Numerical and Experimental Investigations of Flow Pattern and Anti-Vortex Measures of Forebay in a Multi-Unit Pumping Station

Abstract

1. Introduction

2. Engineering Background

2.1. Importance of Engineering

2.2. Project Scale and Parameters

3. Mathematical Formulation

3.1. Mass Continuity Equation

3.2. Momentum Equations

3.3. Turbulence Transport Models

3.4. VOF Fluid Interfaces and Free Surfaces

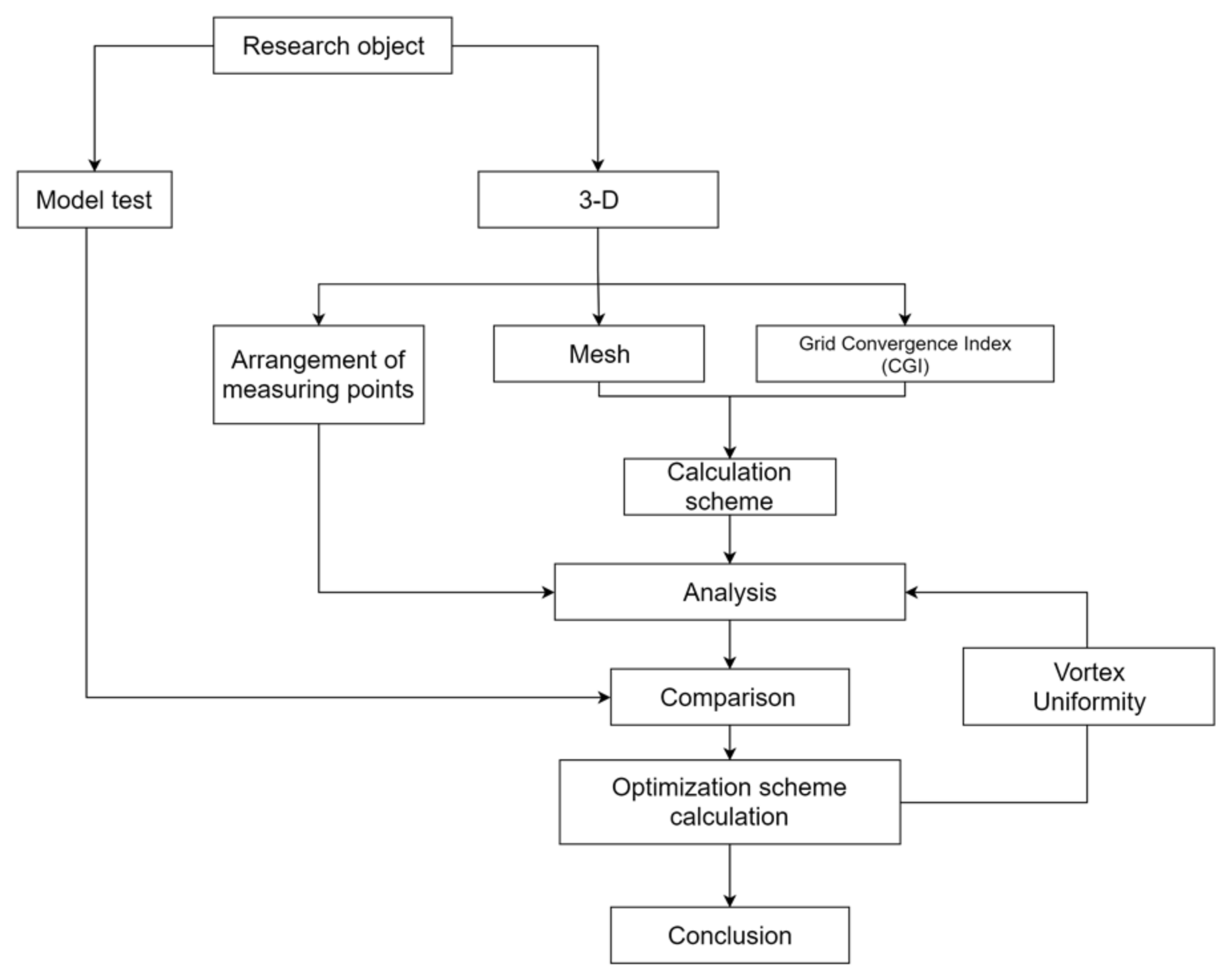

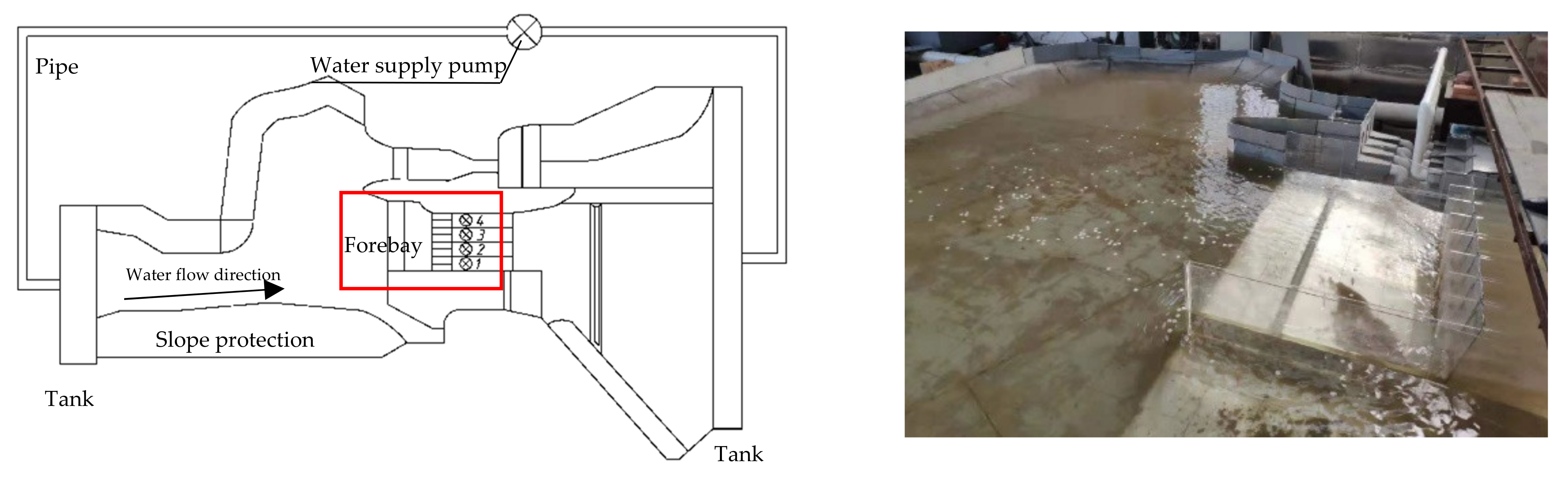

4. Physical Model Test and Numerical Simulation

4.1. Model Test

4.1.1. Similarity Criteria and Scales

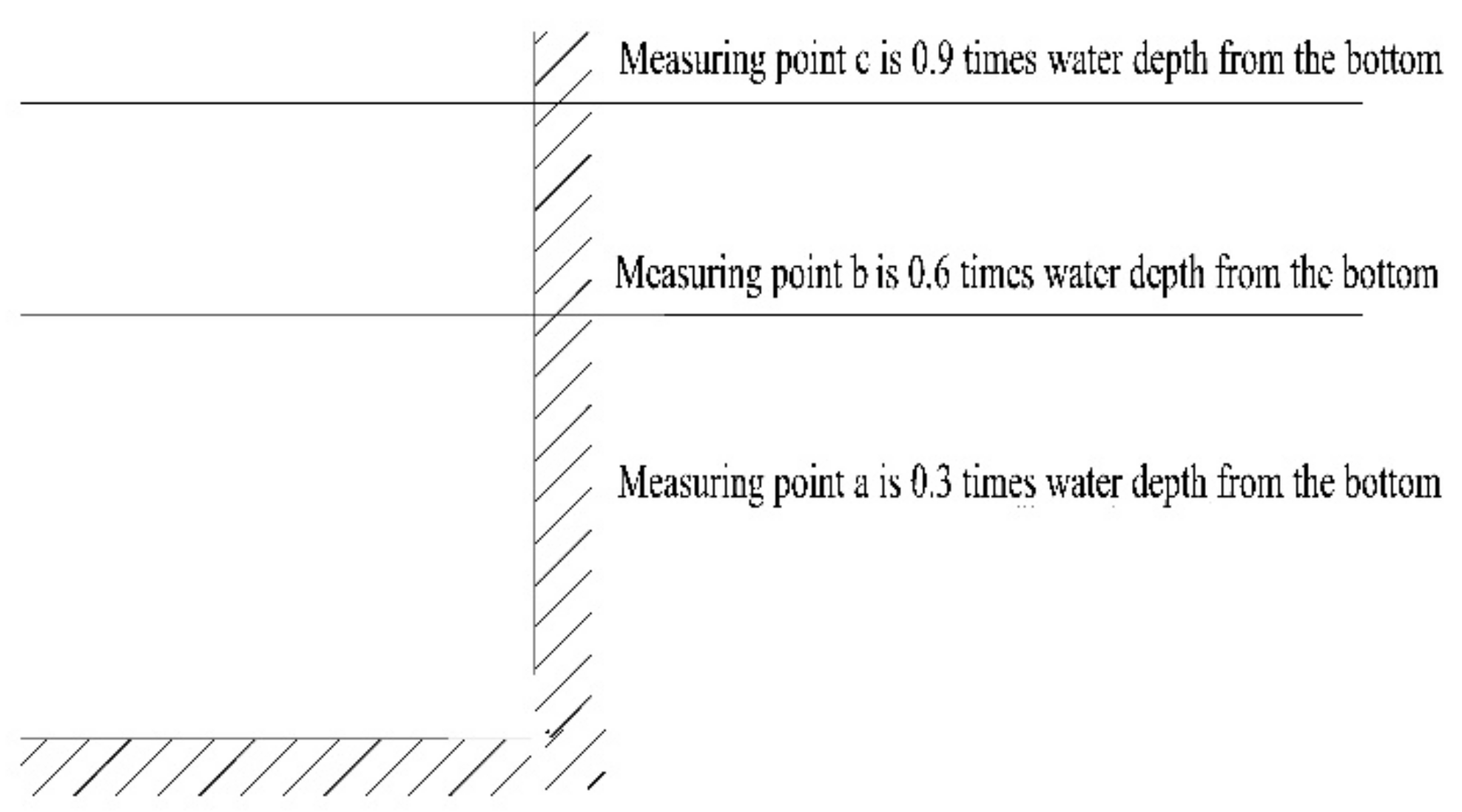

4.1.2. Velocity Measuring System

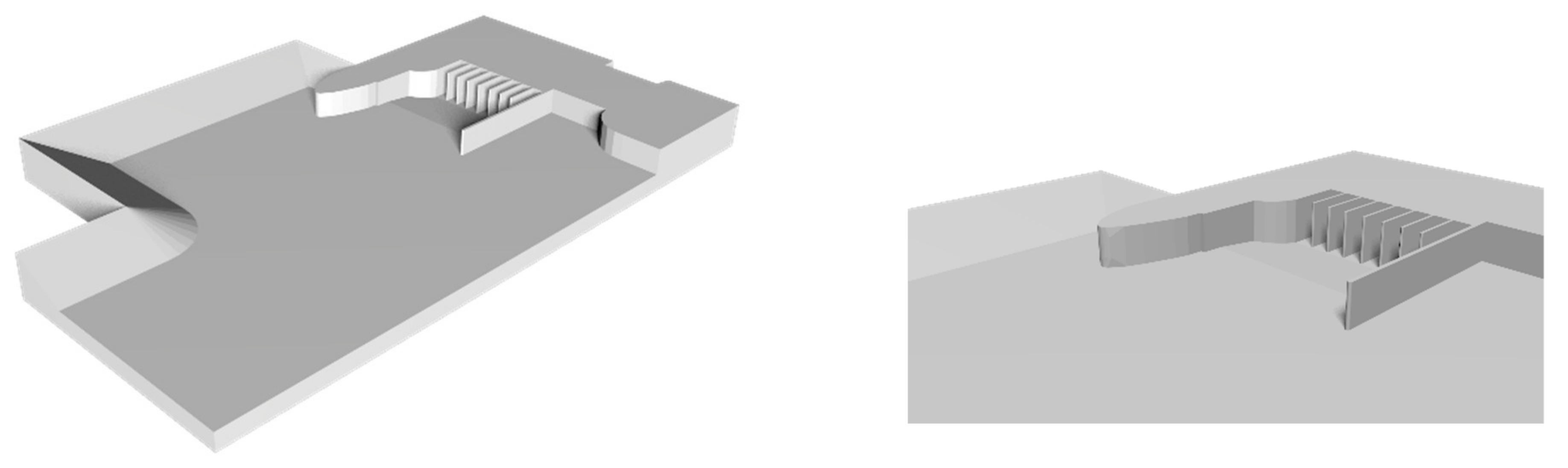

4.2. Numerical Simulation

4.2.1. 3D Modeling

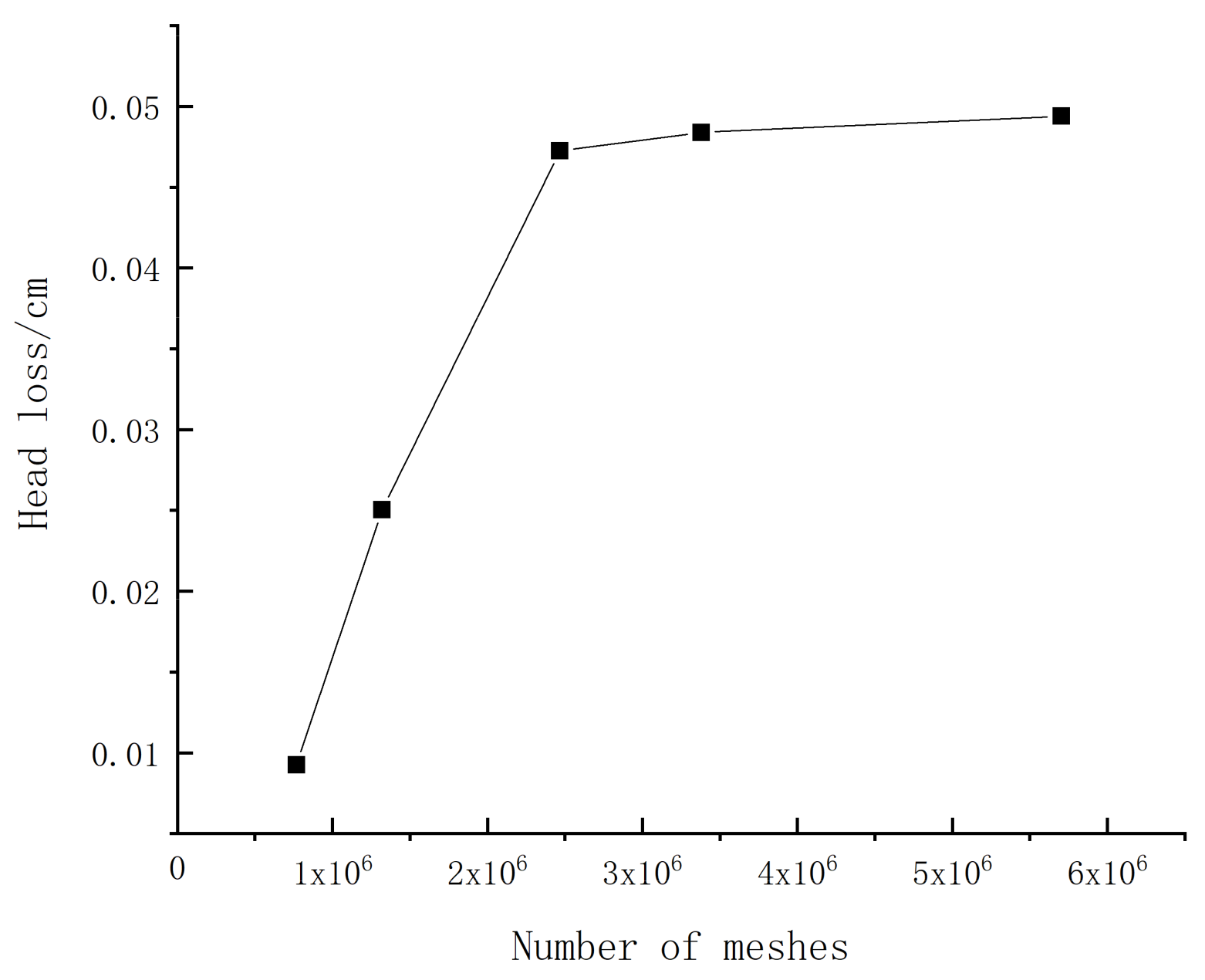

4.2.2. Mesh Independence

4.2.3. Convergence of Grid

4.2.4. Arrangement of Measuring Points

4.3. Rectification Plan

5. Results and Discussion

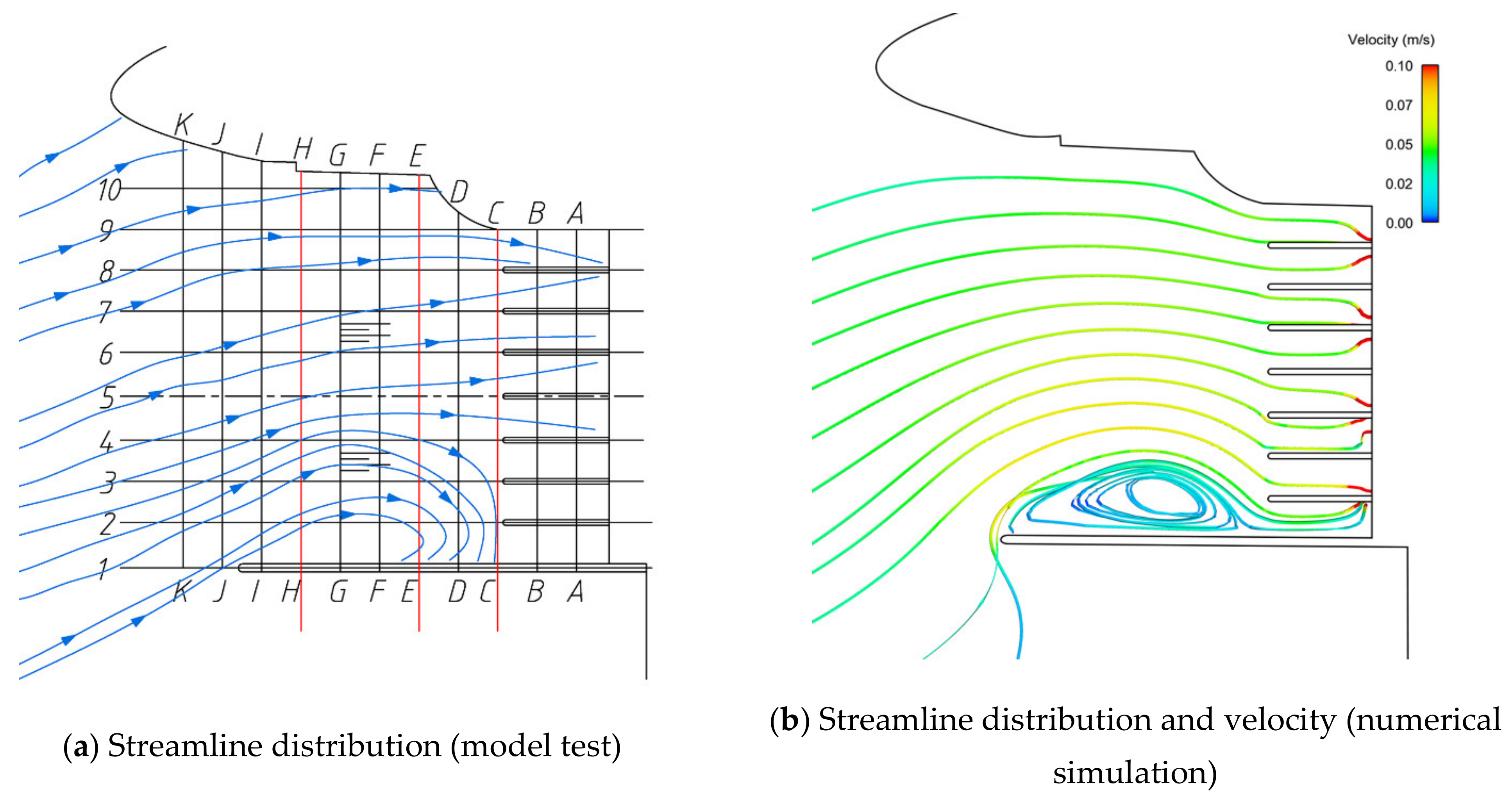

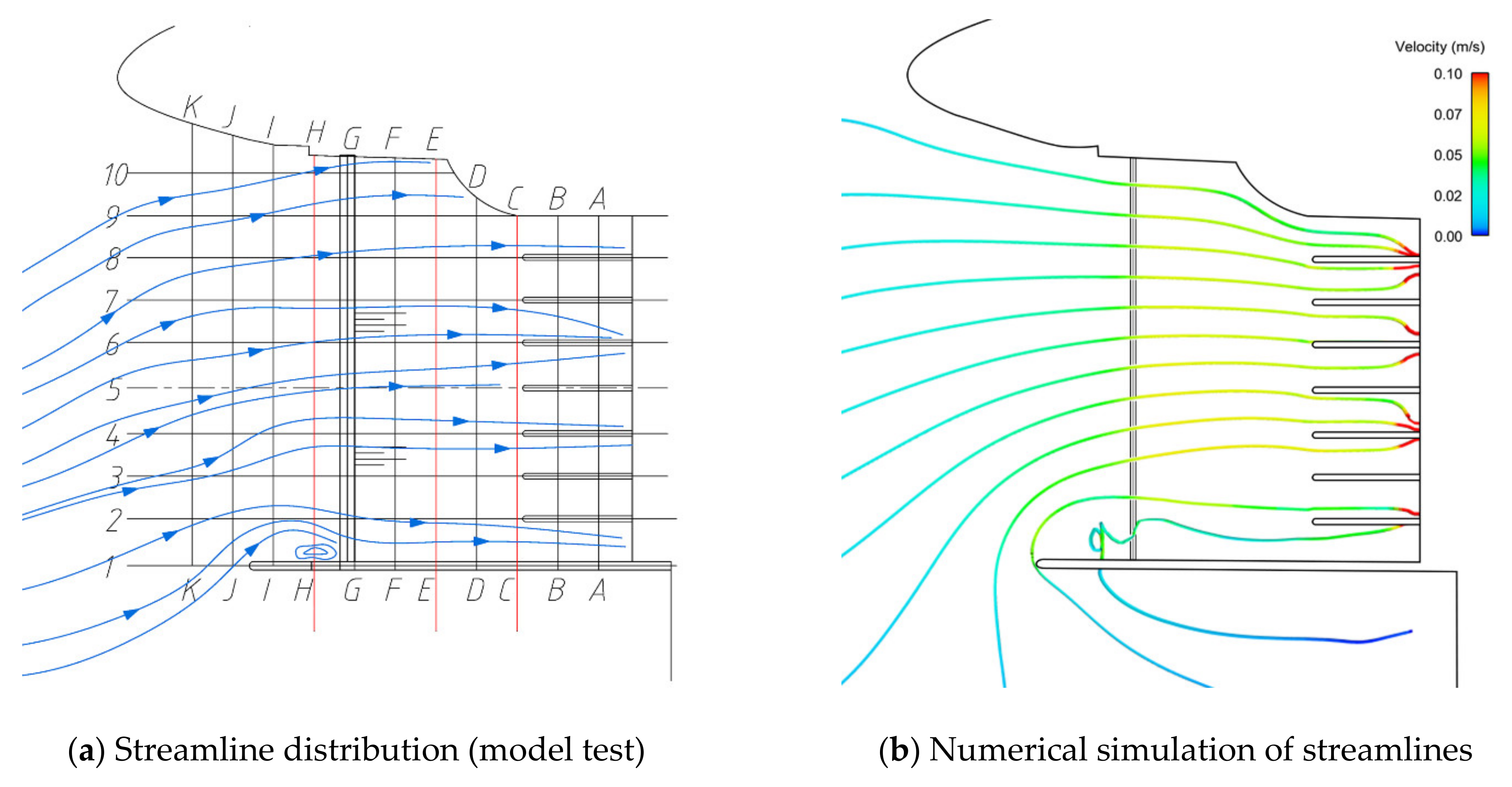

5.1. Flow Pattern Comparison of the Model Test and Numerical Simulation

