The Effect of Sedimentin Yellow River on Hydraulic Characteristics of Spray Sprinkler

Abstract

:1. Introduction

2. Material and Methods

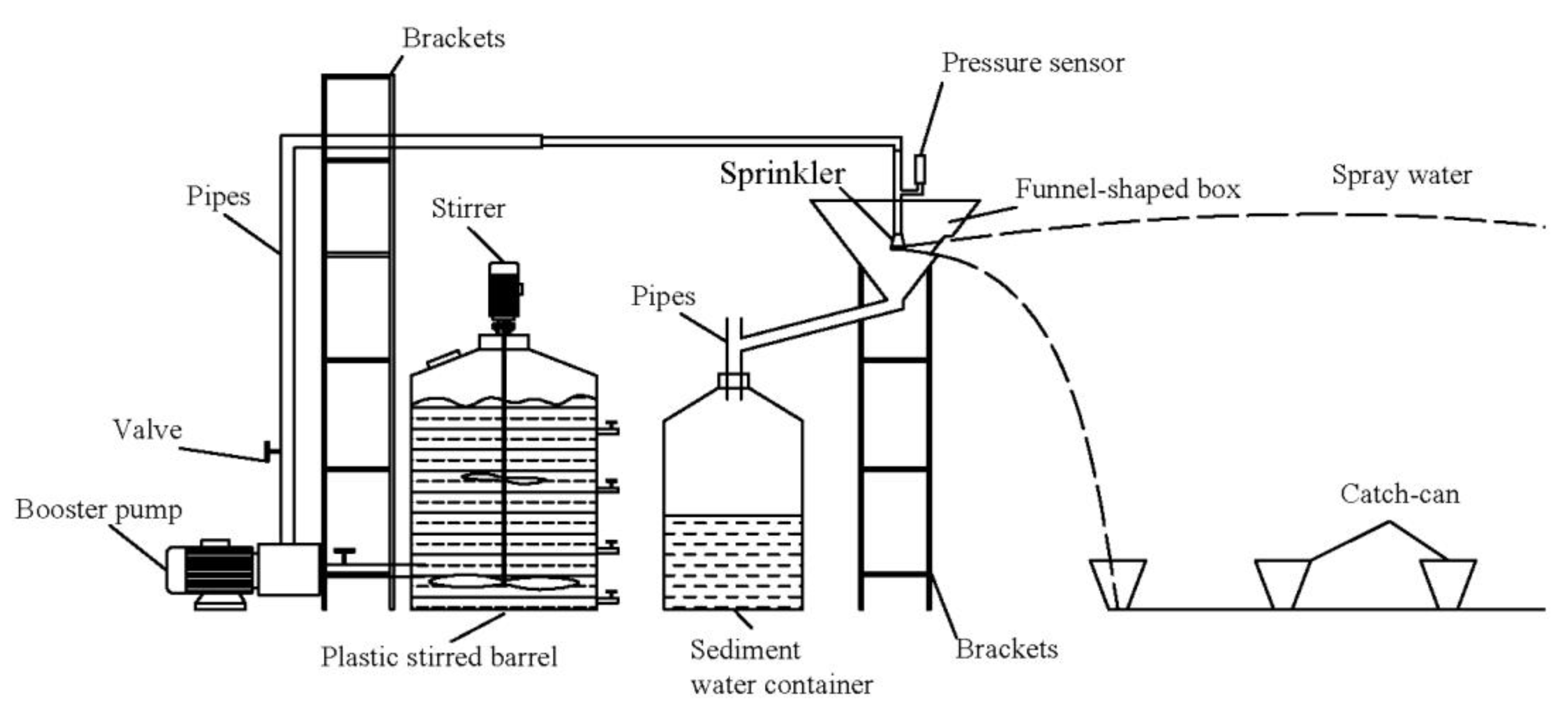

2.1. Indoor Experimental Setup

2.2. Experimental Design

2.3. Data Analysis

3. Results

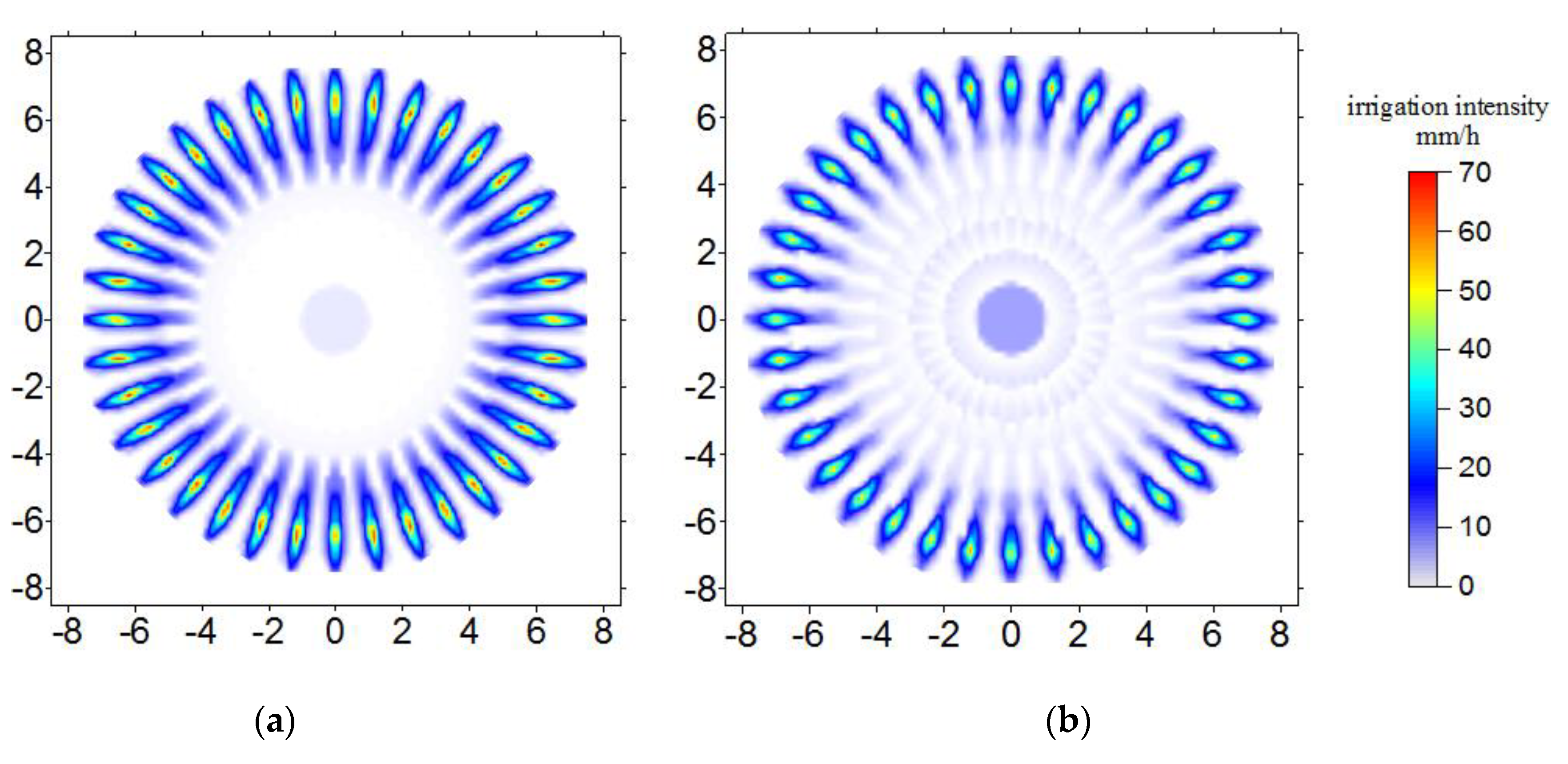

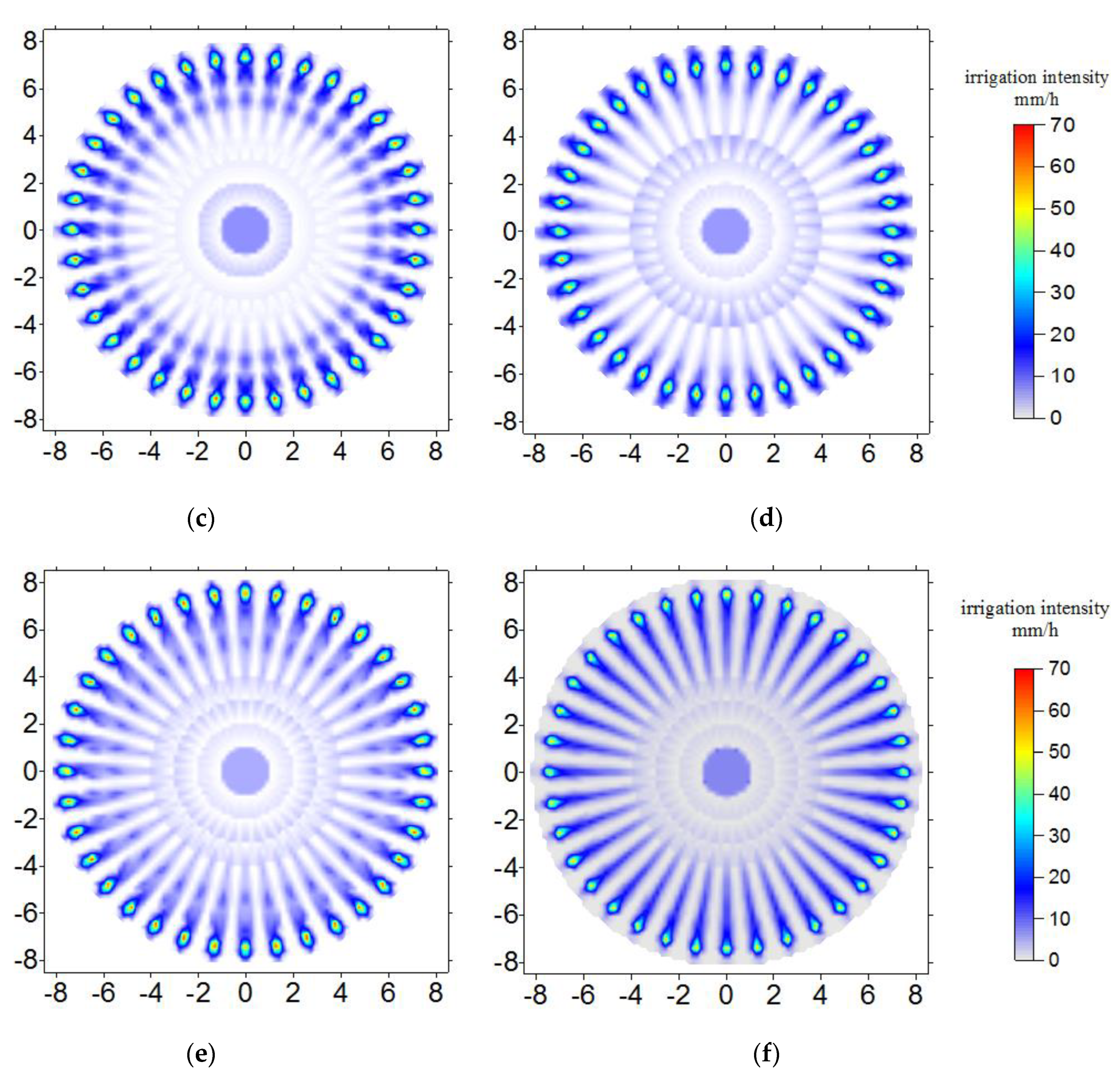

3.1. Water and Sediment Distribution of One Groove

3.2. Water Distribution

3.3. Spray Distance

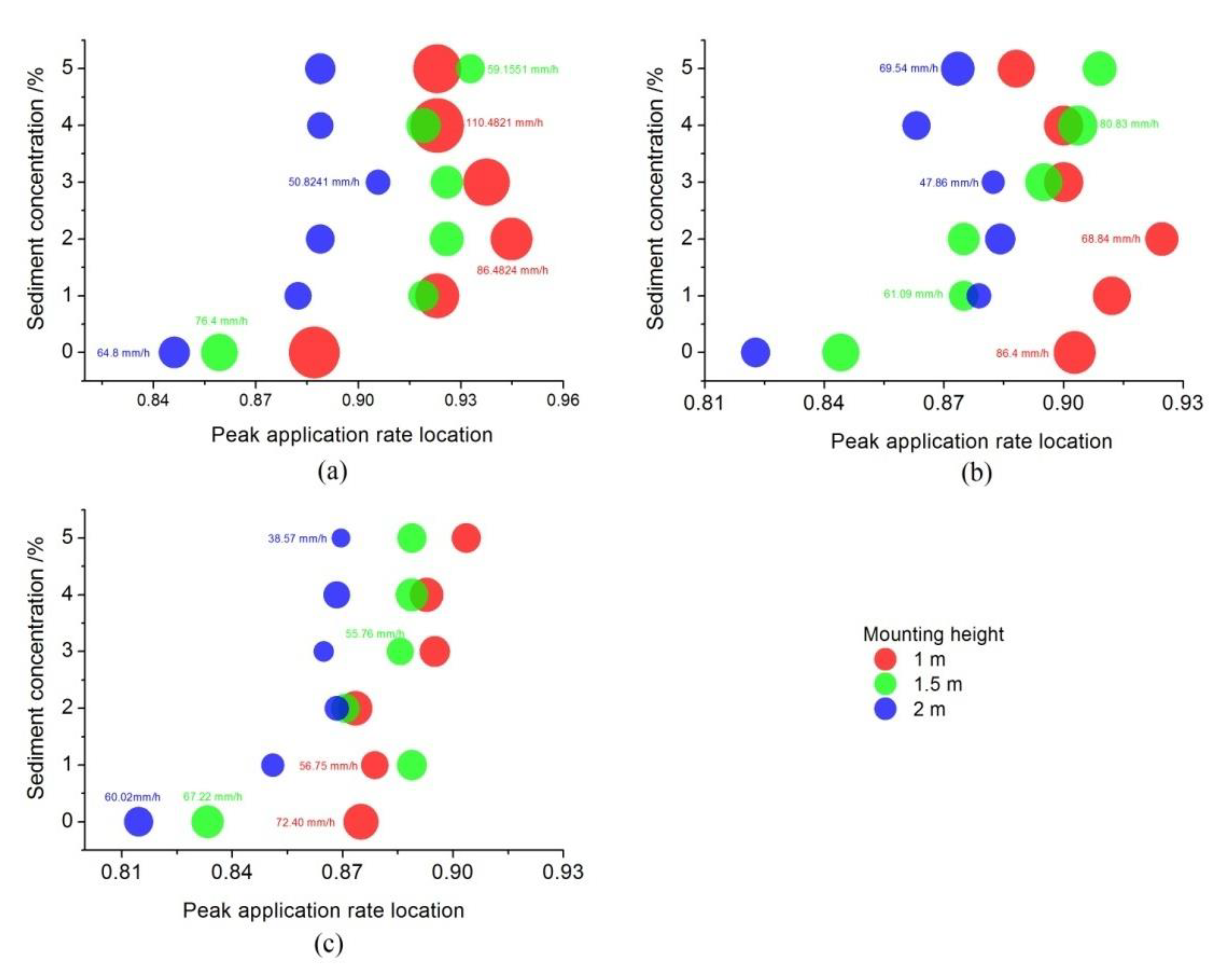

3.4. Peak Application Rate

3.5. Spray Water Diffusion

