An Evaluation of a Novel Air Pollution Abatement System for Ammonia Emissions Reduction in a UK Livestock Building

Abstract

1. Introduction

2. Materials and Methods

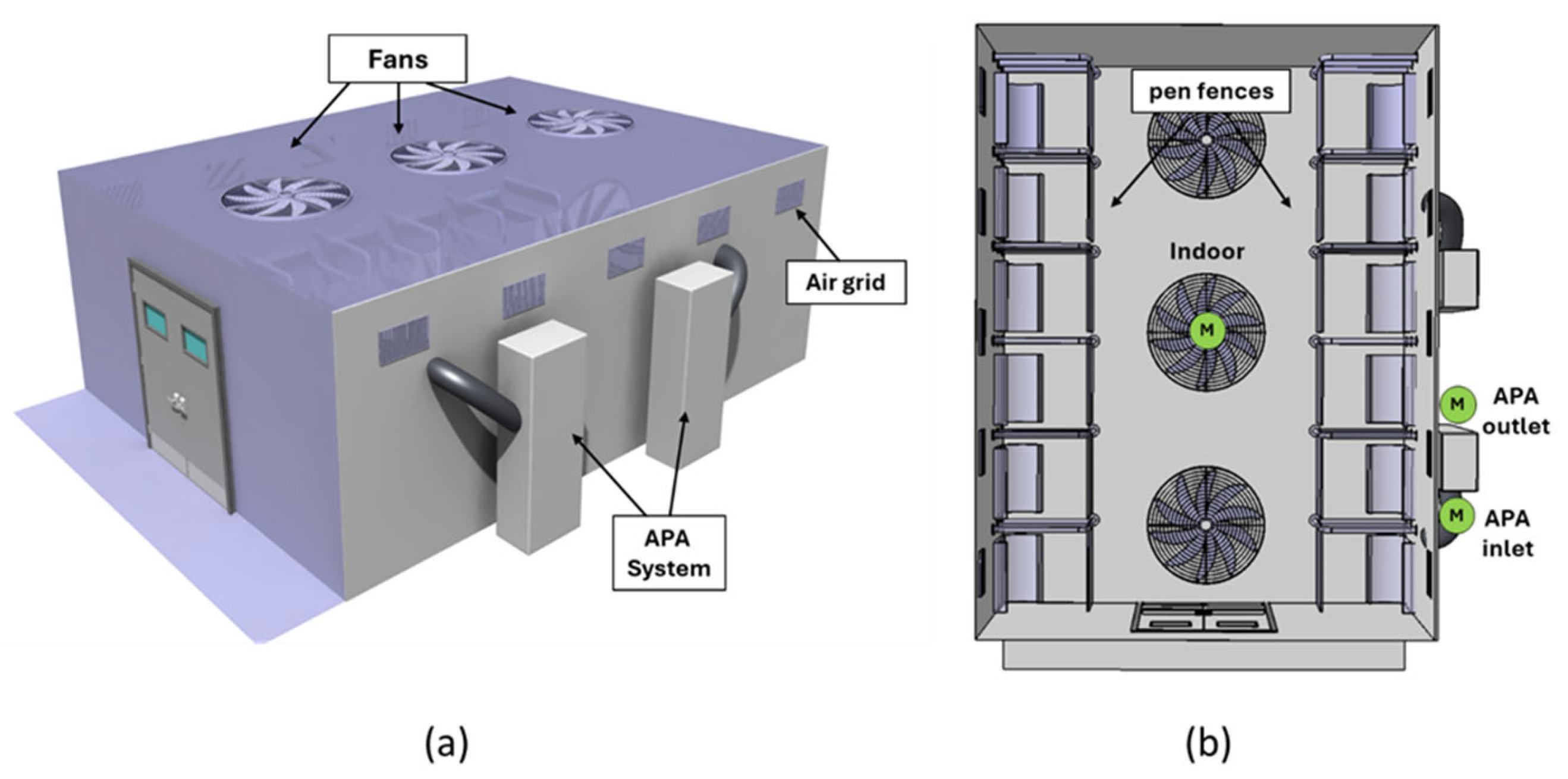

2.1. Livestock Building

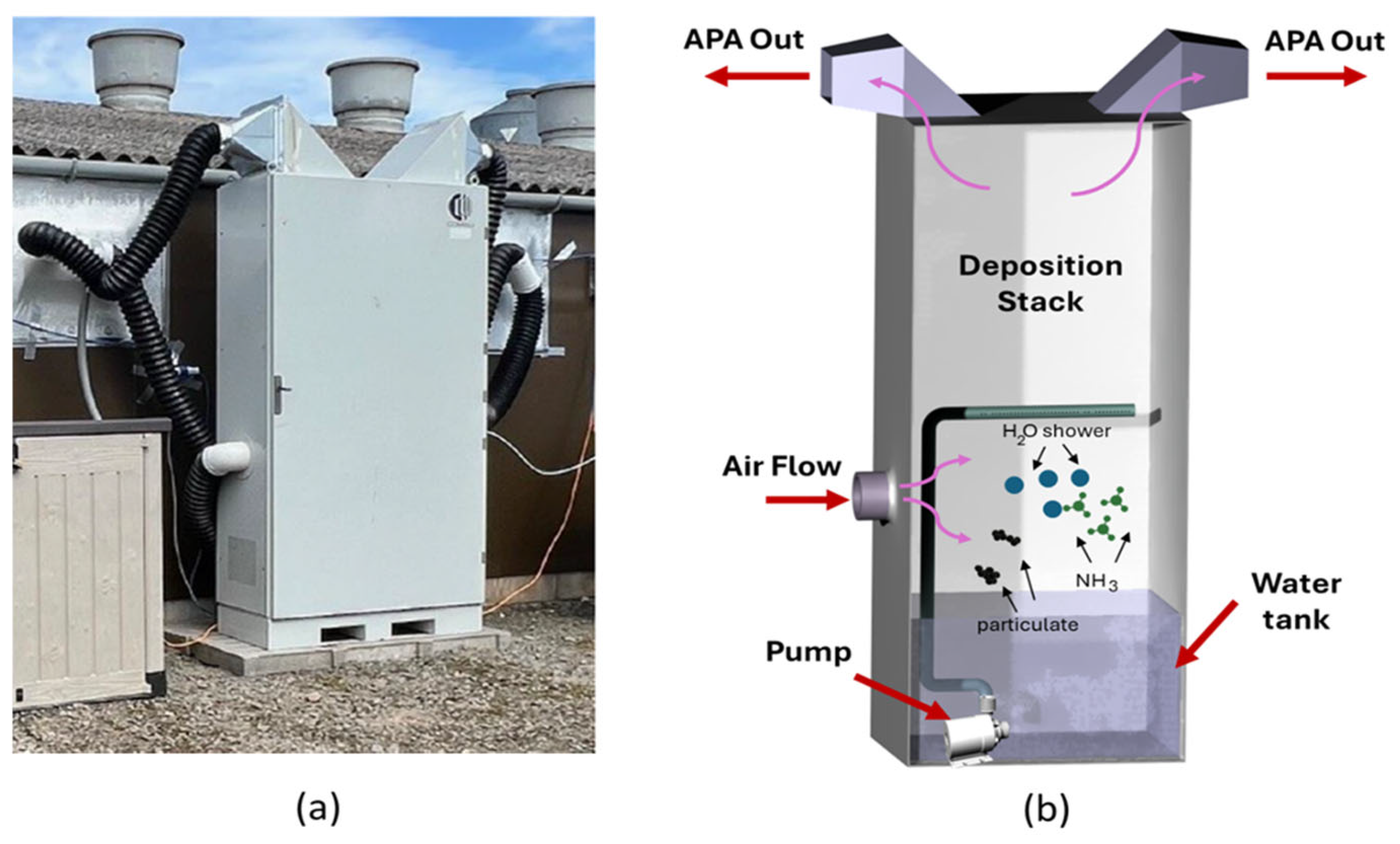

2.2. APA System

2.3. Measurement Setup

2.4. Ammonia Emission Rates

2.5. Ion Chromatography

2.6. SEM-EDX Analysis

2.7. Statistical Analysis

