Precision Irrigation Scheduling Using ECH2O Moisture Sensors for Lettuce Cultivated in a Soilless Substrate Culture

Abstract

:1. Introduction

2. Materials and Methods

2.1. Substrates Preparation

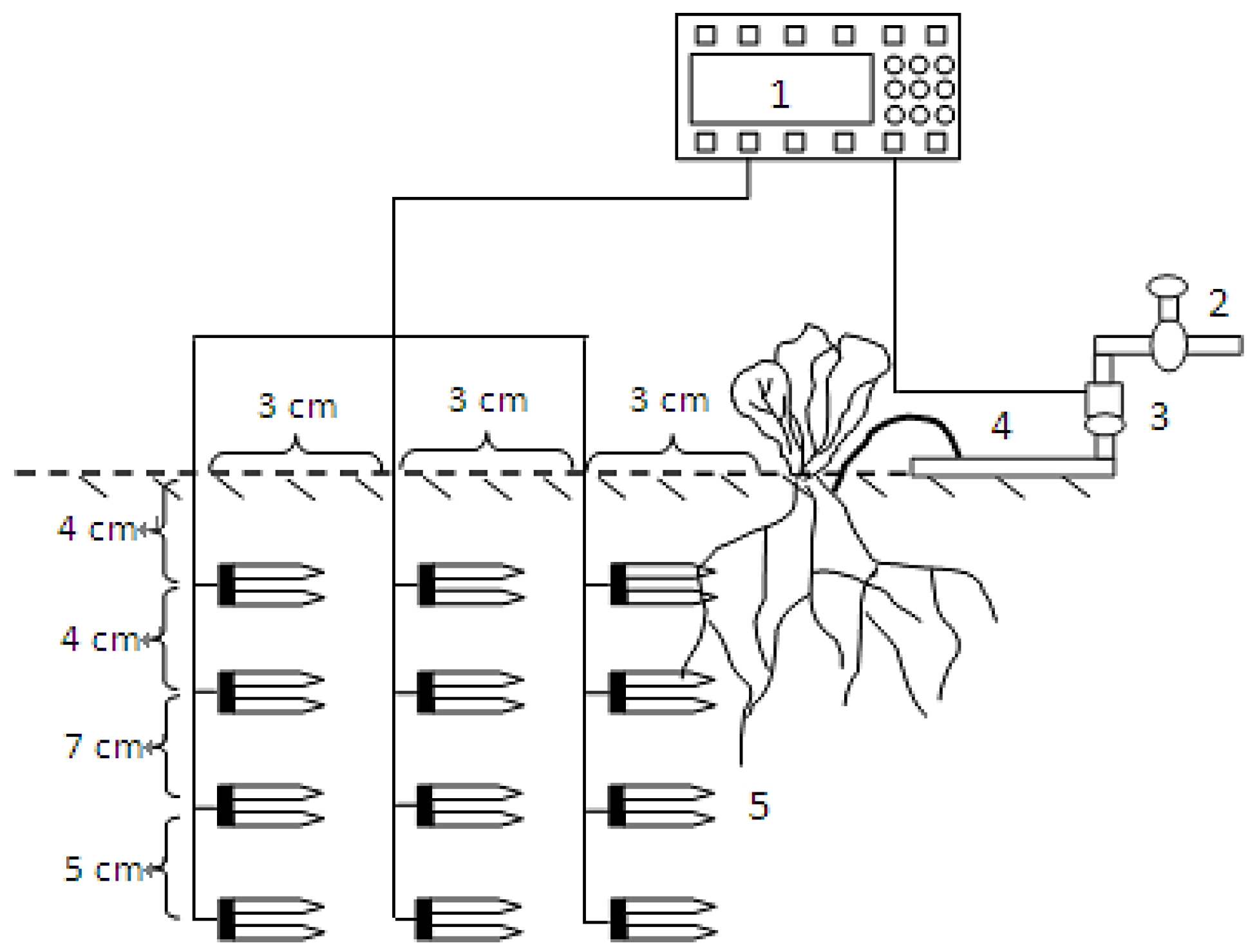

2.2. Sensor Description and Operation

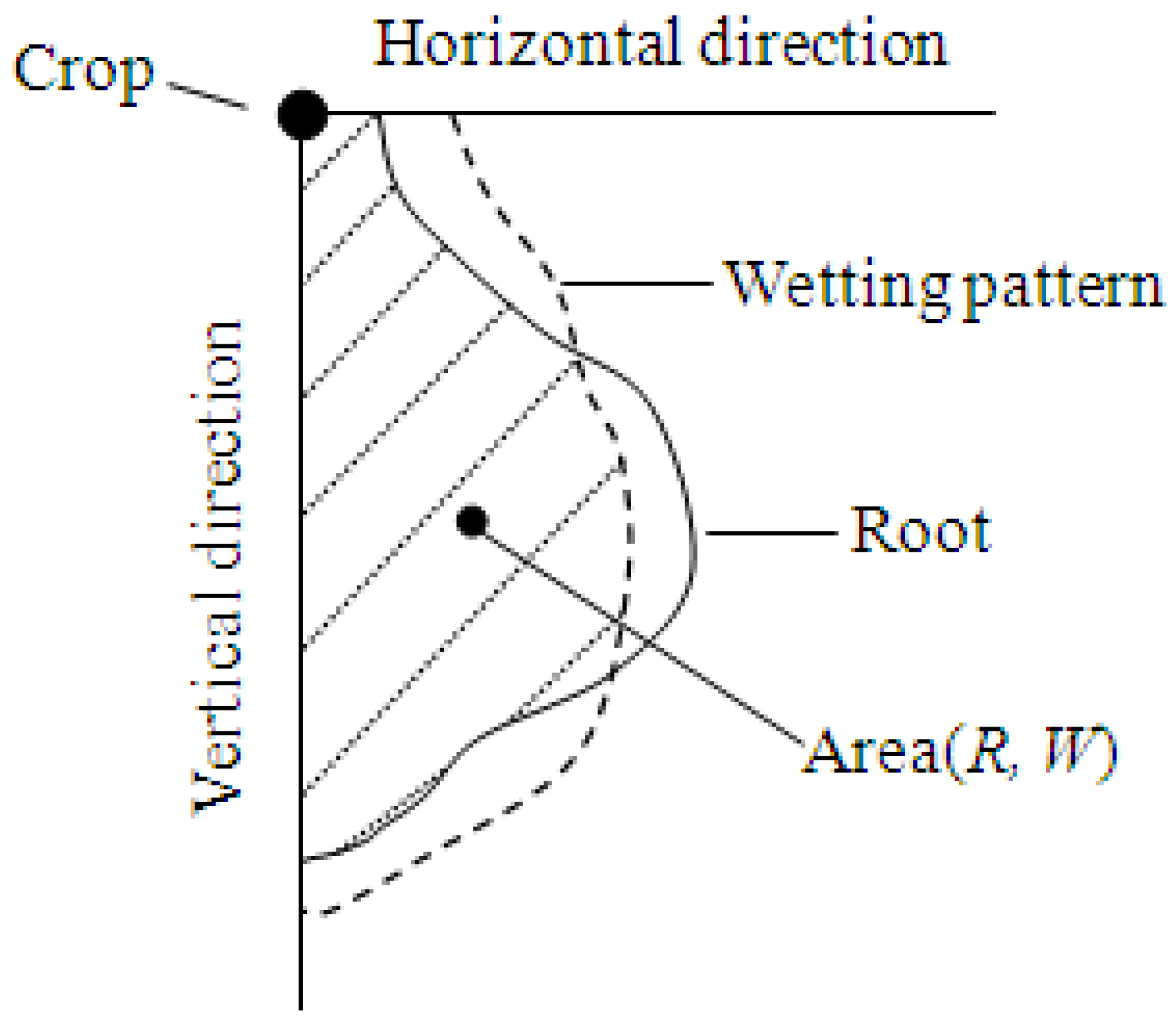

2.3. Wetting Pattern Model

2.4. Root Zone Model

2.5. Matched Model of Wetting Pattern and Crop Root Zone

3. Results and Discussion

3.1. Model Calibration

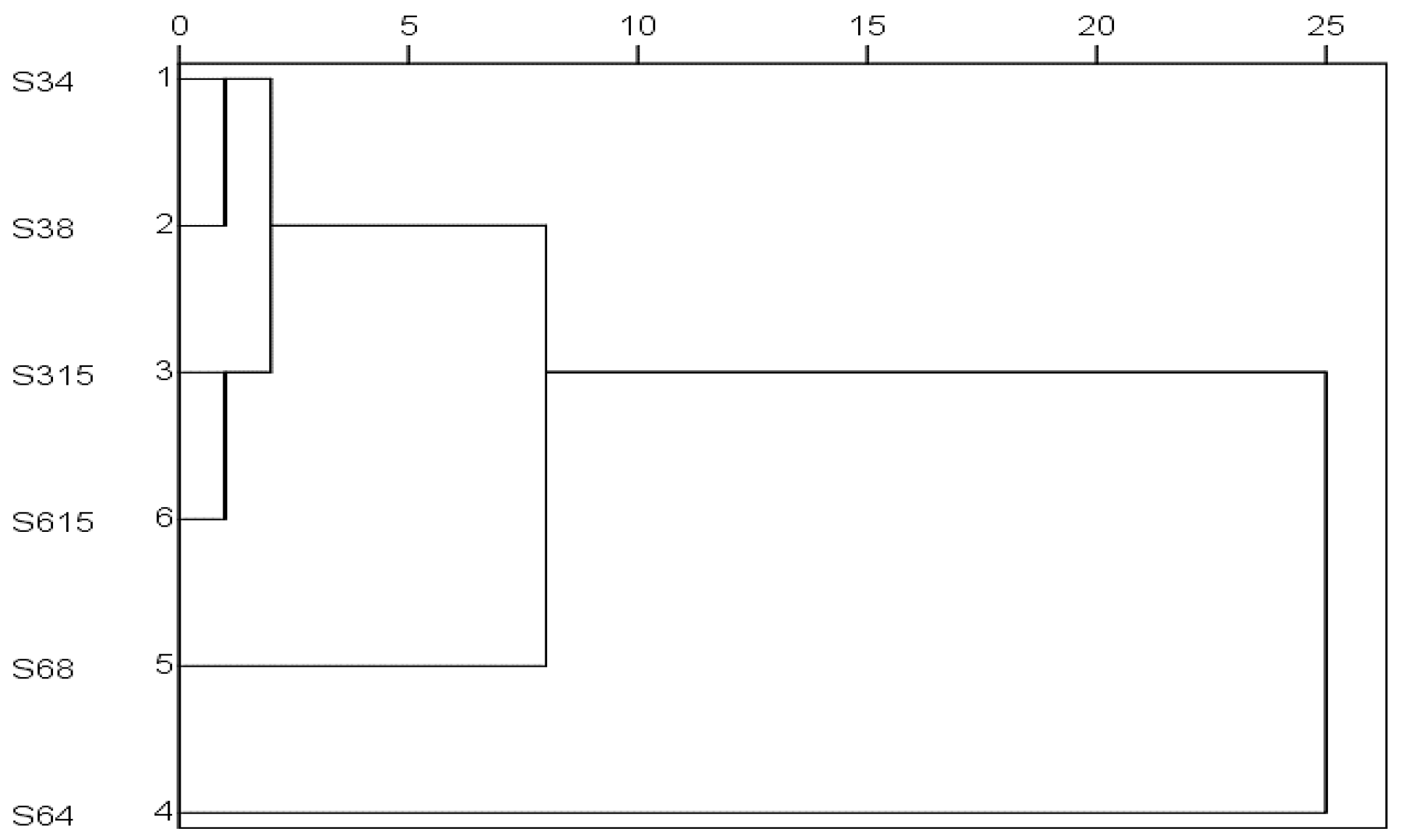

