Enhanced Removal of Sb (III) by Hydroxy-Iron/Acid–Base-Modified Sepiolite: Surface Structure and Adsorption Mechanism

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of HI/ABsep

2.2. Characterization Methods

2.3. Batch Adsorption Experiments

2.3.1. Adsorption Kinetics Experiment

2.3.2. Effect of Adsorbent Dosage and pH Value

2.3.3. Adsorption Thermodynamics

2.3.4. Thermodynamic Parameters

3. Results and Discussion

3.1. Characterization of Sep and HI/ABsep

3.1.1. N2 Adsorption–Desorption Isotherm and Pore Size Distribution

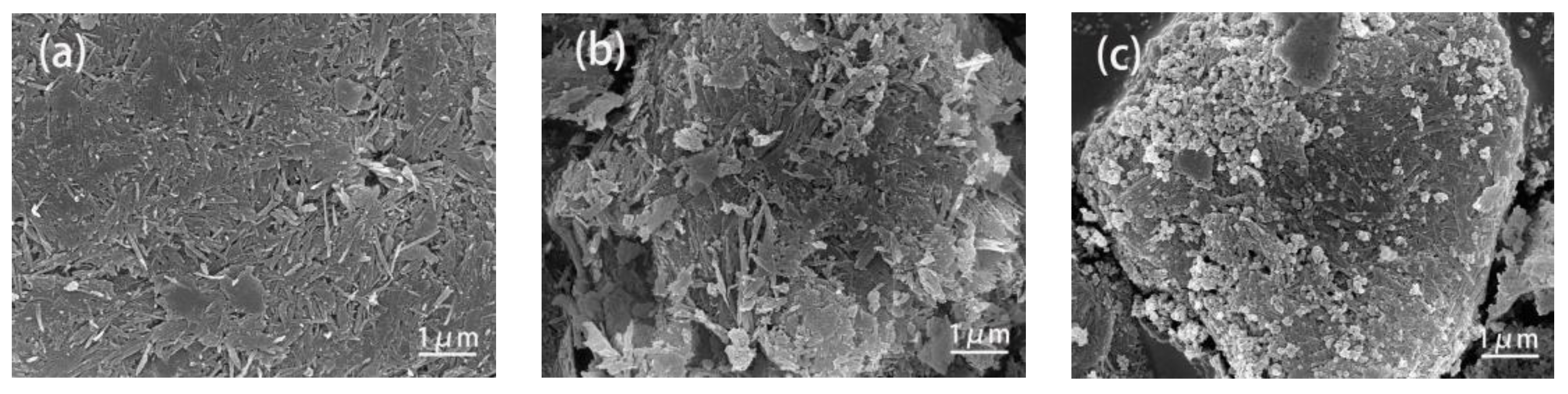

3.1.2. SEM Analysis

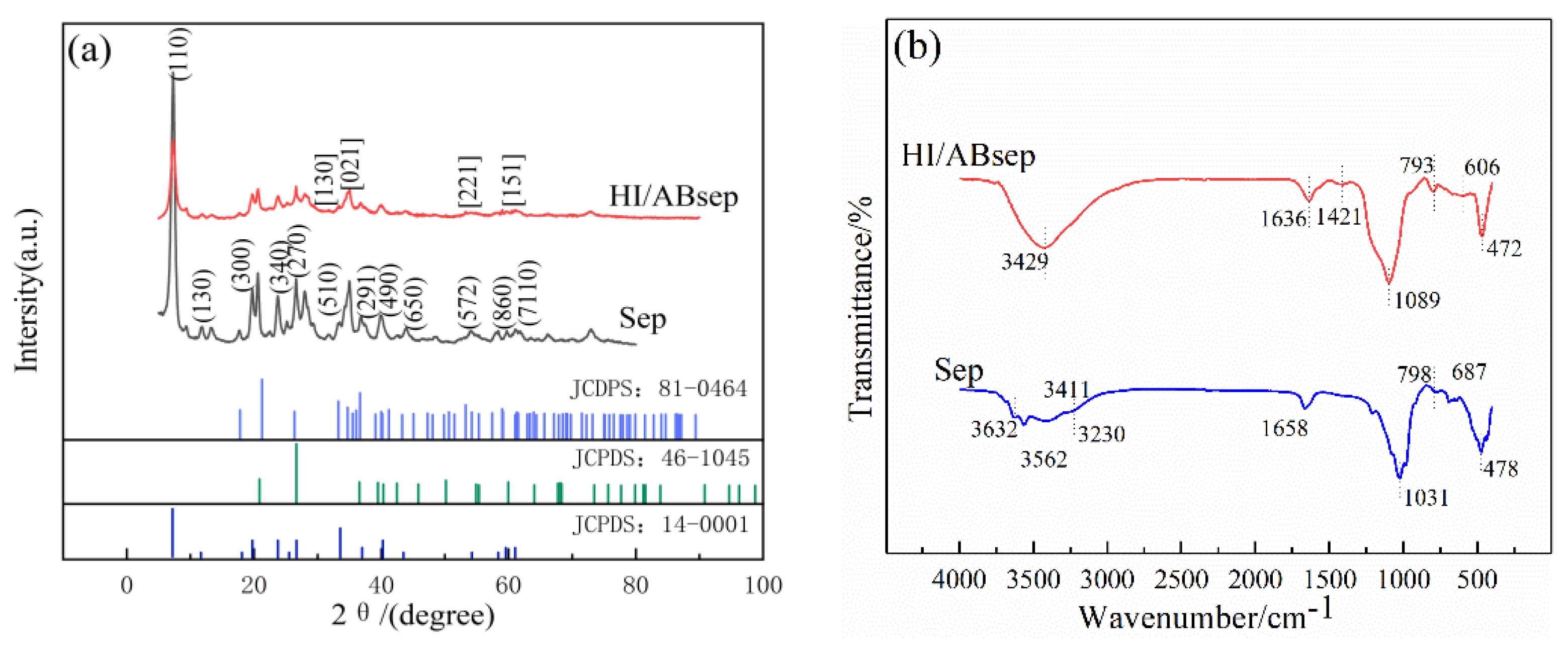

3.1.3. PXRD and FTIR Analysis

