The Impact of Water Temperature on In-Line Turbidity Detection

Abstract

1. Introduction

2. Materials and Methods

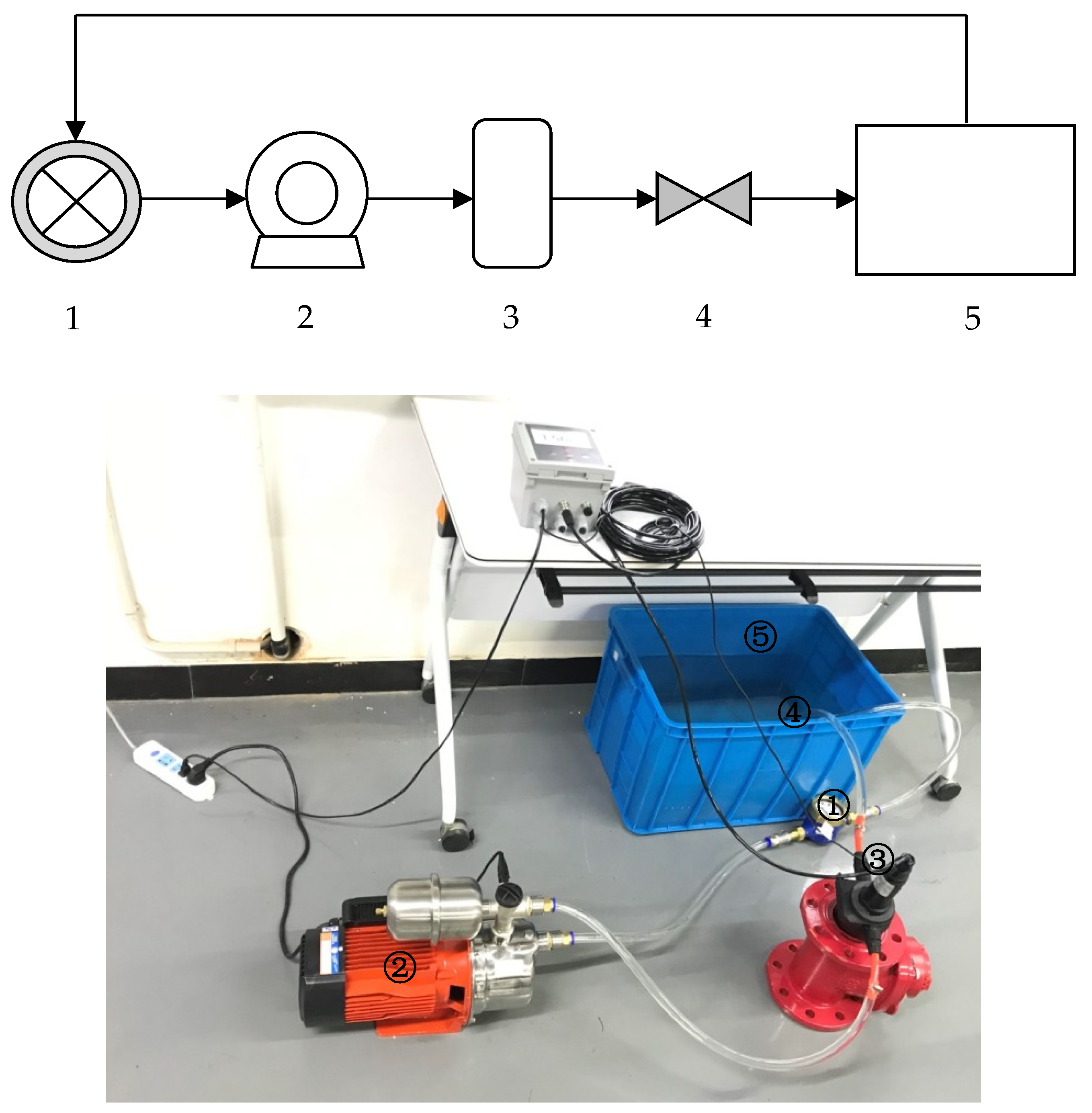

2.1. Experimental Setup

2.2. Operational Mode

2.3. Two Experimental Designs

3. Results and Discussion

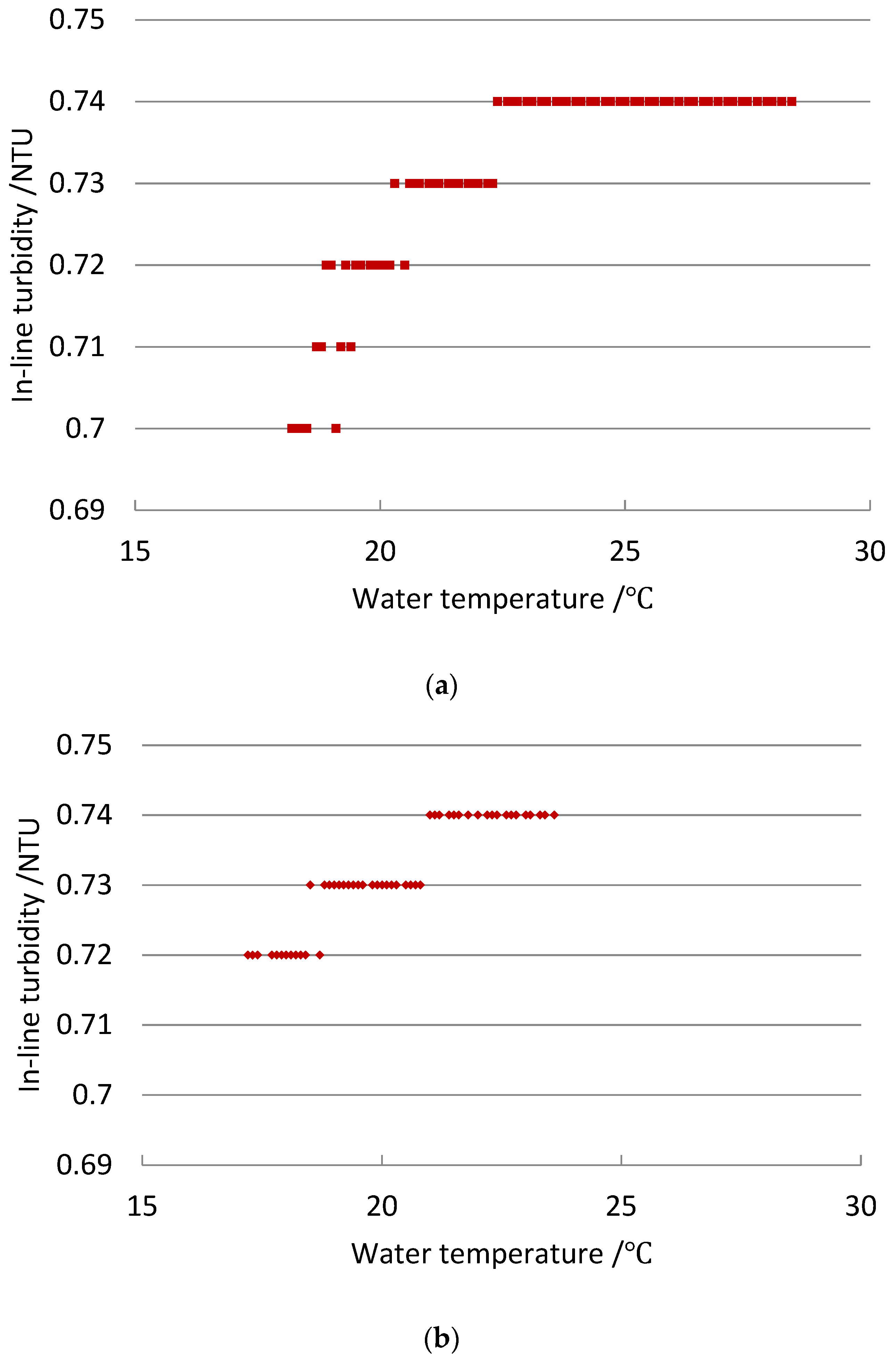

