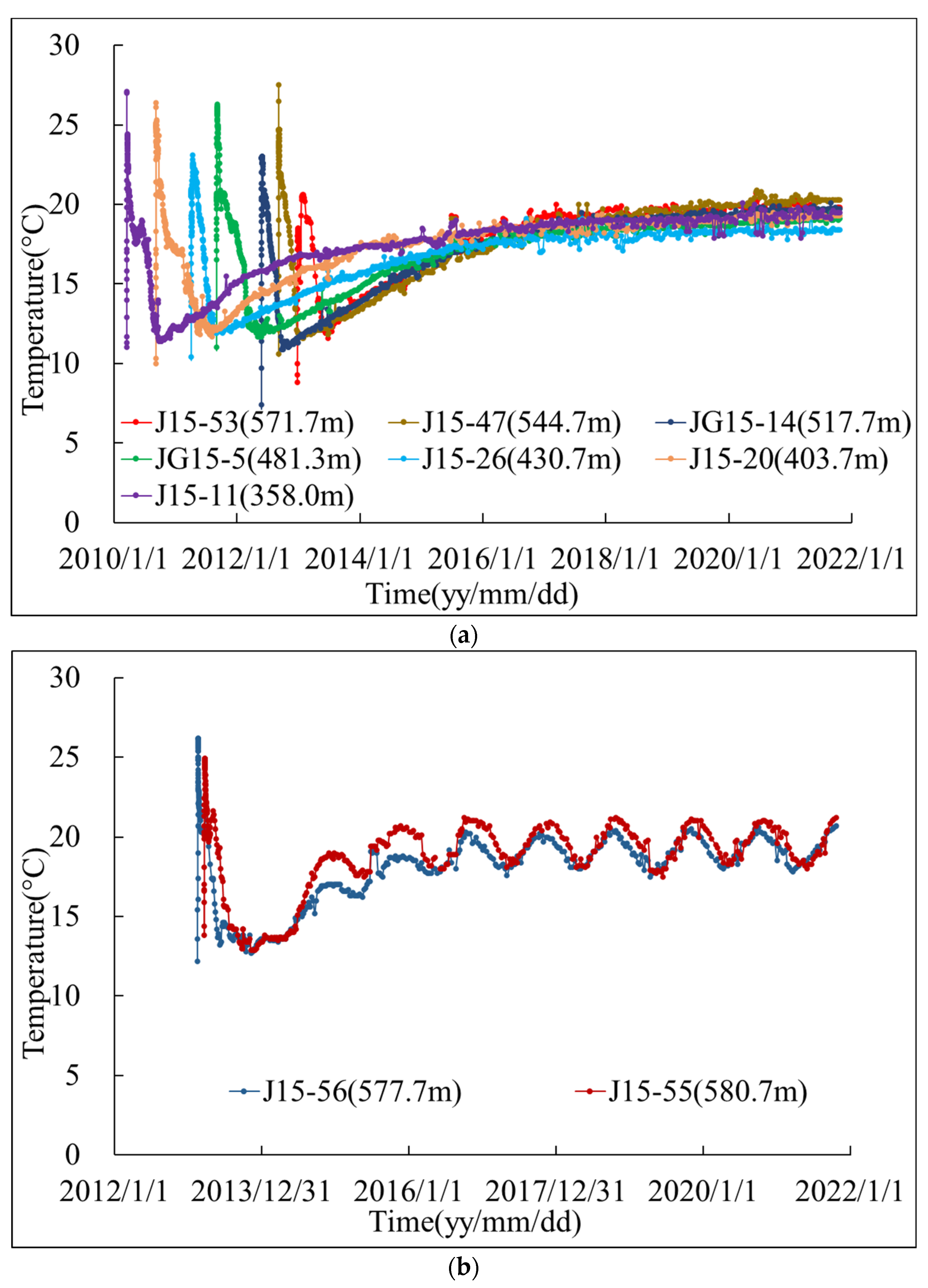

3.3. Analysis of Internal Temperature

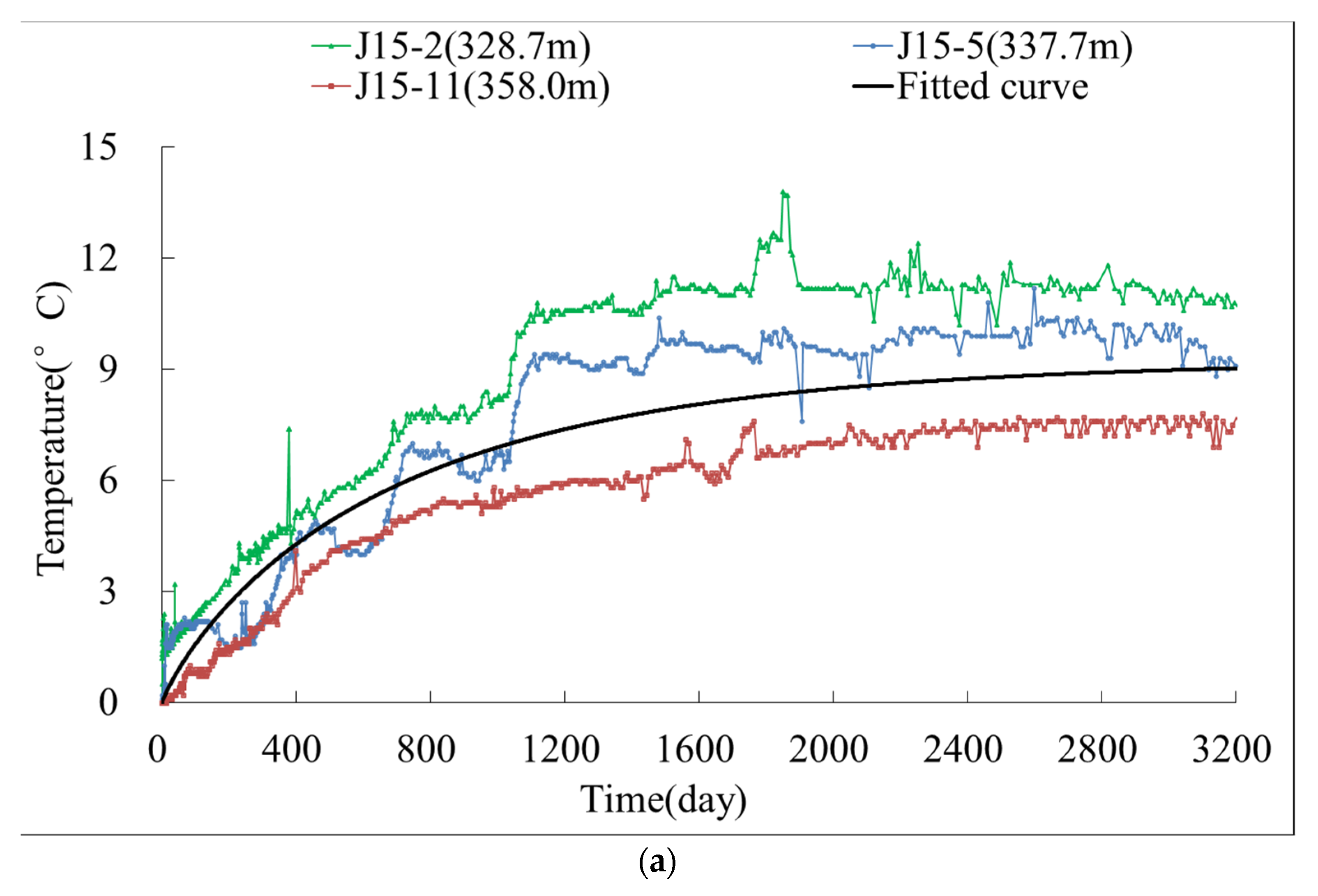

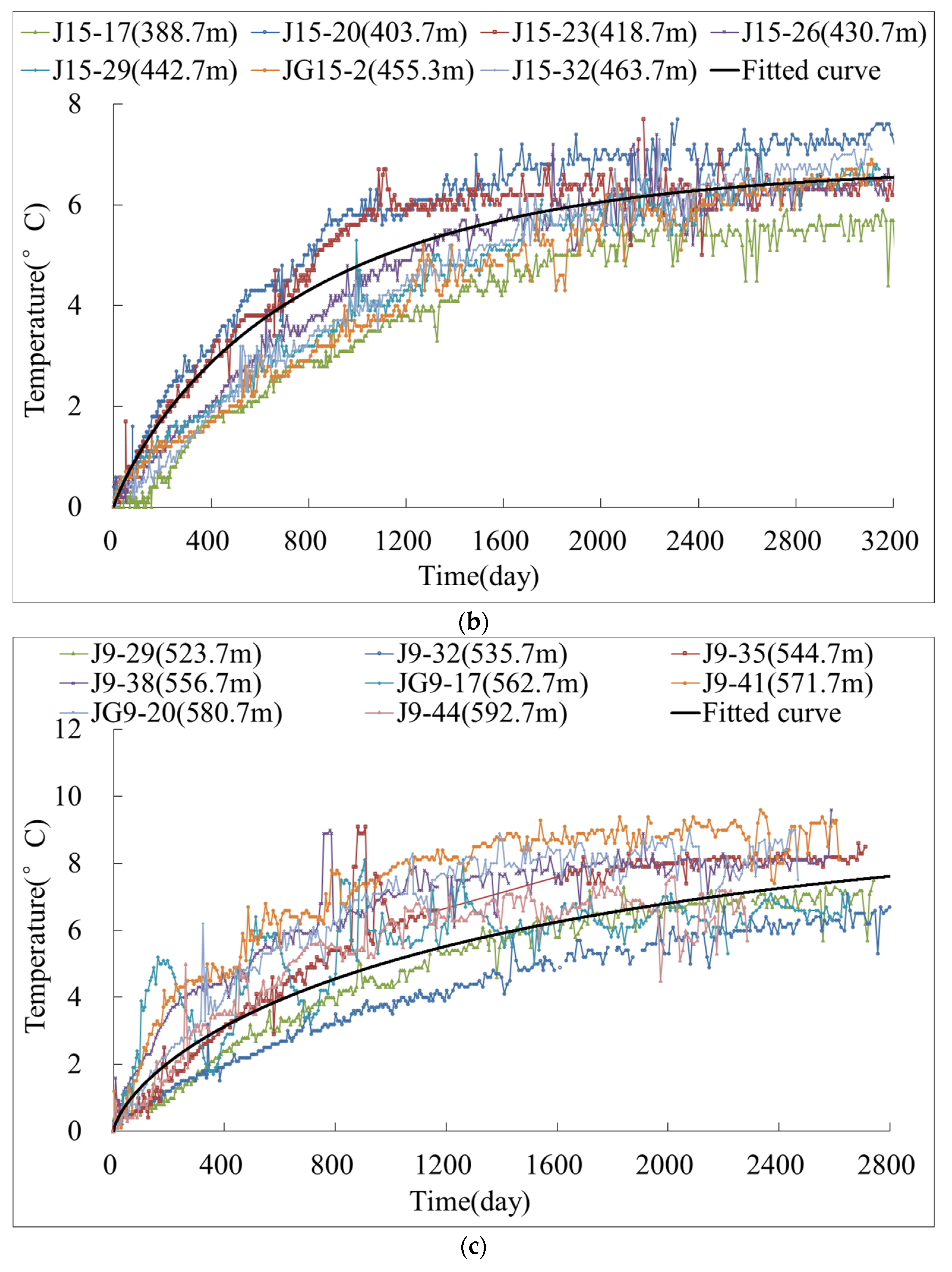

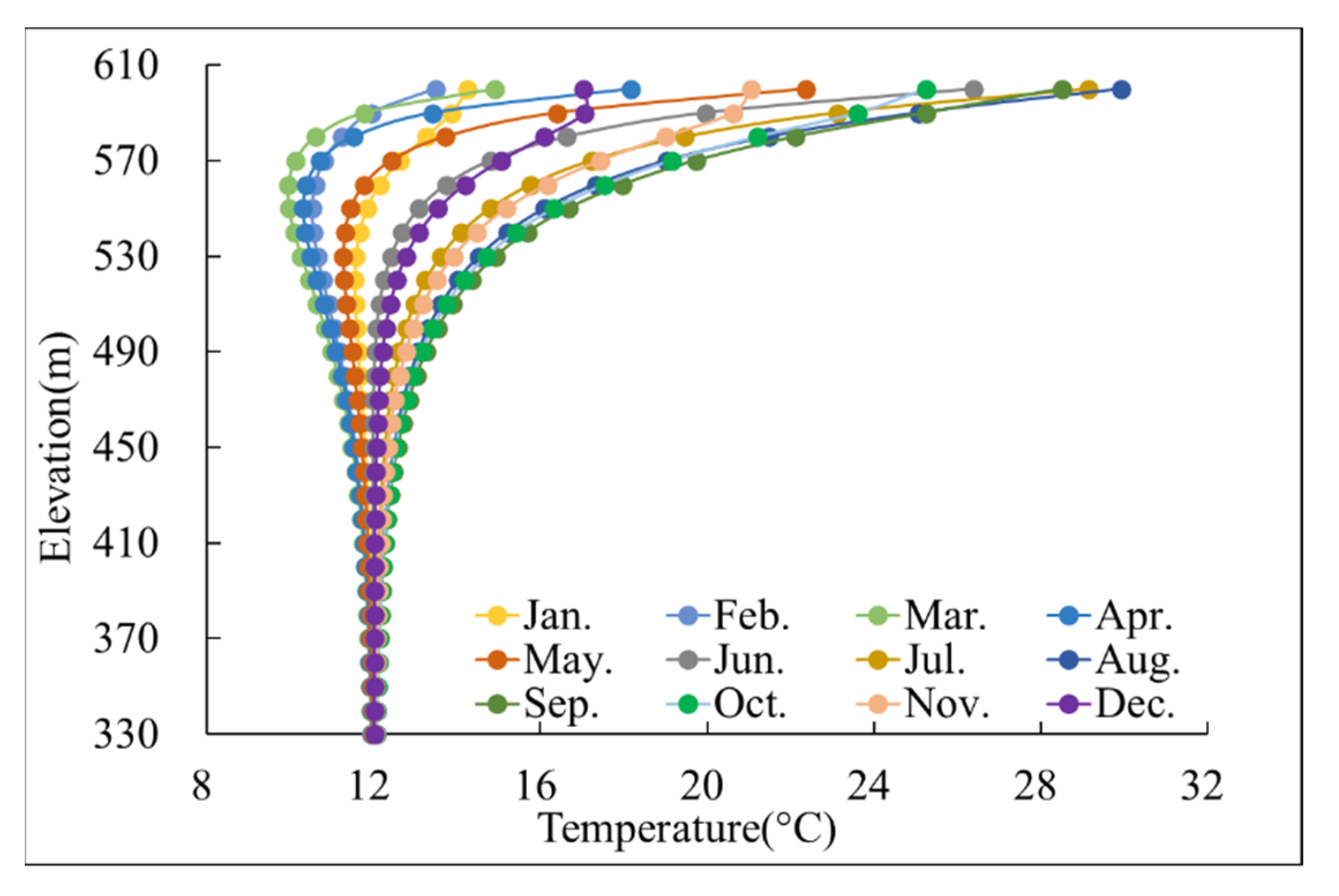