3. Results

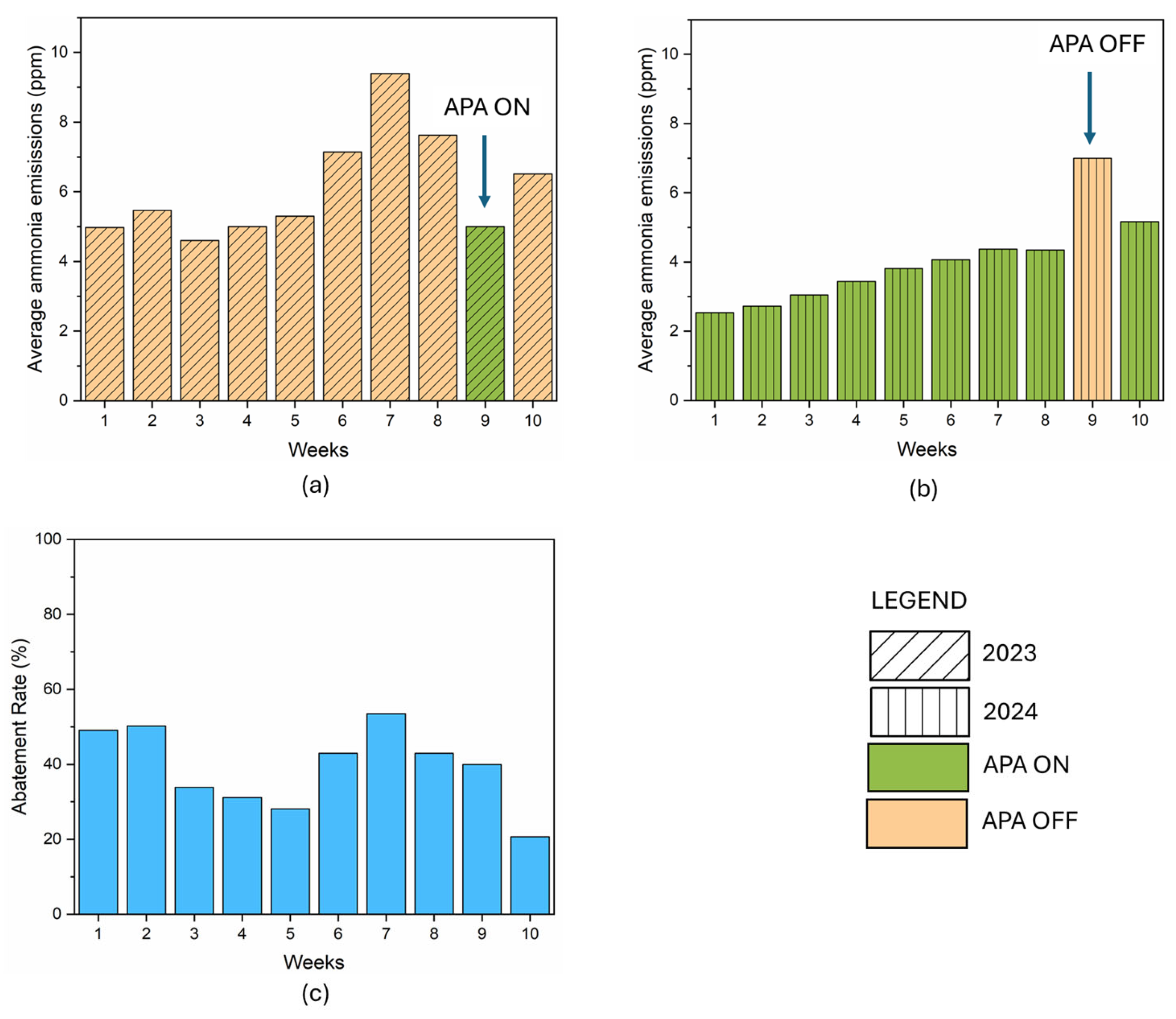

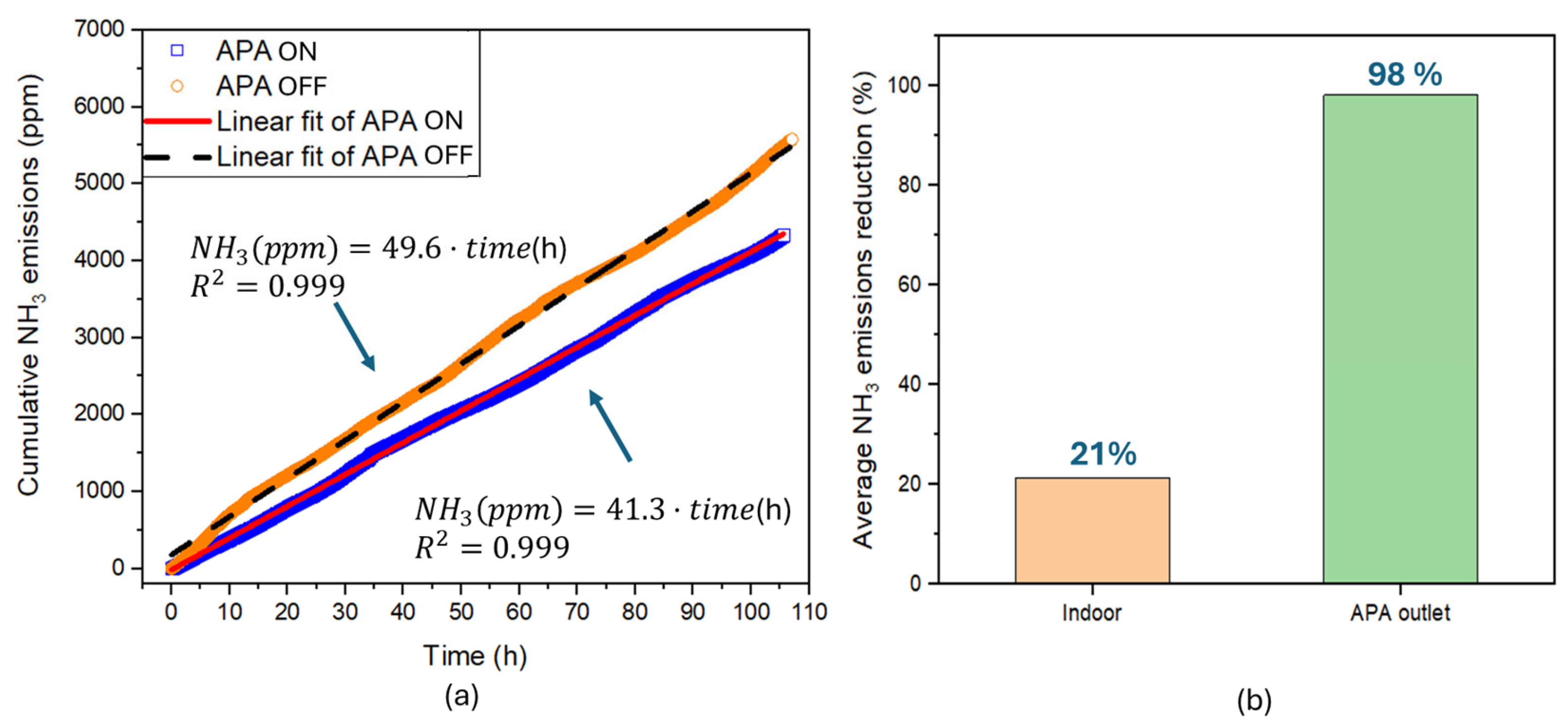

3.1. Average Ammonia Emissions

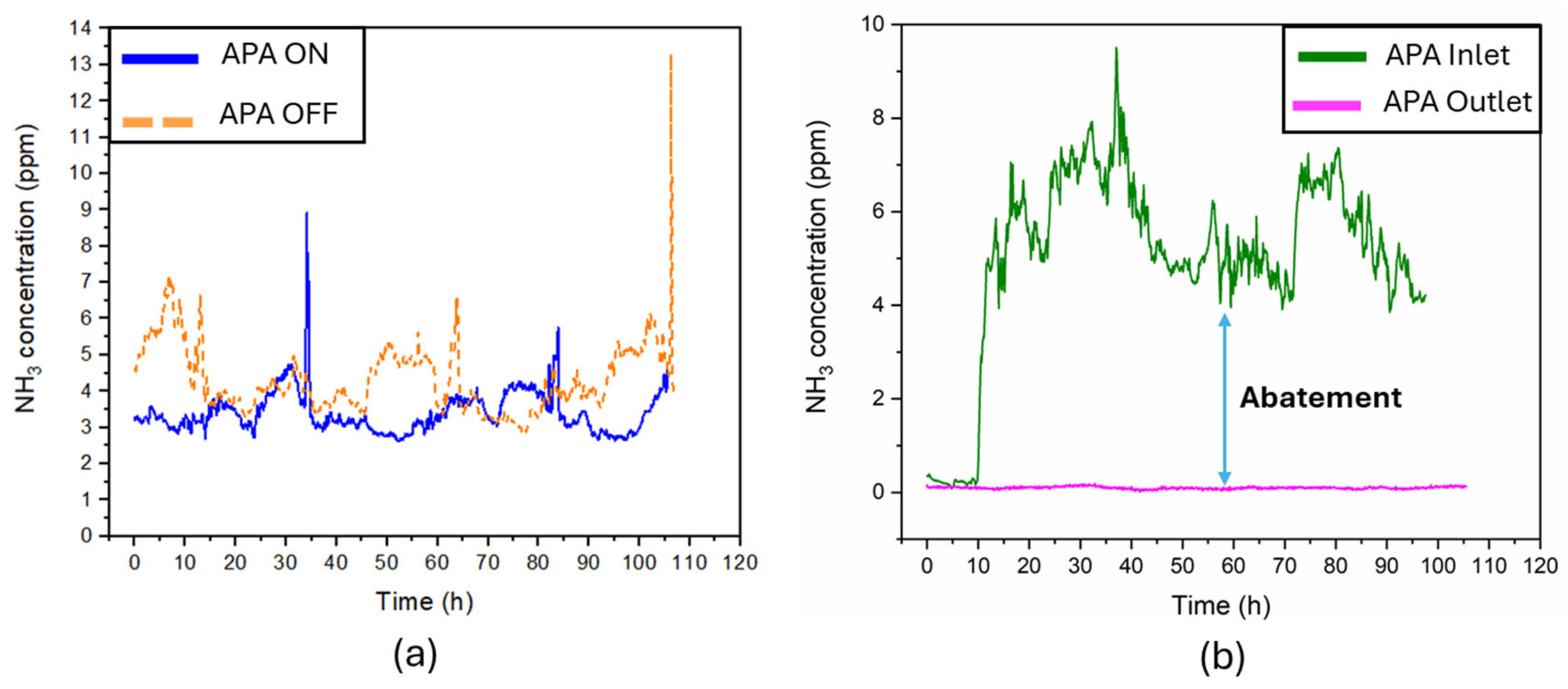

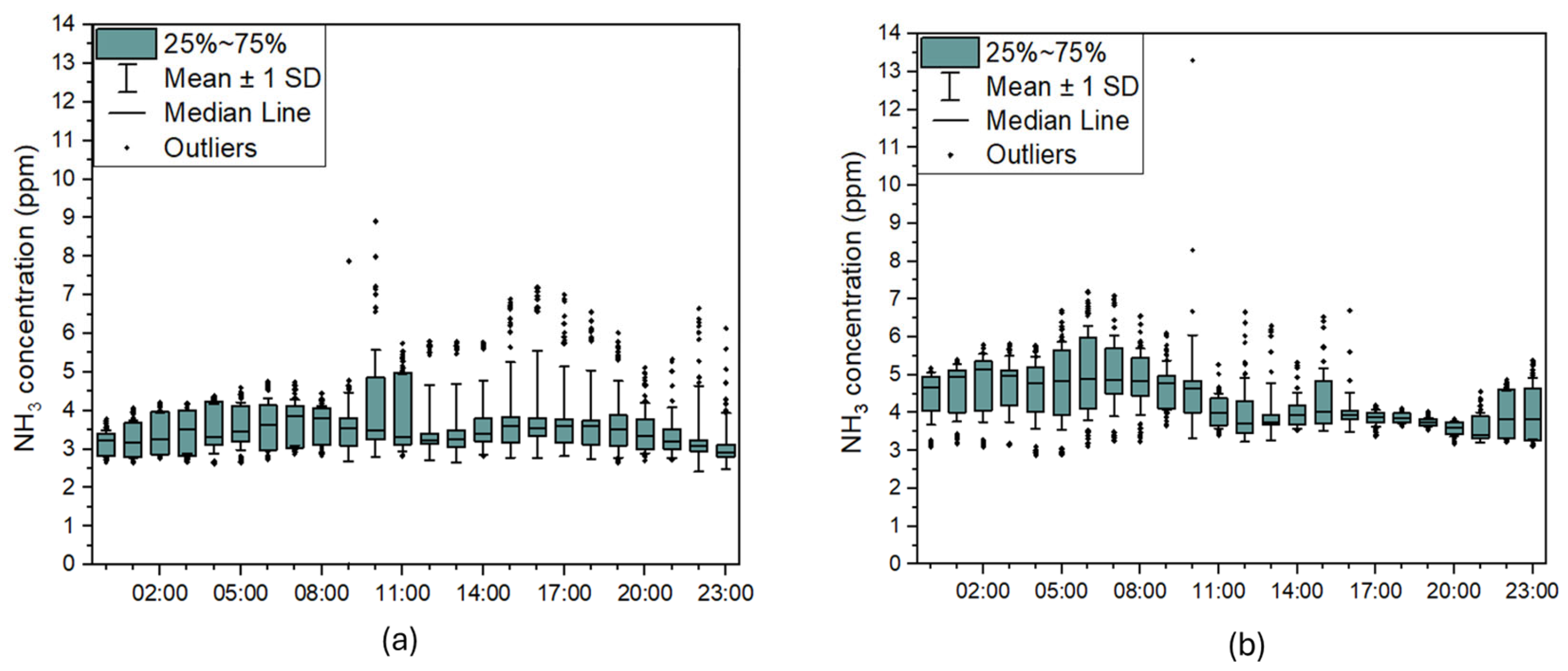

3.2. Hourly Ammonia Concentrations

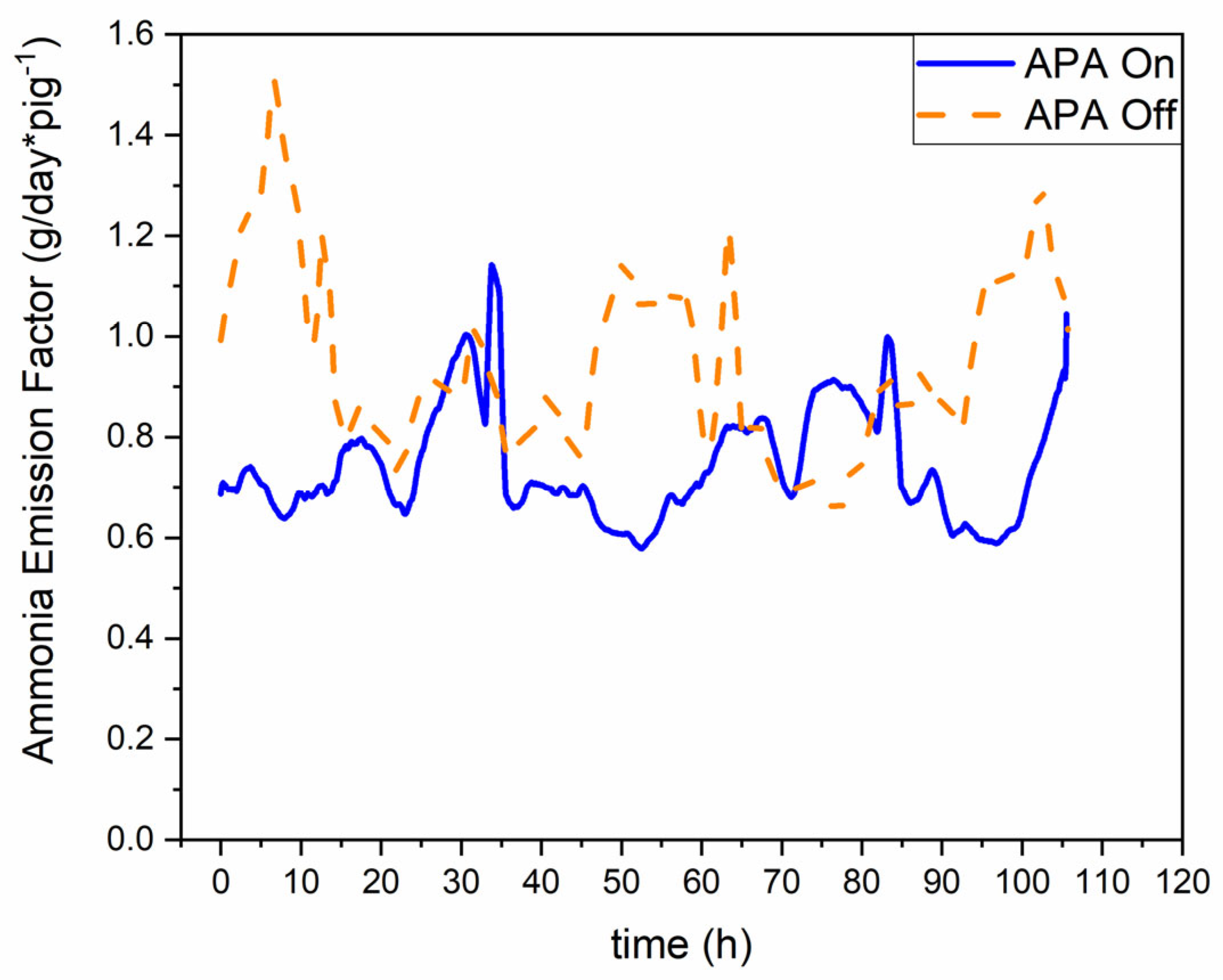

3.3. Ammonia Emission Factors

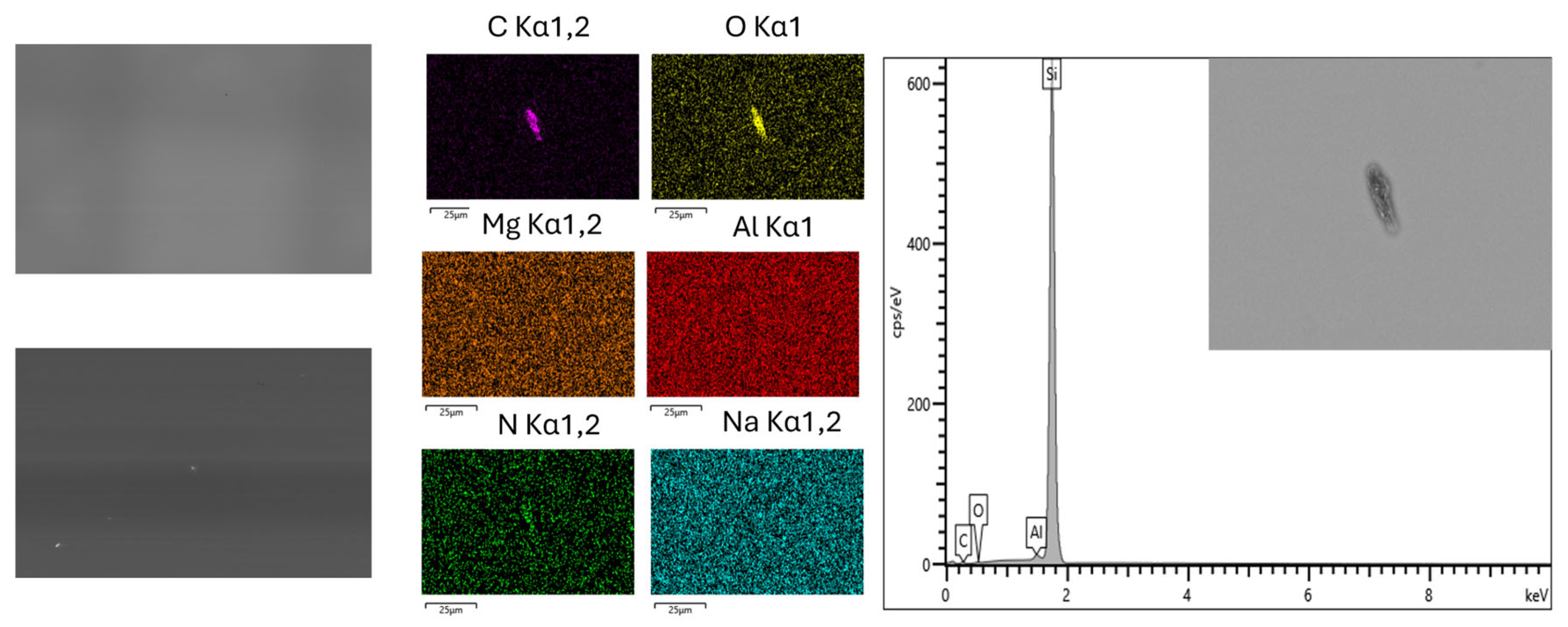

3.4. Water Sample Analysis

4. Discussion

5. Conclusions

- -

- Longer-term assessment during continuous operation of the APA system over a 10-week period in 2024 revealed 40% less ammonia emitted into the atmosphere than during the 2023 baseline, with results also validated during the 2024 trial when temporarily switching off the APA system.

- -

- The APA system, with its simple structure, provides, therefore, an effective technology for high-efficiency ammonia elimination, reducing the overall emissions from the livestock facility. Application on a national scale may lead to an up to 23.8 kt reduction in ammonia emissions from agriculture in the UK, assisting in compliance with air quality regulations and policies. This would result in a conservative economic benefit of GBP 59.5 MGBP/year (2018 prices) corresponding to ~77.36 M/year in 2025.

