Abstract

Unconventional oil and gas extraction is on the rise across the United States and comprises an integral component in meeting the nation’s energy needs. The primary by-product of this industrious process is produced water, which is a challenging matrix to remediate because of its complex physical and chemical composition. Forward osmosis is a viable option to treat high-salinity produced water; however, fouling has been an issue. This study aimed to treat produced water before using forward osmosis as a remediation option. Trials consisted of a series of five experiments in order to evaluate the performance of the membrane. Samples were treated by centrifugation, activated carbon, filtration, ferric chloride, as well as coagulants and a polymer. It can be concluded that forward osmosis can be used to extract water from high-salinity oil field brines and produced water, and that pretreating the produced water decreased the tendency for fouling. The pretreatment with the overall best performance was activated carbon, which also yielded the lowest total organic carbon concentrations of 1.9 mg/L. During remediation trials using produced water pretreated with activated carbon as the feed solution, there was a 14% decrease in flux over the course of the 7 h trials. The membrane performance was restored after washing.

1. Introduction

The energy landscape across the globe has been tremendously influenced by unconventional oil and gas development (UD), which involves horizontal drilling and hydraulic fracturing [1]. With the expansion of activities in the US, potential environmental impacts, primarily focused on the contamination of groundwater [2,3,4,5], surface water [6,7], and air quality [8,9,10], have become a concern. Additionally, high water usage, frequently in arid and semiarid regions, has become an increasing issue [11]. Following the use of up to 12 million gallons of water per well for hydraulic stimulation in some regions, such as in the Permian Basin [12,13], only a fraction of the water is retrieved. The resurfaced water, referred to as produced water (PW), is the largest waste stream throughout the life of the well [14].

Current commonly practiced treatment methods of PW are limited due to the lack of financial incentives for oil and gas operator and limited regulations [15]. The majority of the billions of gallons of PW generated annually are disposed of using saltwater disposal (SWD) wells [16,17], which remove the contaminated water from the water cycle but have been linked to induced seismic events [18,19,20,21,22]. Current methodology for handling PW through the use of subsurface injection is not environmentally sustainable and has led to growing restrictions on this disposal option. There is an increasing need for cost-effective treatment options for large-scale operations that can process 250,000 or more of PW per day [16]. This would allow the reuse of PW in subsequent oil and gas development, which would inherently reduce the volume disposed in injection wells [23,24,25]. Additional PW treatment could be used to return water to the water cycle. Cost-effective treatment options need to be developed to treat the complex matrix of constituents, which can include naturally occurring radioactive material (NORM), scaling compounds, bacteria, biocides, and other organics, such as residual oil and gas hydrocarbons, as well as surfactants [26]. For reuse, the total concentration of petroleum hydrocarbons needs to be less than 20 mg/L; whereas all microbes must be eliminated, and solid particles greater than 20 µm must be removed [16]. Total dissolved solids (TDS) are not particularly problematic with respect to the reuse of PW, as long as pertinent ions (barium, boron, calcium, iron, and strontium), which can cause scaling or negatively impact the solution chemistry used for well development, are reduced to acceptable levels [27,28,29]. However, it is necessary to meet more stringent water quality parameters when considering the recycling of PW for use in other industries, which will require desalination [30]. Forward osmosis (FO) is one of the few approaches considered to be a viable option to treat the high salinity of PW solutions [1].

FO is an osmotically-driven process that moves pure water across a semi-permeable membrane from a feed solution (FS) to a draw solution (DS) [31,32,33,34]. Desalination can be achieved through a two-step process, which includes osmotic dilution of the DS followed by extraction of fresh water from the diluted DS [31,34]. Regeneration of the DS has been suggested through several techniques such as reverse osmosis and membrane distillation [31]. When osmotic dilution of the DS is used independently, it can serve a dual purpose. First, decreasing the volume of PW (the FS) injected into formations reduces concerns related to seismic activity. Second, the diluted DS provides a brine solution can be used or further processed for future well stimulation [35]. However, when paired with a desalination technique to extract the pure water, this process could potentially be used for use in other anthropological activities (i.e., irrigation, agriculture, etc). Moreover, depending on the water quality of the extracted water, it could potentially be discharged, providing an opportunity to recharge depleted aquifers.

Previous studies have evaluated the use of FO as a remediation method for PW; however, fouling was an issue [33,36,37]. Fouling hinders the transport of pure water across the membrane’s surface [38]. This can result from biofilm formation, inorganic scaling, and the formation of a cake layer due to organic constituents physically binding to the membrane surface. In addition to the complex biogeochemical matrix that forms PW, the properties of the solution are continuously changing. Large variations in composition and quantity occur over the lifetime of a given well and between wells [15]. When PW is used as the FS for FO, fouling has been specifically attributed to polyacrylamide, which is commonly used as a friction reducer to enhance oil and gas recovery [37,39,40]. Treatment of FS before FO is a well-established practice [15]; however, the authors found limited studies have treated PW prior to using FO as a remediation technique.