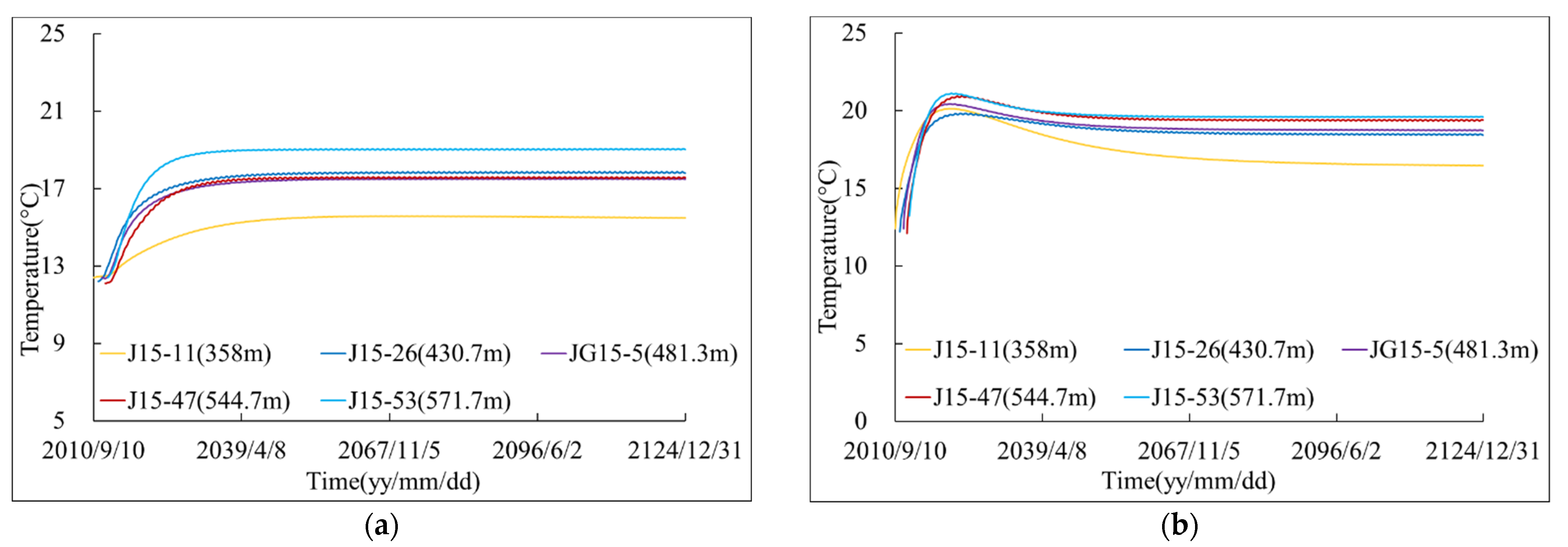

4. Inversion Analysis on Temperature Field of Dam during Operation

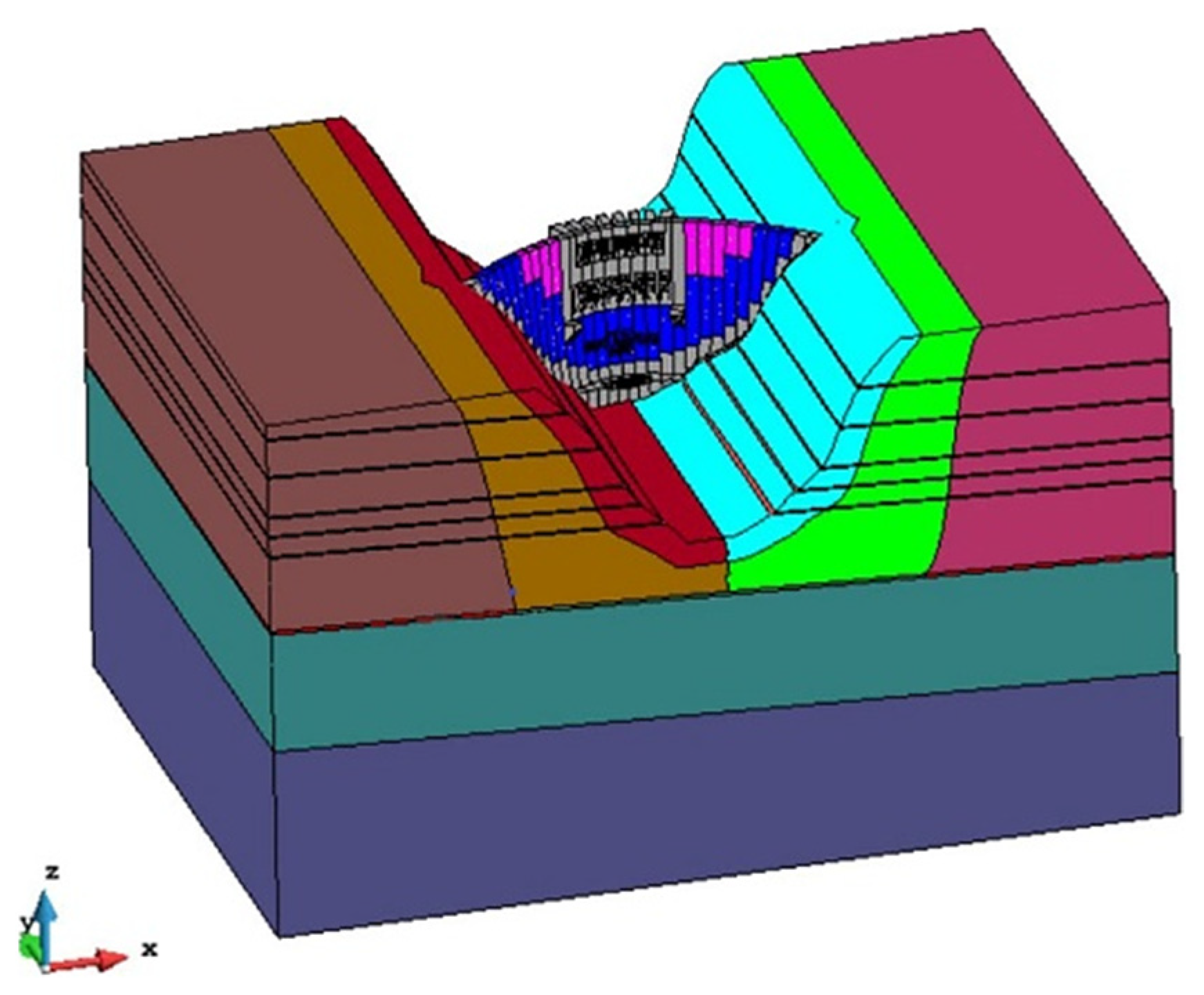

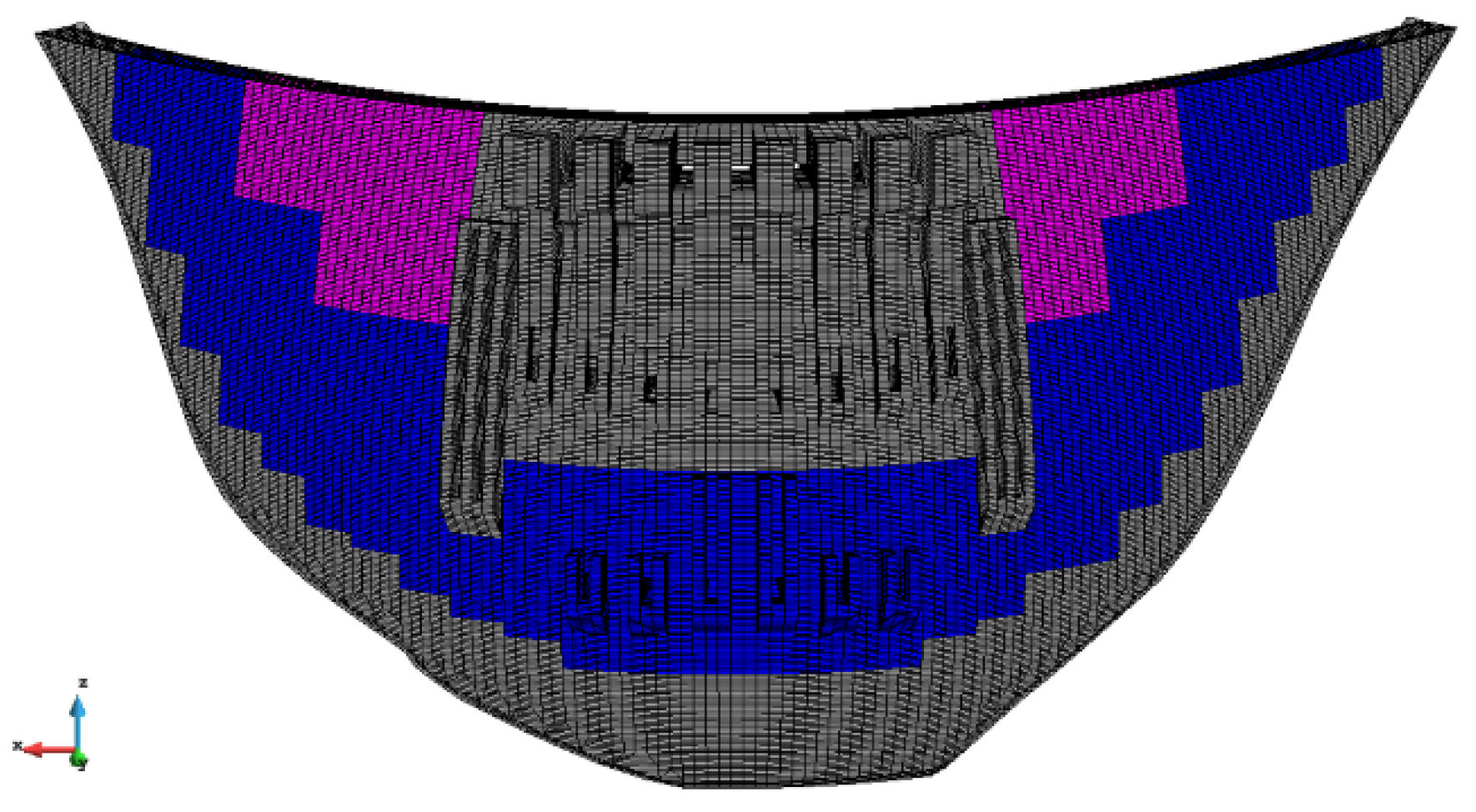

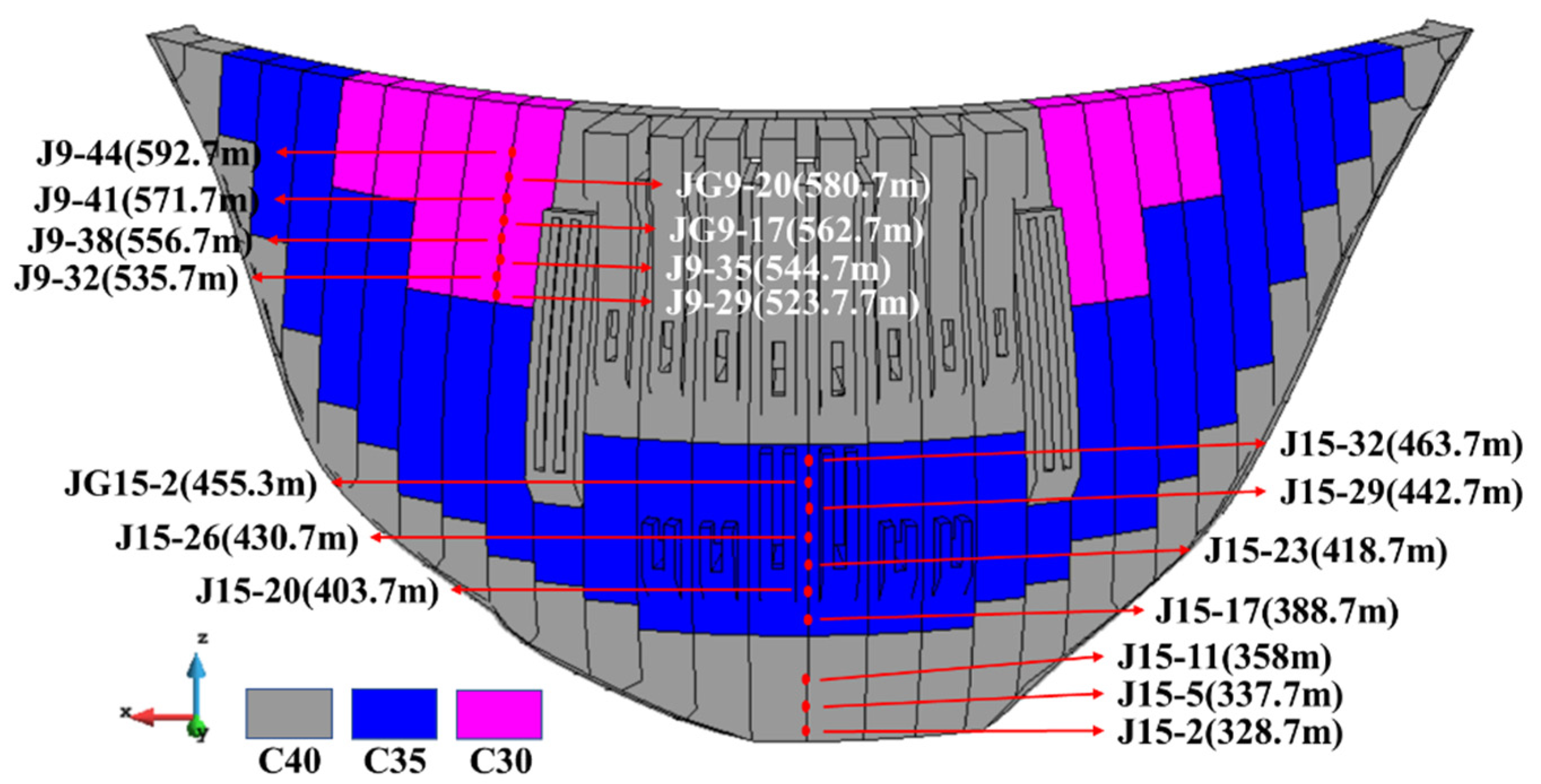