- -

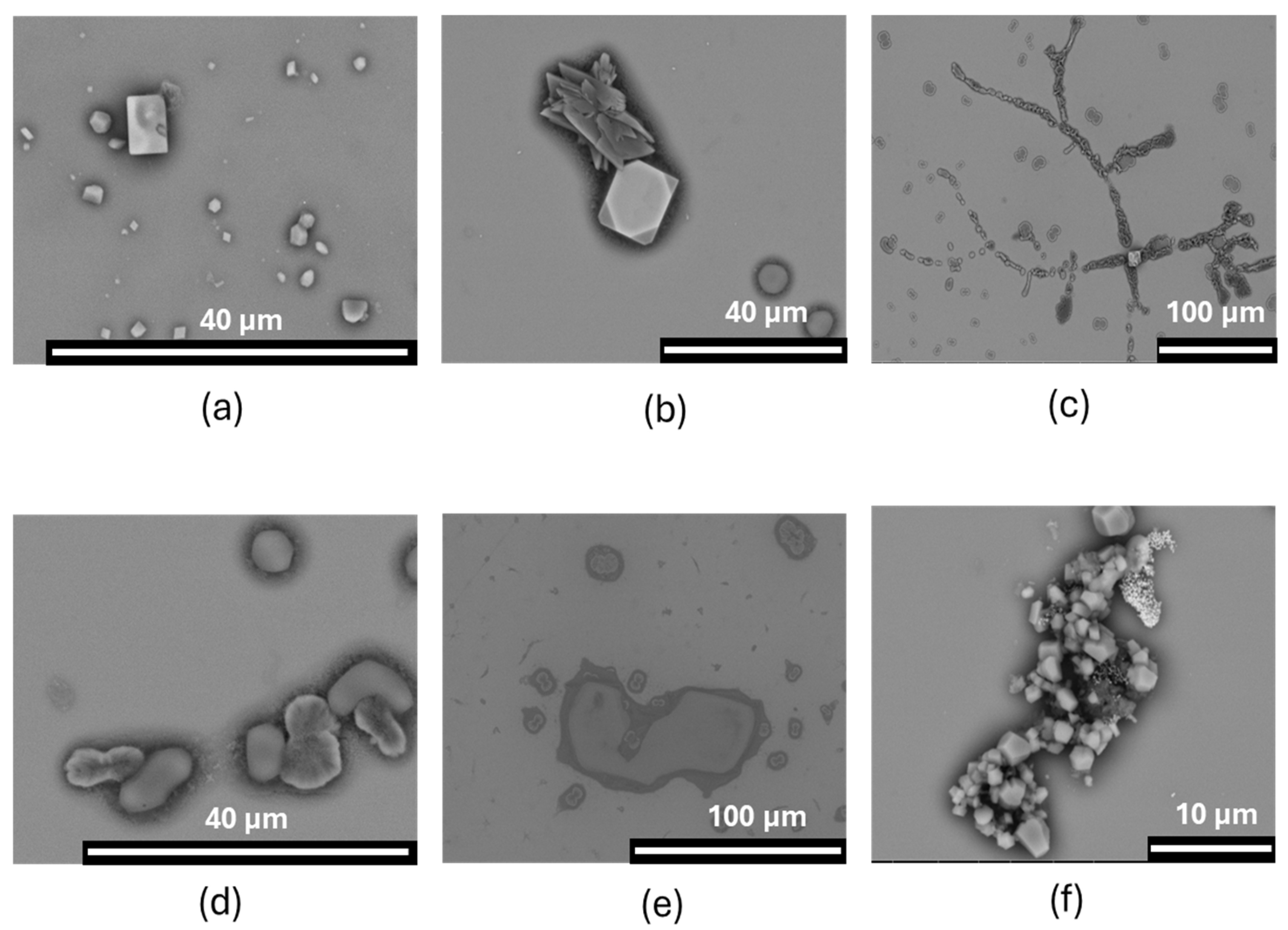

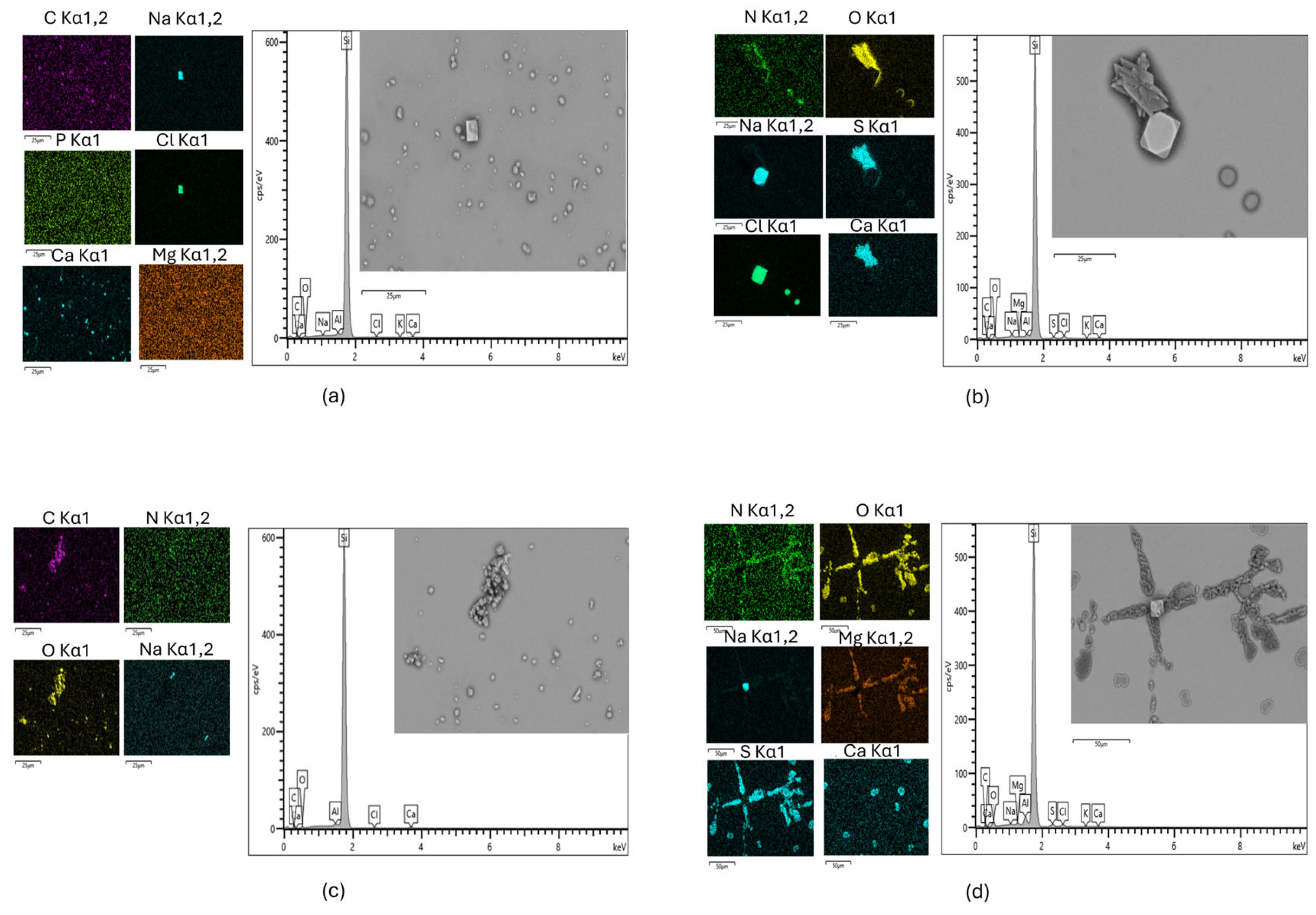

- The high ammonia levels in the process water samples detected by ion chromatography supported the observed reduction in NH3 emissions when APA was in operation. Further SEM investigations on water samples revealed soot-like formations, likely due to the natural mineral content in the water and the animal manure. This demonstrates that besides ammonia, the APA system can also remove particulate and organic matter, lowering PM emissions and preventing negative effects on the environment and human health.

- -

- The APA system allows on-site water treatment and ammonia production, reducing transportation and storage needs. This technology can be effectively used as a polishing step for effective ammonia removal in livestock facilities, preventing ammonia release into the atmosphere and contributing to national NH3 emissions.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mielcarek-Bocheńska, P.; Rzeźnik, W. Reducing Ammonia Emissions in Polish Agriculture, the Implementation of the NEC Directive, and the Context of Sustainable Development—Pilot Studies. Sustainability 2024, 16, 7145. [Google Scholar] [CrossRef]

- Carswell, A.M.; Gilhespy, S.L.; Cardenas, L.M.; Anthony, S.G. Inventory of Ammonia Emissions from UK Agriculture 2022. 2024. Available online: https://uk-air.defra.gov.uk/assets/documents/reports/cat07/2407301154_UK_Agriculture_Ammonia_Emission_Report_1990-2022_23072024.pdf (accessed on 4 March 2025).

- Philippe, F.-X.; Cabaraux, J.-F.; Nicks, B. Ammonia emissions from pig houses: Influencing factors and mitigation techniques. Agric. Ecosyst. Environ. 2011, 141, 245–260. [Google Scholar] [CrossRef]

- Guthrie, S.; Giles, S.; Dunkerley, F.; Tabaqchali, H.; Harshfield, A.; Ioppolo, B.; Manville, C. The Impact of Ammonia Emissions from Agriculture on Biodiversity; RAND Corporation and The Royal Society: Cambridge, UK, 2018. [Google Scholar]

- Wyer, K.E.; Kelleghan, D.B.; Blanes-Vidal, V.; Schauberger, G.; Curran, T.P. Ammonia emissions from agriculture and their contribution to fine particulate matter: A review of implications for human health. J. Environ. Manag. 2022, 323, 116285. [Google Scholar] [CrossRef] [PubMed]

