Study on Dust Distribution Law in Open-Pit Coal Mines Based on Depth Variation

Abstract

1. Introduction

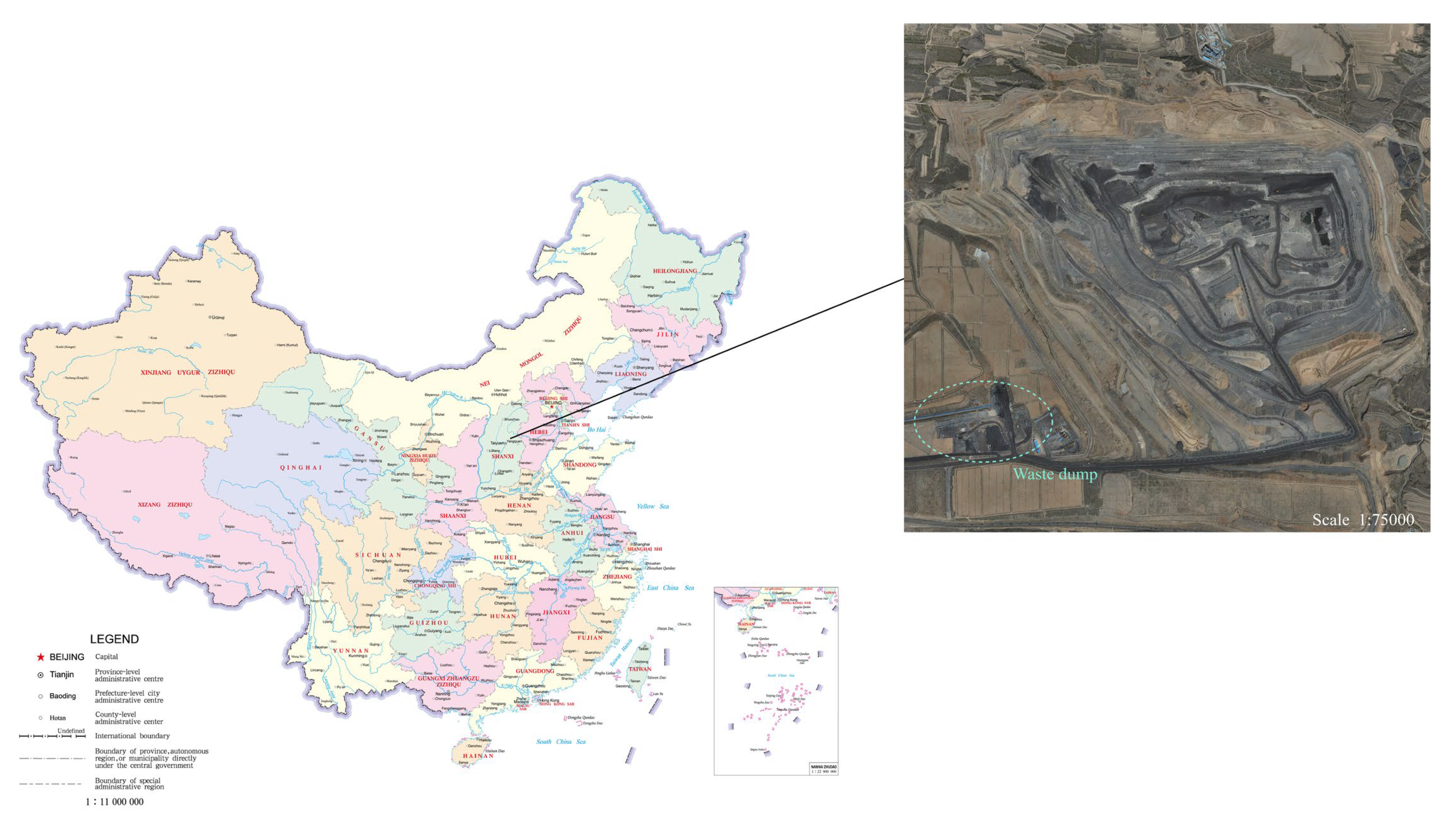

2. Fundamental Characteristics of the An Tai Bao Open-Pit Coal Mine

2.1. Environmental Parameters of the Open-Pit Coal Mine

2.2. The New Model of the Company

3. Influence of Depth Variation on Dust Distribution

3.1. Intensity of Mining Operations

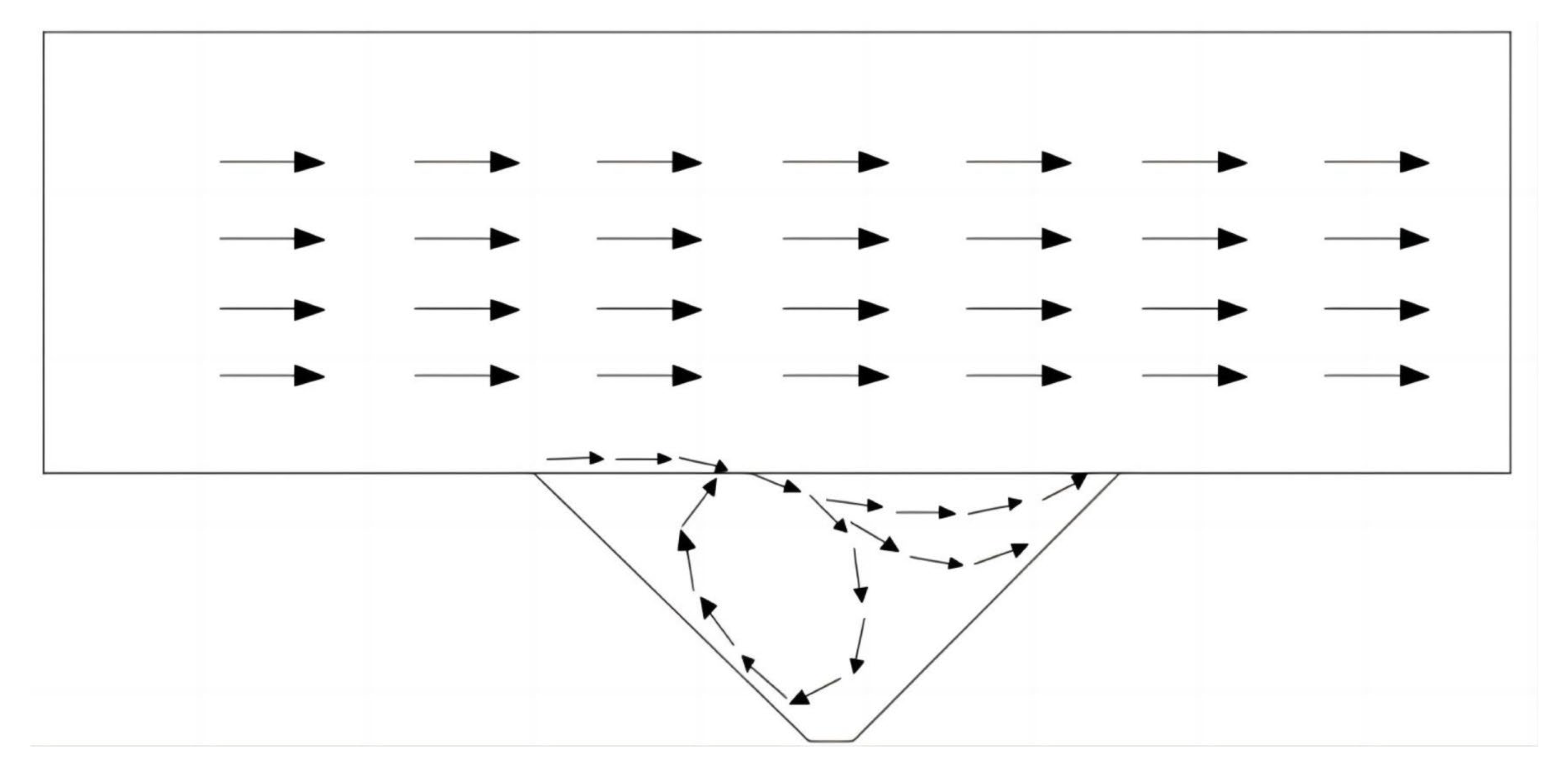

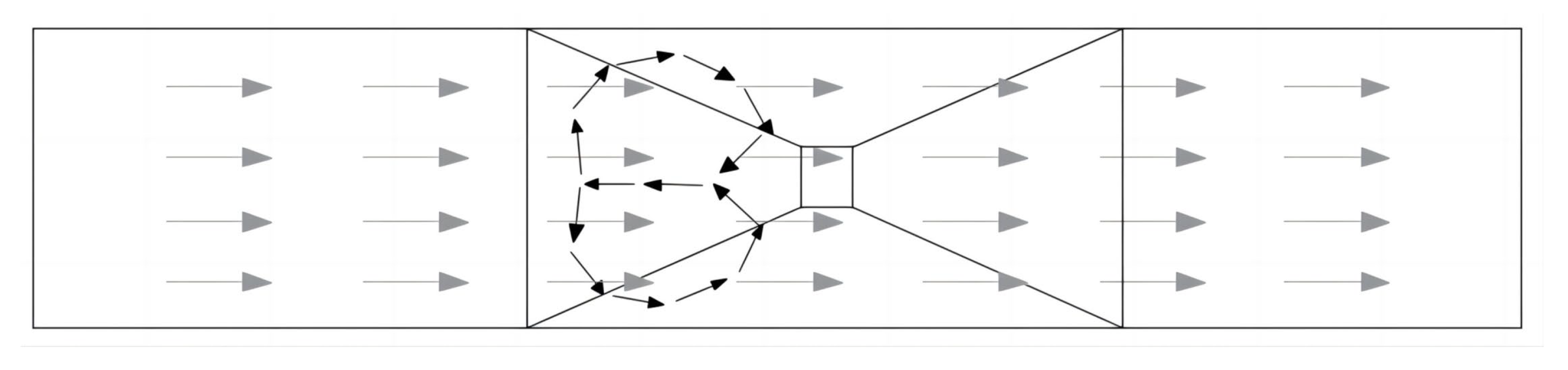

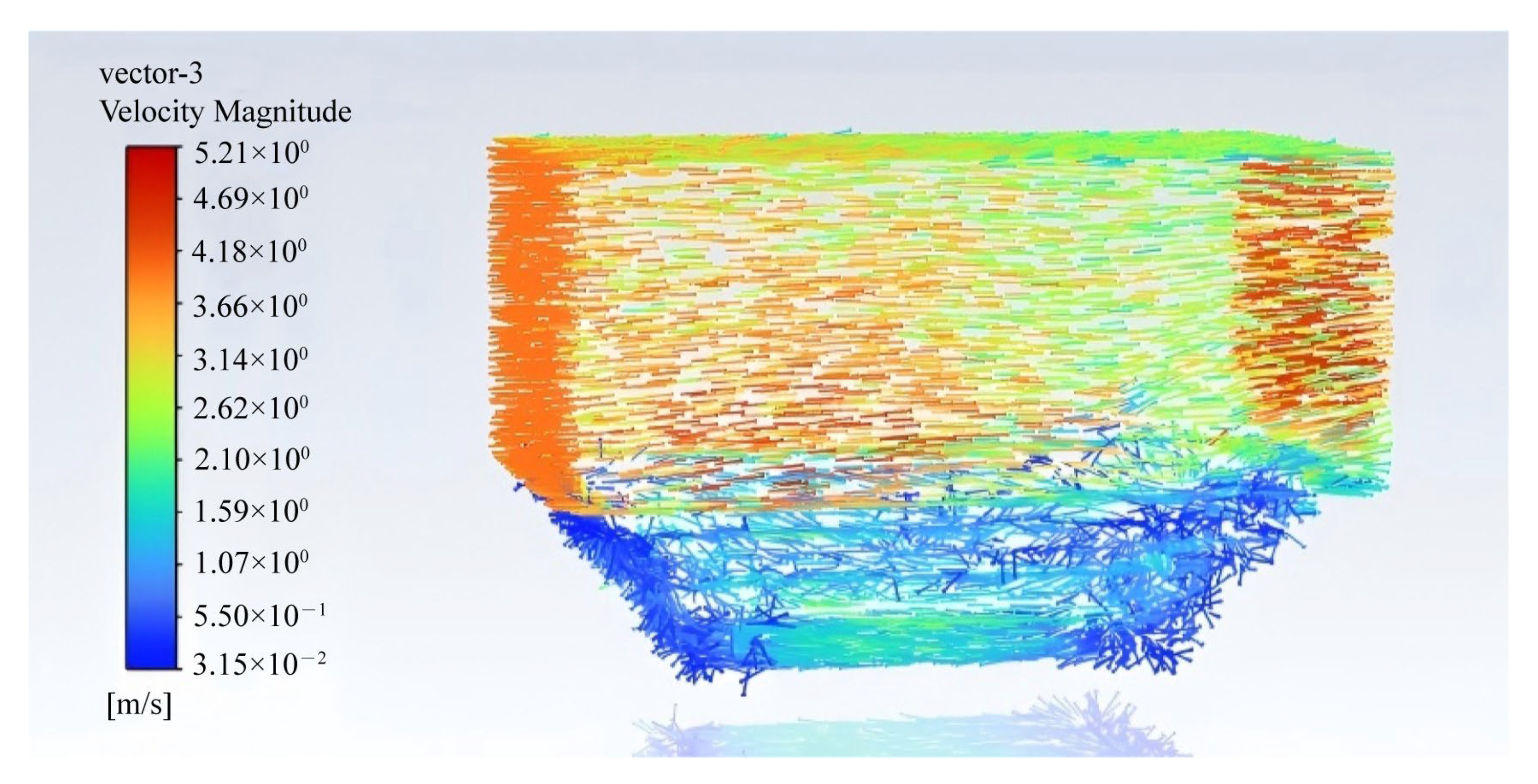

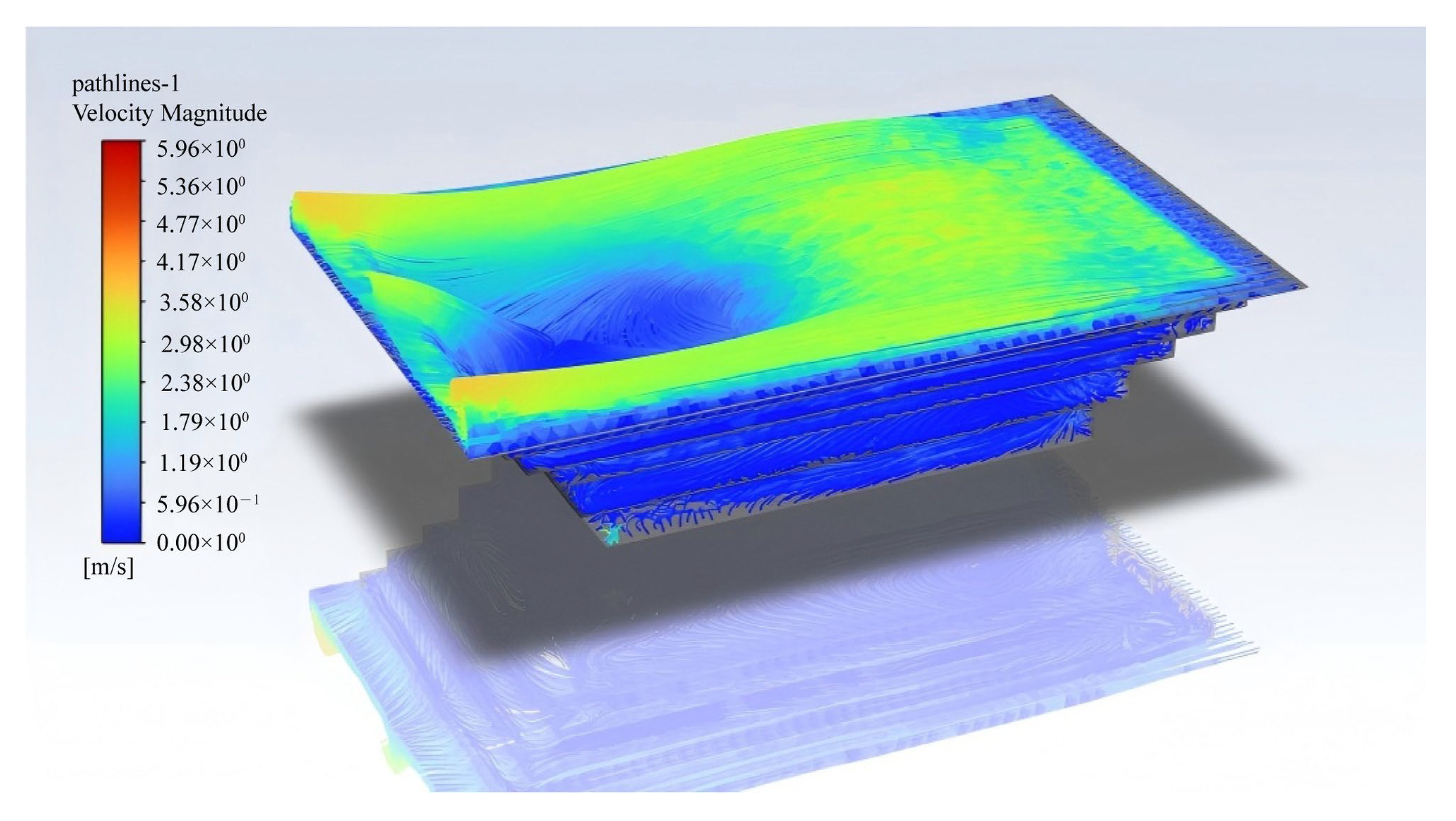

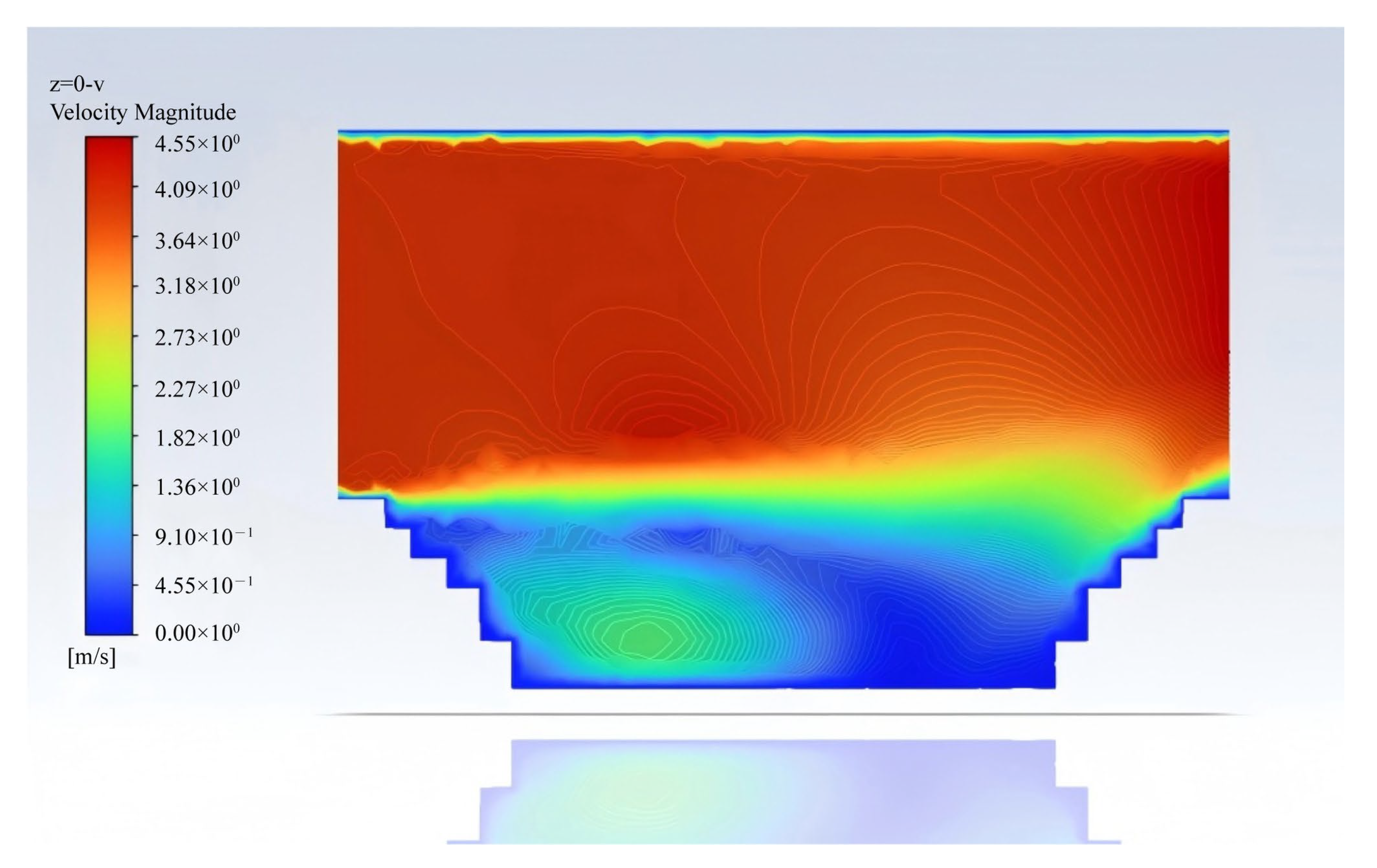

