Investigation on the Water Flow Evolution in a Filled Fracture under Seepage-Induced Erosion

Abstract

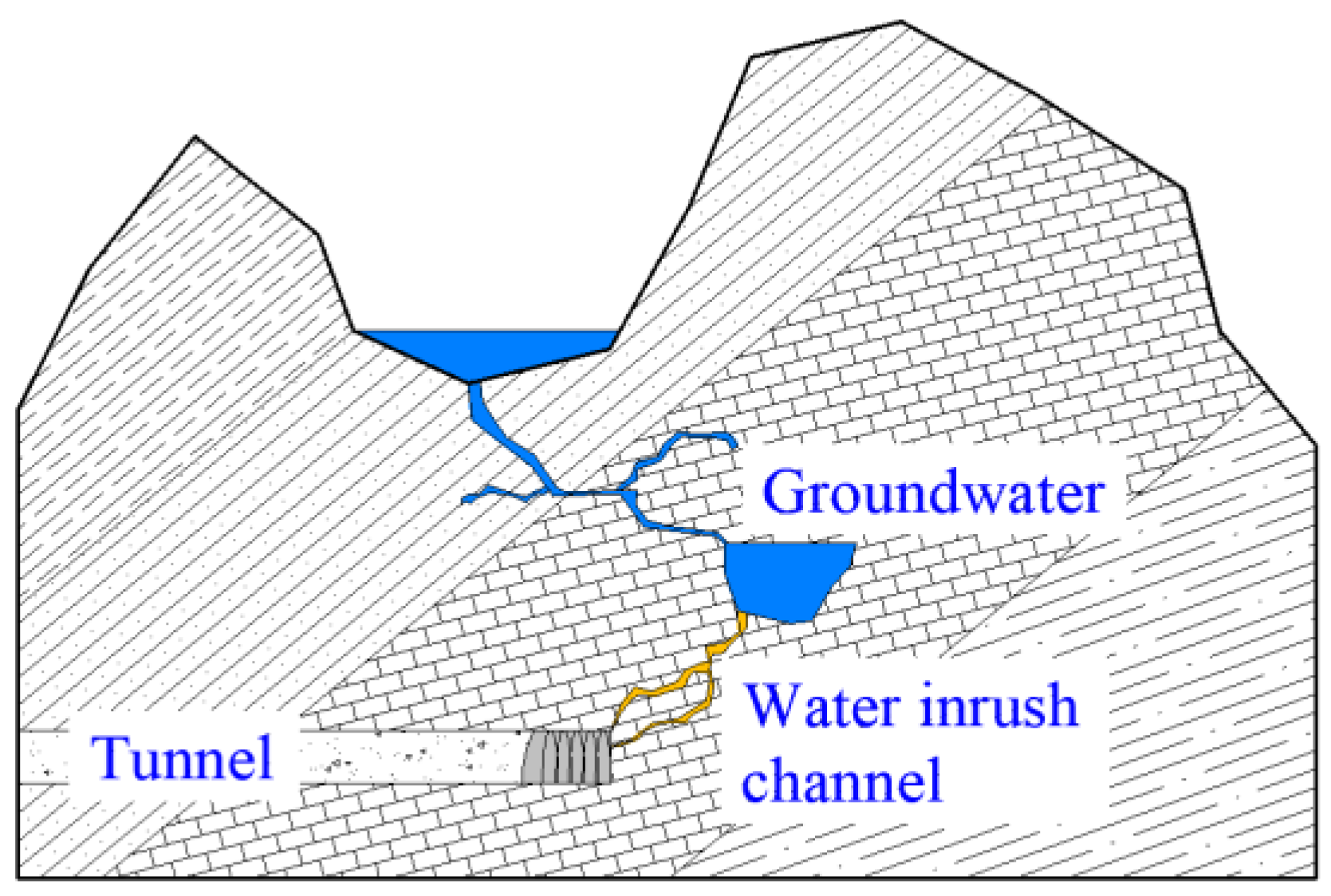

1. Introduction

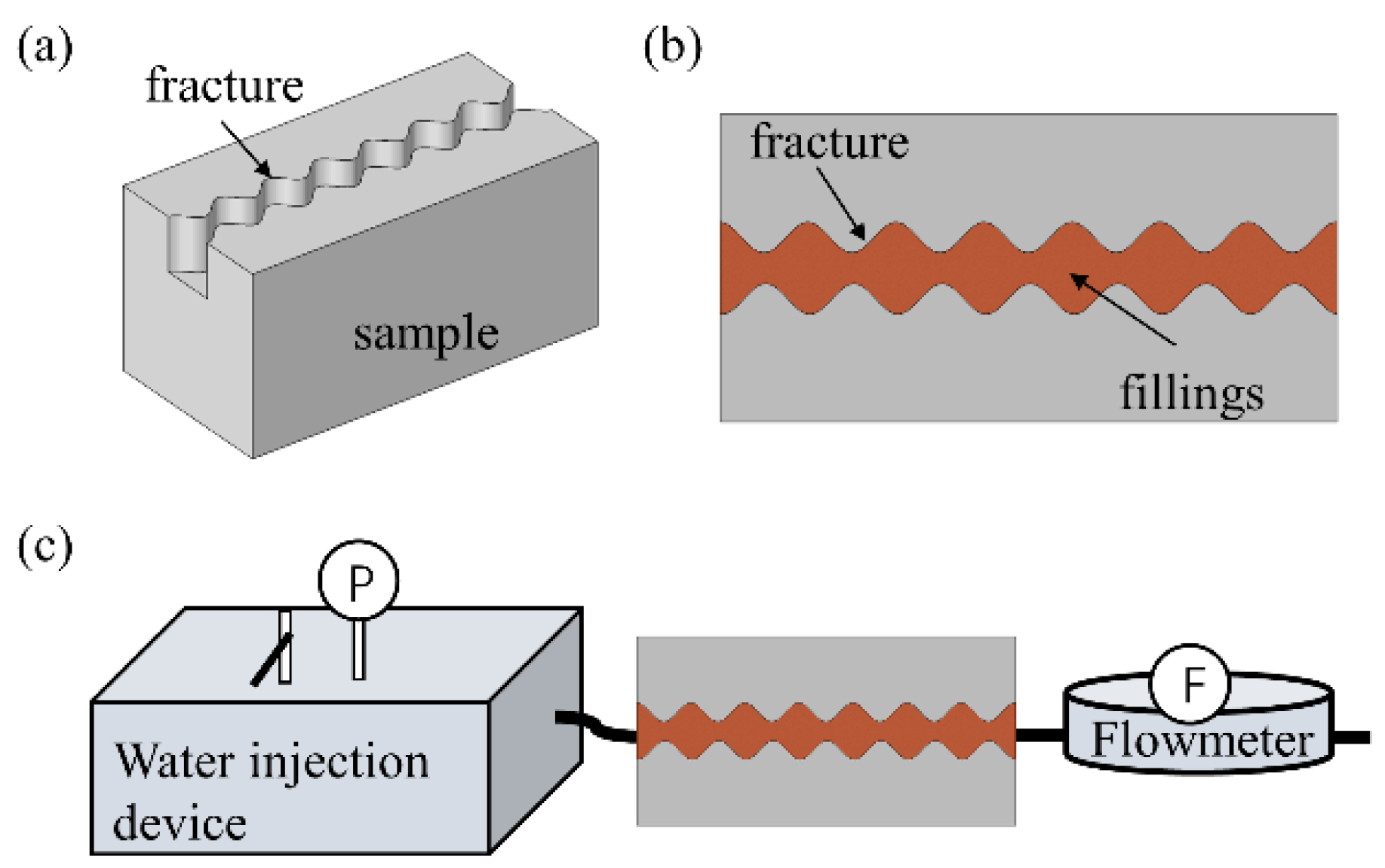

2. Mathematical Model

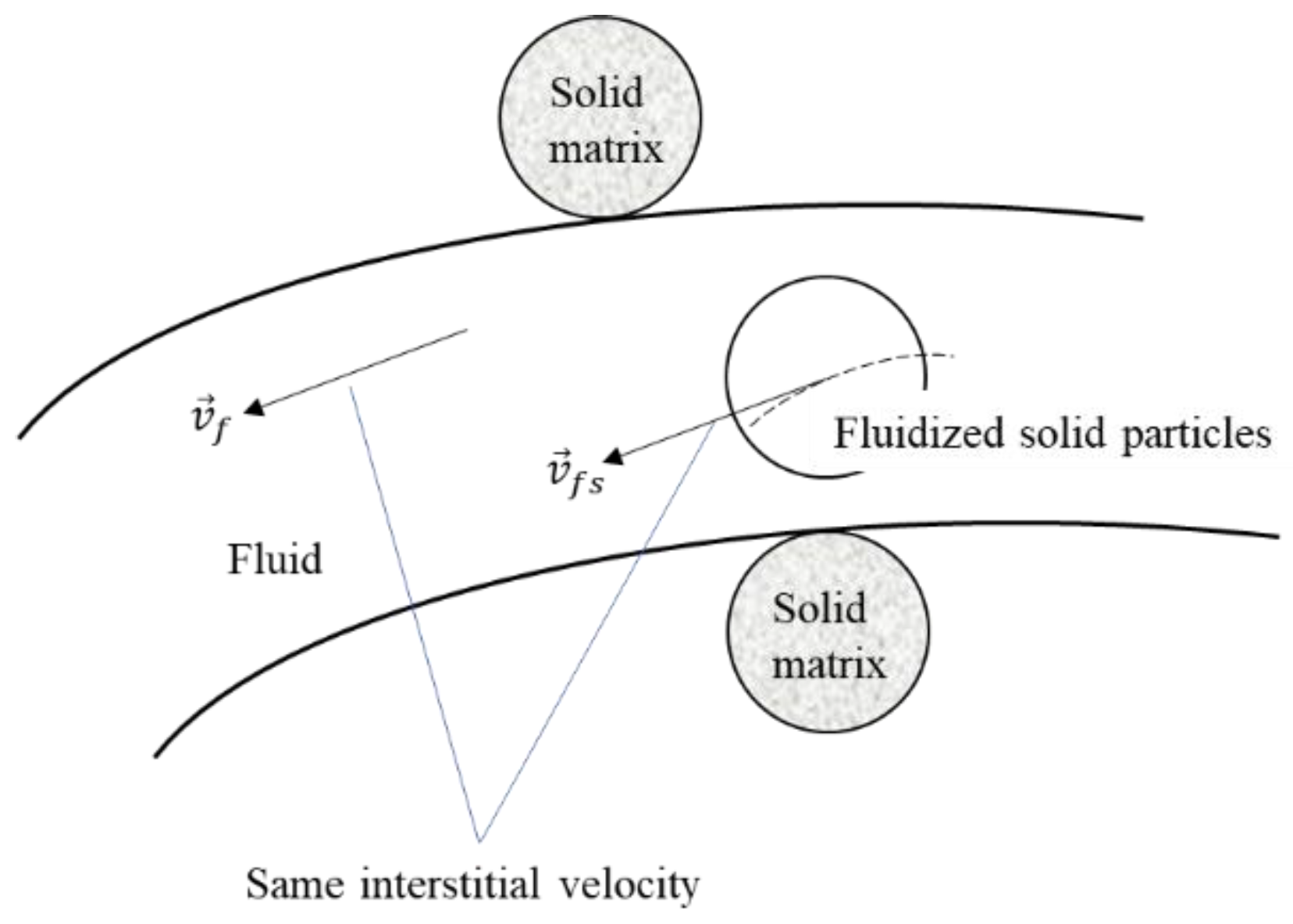

2.1. Basic Assumptions

2.2. Governing Equations

2.2.1. Mass Conservation

2.2.2. Darcy’s Law

2.2.3. Seepage Erosion Equation

2.2.4. Permeability Evolution

2.2.5. Equation Coupling and (Initial) Boundary Conditions

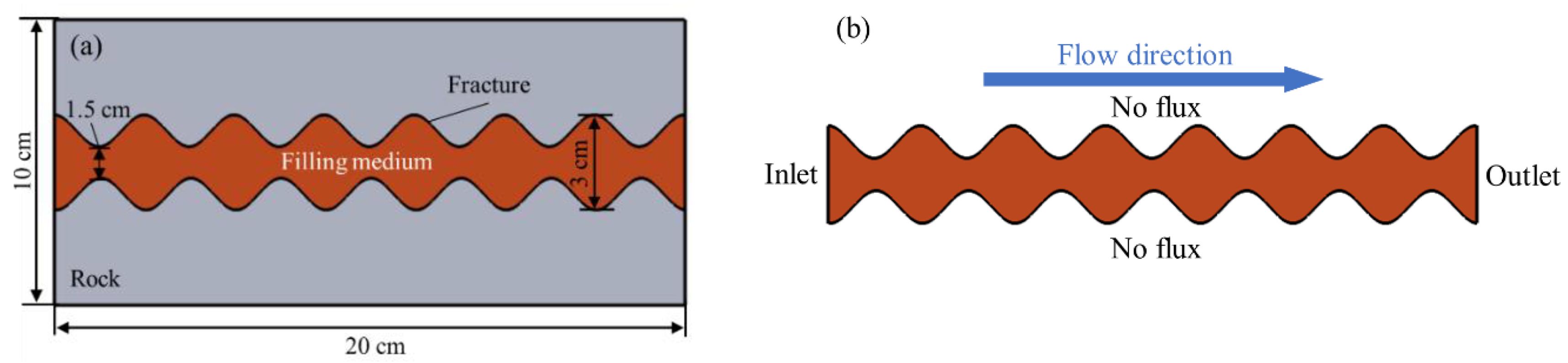

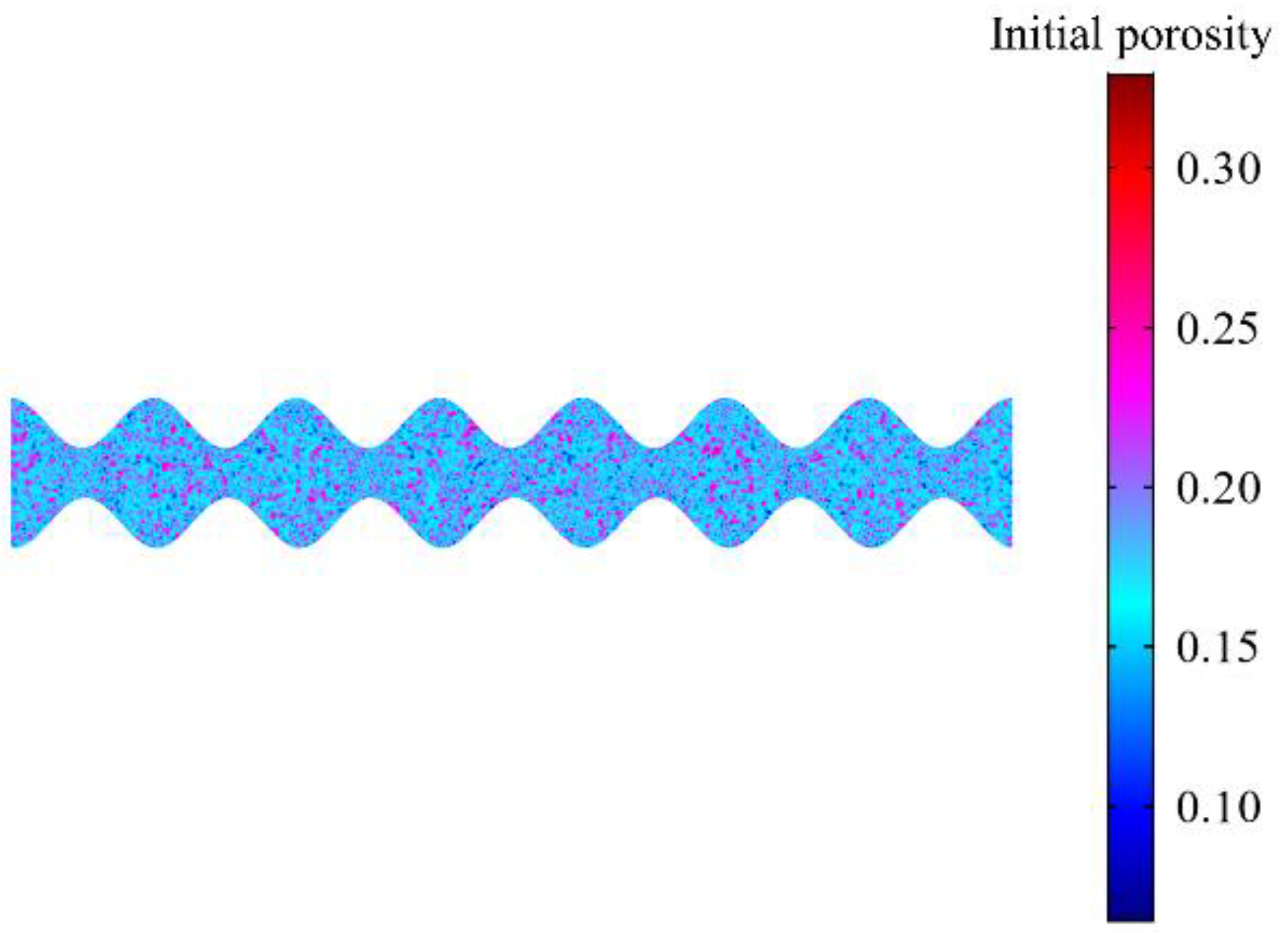

3. Model Implementation

