Field Testing of Porous Pavement Performance on Runoff and Temperature Control in Taipei City

Abstract

1. Introduction

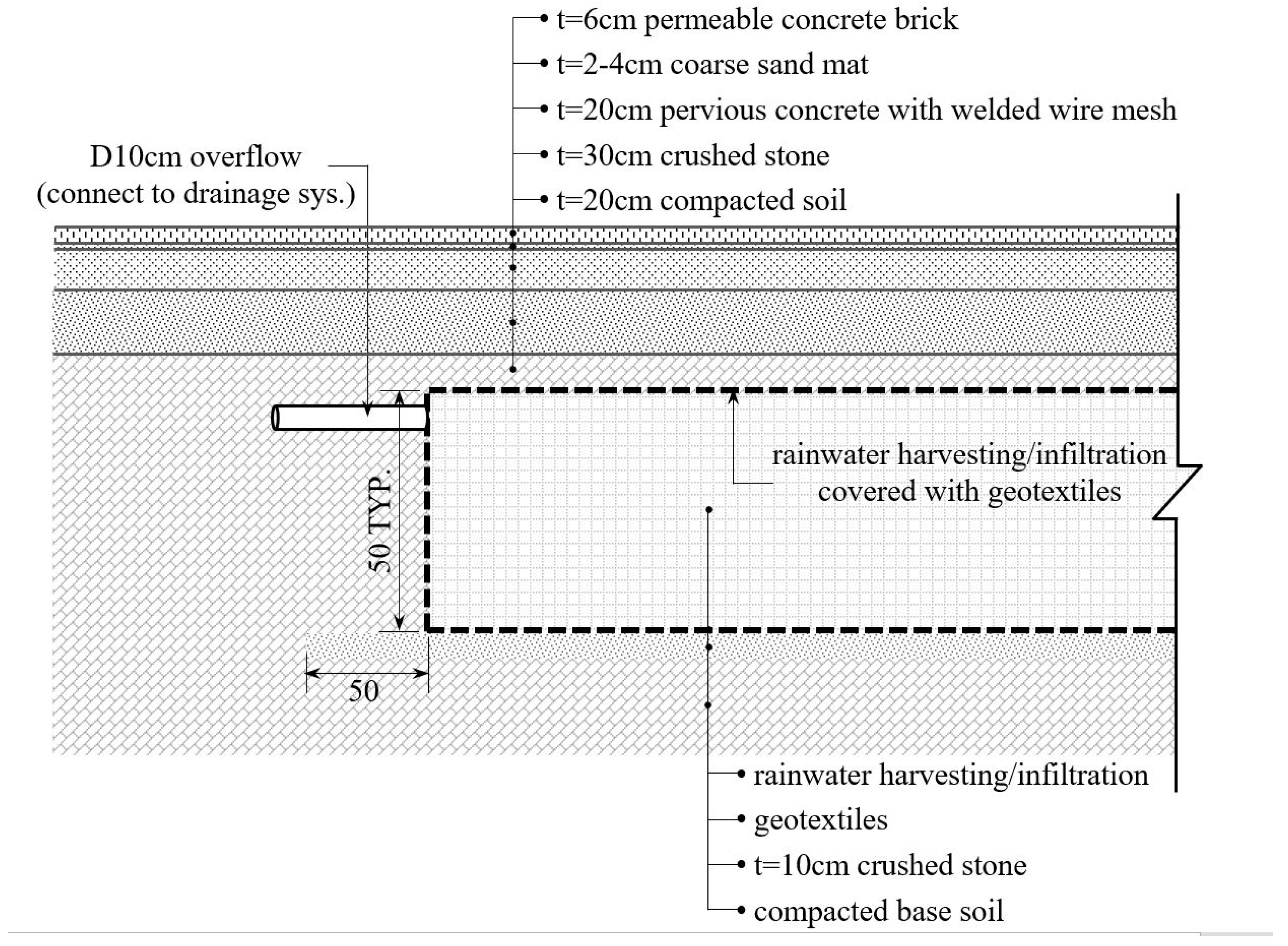

2. Materials and Methods

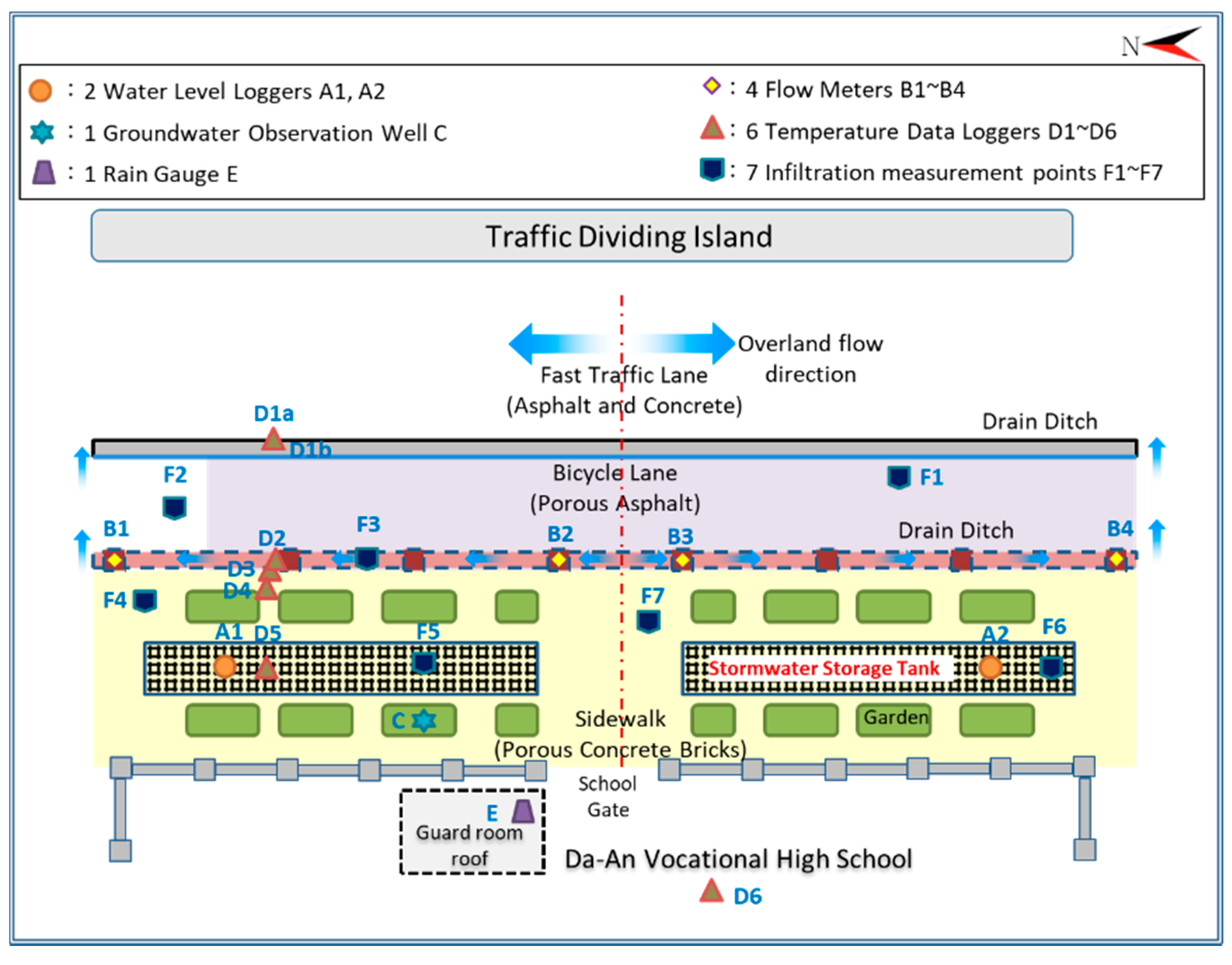

2.1. Site Description

2.2. Monitoring Plan

- Rainfall: One rain gage (HOBO-ON SET self-recording gage) on the roof of a campus security room at the site. Rainfall measured at 10 min intervals.

- Runoff stored at the two underground runoff storage tanks: Two automatic water level recorders. Water level measured at hourly intervals.

- Flow measurements at four locations: Rectangular weirs at 10 min intervals.

- (a)

- One rain gage on top of the guard room roof—E

- (b)

- Two water level recorders, one each at the underground stormwater tanks—A1, A2

- (c)

- Four flow meters—north side B1 and B2, south side B3 and B4

- (d)

- One groundwater level recorder—C

- (e)

