Powdered Activated Carbon Exacerbates Fouling in MBR Treating Olive Mill Wastewater

Abstract

1. Introduction

2. Materials and Methods

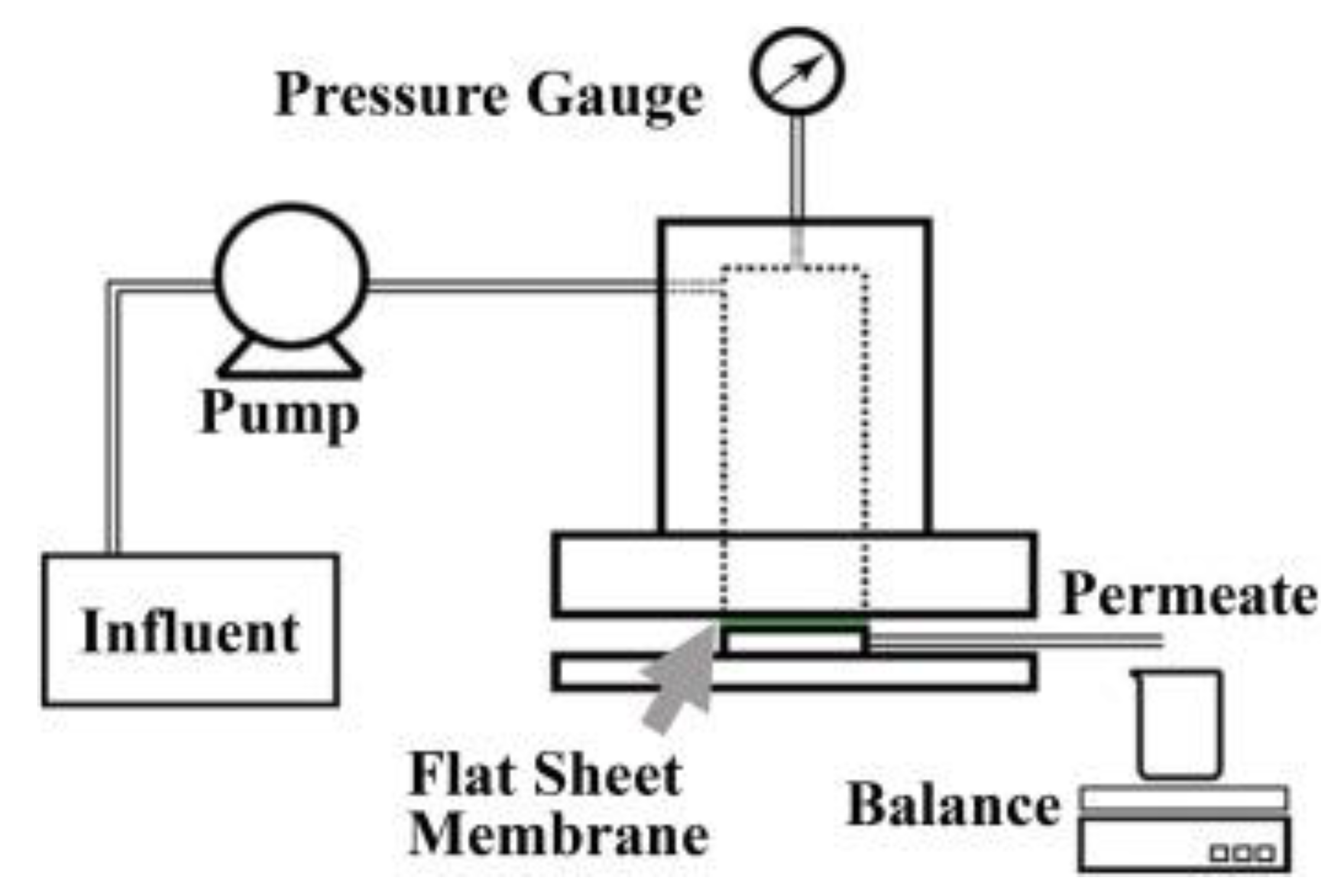

2.1. MBR System and Operating Conditions

2.2. Fouling Rate Analysis with SMP and Membrane Permeability Tests

2.3. QCM-D Sensor Preparation and Coating with PES for SMP and EPS Adhesion Measurements

2.4. SMP Adherence Property Analysis with QCM-D

2.5. Confocal Laser Scanning Microscopy (CLSM)

2.6. Scanning Electron Microscopy (SEM)