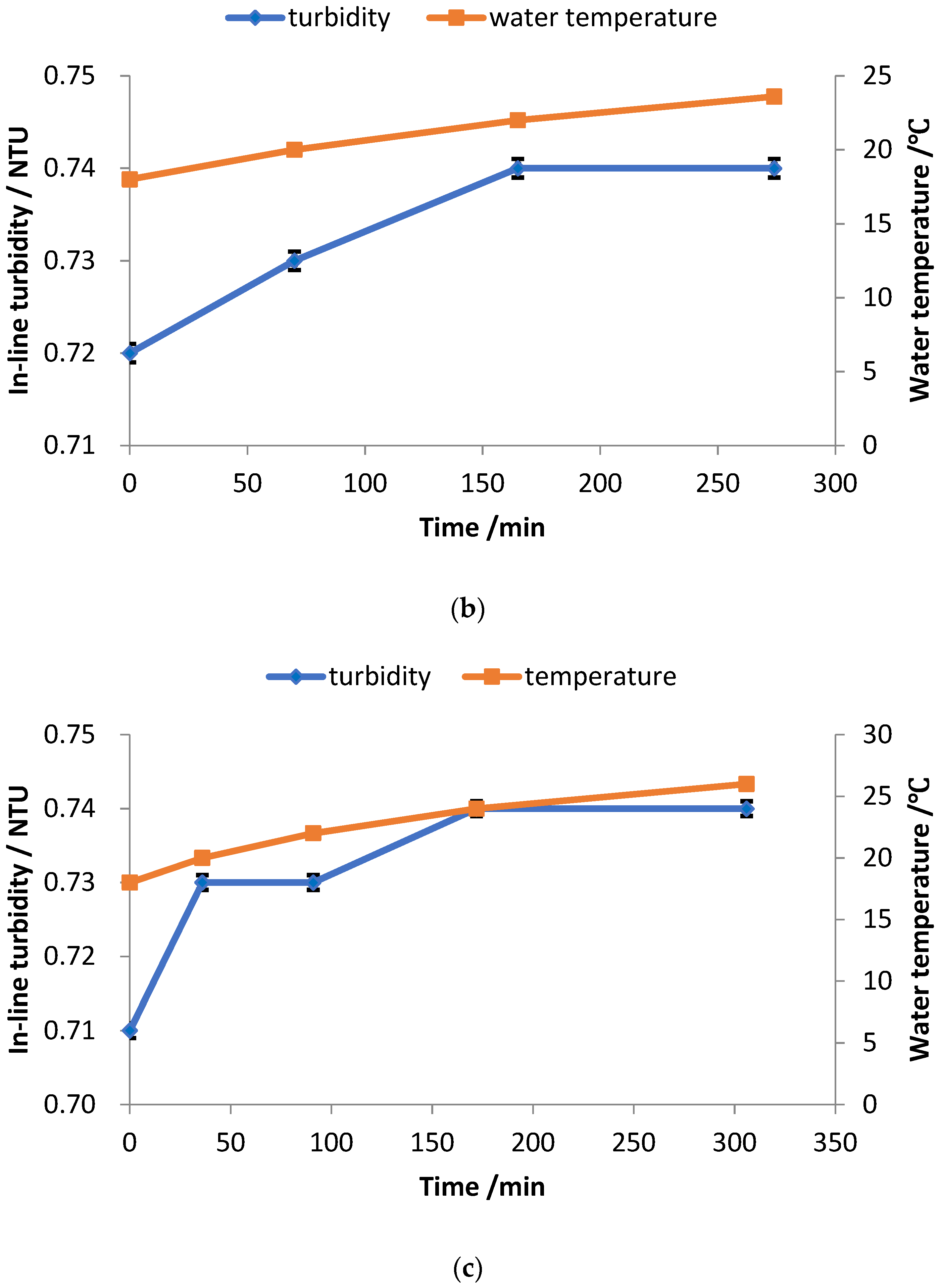

3.1. Relationship between the In-Line Turbidity and Water Temperature at Room Temperature

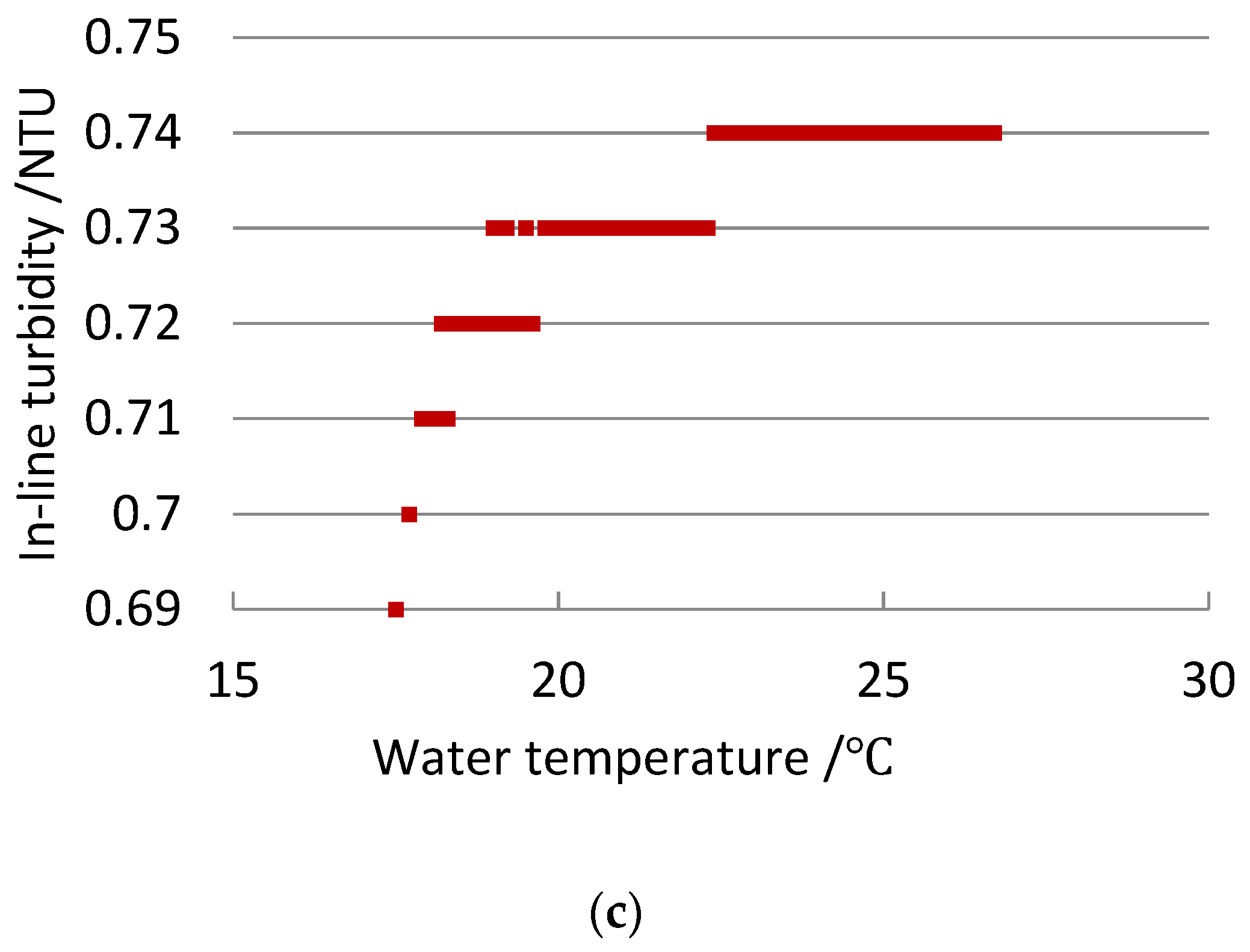

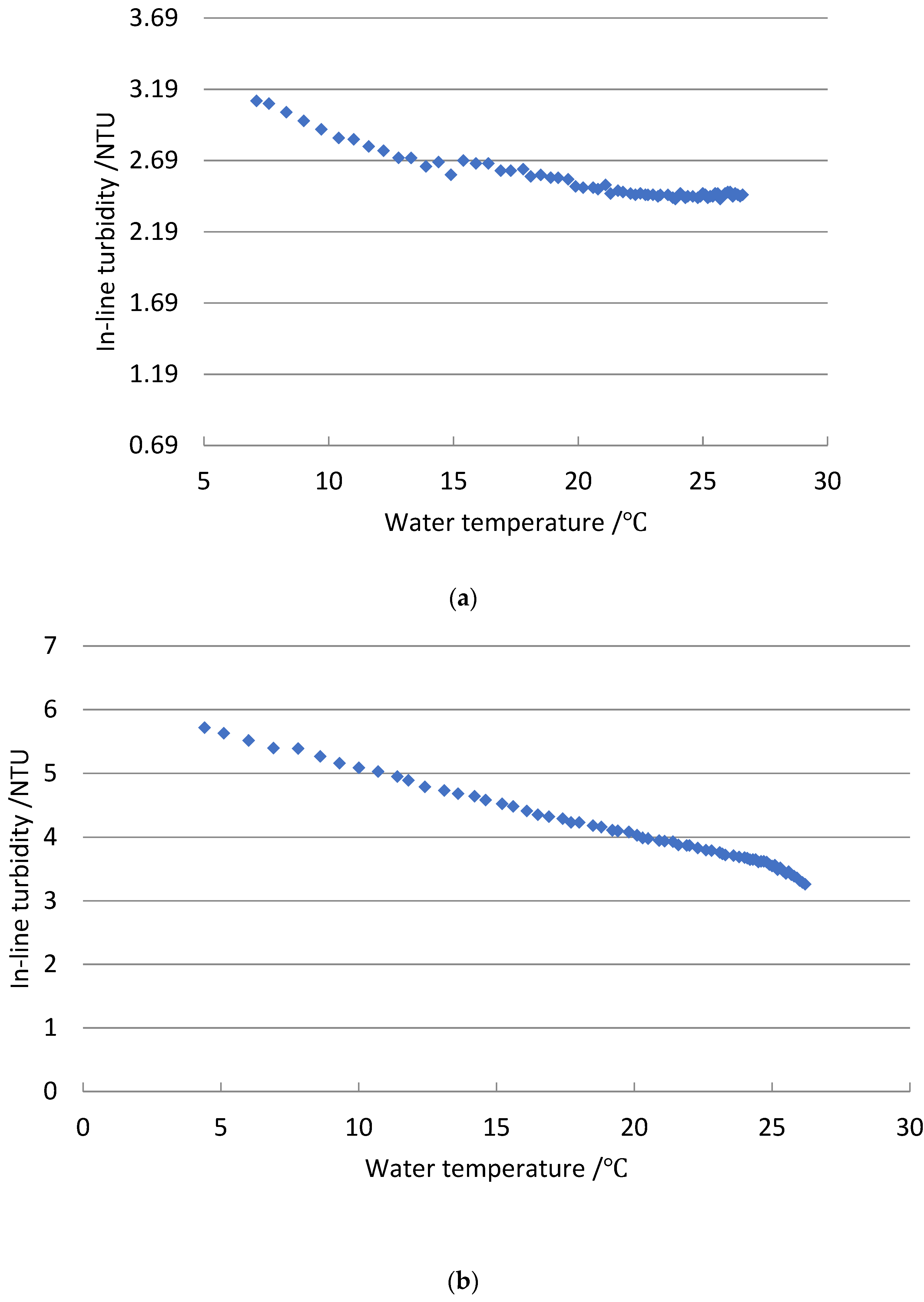

3.2. Relationship between the In-Line Turbidity and Water Temperature after the Water Cooling Treatment