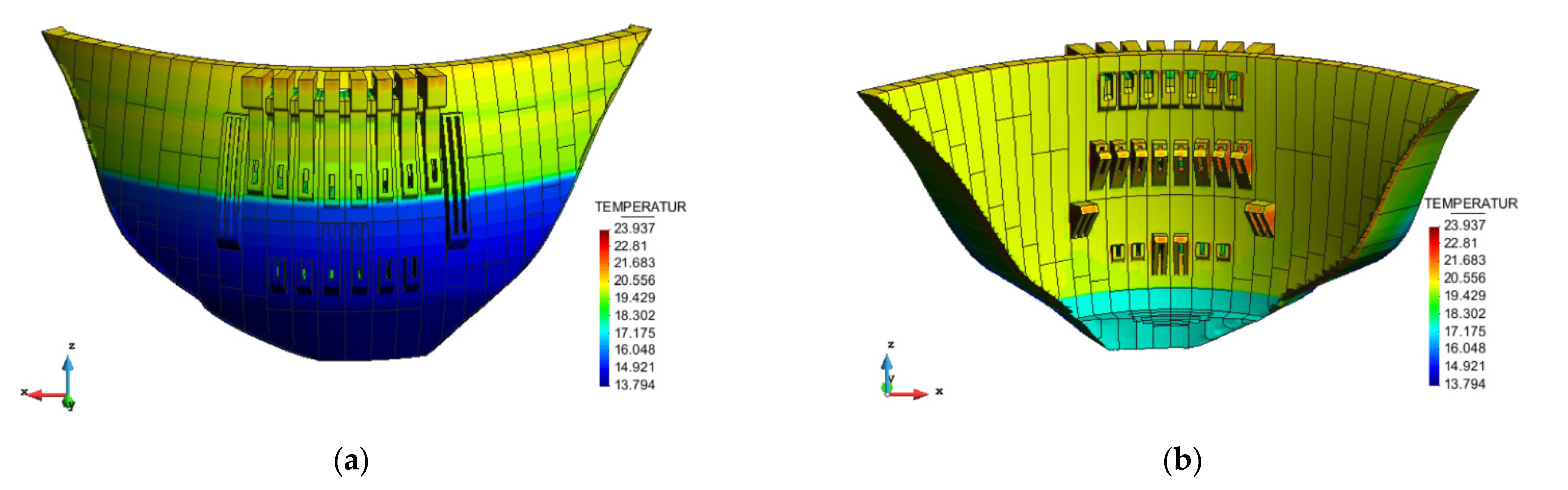

4.1. Computational Model

4.2. Ambient Temperature

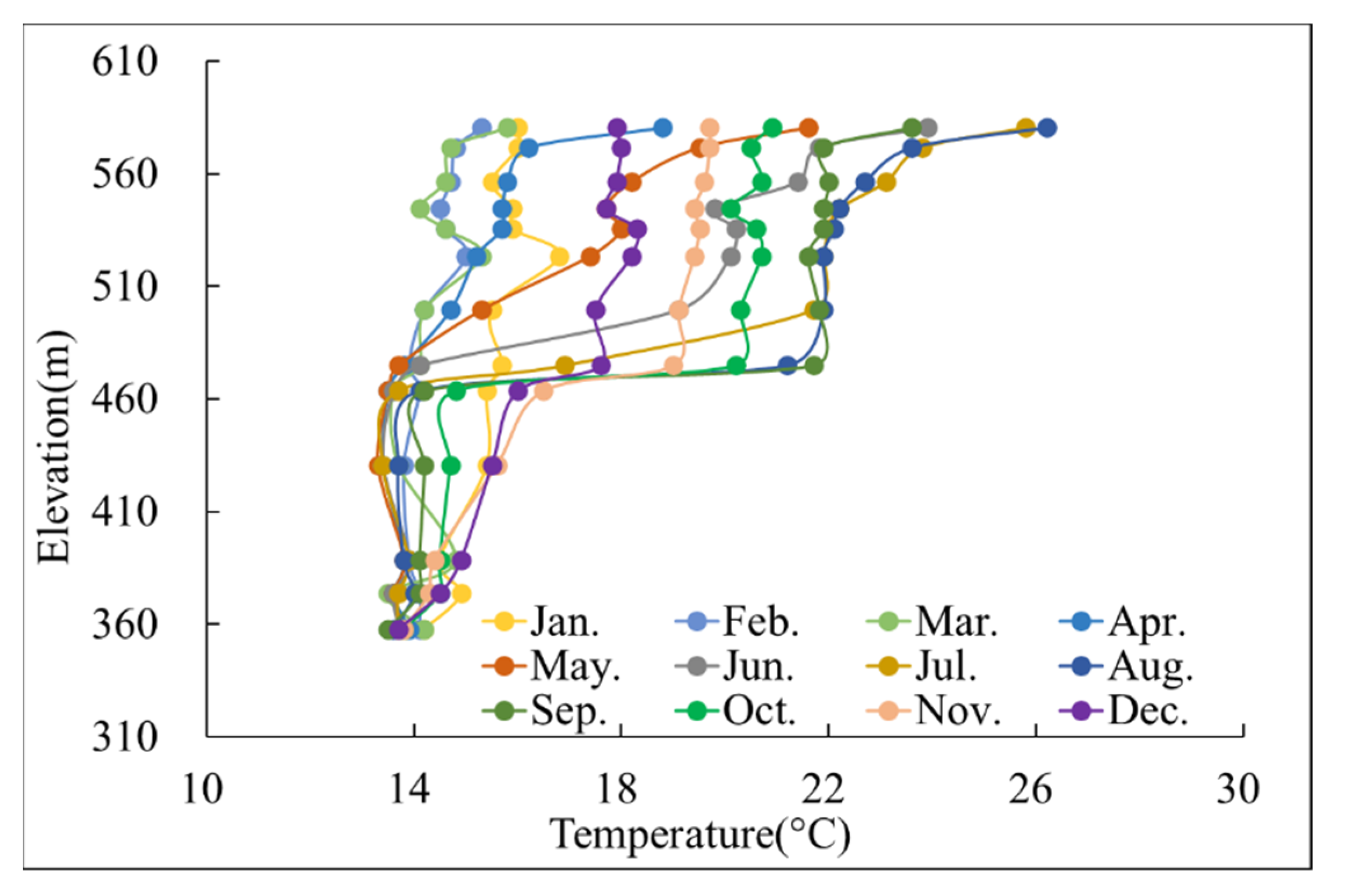

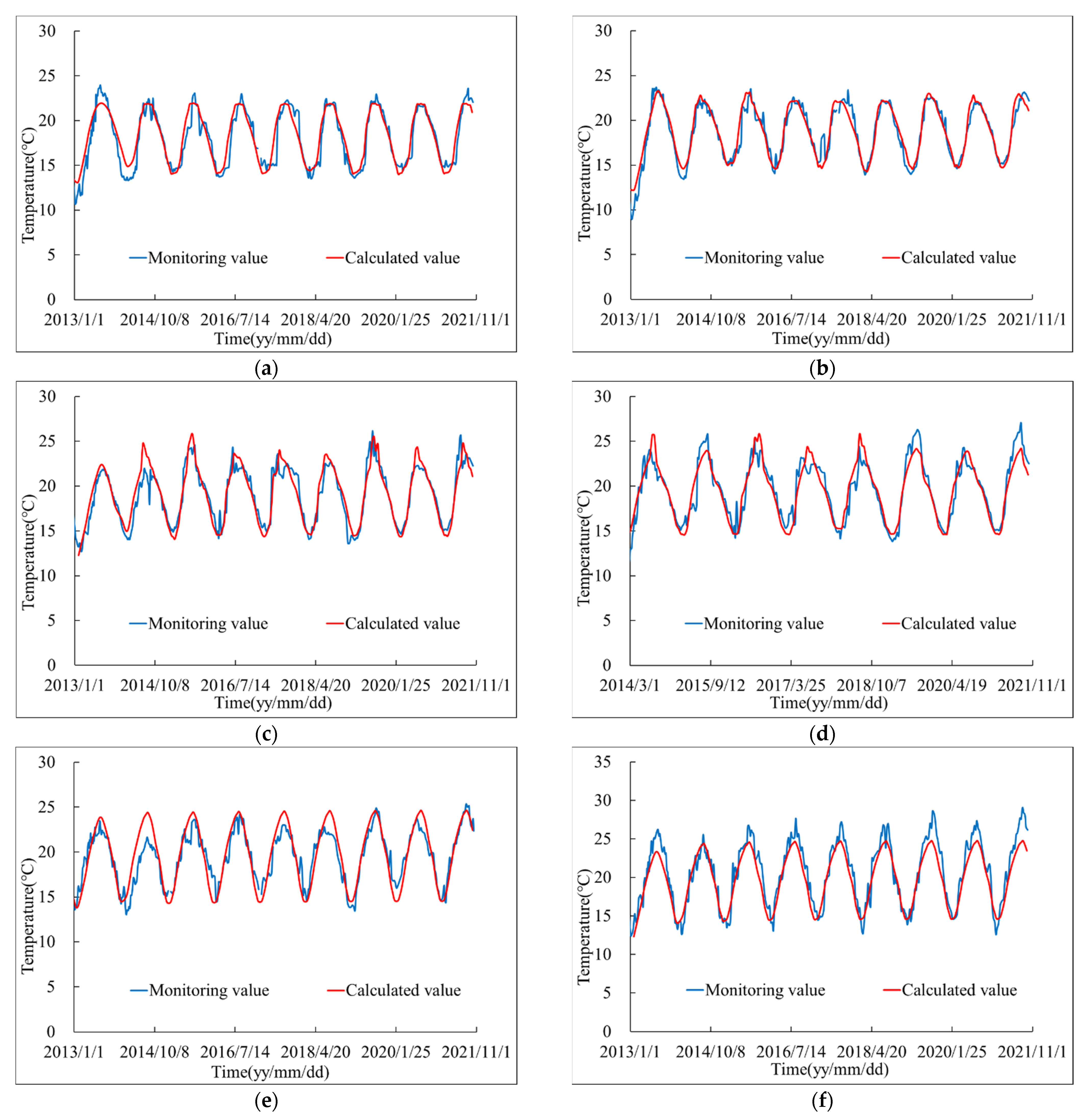

4.3. Inversion of Reservoir Water Temperature