The goal of this study was to characterize PW and evaluate various pretreatment options, including centrifugation, adsorption on activated carbon, filtration, coagulation, and flocculation. Treating oily wastewater using conventional physical processes is a well-established practice making them ideal preliminary treatment options before FO [41]. Five pretreatment options were selected based on the residual total organic carbon (TOC) and the turbidity levels prior to FO. Each of the selected modalities was used to pretreat 20 L of PW. The treated PW was used as FS during FO to evaluate the performance of the module.

2. Methods and Material

2.1. Bench Top System

FO modules, provided by Asahi Kasei Corporation (Fuji, Japan), consisted of a bundle of 20 composite hollow fiber membranes, each with a polyethersulfone support layer and a thin-film polyamide active layer, collectively encased in a plastic shell. The modules were described in more detail in a previous work [33].

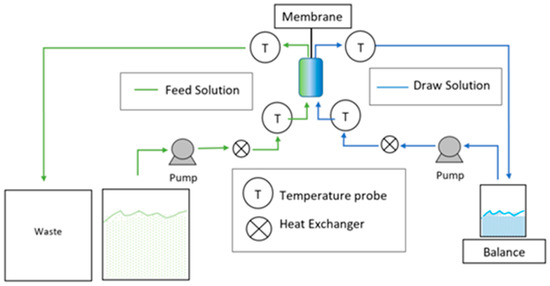

The system, which was custom built (Figure 1), used two variable speed micropumps (Micorpump, Vancouver, WA, USA) to regulate the velocity inside (GA-V21.CFS.A) and outside (GJ-N21.FF2S.A) the hollow fiber membrane. Pumps were controlled with two GPD-2303S bench power supplies (GW Instek, New Taipei City, Taiwan). As with previous trials [33], the DS was a closed-loop system; in contrast to previous trials, the FS was designed here to operate as a single-pass system. Therefore, the FS only came into contact with the membrane surface once, prior to being discarded as waste, as illustrated in Figure 1. The tubing used to connect the FS and DS to the module was primarily polyurethane tubing with a 6 mm OD; however, silicon tubing of approximately 5 cm long with a 6 mm OD was used as a bridge from the polyurethane tubing to the module. The FS and DS were each stored in 20 L plastic buckets throughout the experiment. The flux, measured as liters per square meter per hour ((L/m2/h) LMH), was determined by monitoring the change in mass of the DS with a Shimadzu BX32KS digital balance (Shimadzu Scientific Instruments, Inc., Columbia, MD, USA). Temperatures of the FS and DS were controlled using heat exchangers and a circulating water bath (Polyscience, Niles, IL, USA). Temperatures were monitored with K-type thermocouple probes and a GL240 data logger (Graphtec, Irvine, CA, USA).

Figure 1.

Forward osmosis bench top design. The draw solution (DS) is a closed-loop system while the feed solution (FS) is a single-pass design.

Two hundred liters of PW was collected to use as the FS. PW was collected from a saltwater disposal site in Midland County of the Permian Basin, as previously described [33], in an high density polyethylene (HDPE) barrel. Saturated DS was prepared using ACS-grade magnesium chloride hexahydrate (VWR, Radnor, PA, USA). Previous works [33,36] used saturated sodium chloride to prepare the DS; however, the DS was changed to 35% magnesium chloride to increase the osmotic pressure [42]. Saturation was maintained throughout the course of each trial by suspending a porous cotton pouch at the top of the solution filled with 540 g of anhydrous magnesium chloride (Alfa Aesar, Haverhill, MA, USA).

2.2. Analytical Instrumentation and Chemicals

The carbon content was measured through typical combustion techniques using the Shimadzu TOC-L Analyzer (Shimadzu Scientific Instruments, Inc., Columbia, MD, USA). The total suspended solids were quantified using gravimetric analysis for PW samples which were filtered using 1 µm glass microfiber paper (Ahlstrom, Leominster, MA, USA) and dried overnight at 90 °C. Polyaluminum chloride (PAC) was provided by GEO Specialty Chemicals, Water Treatment Chemicals Division (Ambler, PA, USA). Centrifuges used were a IEC Clinical Rotor 809 (Theremo Scientific, Waltham, MA, USA) for 15 mL centrifuge vials and a Avanti J-E (Beckman-Coulter, Indianapolis, IN, USA) for 500 mL bottles. The DARCO© activated carbon used (Sigma Aldrich, St Louis, MO, USA). Anhydrous ferric chloride was produced by EMD Millipore Corporation (Billerica, MA, USA). Thermogravimetric analysis (TGA) was performed using a Shimadzu TGS 50 (Shimadzu Scientific Instruments, Inc., Columbia, MD, USA). Filtration trials used Grade 410 and 415 crepe filter paper (VWR, Radnor, PA, USA).

3. Experimental Conditions

In previous experiments using untreated PW as the FS, significant variations were seen in the fouling rates. Therefore, PW was manually homogenized using a plastic rod for 30 min before collecting representative samples for each treatment evaluation. Eight treatment techniques were tested using 100 mL of PW, as described in Table 1. These were centrifugation, adsorption on activated carbon, filtration, addition of ferric chloride, addition of three different polyaluminum chlorides (UltraPAC 261, 2346, and 1145), addition of an amine polymer (UltraPAC 560CV), and addition of a combination of UltraPAC 261 and the polymer. The supernatant layer was collected for analysis.