- Health and Safety Executive. EH40/2005 Workplace Exposure Limits; Containing the List of Workplace Exposure Limits for Use with the Control of Substances Hazardous to Health Regulations 2002 (as Amended); Health and Safety Executive: Bootle, UK, 2020. [Google Scholar]

- Tang, Y.S.; Braban, C.F.; Dragosits, U.; Dore, A.J.; Simmons, I.; van Dijk, N.; Poskitt, J.; Dos Santos Pereira, G.; Keenan, P.O.; Conolly, C. Drivers for spatial, temporal and long-term trends in atmospheric ammonia and ammonium in the UK. Atmos. Chem. Phys. 2018, 18, 705–733. [Google Scholar] [CrossRef]

- Hassouna, M.; Eglin, T.; Cellier, P.; Colomb, V.; Cohan, J.-P.; Decuq, C.; Delabuis, M.; Edouard, N.; Espagnol, S.; Eugène, M. Measuring Emissions from Livestock Farming: Greenhouse Gases, Ammonia and Nitrogen Oxides; INRA-ADEME: Paris, France, 2016. [Google Scholar]

- Wagner, S.; Angenendt, E.; Beletskaya, O.; Zeddies, J. Assessing ammonia emission abatement measures in agriculture: Farmers’ costs and society’s benefits–A case study for Lower Saxony, Germany. Agric. Syst. 2017, 157, 70–80. [Google Scholar] [CrossRef]

- Updyke, K.M.; Nguyen, T.B.; Nizkorodov, S.A. Formation of brown carbon via reactions of ammonia with secondary organic aerosols from biogenic and anthropogenic precursors. Atmos. Environ. 2012, 63, 22–31. [Google Scholar] [CrossRef]

- World Health Organization. Air Quality Guidelines: Global Update 2005: Particulate Matter, Ozone, Nitrogen Dioxide, and Sulfur Dioxide; World Health Organization: Geneva, Switzerland, 2006. [Google Scholar]

- Sheppard, L.J.; Leith, I.D.; Mizunuma, T.; Neil Cape, J.; Crossley, A.; Leeson, S.; Sutton, M.A.; van Dijk, N.; Fowler, D. Dry deposition of ammonia gas drives species change faster than wet deposition of ammonium ions: Evidence from a long-term field manipulation. Glob. Change Biol. 2011, 17, 3589–3607. [Google Scholar] [CrossRef]

- Kim, S.W.; Gormley, A.; Jang, K.B.; Duarte, M.E. Current status of global pig production: An overview and research trends. Anim. Biosci. 2023, 37, 719. [Google Scholar]

- UK Government. £3m Support Scheme Launched to Reduce Air Pollution from Farming. 2018. Available online: https://www.gov.uk/government/news/3m-support-scheme-launched-to-reduce-air-pollution-from-farming (accessed on 28 March 2025).