4.4. Inversion of Internal Temperature

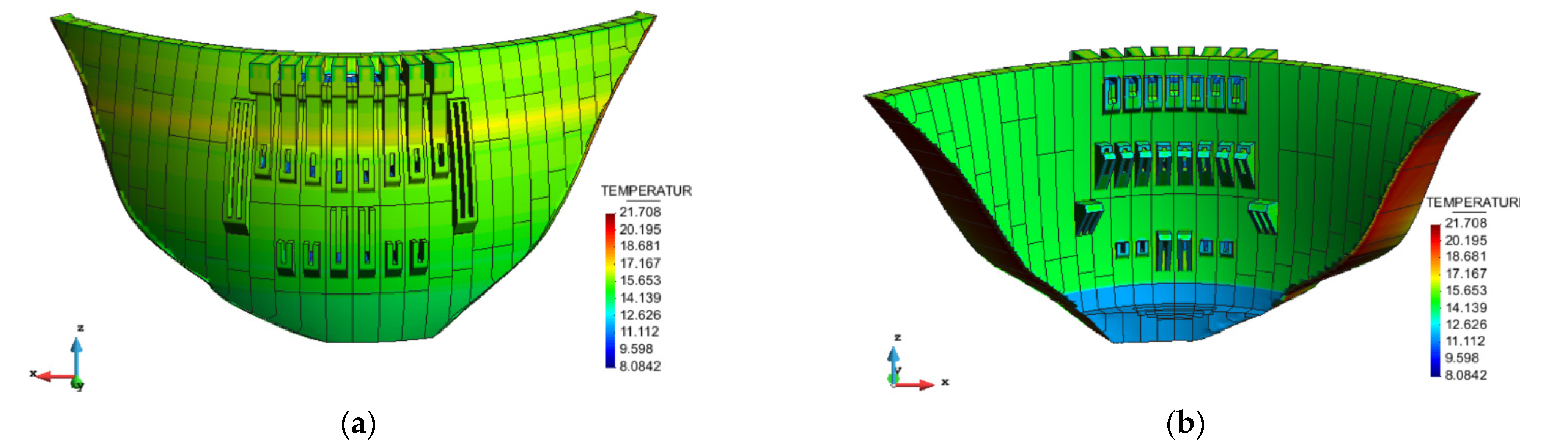

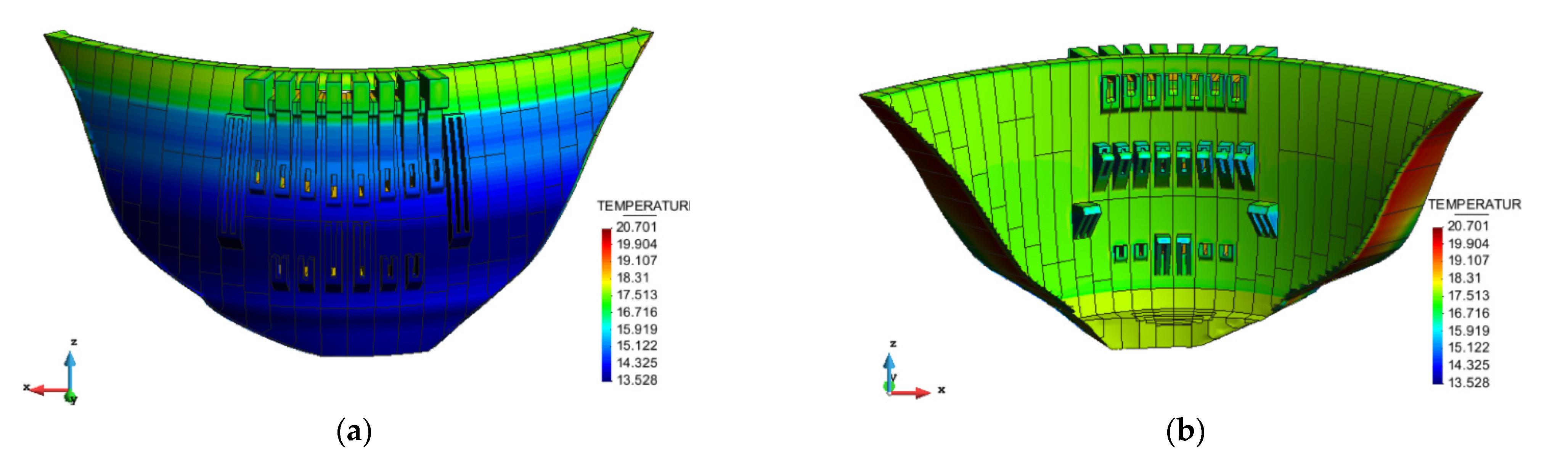

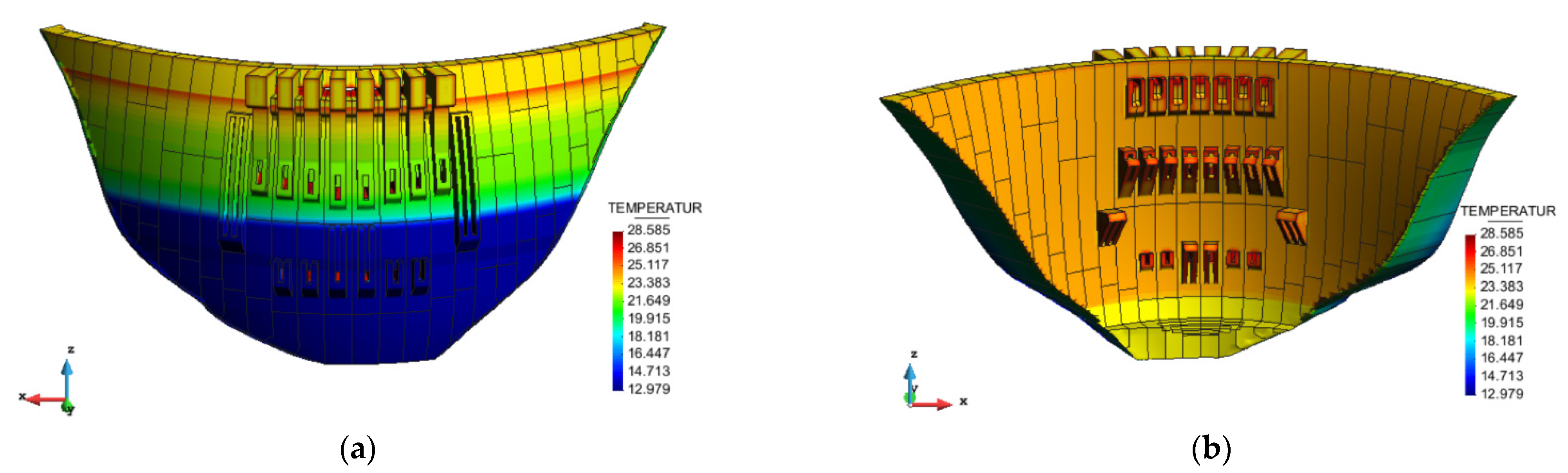

5. Analysis on Temperature Field Difference of Arch Dam under Design Condition and Actual Condition