Table 1.

Experimental conditions for treating produced water.

It was determined in previous work that the decrease in flux during FO trials using PW as the FS could be attributed to membrane fouling and edge blocking [36]. Membrane fouling is characterized as the formation of a cake layer that leads to irreversible fouling, while edge blocking was caused by particulates blocking the inlet of the hollow fiber. Since it is thought that TOC relates to the formation of the cake layer and the particulates responsible for edge blocking, the focus of the pretreatment methods used for the FO trials was to reduce TOC and turbidity. Turbidity measurements provide insight into the smaller constituents in PW, generally less than 1 μm in size, including dissolved solids, colloids, and bacteria [27]. pH was also monitored during the pretreatment trials in order to ensure that the FO membrane surface would not be adversely affected in subsequent experiments.

The membrane performance during FO trials was evaluated with the FS in contact with the active layer (AL-FS) inside of the hollow fiber. The temperature was also maintained near 25 °C for the FS and DS. Each treatment option was evaluated using a five-part experimental series with PW to evaluate the performance of the FO membranes (Table 2). A new FO module containing fresh membranes was used for each trial. The process began with a baseline measurement using 3.5% NaCl to compare the performance to the manufacturer’s specification. Next, the module performance was evaluated by measuring flux over a period of 7 h. Baseline conditions were repeated after the 7 h trial, and after washing the membrane with deionized (DI) water for 1 h, to compare the performance of the membrane to the initial baseline. Flow rates were maintained at 12 mL/min for the FS and 370 mL/min for the DS throughout each part of the FO trials. The module performance was determined using Equation (1) after the FO trial, and the standardized fouling index (SFI) was calculated using Equation (S1) after washing with DI water.

Table 2.

Experimental conditions for the five-part experimental series to evaluate the performance of the forward osmosis (FO) membranes.

Equation (1) for Module Performance (%):

4. Results and Discussion

4.1. Raw PW Characterization

The PW from Midland saltwater disposal had a black hue, due to the distributed particles, with a specific gravity of 1.05 ± 0.01. The only constituents of concern in this sample that were above the direct reuse limit were TOC, calcium, and boron. The PW exhibited a TOC concentration of 147.2 ± 0.3 mg/L and a neutral pH (Table 3). Calcium was 1.5 times greater than the 2000 mg/L reuse limit with a value of 3018 mg/L, while magnesium at a concentration of 432 mg/L was not a scaling concern [13,27,28,43]. Calcium and magnesium, along with other group II cations, are generally the largest contributors to the formation of scale [44]; whereas elevated levels of boron, iron, titanium, and zirconium [45,46], which are metals used as crosslinkers to increase the molecular weight of fracturing fluid, can reduce gel viscosity, alter temperature stability, and reduce the efficiency of proppant dispersion [47]. The boron levels for the untreated PW exceeded the suggested reuse value of 10 mg/L (49.05 mg/L) [13,27,29]; however, iron was below the reuse limit of 10 mg/L [13,27,28]. Other common metals used as crosslinkers were not detected in the sample. Total suspended solids (TSS) were below the reuse limit of 500 mg/L, with a concentration of 300 mg/L [13,27,28,43].

Table 3.

Analytical parameters measured for the raw PW.

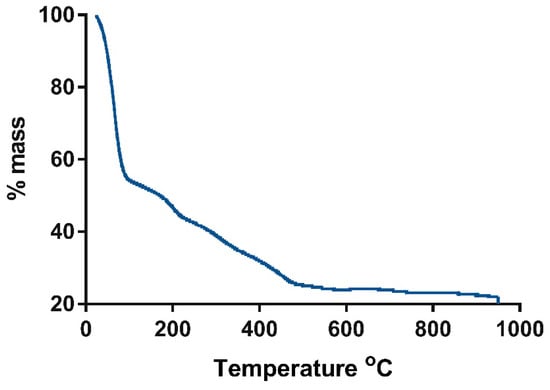

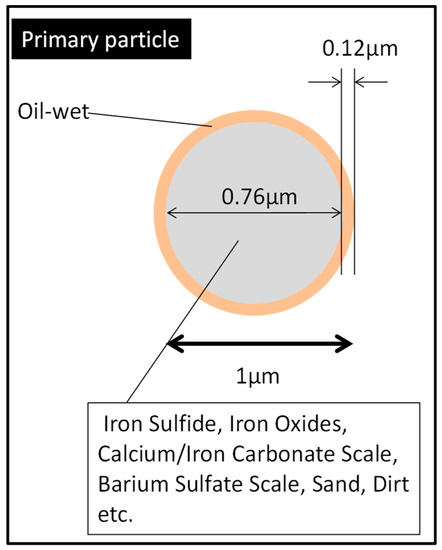

The particles in the solution were also analyzed, and the relevant data are shown in Figure 2. The particles were determined to be oil-wetted solids, which can be categorized into four groups: volatile organics; nonvolatile organics; decomposable inorganics; and thermally stable inorganics. The outer layer represented in Figure 3 for a 1 µm particle is composed of an organic outer layer, which surrounds an inner inorganic core.