4. Results and Model Validation

4.1. Pore Pressure Distribution

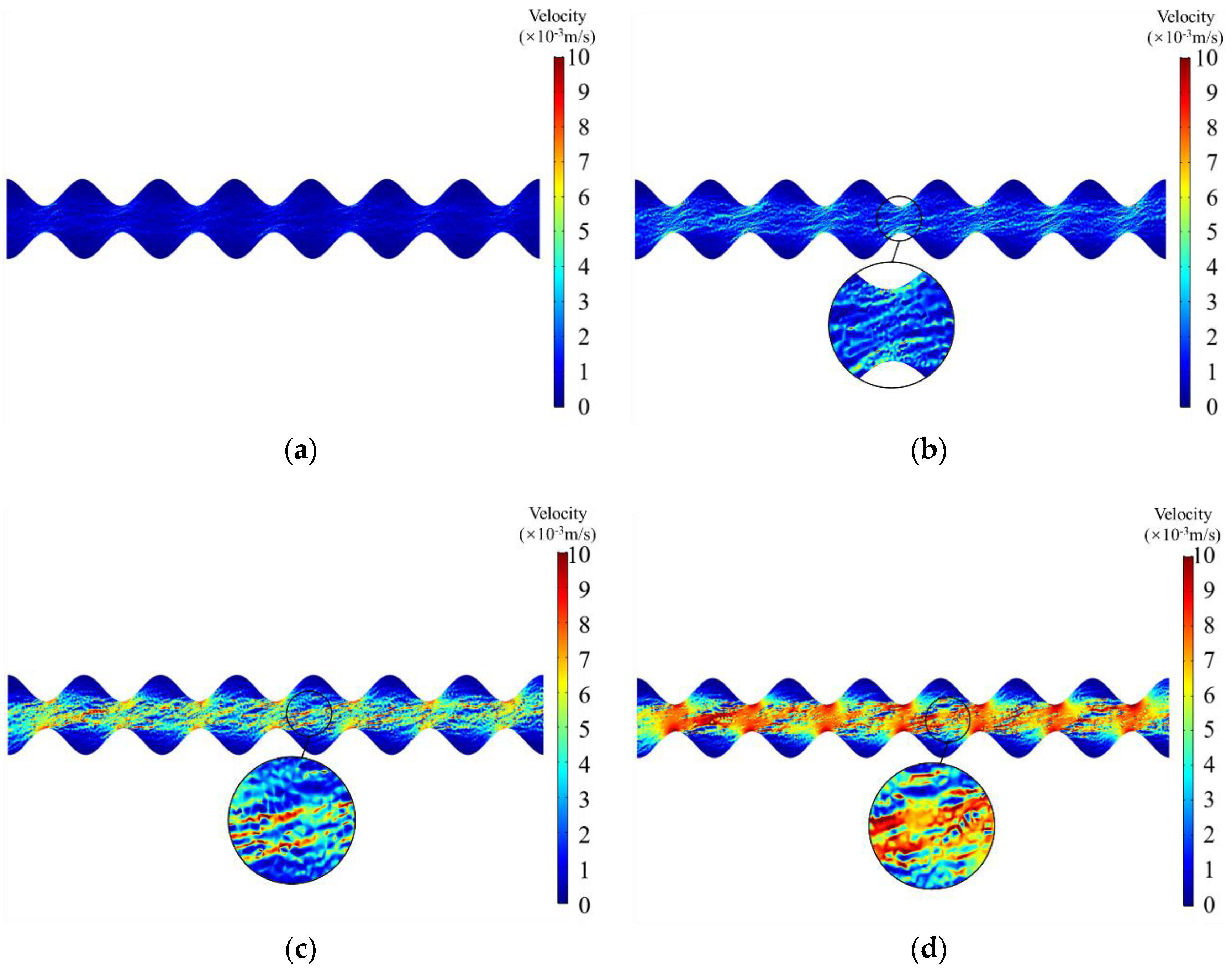

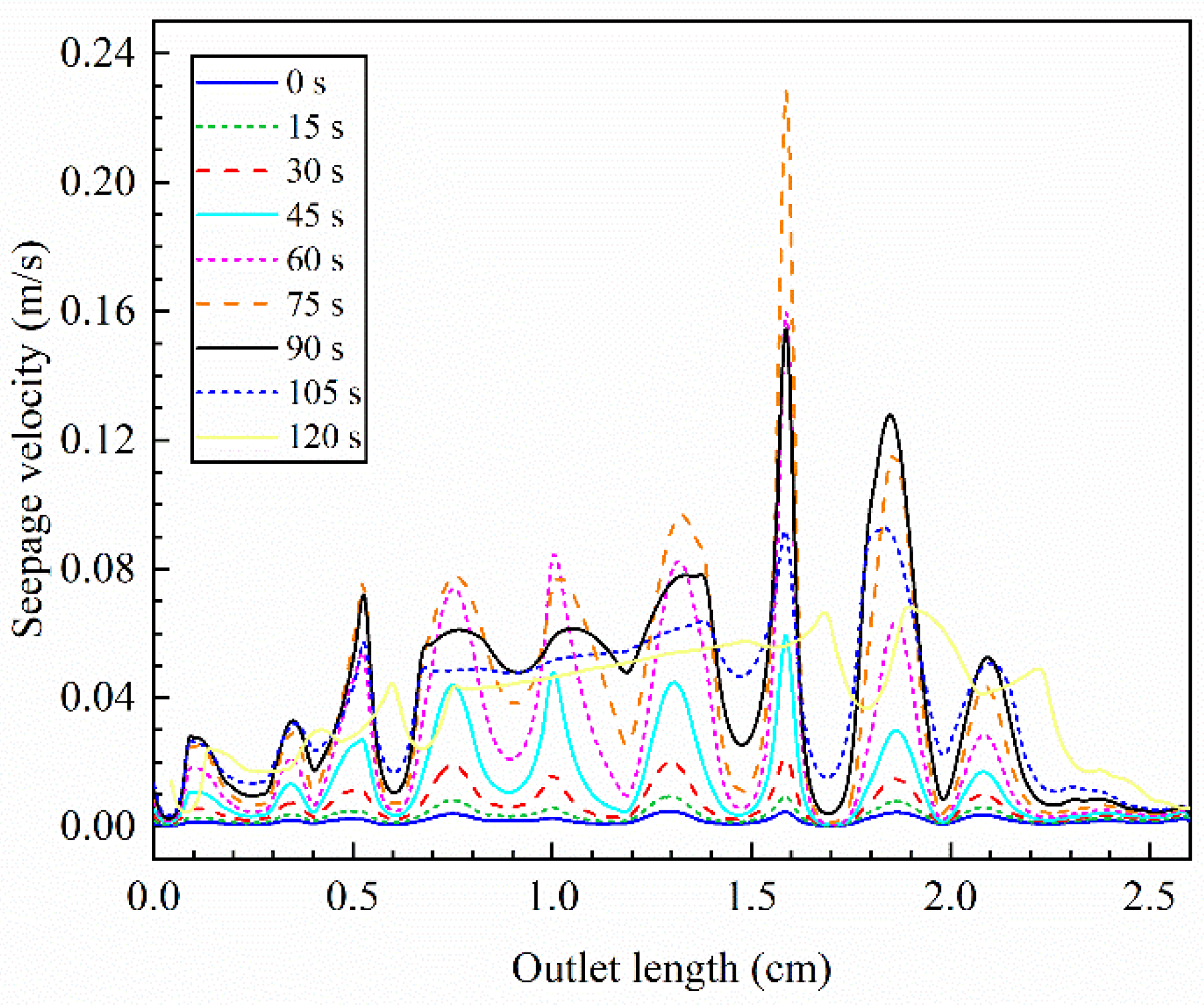

4.2. Evolution of Seepage Velocity

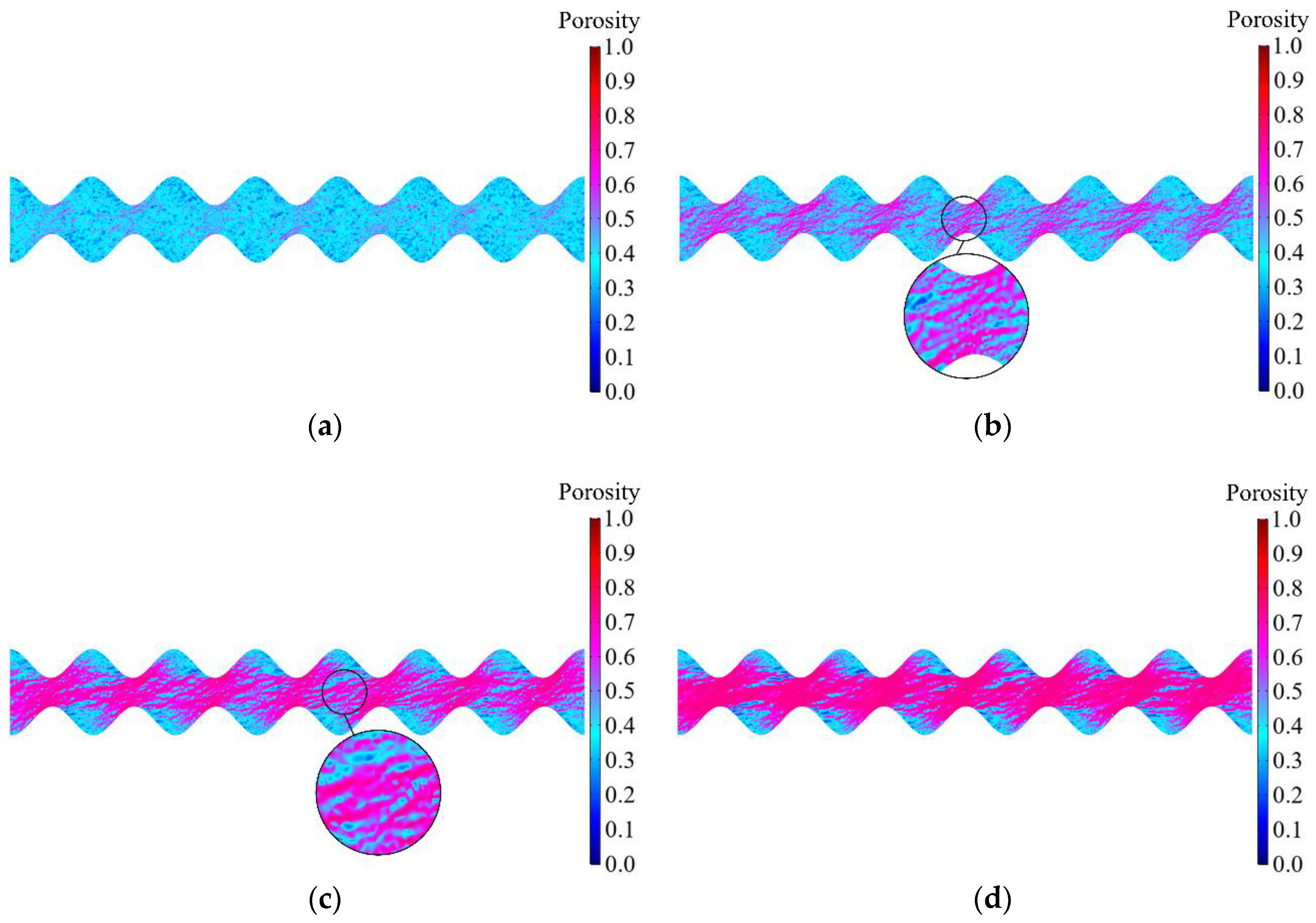

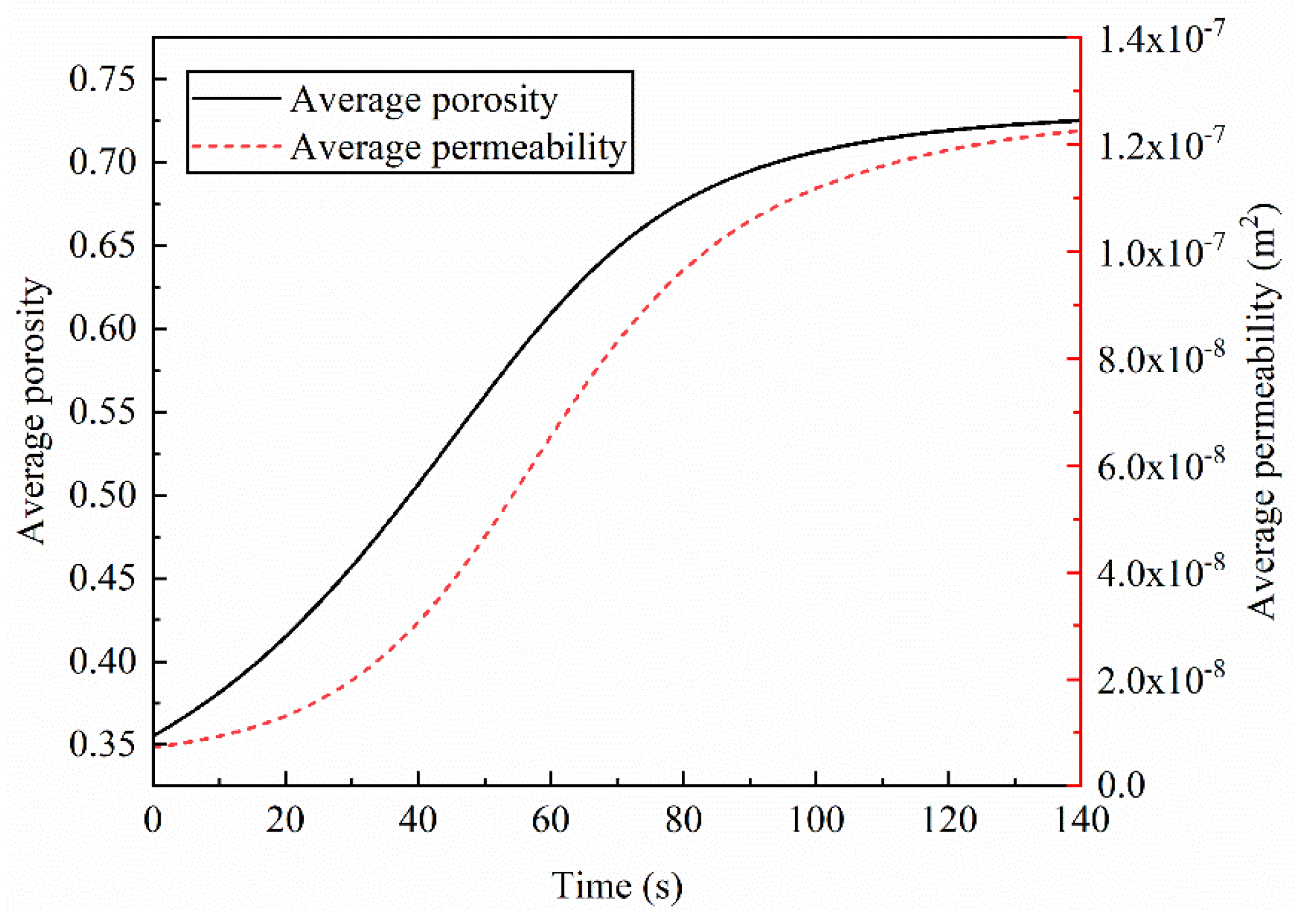

4.3. Evolution of Porosity and Permeability

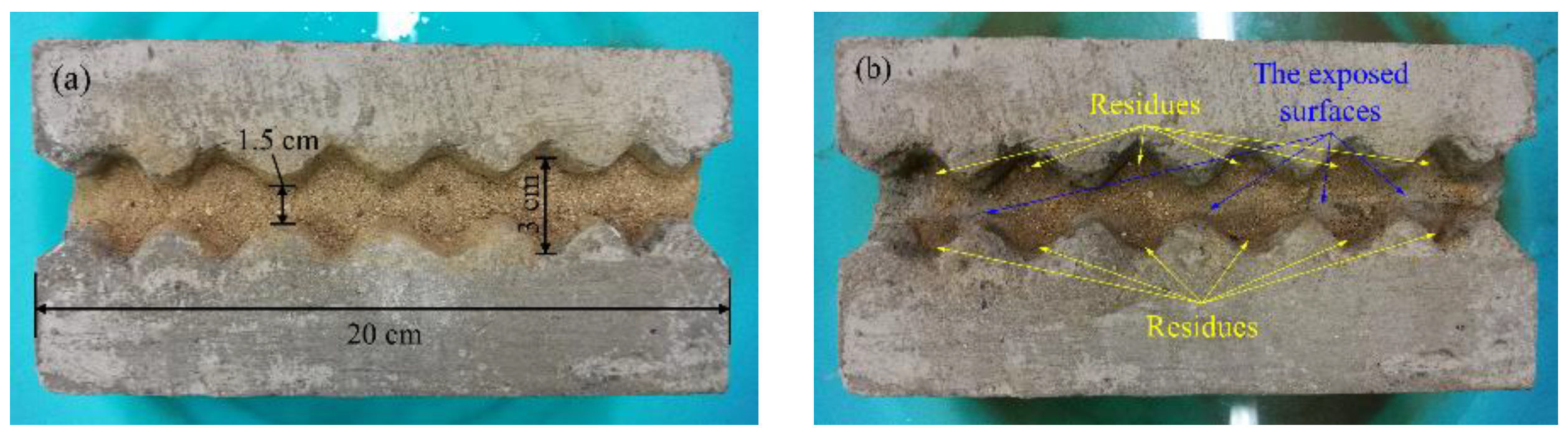

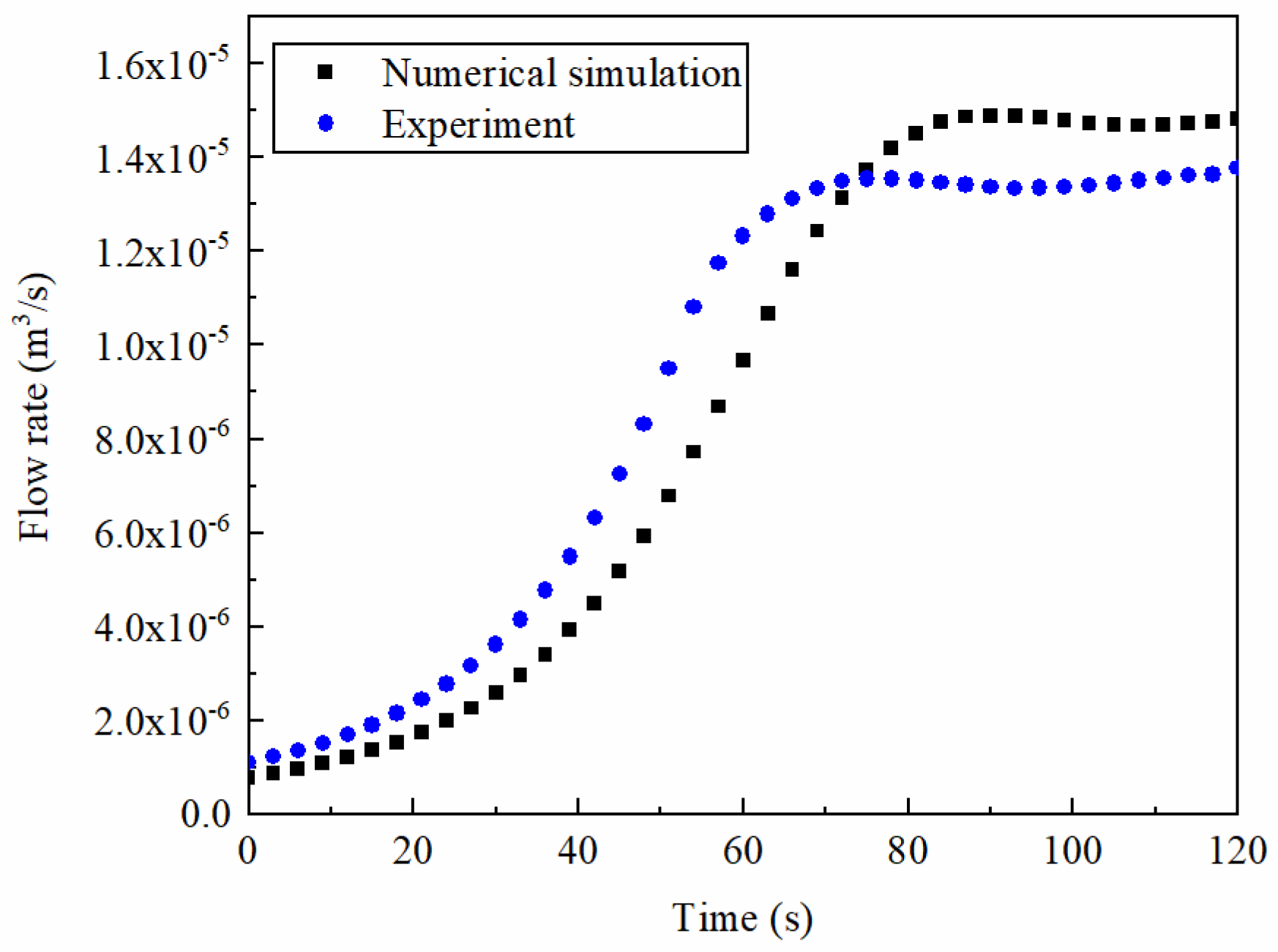

4.4. Model Validation

5. Discussion

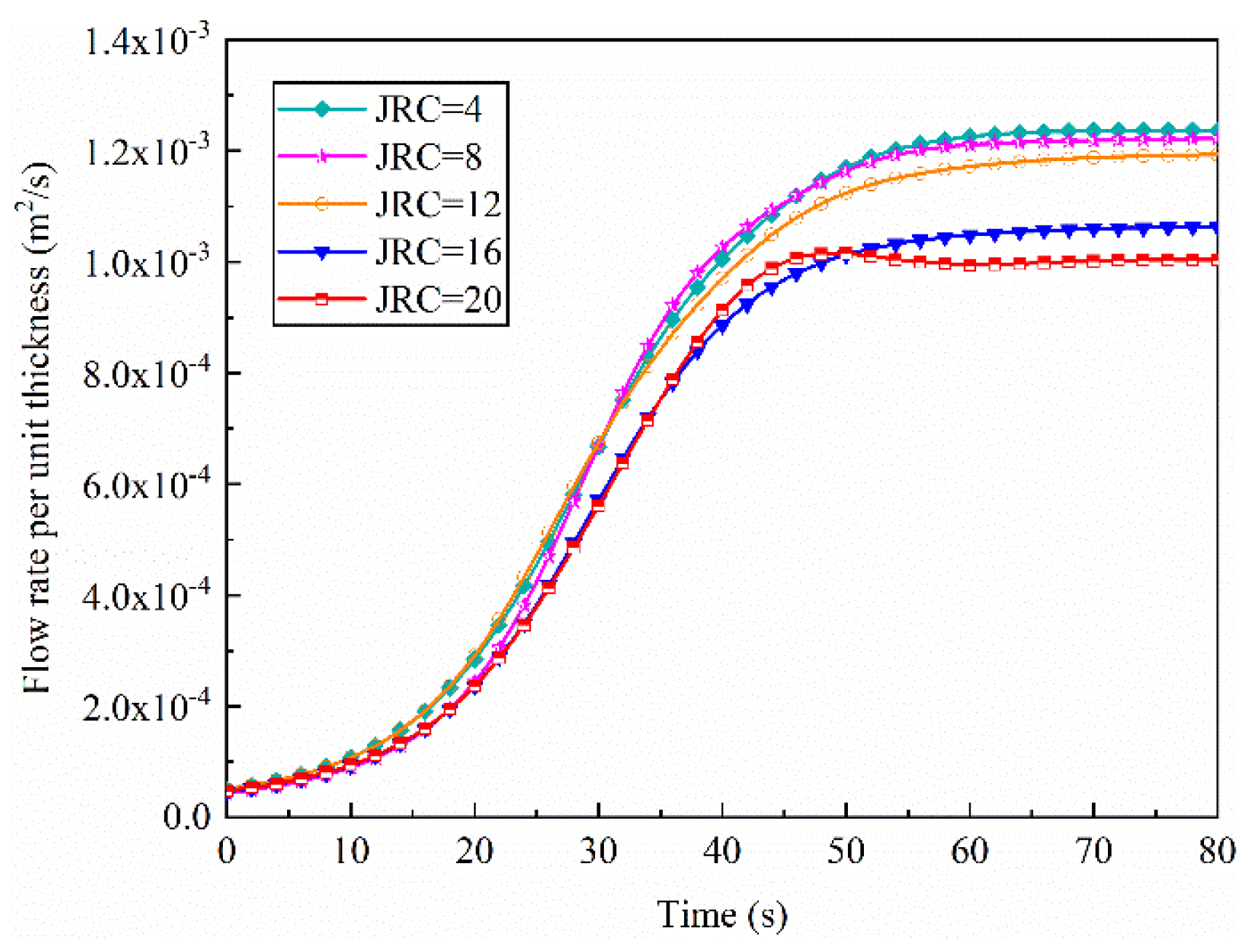

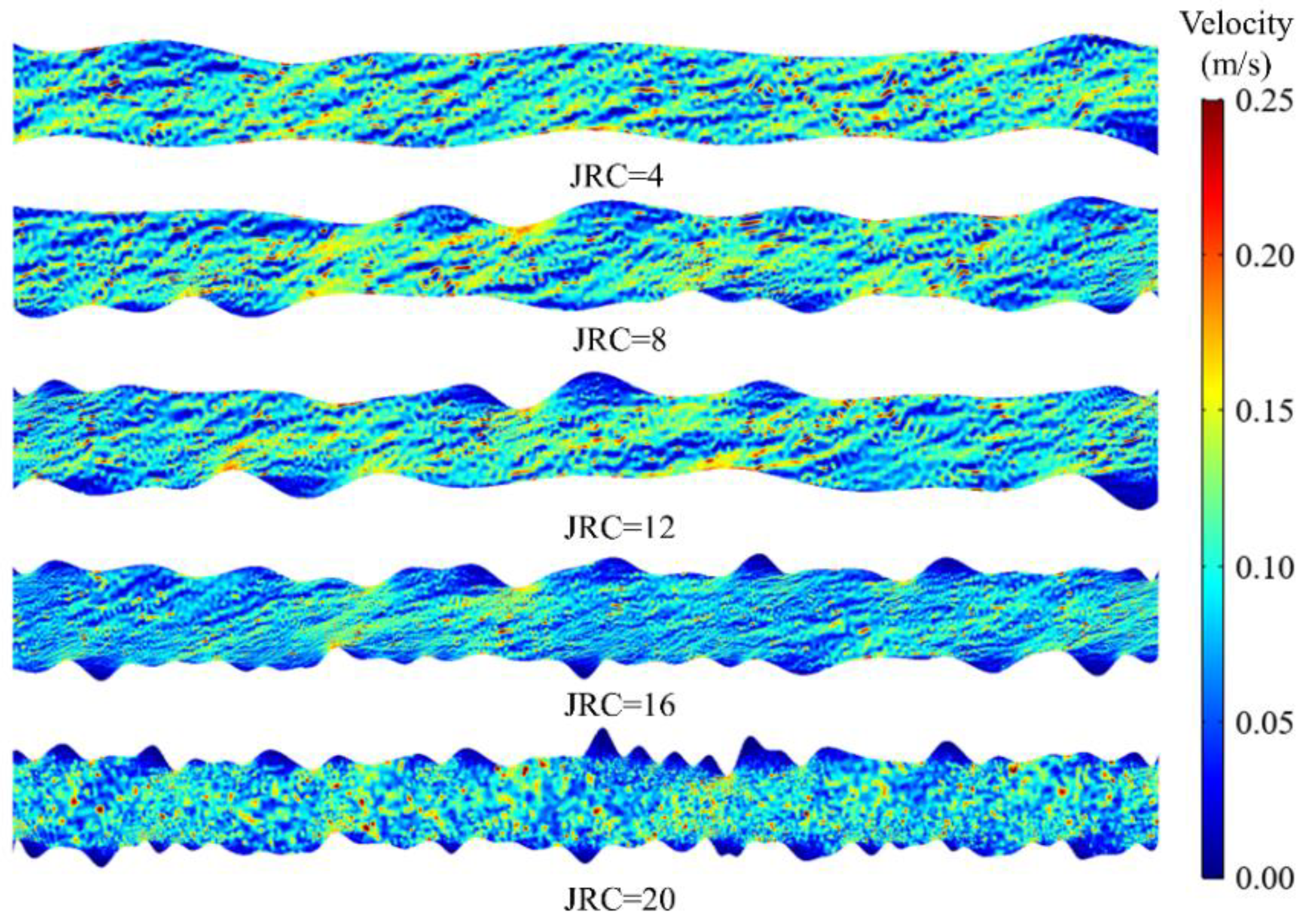

5.1. The Effect of JRC

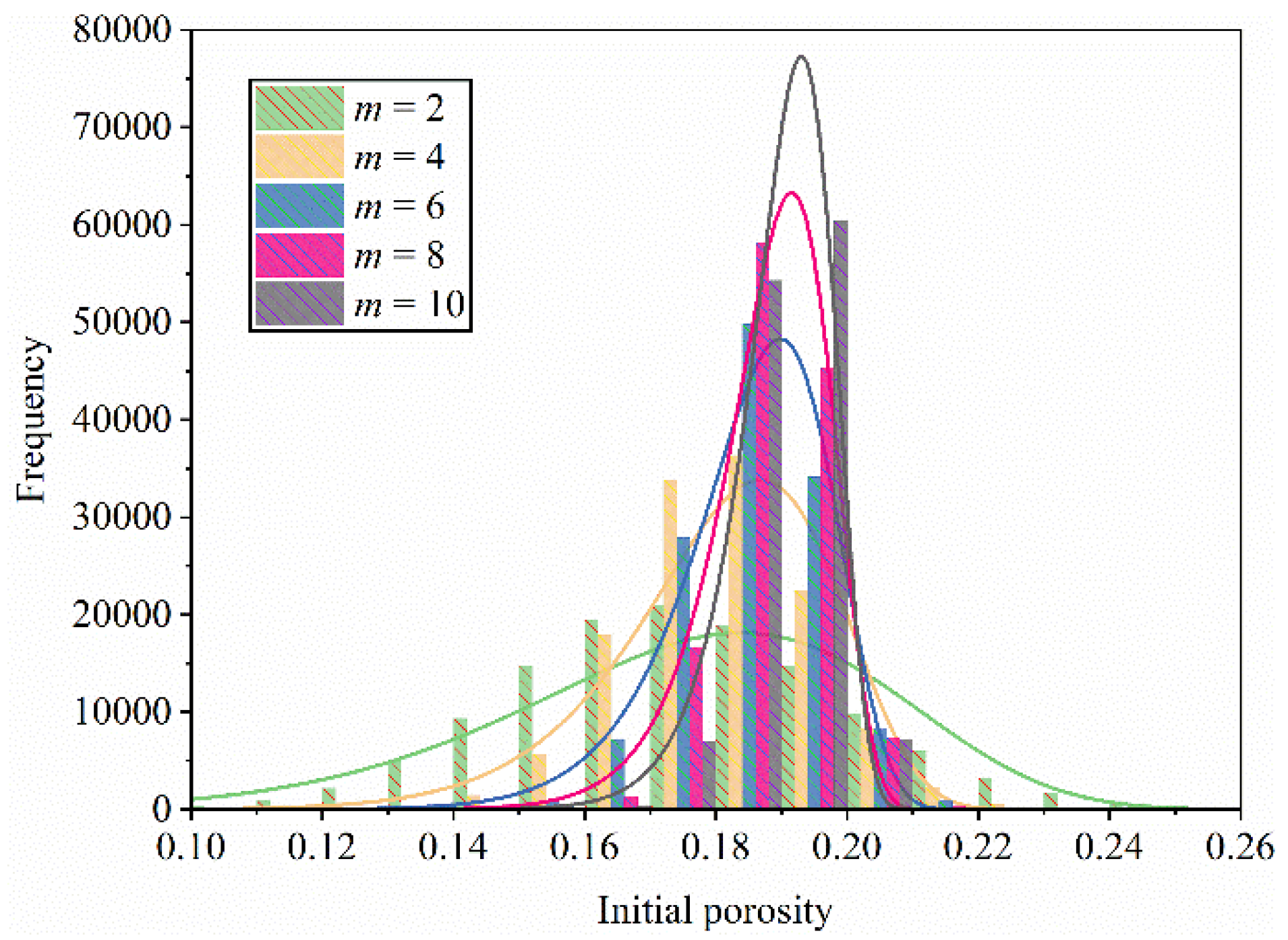