- Giner, S.G.; Georgitzikis, K.; Scalet, B.M.; Montobbio, P.; Roudier, S.; Delgado, S.L. Best Available Techniques (BAT) Reference Document for the Intensive Rearing of Poultry or Pigs. Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control); European Commission: Brussels, Belgium, 2017. [Google Scholar]

- Melse, R.W. Air Treatment Techniques for Abatement of Emissions from Intensive Livestock Production; Wageningen University and Research: Wageningen, The Netherlands, 2009. [Google Scholar]

- Costantini, M.; Bacenetti, J.; Coppola, G.; Orsi, L.; Ganzaroli, A.; Guarino, M. Improvement of human health and environmental costs in the European Union by air scrubbers in intensive pig farming. J. Clean. Prod. 2020, 275, 124007. [Google Scholar] [CrossRef]

- Moore, P.A., Jr.; Li, H.; Burns, R.; Miles, D.; Maguire, R.; Ogejo, J.; Reiter, M.S.; Buser, M.D.; Trabue, S. Development and testing of the ARS air scrubber: A device for reducing ammonia emissions from animal rearing facilities. Front. Sustain. Food Syst. 2018, 2, 23. [Google Scholar] [CrossRef]

- Conti, C.; Costantini, M.; Fusi, A.; Manzardo, A.; Guarino, M.; Bacenetti, J. Environmental impact of pig production affected by wet acid scrubber as mitigation technology. Sustain. Prod. Consum. 2021, 28, 580–590. [Google Scholar] [CrossRef]

- EEA, A.P.F.S., European Environmental Agency. 2014. Available online: https://www.google.com/search?q=Air+pollution+fact+sheet+2014+-+European+Environment+Agency&oq=Air+pollution+fact+sheet+2014+-+European+Environment+Agency&gs_lcrp=EgZjaHJvbWUyBggAEEUYOTIGCAEQRRg80gEIMTE4NGowajSoAgCwAgE&sourceid=chrome&ie=UTF-8 (accessed on 5 May 2025).

- Shen, D.; Wu, S.; Li, Z.; Tang, Q.; Dai, P.; Li, Y.; Li, C. Distribution and physicochemical properties of particulate matter in swine confinement barns. Environ. Pollut. 2019, 250, 746–753. [Google Scholar] [CrossRef] [PubMed]

- Cambra-López, M.; Torres, A.; Aarnink, A.J.A.; Ogink, N.W. Source analysis of fine and coarse particulate matter from livestock houses. Atmos. Environ. 2011, 45, 694–707. [Google Scholar] [CrossRef]

- Marcato, C.E.; Pinelli, E.; Pouech, P.; Winterton, P.; Guiresse, M. Particle size and metal distributions in anaerobically digested pig slurry. Bioresour. Technol. 2008, 99, 2340–2348. [Google Scholar] [CrossRef]

- Patterson, P. Management strategies to reduce air emissions: Emphasis—Dust and ammonia. J. Appl. Poult. Res. 2005, 14, 638–650. [Google Scholar] [CrossRef]

- Van Devener, B.; Anderson, S.L. Breakdown and combustion of JP-10 fuel catalyzed by nanoparticulate CeO2 and Fe2O3. Energy Fuels 2006, 20, 1886–1894. [Google Scholar] [CrossRef]

- Hu, Y.; Schmidhalter, U. Urease inhibitors: Opportunities for meeting EU national obligations to reduce ammonia emission ceilings by 2030 in EU countries. Environ. Res. Lett. 2021, 16, 084047. [Google Scholar] [CrossRef]

- van Grinsven, H.J.; van Dam, J.D.; Lesschen, J.P.; Timmers, M.H.; Velthof, G.L.; Lassaletta, L. Reducing external costs of nitrogen pollution by relocation of pig production between regions in the European Union. Reg. Environ. Change 2018, 18, 2403–2415. [Google Scholar] [CrossRef]

- Giannadaki, D.; Giannakis, E.; Pozzer, A.; Lelieveld, J. Estimating health and economic benefits of reductions in air pollution from agriculture. Sci. Total Environ. 2018, 622, 1304–1316. [Google Scholar] [CrossRef]

- Giannakis, E.; Kushta, J.; Bruggeman, A.; Lelieveld, J. Costs and benefits of agricultural ammonia emission abatement options for compliance with European air quality regulations. Environ. Sci. Eur. 2019, 31, 93. [Google Scholar] [CrossRef]

- Feng, K.; Wang, Y.; Hu, R.; Xiang, R. Continuous Measurement of Ammonia at an Intensive Pig Farm in Wuhan, China. Atmosphere 2022, 13, 442. [Google Scholar] [CrossRef]

- Payraudeau, S.; Van der Werf, H.M.; Vertès, F. Analysis of the uncertainty associated with the estimation of nitrogen losses from farming systems. Agric. Syst. 2007, 94, 416–430. [Google Scholar] [CrossRef]

- UK Historical Weather. Available online: https://www.wunderground.com/history (accessed on 4 July 2025).

- Martin, J.W.; Moore, P.A., Jr.; Li, H.; Ashworth, A.J.; Miles, D.M. Effects of Land-Applied Ammonia Scrubber Solutions on Yield, Nitrogen Uptake, Soil Test Phosphorus, and Phosphorus Runoff. J. Environ. Qual. 2018, 47, 263–269. [Google Scholar] [CrossRef] [PubMed]

- Van der Heyden, C.; Demeyer, P.; Volcke, E.I. Mitigating emissions from pig and poultry housing facilities through air scrubbers and biofilters: State-of-the-art and perspectives. Biosyst. Eng. 2015, 134, 74–93. [Google Scholar] [CrossRef]

- Haque, M.; Cornou, C.; Madsen, J. Estimation of methane emission using the CO2 method from dairy cows fed concentrate with different carbohydrate compositions in automatic milking system. Livest. Sci. 2014, 164, 57–66. [Google Scholar] [CrossRef]

- Haque, M.N.; Hansen, H.H.; Storm, I.M.; Madsen, J. Comparative methane estimation from cattle based on total CO2 production using different techniques. Anim. Nutr. 2017, 3, 175–179. [Google Scholar] [CrossRef]

- Zhuang, S.; Van Overbeke, P.; Vangeyte, J.; Sonck, B.; Demeyer, P. Evaluation of a cost-effective ammonia monitoring system for continuous real-time concentration measurements in a fattening pig barn. Sensors 2019, 19, 3669. [Google Scholar] [CrossRef]