2.7. Gel Permeation Chromatography (GPC)

3. Results and Discussion

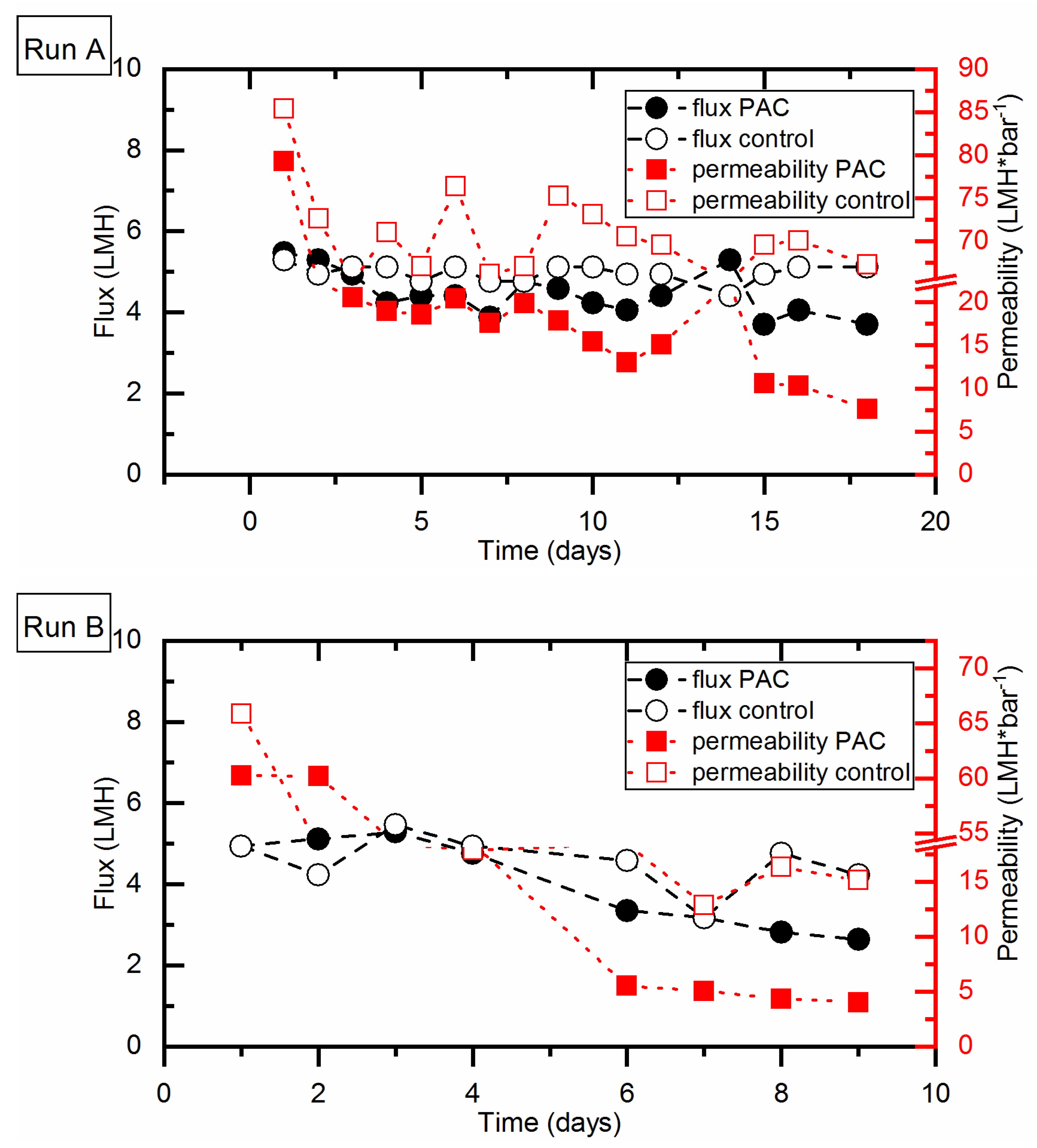

3.1. The Effect of Supplementing MBR with PAC on Membrane Fouling

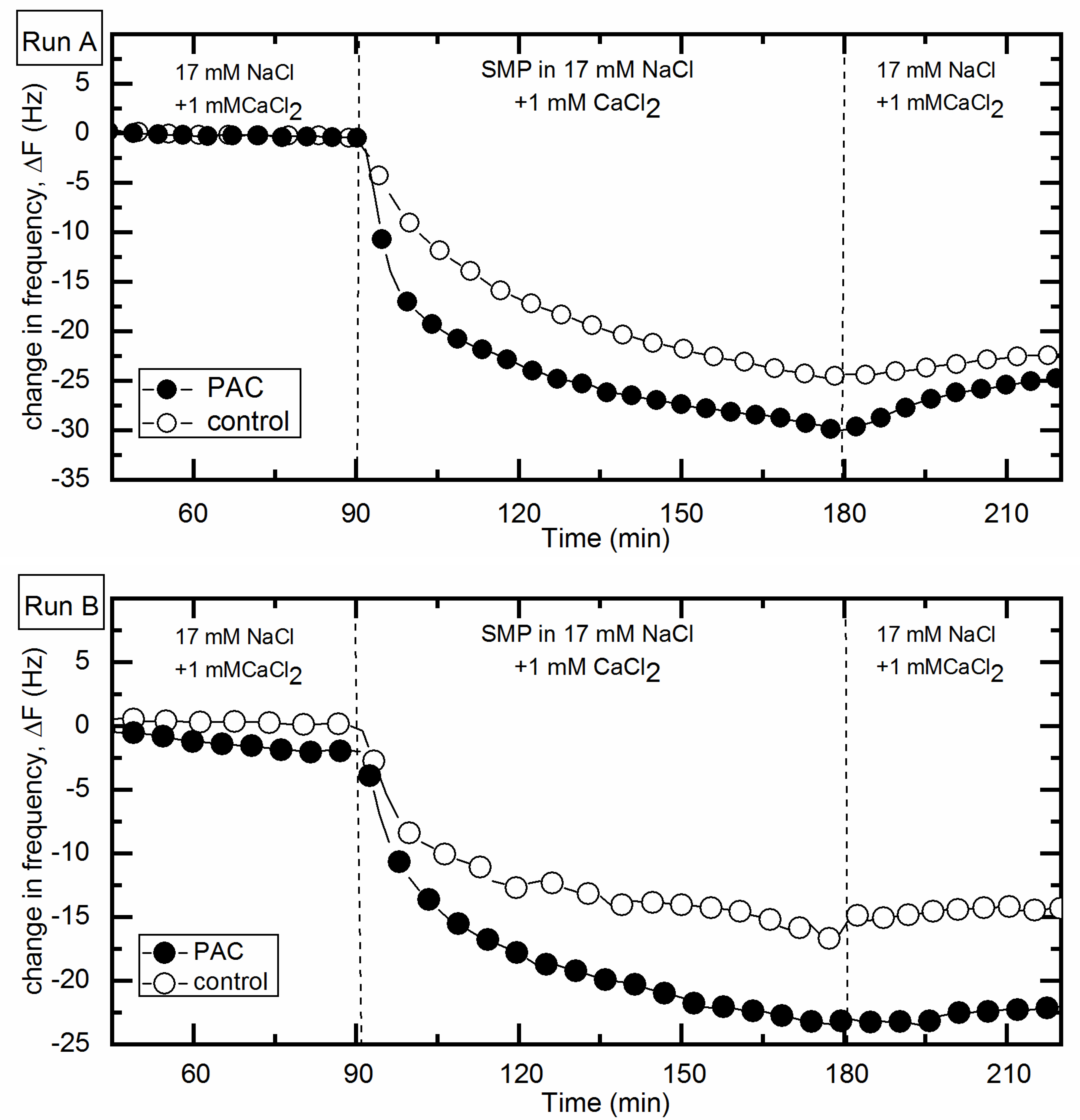

3.2. The Effect of Supplementing an MBR with PAC on the SMP Adherence Properties

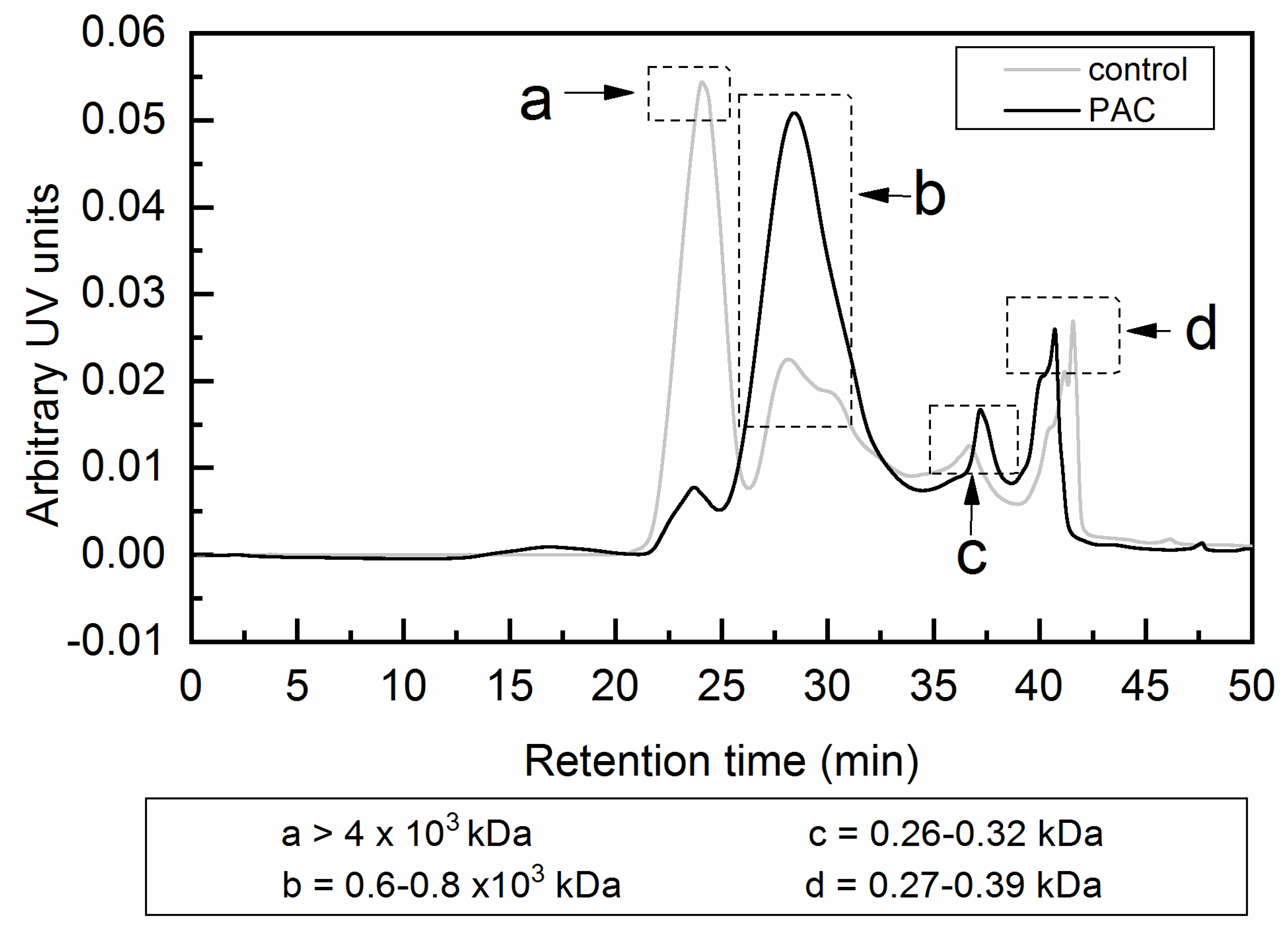

3.3. The Effect of Supplementing an MBR with PAC on SMP Composition

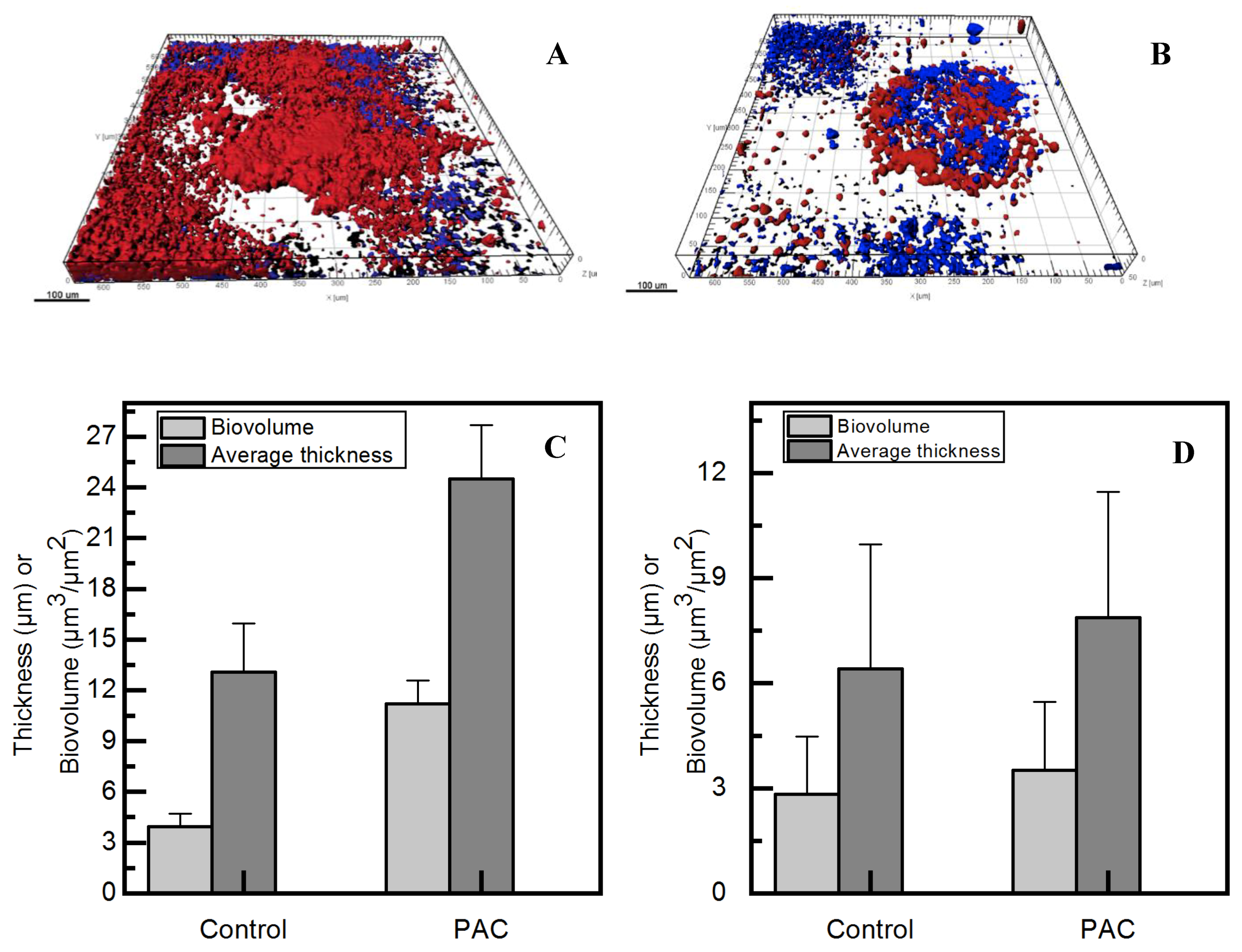

3.4. Variation in Biofilm Formation with PAC Addition