5.1. Calculation Condition Difference

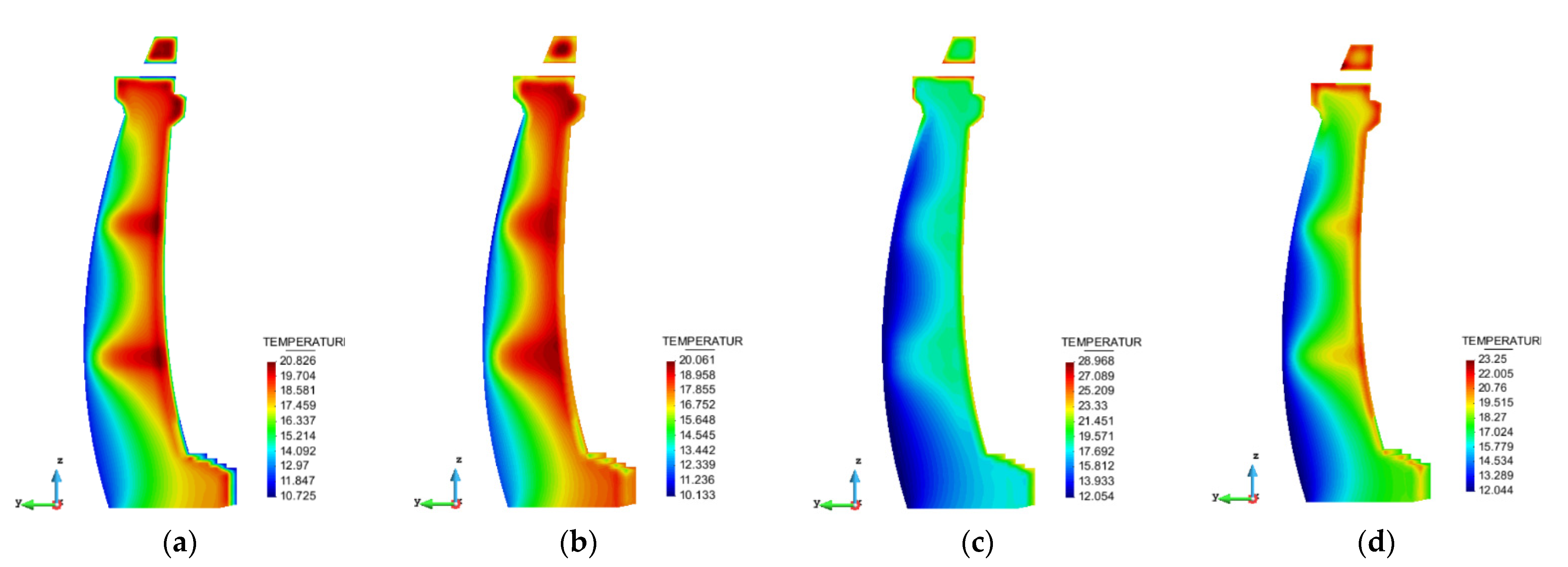

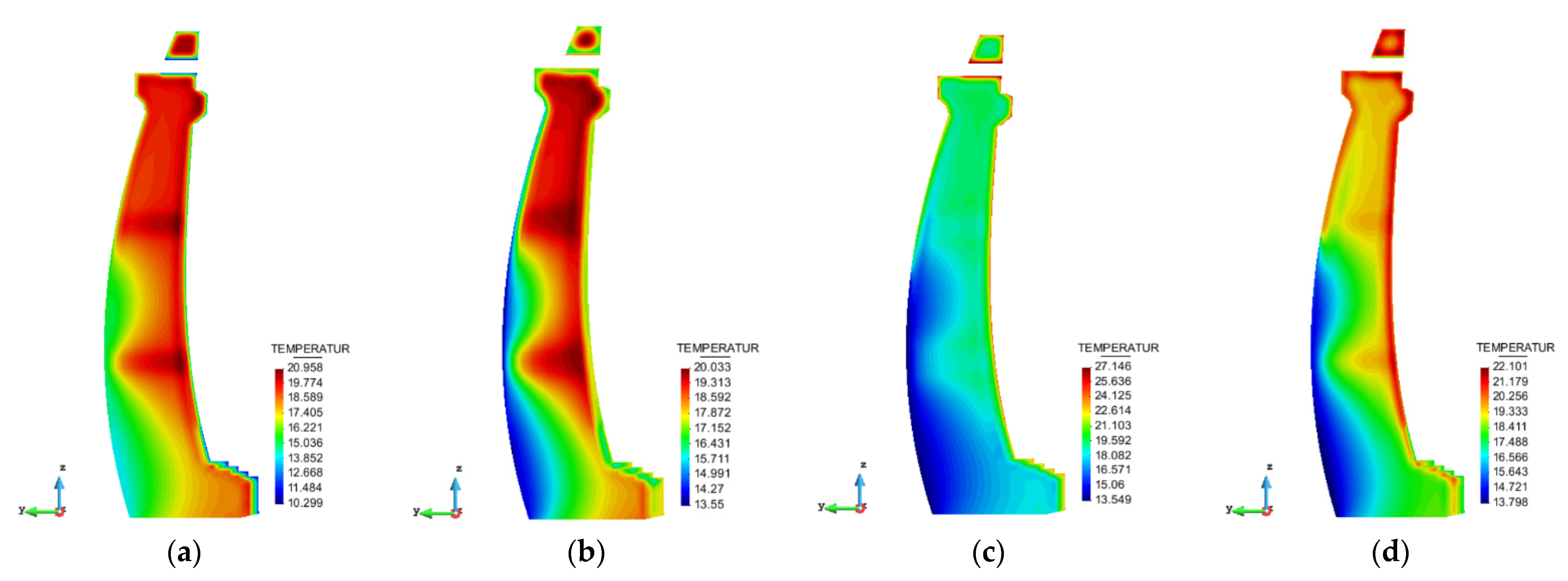

5.2. Results and Discussions

6. Conclusions

- Through the analysis of the monitoring data of temperature at the dam surface measuring points and internal measuring points, it is found that the temporal-spatial evolution law of the overall temperature of the dam accords with conventional knowledge;