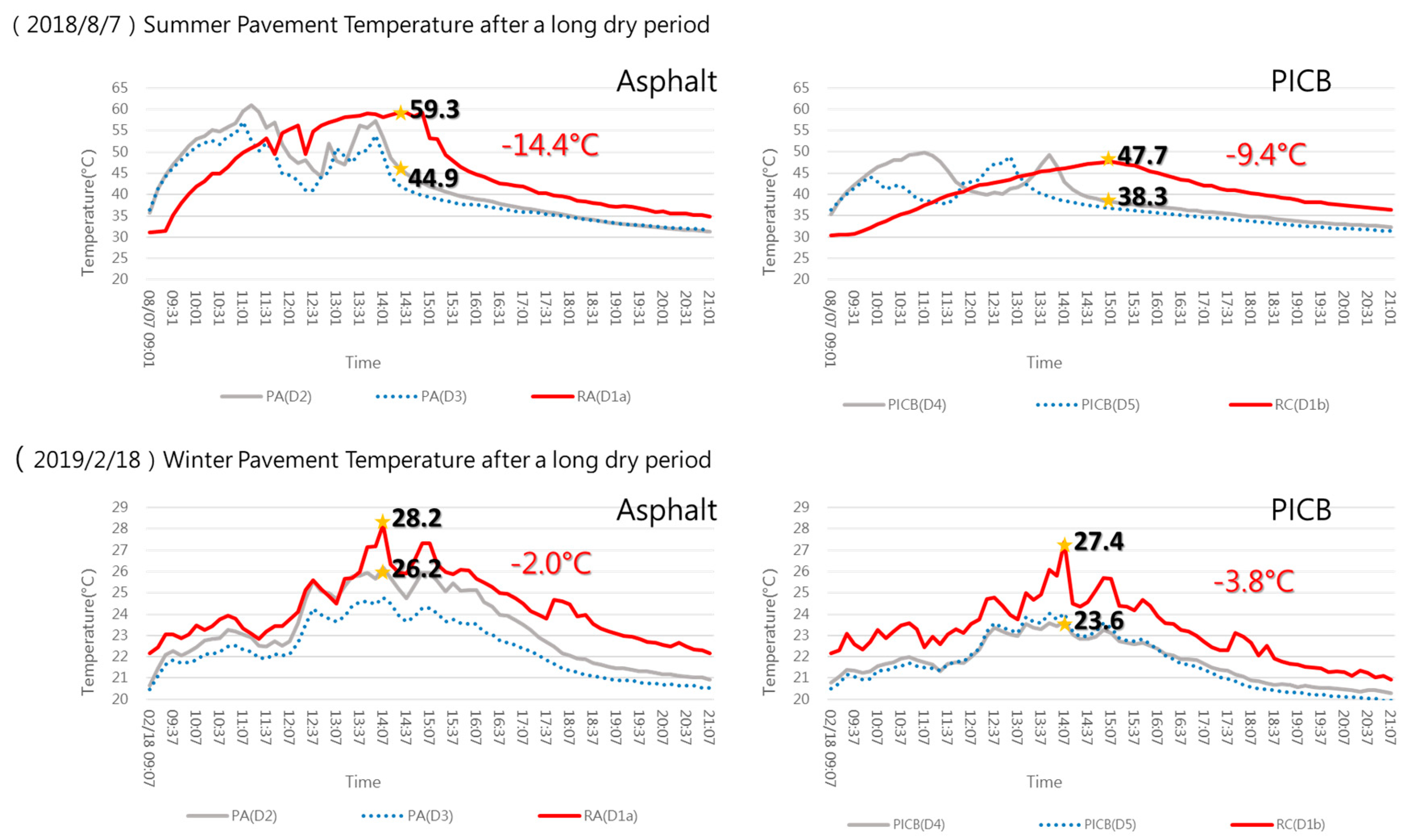

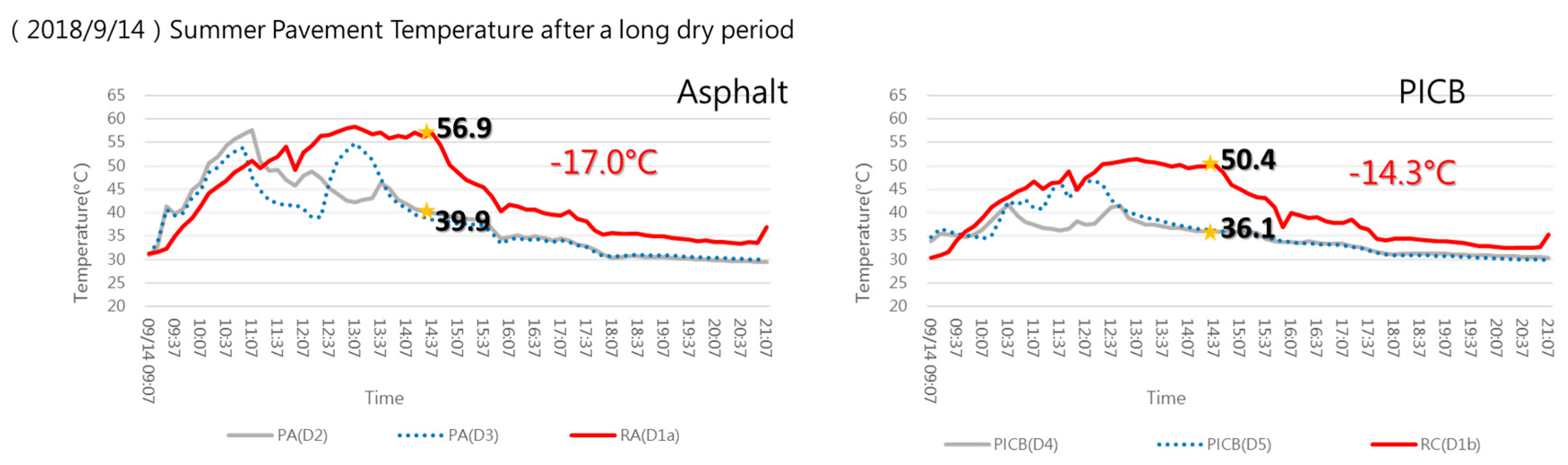

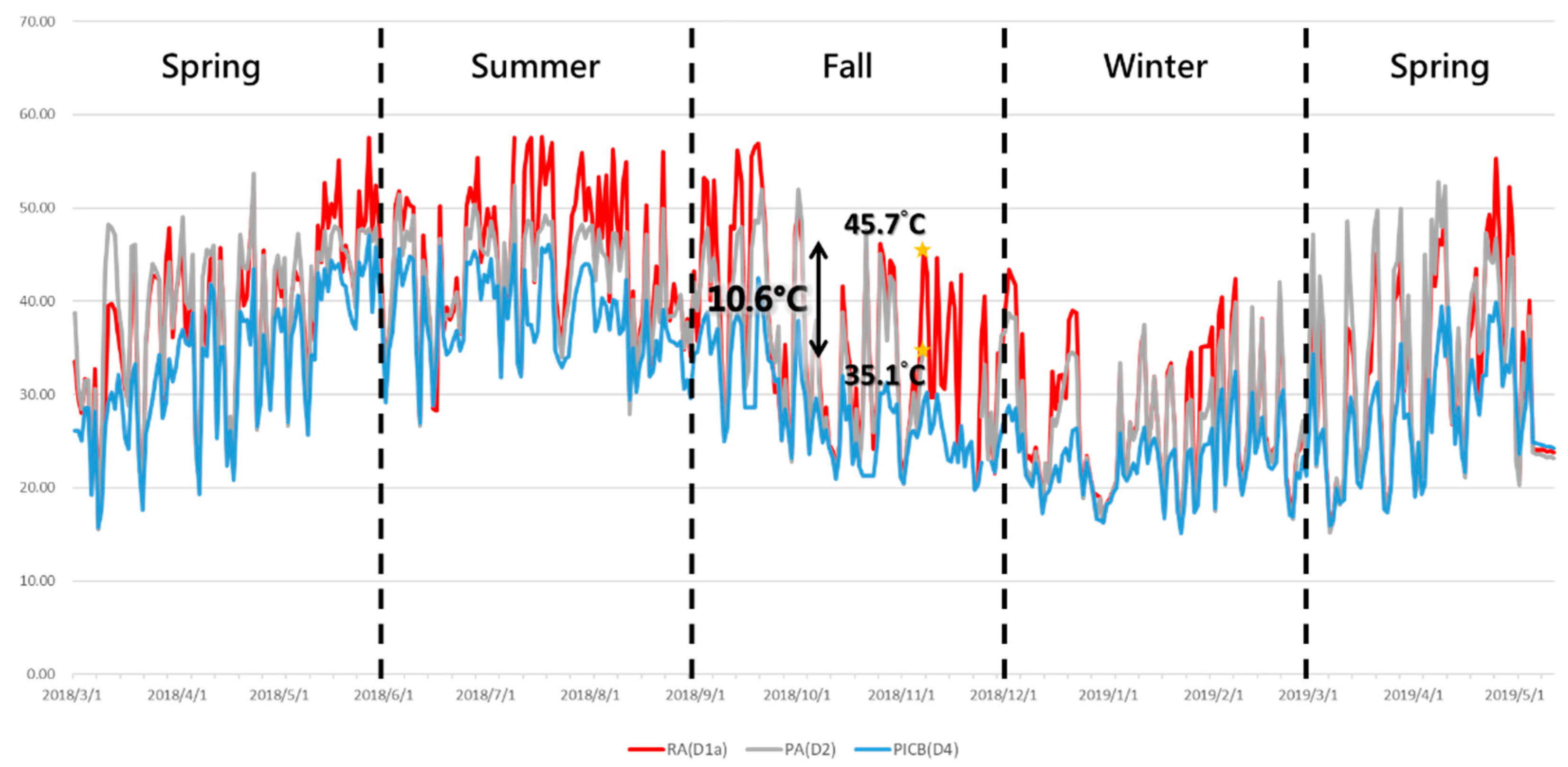

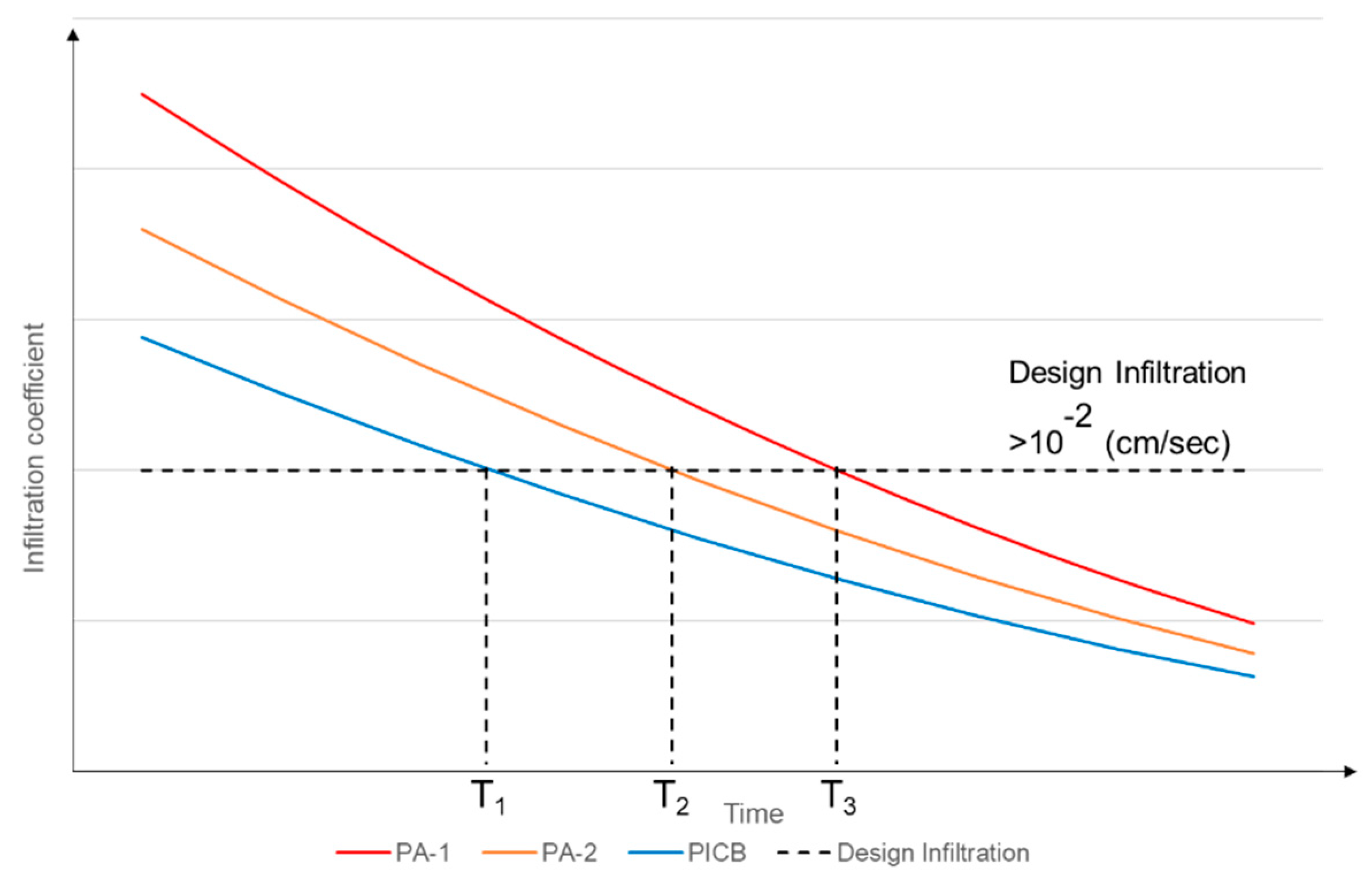

- Six surface temperature recorders—D1 at fast traffic lane with regular pavement; D1a for regular asphalt and D1b for regular concrete section; D2 and D3 for porous asphalt bicycle lanes; D4 and D5 for permeable interlocking concrete brick walkways; and D6 for regular concrete (stucco washing finish) inside the school.

- (f)

- Seven locations for infiltration rate measurements—F1 (south), F2 (north), and F3 (north on top of the drainage ditch) for porous asphalt bike lanes; F4 (north), F5 (north on top of underground stormwater tank); F6 (south on top of underground stormwater tank), and F7 (south) for PICB walkways.