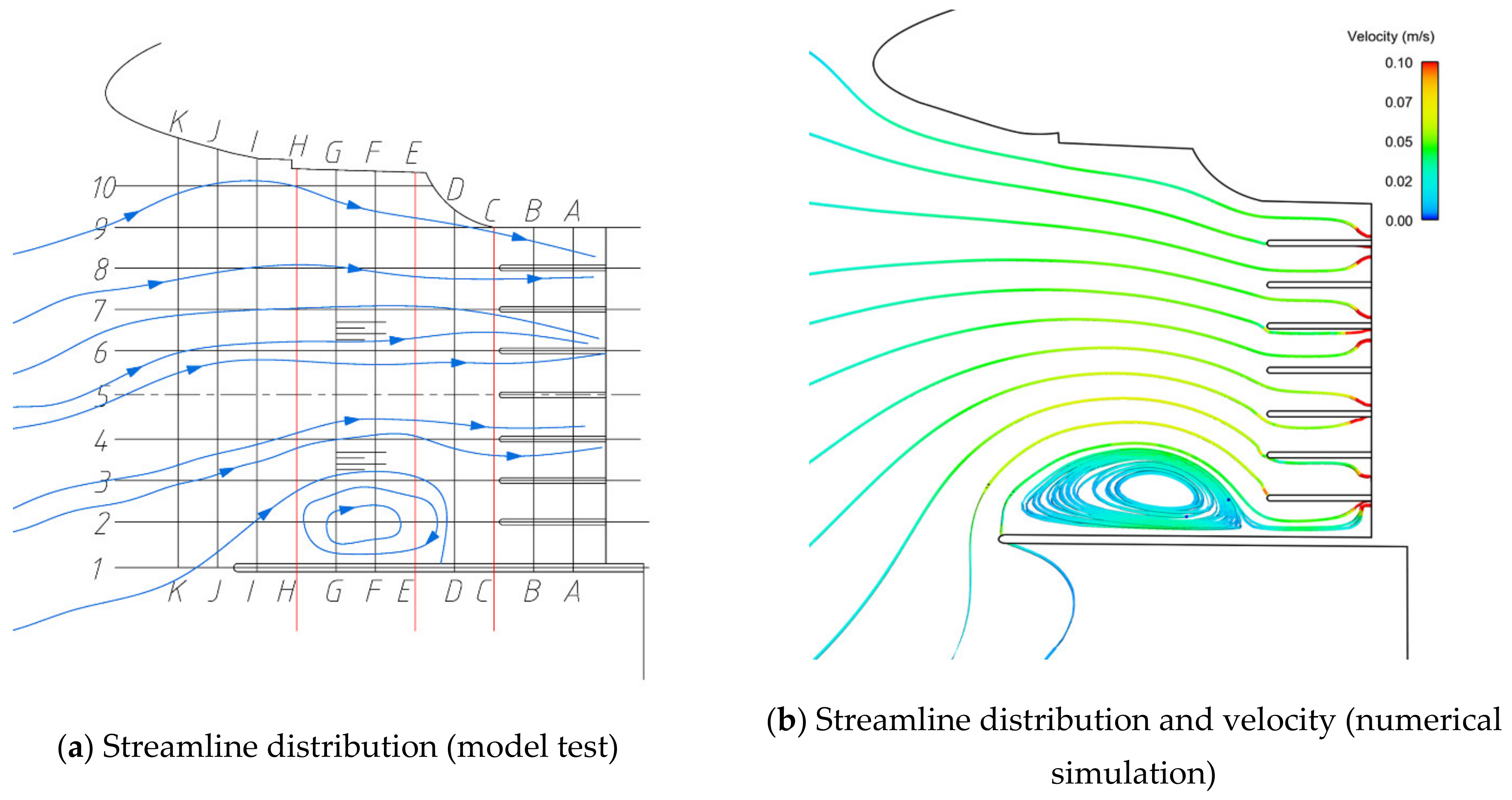

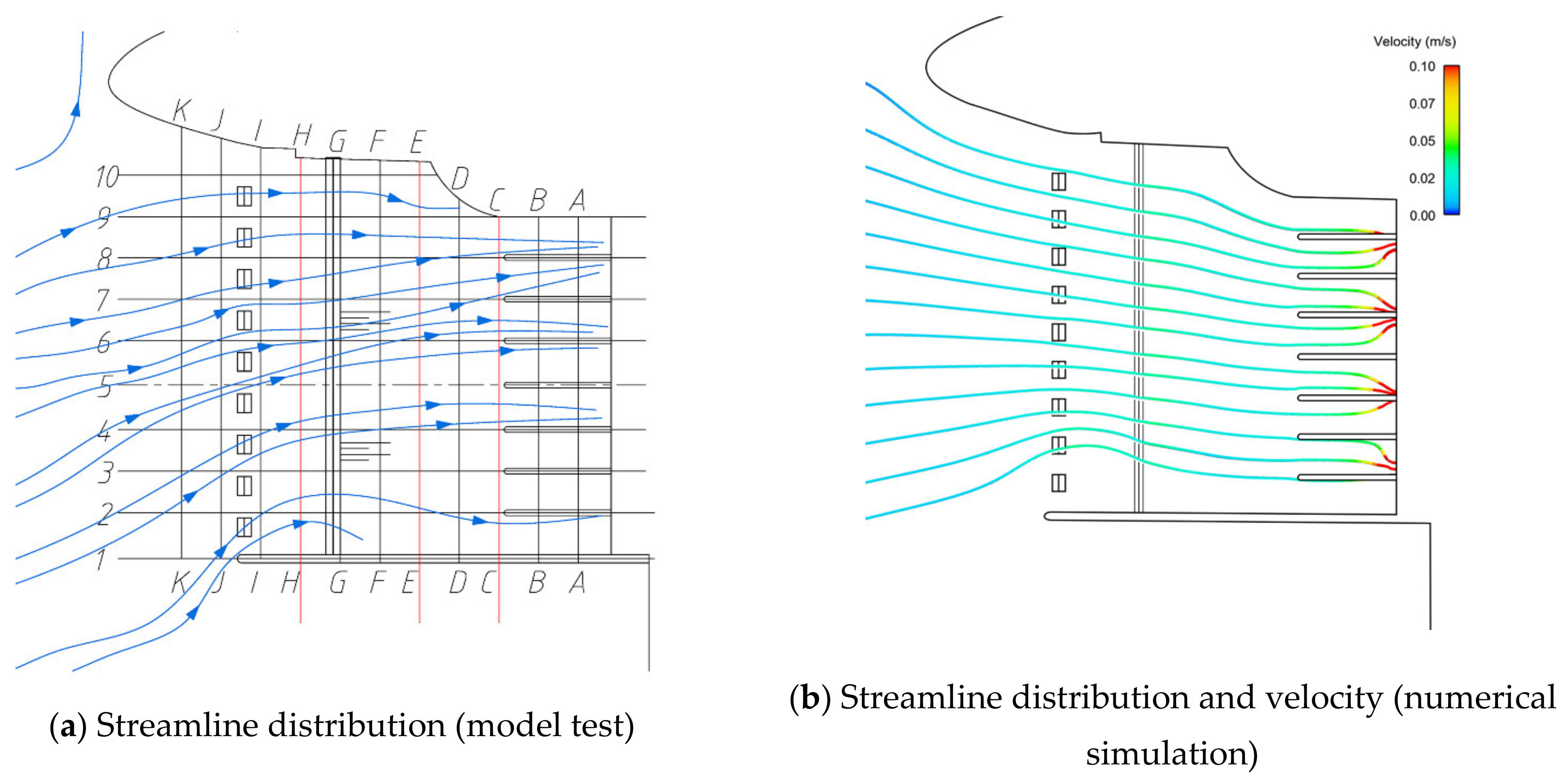

5.1.1. Original Plan

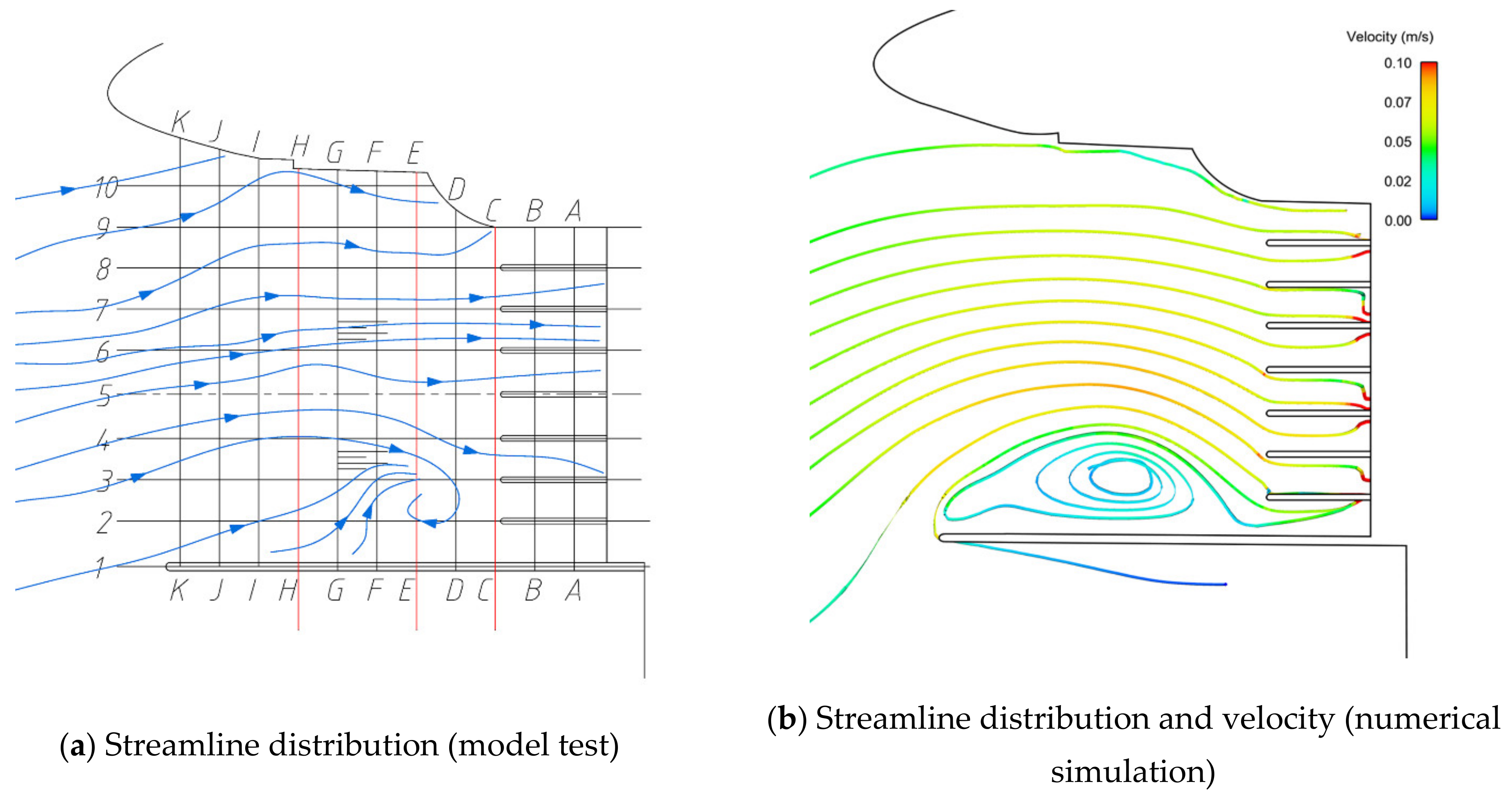

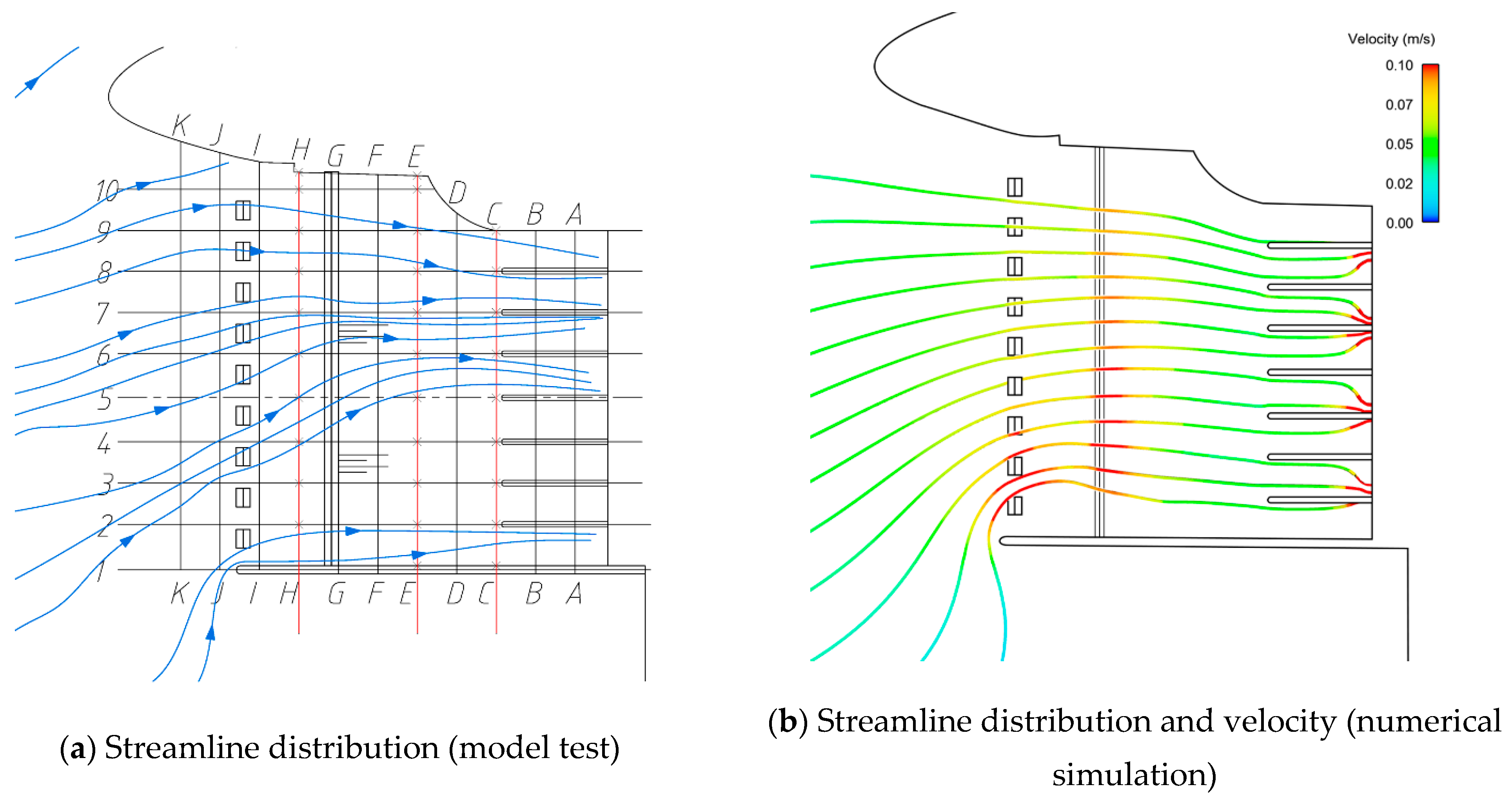

5.1.2. Extended Diversion Wall

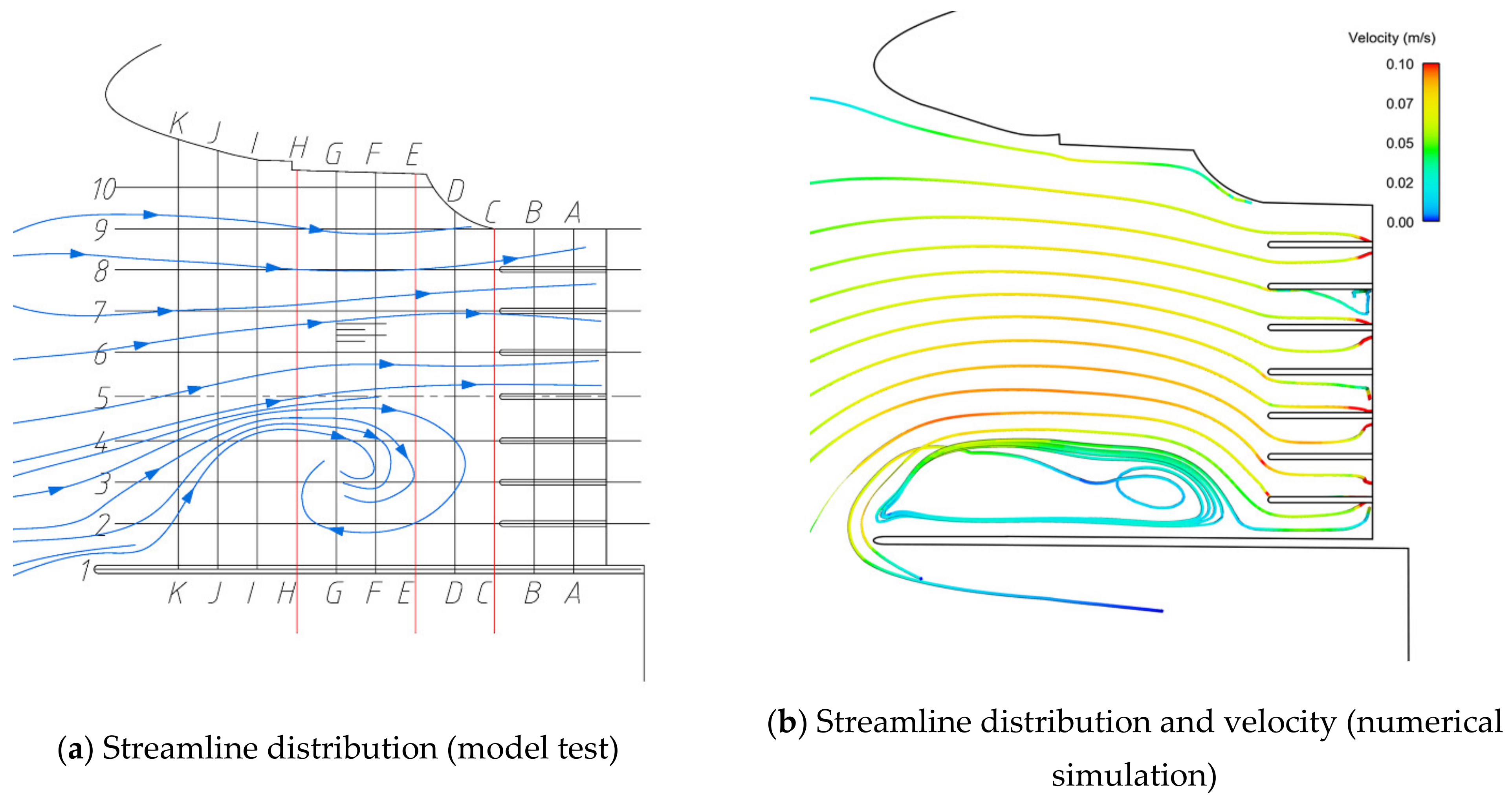

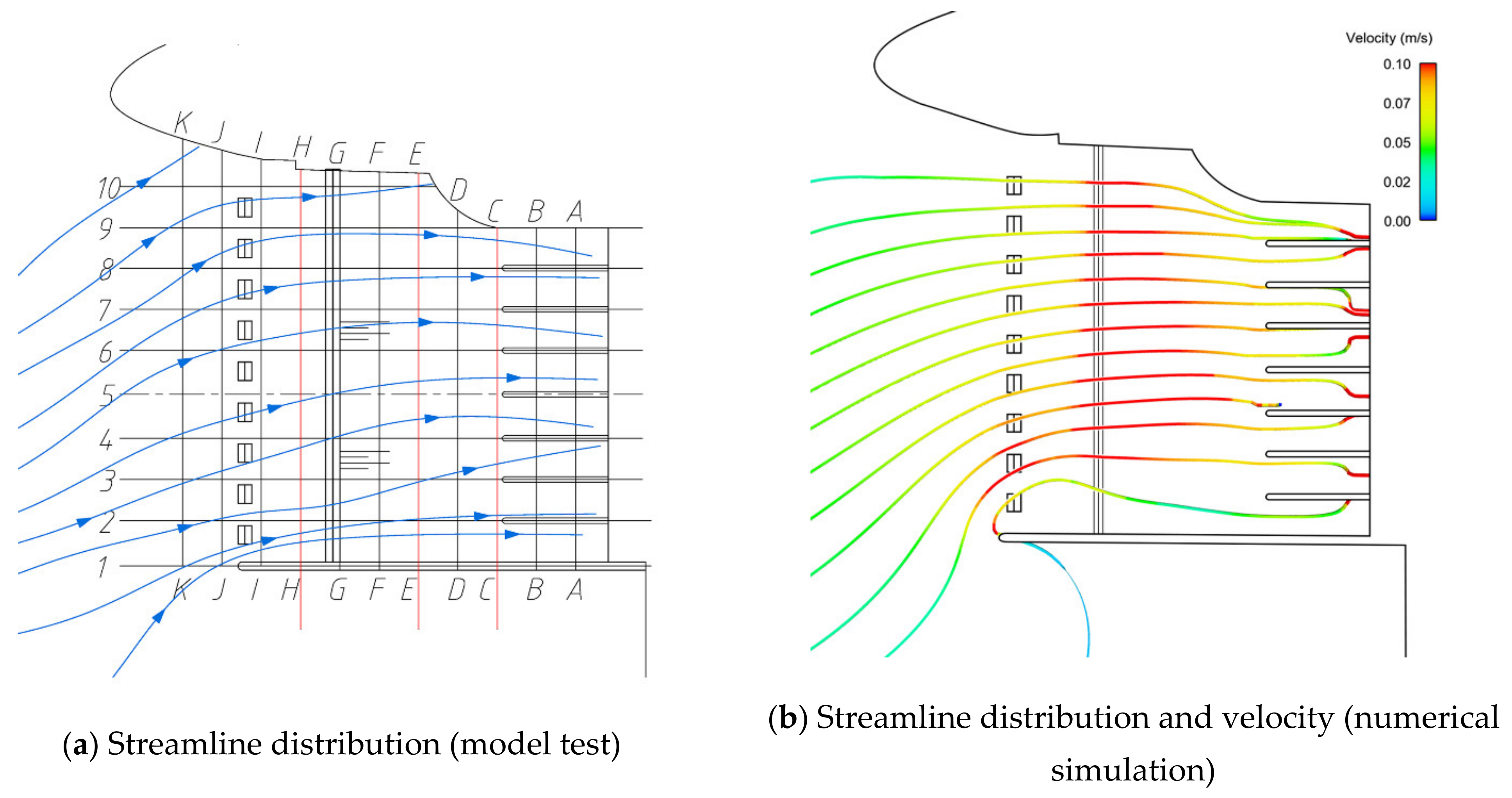

5.1.3. Rectifier Sill

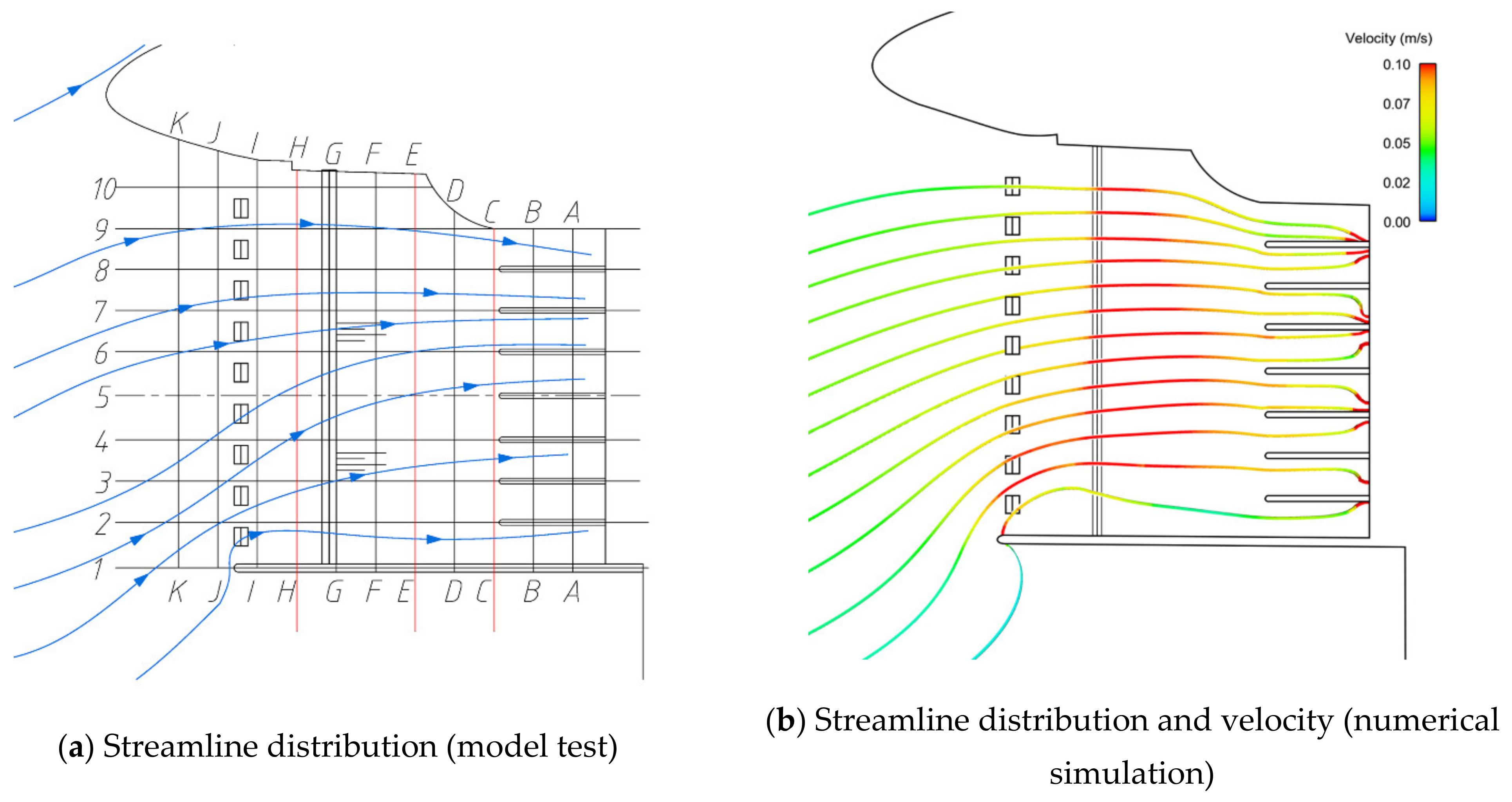

5.1.4. Rectifier Sill and Pier

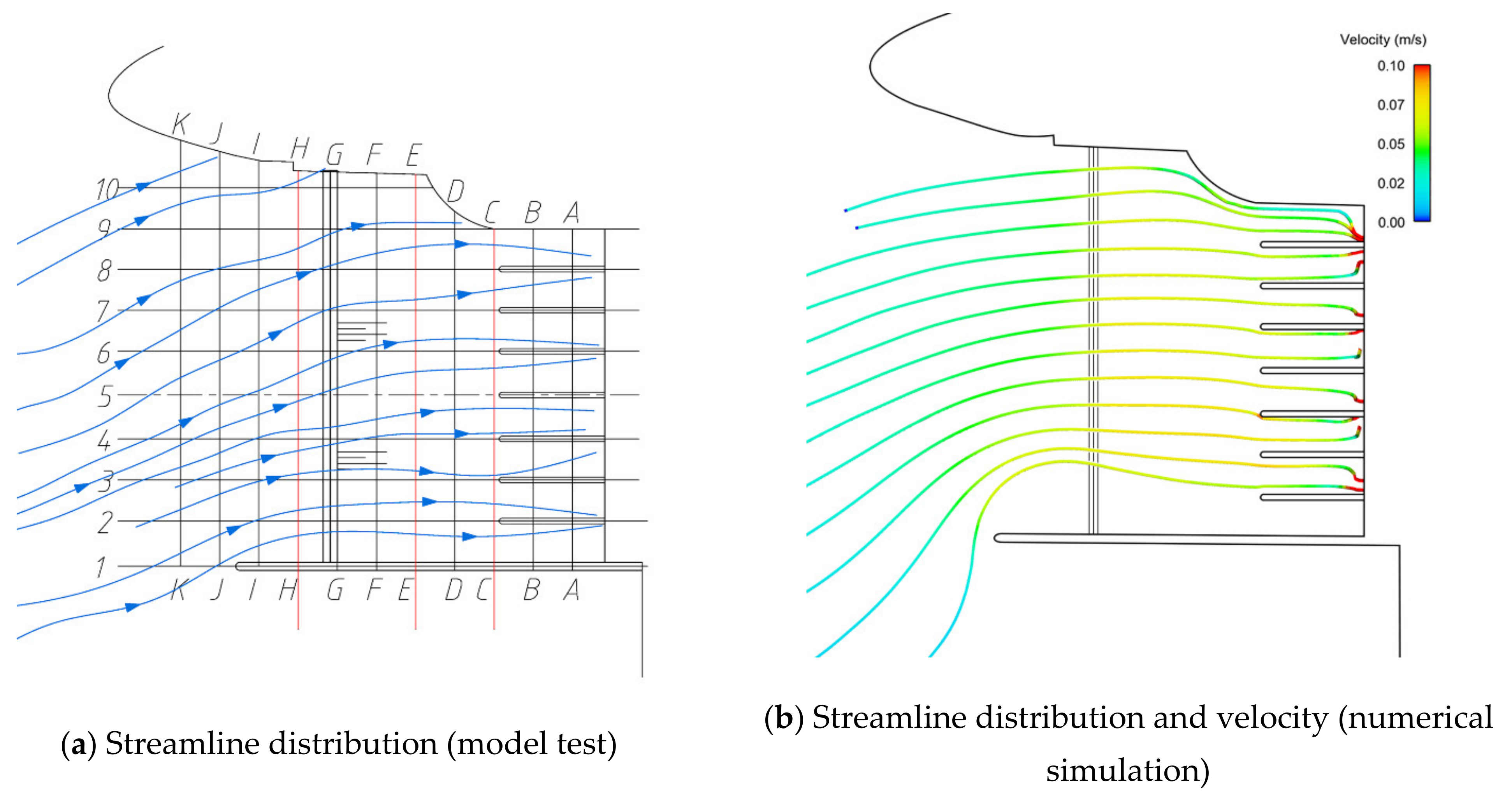

5.1.5. Rectifier Sill and Diversion Wall Opening

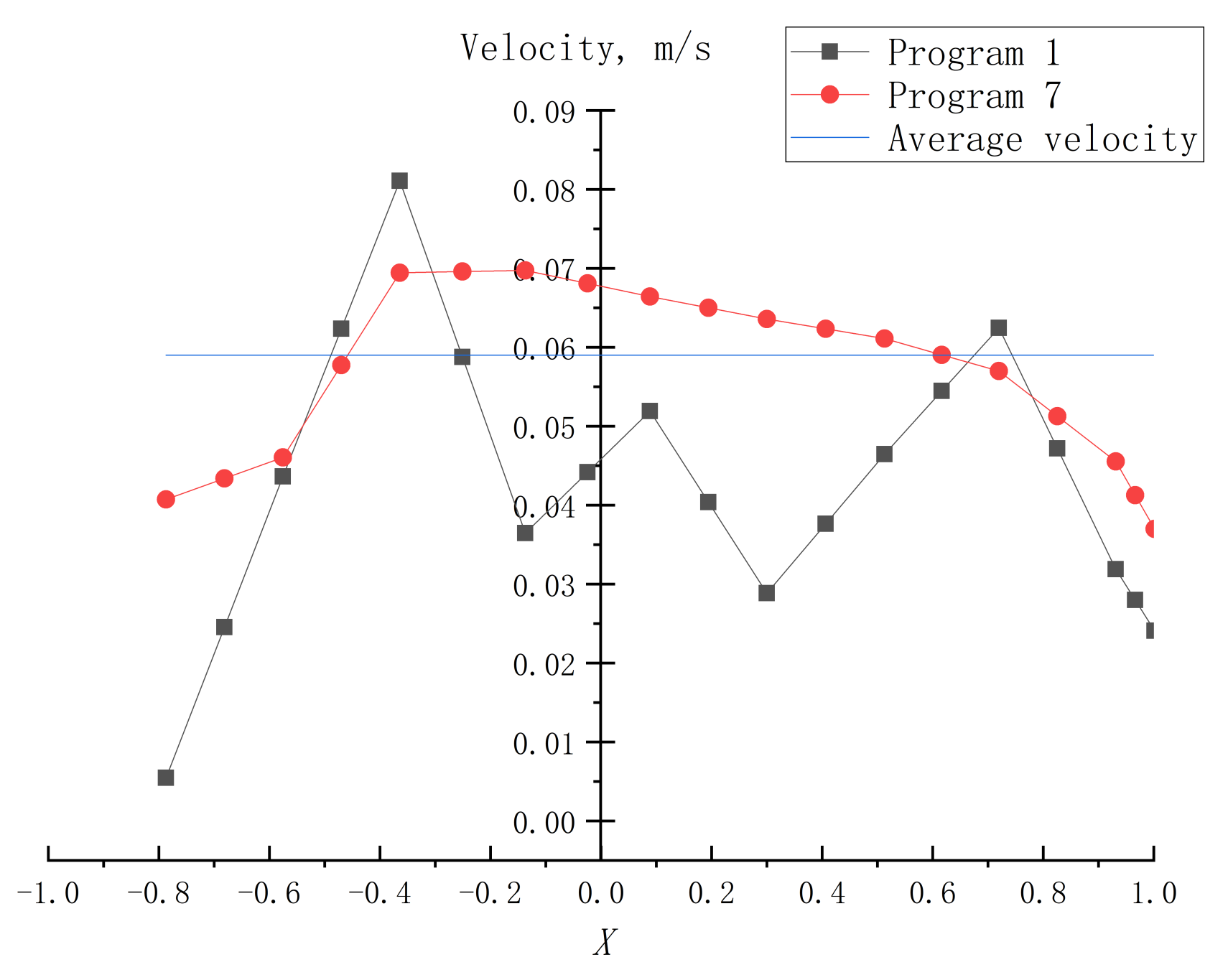

5.2. Quantitative Analysis of Hydraulic Performance Parameters of the Forebay

5.3. The Best Plan

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Q.; Xu, J.; Li, D.; Li, N. Development and Prospect of Irrigation and Drainage Pump Stations in China. China Rural Water Hydropower 2015, 12, 6–10. [Google Scholar]

- Zhang, J.; Lu, Z. Discussion on Type Selection and Application of Pumping Station. China Water Wastewater 2016, 32, 38–40. [Google Scholar]

- Xu, C.D.; Wang, R.R.; Liu, H.; Zhang, R.; Wang, M.Y.; Wang, Y. Flow pattern and anti-silt measures of straight-edge forebay in large pump stations. Int. J. Heat Technol. 2018, 36, 1130–1139. [Google Scholar] [CrossRef]