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Feng, K.; Siu, Y.L.; Guan, D.; Hubacek, K. Assessing regional virtual water flows and water footprints in the Yellow River Basin, China: A consumption based approach. Appl. Geogr. 2012, 32, 691–701. [Google Scholar] [CrossRef]

- Zhao, G.; Tian, P.; Mu, X.; Jiao, J.; Wang, F.; Gao, P. Quantifying the impact of climate variability and human activities on streamflow in the middle reaches of the Yellow River basin, China. J. Hydrol. 2014, 519, 387–398. [Google Scholar] [CrossRef]

- Liu, L.; Ma, J.; Hao, X.; Li, Q. Limitations of Water Resources to Crop Water Requirement in the Irrigation Districts along the Lower Reach of the Yellow River in China. Sustainability 2019, 11, 4680. [Google Scholar] [CrossRef] [Green Version]

- Ayars, J.; Phene, C.; Hutmacher, R.; Davis, K.; Schoneman, R.; Vail, S.; Mead, R. Subsurface drip irrigation of row crops: A review of 15 years of research at the Water Management Research Laboratory. Agric. Water Manag. 1999, 42, 1–27. [Google Scholar] [CrossRef]

- Wang, R.; Kang, Y.; Wan, S.; Hu, W.; Liu, S.; Liu, S. Salt distribution and the growth of cotton under different drip irrigation regimes in a saline area. Agric. Water Manag. 2011, 100, 58–69. [Google Scholar] [CrossRef]

- Wang, R.; Kang, Y.; Wan, S. Effects of different drip irrigation regimes on saline–sodic soil nutrients and cotton yield in an arid region of Northwest China. Agric. Water Manag. 2015, 153, 1–8. [Google Scholar] [CrossRef]

- Wang, Z.; Liao, R.; Lin, H.; Jiang, G.; He, X.; Wu, W.; Zhangzhong, L. Effects of drip irrigation levels on soil water, salinity and wheat growth in North China. Int. J. Agric. Boil. Eng. 2018, 11, 146–156. [Google Scholar] [CrossRef]