Figure 2.

Thermogravimetric analysis of produced water (PW) particles. Four distinct groupings were determined: 1) Loss of water and volatile organics until 100 °C; 2) loss of larger organic molecules such as gas and diesel range compounds up to 500 °C; 3) primarily the loss of decomposing inorganics, such as calcium carbonate, above 500 °C; 4) residual inorganics, such as iron oxides and dirt.

Figure 3.

Representation of the predicted layers of a PW particle based on the mass percentage ratio from thermogravimetric analysis.

Upon settling, it was determined that the PW separated into three layers, each presenting their own different properties. They all had a pH near neutral, but the pH of the bottom layer was slightly more acidic (6.59) than the top (7.36) and middle (7.49) layers. The top layer had a TOC of 24.5 ± 0.8 mg/L. The middle layer, which was the clearest based on visual inspection, has a TOC of 13.7 ± 0.8 mg/L. The bottom layer had the highest particulate concentration and exhibited a TOC value of 180.6 ± 0.3 mg/L.

4.2. Analytical Results for Pretreated PW

Ultimately, five pretreatment options that were selected to produce FS for the FO experiments: centrifugation, activated carbon, filtration, UltraPAC 2346, and the UltraPAC combination 261 and 560CV. The selection was based on the analytical parameters measured after treating 100 mL samples of PW. The greatest influence on treatment selection was a combination of low turbidity and TOC. Water quality results following the different sample pretreatments are listed in Table S1 in the electronic Supplementary Information document, which accompanies this article. Treating PW with activated carbon was selected because this yielded a TOC of less than 2 mg/L due to its ability to readily adsorb organics. Despite the low TOC of 10.4 mg/L after treating PW with FeCl3, the treatment option was not selected because of the elevated turbidity, owing to a high level of residual colloidal particles. Each of the PW aliquots treated with polyaluminum chloride had a comparable TOC concentration; however, UltraPAC 2346 was selected due to the lower turbidity of 56 NTU. The addition of the coagulant, UltraPAC 560CV, reduced the turbidity due to the increase in the size of the of coagulated clusters. The polyaluminum chloride that was combined with the coagulate was determined using jar testing. The UtraPAC 261 and 560CV provided the best water quality condition in the least amount of time.

Twenty liters of homogenized PW was collected and treated using the predetermined conditions. Following centrifugation, the resulting TOC concentration was 16.5 ± 0.5 mg/L with TSS and turbidity values of 360 ± 60 and 46.9 ± 0.6 NTU, respectively (Table 4). The addition of activated carbon followed by 25 µm filtration led to the best conditions with a TOC value of 1.9 ± 0.1 mg/L. The TSS and the turbidity were also the lowest among the treatment options used. Filtration with a 1 µm pore size had a residual TOC level of 12 ± 1 mg/L, with an unexpectedly high TSS value of 220 ± 20 mg/L, represented in Table 4. The addition of the coagulant alone returned a lower TOC value (7.9 ± 0.4 mg/L) than when the combination of a coagulant and polymer was used (12.9 ± 1 mg/L). However, the coagulant alone had higher TSS (300 ± 200 mg/L) and turbidity (54.3 ± 0.9 NTU). Metals measured in the untreated PW were not influenced by pretreatment methodologies.

Table 4.

Analytical parameters for the 20 L of treated PW used as FS.