- The change process of temperature at the monitoring points calculated by the simulation is in good agreement with that of the monitoring value, which indicates that the adopted simulation analysis method and the thermal parameters obtained by inversion are reasonable and reliable;

- Through simulation calculation, the temperature field of the arch dam under the design and actual conditions were obtained. Under the design condition, the temperature rise inside the dam body is not considered. Due to the influence of low-temperature closure grouting and boundary heat transfer, the temperature of the dam body rises slowly after closure grouting and tends to be stable. In this process, the internal temperature of the dam body is always lower than the stable temperature. Under the actual condition, the temperature of the dam body rises rapidly after closure grouting, by 7.5~9.2 °C. After the arch is sealed, it reaches the highest temperature in about 8~12 years, and then gradually falls back to the final stable temperature in 40~80 years;

- The dam surface temperature is greatly influenced by the air temperature and the reservoir water temperature, but the influence depth is shallow. The internal temperature of the dam body is mainly affected by the temperature recovery in the later period, which changes slightly in January, April, August and November. The internal stable temperature of the dam under the design condition is lower than that under the actual condition. The temperature field inside the dam body has little difference below the 490 m elevation of the deep hole orifice, but a great difference above the 490 m elevation under two conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, G.; Chen, P.; Zhou, Q. Real temperature load and the influence on the working performance of super-high arch dam. J. Hydraul. Eng. 2014, 45, 127–134. [Google Scholar]

- Zhang, G.; Liu, Y.; Zhou, Q. Study on real working performance and overload safety factor of high arch dam. Sci. China Ser. E Technol. Sci. 2008, 51, 48–59. [Google Scholar] [CrossRef]

- SL 282–2018; Design Specification for Concrete Arch Dams; Shanghai Investigation, Design & Research Institute Co., Ltd.: Shangai, China; Changjiang (Yangtze River) Institute of Survey, Planning, Design and Research Co., Ltd.: Wuhan, China; Ministry of Water Resources of the People’s Republic of China: Beijing, China, 2018.

- DL/T 5346–2006; Design Specification for Concrete Arch Dams; National Development and Reform Commission (NDRC) People’s Republic of China: Beijing, China, 2006.

- Zhu, B. Improvement of method for computing temperature loads on arch dams. Water Resour. Hydropower Eng. 2006, 37, 19–22. [Google Scholar]

- Li, T.; Wang, Z.; Zhao, L. Discussion on the computation method of temperature load on high arch dams. J. Hydroelectr. Eng. 2010, 29, 35–38. [Google Scholar]

- Fu, S.; Yuan, W. Simplified formula for temperature loads on arch dams based on FEM. Eng. J. Wuhan Univ. 2016, 49, 372–377. [Google Scholar]

- Lin, P.; Li, Q.; Hu, H. A flexible network structure for temperature monitoring of a super high arch dam. Int. J. Distrib. Sens. Netw. 2012, 4, 1238–1241. [Google Scholar] [CrossRef]

- Peng, H.; Lin, P.; Yang, N.; Li, M.; Qiao, Y. Real time thermal field analysis on Wudongde super high arch dam during construction. Glob. Energy Interconnect 2019, 2, 264–269. [Google Scholar] [CrossRef]

- Santillán, D.; Salete, E.; Vicente, D.J.; Toledo, M.Á. Treatment of solar radiation by spatial and temporal discretization for modeling the thermal response of arch dams. J. Eng. Mech. 2014, 140, 05014001. [Google Scholar] [CrossRef]

- Santillán, D.; Saleteb, E.; Toledob, M.A.; Granados, A. An improved 1D-model for computing the thermal behaviour of concrete dams during operation. Comparison with other approaches. Comput. Concr. 2015, 15, 103–126. [Google Scholar] [CrossRef]

- Belmokre, A.; Mihoubi, M.K.; Santillán, D. Analysis of dam behavior by statistical models: Application of the random forest approach. KSCE J. Civ. Eng. 2019, 23, 4800–4811. [Google Scholar] [CrossRef]

- Mirzabozorg, H.; Ghaemian, M.; Roohezamin, A. The reason of cracking in bottom gallery of SefidRud Buttress Dam and earthquake and post earthquake performance. Struct. Monit. Maint. 2019, 6, 103–124. [Google Scholar]

- Shi, N.; Chen, Y.; Li, Z. Crack Risk Evaluation of Early Age Concrete Based on the Distributed Optical Fiber Temperature Sensing. Adv. Mater. Sci. Eng. 2016, 2016, 4082926. [Google Scholar] [CrossRef] [Green Version]

- Peng, H.; Lin, P.; Xiang, Y.; Chen, W.; Zhou, S.; Yang, N.; Qiao, Y. A Positioning Method of Temperature Sensors for Monitoring Dam Global Thermal Field. Front. Mater. 2020, 7, 587738. [Google Scholar] [CrossRef]

- Jin, F.; Zhou, Y. Application of distributed optical-fiber temperature measurement system to monitoring true temperature field of super-high arch dam. Eng. J. Wuhan Univ. 2015, 48, 451–458. [Google Scholar]

- Ouyang, J.; Chen, X.; Huangfu, Z.; Lu, C.; Huang, D.; Li, Y. Application of distributed temperature sensing for cracking control of mass concrete. Constr. Build. Mater. 2019, 197, 778–791. [Google Scholar] [CrossRef]

- Žvanut, P.; Turk, G.; Kryžanowski, A. Thermal Analysis of a Concrete Dam Taking into Account Insolation, Shading, Water Level and Spillover. Appl. Sci. 2021, 11, 705. [Google Scholar] [CrossRef]

- Ghafoori, Y.; Vidmar, A.; Říha, J.; Kryžanowski, A. A Review of Measurement Calibration and Interpretation for Seepage Monitoring by Optical Fiber Distributed Temperature Sensors. Sensors 2020, 20, 5696. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Liu, Y.; Xie, X. Determination of thermal parameters of concrete by reverse analysis of test results. Chin. J. Geotech. Eng. 2002, 24, 175–177. [Google Scholar]

- Chen, F.; Zhu, Y. Application of Genetic Algorithms to the Back Analysis of Thermal Parameters in Arch Dam. J. North China Inst. Water Conserv. Hydroelectr. Power 2007, 28, 33–35. [Google Scholar]

- Liu, X.; Zhang, C.; Chang, X.; Zhou, W.; Cheng, Y.; Duan, Y. Precise simulation analysis of the thermal field in mass concrete with a pipe water cooling system. Appl. Therm. Eng. 2015, 78, 449–459. [Google Scholar] [CrossRef]

- Wang, F.; Zhou, Y.; Zhao, C.; Wang, F. Inverse analysis of concrete dam thermal parameters based on an improved particle swarm optimization method. J. Vib. Shock 2019, 38, 168–174. [Google Scholar]

- Wang, F.; Zhou, Y.; Zhao, C.; Zhou, H.; Chen, W.; Tan, Y.; Liang, Z.; Pan, Z.; Wang, F. Thermal parameter inversion for various materials of super high arch dams based on the hybrid particle swarm optimization method. J. Tsinghua Univ. 2021, 61, 747–755. [Google Scholar]

- Zhou, H.; Zhou, Y.; Zhao, C.; Wang, F.; Liang, Z. Feedback design of temperature control measures for concrete dams based on real-time temperature monitoring and construction process simulation. KSCE J. Civ. Eng. 2018, 22, 1584–1592. [Google Scholar] [CrossRef]