- Wang, F.; Tang, X.; Chen, X.; Xiao, R.; Yao, Z.; Yang, W. A review on flow analysis method for pumping stations. J. Hydraul. Eng. 2018, 49, 47–61, 71. [Google Scholar]

- Xu, C.; Zhang, H.; Zhang, X.; Han, L.; Wang, R.; Wen, Q.; Ding, L. Numerical simulation of the impact of unit commitment optimization and divergence angle on the flow pattern of forebay. Int. J. Heat Technol. 2015, 33, 91–96. [Google Scholar] [CrossRef]

- Li, C.; Chao, L. Hydraulic performance of pump sumps based on CFD approach. J. Hohai Univ. (Nat. Sci.) 2009, 37, 52–56. [Google Scholar]

- Zhou, J.; Zhong, Z.; Liang, J.; Shi, X. Three-dimensional Numerical Simulation of Side-intake Forebay of Pumping Station. J. Irrig. Drain. 2015, 34, 52–55. [Google Scholar]

- Can, L.; Chao, L. Numerical simulation and improvement of side-intake characteristics of multi-unit pumping station. J. Hydroelectr. Eng. 2015, 34, 207–214. [Google Scholar]

- Xia, C.; Cheng, L.; Zhao, G.; Yu, L.; Wu, M.; Xu, W. Numerical simulation of flow pattern in forebay of pump station with single row of square columns. Adv. Sci. Technol. Water Resour. 2017, 37, 53–58. [Google Scholar]