4. Concluding Remarks

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Khan, S.J.; Visvanathan, C.; Jegatheesan, V. Effect of powdered activated carbon (PAC) and cationic polymer on biofouling mitigation in hybrid MBRs. Bioresour. Technol. 2012, 113, 165–168. [Google Scholar] [CrossRef]

- Le-Clech, P.; Chen, V.; Fane, T.A.G. Fouling in membrane bioreactors used in wastewater treatment. J. Membr. Sci. 2006, 284, 17–53. [Google Scholar] [CrossRef]

- Gander, M.; Jefferson, B.; Judd, S. Aerobic MBRs for domestic wastewater treatment: A review with cost considerations. Sep. Purif. Technol. 2000, 18, 119–130. [Google Scholar] [CrossRef]

- Judd, S. The MBR Book: Principles and Applications of Membrane Bioreactors for Water and Wastewater Treatment; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Guo, W.; Ngo, H.H.; Li, J. A mini-review on membrane fouling. Bioresour. Technol. 2012, 122, 27–34. [Google Scholar] [CrossRef] [PubMed]

- Hall-Stoodley, L.; Costerton, J.W.; Stoodley, P. Bacterial biofilms: From the natural environment to infectious diseases. Nat. Rev. Microbiol. 2004, 2, 95. [Google Scholar] [CrossRef]

- Liao, B.; Bagley, D.; Kraemer, H.; Leppard, G.; Liss, S. A review of biofouling and its control in membrane separation bioreactors. Water Environ. Res. 2004, 76, 425–436. [Google Scholar] [CrossRef]

- Herzberg, M.; Dosoretz, C.G.; Tarre, S.; Green, M. Patchy biofilm coverage can explain the potential advantage of BGAC reactors. Environ. Sci. Technol. 2003, 37, 4274–4280. [Google Scholar] [CrossRef]