- Wang, T.; Guo, Z.; Kuo, C.-T. Effects of mixing Yellow River water with brackish water on the emitter’s clogging substance and solid particles in drip irrigation. SN Appl. Sci. 2019, 1, 1269. [Google Scholar] [CrossRef] [Green Version]

- Yan, H.; Hui, X.; Li, M.; Xu, Y. Development in sprinkler irrigation technology in China. Irrig. Drain. 2020, 1–13. [Google Scholar] [CrossRef]

- Mingzhou, Q.; Jackson, R.H.; Zhongjin, Y.; Jackson, M.W.; Bo, S. The effects of sediment-laden waters on irrigated lands along the lower Yellow River in China. J. Environ. Manag. 2007, 85, 858–865. [Google Scholar] [CrossRef]

- Playán, E.; Mateos, L. Modernization and optimization of irrigation systems to increase water productivity. Agric. Water Manag. 2006, 80, 100–116. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Guo, J.; Sun, B.; Fang, H.; Zhu, D.; Wang, H. Modeling and Dynamic-Simulating the Water Distribution of a Fixed Spray-Plate Sprinkler on a Lateral-Move Sprinkler Irrigation System. Water 2019, 11, 2296. [Google Scholar] [CrossRef] [Green Version]

- Clark, G.A.; Srinivas, K.; Rogers, D.H.; Stratton, R.; Martin, V.L. Measured and simulated uniformity of low drift nozzle sprinklers. Trans. ASAE 2003, 46, 321–330. [Google Scholar] [CrossRef]

- Kincaid, D.C. Application rates from center pivot irrigation with current sprinkler types. Appl. Eng. Agric. 2005, 21, 605–610. [Google Scholar] [CrossRef]

- Delirhasannia, R.; Sadraddini, A.; Nazemi, A.; Farsadizadeh, D.; Playán, E. Dynamic model for water application using centre pivot irrigation. Biosyst. Eng. 2010, 105, 476–485. [Google Scholar] [CrossRef] [Green Version]

- Faria, L.C.; Nörenberg, B.G.; Colombo, A.; Dukes, M.D.; Timm, L.C.; Beskow, S.; Caldeira, T.L. Irrigation distribution uniformity analysis on a lateral-move irrigation system. Irrig. Sci. 2019, 37, 195–206. [Google Scholar] [CrossRef]

- Faci, J.; Salvador, R.; Playán, E.; Sourell, H. Comparison of Fixed and Rotating Spray Plate Sprinklers. J. Irrig. Drain. Eng. 2001, 127, 224–233. [Google Scholar] [CrossRef] [Green Version]

- Yan, H.; Jin, H.; Qian, Y. Characterizing center pivot irrigation with fixed spray plate sprinklers. Sci. China Ser. E Technol. Sci. 2010, 53, 1398–1405. [Google Scholar] [CrossRef]

- Sayyadi, H.; Nazemi, A.H.; Sadraddini, A.A.; Delirhasannia, R. Characterising droplets and precipitation profiles of a fixed spray-plate sprinkler. Biosyst. Eng. 2014, 119, 13–24. [Google Scholar] [CrossRef]

- Su, D.; Wang, Y.; Han, L.; Su, D. Comparison of Water Distribution Characteristics for Two Kinds of Sprinklers Used for Center Pivot Irrigation Systems. Appl. Sci. 2017, 7, 421. [Google Scholar] [CrossRef] [Green Version]

- Ouazaa, S.; Burguete, J.; Paniagua, P.; Salvador, R.; Zapata, N. Simulating water distribution patterns for fixed spray plate sprinkler using the ballistic theory. Span. J. Agric. Res. 2014, 12, 850–863. [Google Scholar] [CrossRef] [Green Version]

- Hanson, B.; Orloff, S.B. Rotator nozzles more uniform than spray nozzles on center-pivot sprinklers. Calif. Agric. 1996, 50, 32–35. [Google Scholar] [CrossRef]

- Hills, D.J.; Barragan, J. Application uniformity for fixed and rotating spray plate sprinklers. Appl. Eng. Agric. 1998, 14, 33–36. [Google Scholar] [CrossRef]