3.2. Sensor Number and Placement

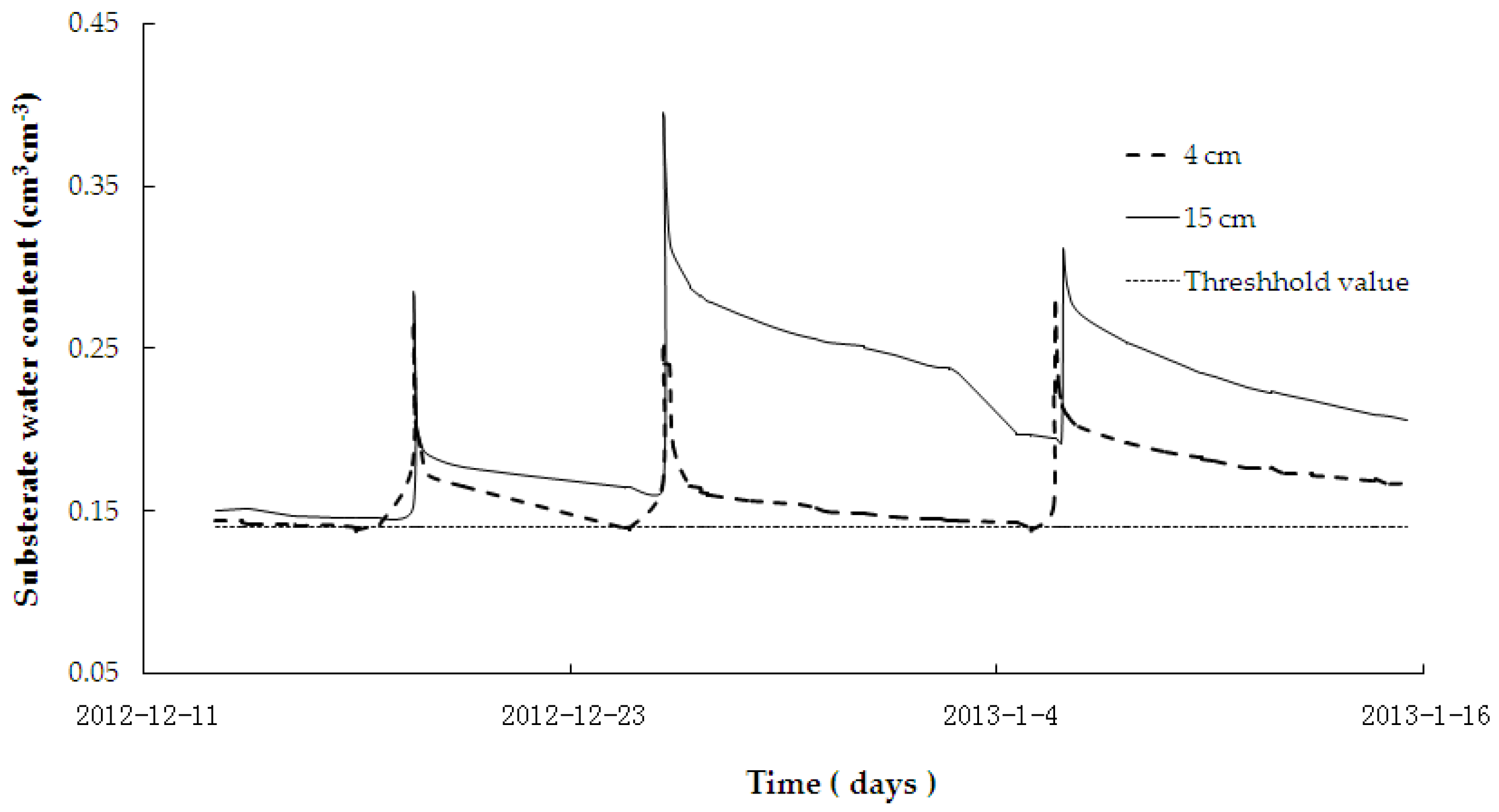

3.3. Moisture Dynamic in Irrigation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nemali, K.S.; Montesano, F.; Dove, S.K.; Van Iersel, M.W. Calibration and performance of moisture sensors in soilless substrates: ECH2O and Theta probes. Sci. Hortic. 2007, 112, 227–234. [Google Scholar] [CrossRef]

- Sánchez-Molina, J.A.; Rodríguez, F.; Guzmán, J.L.; Ramírez-Arias, J.A. Water content virtual sensor for tomatoes in coconut coir substrate for irrigation control design. Agric. Water Manag. 2015, 151, 114–125. [Google Scholar] [CrossRef]

- Cardenas-Lailhacar, B.; Dukes, M.D. Precision of soil moisture sensor irrigation controllers under field conditions. Agric. Water Manag. 2010, 97, 666–672. [Google Scholar] [CrossRef]

- Dobbs, N.A.; Migliaccio, K.W.; Dukes, M.D. Interactive Irrigation Tool for Simulating Smart Irrigation Technologies in Lawn Turf. J. Irrig. Drain. Eng. 2013, 139, 745–854. [Google Scholar] [CrossRef]

- Kenneth, F.; Heaney, J.P.; Miguel, M. Predicting and managing residential potable irrigation using parcel-level databases. J. Am. Water Works Assoc. 2013, 105, 45–46. [Google Scholar]

- Blonquist, J.M., Jr.; Jones, S.B.; Robinson, D.A. Precise irrigation scheduling for turfgrass using a subsurface electromagnetic soil moisture sensor. Agric. Water Manag. 2006, 84, 153–165. [Google Scholar] [CrossRef]

- Raviv, M.; Lieth, J.H. Soilless Culture Theory and Practice; Elsevier: New York, NY, USA, 2008; pp. 6–7. [Google Scholar]