- Lian, J.; Wang, C.; Zhao, S. The convolute analysis of Lijiaxia arch dam material parameter based on BP neural network. J. Hydroelectr. Eng. 2004, 23, 44–48. [Google Scholar]

- Wang, J.; Wang, J.; Liu, Y.; Jin, F.; Wang, R.; Yang, J. Feedback analysis on temperature field of Ertan arch dam in operation period. J. Hydroelectr. Eng. 2008, 27, 65–70. [Google Scholar]

- Sheibani, F.; Ghaemian, M. Thermal Stress Analysis of Concrete Arch Dams Due to Environmental Action. In Proceedings of the ASME 2004 International Mechanical Engineering Congress and Exposition, Analheim, CA, USA, 13–20 November 2004; p. 375. [Google Scholar]

- Mirković, U.; Kuzmanović, V.; Todorović, G. Long-Term Thermal Stress Analysis and Optimization of Contraction Joint Distance of Concrete Gravity Dams. Appl. Sci. 2022, 12, 8163. [Google Scholar] [CrossRef]

- Zhang, G.; Zhou, Q. Study on temperature recovery after arch sealing of super high arch dams and its influence. J. Hydraul. Eng. 2015, 46, 1009–1018. [Google Scholar]

- Ding, J.; Zhang, S.; Chen, S. Simulation and feedback analysis of the temperature field based on composite element method. J. Hydroelectr. Eng. 2013, 32, 190–197. [Google Scholar]

- Liu, Y.; Gaoyang, Q.; Zhang, G.; Zhang, L.; Duan, S.; Zhang, J. Simulation and inversion analysis on working behavior of super-high arch dam of Jinping I Hydropower Station. Water Resour. Hydropower Eng. 2017, 48, 46–51. [Google Scholar]

- Qiang, S.; Xie, Z.; Zhong, R. A p-version embedded model for simulation of concrete temperature fields with cooling pipes. Water Sci. Eng. 2015, 8, 248–256. [Google Scholar] [CrossRef]

- Zhang, L.; Yi, L.; Li, B.; Zhang, G.; Zhang, S. Study on real-time simulation analysis and inverse analysis system for temperature and stress of concrete dam. Math. Probl. Eng. 2015, 2015, 306165. [Google Scholar] [CrossRef] [Green Version]

- Mata, J.; de Castro, A.T.; da Costa, J.S. Time-frequency analysis for concrete dam safety control: Correlation between the daily variation of structural response and air temperature. Eng. Struct. 2013, 48, 658–665. [Google Scholar] [CrossRef] [Green Version]

- Mata, J.; de Castro, A.T.; da Costa, J.S. Constructing statistical models for arch dam deformation. Struct. Control Health Monit. 2014, 21, 423–437. [Google Scholar] [CrossRef] [Green Version]

- Zhang, G.; Liu, Y.; Zheng, C.; Feng, F. Simulation of influence of multi-defects on long-term working performance of high arch dam. Sci. China Ser. E Technol. Sci. 2011, 54, 1–8. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, Y.; Zhu, B.; Wang, R. Theory and method on simulation of actual working performance of high arch dams. J. Hydroelectr. Eng. 2012, 31, 167–174. [Google Scholar]

- Liu, Y.; Zhang, G.; Zhu, B.; Shang, F. Actual working performance assessment of super-high arch dams. J. Perform. Constr. Facil. 2016, 30, 04015011. [Google Scholar] [CrossRef]

- Zhang, G. Development and application of SAPTIS—A software of multi-field simulation and nonlinear analysis of complex structures (Part I). Water Resour. Hydropower Eng. 2013, 44, 31–35. [Google Scholar]

- Zhou, Q.; Zhang, G. Development and application of SAPTIS—Software of multi-field simulation and nonlinear analysis of complex structures (Part II). Water Resour. Hydropower Eng. 2013, 44, 39–43. [Google Scholar]

- Zhang, L.; Zhang, G. Development and application of SAPTIS—Software of multi-field simulation and nonlinear analysis of complex structures (Part III). Water Resour. Hydropower Eng. 2014, 45, 52–55. [Google Scholar]

- Liu, Y.; Zhang, G.; Yang, P. Development and application of SAPTIS—A software of multi-field simulation and nonlinear analysis of complex structures (Part IV). Water Resour. Hydropower Eng. 2014, 45, 33–39. [Google Scholar]

- Zhu, B. Thermal Stresses and Temperature Control of Mass Concrete; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

| XLD Arch Dam in China | |

|---|---|

| Dam type | concrete double-curvature arch dam |

| Dam height | 285.5 m |

| Crest elevation | 610.0 m |

| Normal water elevation | 600.0 m |

| Installed capacity | 13,860 MW |

| Total reservoir capacity | 124.7 × 108 m3 |

| Crest thickness | 14 m |

| Dam bottom thickness | 60 m |

| Thermometers Near the Upstream Surface | Elevation of the Points(m) | Thermometers Near the Downstream Surface | Elevation of the Points(m) | Joint Meters | Elevation of the Points(m) |

|---|---|---|---|---|---|

| T16-1 | 358.0 | T16-4 | 373.7 | J15-11 | 358.0 |

| T16-3 | 373.7 | T16-8 | 403.7 | J15-20 | 403.7 |

| T16-5 | 388.7 | T16-14 | 442.7 | J15-26 | 430.7 |

| T16-7 | 403.7 | T16-18 | 475.0 | JG15-5 | 481.3 |

| T16-17 | 475.0 | T16-20 | 499.7 | JG15-14 | 517.7 |

| T16-19 | 499.7 | T16-22 | 523.7 | J15-47 | 544.7 |

| T16-21 | 523.7 | T16-24 | 535.7 | J15-53 | 571.7 |

| T16-23 | 535.7 | T16-28 | 556.7 | J15-55 | 580.7 |

| T16-25 | 544.7 | T16-30 | 571.7 | J15-56 | 577.7 |

| T16-27 | 556.7 | ||||

| T16-29 | 571.7 | ||||

| T16-31 | 580.7 |

| Measuring Points | Temperature at the End of Second-Stage Cooling (°C) | Maximum Temperature Recovery (°C) | Temperature Recovery (°C) | Time at the End of Second-Stage Cooling | Time of Maximum Temperature Recovery |

|---|---|---|---|---|---|

| J15-11 | 11.4 | 19.8 | 8.4 | 2010/9/27 | 2021/4/1 |

| J15-20 | 12.4 | 19.5 | 7.1 | 2011/6/20 | 2021/5/2 |

| J15-26 | 12.3 | 19.6 | 7.3 | 2011/8/10 | 2021/5/2 |

| JG15-5 | 12.1 | 19.5 | 7.4 | 2012/4/4 | 2021/8/29 |

| JG15-14 | 10.9 | 20.1 | 9.2 | 2012/9/21 | 2021/8/29 |

| J15-47 | 12.1 | 20.9 | 8.8 | 2012/12/20 | 2020/6/16 |

| J15-53 | 11.9 | 20.3 | 8.4 | 2013/6/14 | 2021/2/1 |

| J15-55 | 13.1 | / | / | 2013/9/27 | / |

| J15-56 | 12.8 | / | / | 2013/10/15 | / |

| Month | Jan. | Feb. | Mar. | Apr. | May | Jun. | Jul. | Aug. | Sep. | Oct. | Nov. | Dec. | Year |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Average temperature [°C] | 10.6 | 12.4 | 16.2 | 21.1 | 23.9 | 25.8 | 27.1 | 27.1 | 23.9 | 19.6 | 17.0 | 12.2 | 19.7 |

| Material | Density (kg/m3) | Thermal Conductivity (W/(m·K)) | Specific Heat (kJ/(kg·K)) |

|---|---|---|---|

| Foundation | 2750 | 2.302 | 0.990 |

| Dam body concrete | 2400 | 1.621 | 0.985 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, C.; Chai, D.; Cheng, H.; Ning, S.; Yang, B.; Zhou, Y. Simulation Feedback of Temperature Field of Super-High Arch Dam during Operation and Its Difference with Design Temperature. Water 2022, 14, 4028. https://doi.org/10.3390/w14244028

Hou C, Chai D, Cheng H, Ning S, Yang B, Zhou Y. Simulation Feedback of Temperature Field of Super-High Arch Dam during Operation and Its Difference with Design Temperature. Water. 2022; 14(24):4028. https://doi.org/10.3390/w14244028

Chicago/Turabian StyleHou, Chunyao, Dong Chai, Heng Cheng, Shaoqing Ning, Bo Yang, and Yi Zhou. 2022. "Simulation Feedback of Temperature Field of Super-High Arch Dam during Operation and Its Difference with Design Temperature" Water 14, no. 24: 4028. https://doi.org/10.3390/w14244028