- Rovelo, C.O.R.; Ruiz, N.Z.; Tolosa, J.B.; Félix, J.R.F.; Latorre, B. Characterization and Simulation of a Low-Pressure Rotator Spray Plate Sprinkler Used in Center Pivot Irrigation Systems. Water 2019, 11, 1684. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Sun, B.; Fang, H.; Zhu, D.; Yang, L.; Li, Z. Experimental and Simulation Investigation on the Kinetic Energy Dissipation Rate of a Fixed Spray-Plate Sprinkler. Water 2018, 10, 1365. [Google Scholar] [CrossRef] [Green Version]

- Bohnet, M.; Niesmak, G. Distribution of solids in stirred suspensions. Ger. Chem. Eng. 1980, 3, 57–65. [Google Scholar]

| Levels | Experimental Factors | ||

|---|---|---|---|

| Sediment Concentration | Mounting Height | Working Pressure | |

| (Mass Percent/%) | (m) | (kPa) | |

| 1 | 1 | 1 | 100 |

| 2 | 2 | 1.5 | 150 |

| 3 | 3 | 2 | 200 |

| 4 | 4 | ||

| 5 | 5 | ||

| Working Pressure/kPa | Sediment Concentration/% | Mounting Height/m | Increasing Ratio/% | ||||

|---|---|---|---|---|---|---|---|

| 1 | 1.5 | 2 | 1 | 1.5 | 2 | ||

| 100 | 0 | 6.20 | 6.40 | 6.50 | 0 | 0 | 0 |

| 1 | 6.50 | 6.80 | 6.80 | 4.84 | 6.25 | 4.62 | |

| 2 | 6.35 | 6.75 | 6.75 | 2.42 | 5.47 | 3.85 | |

| 3 | 6.40 | 6.75 | 6.90 | 3.23 | 5.47 | 6.15 | |

| 4 | 6.50 | 6.80 | 6.75 | 4.84 | 6.25 | 3.85 | |

| 5 | 6.50 | 6.70 | 6.75 | 4.84 | 4.69 | 3.85 | |

| 150 | 0 | 7.20 | 7.70 | 7.90 | 0 | 0 | 0 |

| 1 | 7.40 | 8.00 | 8.25 | 2.78 | 3.90 | 4.43 | |

| 2 | 7.30 | 8.00 | 8.20 | 1.39 | 3.90 | 3.80 | |

| 3 | 7.50 | 8.10 | 8.50 | 4.17 | 5.19 | 7.59 | |

| 4 | 7.50 | 8.30 | 8.40 | 4.17 | 7.79 | 6.33 | |

| 5 | 7.60 | 8.25 | 8.30 | 5.56 | 7.14 | 5.06 | |

| 200 | 0 | 8.00 | 8.70 | 8.90 | 0 | 0 | 0 |

| 1 | 8.25 | 9.00 | 9.40 | 3.13 | 3.45 | 5.62 | |

| 2 | 8.30 | 8.90 | 9.50 | 3.75 | 2.30 | 6.74 | |

| 3 | 8.10 | 8.75 | 9.25 | 1.25 | 0.57 | 3.93 | |

| 4 | 8.40 | 9.00 | 9.50 | 5.00 | 3.45 | 6.74 | |

| 5 | 8.30 | 9.00 | 9.20 | 3.75 | 3.45 | 3.37 | |

| Factors | Mean Square | F | sig | Significance |

|---|---|---|---|---|

| Sediment concentration | 40.927 | 8.185 | 0.130 | |

| Mounting height | 204.287 | 102.143 | 0 | ** |

| Working pressure | 254.920 | 107.460 | 0 | ** |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Guo, J.; Wang, H. The Effect of Sedimentin Yellow River on Hydraulic Characteristics of Spray Sprinkler. Water 2020, 12, 1349. https://doi.org/10.3390/w12051349

Zhang Y, Guo J, Wang H. The Effect of Sedimentin Yellow River on Hydraulic Characteristics of Spray Sprinkler. Water. 2020; 12(5):1349. https://doi.org/10.3390/w12051349

Chicago/Turabian StyleZhang, Yisheng, Jinjun Guo, and Huiliang Wang. 2020. "The Effect of Sedimentin Yellow River on Hydraulic Characteristics of Spray Sprinkler" Water 12, no. 5: 1349. https://doi.org/10.3390/w12051349

APA StyleZhang, Y., Guo, J., & Wang, H. (2020). The Effect of Sedimentin Yellow River on Hydraulic Characteristics of Spray Sprinkler. Water, 12(5), 1349. https://doi.org/10.3390/w12051349