- Luo, J.; Lin, Y. Hydraulic test of pump sumps of thermal (nuclear) power plants. J. Hohai Univ. 2000, 28, 106–110. [Google Scholar]

- Constantinescu, G.; Patel, V. Role of turbulence model in prediction of pump-bay vortices. J. Hydraul. Eng. 2000, 126, 387–391. [Google Scholar] [CrossRef]

- Kadam, P.; Chavan, D. CFD analysis of flow in pump sump to check suitability for better performance of pump. Int. J. Mech. Eng. Robot. 2013, 1, 56–65. [Google Scholar]

- Song, W.; Pang, Y.; Shi, X.; Xu, Q. Study on the Rectification of Forebay in Pumping Station. Math. Probl. Eng. 2018, 2018, 2876980. [Google Scholar] [CrossRef]

- Muller, C.J.; Craig, I.K. Energy reduction for a dual circuit cooling water system using advanced regulatory control. Appl. Energy 2016, 171, 287–295. [Google Scholar] [CrossRef]

- Caishui, H. Three-dimensional numerical analysis of flow pattern in pressure forebay of hydropower station. Procedia Eng. 2012, 28, 128–135. [Google Scholar] [CrossRef]

- Zhan, J.M.; Wang, B.C.; Yu, L.H.; Li, Y.; Ling, T. Numerical investigation of flow patterns in different pump intake systems. J. Hydrodyn. Ser. B 2012, 24, 873–882. [Google Scholar] [CrossRef]

- Wang, F. Computational Fluid Dynamics Analysis: Principle and Application of CFD Software; Tsinghua University: Beijing, China, 2004; pp. 7–11. [Google Scholar]

- Wang, F. The Analysis of Computational Fluid Dynamics-CFD Software Theory and Application; Tsinghua University Press: Beijing, China, 2004. [Google Scholar]

- Roache, P.J. Quantification of uncertainty in computational fluid dynamics. Annu. Rev. Fluid Mech. 1997, 29, 123–160. [Google Scholar] [CrossRef]

- Savage, B.M.; Crookston, B.M.; Paxson, G.S. Physical and numerical modeling of large headwater ratios for a 15 labyrinth spillway. J. Hydraul. Eng. 2016, 142, 04016046. [Google Scholar] [CrossRef]

- Liu, H.; Liu, M.; Bai, Y.; Du, H.; Dong, L. Grid convergence based on GCI for centrifugal pump. J. Jiangsu Univ. (Nat. Sci. Ed.) 2014, 35, 279–283. [Google Scholar]

- Wang, S.S.; Roache, P.J.; Schmalz, R.A., Jr.; Jia, Y.; Smith, P.E. (Eds.) Verification and Validation of 3D Free-Surface Flow Models; American Society of Civil Engineers: Reston, VA, USA, 2008. [Google Scholar] [CrossRef]