3.2. Adsorption of Sep and HI/ABsep on Sb (III)

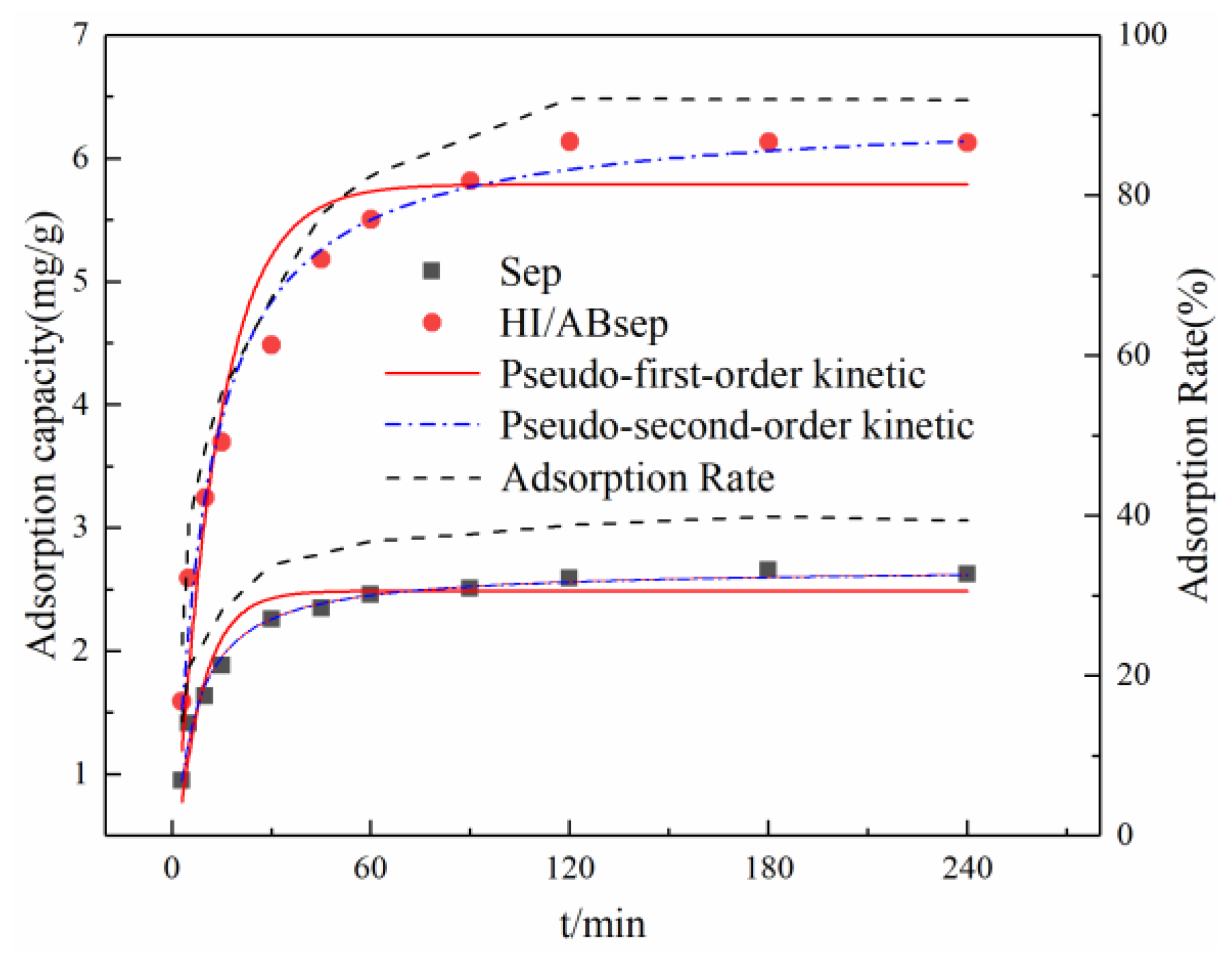

3.2.1. Adsorption Kinetics

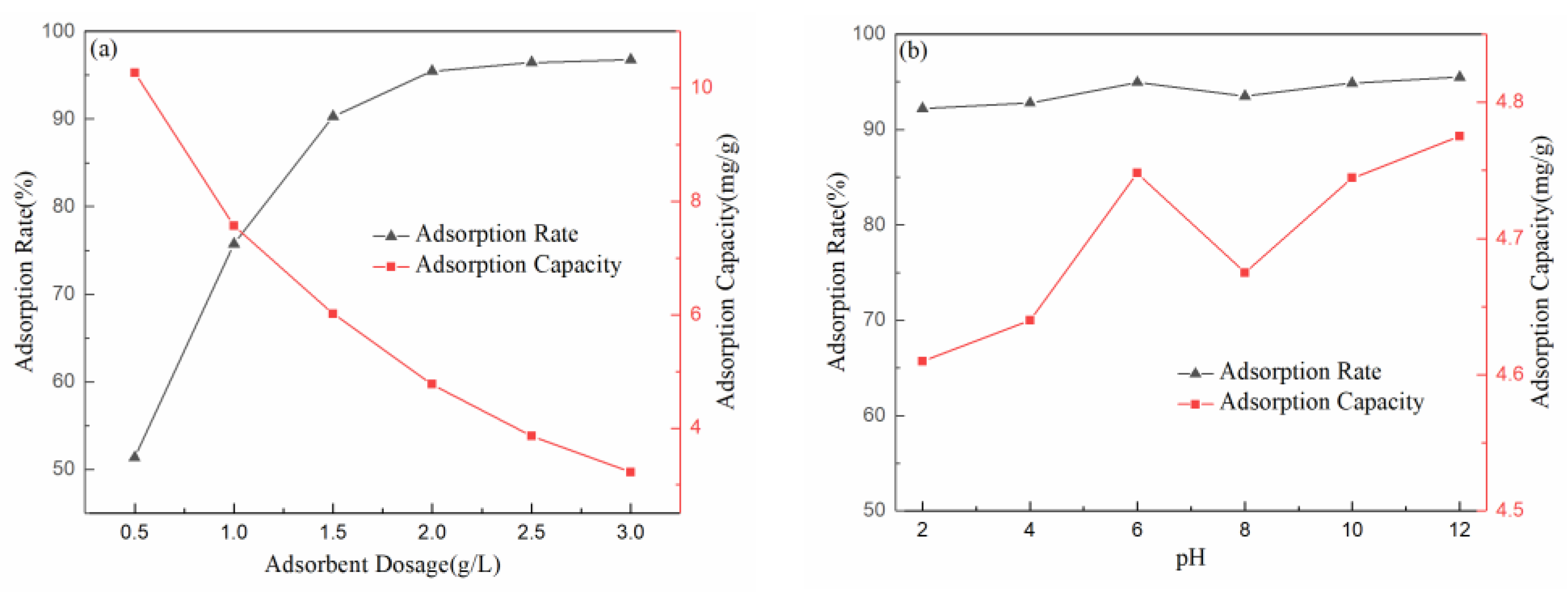

3.2.2. Effect of HI/ABsep Dosage and pH on the Removal of Sb (III)

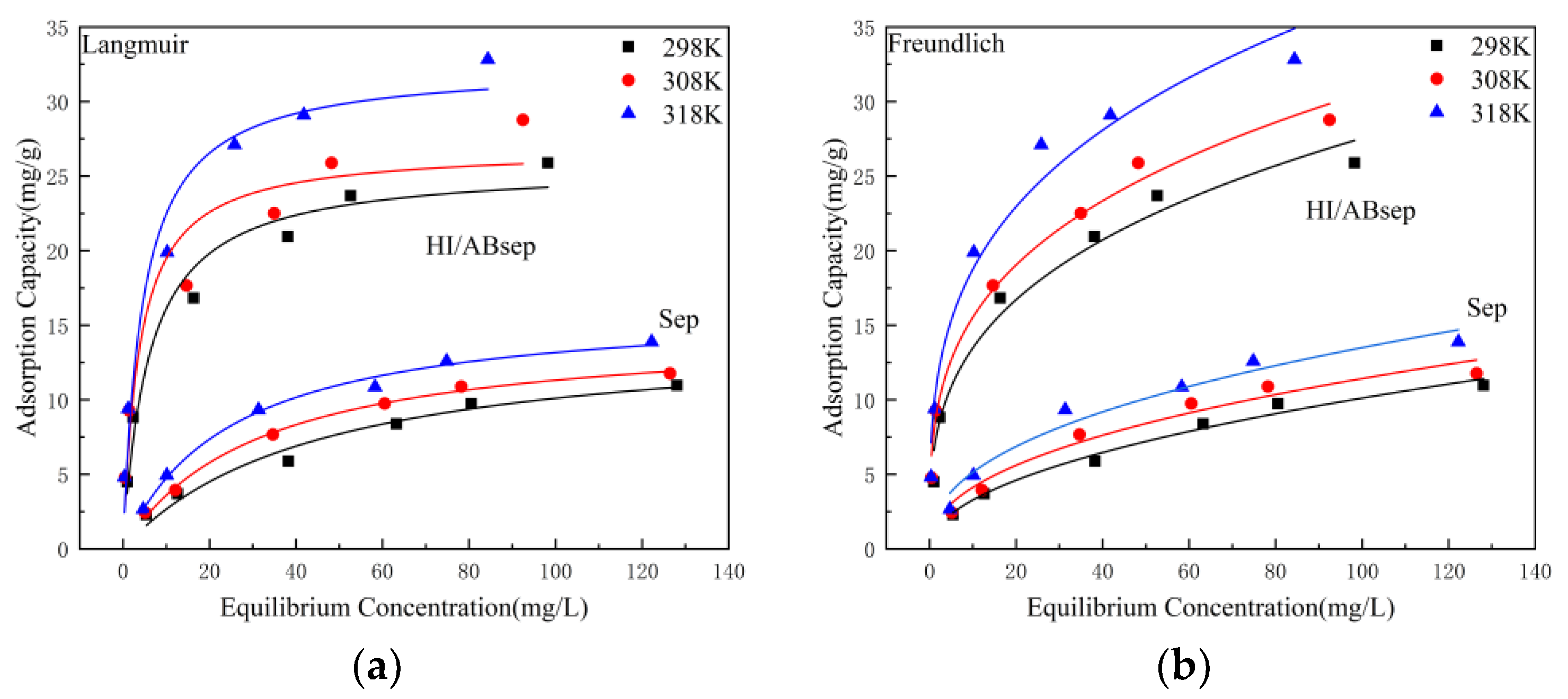

3.2.3. Adsorption Isotherm

3.2.4. Thermodynamic Parameters