3.2. Characteristics of Atmospheric Flow Field in Mining Areas

4. Establishment of Mathematical Model for Dust Diffusion

5. Numerical Simulation

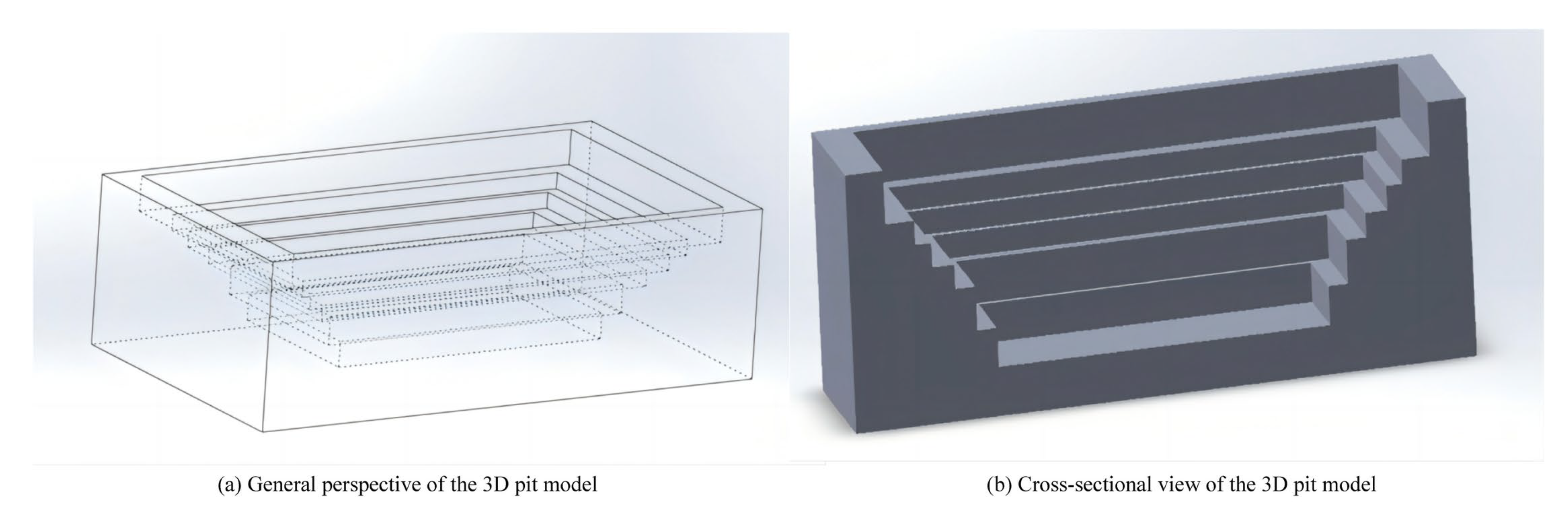

5.1. Open-Pit Coal Mine Model

5.2. Simulation Parameter Settings

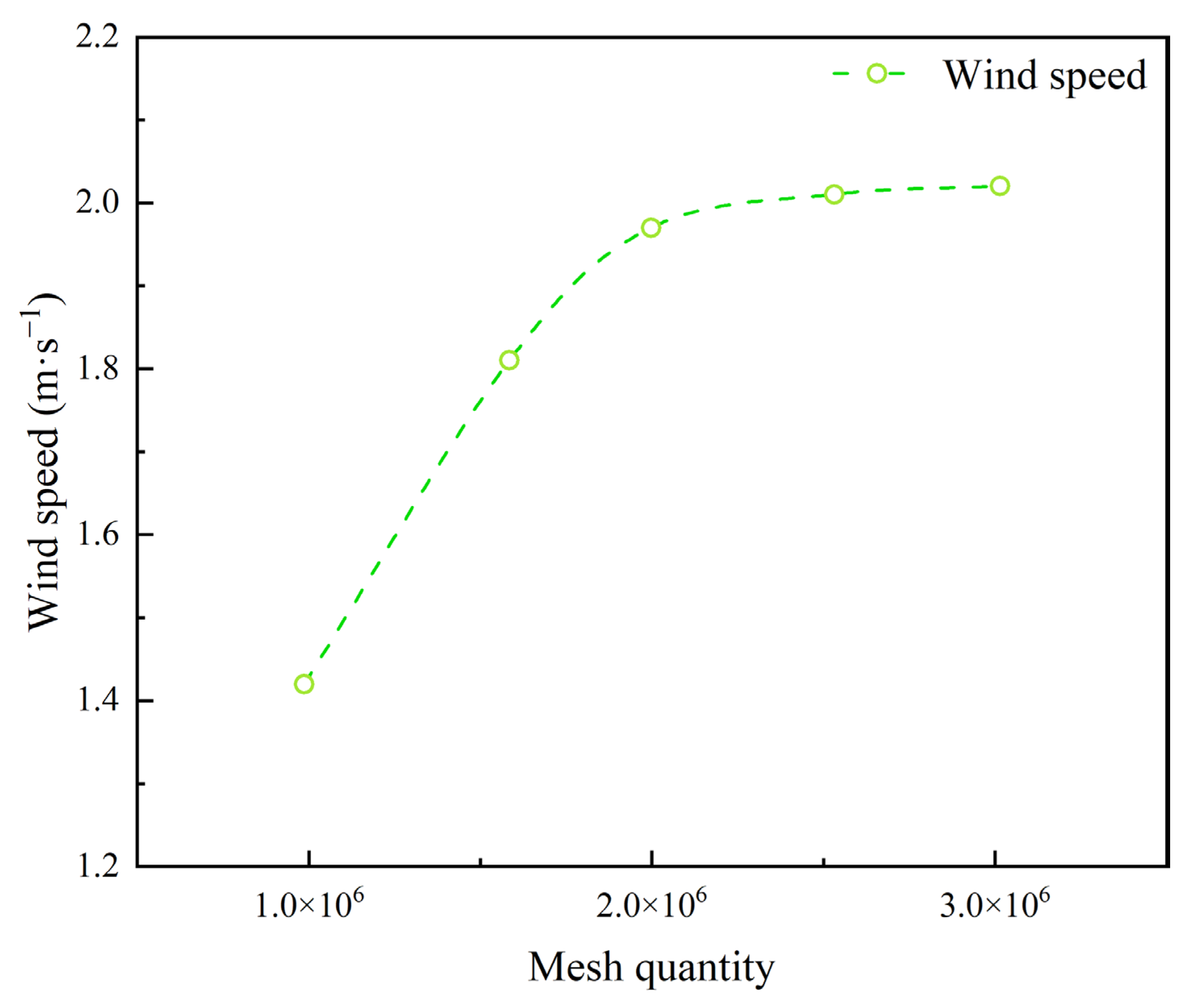

5.3. Validation of Simulation

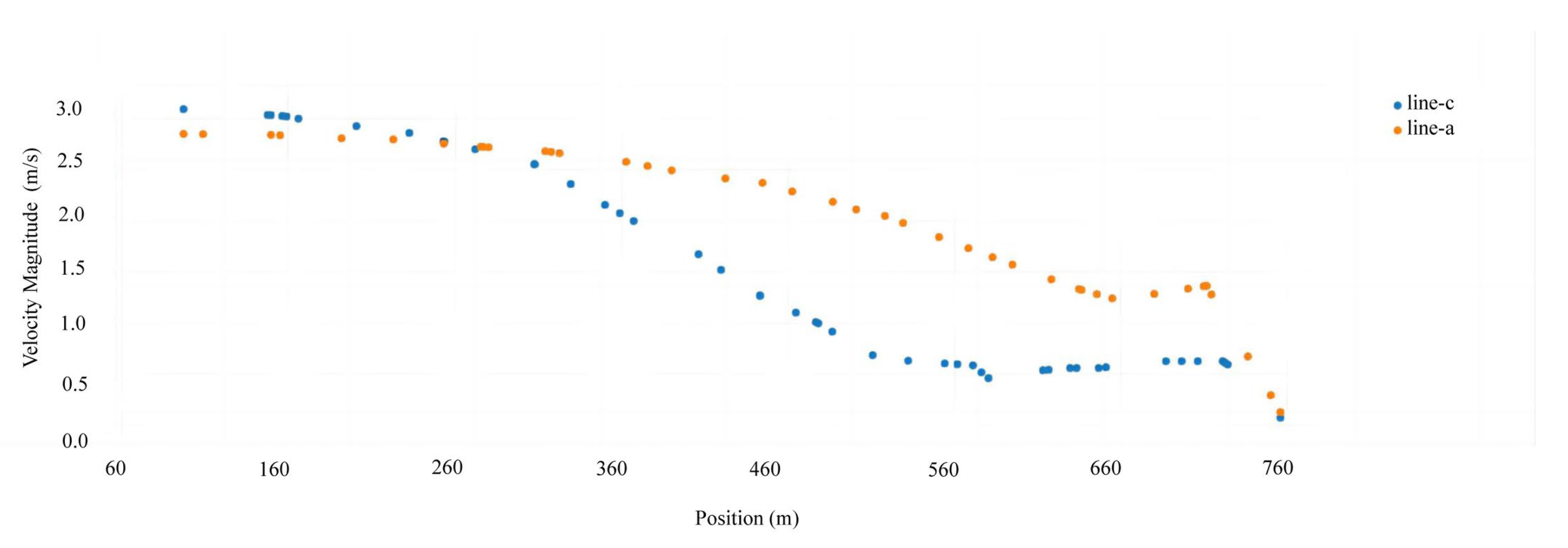

5.4. Results of Wind Intensity Variation with Depth

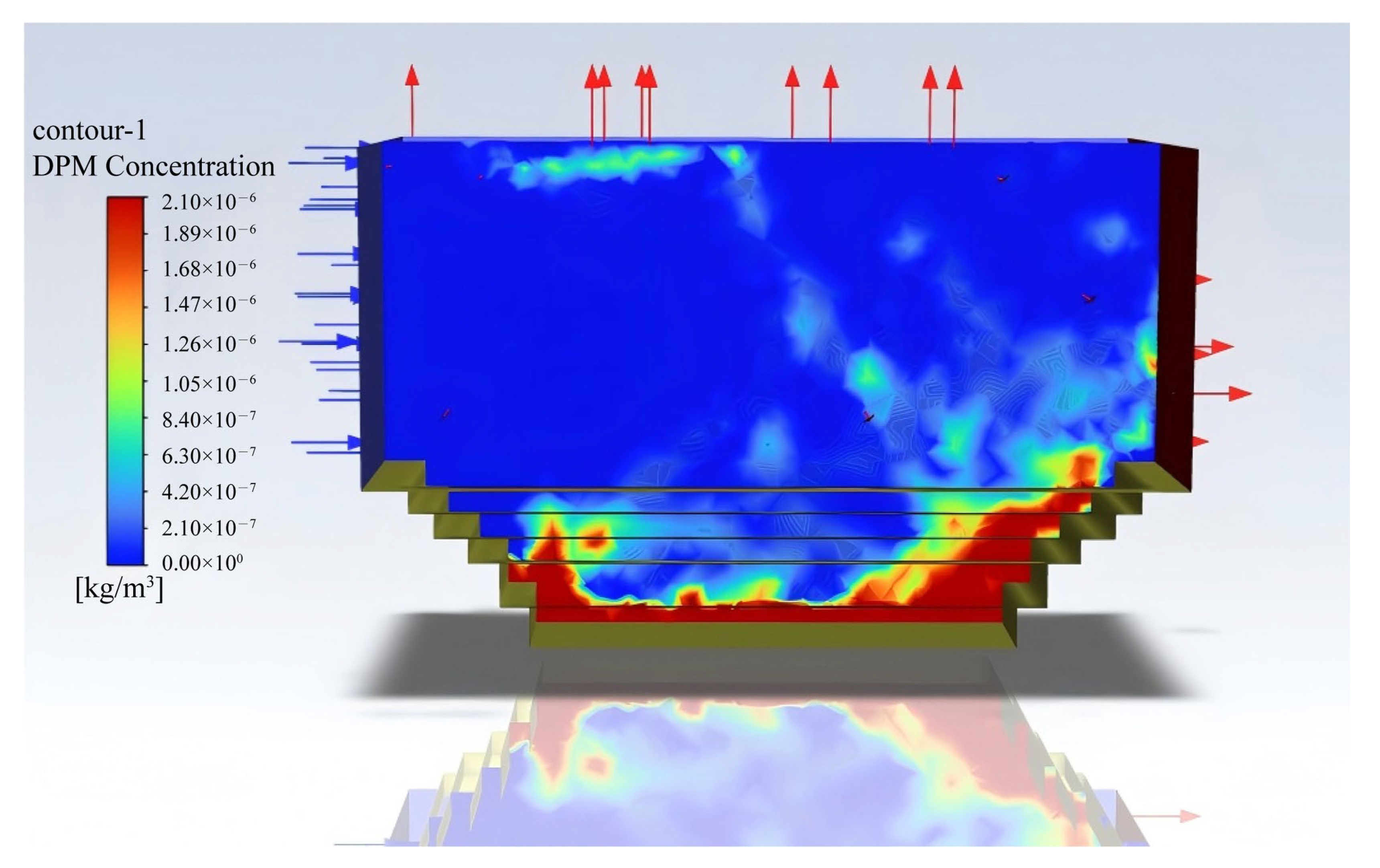

5.5. Results of the Variation in Dust Mass Concentration with Depth

6. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wanjun, T.; Qingxiang, C.A.I. Dust distribution in open-pit mines based on monitoring data and fluent simulation. Environ. Monit. Assess. 