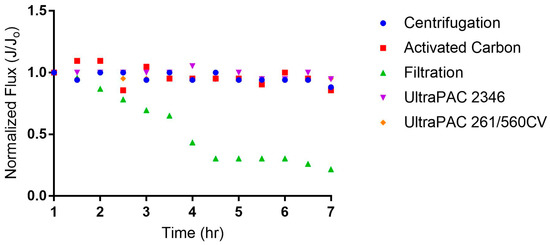

4.3. Forward Osmosis with Pretreated PW

Modules were shipped and stored in a 20% ethanol solution per the manufacturer’s recommendations, which causes swelling of the membrane [48,49,50]. Ethanol swelling has been shown to increase membrane performance. Therefore, modules were washed with DI water in order to ensure the decrease in performance that was measured for all modules was not due to changes in swelling due to the presence of ethanol. Over the 7 h trial, the 20 L of PW that was centrifuged to remove particulates had a 12% decrease in the flux (Table S2). During the trial using the centrifuged FS, no edge blocking was visible, and fouling was not evident based on the module performance of 115%, which showed improved flux compared to the baseline. Overall, the FS that was pretreated with activated carbon, which had the lowest TOC and TSS, performed the best. During the 7 h trial using PW pretreated with activated carbon, the flux decreased by 14%, as shown in Figure 4. Despite the 14% decrease in flux there was an improvement in module performance after the FO trial, 114% when compared to the baseline performance. Additionally, when the module was evaluated using DI water after the trial there was no indication of the membrane surface being fouled during the trial using PW treated with activated carbon (Table S2). Filtered PW with no additional treatment had the worst performance. A build-up of particles at the inlet FO module occurred rapidly, which led to a decrease in the flux of 79% during the 7 h trial (Figure 4). Interestingly, the PW pretreated with filtration alone had the highest turbidity. The elevated turbidity indicates that other pretreatment options reduced the colloidal particles more than filter paper. Measuring turbidity, caused from small particles (1 nm to 1 µm), does not provide insight into the size of the particle. Since the filter paper used to pretreat the PW had a nominal size of 1 µm, it is believed that larger residual particles remained in solution when compared to other pretreat techniques used, which lead to the inlet of the hollow fiber being blocked. The module performance after the FO trial using filtered PW was −16%, indicating that the flux was reversed. The pure water was being extracted from the DS due to the high particulate concentration at the inlet of the hollow fiber tube and possibly, inside the membranes. After washing for one hour with DI water, the SFI revealed an increase in the flux of 5%, when compared to the baseline, showing that the membrane’s surface was not permanently fouled. The flux decreased the least over the course of 7 h for both trials where the PW was pretreated with UltraPAC. The FS treated with the UltraPAC 2346 exhibited a 2% decrease in flux, while a 4% decrease was calculated for the FS treated with a combination of UltraPAC 261 and 560CV. The high SFI, 25% for the polyaluminum chloride trial and 31% for the combination trial, was unexpected based on the minimal decrease in flux over the course of the 7 h trial.

Figure 4.

Normalized flux of the five pretreated produced water samples used for a FS for the FO trials.

When a solution with a neutral pH is utilized as the FS, the membrane has a slightly negative charge, while the coagulant and polymer have a positive charge. When the high-salinity PW was used as the FS, residual coagulant and polymer remained in solution. However, the lines were not drained prior to replacing the FS of treated PW with DI water to replicate baseline conditions. Instead, the flow was controlled by directional knobs to change the FS and DS. Once the FS and DS were changed, the fluid was discarded until the new fluid filled the module and tubing. Once FS became diluted because of the influx of DI water, it is believed that the positively charged additives preferentially interacted with the membrane, leading to fouling. The polymer, with the long hydrophobic tail, would potentially have an increased propensity for adhering to the membrane surface; this was reflected by the lower module performance compared to the coagulant alone. Furthermore, the increased SFI for the coagulant/polymer combination indicates that the polymer has an impact on the membrane fouling.

5. Conclusions

FO is a promising technique for treating high-salinity PW for reuse in subsequent well development. When paired with a desalination method, it can be used to reintroduce previously contaminated water back into the water cycle. Currently, membrane fouling due to the complex biogeochemical nature of PW has been the most significant opposition to widely successful implementation. Membranes are susceptible to scaling due to the high concentration of group 2 cations. Additionally, sulfur-reducing bacteria are a prevalent concern for oil and operations which can lead to biofouling issues. Organics can further complicate the issue by adsorbing onto the membrane surface. Therefore, cost-effective pretreatment methods are required to be able to consistently and reproducibly use FO as a remediation method.

Chemical treatment is a favorable approach, as seen by the limited decrease in flux using the coagulant UltraPAC 2346 and the combination of coagulant and polymer, UltraPAC 261/560CV. However, when treated PW FS was replaced with DI water to replicate the baseline conditions, an unexpected drop in the module performance was measured. It is believed that the decrease in flux was due to residual levels of the PAC and polymer that remained in the FS. Future work on optimizing the coagulant/flocculant ratio should be considered. Moreover, studies that focus on the effects of sedimentation time and prefiltration as a secondary step would be valuable.

Supplementary Materials

The following are available online at https://www.mdpi.com/2073-4441/11/7/1437/s1, Equation S1 for Standardized Fouling Index (SFI), Table S1: Analytical parameters measured for the 100 mL of treated PW, Table S2: The reported flux and reverse solute flux (RSF) from the manufacturer with using FS of DI water and 3.5% NaCl DS. The initial baseline flux, the average flux during the first hour of the 7 h trial, as well as the % decrease over the trial. Finally, for comparison purposes the baseline after FO trials, and baseline after washing module for 1 h with DI water is recorded along with the module performance and standard fouling index is also provided for FO trial using pretreated PW as the FS.

Author Contributions

Conceptualization, T.L.; Methodology, T.L.; Validation and Formal Analysis, T.L.; Data Curation, T.L.; Writing – Original Draft Preparation, T.L. and Z.L.H.; Writing – Review & Editing, T.L., Z.L.H., and K.A.S.; Supervision, K.A.S.; Project Administration, K.A.S.; Funding Acquisition, K.A.S.

Funding

This research was funded by Asahi Kasei Corporation.