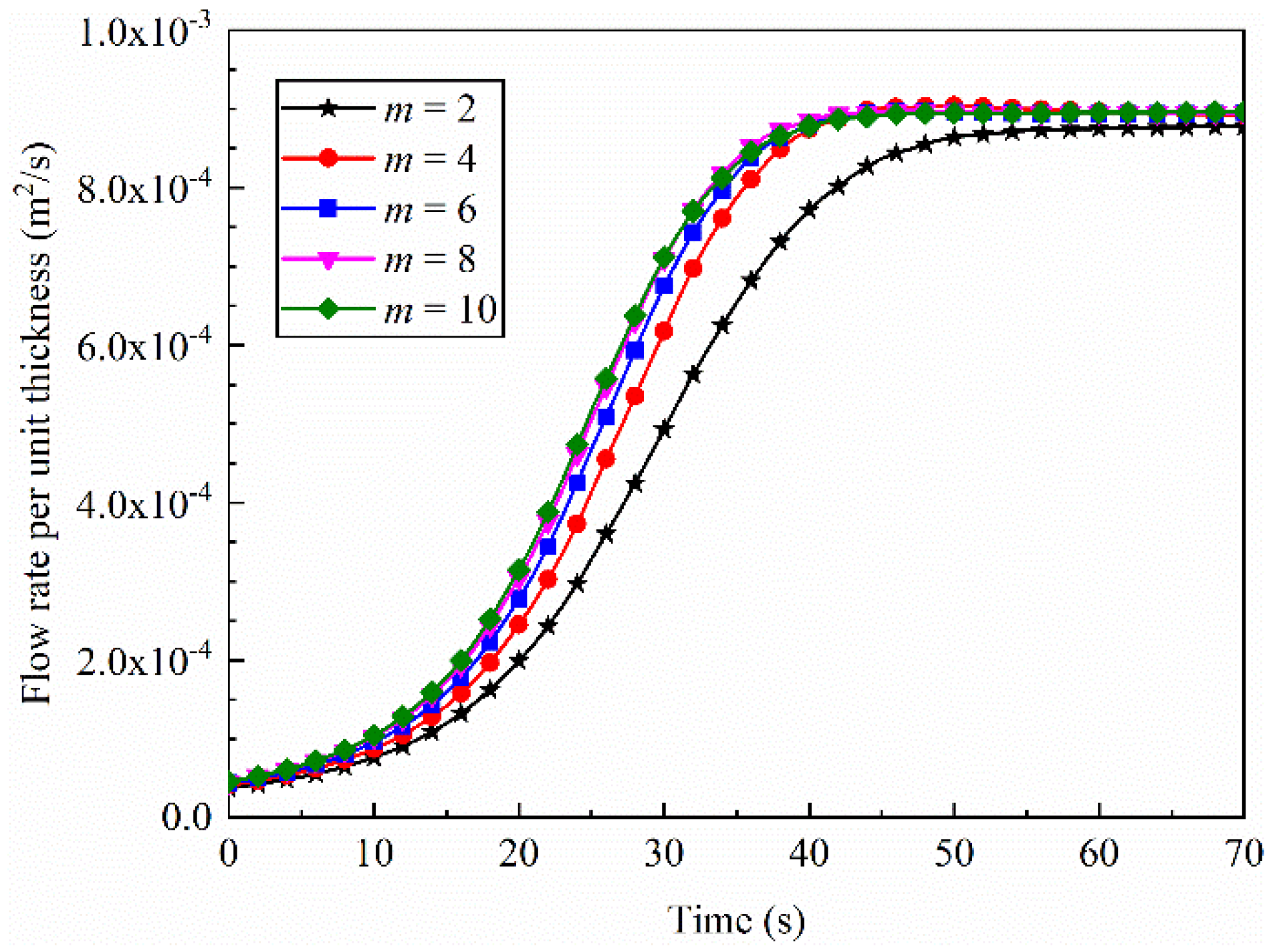

5.2. The Effect of Homogeneity Coefficient

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, J.; Li, S.; Li, L.; Lin, P.; Xu, Z.; Gao, C. Attribute recognition model for risk assessment of water inrush. Bull. Eng. Geol. Environ. 2019, 78, 1057–1071. [Google Scholar] [CrossRef]

- Li, G.Y.; Zhou, W.F. Impact of karst water on coal mining in North China. Environ. Geol. 2006, 49, 449–457. [Google Scholar] [CrossRef]

- Ma, D.; Cai, X.; Li, Q.; Duan, H. In-Situ and Numerical Investigation of Groundwater Inrush Hazard from Grouted Karst Collapse Pillar in Longwall Mining. Water 2018, 10, 1187. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.; Liu, J.; Li, X.; Zhou, Z. The role of gangue on the mitigation of mining-induced hazards and environmental pollution: An experimental investigation. Sci. Total Environ. 2019, 664, 436–448. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Gao, C.; Zhou, Z.; Li, L.; Wang, M.; Yuan, Y.; Wang, J. Analysis on the Precursor Information of Water Inrush in Karst Tunnels: A True Triaxial Model Test Study. Rock Mech. Rock Eng. 2019, 52, 373–384. [Google Scholar] [CrossRef]

- Bai, H.B.; Ma, D.; Chen, Z.Q. Mechanical behavior of groundwater seepage in karst collapse pillars. Eng. Geol. 2013, 164, 101–106. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.; Li, X.; Li, Z.; Zhou, Z.; Li, T. Effects of seepage-induced erosion on nonlinear hydraulic properties of broken red sandstones. Tunn. Undergr. Sp. Tech. 2019, 91, 102993. [Google Scholar] [CrossRef]

- Li, W.P.; Liu, Q.M.; Sun, R.H. Theoretical and experiment study on Vadose conversion of water inrush later occurred from structure broken zone. Coal Sci. Technol. 2011, 39, 10–13. [Google Scholar]

- Li, L.P.; Liu, S.; Li, S.C.; Shi, S.S.; Chen, D.Y.; Zhou, Y.; Lin, P.; Wang, J.H.; Liu, C. Development of testing system for coupled seepage and triaxial stress measurements and its application to permeability characteristic test on filling medium. Rock Soil Mech. 2017, 38, 3053–3061. [Google Scholar]

- Yang, B.; Xu, Z.H.; Yang, T.H.; Yang, X.; Shi, W.H. Experimental study of non-linear water flow through unconsolidated porous media under condition of high hydraulic gradient. Rock Soil Mech. 2018, 39, 109–116. [Google Scholar]

- Louis, C. Rock Hydraulics in Rock Mechanics, 1st ed.; Springer: Vienna, Austria, 1972; pp. 299–387. [Google Scholar]

- Singhal, B.B.S.; Gupta, R.P. Applied Hydrogeology of Fractured Rocks, 2nd ed.; Springer: Dordrecht, The Netherlands, 2010; pp. 139–154. [Google Scholar]

- Zimmerman, R.W.; Bodvarsson, G.S. Hydraulic conductivity of rock fractures. Transp. Porous Media 1996, 23, 1–30. [Google Scholar] [CrossRef]

- Chen, Y.; Lian, H.; Liang, W.; Yang, J.; Nguyen, V.P.; Bordas, S.P.A. The influence of fracture geometry variation on non-Darcy flow in fractures under confining stresses. Int. J. Rock Mech. Min. 2019, 113, 59–71. [Google Scholar] [CrossRef]