- Scottish Farm Buildings Investigation Unit. Report of Working Group on Climatization of Animal Houses; Scottish Farm Buildings Investigation Unit: Aberdeen, UK, 1984. [Google Scholar]

- McKnight, P.E.; Najab, J. Mann-Whitney U Test. In The Corsini encyclopedia of psychology; Wiley: Hoboken, NJ, USA, 2010; p. 1. [Google Scholar]

- Pedersen, S. The influence of diurnal variation in animal activity and digestion on animal heat production. Agric. Eng. Int. CIGR J. 2015, 18–29. [Google Scholar]

- Xu, W.; Zheng, K.; Liu, X.; Meng, L.; Huaitalla, R.M.; Shen, J.; Hartung, E.; Gallmann, E.; Roelcke, M.; Zhang, F. Atmospheric NH3 dynamics at a typical pig farm in China and their implications. Atmos. Pollut. Res. 2014, 5, 455–463. [Google Scholar] [CrossRef]

- Zarebska, A.; Nieto, D.R.; Christensen, K.V.; Norddahl, B. Ammonia recovery from agricultural wastes by membrane distillation: Fouling characterization and mechanism. Water Res. 2014, 56, 1–10. [Google Scholar] [CrossRef]

- de Sousa, P.; Pedersen, S. Ammonia emission from fattening pig houses in relation to animal activity and carbon dioxide production. Agric. Eng. Int. CIGR J. 2004, 6, BC04 003. [Google Scholar]

- Feature: Mitigating Ammonia Emissions—Reduction Priorities and Practical on-Farm Solutions. Available online: https://www.pig-world.co.uk/features/emissions-reduction-priorities-and-practical-on-farm-solutions.html (accessed on 5 July 2025).

- Advice on Cutting Ammonia Emissions on Poultry Farms. Available online: https://www.fwi.co.uk/livestock/poultry/advice-on-cutting-ammonia-emissions-on-poultry-farms (accessed on 5 July 2025).

- Acid Scrubber. Available online: https://emis.vito.be/en/bat/tools-overview/sheets/acid-scrubber#:~:text=Energy%20use%20lies%20between%200.2,EUR%20per%201000%20m%C2%B3/h (accessed on 4 July 2025).

- World Health Organization. Ammonia in Drinking-Water; Background Document for Development of WHO Guidelines for Drinking-Water Quality; World Health Organization: Geneva, Switzerland, 2003. [Google Scholar]

- Environment Agency. Ammonia Emission Factors for Pig and Poultry Screening, Modelling and Reporting. 2024. Available online: https://www.gov.uk/guidance/ammonia-emission-factors-for-pig-and-poultry-screening-modelling-and-reporting#full-publication-update-history (accessed on 4 March 2025).

- Brink, C.; Van Grinsven, H.; Jacobsen, B.H.; Rabl, A.; Gren, M.; Holland, M.; Klimont, Z.; Hicks, K.; Brouwer, R.; Dickens, R. Costs and benefits of nitrogen in the environment. In The European Nitrogen Assessment; Cambridge University Press: Cambridge, UK, 2011; pp. 513–540. [Google Scholar]

- Holland, M.; Watkiss, P.; Pye, S.; de Oliveria, A.; Van Regemorter, D. Cost-benefit analysis of the thematic strategy on air pollution. In Service Contract for Carrying out Cost-Benefit Analysis of Air Quality Related Issues, in particular in the Clean Air for Europe (CAFE) Programme; AEAT/ED48763001/Thematic Strategy; AEA Technology Environment: Didcot, UK, 2005. [Google Scholar]

- Cowan, N.; Ashwood, D.; Drewer, J.; Toteva, G.; Heal, M.R. A low-tech, low-cost method to capture point-source ammonia emissions and their potential use as a nitrogen fertiliser. PLoS ONE 2024, 19, e0296679. [Google Scholar] [CrossRef]

- Broday, D.M.; Rosenzweig, R. Deposition of fractal-like soot aggregates in the human respiratory tract. J. Aerosol Sci. 2011, 42, 372–386. [Google Scholar] [CrossRef]

- Heidari Nejad, S.; Takechi, R.; Mullins, B.J.; Giles, C.; Larcombe, A.N.; Bertolatti, D.; Rumchev, K.; Dhaliwal, S.; Mamo, J. The effect of diesel exhaust exposure on blood–brain barrier integrity and function in a murine model. J. Appl. Toxicol. 2015, 35, 41–47. [Google Scholar] [CrossRef]

- Adachi, K.; Buseck, P. Internally mixed soot, sulfates, and organic matter in aerosol particles from Mexico City. Atmos. Chem. Phys. 2008, 8, 6469–6481. [Google Scholar] [CrossRef]

| Indoors | APA Inlet | APA Outlet | ||||

|---|---|---|---|---|---|---|

| APA ON | APA OFF | APA ON | APA OFF | APA ON | APA OFF | |

| Mean | 3.41 | 4.33 | 5.05 | 0.10 | 0.10 | 0.11 |

| STD | 0.59 | 0.90 | 1.94 | 0.08 | 0.03 | 0.02 |

| Max.–Min. | 8.9–2.6 | 13.3–2.9 | 9.5–0.1 | 0.6–0 | 0.2–0 | 0.17–0 |

| Data points | 1272 | 1288 | 1176 | 866 | 1272 | 1273 |

| Sample | Ammonia (ppm) | Time (days) |

| Sample A | 0.39 | 0 |

| Sample B | 14 | 10 |

| Sample C | 140 | 38 |

| Sample D | 140 | 38 |

| Sample E | 190 | 48 |

| Sample F | 120 | 60 |

| Sample G | 150 | 68 |

| Sample H | 200 | 76 |

| Sample I | 210 | 80 |

| Sample L | 530 | 83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pacino, A.; La Rocca, A.; Magrin, D.; Galatioto, F. An Evaluation of a Novel Air Pollution Abatement System for Ammonia Emissions Reduction in a UK Livestock Building. Atmosphere 2025, 16, 869. https://doi.org/10.3390/atmos16070869

Pacino A, La Rocca A, Magrin D, Galatioto F. An Evaluation of a Novel Air Pollution Abatement System for Ammonia Emissions Reduction in a UK Livestock Building. Atmosphere. 2025; 16(7):869. https://doi.org/10.3390/atmos16070869

Chicago/Turabian StylePacino, Andrea, Antonino La Rocca, Donata Magrin, and Fabio Galatioto. 2025. "An Evaluation of a Novel Air Pollution Abatement System for Ammonia Emissions Reduction in a UK Livestock Building" Atmosphere 16, no. 7: 869. https://doi.org/10.3390/atmos16070869

APA StylePacino, A., La Rocca, A., Magrin, D., & Galatioto, F. (2025). An Evaluation of a Novel Air Pollution Abatement System for Ammonia Emissions Reduction in a UK Livestock Building. Atmosphere, 16(7), 869. https://doi.org/10.3390/atmos16070869