- Naddaf, O.A.; Livieratos, I.; Stamatakis, A.; Tsirogiannis, I.; Gizas, G.; Savvas, D. Hydraulic characteristics of composted pig manure, perlite, and mixtures of them, and their impact on cucumber grown on bags. Sci. Hortic. 2011, 129, 135–141. [Google Scholar] [CrossRef]

- Liu, Z.G.; Li, P.P.; Hu, Y.G.; Wang, J. Modeling the wetting patterns in cultivation substrates under drip irrigation. J. Coast. Res. 2015, SI73, 173–176. [Google Scholar] [CrossRef]

- Rodriguez, D.; Reca, J.; Martínez, J.; Urrestarazu, M. New Adaptive Hybrid–Automatic Irrigation Control System for Soilless Culture. J. Irrig. Drain. Eng. 2015, 141, 04014083. [Google Scholar] [CrossRef]

- Li, J.; Smith, D.W.; Fityus, S.G.; Sheng, D. Numerical analysis of neutron moisture probe measurements. Int. J. Geomech. 2003, 3, 11–20. [Google Scholar] [CrossRef]

- Pelletier, M.G.; Karthikeyan, S.; Green, T.R.; Schwartz, R.C.; Wanjura, J.D.; Holt, G.A. Soil Moisture Sensing via Swept Frequency Based Microwave Sensors. Sensors 2012, 12, 753–767. [Google Scholar] [CrossRef] [PubMed]

- Park, J.S.; Son, J.E. Analysis of Moisture Characteristics in Rockwool Slabs using Time Domain Reflectometry (TDR) Sensors and Their Applications to Paprika Cultivation. Prot. Hortic. Plant Fact. 2009, 18, 238–243. [Google Scholar]

- Seo, T.C.; Kim, Y.C.; Kim, K.Y.; Yun, H.K. Optimal Supply Amount and Strength of Nutrient Solution for Ripe-harvesting Tamatioes Grown under Perlite Culture System of Semi-forcing Cropping. Korean J. Hortic. Sci. Technol. 2003, 21, 79–85. [Google Scholar]

- Morel, P.; Michel, J.C. Control of the moisture content of growing media by time domain reflectometry (TDR). Agronomie 2004, 24, 275–279. [Google Scholar] [CrossRef]

- Liu, Z.G.; Li, P.P.; Hu, Y.G.; Zhang, X. Calibration method for dectection of matrix water content with dielectric-type moisture sensor. Trans. CSAE 2011, 27, 109–202. [Google Scholar]

- Burnett, S.E.; Van Iersel, M.W. Morphology and irrigation efficiency of Gauralindheimeri grown with capacitance sensor-controlled irrigation. Hortscience 2008, 43, 1555–1560. [Google Scholar]

- Mendes, L.B.; Li, H.; Xin, H.; Barbosa do Nascimento, J.W. Evaluation of EC-5 soil moisture sensors for real-time determination of poultry manure or litter moisture content. Appl. Eng. Agric. 2014, 30, 277–284. [Google Scholar]

- Liu, Z.G.; Wang, J.Z.; Xu, Y.F.; Li, P.P. Root Growth Model of Lettuce under Different Cultivation Substrates and Irrigation Modes. Trans. Chin. Soc. Agric. Mach. 2014, 45, 284–288. [Google Scholar]

- Elnesr, M.N.; Alazba, A.A. The effects of three techniques that change the wetting patterns over subsurface drip-irrigated potatoes. Span. J. Agric. Res. 2015, 13, e1204. [Google Scholar] [CrossRef]

- Satchithanantham, S.; Krahn, V.; Sager, S. Shallow groundwater uptake and irrigation water distribution within the potato root zone. Agric. Water Manag. 2014, 132, 101–110. [Google Scholar] [CrossRef]

- Liu, Z.G.; Li, P.P.; Hu, Y.G.; Wang, J. Wetting patterns and water distributions in cultivation media under drip irrigation. Comput. Electron. Agric. 2015, 112, 200–208. [Google Scholar] [CrossRef]

- Ahmadi, S.H.; Sepaskhah, A.R.; Andersen, M.N.; Plauborg, F.; Jensen, C.R.; Hansen, S. Modeling root length density of field grown potatoes under different irrigation strategies and soil textures using artificial neural networks. Field Crops Res. 2014, 162, 99–107. [Google Scholar] [CrossRef]