- Xiong, F.; Jiang, Q.; Xu, C.; Zhang, X.; Zhang, Q. Influences of connectivity and conductivity on nonlinear flow behaviours through three-dimension discrete fracture networks. Comput. Geotech. 2019, 107, 128–141. [Google Scholar] [CrossRef]

- Liu, R.; Li, B.; Jiang, Y. Critical hydraulic gradient for nonlinear flow through rock fracture networks: The roles of aperture, surface roughness, and number of intersections. Adv. Water Resour. 2016, 88, 53–65. [Google Scholar] [CrossRef]

- Li, X.; Jiang, Z.; Min, C. Quantitative Study of the Geometrical and Hydraulic Characteristics of a Single Rock Fracture. Energies 2019, 12, 2796. [Google Scholar] [CrossRef]

- Nandlal, K.; Weijermars, R. Impact on Drained Rock Volume (DRV) of Storativity and Enhanced Permeability in Naturally Fractured Reservoirs: Upscaled Field Case from Hydraulic Fracturing Test Site (HFTS), Wolfcamp Formation, Midland Basin, West Texas. Energies 2019, 12, 3852. [Google Scholar] [CrossRef]

- Shan, P.F.; Lai, X.P. Numerical Simulation of the Fluid–Solid Coupling Process During the Failure of a Fractured Coal–Rock Mass Based on the Regional Geostress. Transp. Porous Media 2018, 124, 1061–1079. [Google Scholar] [CrossRef]

- Zhang, Q. Hydromechanical modeling of solid deformation and fluid flow in the transversely isotropic fissured rocks. Comput. Geotech. 2020, 128, 103812. [Google Scholar] [CrossRef]

- Zhao, J.; Yin, L.; Guo, W. Stress–Seepage Coupling of Cataclastic Rock Masses Based on Digital Image Technologies. Rock Mech. Rock Eng. 2018, 51, 2355–2372. [Google Scholar] [CrossRef]

- Liu, J.; Song, Y.; Skoczylas, F.; Liu, J. Gas migration through water-saturated bentonite-sand mixtures, COx argillite, and their interfaces. Can. Geotech. J. 2016, 53, 60–71. [Google Scholar] [CrossRef]

- Hou, X.; Shi, W.; Yang, T. A non-linear flow model for the flow behavior of water inrush induced by the karst collapse column. RSC Adv. 2018, 8, 1656–1665. [Google Scholar] [CrossRef]

- Xu, Z.H.; Gao, B.; Li, S.C.; Zhang, L.W.; Zhao, S.L.; Shi, X.S. A groundwater seal evaluation method based on water inflow for underground oil storage caverns. Tunn. Undergr. Sp. Tech. 2018, 82, 265–277. [Google Scholar] [CrossRef]

- Feng, M.; Wu, J.; Ma, D.; Ni, X.; Yu, B.; Chen, Z. Experimental investigation on the seepage property of saturated broken red sandstone of continuous gradation. Bull. Eng. Geol. Environ. 2018, 77, 1167–1178. [Google Scholar] [CrossRef]

- Huang, Z.; Li, X.; Li, S.; Zhao, K.; Zhang, R. Investigation of the hydraulic properties of deep fractured rocks around underground excavations using high-pressure injection tests. Eng. Geol. 2018, 245, 180–191. [Google Scholar] [CrossRef]

- Wang, L.; Kong, H. Variation Characteristics of Mass-Loss Rate in Dynamic Seepage System of the Broken Rocks. Geofluids 2018, 2018, 7137601. [Google Scholar] [CrossRef]

- Yao, B.; Chen, Z.; Wei, J.; Bai, T.; Liu, S. Predicting Erosion-Induced Water Inrush of Karst Collapse Pillars Using Inverse Velocity Theory. Geofluids 2018, 2018, 1–18. [Google Scholar] [CrossRef]

- Houben, G.J. Review: Hydraulics of water wells-flow laws and influence of geometry. Hydrogeol. J. 2015, 23, 1633–1657. [Google Scholar] [CrossRef]

- Vardoulakis, I.; Stavropoulou, M.; Papanastasiou, P. Hydro-mechanical aspects of the sand production problem. Transp. Porous Media 1996, 22, 225–244. [Google Scholar] [CrossRef]

- Papamichos, E.; Vardoulakis, I. Sand erosion with a porosity diffusion law. Comput. Geotech. 2005, 32, 47–58. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, Y.; Yang, Z.; Darve, E. Multi-Constitutive Neural Network for Large Deformation Poromechanics Problem. In Proceedings of the Machine Learning and the Physical Sciences Workshop, 34th Conference on Neural Information Processing Systems (NeurIPS), Vancouver, BC, Canada, 6–12 December 2020. [Google Scholar]

- Chapuis, R.P.; Aubertin, M. On the use of the Kozeny Carman equation to predict the hydraulic conductivity of soils. Can. Geotech. J. 2003, 40, 616–628. [Google Scholar] [CrossRef]

- Stigsson, M.; Ivars, D.M. A Novel Conceptual Approach to Objectively Determine JRC Using Fractal Dimension and Asperity Distribution of Mapped Fracture Traces. Rock Mech. Rock Eng. 2019, 52, 1041–1054. [Google Scholar] [CrossRef]

- Wang, C.S.; Wang, L.Q.; Ge, Y.F.; Liang, Y.; Sun, Z.H.; Dong, M.M.; Zhang, N. A nonlinear method for determining two-dimensional joint roughness coefficient based on statistical parameters. Rock Soil Mech. 2017, 38, 565–573. [Google Scholar]

- Li, R.; Xiao, W. Study on a new equation for calculating jrc based on fine digitization of standard profiles proposed by barton. Chin. J. Rock Mech. Eng. 2018, 37, 402–409. [Google Scholar]

- Yang, Z.Y.; Lo, S.C.; Di, C.C. Reassessing the joint roughness coefficient (JRC) estimation using Z 2. Rock Mech. Rock Eng. 2001, 34, 243–251. [Google Scholar] [CrossRef]

- Li, S.; Wang, J.; Li, L.; Shi, S.; Zhou, Z. The theoretical and numerical analysis of water inrush through filling structures. Math. Comput. Simulat. 2019, 162, 115–134. [Google Scholar] [CrossRef]

- Tang, C.A.; Tham, L.G.; Lee, P.K.K.; Yang, T.H.; Li, L.C. Coupled analysis of flow, stress and damage (FSD) in rock failure. Int. J. Rock Mech. Min. Sci. 2002, 39, 477–489. [Google Scholar] [CrossRef]

- Zhu, W.C.; Tang, C.A. Micromechanical model for simulating the fracture process of rock. Rock Mech. Rock Eng. 2004, 37, 25–56. [Google Scholar] [CrossRef]

- Shao, J.; Zhang, Q.; Sun, W.; Wang, Z.; Zhu, X. Numerical Simulation on Non-Darcy Flow in a Single Rock Fracture Domain Inverted by Digital Images. Geofluids 2020, 2020, 1–13. [Google Scholar] [CrossRef]

| m | |||||||

| 1000 | 2 | 0.01 | 0.2 |

| Parameters | Value | ||||

|---|---|---|---|---|---|

| JRC | 4 | 8 | 12 | 16 | 20 |

| Homogeneity coefficient m | 2 | 4 | 6 | 8 | 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, J.; Zhang, Q.; Wu, X.; Lei, Y.; Wu, X.; Wang, Z. Investigation on the Water Flow Evolution in a Filled Fracture under Seepage-Induced Erosion. Water 2020, 12, 3188. https://doi.org/10.3390/w12113188

Shao J, Zhang Q, Wu X, Lei Y, Wu X, Wang Z. Investigation on the Water Flow Evolution in a Filled Fracture under Seepage-Induced Erosion. Water. 2020; 12(11):3188. https://doi.org/10.3390/w12113188

Chicago/Turabian StyleShao, Jianli, Qi Zhang, Xintao Wu, Yu Lei, Xunan Wu, and Zaiyong Wang. 2020. "Investigation on the Water Flow Evolution in a Filled Fracture under Seepage-Induced Erosion" Water 12, no. 11: 3188. https://doi.org/10.3390/w12113188

APA StyleShao, J., Zhang, Q., Wu, X., Lei, Y., Wu, X., & Wang, Z. (2020). Investigation on the Water Flow Evolution in a Filled Fracture under Seepage-Induced Erosion. Water, 12(11), 3188. https://doi.org/10.3390/w12113188