3. Results and Discussion

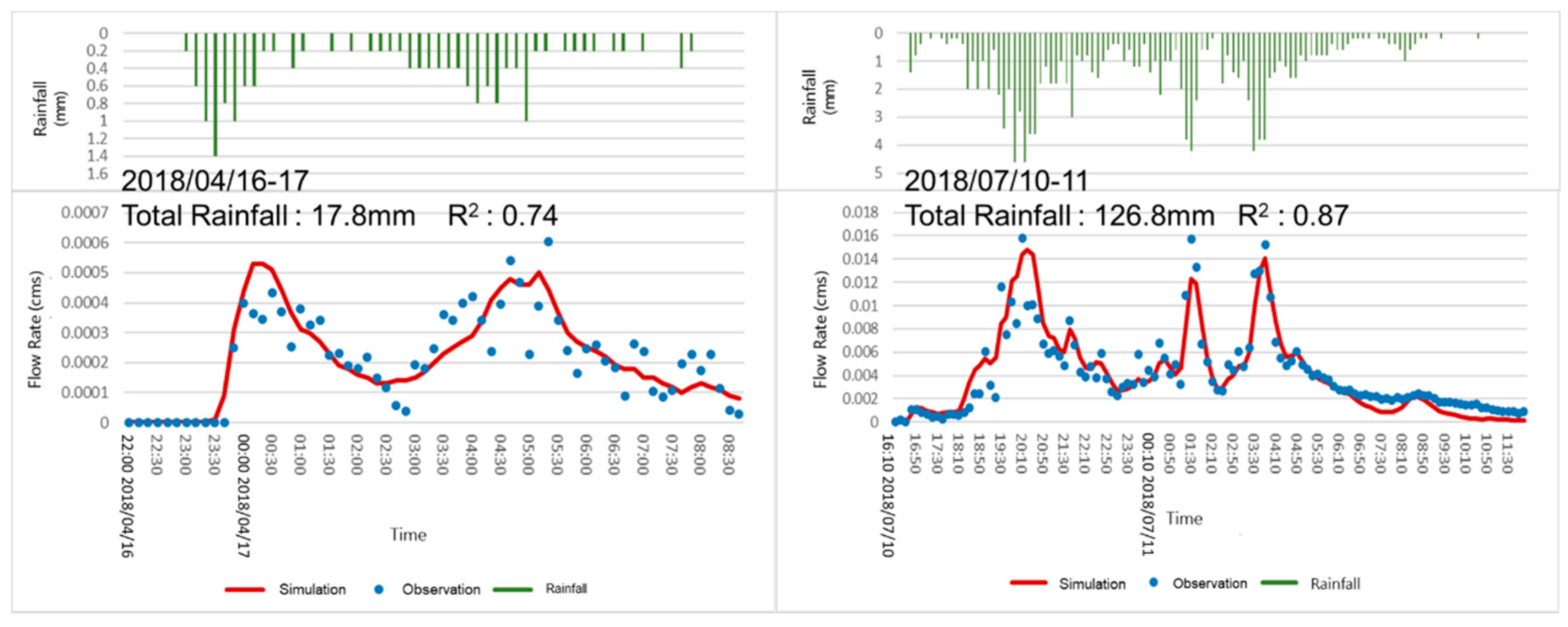

3.1. Rainfall Events

3.2. Groundwater and Stormwater Storage Tank Levels

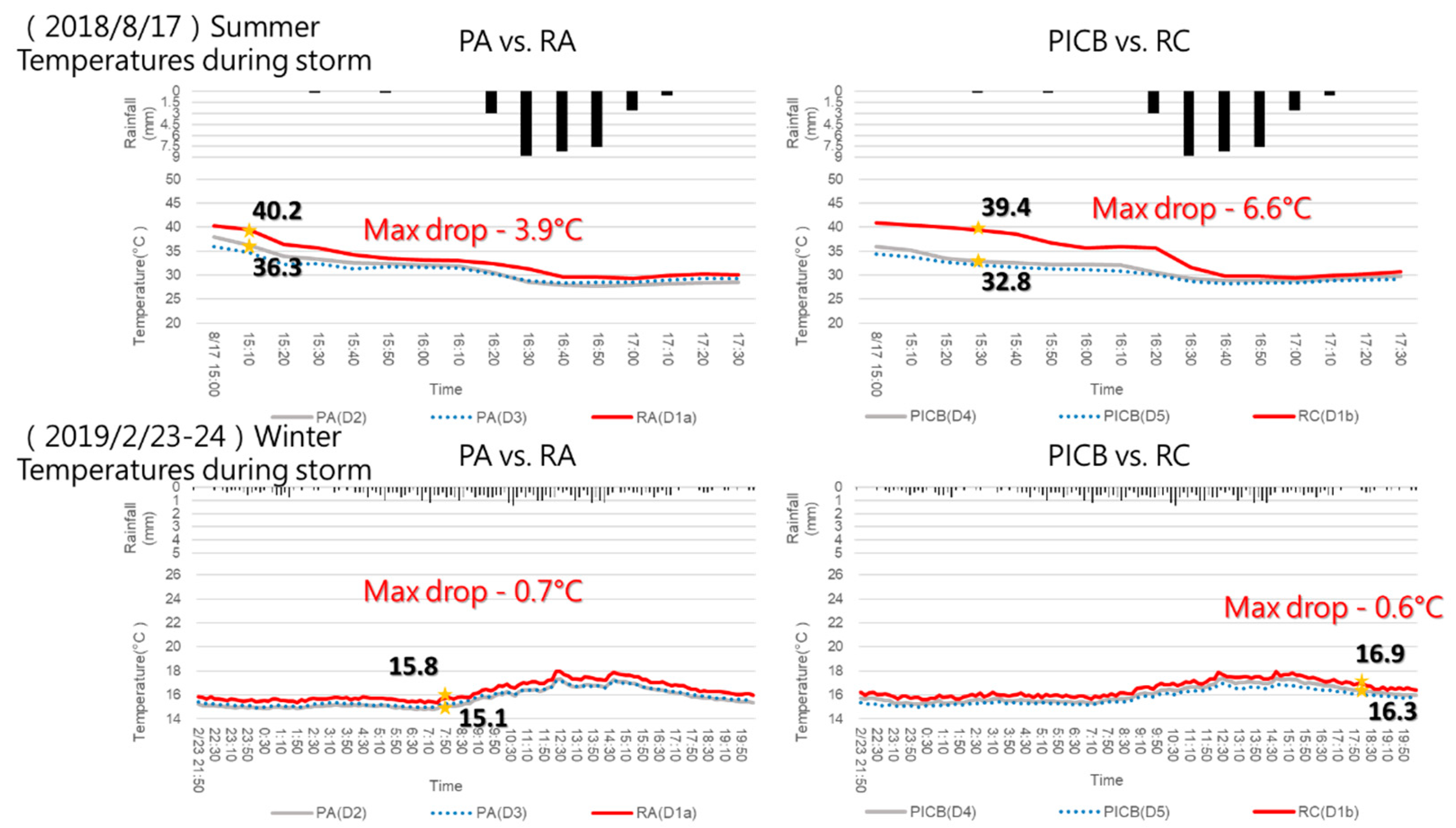

3.3. Surface Temperature Comparison

3.3.1. Temperatures during Storm Events

3.3.2. Temperatures during Dry Periods

3.4. Infiltration Rate Monitoring Results

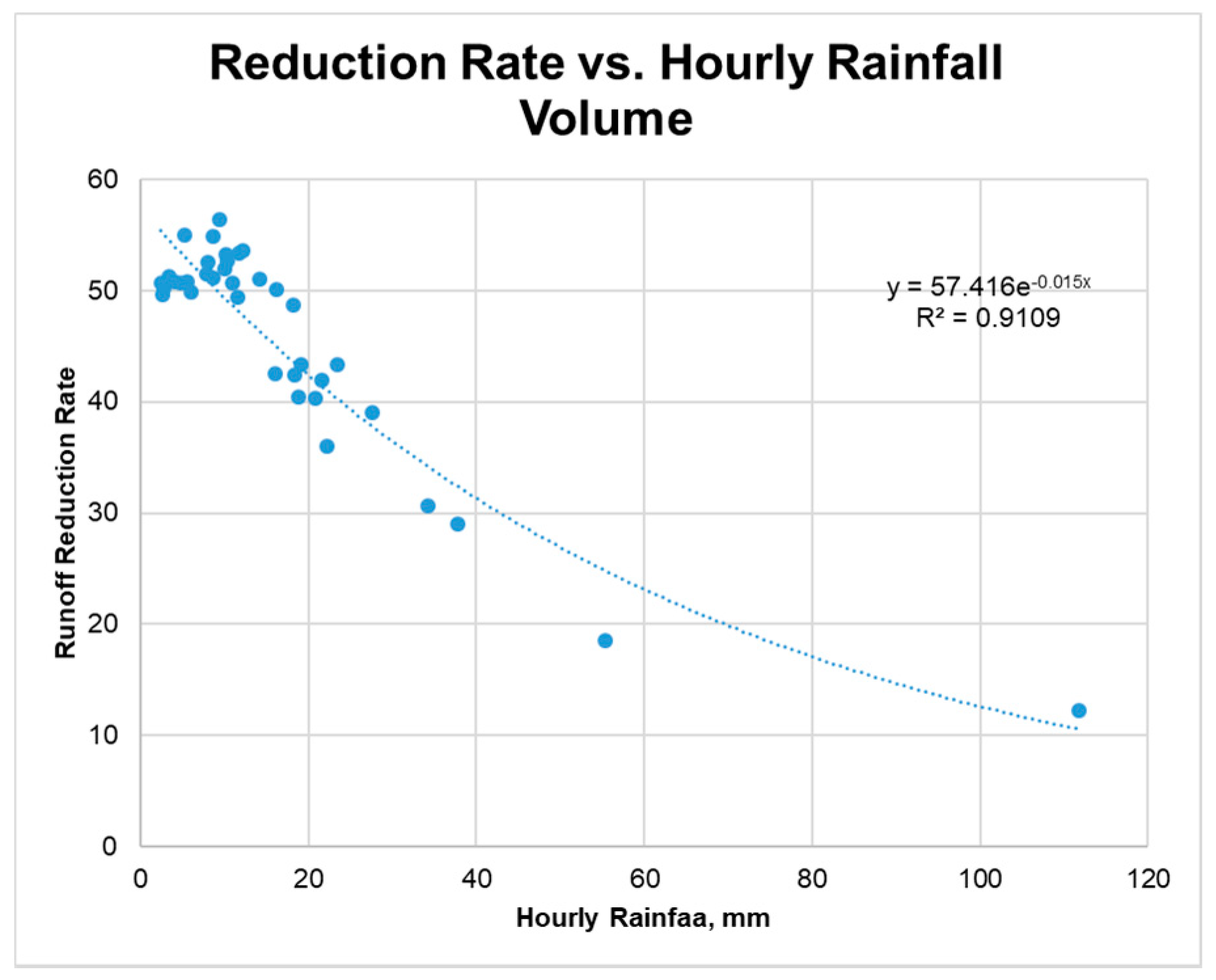

3.5. Runoff Volume Reduction

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Borst, M. Green Infrastructure Research: Permeable Pavement at EPA’S Edison Environmental Center; US EPA Office of Research and Development: Washington, DC, USA, 2016. Available online: https://cfpub.epa.gov/si/si_public_record_report.cfm?Lab=NRMRL&dirEntryId=332590 (accessed on 15 March 2017).

- Field, R.; Masters, H.; Singer, M. Status of Porous Pavement Research. Water Res. 1982, 1, 849–858. [Google Scholar] [CrossRef]

- Jia, H.; Yao, H.; Tang, Y.; Yu, S.L.; Field, R.; Tafuri, A.N. LID-BMPs Planning for Urban Runoff Control and the Case Study in China. J. Environ. Manag. 2015, 149, 65–76. [Google Scholar] [CrossRef] [PubMed]

- Novo, A.V.; Bayon, J.R.; Castro, D.; Rodriguez-Hernandez, J. Temperature Performance of Different Pervious Pavements in Rainwater Harvesting for Energy Recovery Purposes. Water Res. Manag. 2013, 27, 5003–5016. [Google Scholar] [CrossRef]

- Stempihar, J.J.; Pourshams, T.; Kaloush, K.E.; Rodesne, M.C. Porous Asphalt Pavement Temperature Effects on Overall Urban Heat Island. In Proceedings of the Transportation Research Board Annual Meeting, Washington, DC, USA, 16–19 April 2012. [Google Scholar]