- Kage, H.; Kochler, M.; StÜtzel, H. Root growth of cauliflower (Brassica oleracea L. botrytis) under unstressed condition: Measurement and modeling. Plant Soil 2000, 223, 131–145. [Google Scholar] [CrossRef]

| Coefficient | Root Zone Radius (R) | |||

|---|---|---|---|---|

| h | i | j | k | |

| d | 5.04 × 10−10 | −5.61 × 10−7 | 4.24 × 10−5 | 0.08 |

| e | −1.15 × 10−8 | 1.48 × 10−5 | −4.48 × 10−3 | −0.53 |

| f | 4.69 × 10−8 | −7.26 × 10−5 | 2.98 × 10−2 | −0.34 |

| g | −2.67 × 10−8 | 3.58 × 10−5 | −9.95 × 10−3 | −0.46 |

| EC-5 Sensor | Root Depth (Z) | Wetted Radius | Wetted Depth | ||||

|---|---|---|---|---|---|---|---|

| a | b | c | bz | A1 | n1 | A2 | n2 |

| 1.83 | 522.24 | 597.41 | 0.014 | 0.15 | 1.01 | 2.96 | 0.28 |

| Root Radius, R (cm) | Root Depth, Z (cm) | Wetted Radius (cm) | Wetted Depth (cm) | Substrate Moisture (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sim. | Obs. | RAE (%) | Sim. | Obs. | RAE (%) | Sim. | Obs. | RAE (%) | Sim. | Obs. | RAE (%) | Sim. | Obs. | RAE (%) |

| 2.06 | 2.26 | 8.85 | 5.98 | 5.95 | 0.51 | 2.92 | 2.81 | 3.92 | 3.33 | 3.15 | 5.71 | 12.35 | 13.67 | 9.66 |

| 3.58 | 3.47 | 3.17 | 7.74 | 8.50 | 8.94 | 3.85 | 4.20 | 8.33 | 4.43 | 4.60 | 3.70 | 23.71 | 26.93 | 11.96 |

| 4.58 | 4.38 | 4.57 | 9.10 | 9.43 | 3.50 | 4.43 | 4.61 | 3.91 | 5.62 | 5.23 | 7.46 | 39.01 | 35.42 | 10.14 |

| 5.33 | 5.61 | 4.99 | 11.07 | 12.20 | 9.26 | 5.84 | 5.24 | 11.45 | 5.69 | 6.33 | 10.11 | 44.61 | 41.14 | 8.44 |

| 5.26 | 5.85 | 10.09 | 13.67 | 13.15 | 3.95 | 6.71 | 7.34 | 8.58 | 6.49 | 7.03 | 7.68 | 53.26 | 50.12 | 6.27 |

| 6.74 | 7.52 | 10.37 | 15.24 | 16.12 | 5.46 | 7.02 | 7.84 | 10.46 | 7.75 | 7.04 | 10.09 | 64.11 | 60.90 | 5.27 |

| Parameter | Sensor Position | |||||

|---|---|---|---|---|---|---|

| (3,4) cm | (3,8) cm | (3,15) cm | (6,4) cm | (6,8) cm | (6,15) cm | |

| Average value % | 16.3 | 19.8 | 21.4 | 8.6 | 12.1 | 20.3 |

| Standard deviation % | 2.5 | 2.8 | 2.2 | 1.1 | 1.5 | 2.3 |

| Coefficient of variation % | 15.3 | 14.1 | 10.2 | 12.8 | 12.4 | 11.3 |

| Irrigation Method | Irrigation Amount (kg) | Leakage Amount (kg) | Leakage Rate (%) |

|---|---|---|---|

| Conventional Irrigation | 40.26 | 10.48 | 26.03 |

| Precise Irrigation | 32.45 | 3.35 | 10.32 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Xu, Q. Precision Irrigation Scheduling Using ECH2O Moisture Sensors for Lettuce Cultivated in a Soilless Substrate Culture. Water 2018, 10, 549. https://doi.org/10.3390/w10050549

Liu Z, Xu Q. Precision Irrigation Scheduling Using ECH2O Moisture Sensors for Lettuce Cultivated in a Soilless Substrate Culture. Water. 2018; 10(5):549. https://doi.org/10.3390/w10050549

Chicago/Turabian StyleLiu, Zhigang, and Qinchao Xu. 2018. "Precision Irrigation Scheduling Using ECH2O Moisture Sensors for Lettuce Cultivated in a Soilless Substrate Culture" Water 10, no. 5: 549. https://doi.org/10.3390/w10050549

APA StyleLiu, Z., & Xu, Q. (2018). Precision Irrigation Scheduling Using ECH2O Moisture Sensors for Lettuce Cultivated in a Soilless Substrate Culture. Water, 10(5), 549. https://doi.org/10.3390/w10050549