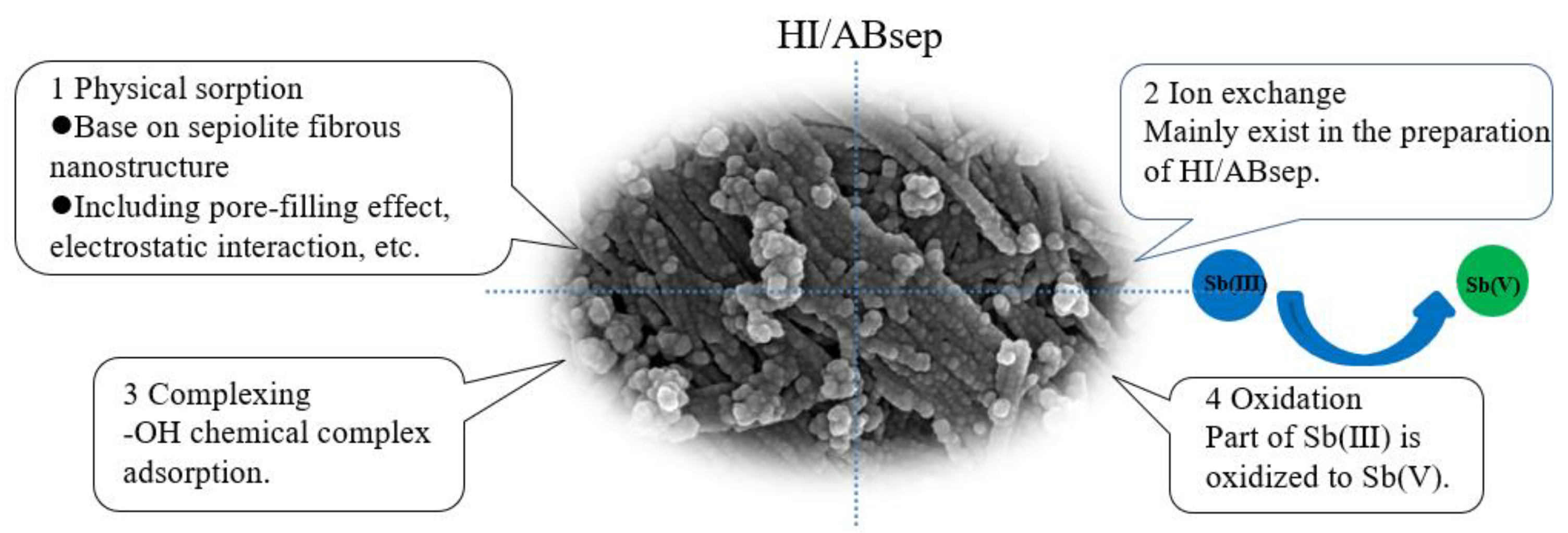

3.2.5. The Mechanism of HI/ABsep Adsorption on Sb (III)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nishad, P.A.; Bhaskarapillai, A. Antimony, a pollutant of emerging concern: A review on industrial sources and remediation technologies. Chemosphere 2021, 277, 130252. [Google Scholar] [CrossRef] [PubMed]