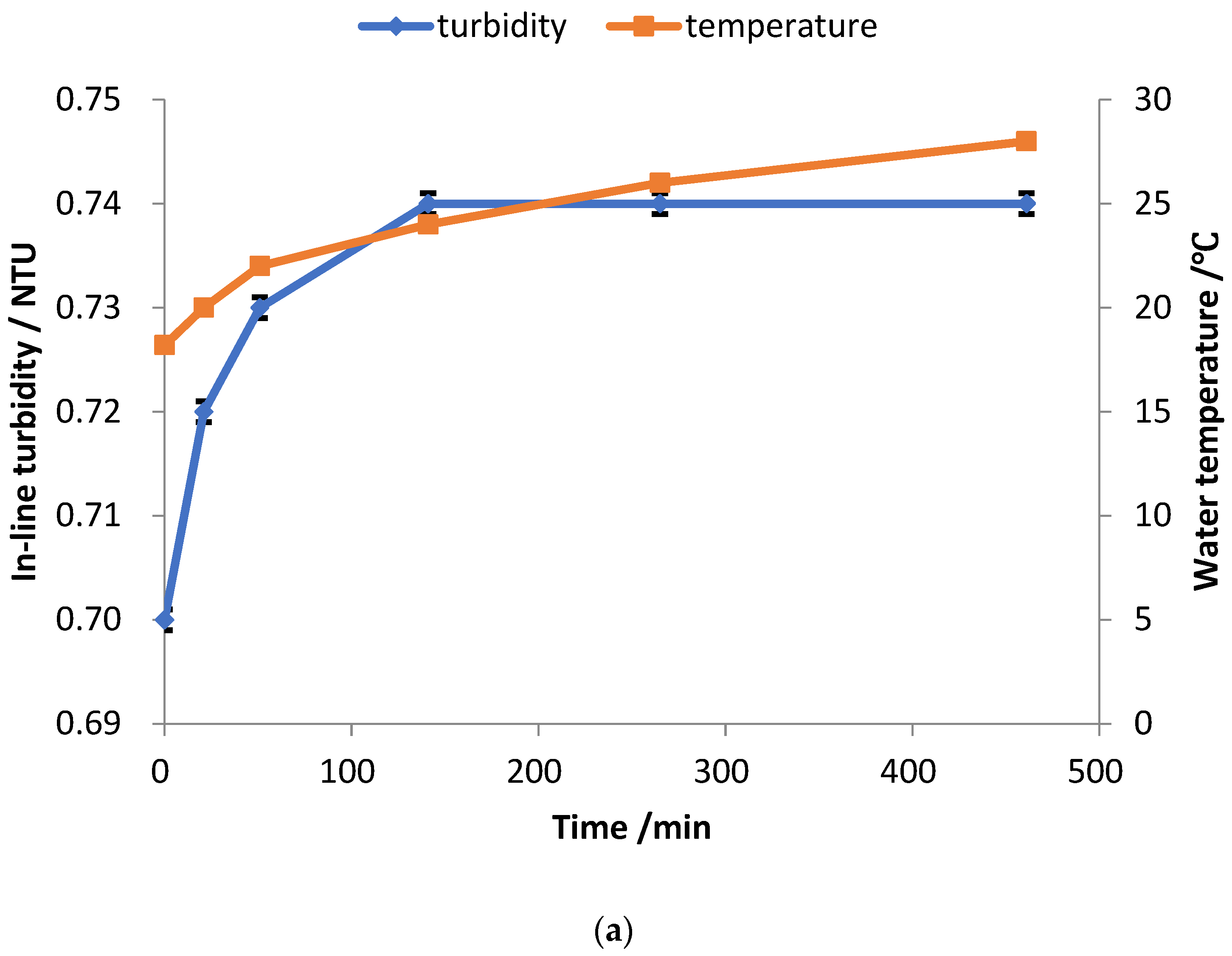

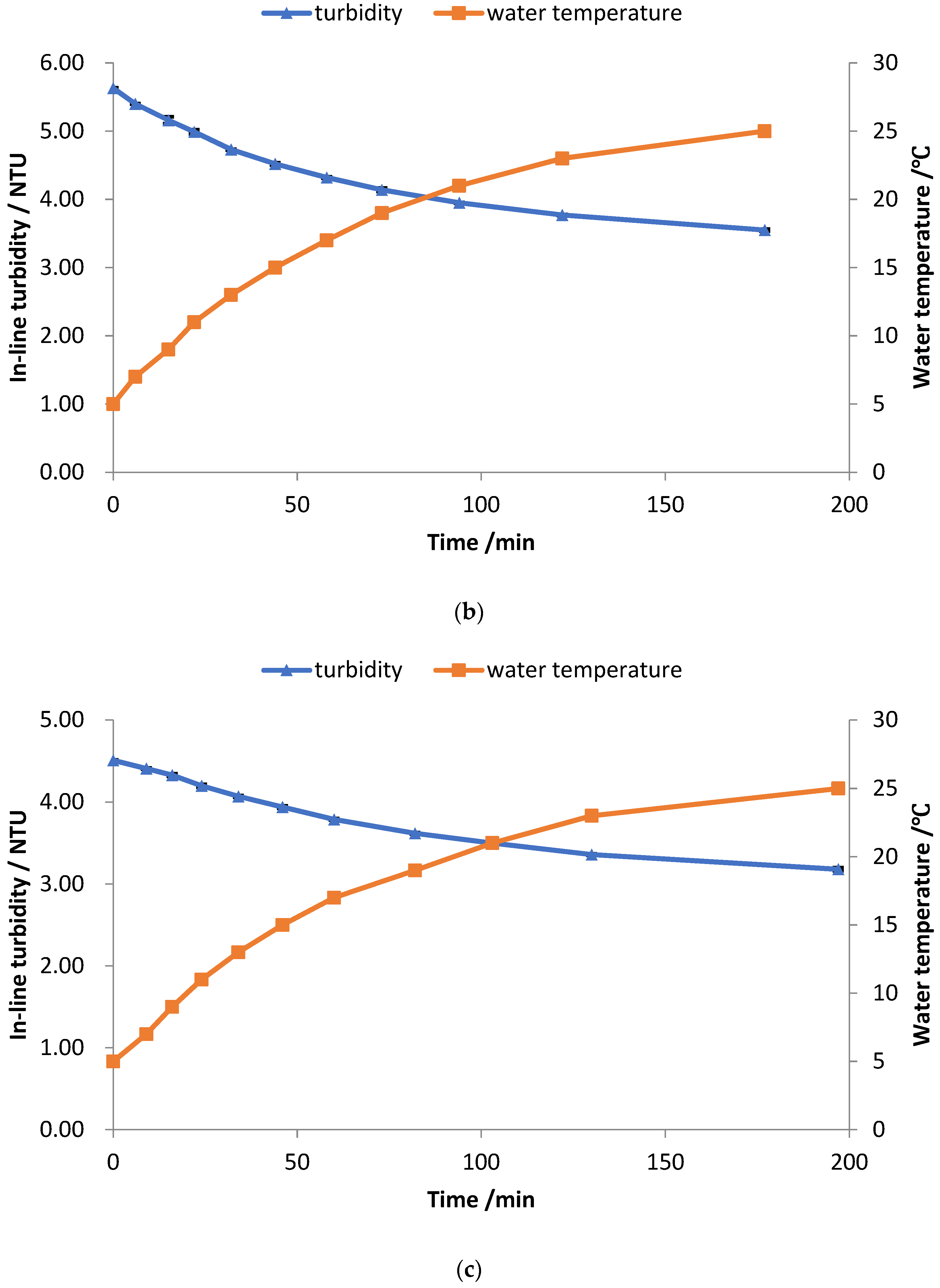

3.3. Comparison between the Two Cases

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Foroughi, M.; Chavoshi, S.; Bagheri, M.; Yetilmezsoy, K.; Samadi, M.T. Alum-based sludge (AbS) recycling for turbidity removal in drinking water treatment: An insight into statistical, technical, and health-related standpoints. J. Mater. Cycles Waste Manag. 2018, 20, 1999–2017. [Google Scholar] [CrossRef]

- Newhart, K.B.; Holloway, R.W.; Hering, A.S.; Cath, T.Y. Data-driven performance analyses of wastewater treatment plants: A review. Water Res. 2019, 157, 498–513. [Google Scholar] [CrossRef] [PubMed]

- Douterelo, I.; Sharpe, R.L.; Husband, S.; Fish, K.E.; Boxall, J.B. Understanding microbial ecology to improve management of drinking water distribution systems. Wiley Interdiscip. Rev. Water 2019, 6, e01325. [Google Scholar] [CrossRef]

- Priya, S.K.; Shenbagalakshmi, G.; Revathi, T. Design of smart sensors for real time drinking water quality monitoring and contamination detection in water distributed mains. Int. J. Eng. Technol. 2018, 7, 47–51. [Google Scholar] [CrossRef]

- Droujko, J.; Molnar, P. Open-source, low-cost, in-situ turbidity sensor for river network monitoring. Sci. Rep. 2022, 12, 10341. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Yao, X.; Wu, Q.; Huang, Y.; Zhou, Z.; Yang, J.; Liu, X. Turbidity prediction of lake-type raw water using random forest model based on meteorological data: A case study of Tai lake, China. J. Environ. Manag. 2021, 290, 112657. [Google Scholar] [CrossRef] [PubMed]