Acknowledgments

Support for this work was provided by Asahi Kasei Corporation and the Collaborative Laboratories for Environmental Analysis and Remediation at The University of Texas at Arlington. Solaris Water Midstream is also gratefully acknowledged for providing PW samples. UltraPAC coagulants and polymer were provided by Geochemicals.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shaffer, D.; Chavez, L.H.A.; Ben-Sasson, M.; Castrillo, S.R.; Yin Yip, N.; Elimelech, M. Desalination and Reuse of High-Salinity Shale Gas Produced Water: Drivers, Technologies, and Future Direction. Environ. Sci. Technol. 2013, 47, 9569–9583. [Google Scholar] [CrossRef] [PubMed]

- Darrah, T.H.; Vengosh, A.; Jackson, R.B.; Warner, N.R.; Poreda, R.J. Noble gases identify the mechanisms of fugitive gas contamination in drinking-water wells overlying the Marcellus and Barnett Shales. Proc. Natl. Acad. Sci. USA 2014, 111, 14076–14081. [Google Scholar] [CrossRef] [PubMed]

- Fontenot, B.E.; Hunt, L.R.; Hildenbrand, Z.L.; Carlton, D.D., Jr.; Oka, H.; Walton, J.L.; Hopkins, D.; Osorio, A.; Bjorndal, B.; Hu, Q.H.; et al. An evaluation of water quality in private drinking water wells near natural gas extraction sits in the Barnett Shale Formation. Environ. Sci. Technol. 2013, 47, 10032–10040. [Google Scholar] [CrossRef] [PubMed]

- Hildenbrand, Z.L.; Carlton, D.D., Jr.; Fontenot, B.E.; Meik, J.M.; Walton, J.L.; Taylor, J.T.; Thacker, J.B.; Korlie, S.; Shelor, C.P.; Henderson, D.; et al. Comprehensive Analysis of Groundwater Quality in The Barnett Shale Region. Environ. Sci. Technol. 2015, 49, 8254–8262. [Google Scholar] [CrossRef] [PubMed]

- Hildenbrand, Z.L.; Carlton, D.D., Jr.; Fontenot, B.E.; Meik, J.M.; Walton, J.L.; Thacker, J.B.; Korlie, S.; Shelor, C.P.; Kadjo, A.F.; Clark, A.; et al. Temporal variation in groundwater quality in the Permian Basin of Texas, a region of increasing unconventional oil and gas development. Sci. Total Environ. 2016, 562, 906–913. [Google Scholar] [CrossRef] [PubMed]

- Drollette, B.D.; Hoelzer, K.; Warner, N.R.; Darrah, T.H.; Karatum, O.; O’Connor, M.P.; Nelson, R.K.; Fernandez, L.A.; Reddy, C.M.; Vengosh, A.; et al. Elevated levels of diesel range organic compounds in groundwater near Marcellus gas operations are derived from surface activities. Proc. Natl. Acad. Sci. USA 2015, 12, 13184–13189. [Google Scholar] [CrossRef] [PubMed]

- Lauer, N.E.; Harkness, J.S.; Vengosh, A. Brine Spills Associated with Unconventional Oil Development in North Dakota. Environ. Sci. Technol. 2016, 50, 5389–5397. [Google Scholar] [CrossRef]

- Harriss, R.; Alvarez, R.A.; Lyon, D.; Zavala-Araiza, D.; Nelson, D.; Hamburg, S.P. Using Multi-Scale Measurements to Improve Methane Emission Estimates from Oil and Gas Operations in the Barnett Shale Region, Texas. Environ. Sci. Technol. 2015, 49, 7524–7526. [Google Scholar] [CrossRef]

- Hildenbrand, Z.L.; Mach, P.M.; McBride, E.M.; Dorreyatim, M.N.; Taylor, J.T.; Carlton, D.D., Jr.; Meik, J.M.; Fontenot, B.E.; Wright, K.C.; Schug, K.A.; et al. Point source attribution of ambient contamination events near unconventional oil and gas developmentn. Sci. Total Environ. 2016, 573, 382–388. [Google Scholar] [CrossRef]

- Payne, B.F.; Ackley, R.; Wicker, A.P.; Hildenbrand, Z.L.; Carlton, D.D., Jr.; Schug, K.A. Characterization of methane plumes downwind of natural gas compressor stations in Pennsylvania and New York. Sci. Total Environ. 2017, 580, 1214–1221. [Google Scholar] [CrossRef]

- Nicot, J.P.; Scanlon, B.R.; Reedy, R.C.; Costley, R.A. Source and Fate of Hydraulic Fracturing Water in the Barnett Shale: A Historical Perspective. Environ. Sci. Technol. 2014, 48, 2464–2471. [Google Scholar] [CrossRef] [PubMed]

- Backstrom, J. Groundwater Regulations and Hydraulic Fracturing: Reporting Water Use in the Permian. Ph.D. Dissertation, Texas A&M University, College Station, TX, USA, 2018. [Google Scholar]

- Liden, T.; Santos, I.C.; Hildenbrand, Z.L.; Schug, K.A. Treatment Modalities for the Reuse of Produced Waste from Oil and Gas Development. Sci. Total Environ. 2018, 643, 107–118. [Google Scholar] [CrossRef] [PubMed]

- Veil, J.; Puder, M.G.; Elcock, D.; Redweik, R.J.J. A White Paper Describing Produced Water from Production of Crude Oil, Natural Gas, and Coal Bed Methane; Argonne National Lab: DuPage, IL, USA, 2004. [Google Scholar]