- Fang, L.; Zhou, A.; Li, X.; Zhou, J.; Pan, G.; He, N. Response of antimony and arsenic in karst aquifers and groundwater geochemistry to the influence of mine activities at the world’s largest antimony mine, central China. J. Hydrol. 2021, 603, 127131. [Google Scholar] [CrossRef]

- Boreiko, C.J.; Rossman, T.G. Antimony and its compounds: Health impacts related to pulmonary toxicity, cancer, and genotoxicity. Toxicol. Appl. Pharmacol. 2020, 403, 115156. [Google Scholar] [CrossRef] [PubMed]

- Chu, J.; Hu, X.; Kong, L.; Wang, N.; Zhang, S.; He, M.; Ouyang, W.; Liu, X.; Lin, C. Dynamic flow and pollution of antimony from polyethylene terephthalate (PET) fibers in China. Sci. Total Environ. 2021, 771, 144643. [Google Scholar] [CrossRef]

- Li, J.; Zheng, B.; He, Y.; Zhou, Y.; Chen, X.; Ruan, S.; Yang, Y.; Dai, C.; Tang, L. Antimony contamination, consequences and removal techniques: A review. Ecotoxicol. Environ. Saf. 2018, 156, 125–134. [Google Scholar] [CrossRef]

- Xiong, N.; Wan, P.; Zhu, G.; Xie, F.; Xu, S.; Zhu, C.; Hursthouse, A.S. Sb (III) removal from aqueous solution by a novel nano-modified chitosan (NMCS). Sep. Purif. Technol. 2020, 236, 116266. [Google Scholar] [CrossRef]

- Wei, D.; Li, B.; Luo, L.; Zheng, Y.; Huang, L.; Zhang, J.; Yang, Y.; Huang, H. Simultaneous adsorption and oxidation of antimonite onto nano zero-valent iron sludge-based biochar: Indispensable role of reactive oxygen species and redox-active moieties. J. Hazard. Mater. 2020, 391, 122057. [Google Scholar] [CrossRef]

- Jiang, F.; Ren, B.; Hursthouse, A.; Deng, R.; Wang, Z. Distribution, source identification, and ecological-health risks of potentially toxic elements (PTEs) in soil of thallium mine area (southwestern Guizhou, China). Environ. Sci. Pollut. Res. 2019, 26, 16556–16567. [Google Scholar] [CrossRef] [Green Version]

- Bagherifam, S.; Brown, T.C.; Fellows, C.M.; Naidu, R.; Komarneni, S. Highly efficient removal of antimonite (Sb (III)) from aqueous solutions by organoclay and organozeolite: Kinetics and Isotherms. Appl. Clay Sci. 2021, 203, 106004. [Google Scholar] [CrossRef]

- Zeeshan, M. Expropriation of Cd(II) from wastewater by ion-selective membrane electrode based on Polypyrrole-Antimony(III)iodophosphate nanocomposite. Mater. Today Proc. 2020, 29, 352–362. [Google Scholar] [CrossRef]

- Ran, Z.; Yao, M.; He, W.; Wang, G. Efficiency analysis of enhanced Sb (V) removal via dynamic preloaded floc in coordination with ultrafiltration. Sep. Purif. Technol. 2020, 249, 117115. [Google Scholar] [CrossRef]

- Long, X.; Wang, X.; Guo, X.; He, M. A review of removal technology for antimony in aqueous solution. J. Environ. Sci. 2020, 90, 189–204. [Google Scholar] [CrossRef] [PubMed]

- Song, K.; Zhang, C.; Shan, J.; Wang, W.; Liu, H.; He, M. Adsorption behavior and surface complexation modeling of oxygen anion Sb (V) adsorption on goethite. Sci. Total Environ. 2022, 833, 155284. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Wu, Z.; He, M.; Meng, X.; Jin, X.; Qiu, N.; Zhang, J. Adsorption of antimony onto iron oxyhydroxides: Adsorption behavior and surface structure. J. Hazard. Mater. 2014, 276, 339–345. [Google Scholar] [CrossRef]

- Bahabadi, F.N.; Farpoor, M.H.; Mehrizi, M.H. Removal of Cd, Cu and Zn ions from aqueous solutions using natural and Fe modified sepiolite, zeolite and palygorskite clay minerals. Water Sci. Technol. 2017, 75, 340–349. [Google Scholar] [CrossRef]

- Xu, G.M.; Shi, Z.; Deng, J. Removal of antimony from water by iron-oxide coated sand (in Chinese). Environmental Chemistry 2006, 25, 481. [Google Scholar]