- Fleet, C.F.; Siebert, K.J. Effect of illumination intensity on visual perception of turbidity. Food Qual. Prefer. 2005, 16, 536–544. [Google Scholar] [CrossRef]

- Goode, K.R.; Asteriadou, K.; Robbins, P.T.; Fryer, P.J. Fouling and cleaning studies in the food and beverage industry classified by cleaning type. Compr. Rev. Food Sci. Food Saf. 2013, 12, 121–143. [Google Scholar] [CrossRef]

- Hach, C.C.; Engelhardt, T.; Sadar, M. Principles of Surface Scatter® Turbidity Measurement: Technical Information Series Booklet; Hach Company: Loveland, CO, USA, 2013. [Google Scholar]

- Sader, M. Turbidity Measurement: A Simple, Effective Indicator of Water Quality Change. OTT Hydromet. 2017. Available online: https://www.ott.com/download/turbidity-white-paper (accessed on 25 August 2022).

- Fay, C.D.; Nattestad, A. Advances in optical based turbidity sensing using LED photometry (PEDD). Sensors 2022, 22, 254. [Google Scholar] [CrossRef] [PubMed]

- Tai, H.; Li, D.; Wei, Y.; Ma, D.; Ding, Q. A simple temperature compensation method for turbidity sensor. In International Conference on Computer and Computing Technologies in Agriculture; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Racey, J.D. Development of Novel Turbidity Calibration Standards and Methodologies Using Appropriate Technology. Master’s Thesis, Purdue University Graduate School, West Lafayette, IN, USA, 2019. [Google Scholar]

- Nazirova, K.; Alferyeva, Y.; Lavrova, O.; Shur, Y.; Soloviev, D.; Bocharova, T.; Strochkov, A. Comparison of in situ and remote-sensing methods to determine turbidity and concentration of suspended matter in the Estuary Zone of the Mzymta River, Black Sea. Remote Sens. 2021, 13, 143. [Google Scholar] [CrossRef]

- Wang, Y.; Rajib, S.M.S.M.; Collins, C.; Grieve, B. Low-cost turbidity sensor for low-power wireless monitoring of fresh-water courses. IEEE Sens. J. 2018, 18, 4689–4696. [Google Scholar] [CrossRef]

- Bardsley, R.; Gardner, G.; Tse, H.M.; Fraker, C.A. Optical sensor arrays designed for guided manufacture of perfluorocarbon nanoemulsions with a non-synthetic stabilizer. Acta Biomater. 2021, 136, 558–569. [Google Scholar] [CrossRef] [PubMed]

- Berkcan, E. Temperature Compensation Method for a Turbidity Sensor Used in an Appliance for Washing Articles. U.S. Patent 005477576A, 26 December 1995. [Google Scholar]

- Engel, C. Method for Temperature Compensation of Measured Values of a Turbidity Sensor in an Automatic Washing Machine or Dishwasher. U.S. Patent 5889192, 30 March 1999. [Google Scholar]

- Malliaris, A.G. Wiener Process. In Time Series and Statistics; Eatwell, J., Milgate, M., Newman, P., Eds.; Palgrave Macmillan: London, UK, 1990; pp. 316–318. [Google Scholar]

- Gottlieb, M.A.; Pfeiffer, R. The Brownian Movement [EB/OL]. California Institute of Technology. 2013. Available online: http://www.feynmanlectures.caltech.edu/I_41.html (accessed on 28 August 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, M.; Ma, J.; Zhang, K. The Impact of Water Temperature on In-Line Turbidity Detection. Water 2022, 14, 3720. https://doi.org/10.3390/w14223720

Shi M, Ma J, Zhang K. The Impact of Water Temperature on In-Line Turbidity Detection. Water. 2022; 14(22):3720. https://doi.org/10.3390/w14223720

Chicago/Turabian StyleShi, Meixia, Jingbo Ma, and Kai Zhang. 2022. "The Impact of Water Temperature on In-Line Turbidity Detection" Water 14, no. 22: 3720. https://doi.org/10.3390/w14223720

APA StyleShi, M., Ma, J., & Zhang, K. (2022). The Impact of Water Temperature on In-Line Turbidity Detection. Water, 14(22), 3720. https://doi.org/10.3390/w14223720