2018, 190, 632. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.; Yang, Z.; Wang, A.; Zhang, K.; Wang, B. A study on movement characteristics and distribution law of dust particles in open-pit coal mine. Sci. Rep. 2021, 11, 14703. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Cui, Y.; Wang, H.; Chen, L.; Xu, K.; Wu, C.; Ren, G. Study on the characteristics of dust diffusion during a truck travelling in an open-pit coal mine affected by the vertical wind shear. J. Hazard. Mater. 2025, 483, 136611. [Google Scholar] [CrossRef]

- Lal, B.; Tripathy, S.S. Prediction of dust concentration in open cast coal mine using artificial neural network. Atmos. Pollut. Res. 2012, 3, 211–218. [Google Scholar] [CrossRef]

- Li, L.; Zhang, R.; Sun, J.; He, Q.; Kong, L.; Liu, X. Monitoring and prediction of dust concentration in an open-pit mine using a deep-learning algorithm. J. Environ. Health Sci. Eng. 2021, 19, 401–414. [Google Scholar] [CrossRef]

- Du, S.; Chen, H.; Ding, X.; Liao, Z.; Lu, X. Development of Dust Emission Prediction Model for Open-Pit Mines Based on SHPB Experiment and Image Recognition Method. Atmosphere 2024, 15, 1118. [Google Scholar] [CrossRef]