- Herzberg, M.; Dosoretz, C.G.; Tarre, S.; Michael, B.; Dror, M.; Green, M. Simultaneous removal of atrazine and nitrate using a biological granulated activated carbon (BGAC) reactor. J. Chem. Technol. Biotechnol. Int. Res. Process Environ.Clean Technol. 2004, 79, 626–631. [Google Scholar] [CrossRef]

- Satyawali, Y.; Balakrishnan, M. Effect of PAC addition on sludge properties in an MBR treating high strength wastewater. Water Res. 2009, 43, 1577–1588. [Google Scholar] [CrossRef]

- Skouteris, G.; Saroj, D.; Melidis, P.; Hai, F.I.; Ouki, S. The effect of activated carbon addition on membrane bioreactor processes for wastewater treatment and reclamation—A critical review. Bioresour. Technol. 2015, 185, 399–410. [Google Scholar] [CrossRef]

- Goswami, L.; Kumar, R.V.; Borah, S.N.; Manikandan, N.A.; Pakshirajan, K.; Pugazhenthi, G. Membrane bioreactor and integrated membrane bioreactor systems for micropollutant removal from wastewater: A review. J. Water Process Eng. 2018, 26, 314–328. [Google Scholar] [CrossRef]

- Cecconet, D.; Molognoni, D.; Callegari, A.; Capodaglio, A. Biological combination processes for efficient removal of pharmaceutically active compounds from wastewater: A review and future perspectives. J. Environ. Chem. Eng. 2017, 5, 3590–3603. [Google Scholar] [CrossRef]

- Li, Y.Z.; He, Y.L.; Liu, Y.H.; Yang, S.C.; Zhang, G.J. Comparison of the filtration characteristics between biological powdered activated carbon sludge and activated sludge in submerged membrane bioreactors. Desalination 2005, 174, 305–314. [Google Scholar] [CrossRef]

- Ying, Z.; Ping, G. Effect of powdered activated carbon dosage on retarding membrane fouling in MBR. Sep. Purif. Technol. 2006, 52, 154–160. [Google Scholar] [CrossRef]

- Johir, M.; Aryal, R.; Vigneswaran, S.; Kandasamy, J.; Grasmick, A. Influence of supporting media in suspension on membrane fouling reduction in submerged membrane bioreactor (SMBR). J. Membr. Sci. 2011, 374, 121–128. [Google Scholar] [CrossRef]

- Zhang, S.; Xiong, J.; Zuo, X.; Liao, W.; Ma, C.; He, J.; Chen, Z. Characteristics of the sludge filterability and microbial composition in PAC hybrid MBR: Effect of PAC replenishment ratio. Biochem. Eng. J. 2019, 145, 10–17. [Google Scholar] [CrossRef]

- Zouboulis, A.; Gkotsis, P.; Zamboulis, D.; Mitrakas, M. Application of powdered activated carbon (PAC) for membrane fouling control in a pilot-scale MBR system. Water Sci. Technol. 2017, 75, 2350–2357. [Google Scholar] [CrossRef]

- Ng, C.A.; Sun, D.; Zhang, J.; Wu, B.; Fane, A.G. Mechanisms of fouling control in membrane bioreactors by the addition of powdered activated carbon. Sep. Sci. Technol. 2010, 45, 873–889. [Google Scholar] [CrossRef]

- Al-Malah, K.; Azzam, M.O.; Abu-Lail, N.I. Olive mills effluent (OME) wastewater post-treatment using activated clay. Sep. Purif. Technol. 2000, 20, 225–234. [Google Scholar] [CrossRef]

- Niaounakis, M.; Halvadakis, C.P. Olive Processing Waste Management: Literature Review and Patent Survey; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Miccio, M.; Poletto, M. Disposal of olive mill waste waters through concentration and combustion: Comparison between different process options. Chem. Eng. Trans. 2009, 17, 221–226. [Google Scholar]

- Aktas, E.S.; Imre, S.; Ersoy, L. Characterization and lime treatment of olive mill wastewater. Water Res. 2001, 35, 2336–2340. [Google Scholar] [CrossRef]

- Rivas, F.J.; Beltrán, F.J.; Gimeno, O.; Frades, J. Treatment of olive oil mill wastewater by Fenton’s reagent. J. Agric. Food Chem. 2001, 49, 1873–1880. [Google Scholar] [CrossRef] [PubMed]