- Selbig, W.R.; Buer, N. Hydraulic, Water-Quality, and Temperature Performance of Three Types of Permeable Pavement Under High Sediment Loading Conditions; U.S. Geological Survey Scientific Investigations Report 2018–5037; U.S. Geological Survey: Madison, WI, USA; Upper Midwest Water Science Center: Middleton, WI, USA, 2018; p. 44. [CrossRef]

- Fitch, G.M.; Bowers, B.F. Evaluation of Porous Asphalt Used at a Virginia Department of Transportation Park & Ride Facility; VTRC Report 18-R19; Virginia Transportation Research Council: Charlottesville, VA, USA, 2018; p. 24. [Google Scholar]

- Vaillancourt, C.; Duchesne, S.; Pelletier, G. Hydrologic Performance of Permeable Pavement as an Adaptive Measure in Urban Areas: Case Studies near Montreal, Canada. J. Hydrol. Eng. ASCE 2019, 24. [Google Scholar] [CrossRef]

- Eisenberg, B.; Collins, K.; Smith, D.R. Permeable Pavements, Permeable Pavements Task Committee; American Society of Civil Engineers: Reston, VA, USA, 2015; p. 262. [Google Scholar]

- Lin, J.Y.; Chen, C.F.; Ho, C.C. Evaluating the Effectiveness of Green Roads for Runoff Control. Sustain. Water Built Environ. ASCE 2018, 4, 04018001. [Google Scholar] [CrossRef]

- Yu, S.L.; Jia, H. The Sponge City Initiative –A New Paradigm: China’s Monumental Efforts in Urban Stormwater Management; Currents of the Environmental and Water Resources Institute, ASCE: Reston, VA, USA, 2016. [Google Scholar]

- The Guardian. Available online: https://www.theguardian.com/cities/2016/mar/15/bicycle-kingdom-reborn-pavement-cycling-taipei-taiwan?CMP=share_btn_fb.%2015%20Mar%202016 (accessed on 15 March 2016).