- Trechera, P.; Moreno, T.; Córdoba, P.; Moreno, N.; Zhuang, X.; Li, B.; Li, J.; Shangguan, Y.; Dominguez, A.O.; Kelly, F.; et al. Comprehensive evaluation of potential coal mine dust emissions in an open-pit coal mine in Northwest China. Int. J. Coal Geol. 2021, 235, 103677. [Google Scholar] [CrossRef]

- Yan, J.; Wang, Z.; Lu, X.; Wu, Y.; Luo, H.; Liu, X. Physical and Chemical Characteristics of Explosive Dust at Large Open-Pit Coal Mines in Inner Mongolia, China and Dust Control Research. Atmosphere 2023, 14, 1678. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, W.; Jiskani, I.M.; Yan, J.; Luo, H. Optimizing open-pit coal mining operations: Leveraging meteorological conditions for dust removal and diffusion. Int. J. Coal Sci. Technol. 2024, 11, 54. [Google Scholar] [CrossRef]

- Li, G.; Hu, Z.; Wang, D.; Wang, L.; Wang, Y.; Zhao, L.; Jia, H.; Fang, K. Instability mechanisms of slope in open-pit coal mines: From physical and numerical modeling. Int. J. Min. Sci. Technol. 2024, 34, 1509–1528. [Google Scholar] [CrossRef]

- Rojano, R.E.; Manzano, C.A.; Toro, R.A.; Morales, R.G.E.S.; Restrepo, G.; Leiva, M.A.G. Potential local and regional impacts of particulate matter emitted from one of the world’s largest open-pit coal mines. Air Qual. Atmos. Health 2018, 11, 601–610. [Google Scholar] [CrossRef]

- Luo, H.; Zhou, W.; Jiskani, I.M.; Wang, Z. Analyzing characteristics of particulate matter pollution in open-pit coal mines: Implications for green mining. Energies 2021, 14, 2680. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, R.; Li, L.; Liu, Z.; Sun, J.; Kong, L.; Liu, X. Analysis of the dust-concentration distribution law in an open-pit mine and its influencing factors. ACS Omega 2022, 7, 43609–43620. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Zhou, W.; Wang, Z.; Lu, X.; Zhang, Y. Characterization and Concentration Prediction of Dust Pollution in Open-Pit Coal Mines. Atmosphere 2024, 15, 1408. [Google Scholar] [CrossRef]