- Inan, H.; Dimoglo, A.; Şimşek, H.; Karpuzcu, M. Olive oil mill wastewater treatment by means of electro-coagulation. Sep. Purif. Technol. 2004, 36, 23–31. [Google Scholar] [CrossRef]

- Adhoum, N.; Monser, L. Decolourization and removal of phenolic compounds from olive mill wastewater by electrocoagulation. Chem. Eng. Process. Process Intensif. 2004, 43, 1281–1287. [Google Scholar] [CrossRef]

- Tsioulpas, A.; Dimou, D.; Iconomou, D.; Aggelis, G. Phenolic removal in olive oil mill wastewater by strains of Pleurotus spp. in respect to their phenol oxidase (laccase) activity. Bioresour. Technol. 2002, 84, 251–257. [Google Scholar] [CrossRef]

- Hamdi, M. Toxicity and biodegradability of olive mill wastewaters in batch anaerobic digestion. Appl. Biochem. Biotechnol. 1992, 37, 155–163. [Google Scholar] [CrossRef]

- Eroğlu, E.; Eroğlu, İ.; Gündüz, U.; Türker, L.; Yücel, M. Biological hydrogen production from olive mill wastewater with two-stage processes. Int. J. Hydrog. Energy 2006, 31, 1527–1535. [Google Scholar] [CrossRef]

- Pulido, J.M.O. A review on the use of membrane technology and fouling control for olive mill wastewater treatment. Sci. Total Environ. 2016, 563, 664–675. [Google Scholar] [CrossRef]

- Stoller, M.; Bravi, M.; Chianese, A. Threshold flux measurements of a nanofiltration membrane module by critical flux data conversion. Desalination 2013, 315, 142–148. [Google Scholar] [CrossRef]

- Ioannou-Ttofa, L.; Michael-Kordatou, I.; Fattas, S.; Eusebio, A.; Ribeiro, B.; Rusan, M.; Amer, A.; Zuraiqi, S.; Waismand, M.; Linder, C. Treatment efficiency and economic feasibility of biological oxidation, membrane filtration and separation processes, and advanced oxidation for the purification and valorization of olive mill wastewater. Water Res. 2017, 114, 1–13. [Google Scholar] [CrossRef]

- Paraskeva, C.; Papadakis, V.; Tsarouchi, E.; Kanellopoulou, D.; Koutsoukos, P. Membrane processing for olive mill wastewater fractionation. Desalination 2007, 213, 218–229. [Google Scholar] [CrossRef]

- Fazal, S.; Zhang, B.; Zhong, Z.; Gao, L.; Chen, X. Industrial wastewater treatment by using MBR (membrane bioreactor) review study. J. Environ. Prot. 2015, 6, 584. [Google Scholar] [CrossRef]

- Dhaouadi, H.; Marrot, B. Olive mill wastewater treatment in a membrane bioreactor: Process feasibility and performances. Chem. Eng. J. 2008, 145, 225–231. [Google Scholar] [CrossRef]

- Wang, X.; Ruengruglikit, C.; Wang, Y.-W.; Huang, Q. Interfacial interactions of pectin with bovine serum albumin studied by quartz crystal microbalance with dissipation monitoring: Effect of ionic strength. J. Agric. Food Chem. 2007, 55, 10425–10431. [Google Scholar] [CrossRef] [PubMed]

- Heydorn, A.; Nielsen, A.T.; Hentzer, M.; Sternberg, C.; Givskov, M.; Ersbøll, B.K.; Molin, S. Quantification of biofilm structures by the novel computer program COMSTAT. Microbiology 2000, 146, 2395–2407. [Google Scholar] [CrossRef] [PubMed]

- Sweity, A.; Zere, T.R.; David, I.; Bason, S.; Oren, Y.; Ronen, Z.; Herzberg, M. Side effects of antiscalants on biofouling of reverse osmosis membranes in brackish water desalination. J. Membr. Sci. 2015, 481, 172–187. [Google Scholar] [CrossRef]

| Run A | Run B | |||

|---|---|---|---|---|

| Parameter | PAC | Control | PAC | Control |

| DO (mg/L) | 0.5 ± 0.2 | 0.7 ± 0.2 | 0.2 ± 0.0 | 0.3 ± 0.0 |

| pH | 6.5 ± 0.2 | 6.3 ± 0.2 | 6.7 ± 0.1 | 5.5 ± 0.05 |

| Volatile suspended solids (VSS, g/L) | 3.3 ± 0.4 | 4.5 ± 0.8 | 3.7 ± 0.6 | 6.7 ± 1.5 |