- Wang, Z.; Liao, L.; Hursthouse, A.; Song, N.; Ren, B. Sepiolite-Based Adsorbents for the Removal of Potentially Toxic Elements from Water: A Strategic Review for the Case of Environmental Contamination in Hunan, China. Int. J. Environ. Res. Public Health 2018, 15, 1653. [Google Scholar] [CrossRef]

- Alshameri, A.; He, H.; Zhu, J.; Xi, Y.; Zhu, R.; Ma, L.; Tao, Q. Adsorption of ammonium by different natural clay minerals: Characterization, kinetics and adsorption isotherms. Appl. Clay Sci. 2018, 159, 83–93. [Google Scholar] [CrossRef]

- Wu, J.; Wang, Y.; Wu, Z.; Gao, Y.; Li, X. Adsorption properties and mechanism of sepiolite modified by anionic and cationic surfactants on oxytetracycline from aqueous solutions. Sci. Total Environ. 2019, 708, 134409. [Google Scholar] [CrossRef]

- Tran, H.N.; Lima, E.C.; Juang, R.-S.; Bollinger, J.-C.; Chao, H.-P. Thermodynamic parameters of liquid–phase adsorption process calculated from different equilibrium constants related to adsorption isotherms: A comparison study. J. Environ. Chem. Eng. 2021, 9, 106674. [Google Scholar] [CrossRef]

- Lima, E.C.; Sher, F.; Saeb, M.R.; Abatal, M.; Seliem, M.K. Reasonable calculation of the thermodynamic parameters from adsorption equilibrium constant. J. Mol. Liq. 2021, 322, 114980. [Google Scholar]

- Lima, E.C.; Hosseini-Bandegharaei, A.; Moreno-Piraján, J.C.; Anastopoulos, I. A critical review of the estimation of the thermodynamic parameters on adsorption equilibria. Wrong use of equilibrium constant in the Van’t Hoof equation for calculation of thermodynamic parameters of adsorption. J. Mol. Liq. 2019, 273, 425–434. [Google Scholar] [CrossRef]

- Addy, M.; Losey, B.; Mohseni, R.; Zlotnikov, E.; Vasiliev, A. Adsorption of heavy metal ions on mesoporous silica-modified montmorillonite containing a grafted chelate ligand. Appl. Clay Sci. 2012, 59–60, 115–120. [Google Scholar] [CrossRef]

- Xie, S.; Wang, L.; Xu, Y.; Lin, D.; Sun, Y.; Zheng, S. Performance and mechanisms of immobilization remediation for Cd contaminated water and soil by hydroxy ferric combined acid-base modified sepiolite (HyFe/ABsep). Sci. Total Environ. 2020, 740, 140009. [Google Scholar] [CrossRef]

- Dou, Q.-S.; Zhang, H.; Wu, J.-B.; Yang, D. Synthesis and Characterization of Fe2O3 and FeOOH Nanostructures Prepared by Ethylene Glycol Assisted Hydrothermal Process. J. Inorg. Mater. 2007, 22, 213–218. [Google Scholar]

- Chen, L.; Han, Y.; Li, W.; Zhan, X.; Wang, H.; Shi, C.; Sun, Y.; Shi, H. Removal of Sb (V) from wastewater via siliceous ferrihydrite: Interactions among ferrihydrite, coprecipitated Si, and adsorbed Sb (V). Chemosphere 2022, 291, 133043. [Google Scholar] [CrossRef]

- Teo, S.H.; Islam, A.; Chan, E.S.; Choong, S.T.; Alharthi, N.H.; Taufiq-Yap, Y.H.; Awual, R. Efficient biodiesel production from Jatropha curcus using CaSO4/Fe2O3-SiO2 core-shell magnetic nanoparticles. J. Clean. Prod. 2019, 208, 816–826. [Google Scholar] [CrossRef]

- Ji, Q.; Kamiya, S.; Jung, J.-H.; Shimizu, T. Self-assembly of glycolipids on silica nanotube templates yielding hybrid nanotubes with concentric organic and inorganic layers. J. Mater. Chem. 2004, 15, 743–748. [Google Scholar] [CrossRef]

- Eren, E.; Gumus, H.; Ozbay, N. Equilibrium and thermodynamic studies of Cu(II) removal by iron oxide modified sepiolite. Desalination 2010, 262, 43–49. [Google Scholar] [CrossRef]

- Lin, Z.; Huan, Z.; Zhang, J.; Li, J.; Li, Z.; Guo, P.; Zhu, Y.; Zhang, T. CTAB-functionalized δ-FeOOH for the simultaneous removal of arsenate and phenylarsonic acid in phenylarsenic chemical warfare. Chemosphere 2022, 292, 133373. [Google Scholar] [CrossRef]

- Yao, S.; Zhu, X.; Wang, Y.; Zhang, D.; Wang, S.; Jia, Y. Simultaneous oxidation and removal of Sb (III) from water by using synthesized CTAB/MnFe2O4/MnO2 composite. Chemosphere 2020, 245, 125601. [Google Scholar] [CrossRef] [PubMed]