- Deng, Y.; Wu, H.; Zhao, T.; Shi, C. Characteristics of atmospheric dustfall fluxes and particle size in an open pit coal mining area and surrounding areas. Sci. Rep. 2025, 15, 9597. [Google Scholar] [CrossRef]

- Zhang, J.; Han, Z.; Chen, T.; Yao, N.; Yang, X.; Chen, C.; Cai, J. A Numerical Simulation of the Coal Dust Migration Law in Directional Air Drilling in a Broken Soft Coal Seam. Processes 2024, 12, 309. [Google Scholar] [CrossRef]

- Hao, T.; Wang, L.; Wang, Z.; Li, F.; Jiang, W.; Jiang, S. Research on Dust Migration and Dust Deposition Rules of Breathing Zone in Fully Mechanized Mining Face. ACS Omega 2023, 8, 39143–39153. [Google Scholar] [CrossRef]

- Nie, W.; Jiang, C.; Sun, N.; Guo, L.; Liu, Q.; Liu, C.; Niu, W. CFD-based simulation study of dust transport law and air age in tunnel under different ventilation methods. Environ. Sci. Pollut. Res. Int. 2023, 30, 114484–114500. [Google Scholar] [CrossRef]

- Jing, D.; Ma, M.; Ge, S.; Zhang, T.; Meng, X.; Ren, S. Study on the dust migration law and a spray dust suppression scheme in transportation roadway. Environ. Sci. Pollut. Res. Int. 2023, 30, 59316–59326. [Google Scholar] [CrossRef]

- Chen, F.; Mo, J.; Ma, W. Study on the coupling migration law of airflow-respiratory dust of an 8-m high fully-mechanized mining face. Energy Explor. Exploit. 2022, 40, 1360–1381. [Google Scholar] [CrossRef]

- Hoomans, B.P.B. Granular Dynamics of Gas-Solid Two-Phase Flows. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 2000. [Google Scholar]

- Comini, G.; Del Giudice, S. A (k-ε) model of turbulent flow. Numer. Heat Transf. 1985, 8, 133–147. [Google Scholar] [CrossRef]

- Lacasse, D.; Turgeon, E.; Pelletier, D. On the judicious use of the k–ε model, wall functions and adaptivity. Int. J. Therm. Sci. 2004, 43, 925–938. [Google Scholar] [CrossRef]

- Suleimenov, I.; Bakirov, A. Prospects for Using Finite Algebraic Rings for Constructing Discrete Coordinate Systems. Symmetry 2025, 17, 410. [Google Scholar] [CrossRef]

- Azmy, Y.; Sartori, E.; Larsen, E.W.; Morel, J.E. Advances in discrete-ordinates methodology. In Nuclear Computational Science: A Century in Review; Springer: Berlin/Heidelberg, Germany, 2010; pp. 1–84. [Google Scholar]

| Mine Depth/m | Rock Stripping Volume /10,000 m3 | Production Volume/10,000 tons | Cumulative Rock Stripping Volume/10,000 m3 | Cumulative Mining Volume/10,000 tons |

|---|---|---|---|---|

| 0–130 | 5.2 | 0.0 | 5.2 | 0.0 |

| 131–260 | 86.2 | 0.0 | 91.5 | 0.0 |

| 261–390 | 400.8 | 4.6 | 492.3 | 4.6 |

| 391–520 | 707.9 | 30.4 | 1200.2 | 35.0 |

| 521–650 | 727.4 | 82.2 | 1927.6 | 117.3 |

| 651–780 | 787.5 | 156.3 | 2715.1 | 273.6 |

| Boundary Conditions | Parameters Setting |

|---|---|

| Turbulence Model | |

| Inlet Boundary | Velocity-Inlet |

| Outlet Boundary | Outflow |

| Pressure–Velocity Coupling | SIMPLE |

| Scheme of Pressure Interpolation | Standard |

| Spatial Discretization | The Second Order Wind |

| Discrete Phase Model | Open |

| Injection Type | Surface |

| Surface Options | Scale Flow Rate by Face Area |

| Density | 1.225 kg/m3 |

| Temperature | 288.16 K |

| Velocity | 4 m/s |

| Viscosity | 1.7894 × 10−5 kg/m2·s |

| Ratio of Specific Heats | 1.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, D.; Wu, X.; Yao, J.; Qu, W.; Shi, J.; Yang, K.; Wang, J. Study on Dust Distribution Law in Open-Pit Coal Mines Based on Depth Variation. Atmosphere 2025, 16, 771. https://doi.org/10.3390/atmos16070771

Tian D, Wu X, Yao J, Qu W, Shi J, Yang K, Wang J. Study on Dust Distribution Law in Open-Pit Coal Mines Based on Depth Variation. Atmosphere. 2025; 16(7):771. https://doi.org/10.3390/atmos16070771

Chicago/Turabian StyleTian, Dongmei, Xiyao Wu, Jian Yao, Weiyu Qu, Jimao Shi, Kaishuo Yang, and Jiayun Wang. 2025. "Study on Dust Distribution Law in Open-Pit Coal Mines Based on Depth Variation" Atmosphere 16, no. 7: 771. https://doi.org/10.3390/atmos16070771

APA StyleTian, D., Wu, X., Yao, J., Qu, W., Shi, J., Yang, K., & Wang, J. (2025). Study on Dust Distribution Law in Open-Pit Coal Mines Based on Depth Variation. Atmosphere, 16(7), 771. https://doi.org/10.3390/atmos16070771