- Yabing, D. Numerical Simulation Study on the Scheme of Trajecmtory Bucket Type Energy Dissipation for Overflow Sam of Shiziya Reservoir; Xi’an University of Technology: Xi’an, China, 2018. [Google Scholar]

- Zhao, Z. Hydrometry; The Yellow River Water Conservancy Press: Zhengzhou, China, 2005. [Google Scholar]

- Jiren, C.L.L.C.Z.; Fangping, T. Numerical Simulation of Turbulent Flow around Sill with RNG k-ε Turbulent Model. J. Trans. Chin. Soc. Agric. Mach. 2005, 3, 37–39. [Google Scholar]

- Haiying, X. Comparison of simulation effect of turbulence model upon flow passing on sill. J. Water Resour. Water Eng. 2012, 23, 163–165. [Google Scholar]

- Feng, X. Flow analysis of bottom sill rectification and back sill of pump station forebay. Jiangsu Water Resour. 1998, 26, 31–33, 38. [Google Scholar]

- Xu, B.; Gao, C.; Xia, H.; Lu, W. Influence of Geometric Parameters of Perforated Diversion Pier on Flow-rectifying Effect in Forebay of Sluice-pump Station Project. J. Yangtze River Sci. Res. Inst. 2019, 36, 58–62. [Google Scholar]