- Foo, K.Y.; Hameed, B.H. Insights into the modeling of adsorption isotherm systems. Chem. Eng. J. 2010, 156, 2–10. [Google Scholar] [CrossRef]

- Liu, Y.; Li, C.; Lou, Z.; Zhou, C.; Yang, K.; Xu, X. Antimony removal from textile wastewater by combining PFS&PAC coagulation: Enhanced Sb (V) removal with presence of dispersive dye. Sep. Purif. Technol. 2021, 275, 119037. [Google Scholar] [CrossRef]

- Tu, Y.-J.; Wang, S.-L.; Lu, Y.-R.; Chan, T.-S.; Johnston, C.T. New insight in adsorption of Sb (III)/Sb (V) from waters using magnetic nanoferrites: X-ray absorption spectroscopy investigation. J. Mol. Liq. 2021, 330, 1156911. [Google Scholar] [CrossRef]

- Hossain, M.D.F.; Akther, N.; Zhou, Y. Recent advancements in graphene adsorbents for wastewater treatment: Current status and challenges. Chin. Chem. Lett. 2020, 31, 2525–2538. [Google Scholar] [CrossRef]

- Huang, L.; Huang, X.; Yan, J.; Liu, Y.; Jiang, H.; Zhang, H.; Tang, J.; Liu, Q. Research progresses on the application of perovskite in adsorption and photocatalytic removal of water pollutants. J. Hazard. Mater. 2022, 442, 130024. [Google Scholar] [CrossRef] [PubMed]

- Leng, Y.; Guo, W.; Su, S.; Yi, C.; Xing, L. Removal of antimony(III) from aqueous solution by graphene as an adsorbent. Chem. Eng. J. 2012, 211–212, 406–411. [Google Scholar] [CrossRef]

- Watkins, R.; Weiss, D.; Dubbin, W.; Peel, K.; Coles, B.; Arnold, T. Investigations into the kinetics and thermodynamics of Sb (III) adsorption on goethite (α-FeOOH). J. Colloid Interface Sci. 2006, 303, 639–646. [Google Scholar] [CrossRef]

- Filella, M.; Belzile, N.; Chen, Y.-W. Antimony in the environment: A review focused on natural waters: II. Relevant solution chemistry. Earth-Science Rev. 2002, 59, 265–285. [Google Scholar] [CrossRef]

- Fu, X.; Song, X.; Zheng, Q.; Liu, C.; Li, K.; Luo, Q.; Chen, J.; Wang, Z.; Luo, J. Frontier Materials for Adsorption of Antimony and Arsenic in Aqueous Environments: A Review. Int. J. Environ. Res. Public Health 2022, 19, 10824. [Google Scholar] [CrossRef]

- Farquhar, M.L.; Charnock, J.M.; Livens, F.R.; Vaughan, D.J. Mechanisms of Arsenic Uptake from Aqueous Solution by Interaction with Goethite, Lepidocrocite, Mackinawite, and Pyrite: An X-ray Absorption Spectroscopy Study. Environ. Sci. Technol. 2002, 36, 1757–1762. [Google Scholar] [CrossRef] [PubMed]

- Saleh, T.A.; Sarı, A.; Tuzen, M. Effective adsorption of antimony(III) from aqueous solutions by polyamide-graphene composite as a novel adsorbent. Chem. Eng. J. 2017, 307, 230–238. [Google Scholar] [CrossRef]

- Chen, H.; Li, T.; Zhang, L.; Wang, R.; Jiang, F.; Chen, J. Pb(II) adsorption on magnetic γ-Fe2O3/titanate nanotubes composite. J. Environ. Chem. Eng. 2015, 3, 2022–2030. [Google Scholar] [CrossRef]

- Xiao, X.; Yang, L.; Zhou, D.; Zhou, J.; Tian, Y.; Song, C.; Liu, C. Magnetic γ-Fe2O3/Fe-doped hydroxyapatite nanostructures as high-efficiency cadmium adsorbents. Colloids Surfaces A: Physicochem. Eng. Asp. 2018, 555, 548–557. [Google Scholar] [CrossRef]

- Zhao, X.; Dou, X.; Mohan, D.; Pittman, C.U.; Ok, Y.S.; Jin, X. Antimonate and antimonite adsorption by a polyvinyl alcohol-stabilized granular adsorbent containing nanoscale zero-valent iron. Chem. Eng. J. 2014, 247, 250–257. [Google Scholar] [CrossRef]

- Zhao, W.; Ren, B.; Hursthouse, A.; Wang, Z. Facile synthesis of nanosheet-assembled γ-Fe2O3 magnetic microspheres and enhanced Sb (III) removal. Environ. Sci. Pollut. Res. 2021, 28, 19822–19837. [Google Scholar] [CrossRef]