- Wischmeier, W.H.; Smith, D.D. Agriculture Handbook; 537; U.S. Department of Agriculture, Science and Education Administration: Hyattsville, MD, USA, 1978; pp. 1–58.

| Date | Total Rainfall (mm) | Rainfall Duration (H:min) | Date | Total Rainfall (mm) | Rainfall Duration (H:min) |

|---|---|---|---|---|---|

| 12 April 2018 | 35.5 | 01:10 | 10,11 October 2018 | 16.8 | 13:05 |

| 16,17 April 2018 | 17.8 | 08:40 | 11,12 October 2018 | 25.8 | 17:45 |

| 8 May 2018 | 26.6 | 04:00 | 16,17 October 2018 | 30.8 | 11:00 |

| 30 May 2018 | 18.2 | 00:30 | 1,2 November 2018 | 21.8 | 42:10 |

| 10,11 July 2018 | 126.8 | 16:10 | 23,24 December 2018 | 41.2 | 30:40 |

| 21 July 2018 | 26.6 | 07:20 | 16,17 January 2019 | 21.1 | 25:00 |

| 24 July 2018 | 27.8 | 02:00 | 23,24 February 2019 | 57.4 | 22:40 |

| 11 August 2018 | 30.2 | 07:50 | 6–10 March 2019 | 89.4 | 84:20 |

| 12 August 2018 | 45.8 | 06:50 | 25 March 2019 | 15.0 | 06:10 |

| 17 August 2018 | 31.2 | 01:40 | 29,30 March 2019 | 24.0 | 05:20 |

| 20 August 2018 | 13.0 | 00:40 | 11 April 2019 | 15.6 | 08:30 |

| 30 August 2018 | 54.4 | 09:20 | 15,16 April 2019 | 29.0 | 24:00 |

| 1 September 2018 | 22.6 | 01:10 | 20,21 April 2019 | 40.6 | 10:40 |

| 7 September 2018 | 39.6 | 03:50 | 22 April 2019 | 23.8 | 05:00 |

| 8 September 2018 | 152.0 | 06:00 | 1 May 2019 | 46.6 | 17:10 |

| 9 September 2018 | 18.4 | 17:20 | 2,3 May 2019 | 14.4 | 20:30 |

| 15,16 September 2018 | 20.4 | 27:30 | 6,7 May 2019 | 24.2 | 27:10 |

| 25–27 September 2018 | 24.2 | 35:00 | 9,10 May 2019 | 14.0 | 08:20 |

| Date | Total Rainfall (mm) | (North) Fullness (%) | (South) Fullness (%) | ||

|---|---|---|---|---|---|

| Before | After | Before | After | ||

| 12 April 2018 | 35.5 | 0 | 1 | 0 | 16 |

| 16,17 April 2018 | 17.8 | 0 | 0 | 0 | 8 |

| 8 May 2018 | 26.6 | 0 | 13 | 0 | 0 |

| 30 May 2018 | 18.2 | 0 | 0 | 0 | 0 |

| 10,11 July 2018 | 126.8 | 0 | 21 | 0 | 100 |

| 21 July 2018 | 26.6 | 0 | 0 | 1 | 20 |

| 24 July 2018 | 27.8 | 0 | 0 | 11 | 36 |

| 11 August 2018 | 30.2 | 0 | 14 | 5 | 81 |

| 12 August 2018 | 45.8 | 17 | 36 | 83 | 87 |

| 17 August 2018 | 31.2 | 0 | 10 | 43 | 85 |

| 20 August 2018 | 13.0 | 13 | 38 | 39 | 71 |

| 30 August 2018 | 54.4 | 18 | 68 | 13 | 81 |

| 1 August 2018 | 22.6 | 18 | 47 | 0 | 44 |

| 7 September 2018 | 39.6 | 21 | 61 | 5 | 65 |

| 8 September 2018 | 152.0 | 44 | 100 | 43 | 100 |

| 9 September 2018 | 18.4 | 100 | 100 | 100 | 100 |

| 15,16 September 2018 | 20.4 | 47 | 59 | 15 | 41 |

| 25–27 September 2018 | 24.2 | 59 | 71 | 12 | 1 |

| 10,11 October 2018 | 16.8 | 0 | 0 | 24 | 30 |

| 11,12 October 2018 | 25.8 | 0 | 0 | 28 | 55 |

| 16,17 October 2018 | 30.8 | 10 | 0 | 16 | 50 |

| 1,2 November 2018 | 21.8 | 0 | 1 | 12 | 21 |

| 23,24 December 2018 | 41.2 | 0 | 41 | 0 | 35 |

| 16,17 January 2019 | 21.1 | 0 | 5 | 14 | 4 |

| 23,24 February 2019 | 57.4 | 3 | 8 | 5 | 61 |

| 6–10 March 2019 | 89.4 | 0 | 33 | 0 | 42 |

| 25 March 2019 | 15.0 | 0 | 0 | 9 | 38 |

| 29,30 March 2019 | 24.0 | 0 | 0 | 35 | 59 |

| 11 April 2019 | 15.6 | 0 | 34 | 20 | 38 |

| 15,16 April 2019 | 29.0 | 48 | 72 | 33 | 62 |

| 20,21 April 2019 | 40.6 | 0 | 0 | 40 | 92 |

| 22 April 2019 | 23.8 | 0 | 23 | 50 | 95 |

| 1 May 2019 | 46.6 | 17 | 28 | 0 | 42 |

| 2,3 May 2019 | 14.4 | 25 | 47 | 32 | 37 |

| 6,7 May 2019 | 24.2 | 36 | 46 | 13 | 32 |

| 9,10 May 2019 | 14.0 | 35 | 36 | 24 | 36 |

| Location | F1 | F2 | F3 | F4 | F5 | F6 | F7 |

|---|---|---|---|---|---|---|---|

| Type of Pavement Date | Porous Asphalt | Permeable Interlocking Concrete Bricks | |||||

| South Side | North Side | North Side (Above Drain Ditch) | North Side | North Side (Above Storage Tank) | South Side (Above Storage Tank) | South Side | |

| February 2018 | 1.41 | 1.53 | 1.55 | 9.6 × 10−3 | 1.6 × 10−3 | 6.0 × 10−4 | 5.0 × 10−3 |