- Fan, Y.; Chuanliu, X.; Chao, L.; Yao, Y.; Lijian, S. Influence of axial-flow pumping system operating conditions on hydraulic performance of elbow inlet conduit. Trans. Chin. Soc. Agric. Mach. 2016, 47, 15–21. [Google Scholar]

| Characteristic Water Level | Upper Reaches/m | Lower Reaches/m | Net Head/m |

|---|---|---|---|

| Minimum operating water level | 9.00 | 10.00 | 1.00 |

| Design operating water level | 10.00 | 12.06 | 2.06 |

| Maximum operating water level | 12.47 | 14.11 | 1.64 |

| Flood control water level | 13.09 | 14.11 | 1.02 |

| Mesh Size (m) | Total Number of Meshes | r (Dk/Dk+1) | p | Q(m3/s) | ||

|---|---|---|---|---|---|---|

| 0.03 | 767,646 | 0.02100 | ||||

| 0.025 | 1,320,405 | 1.20 | 1 | 0.02115 | 0.00714 | 4.46519 |

| 0.02 | 2,467,681 | 1.25 | 1 | 0.02113 | 0.00094 | 0.47039 |

| Plan Number | Plan Description | Action Description (Prototype in Parentheses) |

|---|---|---|

| 1 | Original plan | No rectification measures |

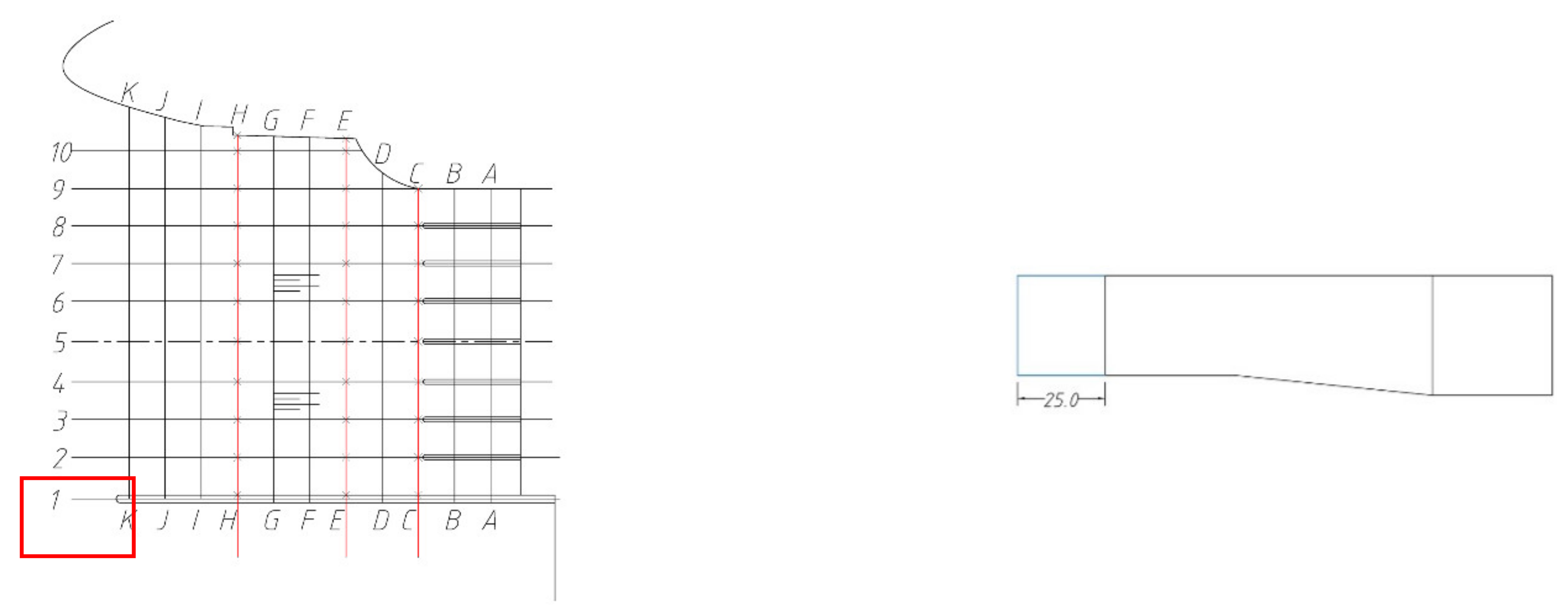

| 2 | Diversion wall | The diversion wall is lengthened by 25 cm (7.5 m). The shape and arrangement of rectification measures are shown in Figure 8. |

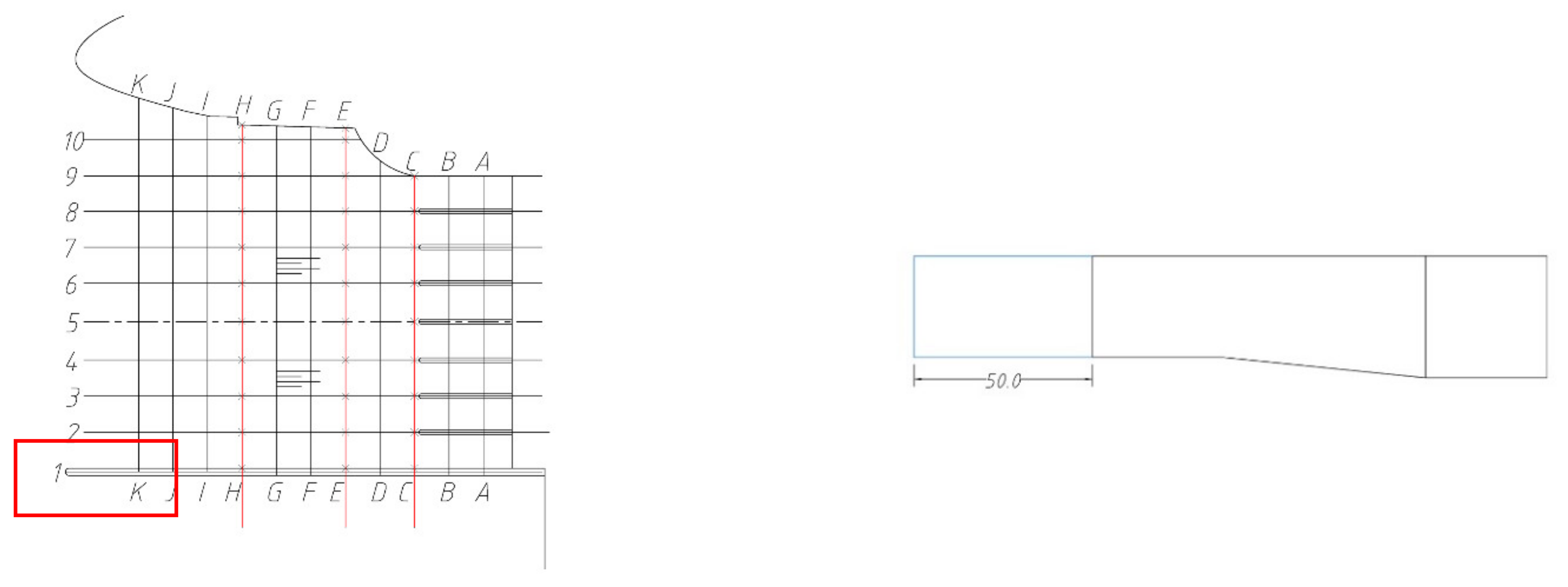

| 3 | Diversion wall | The diversion wall is lengthened by 50 cm (15 m). The shape and arrangement of rectification measures are shown in Figure 9. |