- Zhang, H.; Khanal, S.K.; Jia, Y.; Song, S.; Lu, H. Fundamental insights into ciprofloxacin adsorption by sulfate-reducing bacteria sludge: Mechanisms and thermodynamics. Chem. Eng. J. 2019, 378, 122103. [Google Scholar] [CrossRef]

- Tran, H.N. Improper Estimation of Thermodynamic Parameters in Adsorption Studies with Distribution Coefficient KD (qe/Ce) or Freundlich Constant (KF): Considerations from the Derivation of Dimensionless Thermodynamic Equilibrium Constant and Suggestions. Adsorpt. Sci. Technol. 2022, 2022, 5553212. [Google Scholar] [CrossRef]

- Fu, R.; Yang, Y.; Xu, Z.; Zhang, X.; Guo, X.; Bi, D. The removal of chromium (VI) and lead (II) from groundwater using sepiolite-supported nanoscale zero-valent iron (S-NZVI). Chemosphere 2015, 138, 726–734. [Google Scholar] [CrossRef]

- Li, W.; Fu, F.; Ding, Z.; Tang, B. Zero valent iron as an electron transfer agent in a reaction system based on zero valent iron/magnetite nanocomposites for adsorption and oxidation of Sb (III). J. Taiwan Inst. Chem. Eng. 2018, 85, 155–164. [Google Scholar] [CrossRef]

- Qi, Z.; Lan, H.; Joshi, T.P.; Liu, R.; Liu, H.; Qu, J. Enhanced oxidative and adsorptive capability towards antimony by copper-doping into magnetite magnetic particles. RSC Adv. 2016, 6, 66990–67001. [Google Scholar] [CrossRef]

| Adsorbent | Pseudo-First-Order Kinetic Parameters | Pseudo-Second-Order Kinetic Parameters | ||||

|---|---|---|---|---|---|---|

| qe (mg/g) | K1 (min−1) | R2 | qe (mg/g) | K2 (min−1) | R2 | |

| Sep | 2.4875 | 0.1246 | 0.9078 | 2.6803 | 0.0672 | 0.9865 |

| HI/ABsep | 5.7879 | 0.0769 | 0.9158 | 6.3861 | 0.0163 | 0.9825 |

| Adsorbent | T/K | Langmuir | Freundlich | ||||

|---|---|---|---|---|---|---|---|

| KL/L·mg−1 | Qm/mg·g−1 | R2 | KF/(L·mg−1)1/n | n | R2 | ||

| Sep | 298 | 0.0222 | 14.66 | 0.9654 | 1.0643 | 2.0454 | 0.9807 |

| 308 | 0.0318 | 14.87 | 0.9952 | 1.4890 | 2.2601 | 0.9560 | |

| 318 | 0.0406 | 16.42 | 0.9922 | 1.9511 | 2.3808 | 0.9573 | |

| HI/ABsep | 298 | 0.1673 | 25.73 | 0.9595 | 6.5908 | 3.2202 | 0.9671 |

| 308 | 0.2617 | 26.89 | 0.9062 | 7.8975 | 3.4044 | 0.9854 | |

| 318 | 0.2245 | 32.45 | 0.9545 | 9.5873 | 3.4328 | 0.9660 | |

| Sorbents | Qm (mg/g) | Experimental Conditions | Reference |

|---|---|---|---|

| PVA-Fe0 | 6.99 | pH = 7; T = 298 K | [45] |

| α-Fe2O3 | 23.23 | pH = 4; T = 298 K | [14] |

| γ-FeOOH | 33.08 | pH = 4; T = 298 K | [14] |

| Graphene | 10.919 | pH = 11; T = 298 K | [37] |

| γ-Fe2O3 mesoporousmicrospheres | 47.48 | pH = 7; T = 298 K | [46] |

| HI/ABsep | 25.73 | pH = 6; T = 298 K | This work |

| Temperature (K) | ΔG° (kJ/mol) | ΔH° (kJ/mol) | ΔS° (J/mol × K) |

|---|---|---|---|

| 298 | −1.3062 | 160.18 | 0.5409 |

| 308 | −6.4172 | ||

| 318 | −11.8262 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, Y.; Ren, B.; He, Z.; Deng, X. Enhanced Removal of Sb (III) by Hydroxy-Iron/Acid–Base-Modified Sepiolite: Surface Structure and Adsorption Mechanism. Water 2022, 14, 3806. https://doi.org/10.3390/w14233806

Zou Y, Ren B, He Z, Deng X. Enhanced Removal of Sb (III) by Hydroxy-Iron/Acid–Base-Modified Sepiolite: Surface Structure and Adsorption Mechanism. Water. 2022; 14(23):3806. https://doi.org/10.3390/w14233806

Chicago/Turabian StyleZou, Yu, Bozhi Ren, Zhendong He, and Xinping Deng. 2022. "Enhanced Removal of Sb (III) by Hydroxy-Iron/Acid–Base-Modified Sepiolite: Surface Structure and Adsorption Mechanism" Water 14, no. 23: 3806. https://doi.org/10.3390/w14233806