- Jepsen, K.L.; Bram, M.V.; Pedersen, S.; Yang, Z. Membrane fouling for Produced Water Treatmetn: A Review Study From a Process Control Prespective. Water 2018, 10, 847. [Google Scholar] [CrossRef]

- Liden, T.; Clark, B.G.; Hildenbrand, Z.L.; Schug, K.A. Unconventional Oil and Gas Production: Waste Management and the Water Cycle. In Environmental Issues Concerning Hydraulic Fracturing; Schug, K.A., Hildenbrand, Z.L., Eds.; Academic Press: Cambridge, MA, USA, 2017; Volume 1, pp. 17–45. [Google Scholar] [CrossRef]

- Van der Elst, N.J.; Page, M.T.; Weiser, D.A.; Goebel, T.H.; Hosseini, S.M. Induced earthquake magnitudes are as large as (statistically) expected. J. Geophys. Res. Solid Earth 2016, 121, 4575–4590. [Google Scholar] [CrossRef]

- Veil, J. US Produced Water Volumes and Management Practices in 2012. 2015. Available online: http://www.veilenvironmental.com/publications/pw/prod_water_volume_2012.pdf (accessed on 5 May 2017).

- Hornbach, M.J.; DeShon, H.R.; Ellsworth, W.L.; Stump, B.W.; Hayward, C.; Frohlich, C.; Oldham, H.R.; Olson, J.E.; Magnani, M.B.; Brokaw, C.; et al. Causal factors for seismicity near Azle. Texas Nat. 2015, 6, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Hornbach, M.J.; Jones, M.; Scales, M.; DeShon, H.R.; Magnani, M.B.; Frohlich, C.; Stump, B.; Hayward, C.; Layton, M. Ellenburger wastewater injection and seismicity in North Texas. Phys. Earth Planet. Inter. 2016, 261, 54–68. [Google Scholar] [CrossRef]

- Walsh, F.R.; Zoback, M.D. Oklahoma’s recent earthquakes and saltwater disposal. Sci. Adv. 2015, 1, 1–9. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, X.; Jha, A.N.; Rogers, H. Natural gas from shale formation- The evolution, evidence, and challenges of shale gas revolution in United States. Renew. Sustain. Energy Rev. 2014, 30, 1–28. [Google Scholar] [CrossRef]

- Arthur, D.J.; Bohm, B.; Coughlin, B.J.; Layne, M.; Cornue, D. Evaluating the Environmental Implications of Hydraulic Fracturing in Shale Gas Reservoirs. In Proceedings of the SPE Americas E&P Environmental and Safety Conference, San Antonio, TX, USA, 23–25 March 2009; pp. 1–21. [Google Scholar] [CrossRef]

- Clark, C.E.; Veil, J.A. Produced Water Volumes and Management Practices in the United States; Argonne National Laboratory: DuPage, IL, USA, 2009. [Google Scholar]

- Igunnu, E.T.; Chen, G.Z. Produced water treatment technologies. Int. J. Low Carbon Technol. 2014, 9, 157–177. [Google Scholar] [CrossRef]

- Ground Water Protection Council; All Consulting. Modern Shale Gas—A. Primer; US Department of Energy et Office of Fossil Energy: Washington, DC, USA, 2009.

- Hildenbrand, Z.L.; Santos, I.C.; Liden, T.; Carlton, D.D., Jr.; Varona-Torres, E.; Martin, M.S.; Reyes, M.L.; Mulla, S.R.; Schug, K.A. Characterizing variable biogeochemical changes during the treatment of produced oilfield waste. Sci. Total Environ. 2018, 634, 1519–1529. [Google Scholar] [CrossRef]

- Oetjen, K.; Chan, K.E.; Gulmark, K.; Christensen, J.H.; Blotevogel, J.; Borch, T.; Spear, J.R.; Cath, T.Y.; Higgins, C.P. Temporal characterization and statistical analysis of flowback and produced waters and their potential for reuse. Sci. Total Environ. 2018, 619, 654–664. [Google Scholar] [CrossRef] [PubMed]

- Tipton, S. Treatment Option for Recycling Produced Water. In Proceedings of the Unconventional Oil & Gas Water Management Forum, Grapevine, TX, USA, 9–11 July 2013; pp. 1–26. [Google Scholar]

- Liden, T.; Santos, I.C.; Hildenbrand, Z.L.; Schug, K.A. Analytical Methods for the Comprehensive Characterization of Produced Water. In Evaluating Water Quality to Prevent Future Disasters; Ahuja, S., Ed.; Elsevier: Amsterdam, The Netherlands, 2019; Volume 11, pp. 199–217. [Google Scholar]

- Ansari, A.J.; Hai, F.I.; Guo, W.; Ngo, H.H.; Price, W.E.; Nghiem, L.D. Factors governing the pre-concentration of wastewater using forward osmosis for subsequent resource recovery. Sci. Total Environ. 2016, 566, 559–566. [Google Scholar] [CrossRef] [PubMed]

- Hickenbottom, K.L.; Hancock, N.T.; Hutchings, N.R.; Appleton, E.W.; Beaudry, E.G.; Xu, P.; Cath, T.Y. Forward osmosis treatment of drilling mud and fracturing wastewater from oil and gas operations. Desalination 2013, 312, 60–66. [Google Scholar] [CrossRef]