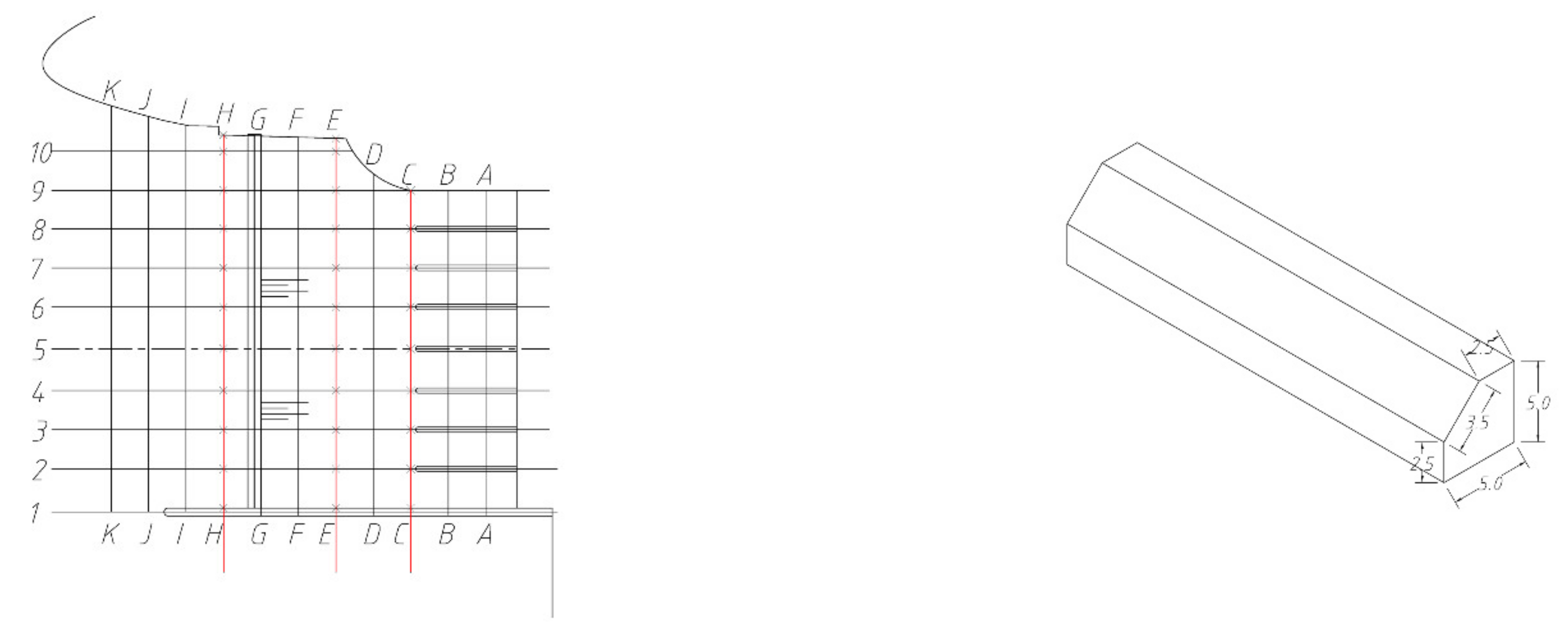

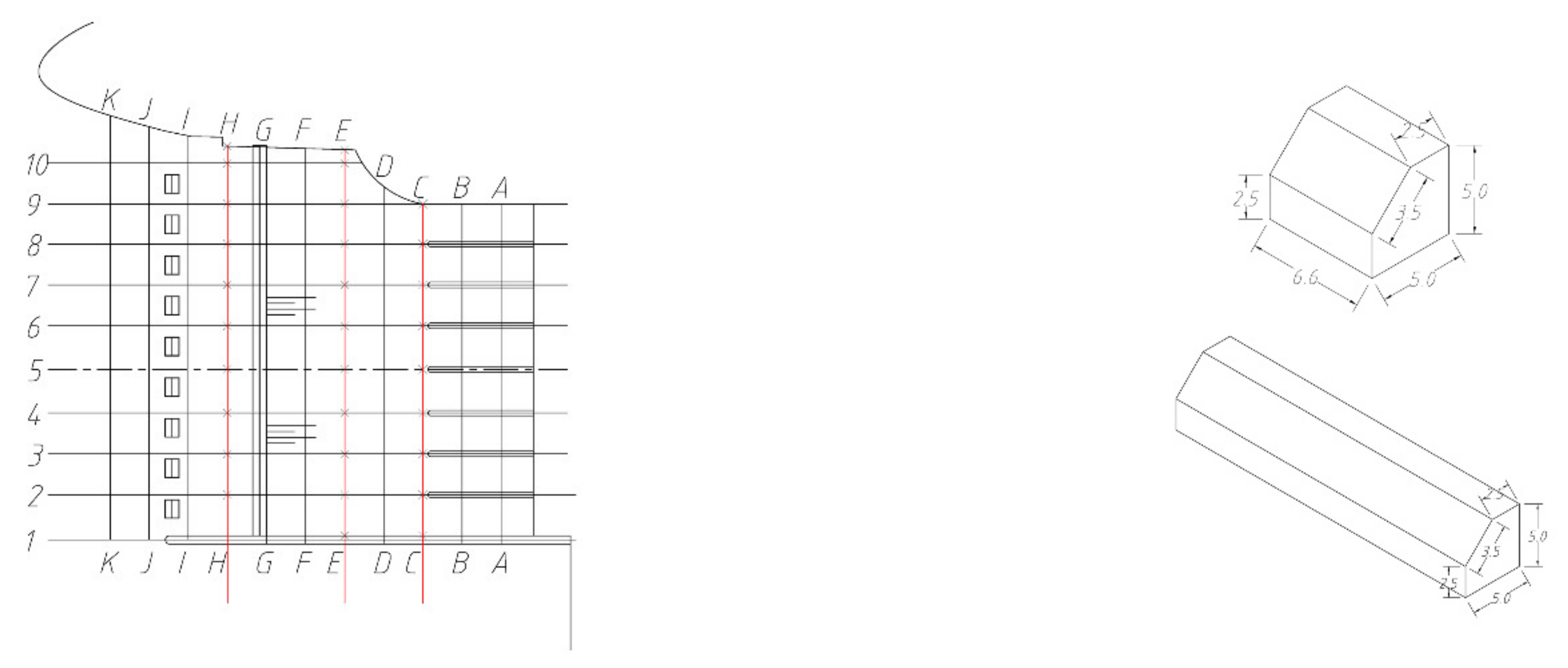

| 4 | Rectifier sill | The bottom width of the sill is 5 cm (1.5 m), the top width is 2.5 cm (0.75 m), and the top elevation is 5 cm (1.5 m). The shape and arrangement of rectification measures are shown in Figure 10. |

| 5 | Rectifier sill and pier | The width of the rectifier pier bottom is 5 cm (1.5 m), top width is 2.5 cm (0.75 m), crest elevation is 5 cm (1.5 m), and length is 6.67 cm (2 m). The shape and arrangement of rectification measures are shown in Figure 11. |

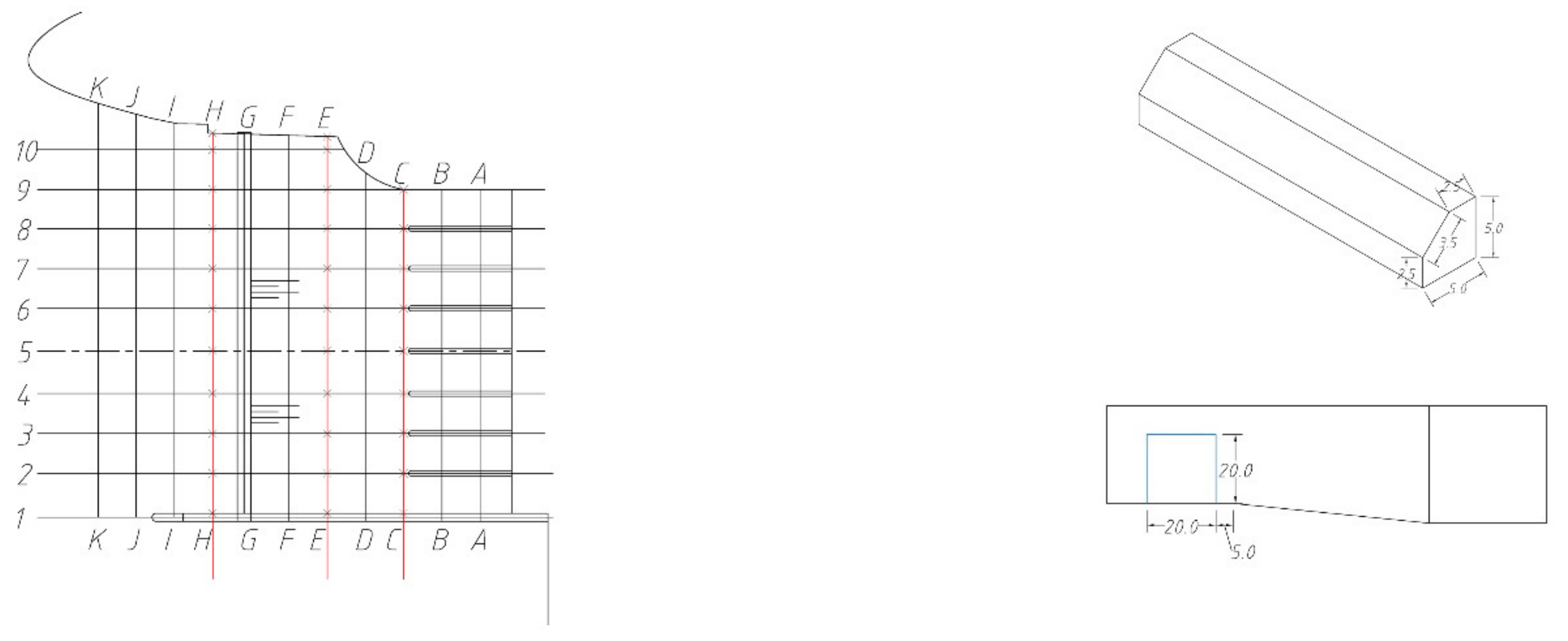

| 6 | Rectifier sill and side opening of diversion wall | The side hole of the diversion wall is 20 × 20 cm (6 × 6 m). The shape and arrangement of rectification measures are shown in Figure 12. |

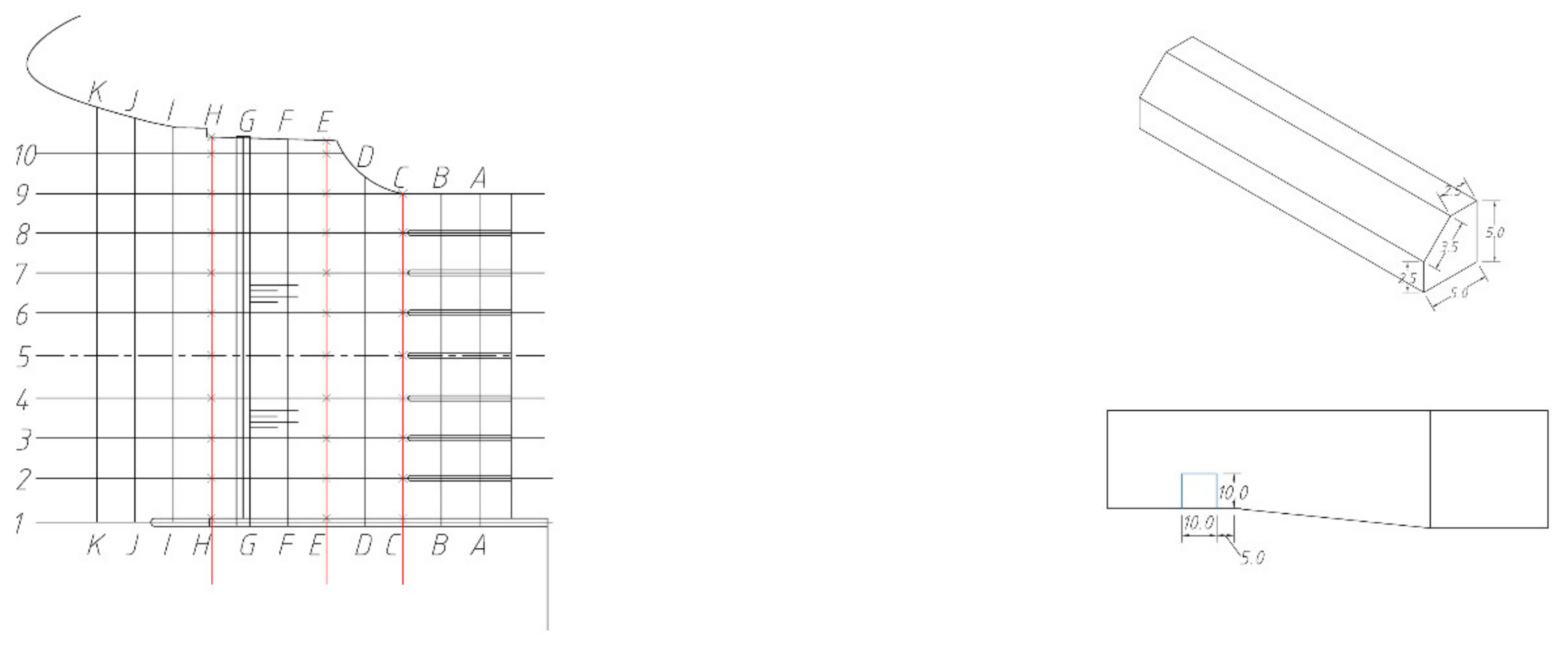

| 7 | Rectifier sill and side opening of diversion wall | The side hole of the diversion wall is 10 × 10 cm (3 × 3 m). The shape and arrangement of rectification measures are shown in Figure 13. |

| Plan Number | Velocity Distribution Uniformity Vu+ (%) | ||

|---|---|---|---|

| C | E | H | |

| 1 | 78.22 | 60.23 | 68.67 |

| 2 | 76.33 | 63.32 | 59.3 |

| 3 | 77.69 | 53.75 | 58.53 |

| 4 | 76.01 | 56.40 | 70.43 |

| 5 | 79.11 | 54.79 | 70.89 |

| 6 | 80.78 | 63.59 | 87.95 |

| 7 | 82.55 | 63.97 | 82.61 |

| Plan Number | Vortex Area (m2) | Area Ratio (%) | Reduction Rate (%) |

|---|---|---|---|

| 1 | 0.284 | 13.590 | — |

| 2 | 0.099 | 4.742 | 65.107 |

| 3 | 0.358 | 17.113 | −25.923 |

| 4 | 0.004 | 0.167 | 98.769 |

| 5 | 0.004 | 0.177 | 98.699 |

| 6 | 0.039 | 1.883 | 86.141 |

| 7 | 0.022 | 1.033 | 92.402 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, F.; Zhang, Y.; Liu, C.; Wang, T.; Jiang, D.; Jin, Y. Numerical and Experimental Investigations of Flow Pattern and Anti-Vortex Measures of Forebay in a Multi-Unit Pumping Station. Water 2021, 13, 935. https://doi.org/10.3390/w13070935

Yang F, Zhang Y, Liu C, Wang T, Jiang D, Jin Y. Numerical and Experimental Investigations of Flow Pattern and Anti-Vortex Measures of Forebay in a Multi-Unit Pumping Station. Water. 2021; 13(7):935. https://doi.org/10.3390/w13070935

Chicago/Turabian StyleYang, Fan, Yiqi Zhang, Chao Liu, Tieli Wang, Dongjin Jiang, and Yan Jin. 2021. "Numerical and Experimental Investigations of Flow Pattern and Anti-Vortex Measures of Forebay in a Multi-Unit Pumping Station" Water 13, no. 7: 935. https://doi.org/10.3390/w13070935

APA StyleYang, F., Zhang, Y., Liu, C., Wang, T., Jiang, D., & Jin, Y. (2021). Numerical and Experimental Investigations of Flow Pattern and Anti-Vortex Measures of Forebay in a Multi-Unit Pumping Station. Water, 13(7), 935. https://doi.org/10.3390/w13070935