| March 2018 | 2.53 | 1.05 | 1.27 | 5.4 × 10−3 | 9.5 × 10−5 | 1.5 × 10−3 | 6.0 × 10−3 |

| April 2018 | 1.26 | 1.11 | 1.35 | 1.1 × 10−2 | 3.2 × 10−4 | 2.0 × 10−3 | 1.1 × 10−3 |

| May 2018 | 2.64 | 1.08 | 1.21 | 9.2 × 10−3 | 3.7 × 10−4 | 4.3 × 10−5 | 1.0 × 10−3 |

| June 2018 | 1.79 | 0.9 | 1 | 1.8 × 10−3 | 3.5 × 10−5 | 1.2 × 10−5 | 2.0 × 10−4 |

| July 2018 | 2.6 | 0.65 | 0.94 | 4.6 × 10−3 | 3.9 × 10−4 | 4.1 × 10−6 | 9.9 × 10−4 |

| August 2018 | 2.71 | 0.58 | 0.81 | 2.0 × 10−3 | 1.3 × 10−4 | 5.4 × 10−5 | 4.8 × 10−4 |

| September 2018 | 1.89 | 0.45 | 0.77 | 2.7 × 10−3 | 1.2 × 10−3 | * | 6.4 × 10−4 |

| October 2018 | 1.86 | 0.42 | 0.84 | 1.17 × 10−3 | 2.66 × 10−4 | 1.66 × 10−5 | 6.82 × 10−4 |

| November 2018 | 1.81 | 0.29 | 0.42 | 1.14 × 10−3 | 1.62 × 10−4 | 9.59 × 10−5 | 2.98 × 10−4 |

| December 2018 | 0 | 0 | 0 | 6 × 10−4 | 1.91 × 10−4 | 2.64 × 10−6 | 1.9 × 10−4 |

| January 2019 | 0 | 0 | 0 | 2.26 × 10−4 | 7.82 × 10−4 | * | 3.04 × 10−3 |

| February 2019 | 0 | 0 | 0 | 9.99 × 10−3 | 1 × 10−3 | * | 2.95 × 10−3 |

| March 2019 | 0 | 0 | 0 | 1.24 × 10−3 | 2.83 × 10−4 | * | 1.22 × 10−3 |

| April 2019 | 0 | 0 | 0 | 1.44. × 10−3 | 1.55 × 10−4 | * | 1.12 × 10−3 |

| Date | Total Rainfall (mm) | Rainfall Duration | (North/South) Reduction Rate (%) |

|---|---|---|---|

| 12 April 2018 | 35.5 | 01:10 | 21/35 |

| 16,17 April 2018 | 17.8 | 08:40 | 47/45 |

| 8 May 2018 | 26.6 | 04:00 | 41/54 |

| 30 May 2018 | 18.2 | 00:30 | 54/52 |

| 10,11 July 2018 | 126.8 | 16:10 | 22/32 |

| 21 July 2018 | 26.6 | 07:20 | 44/42 |

| 24 July 2018 | 27.8 | 02:00 | 43/41 |

| 11 August 2018 | 30.2 | 07:50 | 45/46 |

| 12 August 2018 | 45.8 | 06:50 | 44/46 |

| 17 August 2018 | 31.2 | 01:40 | 45/55 |

| 20 August 2018 | 13.0 | 00:40 | 45/47 |

| 30 August 2018 | 54.4 | 09:20 | 45/45 |

| 1 September 2018 | 22.6 | 01:10 | 44/42 |

| 7 September 2018 | 39.6 | 03:50 | 29/26 |

| 8 September 2018 | 152.0 | 06:00 | 17/16 |

| 9 September 2018 | 35.5 | 17:20 | 41/41 |

| 15,16 September 2018 | 17.8 | 27:30 | 44/43 |

| 25–27 September 2018 | 26.6 | 35:00 | 44/44 |

| 10,11 October 2018 | 16.8 | 13:05 | 45/45 |

| 11,12 October 2018 | 25.8 | 17:45 | 38/36 |

| 16,17 October 2018 | 30.8 | 11:00 | 50/47 |

| 1/2 November 2018 | 21.8 | 42:10 | 55/55 |

| 23,24 December 2018 | 41.2 | 30:40 | 44/43 |

| 16,17 January 2019 | 21.2 | 25:00 | 77/77 |

| 23,24 February 2019 | 57.4 | 22:40 | 43/42 |

| 6–10 March 2019 | 89.4 | 84:20 | 41/40 |

| 25 March 2019 | 15.0 | 06:10 | 43/42 |

| 29,30 March 2019 | 24.0 | 05:20 | 39/28 |

| 11 April 2019 | 15.6 | 08:30 | 47/45 |

| 15,16 April 2019 | 29.0 | 24:00 | 43/42 |

| 20,21 April 2019 | 40.6 | 10:40 | 42/41 |

| 22 April 2019 | 23.8 | 05:00 | 44/42 |

| 1 May 2019 | 46.6 | 17:10 | 43/42 |

| 2,3 May 2019 | 14.4 | 20:30 | 44/43 |

| 6,7 May 2019 | 24.2 | 27:10 | 43/43 |

| 9,10 May 2019 | 14.0 | 08:20 | 43/43 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Y.-Y.; Lo, S.-L.; Ho, C.-C.; Lin, J.-Y.; Yu, S.L. Field Testing of Porous Pavement Performance on Runoff and Temperature Control in Taipei City. Water 2019, 11, 2635. https://doi.org/10.3390/w11122635

Cheng Y-Y, Lo S-L, Ho C-C, Lin J-Y, Yu SL. Field Testing of Porous Pavement Performance on Runoff and Temperature Control in Taipei City. Water. 2019; 11(12):2635. https://doi.org/10.3390/w11122635

Chicago/Turabian StyleCheng, Yung-Yun, Shang-Lien Lo, Chia-Chun Ho, Jen-Yang Lin, and Shaw L. Yu. 2019. "Field Testing of Porous Pavement Performance on Runoff and Temperature Control in Taipei City" Water 11, no. 12: 2635. https://doi.org/10.3390/w11122635

APA StyleCheng, Y.-Y., Lo, S.-L., Ho, C.-C., Lin, J.-Y., & Yu, S. L. (2019). Field Testing of Porous Pavement Performance on Runoff and Temperature Control in Taipei City. Water, 11(12), 2635. https://doi.org/10.3390/w11122635