| Temperature ºC | 23.4 ± 0.4 | 23.5 ± 0.6 | 24.8 ± 0.9 | 24.0 ± 0.3 |

| Volumetric organic loading rate (g/(h·l)) | 0.74 ± 0.1 | 0.66 ± 0.02 | 0.27 ± 0.07 | 0.28 ± 0.05 |

| Specific BOD removal rate (g/ (h·gVSS)) | 0.18 ± 0.03 | 0.12 ± 0.03 | 0.06±0.02 | 0.01 ± 0.00 |

| Specific DOC removal rate (g/ (h·gVSS)) | 0.07 ± 0.02 | 0.06 ± 0.01 | 0.05 ± 0.02 | 0.03 ± 0.01 |

| Run A | ||||||||||

| Parameter | PAC | Control | ||||||||

| Influent | MLSS | Effluent | Biodegradation (%) | Overall removal (%) | Influent | MLSS | Effluent | Biodegradation (%) | Overall removal (%) | |

| BOD (g/L) | 44 ± 0.0 | 8.1 ± 0.2 | 7.4 ± 0.4 | 81.6 ± 2.0 | 83.2 ± 4.5 | 35 ± 0.1 | 5.1 ± 0.7 | 5.8 ± 0.4 | 85.4 ± 11.7 | 83.4 ± 5.7 |

| DOC (g/L) | 21 ± 0.9 | 6.7 ± 1.7 | 5.8 ± 1.9 | 68.1 ± 17.5 | 72.4 ± 23.9 | 20 ± 1.2 | 5.6 ± 0.5 | 5.0 ± 0.2 | 72.0 ± 7.7 | 75 ± 5.4 |

| Phenol content (g/L as gallic acid) | 0.8 ± 0.2 | 0.5 ± 0.1 | 0.4 ± 0.1 | 37.5 ± 12.0 | 50 ± 17.7 | 0.6 ± 0.1 | 0.4 ± 0.1 | 0.4± 0.0 | 33.3 ± 10.0 | 33.3 ± 5.5 |

| Run B | ||||||||||

| PAC | Control | |||||||||

| BOD (g/lL | 21 ± 0.8 | 6.1 ± 0.0 | 5.7 ± 0.5 | 71.0 ± 2.7 | 72.8 ± 7.0 | 17 ± 1.4 | 11.3 ± 0.7 | 8.7 ± 0.4 | 33.5 ± 3.5 | 48.8 ± 13.0 |

| DOC (g/L) | 19 ± 2.1 | 6.3 ± 0.7 | 5.7 ± 1.1 | 66.8 ± 10.5 | 70.0 ± 15 | 19 ± 1.7 | 6.2 ± 1.3 | 5.6 ± 0.9 | 67.4 ± 15.4 | 70.5 ± 13.0 |

| Phenol content (g/L as gallic acid) | 0.7 ± 0.2 | 0.7 ± 0.0 | 0.6 ± 0.1 | 0.0 ± 0.0 | 14.3 ± 4.7 | 0.8 ± 0.1 | 0.5 ± 0.1 | 0.5 ± 0.1 | 37.5 ± 8.8 | 37.5 ± 8.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ran, N.; Gilron, J.; Sharon-Gojman, R.; Herzberg, M. Powdered Activated Carbon Exacerbates Fouling in MBR Treating Olive Mill Wastewater. Water 2019, 11, 2498. https://doi.org/10.3390/w11122498

Ran N, Gilron J, Sharon-Gojman R, Herzberg M. Powdered Activated Carbon Exacerbates Fouling in MBR Treating Olive Mill Wastewater. Water. 2019; 11(12):2498. https://doi.org/10.3390/w11122498

Chicago/Turabian StyleRan, Noya, Jack Gilron, Revital Sharon-Gojman, and Moshe Herzberg. 2019. "Powdered Activated Carbon Exacerbates Fouling in MBR Treating Olive Mill Wastewater" Water 11, no. 12: 2498. https://doi.org/10.3390/w11122498

APA StyleRan, N., Gilron, J., Sharon-Gojman, R., & Herzberg, M. (2019). Powdered Activated Carbon Exacerbates Fouling in MBR Treating Olive Mill Wastewater. Water, 11(12), 2498. https://doi.org/10.3390/w11122498