- Liden, T.; Carton, D.D., Jr.; Miyazaki, S.; Otoyo, T.; Schug, K.A. Forward Osmosis Remediation of High Salinity Permian Basin Produced Water from Unconventional Oil and Gas Development. Sci. Total Environ. 2018, 653, 82–90. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Zou, L.; Tang, C.Y.; Mulcahy, D. Recent developments in forward osmosis: Opportunities and challenges. J. Membr. Sci. 2012, 396, 1–21. [Google Scholar] [CrossRef]

- Hutchings, N.R.; Appleton, E.W.; Mcginnis, R.A. Bear Creek Services, Making High Quality Frac Water out of Oilfield Waste. In Proceedings of the SPE Annunal Technical Conference, Florence, Italy, 19–22 September 2010; pp. 1–10. [Google Scholar]

- Liden, T.; Carlton, D.D., Jr.; Miyazaki, S.; Otoyo, T.; Schug, K.A. Comparison of the Degree of Fouling at various Flux Rate and Modes of Operation when using Forward Osmosis for Remediation of Produced Water from Unconventional Oil and Gas Exploration and Development. Sci. Total Environ. 2019, 675, 73–80. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Z.; Zhou, Y.; Xi, X.; Li, W.; Yang, L.; Wang, X. Study of the contribution of the main pollutants in the oilfield polymer-flooding wastewater to the critical flux. Desalination 2011, 273, 375–385. [Google Scholar] [CrossRef]

- Guo, W.; Ngo, H.H.; Li, J. A mini-review on membrane fouling. Bioresour. Technol. 2012, 122, 27–34. [Google Scholar] [CrossRef]

- Xiong, B.; Roman-white, S.; Piechowicz, B.; Miller, Z.; Farina, B.; Tasker, T.; Burgos, W.; Zydney, A.L.; Kumar, M. Polyacrylamide in hydraulic fracturing fl uid causes severe membrane fouling during fl owback water treatment. J. Membr. Sci. 2018, 560, 125–131. [Google Scholar] [CrossRef]

- Xiong, B.; Zydney, A.L.; Kumar, M. Fouling of microfiltration membranes by flowback and produced waters from the Marcellus shale gas play. Water Res. 2016, 99, 162–170. [Google Scholar] [CrossRef]

- Ahmad, A.; Goh, P.S.; Karim, Z.A.; Ismail, A.F. Thin Film Composite for Oily Waste Water Treatment: Recent Advances and Challenges. Mebranes 2018, 8, 86. [Google Scholar] [CrossRef] [PubMed]

- Coday, B.D.; Xu, P.; Beaudry, E.G.; Herron, J.; Lampi, K.; Hancock, N.T.; Cath, T.Y. The sweet spot of forward osmosis: Treatment of produced water, drilling wastewater, and other complex and difficult liquid streams. Desalination 2014, 333, 23–35. [Google Scholar] [CrossRef]

- King, G.E. Treating Produced Water For Shale Fracs; Society of Petroleum Engineers Gulf Coast Section: Houston, TX, USA, 2011; pp. 1–20. [Google Scholar]

- Hu, Y.; Mackay, E.; Ishkov, O.; Strachan, A. Predicted and Observed Evolution of Produced-Brine Compositions and Implications for Scale Management. SPE Prod. Oper. 2016, 31, 270–279. [Google Scholar] [CrossRef]

- Esmaeilirad, N.; White, S.; Terry, C.; Prior, A.; Carlson, K. Influence of inorganic ions in recycled produced water on gel-based hydraulic fracturing fluid viscosity. J. Pet. Sci. Eng. 2016, 139, 104–111. [Google Scholar] [CrossRef]

- Montgomery, C. Fracturing Fluid Components. In Effective and Sustainable Hydraulic Fracturing; Brnger, A., McLennan, J., Jeffrey, R., Eds.; IntechOpen: London, UK, 2013; pp. 25–45. [Google Scholar]

- Wasylishen, R.; Fulton, S. Reuse of Flowback & Produced Water for Hydraulic Fracturing in Tight Oil; The Pertroleum Technology Allance of Canada: Calgary, AB, Canada, 2012. [Google Scholar]

- Liu, Z.; Chen, J.; Cao, Z.; Wang, J.; Guo, C. Enhanced Performance of Thin Film Composite Forward.Osmosis Membrane by Chemical Post-Treatment. Earth Environ. Sci. 2018, 108, 1–6. [Google Scholar]

- Shin, M.G.; Park, S.; Kwon, S.J.; Kwon, H.; Park, J.B.; Lee, J. Facile performance enhancement of reverse osmosis membranes via solvent activation with benzyl alcohol. J. Membr. Sci. 2019, 578, 220–229. [Google Scholar] [CrossRef]

- Wang, X.; Duitsman, E.; Rajagopalan, N.; Namboodiri, V.V. Chemical treatment of commercial reverse osmosis membranes for use in FO. Desalination 2013, 319, 66–72. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).